Page 1

Installation instructions

instructions d'lnstallation

Q

x

P/N 1S7217800A (0905)

Page 2

Table of Contents

{mportant Safety {nstructions ................................................ 2 {nsta{{ation {nstructions ..................................................... 8-9

Pre-{nsta{{ation Requirements ................................................ 2 Accessories ......................................................................... 10

{nsta{{ation Requirements .................................................. 3-4 Notes.................................................................................. 12

{nsta{{ed Dryer Dimensions .................................................... 5 Francais .............................................................................. 13

Unpacking Washer ............................................................ 6-7

Important Safety Instructions

Foryour safety the information in this manual must be followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

Recognize safety symbols, words and labels

Safety items throughout this manua{ are labe{ed with a

WARNING or CAUTION based on the risk type as described:

This symbol alerts you to situations that

may cause serious body harm, death or

property damage.

This symbol alerts you to situations that may

cause bodily injury or property damage.

Read all of the following instructions before installing and using this appliance:

• Destroy the carton and plastic bags after the washer is unpacked. Children might use them for play. Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Placeall materials in a garbage con-

tainer or make materials inaccessible to children.

The electrical service to the washer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA 70, or in Canada, CSA 22.1 Canadian Electrical Code Part 1.

Toavoid back or other injury, have more than one person move or lift the washer.

The instructions in this manual and all other literature included with this washer are not meant to cover every possible condi-

tion and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and main-

taining any appliance.

Save these instructions for future reference.

Pre-lnstallation Requirements

Tools and materia{s needed for insta{{ation:

OR OR

Adjustable 3/8"or 10 mm Ratchet and

wrench box wrench socket set

AND

Adjustable

pliers

AND

Carpenter's level

Page 3

Installation Requirements

Electrical system requirements

CIRCUIT- Individual, properly polarized and grounded 15

amp. branch circuit fused with 15 amp. time delay fuse or

circuit breaker.

POWERSUPPLY- 2-wire, with ground, 120 volt single phase,

60 Hz, Alternating Current.

Because of potentially inconsistent voltage capabili-

ties, the use of this washer with power created by gas pow-

ered generators, solar powered generators, wind powered

generators or any other generator other than the local utility

company is not recommended.

OUTLETRECEPTACLE- Properly grounded 3-prong receptacle

to be located so the power supply cord is accessible when

the washer is in an installed position.

Grounding requirements

Groundin

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong,

Powercord with

3-prong grounded plug

_i:_'__i_ GF{(Ground Fault Interrupter) receptacle is not re-

quired.

- ELECTRICAL SHOCK HAZARD - {mproper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance isproperly

grounded.

1. The washer MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. Since your washer is equipped with a power supply

cord having an equipment-grounding conductor and

Water supply requirements

Hot and cold water faucets MUST be installed within 42

inches (107 cm) of your washer's water inlet. The faucets

MUST be 3/4 inch (1.9 cm) with threading for laundry hose

connection. Water pressure MUST be between 30 and 120

psi. Pressuredifference between hot and cold cannot be more

than 10 psi. Your water department can adviseyou of your

water pressure.

a grounding plug, the plug MUST be plugged into an

appropriate, copper wired receptacle that isproperly

installed and grounded in accordance with all local codes

and ordinances or in the absence of local codes, with the

National Electrical Codes, ANSI/NFPA70 (latest edition).

If in doubt, call a licensed electrician. DO NOT cut off or

alter the grounding prong on the power supply cord. In

situations where a two-slot receptacle is present, it is the

owner's responsibility to have a licensed electrician replace

it with a properly grounded three prong grounding type

receptacle.

96"

(244cm)

max.

Drain system requirements

1. Drain capable of eliminating 17 gais (64.3 L) per minute.

2. A standpipe diameter of 1-1/4 in. (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm)

.......... Drain hose attached to the washer can reach a 74 in.

(188 cm) high standpipe. For higher standpipe, use hose P/N

137098000, available from an authorized parts distributor.

Page 4

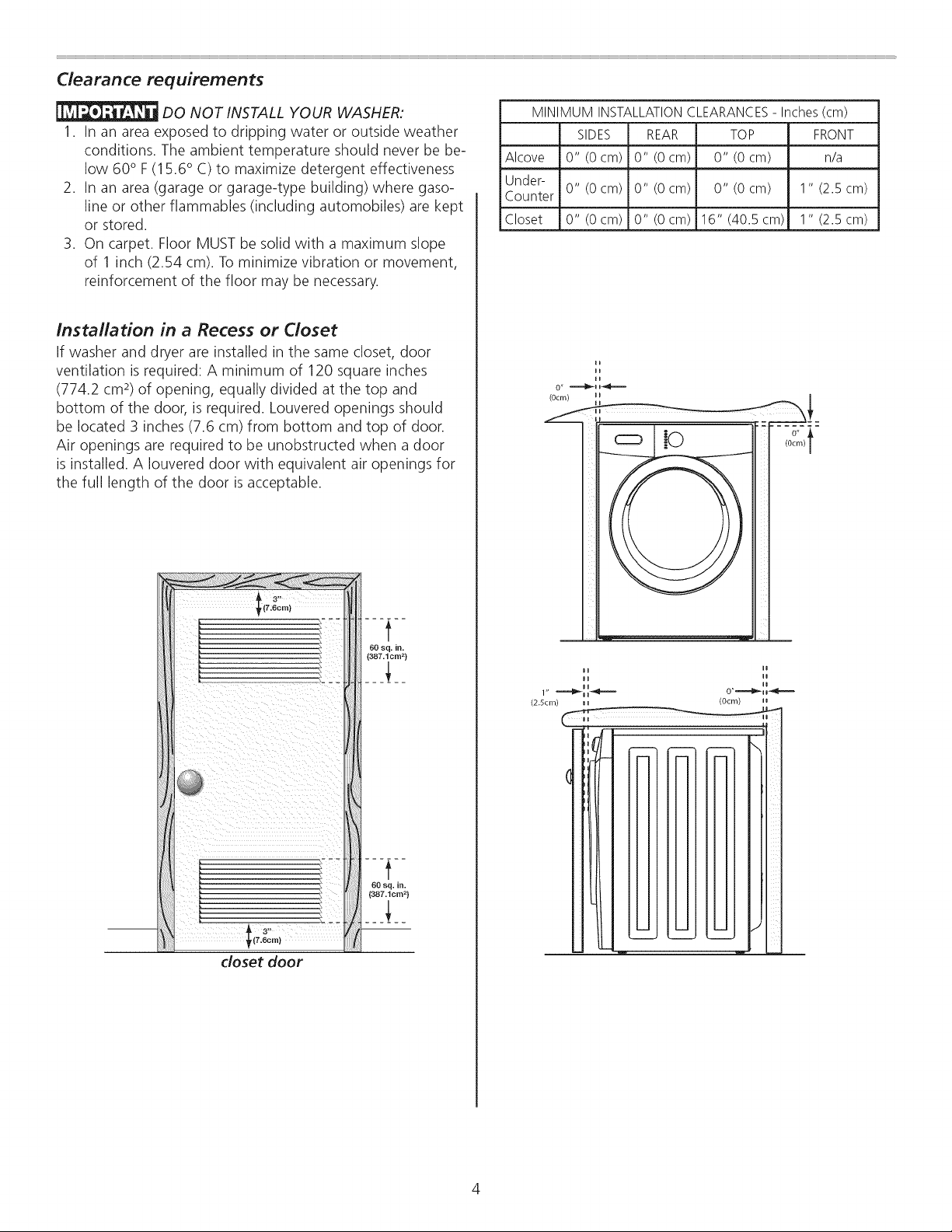

Clearance requirements

DO NOT INSTALL YOUR WASHER:

1. In an area exposed to dripping water or outside weather

conditions. The ambient temperature should never be be-

low 60 ° F (15.6 ° C) to maximize detergent effectiveness

2. In an area (garage or garage-type building) where gaso-

line or other flammables (including automobiles) are kept

or stored.

3. On carpet. Floor MUST be solid with a maximum slope

of 1 inch (2.54 cm). To minimize vibration or movement,

reinforcement of the floor may be necessary.

Installation in a Recess or Closet

If washer and dryer are installed in the same closet, door

ventilation isrequired: A minimum of 120 square inches

(774.2 cm2) of opening, equally divided at the top and

bottom of the door, isrequired. Louvered openings should

be located 3 inches (7.6 cm) from bottom and top of door.

Air openings are required to be unobstructed when a door

is installed. A Iouvered door with equivalent air openings for

the full length of the door is acceptable.

MINIMUM INSTALLATIONCLEARANCES- Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm) 0" (0 cm) n/a

Under-

Counter

0" (0 cm) 0" (0 cm) 0" (0 cm) 1" (2.5 cm)

Closet 0" (0 cm) 0" (0 cm) 16" (40.5 cm) 1" (2.5 cm)

Ii

II

10

0" ====ll_-i i_=lF-===

(Ocm)

[

" " O" _

(0cm)

/

closet door

f

60 sq. in.

(387.1 cm 2}

______

f

60 sq. in.

(387.1cm 2)

1" _""_01 _l==m"

(2.5cm) I I

It

It

II

f_

--i --i --

(Ocm) al

[ J

ii

ii

II

Page 5

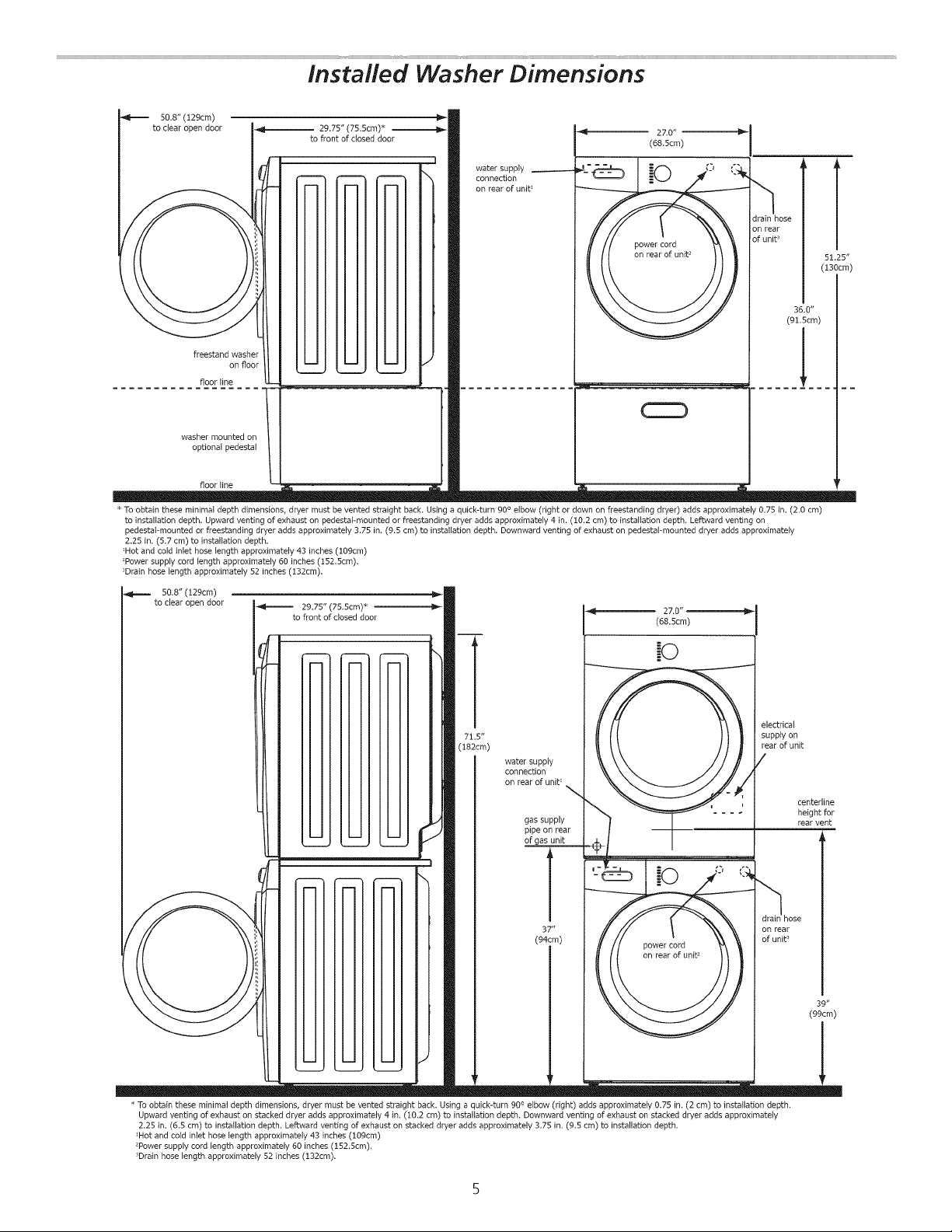

Installed Washer Dimensions

50.8" (129cm)

to clear open door _,_--

29.75"(75.5cm)*

to front of closed door

water supply

connection

on rear of unit _

_'_ 27.0" --

(68.5cm)

drain hose

on rear

of uniP

l

36.0"

(9t.5cm)

freestand washer

on _oor

floorline

washer mounted on

optional pedestal

floorline

To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90 ° elbow (right or down on freestanding dryer) adds approximately 0.75 in. (2.0 cm)

to installation depth. Upward venting of exhaust on pedestal-mounted or freestanding dryer adds approximately 4 in. (10.2 cm) to installation depth. Leftward venting on

pedestaFmounted or freestanding dryer adds approximately 3.75 in. (9.5 cm) to installation depth. Downward venting of exhaust on pedestaFmounted dryer adds approximately

2.25 in. (5.7 cm) to installation depth.

_Hot and cold inlet hose length approximately 43 inches (109cm)

2Powersupply cord length approximately 60 inches (t52.5cm).

3Drain hose length approximately 52 inches (132cm).

50.8" (129cm)

to clear open door

29.75" (75.5cm)*

to front of closed door

r--

27.0'

(68,5cm)

!

51.25"

(130cm)

71.5"

(t82cm)

water supply

connection

on rear of unit _

gas supply

pipe on rear

of gas unit

37"

(94cm)

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90° elbow (right) adds approximately 0.75 in. (2 cm) to installation depth.

Upward venting of exhaust on stacked dryer adds approximately 4 in. (10.2 cm) to installation depth. Downward venting of exhaust on stacked dryer adds approximately

2.25 in. (6.5 cm) to installation depth. Leftward venting of exhaust on stacked dryer adds approximately 3.75 in. (9.5 cm) to installation depth.

_Hot and cold inlet hose length approximately 43 inches (109cm)

2Powersupply cord length approximately 60 inches (152.5cm).

3Drain hose length approximately 52 inches (132cm).

power cord

on rear of unit2

electrical

supply on

rear of unit

on rear

of uniP

centerline

height for

rear vent

39"

(99cm)

Page 6

Installed Washer Dimensions

1_ 48.25" (122,5cm)

to clear open door

freestand washer

fleer}ine

washer mounted on

optional pedestal

floorline

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90° elbow (right or down on freestanding dryer) adds approximately 0.75 in. (2.0 cm) to

installation depth. Upward venting of exhaust on pedestabmounted or freestanding dryer adds approximately 4 in. (:[0.2 cm) to installation depth. Leftward venting on pedestabmounted or

freestanding dryer adds approximately 3.75 in. (9.5 cm) to installation depth. Downward venting of exhaust on pedestal-mounted dryer adds approximately 2.25 in. (5.7 cm) to installation

depth. These dimensions are based on matching 7.0 cu. ft. dryer. If matching dryer is 5.8 cu. ft. version with optional side venting knockouts, dimensions will vary.

_Hot and cold inlet hose length approximately 43 inches (:[09cm)

2Powersupply cord length approximately 60 inches (:[52.5cm).

3Drain hose length approximately 52 inches (:[32cm).

48,25"(122.5cm)

to clear open door

._--- 30.5" (77.5cm)*

on _oor

to front of closed door

to front of closed door

30.5" (77.5cm)* __

water supply

connection

on rear of unit _

27.0"

(68.5cm)

0

27.0

(68.5cm)

drain hose

of uniP

36.0"

(9:[.5cm)

[

(130cm)

51.25"

7:[.5"

(:[82cm)

water supply

connection

on rear of unit _

gas supply

pipe on rear

of gas unit

37"

(94cm)

0

0

power cord

on rear of unitz

electrical

supply on

rear of unit

hose

on rear

of unit _

centerline

height for

rear vent

39"

(99cm)

To obtain these minimal depth dimensions dryer must be vented straight back. Using a quick-turn 90° elbow (right) adds approximately 0.75 in. (2 cm) to installation depth. Upward

vent ng of exhaust on stacked dryer adds approx mately 4 n. (:[0.2 cm) to nstallat on depth. Downward vent ng of exhaust on stacked dryer adds approx mately 2.25 n. (6.5 cm) to

installation depth. Leftward venting of exhaust on stacked dryer adds approximately 3.75 in. (9.5 cm) to installation depth. These dimensions are based on matching 7.0 cu. ft. dryer. If

matching dryer is 5.8 cu. ft. version with optional side venting knockouts, dimensions will vary.

_Hot and cold inlet hose length approximately 43 inches (:[09cm)

2Powersupply cord length approximately 60 inches (:[52.5cm).

3Drain hose length approximately 52 inches (:[32cm).

Page 7

Removing foam packaging

- SUFFOCATION HAZARD - Destroy the

carton and plastic bags after the washer is unpacked. Chil-

dren might use them for play. Cartons covered with rugs,

bedspreads, or plastic sheets can become airtight chambers

causing suffocation. Placeall materials in a garbage container

or make materials inaccessible to children.

1. Temporarily remove door tape.

2. Open washer door and remove everything from the drum.

3. Close door and reapply door tape.

4. Using a rug, blanket or piece of cardboard to protect the

floor, carefully lay the washer on it's back.

- EXCESSIVE WEIGHT HAZARD - Toavoid

back or other injury, have more than one person move or lift

the washer.

5. Remove styrofoam base and shipping plug and set them

aside.

6. Carefully return the washer to an upright position.

7. Carefully move the washer to within 4 feet (1 m) of its

final location.

Savestyrofoam base and shipping plug for

use to help prevent washer damage during any future moves.

Page 8

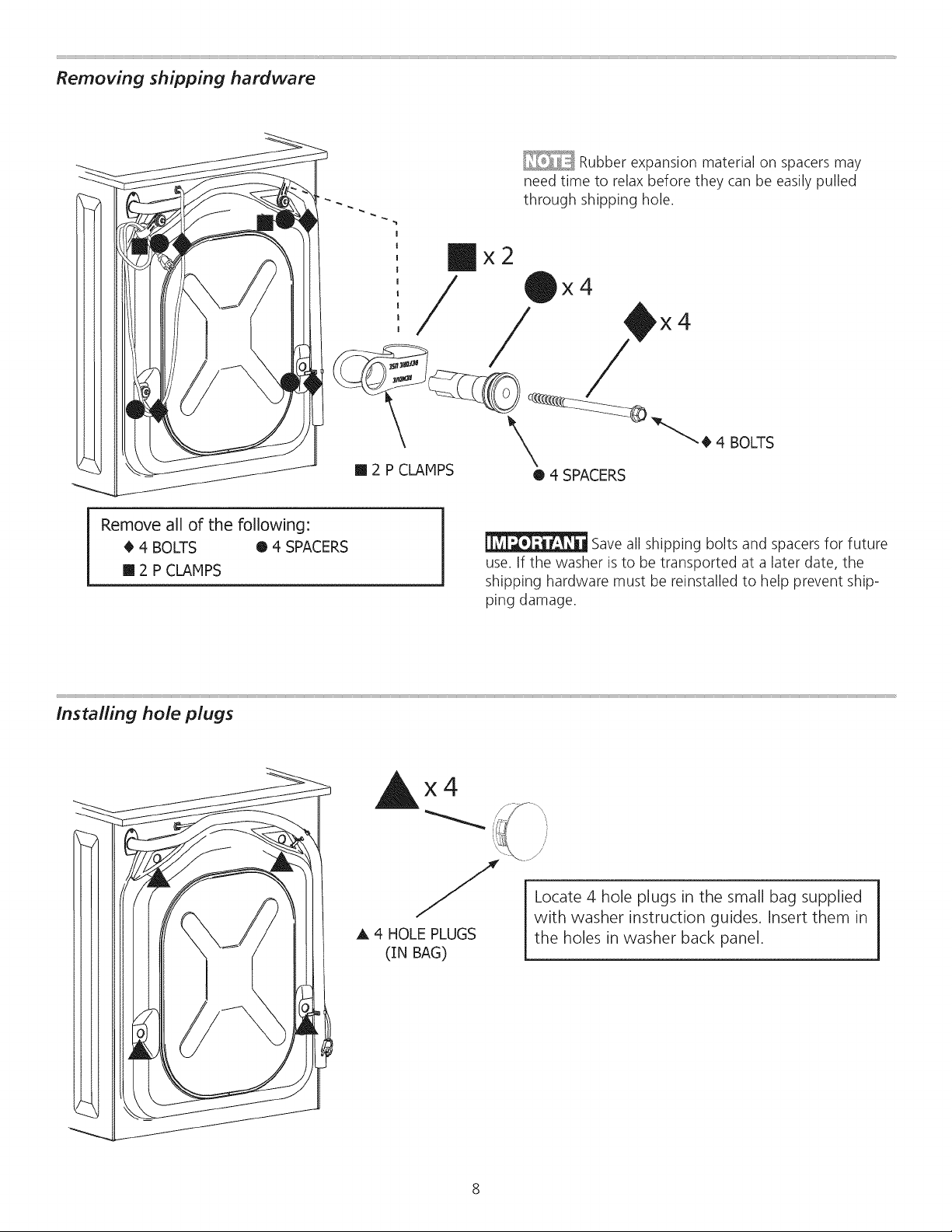

Removing shipping hardware

Remove all of the following:

4 BOLTS ® 4 SPACERS

2 P CLAMPS

Rubber expansion material on spacers may

need time to relax before they can be easily pulled

through shipping hole.

/ x4 x4

BOLTS

Saveall shipping bolts and spacers for future

use. If the washer is to be transported at a later date, the

shipping hardware must be reinstalled to help prevent ship-

ping damage.

Installing hole plugs

Ax4

/__ Locate 4 hole plugs in the small bag supplied

with washer instruction guides. Insert them in

A 4 HOLE PLUGS the holes in washer back panel.

(IN BAG)

Page 9

Leveling your washer

leveling thewasher.EXcessivenoise and vibration can be prevented by properly

1. For free standing installation and with the washer within I

4 feet (1 m)of its final location, place a level on top of the

washer.

2. Use adjustable pliers to adjust the leveling legs so the

washer is level front-to-rear and side-to-side, and stable

corner-to-corner, lower3. Pressdown on alternate corners and sides and feel for the

washerslightestsitsmovement,solidly onAdjustthe floortheonappropriateALL four legs.leg(s)Keepso thethe

leveling leg extension at a minimum for best performance

of the washer.

For pedestal installations, see additional installation

instructions included with the pedestal.

Connecting inlet water

1. Run some water from the hot and cold faucets to flush the

water linesand remove particles that might clog the water

valve screensand to determine which faucet is hot and

which iscold supply.

2. Remove the inlet hoses and rubber washers from the

plastic bag located in the drum of the washer and install

the rubber washers in each end of the inlet hoses.

RUBBERWASHERS

MUST BEPRESENT

3. Connect the HOT inlet hose to the HOT inlet connection

on the washer and the COLD inlet hose to the COLD inlet

connection on the washer. Tighten by hand until snug.

Then tighten each supply connection another 2/3 turn

with pliers. Do not cross thread or over-tighten these

connections.

4. Connect the HOTinlet hose to the HOTwater supply and

the COLD inlet hose to the COLD water supply. Tighten

by hand until snug. Then tighten each supply connection

another 2/3 turn with pliers.

5. Turn on the water and check for leaks.

USE ONLY

NEW HOSES

J

COLD

HOT

f

Page 10

Connecting drain and electrical

,

Snap one end of the drain hose hanger (shipped in washer

drum) onto the drain hose. Continue wrapping it around

the hanger and snap it in place.

,

Placethe hook end of the drain hose in the drain opening.

Secure the drain hose with the cable tie (provided in the

enclosure package) to the standpipe, inlet hose, laundry

tub, etc. so the hose does not pull out from the force of

the water.

Check to ensure the power is off at circuit

breaker/fuse box before plugging the power cord into outlet.

3. Plug the power cord into a grounded outlet.

Do not, under

anycircumstances,

cut,remove, |

or bypass the |

grounding _

CABLE TIE

Powercordwith

:3-prong grounded p!ug

4. Turn on the power at a circuit breaker/fuse box.

5. Carefully slide the washer to its final position. Recheck

for level and rock corners for stability. Remove and discard

door tape.

6. Readthe Use & Care Guide provided with the washer. It

contains valuable and helpful information that will save

you time and money.

7. If you have any questions during initial operation, please

review the "Service Prevention Checklist" in your Use &

Care Guide before calling for service.

8. Placethese instructions in a location near the washer for

future reference.

A wiring diagram and technical data sheet

are located under the washer top panel, on top of the

detergent dispenser housing.

10

Page 11

Accessories

Failureto use accessoriesmanufactured by (or

approved by) the manufacturer could result in personal injury,

property damage or damage to the dryer.

DRYER STACKING KIT

P/N134700600

Depending on the model you purchased, a kit for stacking

a matching dryer on top of this washer may have been

included in the initial purchase of your dryer. If your model

did not include a stacking kit or you desire another stacking

kit, you may order one.

DRAIN HOSE EXTENSION KIT

P/N137098000

In order to reach standpipe heights or distances beyond the

reach of the drain hose supplied, order the DRAIN HOSE

EXTENSIONKIT.

MOBILE HOME INSTALLATION KIT

P/N137067200

Installations in mobile homes require use of MOBILEHOME

INSTALLATIONKIT.

UNIVERSAL APPLIANCE WRENCH

P/N137019200

A UNIVERSALAPPLIANCEWRENCH

is available to aid in dryer/washer/

pedestal feet adjustment.

MATCHING STORAGE PEDESTAL

Seechart below for style,color and P/N

A storage pedestal accessory, specifically designed for this

washer may be used to elevate the washer for ease of use.

This pedestal will add about 15" (38 cm) to the height of

your unit for a total height of 51.25" (130 cm).

&00',

This type of washer: This type of washer:

TOUCH UP PAINT PENS*

White TouchUpPen- P/N5303321319

BlackTouchUp Pen- P/N5304458932

SilverTouchUp Pen- P/N5304471228

*Other colors may be available. Contact the source where you purchased

your washer.

Pedestal

white

black

color*

• J ............... i

NLPWD15or APWD15or

48062 46262

NLPWD15Eor APWD15E

48066

silver

NLPWD15Aor N/A

46267

*Not all pedestal colors are available on all models. Other colors may

be available that are not listed above. Contact the source where you

purchased your washer.

Replacement parts:

If replacements parts are needed for your washer, contact the _ - ELECTRICAL SHOCK HAZARD - Label all

source where you purchased your washer, wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify

proper operation after servicing.

11

Page 12

Notes

12

Page 13

Table des Matieres

Mesures de securite importantes ......................................... 13

Exigences avant I'installation ............................................... 13

Exigences d'installation ................................................. 14-15

Dimensions, appareil installe ......................................... 16-17

Deballage de la laveuse................................................. 18-19

Instructions d'installation .............................................. 20-21

Accessoires ......................................................................... 22

Remarques.......................................................................... 23

Mesures de Securite lmportantes

Pour votre securite, I'information contenue dans ces instructions doit @tresuivie afin de reduire les risques

d'incendie ou d'explosion ou pour prevenir les dommages materiels, lesblessuresou la mort. Vous ne devez ni entreposer, ni utiliser

d'essenceou d'autres vapeurs ou liquides inflammables a proximite de cet appareil ou de tout autre appareil electromenager.

Sachez reconna}tre les symboles, les avertissements

et {es _tiquettes de s_curit_.

Lesmesures de securite presentees clans ce guide sont identi-

_ , o ,,., Cesymbolevousavertit

propos des situations pouvant

causer des dommages materiels, des blessuresgraves ou

m@mela mort.

fiees par le mot AVERTISSEMENTou ATTENTIONselon le type

de risque presente ci-dessous:

Ce symbole vous avertit apropos des

situations pouvant causer des domma-

ges materiels ou des blessures.

Lisez toutes les instructions de securite suivantes avant d'installer et d'utiliser votre appareil:

• Detruisez le carton d'emballage et lessacs en plastique apres avoir deballe I'appareil. Lesenfants pourraient les utiliser pour

jouer. Le carton recouvert de tapis, les couvertures et les feuilles de plastique peuvent @treetanches a I'air et provoquer la

suffocation. Deposez tousles materiaux d'emballage clans un conteneur a dechets ou faites en sorte que les enfants ne puis-

sent y avoir acces.

L'installation electrique de la laveuse doit @treconforme aux codes et aux reglements Iocaux ainsi qu'a la toute derniere edi-

tion du National Electrical Code (ANSI/NFPA70), ou au Canada, au Code canadien de I'electricite (C22.1, article 1).

Pour eviter les blessuresau dos ou d'autres types de blessure, demandez I'aide d'autres personnes pour deplacer ou soulever la

laveuse.

Lesinstructions comprisesdansce guide et toute autre documentation fournie aveccet appareil ne sont pasconcues pour couvrir

toutes leseventualitesou situations qui pourraient survenir.VousDEVEZfaire preuvede bon senset de prudence durant I'installation,

I'utilisation et I'entretien de tout appareilmenager.

Conservez ces instructions pour vous y reporter ulterieurement.

Exigences avant i'installation

Outils necessaires b I'installation •

OU "," OU

C1_5

molette

\',,

\

CI6 polygonale Cliquet et

de 3/8 po ensemble

ou de 10 mm de douilles

ET

13

Pince

r6glable

ET

Niveau de charpentier

Page 14

Exigences d'lnstallation

Exigences des systemes electriques

CIRCUIT- Circuit independant de 15 amperes, polarise et mis

a la terre, avec fusible temporise ou disjoncteur de 15 A.

ALIMENTATION ELECTRIQUE- Cable monophase a deux ills

mis a la terre, 120 volts, 60 Hz; courant alternatif.

_/' _ Etant donne les variations de tension possi-

bles, I'utilisation de cette laveuse avec une source d'alimen-

tation produite par une generatrice a essence, solaire ou eo-

lienne ou par toute autre source d'alimentation differente de

celle fournie par les services publics n'est pas recommandee.

PRISE- Prisea trois alveoles et mise a la terre situee a un endroit

ou il est possible de raccorder le cordon d'alimentation de la

laveuseune fois que cette derniere est insta%e.

Exigences relatives b la mise b la terre

- RISQUE DE CHOC ELECTRIQUE

- Un raccordement inadequat du conducteur de terre de

I'equipement peut accrottre les risques de choc electrique. En

cas de doute quanta la mise a la terre de I'appareil, consultez

un electricien qualifie.

1. Cet appareil DOlT _tre mis a la terre. En casde mauvais

fonctionnement ou de panne, la mise a la terre diminue

lesrisques de choc electrique en fournissant au courant

electrique une trajectoire de moindre resistance.

2. Etant donne que votre laveuseest equipee d'un cordon

d'alimentation pourvu d'un conducteur de mise a la terre et

Prise murale avec

mise _ la terre

e coupez pas. n enlevez

pas et ne mettez pas hors

circuitlabrochederaise

laterrede cettefiche.

Cordon _lectrique muni

d'unefiche

avec mise _ laterre

_ Une prise GFI(disjoncteur de fuite de terre)

n'est pas necessaire.

d'une fiche de mise a la terre, la fiche DOlT_tre raccordee

une priseappropriee (avecconducteurs en cuivre)

correctement installee et mise a la terre conformement aux

codes et reglements Iocaux ou, si aucun code local ne regit

ce type d'installation, a la plus recente edition du National

ElectricalCode (ANSI/NFPA70). Encas de doute, faites appel

un electricien qualifie. NE COUPEZPASet NEMODIFIEZ

PASla broche de mise a la terre du cordon d'alimentation.

Si votre prise murale n'est pourvue que de deux fentes,

il incombe au proprietaire de faire appel a un electricien

qualifie pour la remplacer par une prise a trois alveoles et

raisea la terre de fa_on adequate.

J

Exigences relatives a I'alimentation en eau ,__

Lesrobinets d'eau chaude et d'eau froide DOIVENT_tre insta%s |

une distance de 107 cm (42 po) ou moins de I'arrivee d'eau

de votre laveuse. Lesrobinets DOIVENT_tre de 1,9 cm (3/4 po)

et filetes en fonction d'un raccordement de tuyau de laveuse. 96"

La pression de I'eau DOlT se situer entre 206,8 et 827,4 kPa (30 (244cm)

et 120 Ib/po_). Ladifference de pression entre I'eau chaude et max.

I'eau froide ne doit pas depasser68,9 kPa (10 Ib/po_).Le service

des eauxde votre Iocalite peut vous informer sur la pression de

votre alimentation en eau.

Exigences relatives au systeme d'evacuation

1.Le drain doit pouvoir evacuer 64,3 L(17 gal) d'eau a la minute.

2.Tuyau d'evacuation d'au moins 3,18 cm (1-1/4 po) de diametre. I_ _$q:::_Le tuyau de vidange raccorde a la laveuse

3.Le tuyau d'evacuation doit _tre situe entre une hauteur peut convenir a un tuyau d'evacuation de 188 cm (74 po) de

minimale de 61 cm (24 po) et une hauteur maximale de 244 hauteur. Pour des tuyaux d'evacuation plus hauts, utilisez le

cm (96 po). tuyau portant le numero de piece 137098000 que vous pou-

vez obtenir aupres d'un distributeur de pieces autorise.

14

/

24"

(61cm)

min.

'H

!

Page 15

Exigences de degagement

N'INSTALLEZ PAS VOTRE LAVEUSE "

1. A un endroit expose aux ecoulements d'eau ou aux aleas

des conditions meteorologiques exterieures. La tempe-

rature ambiante ne devrait jamais tomber sous 15,6 °C

(60 °F)afin d'optimiser I'efficacite du detergent.

2. A un endroit (garage ou b_timent similaire) ou de I'es-

sence ou d'autres substances inflammables sont entrepo-

sees (incluant des automobiles).

3. Sur un tapis. Le plancher DOlT 6tre solide et presenter

une pente inferieure a 2,54 cm (1 po). Afin d'eviter los

vibrations et le deplacement de I'appareil, il pout 6tre

necessaire de renforcer le plancher.

Installation clans un Endroit en Retrait ou une

Armoire

Si la laveuse et lasecheuse sont installees dans le re#me

placard, une ventilation est requise dans la porte : Une

ouverture d'au moins 774,2 cm2 (120 po2), divisee egalement

au-dessus et au-dessous de la porte, est requise. Les ouvertures

persiennes doivent #tre situees a 7,6 cm (3 po) du haut et

du basde la porte. Lesouvertures d'aeration ne doivent pas

#tre obstruees Iorsqu'une porte est installee. Une porte a

persiennes dont les ouvertures sur I'ensemble de la porte sont

equivalentes aux recommandations peut #tre utilisee.

DCGAGEMENTSMINIMAUX - Centimetres (pouces)

COTES ARRIERE DESSUS AVANT

AlcOve

Sous le

comptoir

Placard

0" (0 cm)

0" (0 cm)

0" (0 cm)

0" -----4a_l i_,11._

(Ocm)

0" (0 cm)

0" (0 cm)

0" (0 cm)

Ii

10

10

0" (0 cm n/a

0" (0 cm) 1" (2.5 cm)

16" (40.5 cm) 1" (2.5 cm)

[

" " O" _

(Ocm)

|

, 3'

,{7.6cm}

Porte de placard

f

60 sq. in.

(387,10m2)

---_--

60 sq. in.

(387.1cm 2)

1" "m'_l F4"_

(2.5cm) I I

(Ocm) al

[ J

io

to

II

ml

ol

ii

--i --i --

15

Page 16

50.8" (129cm)

Avec la porte

grande ouverte

Laveuse autonome

Laveuse mont6e sur

le sode optionnel

sur {e p{ancher

Plancher

Dimensions AppareH lnstalle

29.75" (75.5cm)*

_, partir de I'avant de la porte

Iorsqu'el{e est ferrule

Raccord de

I'alimentation en eau

I'arri_re de la }aveuse _

_'_ 27.0" --

(68.5cm)

l

Tuyau de

vidange

I_rri_re

de la

taveuse_

36.0"

(91.5cm)

51.25"

(130cm)

Plancher

* Pour obtenir ces dimensions de profondeur minimales, las4cheuse dolt _tre ventil_e tout droit par I'arri&re. L'utilisation d'un coude _ 90° _ courbe imm4diate (vers la droite ou vers le bas sur une s4cheuse autonome)

n_cessite environ 2 cm (0.75 po) de profondeur de plus pour I'installation. Les s_cheuses mont_es sur un sode ou autonomes munies d'un syst_me d'_vacuation de Fair vers le haut requi_rent environ 10.2 cm (4 po) de

profondeur de plus pour I'installation. Less_cheuses mont_es sur un socle ou autonomes munies d'un syst_me d'_vacuation vers la gauche n_cessitent environ 3.75 cm (9.5 po) de profondeur de ptus pour I'installation.

Les s_cheuses mont_es sur un sode munies d'un syst_me d'_vacuation de I'air vers le bas requi_rent environ 5.7 cm (2.25 po) de profondeur de ptus pour I'installation.

_Longueur des tuyaux d'entr_e d'eau chaude et froide, environ 109 cm (43 po).

2Longueur du cordon d'alimentation, environ 152,5 cm (60 po).

3Longueur de tuyau de vidange, environ 132 cm (52 po).

50.8" (129cm)

Avec la porte

grande ouverte

29.75" (75.5cm)*

partir de }'avant de la porte

Iorsqu'elle est ferm_e

r--

_ i i

71.5"

Raccord de

I'alimentation

en eau _ I'arri&re

de la laveuse1

Alimentation en

gaz _ I'arri&re de

I'appareil _ gaz

37"

(94cm)

27.0'

(68,5cm)

Cordon d'alimentation

I'arri&re de {a {aveuse2

Alimentation

_lectrique

I'arrJ&re de

la s_cheuse

Hauteur de la

ligne centrate

de I'_vent arri&re

I'arri_re

f

39"

(99cm)

_ i _

* Pour obtenir ces dimensions de profondeur minimales, las4cheuse dolt _tre ventil_e tout droit par I'arri&re. L'utilisation d'un coude _ 90° _ courbe imm4diate (vers la droite ou vers le bas sur une s4cheuse autonome)

n_cessite environ 2 cm (0.75 po) de profondeur de plus pour I'}nstallation. Les s_cheuses mont_es sur un sode ou autonomes munies d'un syst_me d'_vacuation de Fair vers le haut requi_rent environ 10.2 cm (4 po) de

profondeur de plus pour I'installation. Less_cheuses mont_es sur un socle ou autonomes munies d'un syst&me d'_vacuation vers la gauche n_cessitent environ 3.75 cm (9.5 po) de profondeur de ptus pour I'installation.

Les s_cheuses mont_es sur un sode munies d'un syst_me d'_vacuation de I'air vers le bas requi_rent environ 5.7 cm (2.25 po) de profondeur de ptus pour I'installation.

_Longueur des tuyaux d'entr_e d'eau chaude et froide, environ 109 cm (43 po).

2Longueur du cordon d'alimentation, environ 152,5 cm (60 po).

3Longueur de tuyau de vidange, environ 132 cm (52 po).

16

Page 17

Dimensions, Apparei! lnstalle

Avecla pore

grande ouverte

48.25"(122.5cm)

Laveuse autonome

sur le plancher

Plancher

Laveuse mont_esur

le sode optionnel

Plancher

* Pour obtenir ces dimensions de profondeur minimales, la s6cheuse dolt @treventil_e tout droit par I'arri&re. L'utilisation d'un coude _ 90° _ courbe imm6diate (vers la droite ou vers le bas sur une s6cheuse autonome)

n_cessite environ 2 cm (0#5 po) de profondeur de plus pour I'installation. Les s_cheuses mont_es sur un sode ou autonomes munies d'un syst_me d'_vacuation de I'air vers le haut requi_rent environ 10.2 cm (4

po) de profondeur de plus pour I'installation. Les s@cheusesmont_es sur un socle ou autonomes munies d'un syst_me d'_vacuation vers la gauche n_cessitent environ 3.75cm (9.5 po) de profondeur de plus pour

Finstallation. Less6cheuses mont_es sur un socle munies d'un syst_me d'_vacuation de I'air vers le bas requi&rent environ 5.7 cm (2.25 po) de profondeur de plus pour I'installation. Cesdimensions correspondent

une s_cheuse de 0,2 m _ (7 pi_). Ellespeuvent varier pour une s_cheuse de 0,16 m _ (5,8 pi_) avec alv_oles lat_rales de ventilation en option.

1Longueur des tuyaux d'entr_e d'eau chaude et froide, environ 109 cm (43 po).

_Longueur du cordon d'aiimentation, environ 152,5 cm (60 po).

_Longueur de tuyau de vidange, environ 132 cm (52 po).

48.25"(122.5cm)

Avecla porte

grande ouverte

30.5" (77.5cm)*

partir de l'avant de la porte

Iorsqu'elle est ferm_e

30.5" (77.5cm)*

#, partir de I'avant de la porte

Iorsqu'elle est ferm6e

Raccord de

I'alimentation en eau

I'arri&re de la laveuse 1

27.0" --

(68.5cm)

27.0

(68.5cm)

Tuyau de

vidange

I_rri_re

de la

laveuse_

(130cm)

36.0"

(9t.5cm)

0

Alimentation

_tectrique

71.5"

(182cm)

Raccord de

I_limenta_on

en eau _ Ihrri_re

de la laveuse_

Alimentation en

gaz _ l'arri&re de

I'appareil _ gaz

37"

(94cm)

* Pour obtenir ces dimensions de profondeur minimales, la s6cheuse dolt @treventil_e tout droit par I'arri&re. L'utilisation d'un coude _ 90° _ courbe immediate (vers la droite ou vers lebas sur une s_cheuse autonome)

n_cessite environ 2 cm (0.75 po) de profondeur de plus pour Iqnstallation. Les s_cheuses mont_es sur un sode ou autonomes munies d'un syst_me d'6vacuation de Fair vers le haut requi_rent environ 10.2 cm (4

po) de profondeur de plus pour I'installation. Les s@cheusesmont_es sur un socle ou autonomes munies d'un syst_me d'_vacuation vers la gauche n_cessitent environ 3.75 cm (9.5 po) de profondeur de plus pour

Finstallation. Less6cheuses mont_es sur un socle munies d'un syst_me d'_vacuation de I'air vers le bas requJ&rent environ 5.7 cm (2.25 po) de profondeur de plus pour I'installation. Ces dimensions correspondent

une s_cheuse de 0,2 m_ (7 pi_). Elles peuvent varier pour une s_cheuse de 0,16 m_ (5,8 pia) avec alv_oles lat_rales de ventilation en option.

_Longueur des tuyaux d'entr_e d'eau chaude et froide, environ 109 cm (43 po).

_Longueur du cordon d'alimentation, environ 152,5 cm (60 po).

_Longueur de tuyau de vidange, environ 132 cm (52 po).

I'arri_re de la laveuse_

I'arri&re de

la s_cheuse

Hauteur de la

ligne centrale

de l'_vent arri&re

Tuyau de

_idange

I'arrJ&re

e la laveuse3

39"

(99cm)

17

Page 18

Retrait de I'emballage en mousse

- RISQUE D'ETOUFFEMENT-

Detruisez le carton d'emballage et lessacs en plastique apres

avoir deballe I'appareil. Lesenfants pourraient les utiliser

pour jouer. Le carton recouvert de tapis, les couvertures et les

feuilles de plastique peuvent _tre etanches a I'air et provo-

quer la suffocation. Deposez tousles materiaux d'emballage

dans un conteneur a dechets ou faites en sorte que les en-

fants ne puissent y avoir acces.

1. Retirez temporairement le ruban de la porte.

2. Ouvrez la porte de la laveuse et retirez tout ce qui se

trouve dans le tambour.

3. Fermez la porte et posez le ruban de porte anouveau.

4. Pour proteger le plancher, utilisez un tapis, une couverture

ou une piece de carton et couchez la laveuse sur le cote

arriere.

- DANGER DE POIDS EXCESSIF- Pour

eviter les blessures au dos ou d'autres types de blessure, de-

mandez I'aide d'autres personnes pour deplacer ou soulever

la laveuse.

/

5. Retirez la base en styromousse et le bouchon d'expedition;

mettez-les de cote.

6. Remettez soigneusement la laveuse en position verticale.

7. Deplacez soigneusement la laveuse a moins de 1,2 m

(4 pi) de son emplacement ddinitif.

Conservez la base en styromousse et le bou-

chon d'expedition afin d'eviter d'endommager I'appareil dans

le cas d'un deplacement eventuel.

18

Page 19

Retrait de la quincaillerie d'expedition

Retirez les composants suivants •

4 BOULONS • 4 CALES D'ESPACEMENT

II 2 SERRESEN P

II se peut que le materiel de caout-

chouc utilise pour lesespaceurs necessite quelque

temps pour se relacher afin de pouvoir _tre retire

des trous d'expedition.

/ x4 x4

€' 4 BOULONS

® 4 CALESD'ESPACEMENT

Conservez les boulons et cales d'espacement

d'expedition pour un usage ulterieur. Si la laveuse dolt _tre

transportee plus tard, ces pieces d'expedition doivent _tre

installees pour eviter de I'endommager.

Pose des bouchons

Ax4

'_ rouvez les 4 bouchons du petit sac fourni avec

les guides de votre laveuse. Inserez-les dans les

A 4 BOUCHONS trous du panneau arriere de la laveuse.

(DANS UN SAC)

19

Page 20

Mise b niveau de votre appareil

Lesbruits excessifs et lesvibrations peuvent _tre evites en

1. Pour une installation autonome ou la laveuse est a moins de

surledessusdeI'appareil.

1,2 m (4 pi)de son emplacement definitif, placez un niveau

mettant correctement la laveuse a niveau. _ J., ,I.

niveau de facon ace que la laveuse soit de niveau d'avant en

arriere et lateralement, et qu'elle soit stable aux quatre coins.

3. AppuyeZendroitsquiSUrnecessitentchaquecOinunetreglage.Chaquec0teAjustezpOUrlesdeterminerpieclsde miseleS _ )

a niveau appropries de maniere a ce que la laveuse repose

solidement sur ses QUATREpieds. Gardez les pieds de mise

a niveau le plus pres possible de la laveuse afin d'optimiser le

rendement de la laveuse.

instructions d'installation complementaires incluses avec le socle.

Branchement de I'entree d'eau

1. Faites couler de I'eau chaude et froide des robinets pour

purger lestuyaux d'eau, pour eliminer toute particule

qui pourrait obstruer les grillages des robinets, et pour

determiner quels robinets fournissent I'eau chaude et I'eau

froide.

2. Enlevez du sac en plastique les tuyaux d'arrivee et les

rondelles caoutchoucet installez les rondelles achaque

extremite.

u micra

Pour une installation sur socle, reportez-vous aux

UTIUSEZ SEULE-

LESROnDELLESE. .......-Ok',

CAOUTCHOUC "-

DOIVENT CTREPRE-

SENTES

MENT LES NOU-

VEAUX TUYAU

D'ENTREE D'EAU

\

3. Raccordez le tuyau d'entree d'eau CHAUDE au raccord

pour I'eau CHAUDE de lalaveuse et letuyau d'entree d'eau

FROIDE au raccord pour I'eau FROIDE de la laveuse. Serrez

fermement a la main. Avec des pinces, serrez chaque raccord

de 2/3 de tour. Ne faussez pas le filetage et ne serrez pas

trop.

4. Branchez le tuyau d'entree d'eau CHAUDE au robinet cl'eau

CHAUDE, et le tuyau d'eau d'entree d'eau FROIDE au

robinet d'eau FROIDE. Serrez fermement a la main. Avec des

pinces, serrez chaque raccord de 2/3 de tour.

5. Ouvrir lesrobinets et s'assurer qu'il n'y a pas de fuite.

COLD

HOT (FROIDE)

(CHAUDE)

20

Page 21

Branchement electrique et branchement du

tuyau de vidange

,

FixezI'une des extremites du crochet du tuyau de vidange

(inclus dans la cuve) au tuyau de vidange. Continuez de

I'enrouler autour du crochet et pincez-le en position.

,

Placez le cote du tuyau de vidange en forme de crochet dans

I'ouverture du tuyau d'evacuation. Fixezle tuyau de vidange

au moyen d'une attache (incluse dans la trousse d'installation

fournie) au tuyau d'evacuation, au tuyau d'entree, a la cuve

lessive, etc. de facon a ce que le tuyau ne puisse _tre attache

sous la force de I'eau.

Assurez-vous que I'alimentation electrique

est coupee au disjoncteur ou au bottler de fusibles avant de

brancher le cordon d'alimentation dans une prise electrique.

3. Branchez le cordon d'alimentation a la prise electrique mise

la terre.

mise_ laterre

coupez pas,

pas et ne mettez pas hors

circuit la broche de raise

la terre de cette fiche.

cordon i ,que,

d'unefiche_

avecrnise_laterre

4. Ouvrez I'alimentation electrique au disjoncteur ou au bottler

de fusibles.

5. Faitesglisser soigneusement la laveuse a son emplacement

ddinitif. Verifiez a nouveau la stabilite de I'appareil. Retirez

et jetez le ruban de la porte.

6. Reportez-vous au Guide d'utilisation et d'entretien fourni

avec la laveuse. II contient des renseignements tres utiles qui

vous permettent d'economiser temps et argent.

7. Pour toute question relative a I'utilisation initiale, veuillez

revolt la section intitulee <<Liste de verification avant service >>

de votre Guide d'utilisation et d'entretien avant d'effectuer

une demande de service.

8. Laissezces instructions a proximite de la laveuse pour vous y

reporter ulterieurement.

ATTACHE

_,,_,,_::_:1'_,_',_:_>'l__:_Un schema electrique et une fiche tech-

nique sont situes sous le panneau superieur de la laveuse,

au-dessus du Iogement de distributeur de detergent.

21

Page 22

Accessoires

Tout defaut d'utiliser les accessoires

fabriques ou certifies par le fabricant pourrait entratner des

blessures, des dommages aux biens ou a la laveuse.

NECESSAIRE DE SUPERPOSITION DE SECHEUSE

PIECEN° 134700600

Selon le modele que vous avez achete, ilse peut qu'un

necessaire pour superposer cette secheuse sur une laveuse

assortie ait ete inclus dans I'achat initial de votre secheuse.

Si votre modele ne comprenait pas de necessaire de

superposition ou que vous en desirez un autre, il vous est

possible d'en commander un.

NECESSAIRE DE RALLONGE DE TUYAU DE VIDANGE

PIECEN° 137098000

Pour atteindre un tuyau d'evacuation qui est trop haut ou

trop loin pour la Iongueur de tuyau fournie, commandez le

NECESSAIREDE RALLONGEDETUYAU DEVIDANGE.

TROUSSE D'INSTALLATION DE MAISON MOBILE

PI[CEN° 137067200

Toute installation dans une maison mobile necessite

I'utilisation d'une TROUSSED'INSTALLATIONDEMAISON

MOBILE.

SOCLE DE RANGEMENT ASSORTI

Consultezletableau ci-dessouspour le style,la couleuret le

numerode piece.

Un socle de rangement, concu expressement pour cette

laveuse, peut _tre utilise afin de soulever votre appareil,

facilitant ainsi son utilisation. Le socle ajoute environ 38 cm

(15 po) a votre laveuse, pour une hauteur totale de 130 cm

(51.25 po).

CLI_ D'APPAREIL UNIVERSELLE

PIECEN° 137019200

UNE CLE D'APPAREILUNIVERSELLE

est offerte pour faciliter le reglage

Ce type de laveuse • Ce type de laveuse •

des pieds de secheuse/laveuse/socle.

CRAYONS DE PEINTURE DE RETOUCHE*

Crayonde retouche Blanc- PIECEN° 5304468812

Crayonde retouche Noir - PIECEN° 5304458932

Crayonde retoucheArgentes- PIECEN° P/N5304471228

*11se peut que d'autres couleurs soient disponibles. Communiquez avec le

marchand qui vous a vendu votre laveuse.

Couleur du

socle* '_..................

Blanc NLPWD15or APWD15or

48062 46262

Noir NLPWD15Eor APWD15E

48066

Argent_s NLPWD15A or N/A

46267

• Les couleurs ne sont pas toutes disponibles pour les socles de ces

modeles. II se peut que d'autres couleurs non mentionn_es ci-dessus

soient disponibles. Communiquez avec le marchand qui vous a vendu

votre laveuse.

Pieces de rechange:

Si vous devez commander des pieces de rechange pour votre _ - RISQUE ELECTRIQUE - Etique-

laveuse, communiquez avec le marchand qui vous a vendu tez tousles ills avant de lesdebrancher pendant I'entretien

votre appareil, des commandes. Des erreurs de c_blage pourraient nuire au

bon fonctionnement de I'appareil, et m_me _tre dangereu-

ses.Verifiez le bon fonctionnement de I'appareil apres tout

entretien.

22

Page 23

REMARQUES

23

Page 24

Loading...

Loading...