Crosley CDEC450KW0 Installation Guide

Installation instructions

instructions 'installation

P/N 137217600A (0905)

Table of Contents

Important Safety Instructions ................................................ 2

Pre-installation Requirements ................................................ 2

Installation Requirements .................................................. 3-7

Installed Dimensions ............................................................. 8

Installation Instructions ................................................... 9-13

Reversing door .............................................................. 14-15

Accessories/Replacement parts............................................ 16

Francais .............................................................................. 17

Important Safety Instructions

Foryour safety the information in this manual must be followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

Recognize safety symbols, words and labels

Safety items throughout this manua{ are labe{ed with a

WARNING or CAUTION based on the risk type as described:

- RISK OF FIRE - Read all of the following instructions before installing and using this appliance:

• Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Placeall materials in a garbage

container or make materials inaccessible to children.

Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

Install the clothes dryer according to the manufacturer's instructions and local codes.

The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA70, or in Canada, the Canadian electrical code C22.1 part 1.

The gas serviceto the dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas

Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

The dryer is designed under ANSI Z 21.5.1 or ANSI/UL2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE

only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

Do not install aclothes dryer with flexible plastic venting material. Flexible venting materials are known to collapse, be eas-

ily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

The instructions in this manual and all other literature included with this dryer are not meant to cover every possible

condition and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and

maintaining any appliance.

may cause serious body harm, death or property damage.

_This symbol alerts you to situations that may

cause bodily injury or property damage.

This symbol alerts you to situations that

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Save these instructions for future reference.

Pre-lnstallation Requirements

Tools and materials needed for installation:

• Adjustable pliers

Phillips, straight, & square bit screw-

drivers

Adjustable wrench

Pipe wrench for gas supply (gas dryer)

LP-resistant thread tape (for natural

gas or LPsupply, gas dryer)

Carpenter's level

External vent hood

4-inch (10.2 cm), rigid metal or semi-

rigid metal exhaust duct work

3-wire or 4-wire 240 volt cord kit

(electric dryer)

4 in. (10.2 cm) clamp

Gas line shutoff valve (gas dryer)

1/2NPT union flare adapters (x2) and

flexible gas supply line (gas dryer)

Metal foil tape (not duct tape)

Electrical System Requirements

Because of potentially inconsistent voltage capabilities, the use of this dryer with power created by gas powered gen-

erators, solar powered generators, wind powered generators or any other generator other than the local utility company is not

recommended.

Electrical requirements for electric dryer

CIRCUIT- Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately fused

circuits for washer and dryer. DO NOT operate a washer and a dryer on the same circuit.

POWERSUPPLY- 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

This dryer is internally grounded to neutral unless it was manufactured for sale in Canada.

Only a 4-conductor cord shall be used when the appliance is installed in a location where grounding through the neutral

conductor is prohibited. Grounding through the neutral link is prohibited for: (1) new branch circuit installations, (2) mobile

homes, (3) recreational vehicles, and (4) areas where local codes do not permit grounding through the neutral.

OUTLETRECEPTACLE- NEMA 10-30R or NEMA 14-30R receptacle to be located so the power supply cord isaccessiblewhen the

dryer is in the installed position.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical Installation section.

3-WIRE POWER SUPPLY CORD KIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3-conductor power supply cord

NEMA 10-30 type SRDTrated at 240 volt AC minimum,

30 amp, with 3 open end spade lug connectors with

upturned ends or closed loop connectors and marked

for use with clothes dryers. For 3-wire cord connection

instructions see ELECTRICALCONNECTIONSFORA

3-WIRE SYSTEM.

Electrical requirements for gas dryer

CIRCUIT- Individual, properly polarized and grounded 15

amp. branch circuit fused with 15 amp. time delay fuse or

circuit breaker.

POWERSUPPLY- 2-wire, with ground, 120 volt, single phase,

60 Hz, Alternating Current.

POWERSUPPLYCORD - The dryer is equipped with a 120 volt

3-wire power cord.

GROUNDING CONNECTION - See "Grounding requirements"

in Electrical Installation section.

4-WIRE POWER SUPPLY CORD KIT (not supplied)

4-wire receptacle

(NEMA type 14-30R)

The dryer MUST employ a 4-conductor power supply cord

NEMA 14-30 type SRDTor ST(as required) rated at 240

volt AC minimum, 30 amp, with 4 open end spade lug

connectors with upturned ends or closed loop connectors

and marked for usewith clothes dryers. For4-wire cord

connection instructions see ELECTRICALCONNECTIONS

FORA 4-WIRE SYSTEM.

Dryers manufactured for sale in Canada have factory-

installed, 4-wire power supply cord (NEMA 14-30R).

Do not, under "_

any circumstances,

cut, remove,

or bypassthe

,_grounding prong. _,

Powercord with

3-prong grounded plug

]

Gas supply requirements

- EXPLOSION HAZARD - Uncoated copper

tubing will corrode when subjected to natural gas, causing

gas leaks. Use ONLY black iron, stainless steel, or plastic-coat-

ed brass piping for gas supply.

1. Installation MUST conform with local codes, or in the

absence of local codes, with the National FuelGas Code,

ANSI Z223.1 (latest edition).

2. The gas supply line should be 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to

connect your dryer to the gas supply line. The tubing

MUST be constructed of stainless steel or plastic-coated

brass.

4. The gas supply line MUST have an individual shutoff valve.

Exhaust system requirements

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When

the dryer stops, the dampers automatically closeto prevent

drafts and the entrance of insects and rodents. Toavoid

restricting the outlet, maintain a minimum of 12 inches (30.5

cm) clearance between the vent hood and the ground or any

other obstruction.

5. A 1/8 inch (0.32 cm) N.RT. plugged tapping, accessible

for test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply

piping system during any pressure testing of the gas

supply piping system at test pressures in excess of 1/2 psig

(3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping

system during any pressure testing of the gas supply

piping system at test pressures equal to or lessthan 1/2

psig (3.45 kPa).

8. Connections for the gas supply must comply with the

Standard for Connectors for Gas Appliances, ANSI Z21.24.

- FIRE HAZARD - Failure to follow these in-

structions can create excessive drying times and fire hazards.

The following are specific requirements for

proper and safe operation of your dryer.

- FIRE HAZARD - Do not install a clothes

dryer with flexible plastic or metal foil venting materials.

Flexible venting materials are known to collapse, be easily

crushed and trap lint. These conditions will obstruct clothes

dryer airflow and increase the risk of fire.

If your present system is made up of plastic duct or metal foil

duct, replace it with a rigid or semi-rigid metal duct. Also,

ensure the present duct isfree of any lint prior to installing

dryer duct.

Correct

ii

Correct

'1i

Incorrect

'1ii

Incorrect

Exhaust system requirements, continued

- FIRE HAZARD - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building. A clothes dryer produces combustible lint. If

the dryer is not exhausted outdoors, some fine lint will be

expelled into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and remove

any accumulation of lint around the outdoor exhaust opening

and in the surrounding area.

- FIRE HAZARD -

• Do not allow combustible materials (for example: clothing,

draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUST NOT be exhausted into a chim-

ney, a wall, a ceiling, or any concealed space of a building

which can accumulate lint, resulting in a fire hazard.

Do not screen the exhaust ends of the vent system, or use

any screws, rivets or other fasteners that extend into the

duct to assemble the exhaust system. Lint can become

caught in the screen, on the screws or rivets, clogging the

duct work and creating a fire hazard as well as increasing

drying times. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with metal foil duct tape.

All male duct pipe fittings MUST be installed downstream

with the flow of air.

- FIRE HAZARD - Exceeding the length of

duct pipe or number of elbows allowed in the "MAXIMUM

LENGTH" charts can cause an accumulation of lint in the ex-

haust system. Plugging the system could create a fire hazard,

as well as increase drying times.

MAXIMUM LENGTH

of 4" (10.2cm) Rigid Metal Duct

VENT HOOD TYPE

o

o_

0

1

2

3

4

o

(lO.2cm)

(Preferred)

4"

64 ft. (19.5 m)

52 ft. (15.9 m)

44 ft. (13.5 m)

32 ft. (9.8 m)

28 ft. (9.5 m)

Iouvered

2.5"

(6.35cm)

48 ft. (14.6 m)

40 ft. (12.2 m)

32 ft. (9.8 m)

24 ft. (7.3 m)

16 ft. (4.9 m)

- FIRE HAZARD -

Do not install flexible plastic or flexible foil venting mate-

rial.

If installing semi-rigid venting, do not exceed 8 ft. (2.4 m)

duct length.

Install male fittings in correct direction:

CORRECT INCORRECT

Exhaust system requirements, continued

In installations where the exhaust system is not described in

the charts, the following method must be used to determine

if the exhaust system is acceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3. Readthe measurement on the manometer.

4. The system back pressure MUST NOT be higher than

0.75 inches of water column. If the system back pressure

is lessthan 0.75 inches of water column, the system is

acceptable. If the manometer reading is higher than .075

inches of water column, the system is too restrictive and

the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could affect

the performance of the dryer:

• Only the rigid metal duct work should be used.

Venting vertically through a roof may expose the exhaust

system to down drafts causing an increase in vent

restriction.

Running the exhaust system through an uninsulated area

may cause condensation and faster accumulation of lint.

Compression or crimping of the exhaust system will cause

an increase in vent restriction.

The exhaust system should be inspected and cleaned a

minimum of every 18 months with normal usage. The

more the dryer is used, the more often you should check

the exhaust system and vent hood for proper operation.

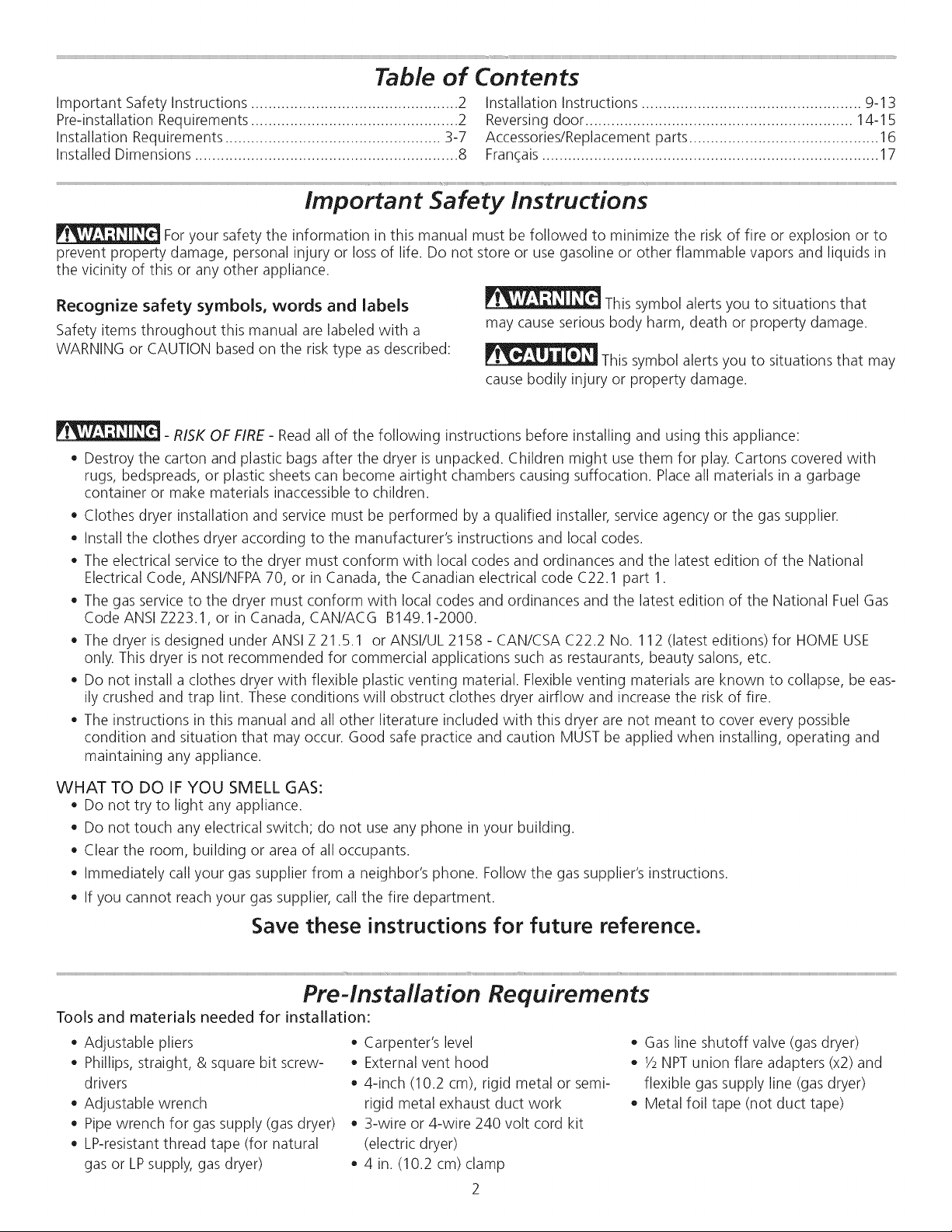

Exhaust direction

Directional exhausting can be accomplished by installing a

quick-turn 90° dryer vent elbow directly to exhaust outlet of

dryer. Dryer vent elbows are available through your local parts

distributor or hardware store.

See also CLEARANCE REQUIREMENTSon the next page.

Use of 90° quick-turn elbow required to meet mini-

mum installation depth of free-standing dryer:

Straight back venting allows for 0" (0 cm) installation.

Venting right with 90° elbow allows for 0.75" (2 cm)

installation.

Venting downward with 90° elbow allows for 0.75" (2 cm)

installation.

Venting left with short, straight adapter and 90° elbow

allows for 3.75" (9.5 cm) installation.

Venting upward with short, straight adapter and 90°

elbow allows for 4" (10.5 cm) installation.

Manufactured or mobile home installation

1. Installation MUST conform to current Manufactured

Home Construction & Safety Standard, Title 24 CFR, Part

32-80 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280) or

Standard CAN/CSAZ240 MH.

2. Dryer MUSTbe exhausted outside (outdoors, not beneath

the mobile home) using metal ducting that will not support

combustion. Metal ducting must be 4 inches (10.16 cm)in

diameter with no obstructions. Rigid metal duct ispreferred.

3. If dryer is exhausted through the floor and area beneath

the mobile home is enclosed, the exhaust system MUST

terminate outside the enclosure with the termination

securely fastened to the mobile home structure.

4. Refer to previous sections in this guide for other important

exhaust venting system requirements.

5. When installing a gas dryer into a mobile home, a

provision must be made for outside make up air. This

provision isto be not lessthan twice the area of the dryer

exhaust outlet.

6. Installer MUST anchor this (1) dryer or (2) dryer mounted

on pedestal to the floor with approved Mobile Home

Installation Kit- P/N 137067200.

Clearance requirements

- EXPLOSION HAZARD - Do not install the

dryer where gasoline or other flammables are kept or stored.

If the dryer is installed in a garage, it must be a minimum

of 18 inches (45.7 cm) above the floor. Failure to do so can

result in death, explosion, fire or burns.

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather

conditions.

2. In an area where it will come in contact with curtains,

drapes, or anything that will obstruct the flow of com-

bustion and ventilation air.

3. On carpet. Floor MUST be solid with a maximum slope of

1 inch (2.54 cm).

INSTALLATION IN A RECESS OR CLOSET

1. A dryer installed in a bedroom, bathroom, recessor closet,

MUST be exhausted outdoors.

2. No other fuel burning appliance shall be installed in the

same closet asthe gas dryer.

3. Your dryer needs the space around it for proper

ventilation.

DO NOT install your dryer in a closet with a solid door.

4. Closet door ventilation required: A minimum of 120

square inches (774.2 cm2)of opening, equally divided at

the top and bottom of the door, is required. Openings

should be located 3 inches (7.6 cm) from bottom and top

of door. Openings are required to be unobstructed when

a door is installed. A Iouvered door with equivalent air

openings for the full length of the door is acceptable.

MINIMUM INSTALLATIONCLEARANCES -Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Under-

Counter

Closet 0" (0 cm) 0" (0 cm)* 0" (0 cm) 1" (2.5 cm)

* For other than straight back venting, a quick-turn 90°

dryer vent elbow (vented right or down in free-standing

dryer or right on pedestal-mounted dryer) must be

installed to achieve 0" (0 cm)installation.

0" (0 cm) 0" (0 cm)* 0" (0 cm) 1" (2.5 cm)

ii

ii

0" -----I1_ _---

(0cm) _ I

_L

0

! t

!

ii ii

ii H

1" --"!l_h _--" 0" _"'€_ m "_'-_

(2.54cm) i _ (Ocm) ii

closet door

i

To achieve an installation with 0" (0 cm) clearance

for the back of the dryer (for other than straight back vent-

ing), a quick-turn 90° dryer vent elbow must be installed as

described previously in this manual.

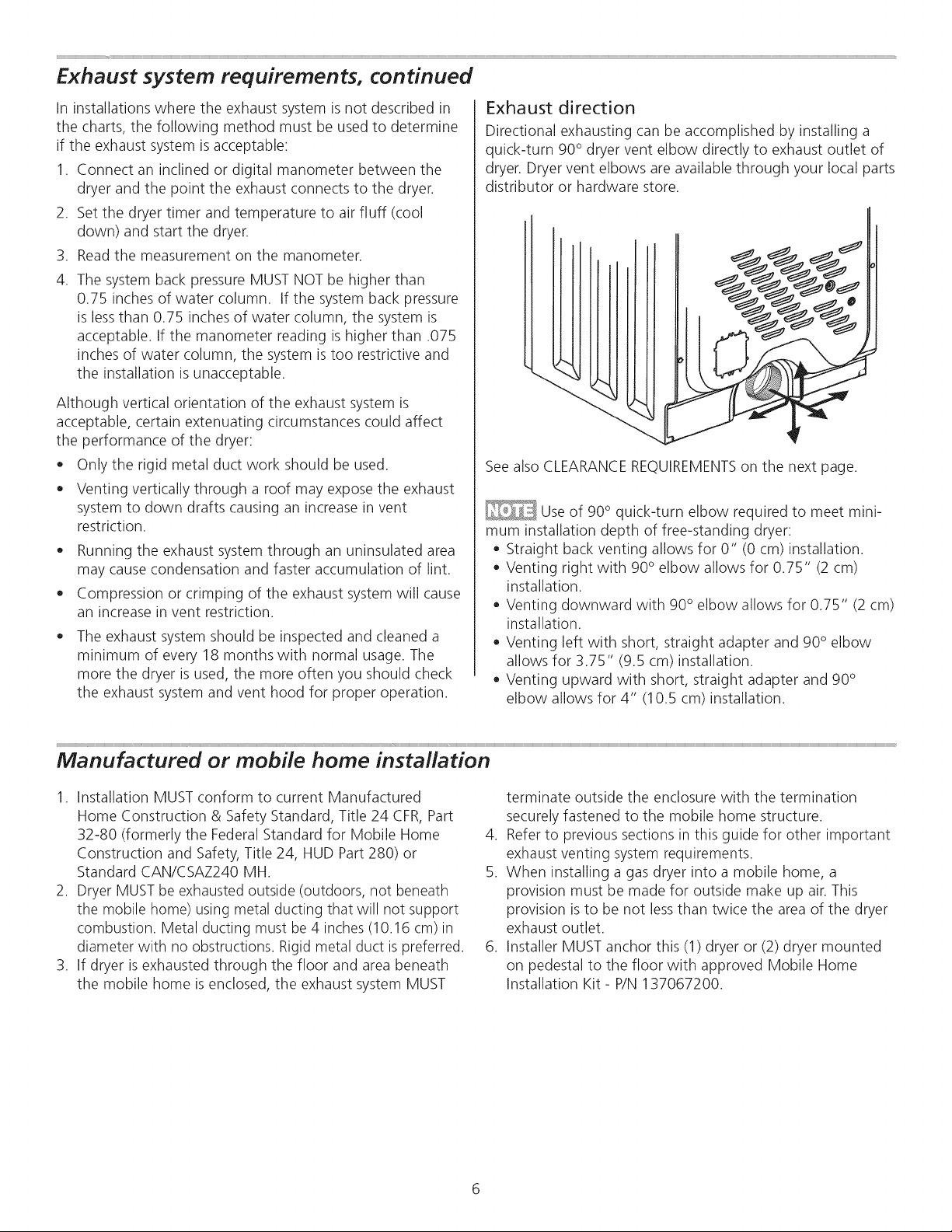

Installed dryer dimensions

._=== 48.25" (122.5cm)'

to clear open door

freestand dryer

on floor

.......... fLo_r=l_ = = =

30.5" (77,5cm)* _-

to front of dosed door

51,25"

(130cm)

36.0"

(91.5cm)

gas supply

pipe on rear

of gas unit

27.0"

(68.5cm)

0

electrical

supply on

rear of unit

c_'_enterline

height for

rear vent

dryer mounted on

optional pedestal

* To obtain these minimal depth dimensions, dryer must be vented straight back.

Using a quick-turn 90 ° elbow (right or down on freestanding dryer) adds approximately

0.75 in. (2.0 cm) to instanation depth. Upward venting of exhaust on pedestal-mounted

or freestanding dryer adds approximately 4 in. (10.2 cm) to installation depth. Leftward

venting on pedestal-mounted or freestanding dryer adds approximately 3.75 in. (9.5 cm)

to installation depth. Downward venting of exhaust on pedestal-mounted dryer adds

approximately 2.25 in. (5.7 cm) to installation depth.

_,_===48.25" (122.5cm)'

to clear open door

f 6.9"

(43cm)

3.75"_ _l====

(9.5cm) _==== 13.50"_

gas supply

pipe on

of gas unit

(34.5cm)

to center of rear vent

27,0'

(68.5cm)

0

19.0"

(48cm)

electrical

supply on

rear of unit

centerline

height for

rear vent

0

l

39"

(99cm)

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90 ° elbow (right) adds approximately 0.75 in. (2 cm) to

installation depth. Upward venting of exhaust on stacked dryer adds approximately 4 in. (40.2 cm) to installation depth. Downward venting of exhaust on

stacked dryer adds approximately 2.25 in. (6.5 cm) to installation depth. Leftward venting of exhaust on stacked dryer adds approximately 3.75 in. (9.5 cm) to

installation depth.

Electrical installation

The following are specific requirements for proper and safe

electrical installation of your dryer. Failure to follow these

instructions can create electrical shock and/or a fire hazard.

- ELECTRICAL SHOCK HAZARD -

• This appliance MUST be properly grounded. Electrical

shock can result if the dryer is not properly grounded.

Follow the instructions in this manual for proper ground-

ing.

Do not use an extension cord with this dryer. Some ex-

tension cords are not designed to withstand the amounts

of electrical current this dryer utilizes and can melt, creat-

ing electrical shock and/or fire hazard. Locate the dryer

within reach of the receptacle for the length power cord

to be purchased, allowing some slack in the cord. Refer

to the pre-installation requirements in this manual for the

proper power cord to be purchased.

longer drying times than dryers operating on 240 volt power

supply.

Grounding requirements - Electric dryer (USA)

- ELECTRICAL SHOCK HAZARD - Improper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance isproperly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. After you purchase and install a 3 wire or 4 wire power

supply cord having an equipment-grounding conductor

and a grounding plug that matches you wiring system,

3. DO NOT modify the plug you've installed on this

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal,

- ELECTRICAL SHOCK HAZARD -

A U.L.-approved strain relief must be installed onto pow-

er cord. If the strain relief is not attached, the cord can be

pulled out of the dryer and can be cut by any movement

of the cord, resulting in electrical shock.

Do not use an aluminum wired receptacle with a copper

wired power cord and plug (or vice versa). A chemical

reaction occurs between copper and aluminum and can

cause electrical shorts. The proper wiring and receptacle

is a copper wired power cord with a copper wired recep-

tacle.

Dryers operating on 208 volt power supply will have

the plug MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

appliance. If it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the appliance.

Grounding requirements - Electric dryer (Canada)

- ELECTRICAL SHOCK HAZARD - Improper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance isproperly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

3. DO NOT modify the plug provided with this appliance. If

it will not fit the outlet, have a proper outlet installed by a

qualified electrician.

1.Thedryerisequippedwithathree-prong(grounding)plug

foryourprotectionagainstshockhazardandshouldbe

pluggeddirectlyintoaproperlygroundedthree-prong

receptacle.

2. Theplugmustbepluggedintoanappropriateoutletthat

isproperlyinstalledandgroundedinaccordancewithall

localcodesandordinances.Ifindoubt,callalicensed

electrician.

3. DONOTmodifytheplugprovidedwiththisappliance.If

itwillnotfit theoutlet,haveaproperoutletinstalledbya

qualifiedelectrician.

Gas connection

Grounding type

wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong,

Powercord with

3-prong grounded plug

,J

"X

/

1. Remove the shipping cap from gas pipe at the rear of the

dryer.

DO NOT connect the dryer to L.R gas service

without converting the gas valve. An L.R conversion kit must

be installed by a qualified gas technician.

2. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27 cm to 0.96 cm) reducer for the connection.

Apply an approved thread sealer that is resistant to the

corrosive action of liquefied gases on all pipe connections.

Manual GASFLOW

Shutoff Flare _ Flare

Valve Union Union

; 1 1

--los R Nipple Flexible Inlet Plpeon

Open Connector Back of Dryer

All connections must be wrench-tightened

The supply line must be equipped with an ap-

proved manual shutoff valve. This valve should be located in

the same room asthe dryer and should be in a location that

allows easeof opening and closing. Do not block accessto

the gas shutoff valve.

3. Open the shutoff valve in the gas supply line to allow gas

to flow through the pipe. Wait a few minutes for gas to

move through the gas line.

Shutoff Valve-

Open position

4. Check for gas system leaks with a manometer. If a

manometer is not available, test all connections by

brushing on a soapy water solution.

- EXPLOSION HAZARD - NEVERtest for gas

leaks with an open flame.

10

3-wire receptacle

(NEMA type 10-30R)

- ELECTRICAL SHOCK HAZARD - Failure

to disconnect power source before servicing could result in

personal injury or even death.

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block access

cover in the lower corner on the back of the dryer.

,

Install a UL-approved strain relief according to the power

cord/strain relief manufacturer's instructions in the power

cord entry hole below the accesspanel. At this time, the

strain relief should be loosely in place.

4. Thread an UNPLUGGED,UL-approved, 30 amp. power

cord, NEMA 10-30 type SRDT,through the strain relief.

5. Attach the power cord neutral (center wire) conductor to

the SILVERcolored center terminal on the terminal block.

Tighten the screw securely.

6. Attach the remaining two power cord outer conductors

to the outer, BRASScolored terminals on the terminal

block. Tighten both screws securely.

_ _ Access cover

screw

Terminal

_S ____ block

_______f (BRASS terminal)

___ (BRASS terminal)

........... UL-approved

.................. _// strain relief here

___ Install

Line 2

Neutral

Internal ground

(GREENscrew)

Terminal screw

recovery slot

- ELECTRICAL SHOCK HAZARD - Do not

make a sharp bend or crimp wiring/conductor at connections.

7. Follow manufacturer's guidelines for firmly securing the

strain relief and power cord.

8. Reinstall the terminal block cover.

If moving dryer from a 4-wire system and

installing it in a 3-wire system, move the internal ground from

the center terminal back to the GREENscrew next to the

terminal block.

If a terminal screw falls during cord installation, it

can be retrieved in the terminal screw recovery slot below the

access panel.

DO NOT remove

internal ground in

a 3-wire system!!

Neutral

terminal

11

Electrical connection (non-Canada) - 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

- ELECTRICAL SHOCK HAZARD - Failure

to disconnect power source before servicing could result in

personal injury or even death.

-- Neutral

',WHITEwire)

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block access

cover in the lower corner on the back of the dryer.

3. Install a UL-approved strain relief according to the power

cord/strain relief manufacturer's instructions in the power

cord entry hole below the accesspanel. At this time, the

strain relief should be loosely in place.

4. Thread an UNPLUGGED,UL-approved, 30 amp. power

cord, NEMA 14-30 type ST or SRDT,through the strain

relief.

5. Disconnect the internal (BLACK) dryer harness ground

wire from the (GREEN)ground screw next to the terminal

block.

6. Attach the ground (GREEN)power cord wire to the

cabinet with the ground (GREEN)screw. Tighten the

screw securely.

7. Move the internal dryer harness ground (BLACK) wire to

the terminal block and attach it along with the neutral

(WHITE) power cord wire conductor to the center, SILVER

colored terminal on the terminal block. Tighten the screw

securely.

8. Attach the REDand BLACK power cord conductors to

the outer, BRASScolored terminals on the terminal block.

Tighten both screws securely.

- ELECTRICAL SHOCK HAZARD - Do not

make a sharp bend or crimp wiring/conductor at connections.

9. Follow manufacturer's guidelines for firmly securing the

strain relief and power cord.

10. Reinstall the terminal block cover.

Access cover

screw

block

Line 2

(BRASSterminal)

Neutral

(SILVERterminal)

Line 1

(BRASSterminal)

Internal ground

(GREENscrew)

............ UL-approved

____ Install

strain relief here

Terminal screw

recovery slot

If a terminal screw falls during cord installation, it

can be retrieved in the terminal screw recovery slot below the

access panel.

Move internal ground (BLACK)

neutral (SILVER)

wire to for 4-wire system. "_h

terminal

/

"\\\

GREEN

|

Neutral

terminal

WHITE

neutral wire

ground screw

12

GREEN

ground wir,

RED power wir

BLACK

or RED

power wire

BLACK or

General installation

.

Connect the exhaust duct to the outside exhaust system

(see pages 4 through 6). Use of a 4" (10.2 cm) clamp (item

A) isrecommended to connect the dryer to the exhaust

vent system. Use metal foil tape to seal all other joints.

.

Carefully slide the dryer to its final position. Adjust one or

more of the legs until the dryer is resting solidly on all four

legs. Place a level on top of the dryer. The dryer MUST be

level and resting solidly on all four legs. Rock alternating

corners to check for stability. Remove and discard door

tape.

Be sure the power isoff at a circuit breaker/

fuse box before plugging the power cord into an outlet.

3. Plug the power cord into a grounded outlet.

4. Turn on the power at the circuit breaker/fuse box.

5. Readthe Use& Care Guide provided with the dryer. It

contains valuable and helpful information that will save

you time and money.

6. If you have any questions during initial operation, please

review the "Avoid Service Checklist" in your Use & Care

Guide before calling for service.

7. Placethese instructions in a location near the dryer for

future reference.

A wiring diagram and technical data sheet are

located inside the dryer console,

wall rece

any circumstances,

Power coid with

3-prong grounded p!ug

13

Window Door Reversal Instructions

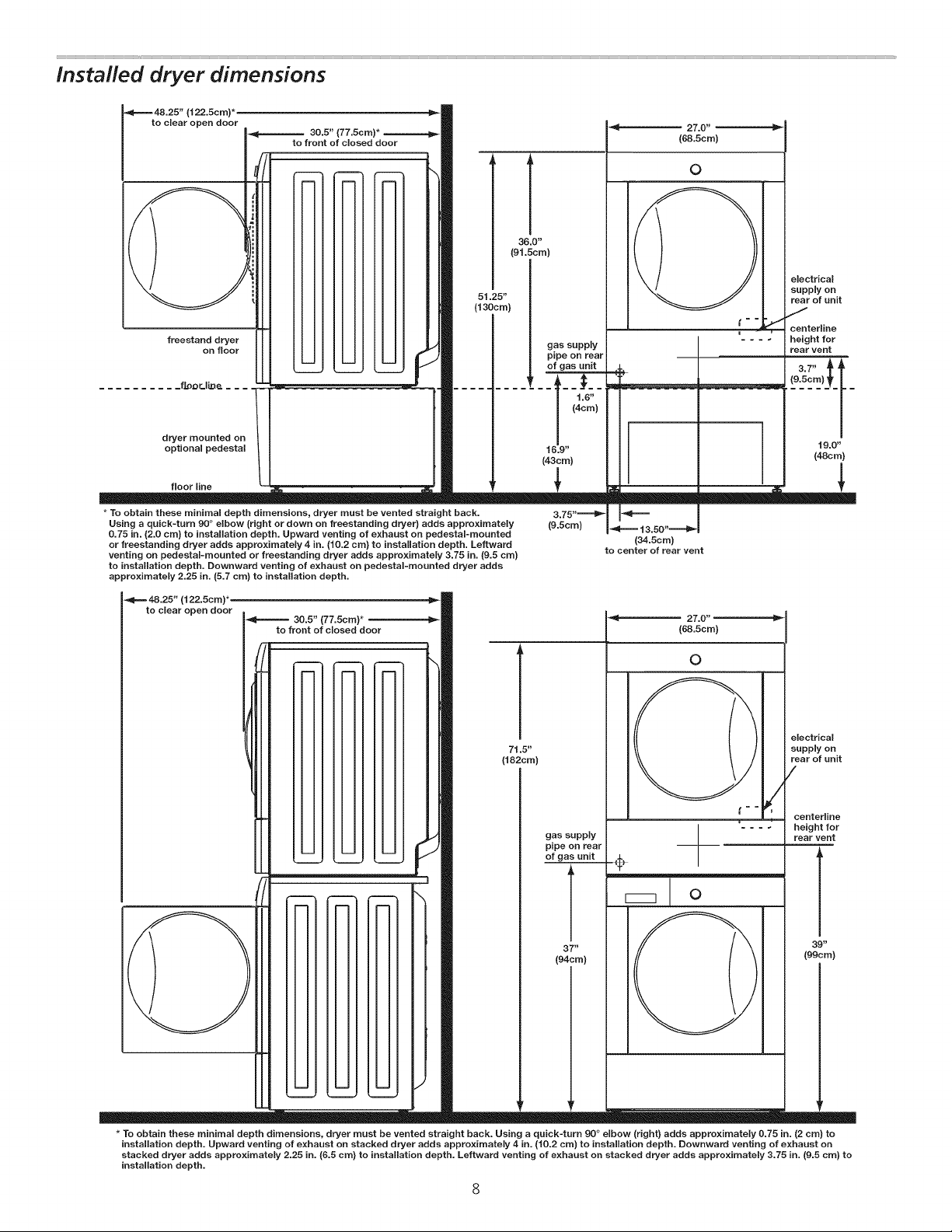

Figure I

1.Open door and remove four (4) plugs in the door opening

opposite the hinges. Retain all parts for uses later, unless

otherwise noted. (Figure 1) Note; Use care in removing plugs

in not scratching paint on the front panel.

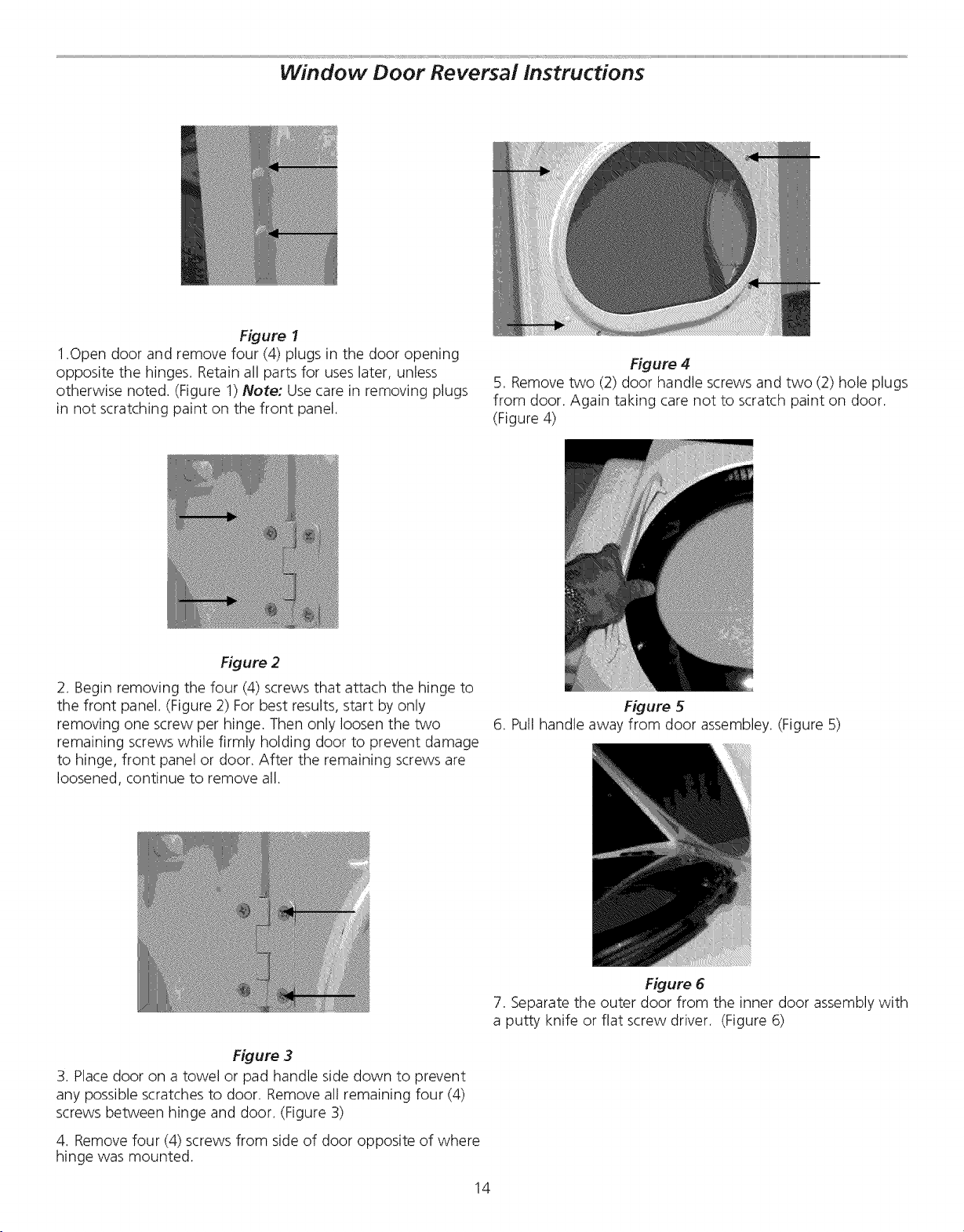

Figure 4

5, Remove two (2) door handle screws and two (2) hole plugs

from door. Again taking care not to scratch paint on door,

(Figure 4)

Figure 2

2, Begin removing the four (4) screws that attach the hinge to

the front panel. (Figure 2) For best results, start by only

removing one screw per hinge. Then only loosen the two

remaining screws while firmly holding door to prevent damage

to hinge, front panel or door. After the remaining screws are

loosened, continue to remove all.

Figure 3

3. Place door on a towel or pad handle side down to prevent

any possible scratches to door. Remove all remaining four (4)

screws between hinge and door. (Figure 3)

Figure 5

6. Pull handle away from door assembley. (Figure 5)

Figure 6

7. Separate the outer door from the inner door assembly with

a putty knife or flat screw driver, (Figure 6)

4. Remove four (4) screws from side of door opposite of where

hinge was mounted,

14

Figure 7

8. Remove lens locating screw. (Figure 7)

11.Reassemblelenstotransitionringwithholesto install

handleonright-handsideofdoorassembly.Forproperfit

insuretheretentiontabsontransitionringareontopoflens

Figure 11

12. Reassembly outer door to inner door assembly. (Figure 11)

13. Install four (4) screws securing hinge to door assembly in

the new location, take note to place hinge in correct

orientation.

14. Install four (4) screws into holes that had secured the

hinge.

15. Remove striker and discard.

Figure 8

9. Disengaging several of the retention tabs and pull lens away

from the transition ring. (Figure 8)

Figure 9

16. Remove square plug and reinstall in hole striker was just

removed.

17. Install striker (included in literature bag) into hole square

plug was previously installed.

Figure 12

18. Reinstall door handle by placing the handle mounting

bossesthrough holes in lens and transition ring and installing

screws through inner door and tighten into handle bosses.

(Figure 12).

Figure 10

10. Remove two (2) transition ring plugs and reinstall on

previous handle side. (Figures 9 and 1O)

19. Grasping firmly the top of the door, position the door near

the door opening and align the top hinge hole to the top hole

in the front panel door opening. Once the first screw is started,

attach the second screw to the lower hinge. Once both screws

are tightened, instal{ the remaining two screws.

20. Install four (4) plugs into the front panel door opening

where hinges were originally installed.

15

Accessories

MATCHING STORAGE PEDESTAL*

White Pedestal-P/NNLPWD15or 48062

BlackPedestal- P/NNLPWD15Eor 48066

SilverPedestal- P/NNLPWD15Aor 46267

*Other colors may be available. Contact the source where you purchased

your dryer.

A storage pedestal accessory, specifically designed for this

dryer may be used to elevate the dryer for ease of use. This

pedestal will add about 15" (38 cm) to the height of your

unit for a total height of 51.25" (130 cm).

DRYER STACKING KIT

P/N134700600

Depending on the model you purchased, a kit for stacking

this dryer on top of matching washer may have been

included in the initial purchase of your dryer. If your model

did not include a stacking kit or you desire another stacking

kit, you may order one.

LP CONVERSION KIT

P/NPCK4200

Gas dryers intended for use in a location supplied with LP

must use a conversion kit prior to installation.

MOBILE HOME INSTALLATION KIT

P/N137067200

Installations in mobile homes require use of MOBILE HOME

INSTALLATIONKIT.

Failureto use accessoriesmanufactured by (or

approved by) the manufacturer could result in personal injury,

property damage or damage to the dryer.

7_00',

'S,00,,

DRYING RACK

P/N137067300

Depending on the model you purchased, a drying rack may

have been included in the initial purchase of your dryer.

If your model did not include a drying rack or you desire

another drying rack, you may order one.

UNIVERSAL APPLIANCE WRENCH

P/N137019200

A UNIVERSALAPPLIANCEWRENCH is available to aid in

dryer/washer/pedestal feet adjustment.

TOUCH UP PAINT PENS*

White TouchUpPen- P/N5303321319

BlackTouchUp Pen- P/N5304458932

SilverTouchUp Pen- P/N5304471228

*Other colors may be available. Contact the source where you purchased

your dryer.

Replacement parts:

If replacements parts are needed for your dryer, contact the _ - ELECTRICAL SHOCK HAZARD - Label all

source where you purchased your dryer, wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify

proper operation after servicing.

16

Table des matieres

Mesures de securite importantes ......................................... 17 Instructions d'installation .............................................. 24-28

Exigences avant I'installation ............................................... 17 Inversion de la porte ..................................................... 29-30

Exigences d'installation ................................................. 18-22 Accessoires/Piecesde rechange ........................................... 31

Dimensions, appareil installe ............................................... 23

Mesures de securite importantes

Pourvotre securite, I'information contenue clansces instructions dolt _tre suivie afin de reduire lesris-

ques d'incendie ou d'explosion ou pour prevenir lesdommages materiels, lesblessuresou la mort. Vous ne devez ni entreposer, ni

utiliser d'essence ou d'autres vapeurs ou liquides inflammables a proximite de cet appareil ou de tout autre appareil electromenager.

Sachez reconna_tre les symboles, les avertisse-

ments et les _tiquettes de s_curit_.

Lesmesures de securite presentees dans ce guide sont identi-

flees par le mot AVERTISSEMENTou ATTENTIONselon le type

de risque presente.

- RISQUE D'INCENDIE - Lisez toutes les instructions de securite suivantes avant d'installer et d'utili-

set votre appareil :

• Detruisez lecarton d'emballage et lessacsen plastique apresavoir deballe I'appareil. Lesenfants pourraient lesutiliser pour jouer.

Lecarton recouvert de tapis, lescouvertures et lesfeuilles de plastique peuvent _tre etanchesa I'air et provoquer lasuffocation.

Deposeztousles materiaux d'emballage dans un conteneur a dechetsou faites en sorte que les enfants ne puissenty avoir acces.

L'installation et I'entretien de cette secheuse doivent _tre realises par un installateur qualifie, un technicien de service ou le

fournisseur de gaz.

Installez I'appareil conformement aux instructions du fabricant et aux codes Iocaux.

L'installation electrique de la secheuse dolt _tre conforme aux codes et aux reglements Iocaux ainsi qu'a la toute derniere

edition du National Electrical Code (ANSI/NFPA70), ou au Canada, au Code canadien de I'electricite (C22.1, article 1).

L'installation de gaz de la secheuse dolt _tre conforme aux codes et aux reglements Iocaux ainsi qu'a la toute derniere

edition du Fuel Gas Code (ANSI Z223.1), ou au Canada, au CAN/ACG B149.1-2000.

La secheuse est classee, en vertu des reglements ANSI Z 21.5.1 ou ANSI/UL 21 58 - CAN/CSA C22.2 N° 112 (dernieres

versions), pour un USAGE DOMESTIQUEuniquement. II n'est pas recommande d'utiliser cette secheuse pour des usages

commerciaux, comme des restaurants, des salons de coiffure, etc.

N'installez pas une secheuse avec du materiel d'evacuation en plastique ou en feuille metallique flexible. Le materiel de

ventilation flexible peut s'ecraser facilement et emprisonner la charpie. Ces conditions nuiraient a I'ecoulement d'air de

votre secheuse et pourraient accrottre le risque d'incendie.

Lesinstructions comprises dans ce guide et toute autre documentation fournie avec cet appareil ne sont pas concues pour

couvrir toutes les eventualites ou situations qui pourraient survenir. Vous DEVEZfaire preuve de bon sens et de prudence

durant I'installation, I'utilisation et I'entretien de tout appareil menager.

des situations pouvant causer des dommages materiels, des

blessures graves ou m#me la mort.

_Ce symbole vous avertit apropos des

situations pouvant causer des dommages mat#riels ou des

blessures.

Ce symbole vous avertit a propos

QUE FAIRE SI VOUS Dt_TECTEZ UNE ODEUR DE GAZ :

Ne mettez pas d'appareil en marche.

Ne touchez a aucun commutateur electrique; n'utilisez aucun telephone de votre domicile.

Evacuez la piece, le b_timent ou la zone touchee.

En utilisant le telephone d'un voisin, appelez immediatement le fournisseur de gaz. Suivez ses instructions.

Si vous ne pouvez joindre votre fournisseur de gaz, appelez les pompiers.

Conservez ces instructions pour vous y reporter ulterieurement.

Exigences avant i'installation

Outils et materiel necessaires a I'installation :

Pince reglable

Tournevis Phillips a pointe plate et

pointe carree

Cle a molette

Cle a tuyau pour I'alimentation en gaz

Ruban a filetage resistant au GPL

(pour I'alimentation en gaz naturel ou

en GPL)

Niveau de charpentier

Event exterieur

Conduit d'evacuation de 10,2 cm (4

po) en metal rigide ou semi-rigide

Ensemble pour cordon d'alimenta-

tion de 240 V a 3 ou 4 ills (secheuse

electrique)

Collier de 10,2 cm (4 po)

17

Robinet d'arr@tpour conduite de gaz

(secheuse a gaz)

Deux raccords-unions a evasement de

1/2 po (1,3 cm) NPTet une conduite

flexible d'alimentation en gaz (se-

cheuse a gaz)

Ruban metallique (et non du ruban

conduits)

Exigences des systemes electriques

_;;:::_ _::_ Etant donne les variations de tension possibles, I'utilisation de cette secheuse avec une source d'alimentation

produite par une generatrice a essence, solaire ou eolienne ou par toute autre source d'alimentation differente de celle fournie

par lesservices publics n'est pas recommandee.

Exigences electriques de la secheuse electrique:

CIRCUIT- Circuit independant de 30 amperes avec fusible temporise ou disjoncteur de 30 A. Utilisez des circuits independants

pour la laveuse et la secheuse. NE BRANCHEZPASla laveuse et la secheuse sur le m_me circuit.

ALIMENTATION ELECTRIQUE- Cable monophase a trois ou quatre ills, 240 volts, 60 Hz; courant alternatif.

Cette secheuse est mise a la terre par le fil d'alimentation neutre, sauf si elle est destin@ a la vente au Canada.

II est imperatif d'utiliser un cordon d'alimentation a 4 ills Iorsque I'appareil est installe dans une region ou la mise a la terre

par le fil d'alimentation neutre est interdite. La mise a la terre par le fil d'alimentation neutre est interdit pour : (1) un nouveau

circuit de derivation, (2) les maisons mobiles, (3) lesvehicules recreatifs, et (4) les regions ou les codes Iocaux ne permettent

pas la mise a la terre par le fil d'alimentation neutre.

PRISE- PriseNEMA 10-30R ou NEMA 14-30R situee de maniere a permettre I'ac@s au cordon d'alimentation Iorsque la

secheuse est a sa position de fonctionnement.

CONNEXION DE MISEA LA TERRE- Consultez la rubrique <<Exigencesde mise a la terre >>dans la section d'installation

electrique.

TROUSSE DECORDON D'ALIMENTATION _, TROIS FILS

(non fournie)

Prise a 3 alv_oles

(NEMA type 10-30R)

La secheuse DOlT utiliser un cordon d'alimentation a

trois ills NEMA 10-30 de type SRDTd'une capacite de

240 volts (c.a.) et d'au moins 30 amperes, avec trois

connecteurs ouverts embrochables avec extremites

renvers@s, ou connecteurs a boucle fermee, specialement

indiques pour une utilisation avec une secheuse. Pour les

instructions de raccordement du cordon a 3 ills, consultez

la section CONNEXIONS ELECTRIQUESPOURUN SYSTEME

A TROISFILS.

TROUSSE DECORDON D'ALIMENTATION _, QUATRE FILS

(non fournie)

Prise a 4 alv_oles

(NEMA type 14-30R)

La secheuse DOlT utiliser un cordon d'alimentation a

quatre ills NEMA 14-30 de type SRDTd'une capacite de

240 volts (c.a.) et d'au moins 30 amperes, avec quatre

connecteurs ouverts embrochables avec extremites

renvers@s, ou connecteurs a boucle fermee, specialement

indiques pour une utilisation avec une secheuse. Pour

les instructions de raccordement du cordon a quatre ills,

consultez la section CONNEXIONS ELECTRIQUESPOURUN

SYSTEMEA QUATREFILS.

'_:s _i; ® _]_ Lessecheusesdestin@s a la vente au Canada

sont munies d'un cordon d'alimentation a 4 ills (NEMA 14-30R).

Exigences electriques de la secheuse b gaz: Prise muraleavec

CIRCUIT- Circuit independant de 15 amperes, polarise et mis a la terre,

avec fusible temporise ou disjoncteur de 15 A.

ALIMENTATION ELECTRIQUE- Cable monophase a deux ills mis a la terre,

120 volts, 60 Hz; courant alternatif.

CORDON D'ALIMENTATION - La secheuse est dotee d'un cordon

d'alimentation de 120 volts a trois ills.

CONNEXION DE MISEA LA TERRE- Consultez la rubrique <<Exigencesde

mise a la terre >>dans la section d'installation electrique.

raise _ la terre

[/Ne coupez pas, n'enlevez_

_lpas et ne mettez pas hors I

circuitlabrochederaise I

laterrede cettefiche.j,)

C rdon

o ._ectiq " _[I

d'unefiche_troisbroches_

avecmise_laterre _

18

-RISQUE D'EXPLOSION - Un tuyau

en cuivre sans rev_tement secorrode Iorsqu'il entre en contact

avec le gaz naturel, entra;nant des fuites. Utilisez SEULEMENT

des tuyaux en fer noir, en acier inoxydable ou encore en cuivre

avec rev_tement en plastique pour I'alimentation en gaz.

1. L'installation DOlT _tre conforme aux codes Iocaux ou au

code national sur le combustible, ANSI Z223.1 (derniere

version), s'il n'existe pas de codes Iocaux.

2. Letuyau d'alimentation en gaz dolt _tre d'un diametre

interieur de 1,27 cm (1/2 po).

3. Si les codes le permettent, un tuyau metallique flexible

peut _tre utilise pour raccorder votre secheuse au tuyau

d'alimentation en gaz. Le tuyau DOlT _tre fabrique

en acier inoxydable ou en laiton avec rev_tement en

plastique.

4. Letuyau d'alimentation en gaz DOlT _tre muni d'un

Exigences du systeme d'evacuation

Utilisez seulement des conduites metalliques rigides ou flexibles

d'au moins 10,2 cm (4 po) de diametre, et une bouche

d'evacuation qui possedeun ou desvolets qui s'ouvrent Iorsque

I'appareil est en fonction. Lorsquela secheuses'arr_te, lesvolets

seferment automatiquement pour emp_cher les infiltrations

d'air, d'insectes et de rongeurs. Pour eviter de bloquer la sortie,

gardez un espaceminimal de 30,5 cm (12 po) entre le has de la

bouche d'evacuation et le sol ou toute autre obstruction.

robinet d'arr_t distinct.

5. Un orifice taraude de 0,32 cm (1/8 po) bouche, accessible

pour le branchement de la jauge d'essai, DOlT _tre

insta% directement en amont du branchement du tuyau

d'alimentation en gaz avec la secheuse.

6. Cette secheuse DOlT _tre debranchee de la canalisation

de gaz pendant toute verification de pression de la

canalisation de gaz a des pressions superieures a 3,45 kPa

(1/2 Ib/po2).

7. Cette secheuse DOlT _tre isolee de la canalisation de gaz

pendant toute verification de pression de la canalisation

de gaz a des pressions egales ou inferieures a 3,45 kPa

(1/2 Ib/po2).

8. Lesbranchements d'alimentation en gaz doivent _tre

conformes a la norme Connectors for GasAppliances

(Raccords pour appareils au gaz) ANSI Z21.24.

- RISQUE D'INCENDIE - Le non-res-

pect de ces instructions pourrait augmenter demesurement

les temps de sechage et entratner des risques d'incendie.

Vous trouverez ci-dessous les exigences pour

I'utilisation adequate et s_curitaire de votre

appareil.

- RISQUE D'INCENDIE - N'installez

pas une secheuse avec du materiel d'evacuation en plastique

ou en feuille metallique flexible. Le materiel de ventilation

flexible peut s'ecraser facilement et emprisonner la charpie.

Ces conditions nuiraient a I'ecoulement d'air de votre secheu-

se et pourraient accrottre le risque d'incendie.

Sivotre systeme actuel utilise une conduite en plastique ou en

feuille metallique, remplacez-la par une conduite metallique

rigide ou semi-rigide. De plus, assurez-vousque la conduite

en place est libre de charpie avant d'installer la conduite de

secheuse.

Correct

ii

Correct

'1i

Incorrect

Incorrect

19

Exigences de systeme d'evacuation (suite)

- RISQUE D'INCENDIE - Une se-

cheuse dolt _tre evacuee vers I'exterieur. N'evacuez pas une

secheuse dans une cheminee, un mur, un plafond, un grenier,

un vide sanitaire ou dans tout espace clos d'un b_timent. La

secheuse produit de la charpie inflammable. Si la secheuse

n'est pas evacuee vers I'exterieur, de la charpie pourrait _tre

evacuee dans I'aire de buanderie. L'accumulation de charpie

dans toute piece de la maison peut entratner des risques pour

la sante et des risques d'incendie.

La secheuse dolt _tre branchee a une evacuation exterieure.

Inspectez regulierement I'ouverture de I'evacuation exterieure

et retirez toute accumulation de charpie pres de I'ouverture et

de la region avoisinante.

- RISQUE D'INCENDIE -

• Ne laissez pas de matiere combustible (par exemple : des

v_tements, des rideaux, du papier) entrer en contact avec

le systeme d'evacuation. La secheuse NEDOlT PAS_tre

evacuee dans une cheminee, un mur, un plafond, ou dans

tout espace confine d'un b_timent qui pourrait accumuler

la charpie, entratnant un risque d'incendie.

Ne placez pas de grillage a I'extremite du systeme d'eva-

cuation, ni de vis, de rivet ou autre fixation de maniere

ce qu'ils se prolongent dans la conduite du systeme d'eva-

cuation. De la charpie pourrait s'accumuler sur le grillage,

lesvis ou les rivets, et obstruer I'ecoulement d'air dans le

systeme, entratnant un risque d'incendie et I'augmenta-

tion des temps de sechage. Utilisez une bouche d'evacua-

tion approuvee pour terminer la conduite a I'exterieur, et

scellez tousles joints avec du ruban metallique. Toutes les

extremites m_les des conduites doivent _tre installees en

aval relativement au sens de I'ecoulement d'air.

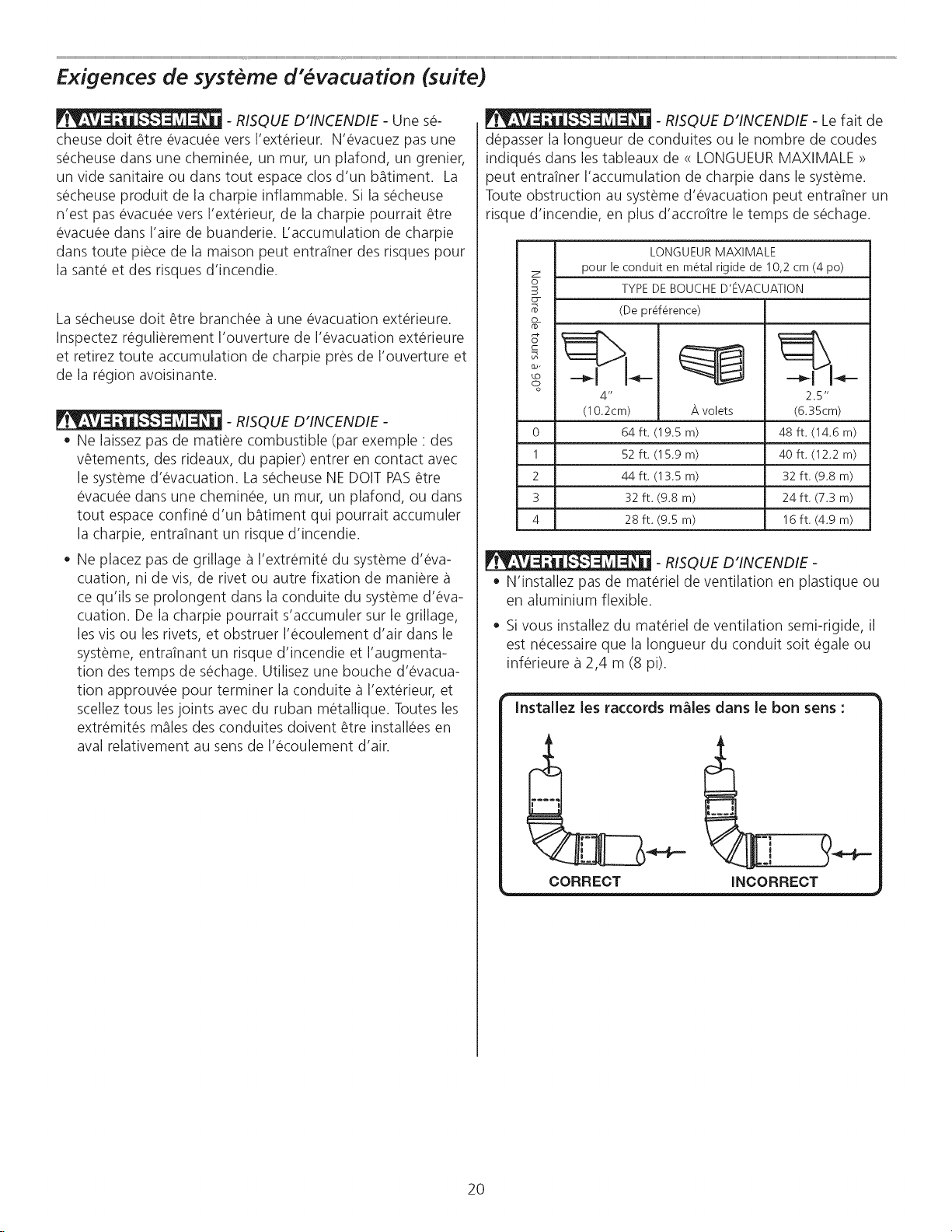

- RISQUE D'INCENDIE - Le fait de

depasser la Iongueur de conduites ou le nombre de coudes

indiques dans les tableaux de <<LONGUEURMAXIMALE >>

peut entratner I'accumulation de charpie dans le systeme.

Toute obstruction au systeme d'evacuation peut entratner un

risque d'incendie, en plus d'accrottre le temps de sechage.

LONGUEUR MAXIMALE

z pour le conduit en m_tal rigide de 10,2 cm (4 pc)

o

c

o_

0

1

2

3

4

o

TYPE DE BOUCHE D'EVACUATION

(De preference)

4"

(10.2cm)

64 ft. (19.5 m)

52 ft. (15.9 m)

44 ft. (13.5 m)

32 ft. (9.8 m)

28 ft. (9.5 m)

_,volets

2.5"

(6.35cm)

48 ft. (14.6 m)

40 ft. (12.2 m)

32 ft. (9.8 m)

24 ft. (7.3 m)

16 ft. (4.9 m)

- RISQUE D'INCENDIE -

N'installez pas de materiel de ventilation en plastique ou

en aluminium flexible.

Si vous installez du materiel de ventilation semi-rigide, il

est necessaireque la Iongueur du conduit soit egale ou

inferieure a 2,4 m (8 pi).

Installez les raccords m_les dans le bon sens :

20

CORRECT INCORRECT

Loading...

Loading...