CROSLEY NTW5800TQ, 1CWTW5700SW, CAWS833ST, CAWS833SQ, ATW4471TQ Installation Instructions

...Page 1

WASHER INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION DE LA LAVEUSE

Table of Contents / Table des matières

WASHER SAFETY.................................................................................. 1

INSTALLATION REQUIREMENTS........................................................ 2

Tools and Parts ................................................................................... 2

Location Requirements....................................................................... 3

Drain System ....................................................................................... 3

Electrical Requirements ...................................................................... 4

INSTALLATION INSTRUCTIONS.......................................................... 4

Before You Start.................................................................................. 4

Remove Shipping Materials ................................................................ 4

Connect Drain Hose............................................................................ 6

Connect the Inlet Hoses...................................................................... 6

Secure the Drain Hose ........................................................................ 7

Level the Washer................................................................................. 7

Complete Installation ........................................................................... 8

Para obtener acceso al manual de uso y cuidado en español, o para obtener información adicional acerca de su producto, visite:

www.whirlpool.com.

Tenga listo su número de modelo completo. Podrá encontrar el número de modelo y de serie en la etiqueta ubicada debajo de la tapa

de la lavadora.

SÉCURITÉ DE LA LAVEUSE......................................................................9

EXIGENCES D’INSTALLATION .................................................................9

Outillage et pièces....................................................................................9

Exigences d’emplacement ....................................................................10

Système de vidange ..............................................................................10

Spécifications électriques......................................................................11

INSTRUCTIONS D’INSTALLATION.........................................................12

Avant de commencer.............................................................................12

Retrait du matériel d'expédition.............................................................12

Raccordement du tuyau de vidange .....................................................13

Raccordement des tuyaux d’arrivée d’eau ...........................................13

Immobilisation du tuyau de vidange......................................................14

Réglage de l’aplomb de la laveuse........................................................15

Achever l’installation..............................................................................16

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

W10150593A

Page 2

INSTALLATION REQUIREMENTS

Tools and Parts

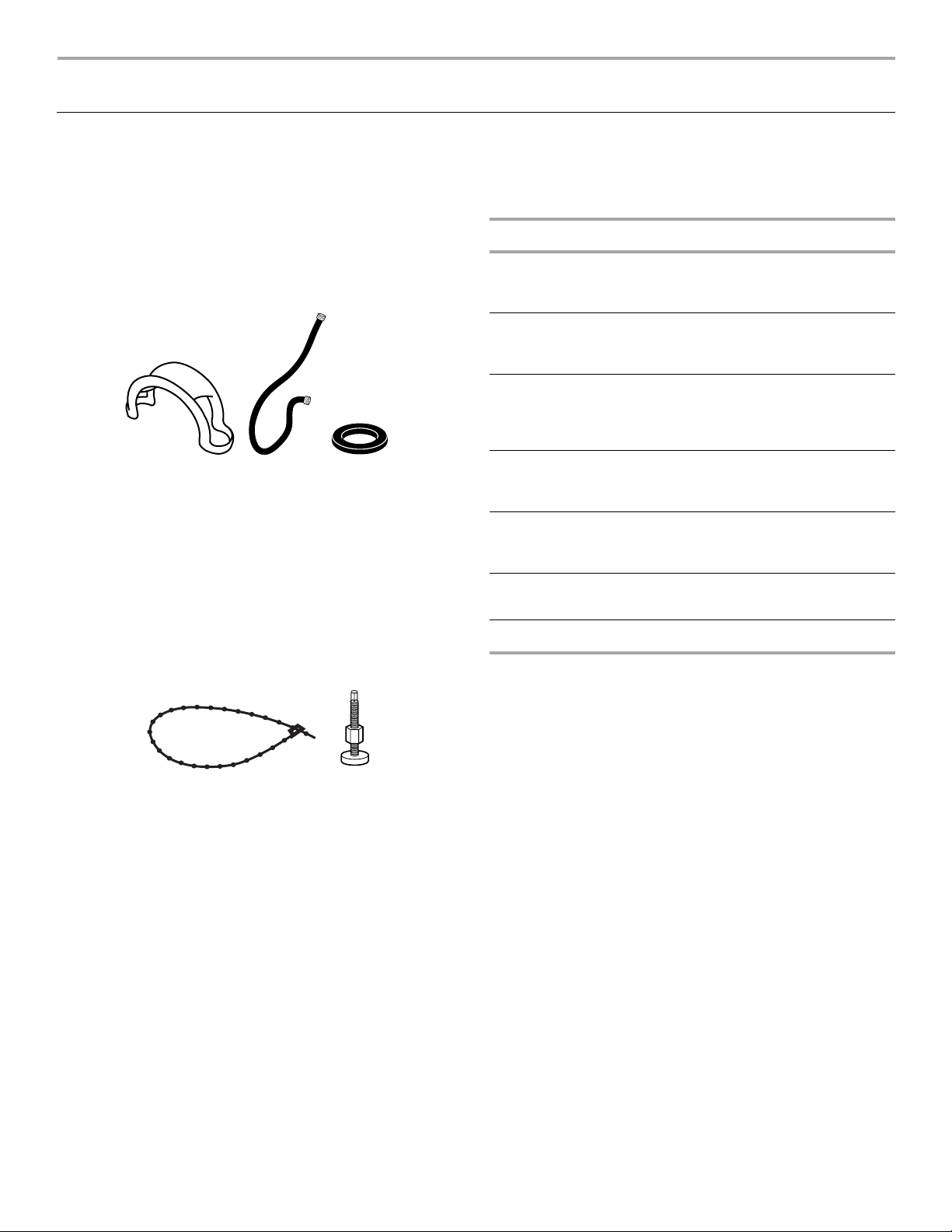

Gather the required tools and parts before starting installation.

The parts supplied are in the washer basket.

Tools needed for connecting the drain hose and water

inlet hoses:

■ Pliers that open to 1⁹⁄₁₆"

(3.95 cm)

Parts supplied:

■ Flashlight (optional)

Alternate Parts

Your installation may require additional parts. For information on

ordering, please refer to the toll-free phone numbers on the front

page of the Washer User Instructions.

If You Have: You Will Need to Buy:

Laundry tub or

standpipe taller

than 96" (2.4 m)

Sump pump system (if not already

available)

AB

A. Drain hose form

B. Water inlet hoses (2)

C. Flat water inlet hose washers (4)

C

Tools needed for securing the drain hose and leveling

the washer:

■ Adjustable or open end

wrench ⁹⁄₁₆" (14 mm)

■ Level

■ Wood block

■ Ruler or measuring tape

Parts supplied:

1" (2.5 cm)

diameter

standpipe

Overhead sewer Standard 20 gal. (76 L) 39" (99 cm) tall

Floor drain Siphon break kit, Part Number 280129;

Water faucets

beyond reach of fill

hoses

Drain hose too

short

Lint clogged drain Drain protector, Part Number 367031

1¹⁄₄" (3.2 cm) diameter to 1" (2.5 cm)

diameter standpipe adapter,

Part Number 280130

drain tub or utility sink, sump pump and

connectors (available from local

plumbing suppliers)

additional drain hose,

Part Number 3357090

2 longer water fill hoses:

6 ft (1.8 m) Part Number 76314,

10 ft (3.0 m) Part Number 350008

Kit Part Number 280131

A

A. Beaded tie strap

B. Front leveling feet with nuts (2)

B

2

Page 3

Location Requirements

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room, closet,

or recessed area. See “Drain System.”

IMPORTANT: Do not install or store the washer where it will be

exposed to the weather.

Proper installation is your responsibility.

You will need:

■ A water heater set to deliver 120°F (49°C) water to the washer.

■ A grounded electrical outlet located within 4 ft (1.2 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

■ Hot and cold water faucets located within 3 ft (90 cm) of the

hot and cold water fill valves, and water pressure of 5-100 psi

(34.5-690 kPa). Washers with triple dispensers require

20-100 psi (138-690 kPa) for best performance.

■ A level floor with a maximum slope of 1" (2.5 cm) under entire

washer. Installing the washer on carpeting is not

recommended.

■ A sturdy floor to support the washer weight (washer, water

and load) of 315 lbs (143 kgs).

Do not store or operate your washer in temperatures at or below

32°F (0°C). Some water can remain in the washer and can cause

damage in low temperatures. See “Washer Care” in the Washer

User Instructions for information on winterizing.

Recessed area or closet installation

Drain System

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need. See

“Tools and Parts.”

Standpipe drain system—wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe of

2" (5 cm). The minimum carry-away capacity can be no less than

17 gal. (64 L) per minute. A 1¹⁄₄" (3.2 cm) diameter to 1" (2.5 cm)

diameter standpipe adapter kit is available. See “Tools and Parts.”

The top of the standpipe must be at least 39" (99 cm) high and no

higher than 96" (244 cm) from the bottom of the washer.

To avoid siphoning, no more than 8" (20.3 cm) of drain hose

should be inside the standpipe. Secure drain hose with beaded tie

strap.

39"

(99 cm)

A

B

The dimensions shown are for the recommended spacing allowed

(A and B), except the closet door ventilation openings. The

dimensions shown for the closet door ventilation openings (C) are

the minimum required.

3"

14" max.

(35.6 cm)

19"

(48.3 cm)

0"

(0 cm)

(68.6 cm)

A

■ Additional spacing should be considered for ease of

0"

27"

1"

(0 cm)

(2.5 cm)

A. Front view

B. Side view

C. Closet door with vents

25

¹⁄₂"

(64.8 cm)

B

2

48 in.

2

(310 cm )

2

24 in.

2

(155 cm )

4"

(10.2 cm)

(7.6 cm)

3"

(7.6 cm)

C

installation and servicing.

■ Additional clearances may be required for wall, door and floor

moldings.

■ Additional spacing of 1" (2.5 cm) on all sides of the washer is

recommended to reduce noise transfer.

■ If a closet door is installed, the minimum air openings in the

top and bottom of the door are required (C). Louvered doors

with air openings in the top and bottom are acceptable.

■ Companion appliance spacing should also be considered.

Laundry tub drain system (view C)

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top

of the laundry tub must be at least 39" (99 cm) above the floor and

no higher than 96" (244 cm) from the bottom of the washer.

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See “Tools and Parts.”

The siphon break must be a minimum of 28" (71 cm) from the

bottom of the washer. Additional hoses might be needed.

To avoid siphoning, no more than 8" (20.3 cm) of drain hose

should be below the top of the wash tub. Secure drain hose with

beaded tie strap.

39"

(99 cm)

C

28"

(71 cm)

D

3

Page 4

Electrical Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

■ A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit

serving only this appliance be provided.

■ This washer is equipped with a power supply cord having a

3 prong grounding plug.

■ To minimize possible shock hazard, the cord must be plugged

into a mating, 3 prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

■ Do not ground to a gas pipe.

■ Check with a qualified electrician if you are not sure the

washer is properly grounded.

■ Do not have a fuse in the neutral or ground circuit.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING:

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance – if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

Improper connection of the equipment-

INSTALLATION INSTRUCTIONS

Before You Start

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

NOTE: To avoid floor damage, set the washer onto cardboard

before moving across floor.

Remove Shipping Materials

Removing the shipping material is necessary for proper operation.

If the shipping material is not removed, the washer will make

excessive noise.

1. Move the washer to within approximately 3 ft (90 cm) of its

final location.

2. The washer must be in the upright position and not tilted

before removing the shipping material.

3. Locate the yellow shipping materials on the rear of the

machine, near the bottom. Follow the steps for your particular

model, either the one with the straight power cord and cord

restraint or the looped power cord version.

4

Page 5

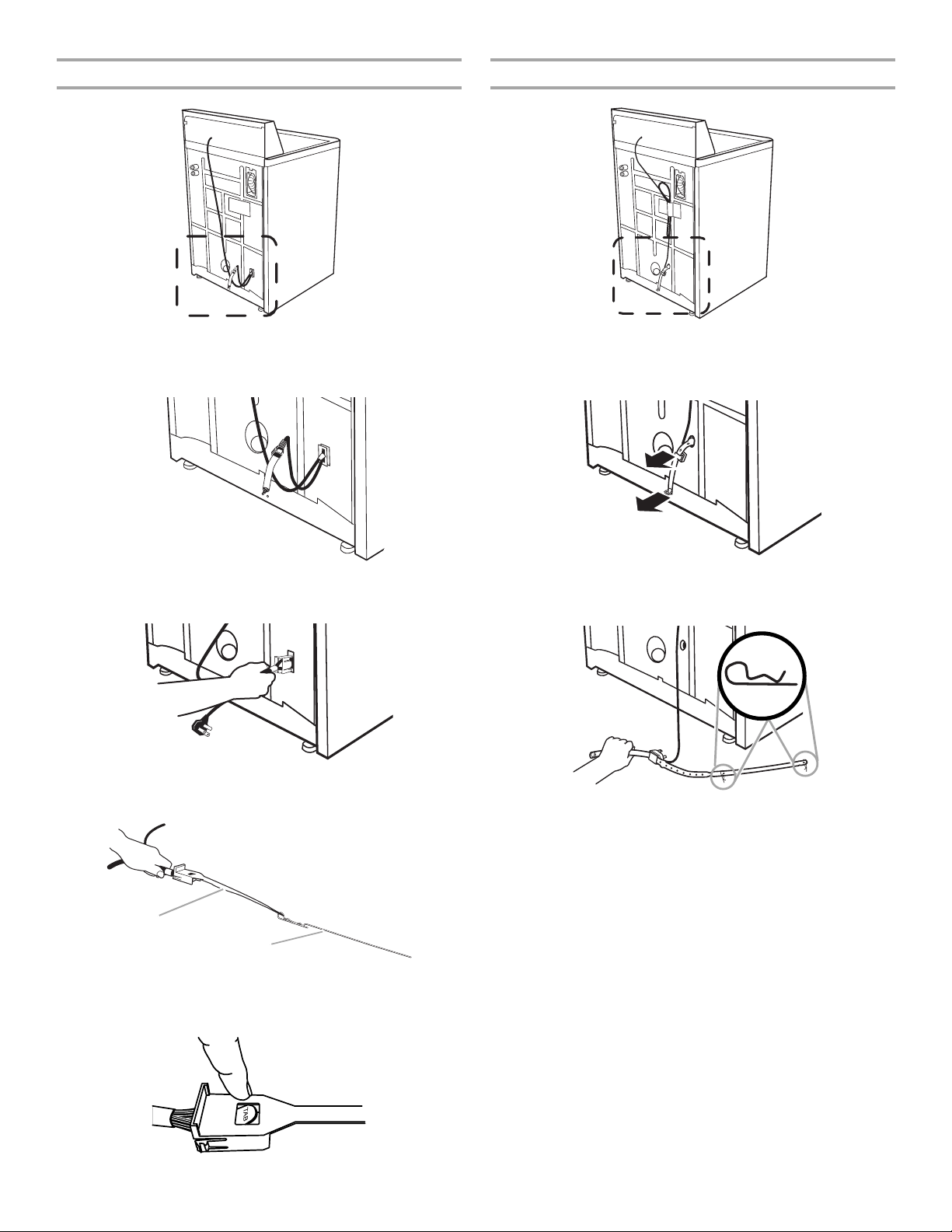

Straight power cord

Looped power cord

Straight power cord

1. Remove power plug and yellow strap from machine base to

release the rear leveling system.

2. Firmly grasp the power cord and pull to completely remove

the power cord, cord restraint, and pin from the rear panel.

Looped power cord

1. Firmly grasp the yellow shipping strap and pull until both ends

are completely removed from washer.

2. Check that two (2) shipping pins were removed with the

shipping strap.

3. Confirm that the power cord restraint (A), and pin (B) are

removed.

A

B

A. Power cord restraint B. Pin

4. To remove the power cord from the cord restraint, push the

power cord in, press TAB, and then pull the power cord out.

5

Page 6

Connect Drain Hose

Proper connection of the drain hose protects your floors from

damage due to water leakage. Read and follow these instructions.

The drain hose is connected to your washer and is stored inside

the washer cabinet.

Remove drain hose from washer cabinet

Gently pull the corrugated drain hose out of the washer from the

top of the hose. Continue to pull the hose until the end emerges.

Do not force excess drain hose back into the rear of the washer.

Laundry tub drain or standpipe drain

Connecting the drain hose form to the corrugated

drain hose

Connect the Inlet Hoses

The washer must be connected to the water faucets using the

new inlet hoses. Do not use old hoses.

Insert new flat washers (supplied) into each end of the inlet hoses.

Firmly seat the washers in the couplings.

AB

A. Coupling

B. Washer

Connect the inlet hoses to the water faucets

Make sure the washer basket is empty.

1. Attach the hose labeled hot to the hot water faucet. Screw

on coupling by hand until it is seated on the washer.

2. Attach the hose labeled cold to the cold water faucet. Screw

on coupling by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with an additional two-

thirds turn.

A

A. Drain hose reliefs

1. Feed end of drain hose into one end of form. Place end of

drain hose form into the drain hose relief.

2. Bend the hose over the top of the form and feed into the other

end of the form.

To keep drain water from going back into the washer:

■ Do not force excess drain hose into standpipe. Hose should

be secure but loose enough to provide a gap for air.

■ Do not lay excess hose on the bottom of the laundry tub.

Floor drain

Do not install the drain hose form on to the corrugated drain hose.

You may need additional parts. See Floor drain under “Tools and

Parts.”

NOTE: Do not overtighten or use tape or sealants on the

valve. Damage to the valves can result.

Clear the water lines

■ Run water through both faucets and inlet hoses, into a laundry

tub, drainpipe or bucket, to get rid of particles in the water

lines that might clog the inlet valve screens.

■ Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and that the

cold water hose is connected to the cold water faucet.

6

Page 7

Connect the inlet hoses to the washer

A

A

B

A. Cold water inlet valve

B. Hot water inlet valve

1. Attach the hot water hose to the bottom inlet valve.

2. Attaching the hot water coupling first makes it easier to

tighten connection with pliers.

3. Screw on coupling by hand until it is seated on the washer.

Secure the Drain Hose

1. Remove the shipping material from the power cord. Drape the

power cord over the console.

2. Remove any cardboard used to move washer.

Beaded tie strap

3. Wrap the drain hose to the laundry tub leg, drain standpipe or

inlet hoses, with the beaded tie strap. Push fastener into the

nearest hole in the beaded tie strap. See view A or B.

CBA

4. Using pliers, tighten the couplings with an additional two-

thirds turn.

NOTE: Do not overtighten or use tape or sealants on the

valve. Damage to the valves can result.

5. Attach the cold water hose to the top inlet valve.

6. Screw on coupling by hand until it is seated on the washer.

7. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the

valve. Damage to the valves can result.

Check for leaks

Turn on the water faucets and check for leaks. A small amount of

water might enter the washer. You will drain this later.

NOTE: Replace inlet hoses after 5 years of use to reduce the risk

of hose failure. Record hose installation or replacement dates for

future reference.

■ If you connect only one water hose, you must cap off the

remaining water inlet port.

■ Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

If the washer faucets and the drain standpipe are recessed,

put the formed end of the drain hose into the standpipe.

Tightly wrap the tie strap around the water inlet hoses and the

drain hose. See view C.

Level the Washer

Properly leveling your washer avoids excessive noise and

vibration.

Install the Front Leveling Feet

1. Prop up the front of the washer about 4" (10.2 cm) with a

wood block or similar object. The block needs to support the

weight of the washer.

4"

(10.2 cm)

A. Threaded holes for feet

7

Page 8

2. Screw the locknut onto each foot to within 1" (2.5 cm) of the

A

foot base.

1"

(2.5 cm)

3. Screw the feet into the threaded holes at the front corner of

the washer until the nuts touch the washer. Twist the feet to

install.

NOTE: Do not tighten the nuts until the washer is level.

4. If the washer is not level, move the washer out slightly, tip

back, prop up the front of the washer with the wood block and

adjust the feet up or down as necessary by twisting the feet.

Turn the feet clockwise to raise the washer or

counterclockwise to lower the washer. Repeat steps

1 through 4 until washer is level.

5. After the washer is in its final location and level, use a ⁹⁄₁₆" or

14 mm open-end wrench to turn the nuts counterclockwise on

the feet tightly against the washer cabinet.

IMPORTANT: If the nuts are not tight against the washer

cabinet, the washer may vibrate.

4. Tilt the washer back and remove the wood block. Gently lower

the washer to the floor.

Steps in Final Location

1. Slide the washer to its final location.

2. Tilt the washer forward until the rear of the washer is at least

4" (10.2 cm) off the floor. You may hear the self-adjusting rear

feet click into place. Lower the washer to the floor.

4"

(10.2 cm)

A. Self-adjusting feet

3. Check the levelness of the washer by placing a level on the

top edges of the washer, first side to side, then front to back.

Complete Installation

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See “Electrical Requirements.”

2. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

3. Check that you have all of your tools.

4. Check that the yellow shipping materials were completely

removed from the lower back of the washer.

5. Dispose of/recycle all packaging materials.

6. Check that the water faucets are on.

7. Check for leaks around faucets and inlet hoses.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

8. Plug into a grounded 3 prong outlet.

9. Remove the protective film on the console and any tape

remaining on the washer.

10. Read “Washer Use” in the Washer User Instructions.

11. To test and to clean your washer, measure ¹⁄₂ of the normal

recommended amount of powdered or liquid detergent and

pour it into the washer basket or detergent dispenser (on

some models). Close the lid. Select any cycle, and then pull

the Cycle Control knob out to start the washer. Allow it to

complete one whole cycle.

8

Page 9

INSTRUCTIONS D’INSTALLATION DE LA LAVEUSE

SÉCURITÉ DE LA LAVEUSE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Les pièces fournies se trouvent dans le panier de la

laveuse.

Outillage nécessaire pour le raccordement du tuyau de

vidange et des tuyaux d’arrivée d’eau :

■ Pince ouverture à 1⁹⁄₁₆"

(3,95 cm)

Pièces fournies :

AB

A. Bride de retenue du tuyau de vidange

B. Tuyaux d’arrivée d’eau (2)

C. Joints plats pour les raccords des tuyaux d’arrivée d’eau (4)

■ Lampe de poche (option)

C

Outillage nécessaire pour le raccordement du tuyau de

vidange et le réglage de l’aplomb de la laveuse :

■ Clé plate ou réglable de

⁹⁄₁₆" (14 mm)

■ Niveau

Pièces fournies :

A

A. Attache de fixation perlée

B. Pieds de nivellement avant avec écrous (2)

■ Bloc de bois

■ Règle ou mètre-ruban

B

9

Page 10

Autres pièces

Votre installation peut nécessiter des pièces supplémentaires.

Pour commander, veuillez consulter les numéros sans frais

d'interurbain sur la première page des Instructions pour

l'utilisateur de la laveuse.

Si vous avez : Vous devrez acheter :

Évier de buanderie

ou canalisation

Système de pompage (si pas déjà

installé)

d’évacuation

rigide plus haut

que 96" (2,4 m)

Tuyau rigide de

1" (2,5 cm) de

diamètre

Adaptateur pour passer d’un tuyau rigide

de 1¹⁄₄" (3,2 cm) de diamètre à

1" (2,5 cm) de diamètre, pièce n

o

280130

Égout en hauteur Évier de buanderie standard de

20 gal. (76 L), hauteur 39" (99 cm) ou

évier utilitaire, pompe de transfert et

raccords (disponibles chez un

fournisseur local de plomberie)

o

Drain de plancher Brise-vide (pièce n

vidange additionnel, pièce n

Robinets d’eau

trop éloignés des

tuyaux

2 tuyaux d’alimentation plus longs :

6 pi (1,8 m) pièce n

10 pi (3 m) pièce n

280129); tuyau de

o

76314,

o

350008

o

3357090

d'alimentation

Tuyau de vidange

trop court

Canalisation

Ensemble de connexion, pièce

o

280131

n

Filtre de protection, pièce n

o

367031

d’évacuation

obstruée

Exigences d’emplacement

La sélection de l’emplacement approprié pour la laveuse

permettra d’optimiser sa performance et de minimiser le bruit et

les risques de mouvement de la laveuse.

On peut installer la laveuse dans un sous-sol, une buanderie, un

placard, ou un espace d’encastrement. Voir “Système de

vidange”.

IMPORTANT : Ne pas installer ni remiser la laveuse à un endroit

exposé aux intempéries.

C’est à l’utilisateur du produit qu’incombe la responsabilité de

l’installation.

Il vous faudra :

■ Chauffe-eau réglé pour fournir à la laveuse de l’eau à 120°F

(49°C).

■ Prise de courant électrique reliée à la terre, à moins de 4 pi

(1,2 m) du point de connexion du cordon d’alimentation à

l’arrière de la laveuse. Voir “Spécifications électriques”.

■ Robinets d’eau chaude et d’eau froide situés à moins de 3 pi

(90 cm) des électrovannes de remplissage de la laveuse; une

pression d’eau de 5-100 lb/po

dotées de trois distributeurs nécessitent une pression de

20-100 lb/po

2

(138-690 kPa) pour le meilleur rendement.

2

(34,5-690 kPa). Les laveuses

■ Plancher horizontal avec une pente maximale de 1" (2,5 cm)

sous l’ensemble de la laveuse. L’installation de la laveuse sur

un tapis est déconseillée.

■ Plancher robuste capable de soutenir la laveuse avec une

charge totale (laveuse, eau et linge) de 315 lb (143 kg).

Ne pas ranger ni faire fonctionner la laveuse à des températures

inférieures à 32°F (0°C). Un résidu d’eau dans la laveuse risque de

causer des dommages à basse température. Voir “Entretien de la

laveuse” pour des renseignements sur l'hivérisation.

Installation dans un encastrement ou un placard

Les dimensions indiquées ci-après sont pour l’espacement

recommandé autorisé (A et B), sauf les passages d’air d’une porte

de placard. Les dimensions indiquées pour les passages d’air

d’une porte de placard (C) sont les espacements minimaux requis.

3"

14" max.

(35,6 cm)

19"

(48,3 cm)

0"

(0 cm)

■ Accorder plus d’espace libre pour faciliter l’installation et

27"

(68,6 cm)

A

A. Vue avant

B. Vue de profil

C. Porte de placard avec ouvertures d’aération

0"

(0 cm)

1"

(2,5 cm)

25½"

(64,8 cm)

B

2

48 po

2

(310 cm )

2

24 po

2

(155 cm )

4"

(10,2 cm)

(7,6 cm)

3"

(7,6 cm)

C

l’entretien.

■ Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

■ On recommande un espace libre additionnel de 1" (2,5 cm) de

chaque côté de la laveuse pour minimiser le transfert de bruit.

■ Si un placard est fermé par une porte, celle-ci doit comporter

des ouvertures d’aération en haut et en bas de dimensions

minimales (C). Des portes à jalousies avec ouvertures de

passage d’air en haut et en bas sont acceptables.

■ Il faut aussi prendre en compte l’espace requis entre les

appareils voisins.

Système de vidange

Le tuyau de vidange de la laveuse peut être raccordé à une

canalisation d’évacuation (mur ou plancher), ou bien on peut

rejeter l’eau de vidange dans un évier de buanderie ou un siphon

de plancher. Sélectionner la méthode appropriée d’installation du

tuyau de vidange. Voir “Outillage et pièces”.

Raccordement à une canalisation d’évacuation—

mur ou plancher (illustrations A et B)

Le diamètre de la canalisation d’évacuation doit être d’au moins

2" (5 cm). La capacité d’évacuation de la canalisation ne doit pas

être inférieure à 17 gal. (64 L) par minute. Un adaptateur de 1¹⁄₄"

(3,2 cm) à 1" (2,5 cm) de diamètre est disponible pour le tuyau de

rejet à l'égout. Voir “Outillage et pièces”.

La partie supérieure de la canalisation (point de raccordement)

doit être située entre 39" (99 cm) (mini) et 96" (244 cm) (maxi) audessus du bas de la laveuse.

10

Page 11

Pour éviter un effet de siphon, pas plus de 8” (20,3 cm) de tuyau

de vidange ne devrait être inséré à l’intérieur de la canalisation

d’évacuation. Immobiliser le tuyau de vidange avec l’attache de

fixation perlée.

39"

(99 cm)

Siphon de plancher (illustration D)

Le siphon de plancher doit comporter un brise-vide qui peut être

acheté séparément. Voir “Outillage et pièces”.

Le brise-vide doit être situé au moins à 28" (71 cm) au-dessus du

bas de la laveuse. Des tuyaux additionnels peuvent être

nécessaires.

Pour éviter un effet de siphon, ne pas placer plus de 8" (20,3 cm)

de tuyau de vidange en dessous de la partie supérieure de la cuve

de lavage. Immobiliser le tuyau de vidange avec l'attache de

fixation perlée.

A

B

Évier de buanderie (illustration C)

La capacité de l’évier doit être d’au moins 20 gal. (76 L). La partie

supérieure de l’évier (point de raccordement) doit être située entre

39" (99 cm) (mini) et 96" (244 cm) (maxi) au-dessus du bas de la

laveuse.

Spécifications électriques

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

■ Une alimentation de 120 volts, 60 Hz, CA seulement, de 15 ou

20 ampères, protégée par un fusible est requise. On

recommande l’emploi d’un fusible temporisé ou disjoncteur. Il

est recommandé d’utiliser un circuit distinct pour alimenter

uniquement cet appareil.

■ Cette laveuse est dotée d’un cordon d’alimentation avec fiche

de branchement à 3 broches, pour liaison à la terre.

■ Pour minimiser le risque de choc électrique, on doit brancher

le cordon d’alimentation sur une prise de courant murale de

configuration correspondante (3 alvéoles) reliée à la terre

conformément aux codes et règlements locaux. Si une prise

de configuration correspondante n’est pas disponible, c’est

au client qu’incombent la responsabilité et l’obligation

personnelles de faire installer par un électricien qualifié une

prise adéquatement mise à la terre.

■ Si les codes le permettent et si un conducteur distinct de mise

à la terre est utilisé, il est recommandé qu’un électricien

qualifié détermine si la liaison à la terre est adéquate.

39"

(99 cm)

C

■ Ne pas effectuer la liaison à la terre sur une canalisation de

28"

(71 cm)

D

gaz.

■ En cas de doute quant à la qualité de la liaison à la terre de la

laveuse, vérifier auprès d’un électricien qualifié.

■ Ne pas utiliser un fusible dans le circuit neutre ou de liaison à

la terre.

INSTRUCTIONS DE LIAISON À LA TERRE

Pour une laveuse reliée à la terre et connectée par

un cordon :

Cette laveuse doit être reliée à la terre. En cas d’anomalie

de fonctionnement ou de panne, la liaison à la terre réduira

le risque de choc électrique en offrant au courant électrique

un itinéraire d’évacuation de moindre résistance. Cette

laveuse est alimentée par un cordon électrique comportant

un conducteur relié à la terre et une fiche de branchement

munie d’une broche de liaison à la terre. La fiche doit être

branchée sur une prise de courant appropriée qui est bien

installée et reliée à la terre conformément à tous les codes

et règlements locaux.

AVERTISSEMENT : Le raccordement incorrect de cet

appareil au conducteur de liaison à la terre peut susciter un

risque de choc électrique. En cas de doute quant à la qualité

de la liaison à la terre de l’appareil, consulter un électricien

ou technicien d’entretien qualifié.

Ne pas modifier la fiche de branchement fournie avec

l’appareil – si la fiche ne correspond pas à la configuration

de la prise de courant, demander à un électricien qualifié

d’installer une prise de courant convenable.

Pour une laveuse raccordée en permanence :

Cette laveuse doit être raccordée à un système de câblage

permanent en métal relié à la terre ou un conducteur relié à

la terre doit être en fonction avec les conducteurs de circuit

et raccordés à la borne de liaison à la terre ou la borne sur

l’appareil ménager.

11

Page 12

INSTRUCTIONS D’INSTALLATION

Avant de commencer

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer la laveuse.

Le non-respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

2. Saisir fermement le cordon d'alimentation et tirer pour le sortir

complètement avec le dispositif d'immobilisation ainsi que la

broche du panneau arrière.

REMARQUE : Placer la laveuse sur du carton pour protéger le

plancher, avant de la déplacer.

Retrait du matériel d'expédition

Le retrait du matériel d'expédition est nécessaire au bon

fonctionnement de l'appareil. Si on ne retire pas le matériel

d'expédition, on constatera un bruit excessif de la laveuse.

1. Approcher la laveuse jusqu'à environ 3 pi (90 cm) de son

emplacement d'installation final.

2. La laveuse doit se trouver en position verticale et ne doit pas

être inclinée avant le retrait du matériel d'expédition.

3. Localiser le matériel d'expédition jaune à l'arrière de l'appareil,

près de la partie inférieure. Suivre les étapes concernant votre

modèle (laveuse avec cordon d'alimentation droit et dispositif

d'immobilisation ou version avec cordon d'alimentation en

boucle).

Cordon d'alimentation droit

3. Vérifier que le dispositif d'immobilisation (A) et la broche (B)

ont été retirés.

A

B

A. Dispositif d'immobilisation du

cordon d'alimentation

4. Pour retirer le cordon d'alimentation du dispositif

d'immobilisation, enfoncer le cordon d'alimentation, appuyer

sur TAB (languette), puis tirer sur le cordon d'alimentation pour

le sortir.

Cordon d'alimentation en boucle

B. Broche

Cordon d'alimentation

droit

1. Ôter la fiche du cordon d'alimentation et la sangle jaune de la

base de l'appareil pour libérer le système de nivellement

arrière.

12

Cordon d'alimentation en boucle

Page 13

1. Saisir fermement la sangle d'expédition jaune et tirer jusqu'à

ce que les deux extrémités soient complètement dégagées de

la laveuse.

2. Vérifier que deux (2) goupilles ont été retirées avec la sangle

d'expédition.

Raccordement du tuyau de vidange

Veiller à raccorder correctement le tuyau de vidange pour

qu’aucune fuite d’eau ne puisse détériorer le plancher. Lire les

instructions ci-dessous et les suivre à la lettre.

Le tuyau de vidange est connecté à la laveuse et est remisé à

l'intérieur de la caisse de la laveuse.

Retirer le tuyau de vidange de la caisse de la laveuse

Tirer doucement sur le haut du tuyau pour extraire le tuyau de

vidange ondulé de la laveuse. Continuer de tirer sur le tuyau

jusqu'à ce que l'extrémité apparaisse. Ne pas réinsérer de force

l'excédent de tuyau de vidange dans l’arrière de la laveuse.

Vidange dans l'évier de buanderie ou dans le tuyau de rejet à

l'égout

Connexion de la bride de retenue sur le tuyau de vidange

ondulé

A

A. Redressements du tuyau de vidange

1. Faire passer l'extrémité du tuyau de vidange dans l'une des

extrémités de la bride de retenue. Placer l’extrémité de la

bride de retenue dans le redressement du tuyau de vidange.

2. Plier le tuyau sur la partie supérieure de la bride de retenue et

le faire passer dans l'autre extrémité de la bride de retenue.

Pour empêcher l’eau de vidange de refluer dans la laveuse :

■ Ne pas forcer l'excédent de tuyau dans le tuyau de rejet à

l'égout. Le tuyau de vidange devrait être bien immobilisé, tout

en permettant le passage de l'air.

■ Ne pas mettre l'excédent du tuyau au fond de l'évier de

buanderie.

Drain de plancher

Ne pas installer la bride de retenue sur la section ondulée du

tuyau de vidange. Des pièces additionnelles peuvent être

nécessaires. Voir Drain de plancher à la section “Outillage et

pièces”.

Raccordement des tuyaux d’arrivée d’eau

La laveuse doit être connectée aux robinets d'eau à l'aide des

nouveaux tuyaux d'arrivée d'eau. Ne pas utiliser de tuyaux

usagés.

Installer une rondelle plate neuve (fournie) dans chaque extrémité

du tuyau d'arrivée d'eau. Enfoncer fermement chaque rondelle

dans le raccord.

AB

A. Raccord

B. Rondelle

Raccordement des tuyaux d’arrivée d’eau aux robinets

Vérifier que le panier de la laveuse est vide.

1. Connecter le tuyau comportant la mention Hot (chaud) au

robinet d’eau chaude. Visser complètement le raccord à la

main pour qu’il comprime la rondelle.

2. Connecter le tuyau comportant la mention Cold (froid) au

robinet d’eau froide. Visser complètement le raccord à la main

pour qu’il comprime la rondelle.

13

Page 14

3. Terminer le serrage des raccords—deux tiers de tour—avec

une pince.

REMARQUE : Ne pas serrer excessivement ni utiliser du

ruban adhésif ou un matériau d'étanchéité sur la valve. Des

dommages pourraient en résulter.

Purger les canalisations d’eau

■ Faire couler de l’eau par les deux robinets et les tuyaux

d’arrivée d’eau, dans un un évier de buanderie, dans un tuyau

de rejet à l'égout ou dans un seau pour éjecter toutes les

particules solides présentes dans la canalisation qui

pourraient obstruer les tamis à l’entrée de la laveuse.

■ Vérifier la température de l'eau pour s'assurer que le tuyau

d'eau chaude est connecté au robinet d'eau chaude et que le

tuyau d'eau froide est connecté au robinet d'eau froide.

3. Visser complètement le raccord à la main pour qu’il comprime

la rondelle.

4. Terminer le serrage des raccords—deux tiers de tour—avec

une pince.

REMARQUE : Ne pas serrer excessivement ni utiliser du

ruban adhésif ou un matériau d'étanchéité sur la valve. Des

dommages pourraient en résulter.

Raccorder les tuyaux d’arrivée d’eau à la laveuse

A

B

A. Électrovanne d’alimentation—eau froide

B. Électrovanne d’alimentation—eau chaude

5. Connecter le tuyau d'eau froide à l'électrovanne supérieure.

6. Visser complètement le raccord à la main pour qu’il comprime

la rondelle.

7. Terminer le serrage des raccords—deux tiers de tour—avec

une pince.

REMARQUE : Ne pas serrer excessivement ni utiliser du

ruban adhésif ou un matériau d'étanchéité sur la valve. Des

dommages pourraient en résulter.

Inspection—recherche des fuites

Ouvrir les robinets d’eau; inspecter pour rechercher les fuites. Une

petite quantité d’eau peut pénétrer dans la laveuse. Il suffira de la

vidanger plus tard.

REMARQUE : Remplacer les tuyaux d’arrivée d’eau après 5 ans

d’utilisation pour réduire le risque de défaillance intempestive.

Prendre note de la date d’installation ou de remplacement des

tuyaux d’arrivée d’eau, pour référence ultérieure.

■ Si on ne raccorde qu’une canalisation d’eau, il faut mettre un

bouchon sur l’autre entrée d’arrivée d’eau.

■ Inspecter périodiquement les tuyaux; les remplacer en cas de

gonflement, d’écrasement, de coupure, d’usure ou si une fuite

se manifeste.

Immobilisation du tuyau de vidange

1. Ôter la sangle d'expédition du cordon d'alimentation. Faire

passer le cordon d’alimentation par-dessus la console.

2. Enlever tout carton utilisé pour le déplacement de la laveuse.

1. Connecter le tuyau d'eau chaude à l'électrovanne inférieure.

2. La connexion du tuyau d'eau chaude en premier facilite le

serrage du raccord avec la pince.

14

Attache de fixation perlée

Page 15

3. Attacher le tuyau de vidange au pied de l’évier de buanderie,

A

A

au tuyau rigide de rejet à l’égout ou aux tuyaux d’arrivée

d’eau, avec l'attache de fixation perlée. Pousser l'élément de

fixation dans le trou le plus proche de l’attache de fixation.

Voir l'illustration A ou B.

CBA

Si les robinets d’eau et le tuyau rigide de rejet à l’égout

sont placés en retrait, introduire l’extrémité de la bride de

retenue du tuyau de vidange dans le tuyau rigide de rejet à

l’égout. Attacher fermement les tuyaux d’arrivée d’eau et le

tuyau de vidange ensemble, avec l’attache de fixation. Voir

l’illustration C.

Réglage de l’aplomb de la laveuse

Un bon aplomb de la laveuse évite le bruit et les vibrations

excessifs.

3. Visser les pieds dans les trous taraudés aux coins avant de la

laveuse jusqu’à ce que les écrous touchent la laveuse. Faire

pivoter le pied pour l'installer.

REMARQUE : Ne pas serrer les écrous tant que la laveuse

n’est pas d’aplomb.

4. Incliner la laveuse vers l’arrière et enlever le bloc de bois.

Abaisser doucement la laveuse jusqu’au plancher.

Étapes dans l'emplacement final

1. Faire glisser la laveuse à son emplacement final.

2. Incliner la laveuse vers l’avant pour soulever l’arrière à au

moins 4" (10,2 cm) du plancher. On peut percevoir le son émis

lors de l’auto-réglage des pieds arrière. Abaisser la laveuse

jusqu’au plancher.

Installation des pieds de nivellement avant

1. Soulever l’avant de la laveuse d’environ 4" (10,2 cm) avec un

bloc de bois ou un objet semblable. Le bloc doit pouvoir

supporter le poids de la laveuse.

4"

(10,2 cm)

A. Trous taraudés pour les pieds

4"

(10,2 cm)

A. Pieds autoréglables

3. Vérifier l’aplomb de la laveuse en plaçant un niveau sur les

bords supérieurs de la laveuse transversalement, puis dans le

sens avant arrière.

2. Visser l’écrou sur chaque pied de nivellement jusqu’à

1" (2,5 cm) de la base.

1"

(2,5 cm)

4. Si la laveuse n’est pas d’aplomb, la déplacer légèrement,

l’incliner vers l’arrière et soulever l’avant avec un bloc de bois

et ajuster le déploiement des pieds selon le besoin en faisant

pivoter les pieds. Tourner les pieds dans le sens horaire pour

lever la laveuse ou dans le sens antihoraire pour baisser la

laveuse. Répéter les étapes 1 à 4 jusqu'à ce que la laveuse

soit d'aplomb.

5. Après avoir placé la laveuse d’aplomb à son emplacement

final, utiliser une clé plate de ⁹⁄₁₆" (14 mm) pour visser les

écrous sur les pieds dans le sens antihoraire, fermement

contre la caisse de la laveuse.

15

Page 16

IMPORTANT : Si les écrous ne sont pas bloqués contre la

caisse de la laveuse, la laveuse peut vibrer.

Achever l’installation

1. Consulter les spécifications électriques. Vérifier que la tension

électrique disponible est correcte et que la prise de courant

est convenablement reliée à la terre. Voir “Spécifications

électriques”.

2. Vérifier que toutes les pièces sont maintenant installées. S’il

reste des pièces, étudier attentivement la description de

chaque étape pour identifier quelle étape a été omise.

3. Vérifier que tous les outils utilisés sont présents.

4. Vérifier que la sangle d’expédition jaune a été enlevée

complètement de l’arrière de la laveuse.

5. Jeter ou recycler tous les matériaux d'emballage.

6. Vérifier que chaque robinet d’arrivée d’eau est ouvert.

7. Inspecter pour rechercher les fuites - autour des robinets et

des tuyaux d’arrivée d’eau.

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

8. Brancher sur une prise à 3 alvéoles reliée à la terre.

9. Enlever la pellicule de protection sur la console, et les rubans

adhésifs qui peuvent rester collés sur la laveuse.

10. Lire la section “Utilisation de la laveuse” dans les Instructions

pour I’utilisateur de la laveuse.

11. Pour tester et nettoyer la laveuse, mesurer la moitié de la

quantité normale recommandée de détergent en poudre ou

liquide et la verser dans le panier de la laveuse ou dans le

distributeur de détergent (sur certains modèles). Fermer le

couvercle. Sélectionner n'importe quel programme, puis tirer

le bouton de commande de programme pour mettre la

laveuse en marche. Laisser la machine exécuter un

programme complet.

W10150593A

SP PN W10150594A

© 2007 Whirlpool Corporation.

Benton Harbor, Michigan 49022

Printed in U.S.A.

Imprimé aux É.-U.

8/07

Loading...

Loading...