CROSLEY QCAM2730YQ, CAW2762KQ, CAE2761KQ, CAW2762RQ, CAW2752RQ Installation Instructions

...Page 1

Installation Instructions

IMPORTANT:

Read and save

these instructions

IMPORTANT:

Installer:Leave Installation Instructions

with the owner.

Owner:Keep Installation Instructions for

future reference.

SaveInstallation Instructions for local

electrical inspector’s use.

www.whirlpoolcommerciallaundry.com

COMMERCIAL

WASHER

120-volt, 60-Hz Models

Part No. 8524739C

COMMERCIAL

LAUNDRY

PRODUCTS

®

Page 2

Hot and cold water faucets: Must be

Before you start...

Your safety and the safety of others are very important.

We have provided many important

safety message in this manual and

on your appliance. Always read

and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to

potential hazards that can kill or

hurt you and others.

All safety messages will be preceded

by the safety alert symbol and the

word “DANGER” or “WARNING”.

These words mean:

IMPORTANT SAFETY INSTRUCTIONS

You can be killed or seriously

injured if you don’t immediately

follow instructions.

You can be killed or seriously

injured if you don’t follow

instructions.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

DANGER

WARNING

WARNING:

when using your washer, follow basic precautions, including the following:

• Read all instructions before using

the washer.

• Do not wash articles that have

been previously cleaned in,

washed in, soaked in, or spotted

with gasoline, dry-cleaning

solvents, other ammable or

explosive substances as they give

o vapors that could ignite or

explode.

• Do not add gasoline, dry-cleaning

solvents, or other ammable or

explosive substances to the wash

water. These substances give o

vapors that could ignite or

explode.

• Under certain conditions,

hydrogen gas may be produced in

a hot water system that has not

been used for 2 weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been

used for such a period, before

using a washing machine, turn on

all hot water faucets and let the

water ow from each for several

minutes. This will release any

accumulated hydrogen gas. As

the gas is ammable, do not

smoke or use an open ame

during this time.

To reduce the risk of re, electric shock, or injury to persons

• Do not allow children to play on or

in the washer. Close supervision of

children is necessary when the

washer is used near children.

• Before the washer is removed from

service or discarded, remove the

lid.

• Do not reach into the washer if the

tub or agitator is moving.

• Do not install or store this washer

where it will be exposed to the

weather.

• Do not tamper with controls.

• Do not repair or replace any part

of the washer or attempt any

servicing unless specically

recommended in the Owner's

Manual or in published user-repair

instructions that you understand

and have the skills to carry out.

• See Page 4 of this booklet for

recommended grounding

instructions.

SAVE THESE INSTRUCTIONS

2

Page 3

Check location where washer will be

Before you start...

We have provided many important

safety message in this manual and

on your appliance. Always read

and obey all safety messages.

WARNING

This is the safety alert symbol.

This symbol alerts you to

potential hazards that can kill or

hurt you and others.

All safety messages will be preceded

by the safety alert symbol and the

word “DANGER” or “WARNING”.

These words mean:

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

You can be killed or seriously

injured if you don’t immediately

follow instructions.

You can be killed or seriously

injured if you don’t follow

instructions.

DANGER

Your safety and the safety of others are very important.

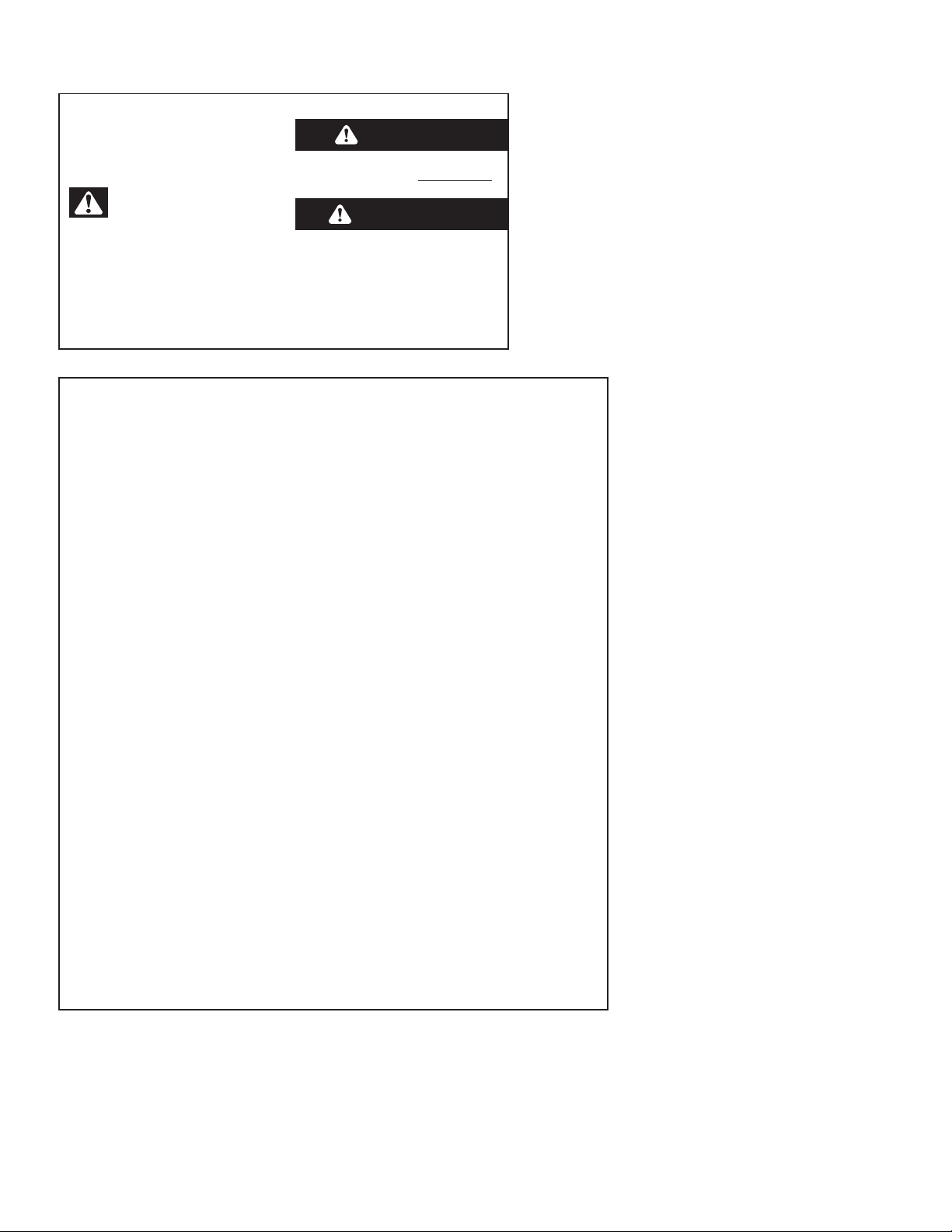

Hot and cold water faucets: Must be

within 4 feet (1.2 meters) of the back

of the washer and provide water

pressure 10-100 PSI (69-690 kPa). A

pressure reduction valve should be

used in the supply line where inlet

pressure entering the building

exceeds 100 PSI (690 kPa) to avoid

damage to the washer mixing valve.

Grounded

electrical outlet

is required. See

Electrical

requirements.

Water heater: Set to

deliver 120°F (49°C)

water to the washer.

Standpipe drain system: Needs a two-

inch (50 mm) minimum carry-away

capacity of 17 gallons (64.4 liters) per

minute. Top of standpipe must be at

least 39 inches (990 mm) high and no

higher than 72 inches (1.83 m) from

bottom of washer.

IMPORTANT: Floor must be sturdy

enough to support loaded washer

weight of 315 pounds (143 Kg).

installed. Proper installation is your

responsibility. Make sure you have

everything necessary for correct

installation.

Do Not store or operate washer below

32°F (0°C) (some water may remain in

washer).

Untape and

open washer

lid. Remove

packages and

hoses from

washer.

Single washer

installations require

12-inch (300 mm)

minimum risers to

provide an air

cushion and

avoid noise and

damage to valves.

Grounded

electrical outlet

is required. See

Electrical

requirements.

Hot and cold water faucets: Must be

within 4 feet (1.2 meters) of the back

of the washer and provide water

pressure 10-100 PSI (69-690 kPa). A

pressure reduction valve should be

used in the supply line where inlet

pressure entering the building

exceeds 100 PSI (690 kPa) to avoid

damage to the washer mixing valve.

Water heater: Set to

deliver 120°F (49°C)

water to the washer.

†

No. T20 TORX

screws

Front access to the pump area is

available by removing 2 No. T20

†

®

Torx

screws and then removing the

front panel.

IMPORTANT: Observe all governing

codes and ordinances.

®

Level oor: Maximum slope

under washer — 1 inch (25 mm).

A oor drain should be

provided under the bulkhead.

Prefabricated bulkheads with

electrical outlets, water supply

lines, and drain facilities should

be used only where local

codes permit.

Standpipe drain system: Needs a two-

inch (50 mm) minimum carry-away

capacity of 17 gallons (64.4 liters) per

minute. Top of standpipe must be at

least 39 inches (990 mm) high and no

higher than 72 inches (1.83 m) from

bottom of washer.

IMPORTANT: Floor must be sturdy

enough to support loaded washer

weight of 315 pounds (143 Kg).

† ® TORX is a registered trademark of Saturn Fasteners, Inc.

3

Page 4

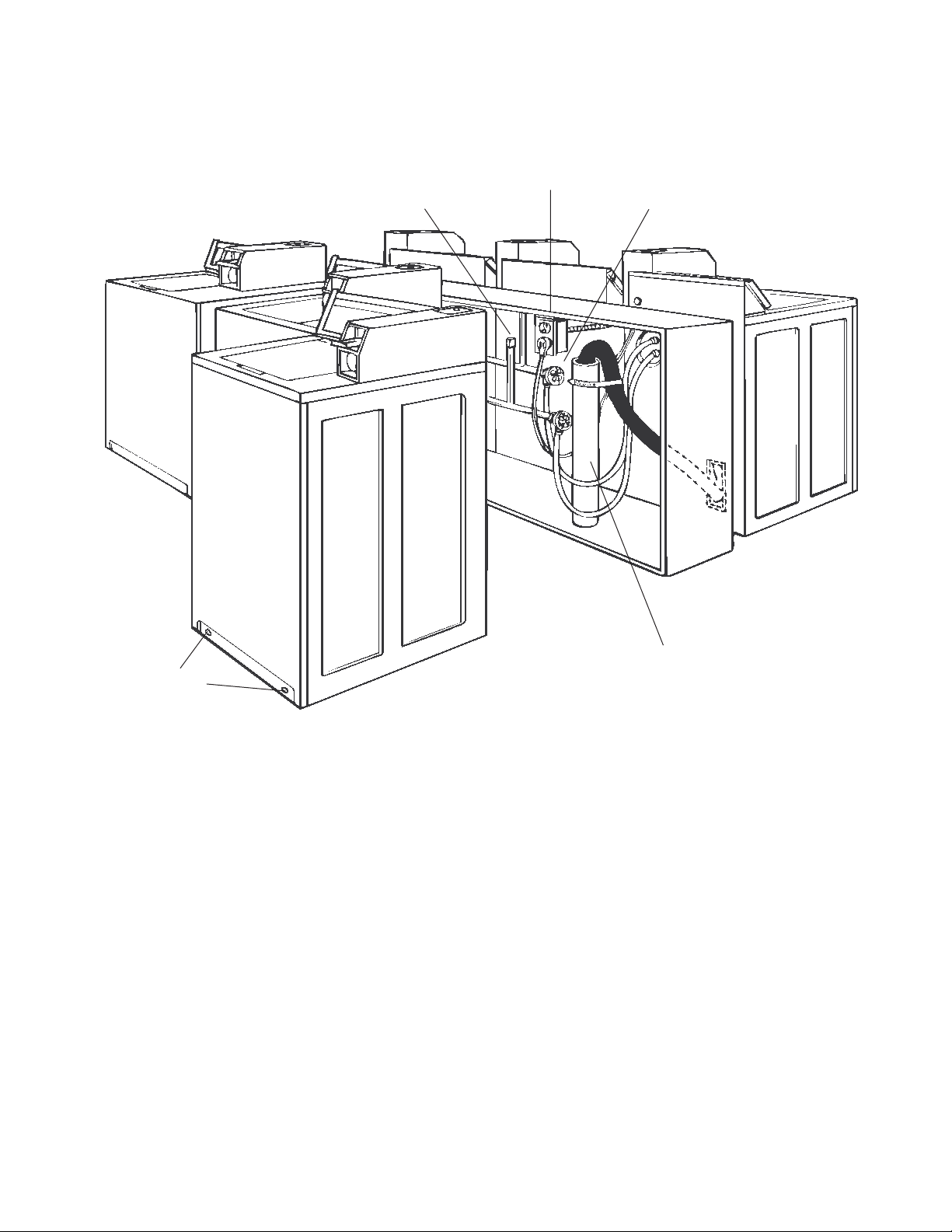

Tools needed for

Electrical requirements

s

Grounding instructions

Recessed area

instructions

This washer may be installed in a

recessed area or closet.

The installation dimensions shown are

the minimum spaces allowable.

Additional spacing should be

considered for ease of installation

and servicing. If closet door is

installed, the minimum air openings in

top and bottom of door are required.

Louvered doors with air openings in

top and bottom are acceptable.

Companion appliance spacing

should be considered.

Minimum installation spacing

Front view

48 sq. in.

(3.10 sq. m)

24 sq. in.

(1.55 sq. m)

Front view

(door not shown)

Closet door

3"

(76 mm)

3"

(76 mm)

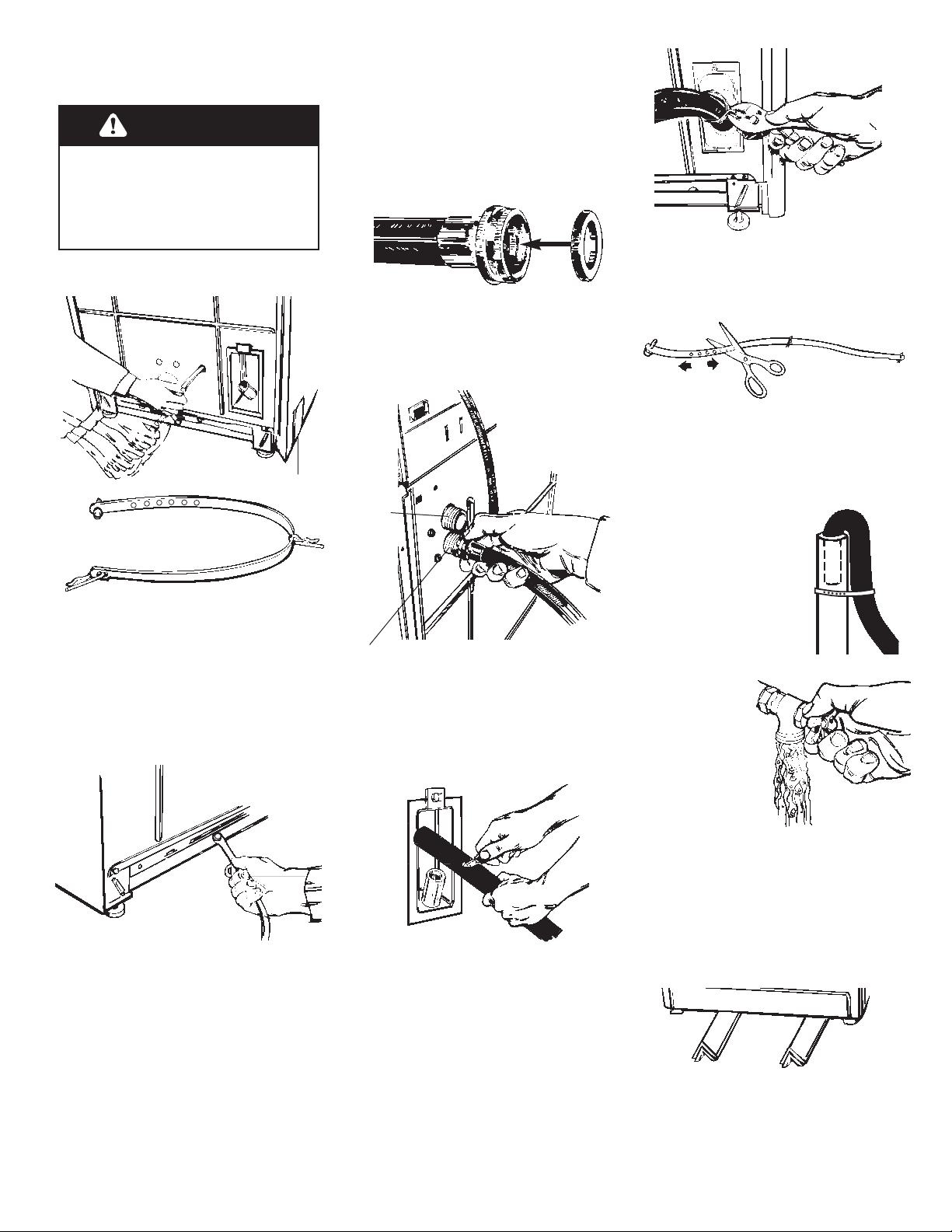

installation:

Level

Utility

knife

Wrench

Flat-blade

screwdriver

Scissors

Pliers

Parts supplied for

installation:

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions

can result in death, fire, or electrical

shock.

If codes permit and a separate ground wire

is used, it is recommended that a qualied

electrician determine that the ground path

is adequate.

Do Not ground to a gas pipe.

Check with a qualied electrician if you are

not sure the washer is properly grounded.

Do Not have a fuse in the neutral or ground

circuit.

A 120-volt, 60-Hz, AC-only, 15- or

20-ampere fused electrical supply is

required. (Time-delay fuse or circuit breaker

is recommended.) It is recommended that

a separate circuit serving only this

appliance be provided.

WARNING

Electrical Shock Hazard

Side view

48 sq. in.

(3.10 sq. m)

24 sq. in.

(1.55 sq. m)

PAGE 3

4

17"

(430 mm)

0"

Closet door

14"

(350 mm)

max.

1" (25 mm)

min.

This appliance must be grounded. In the

event of a malfunction or breakdown,

grounding will reduce the risk of electric

Remove parts from packages. Check

that all parts were included.

0"

1 hose clamp

4"

(100 mm)

min.

2 inlet hoses

4 at water hose washers

2 front-leveling legs with nuts

1 drain hose

shock by providing a path of least

resistance for the electric current. This

appliance is equipped with a cord having

an equipment-grounding conductor and

a grounding plug. The plug must be

plugged into an appropriate outlet that is

properly installed and grounded in

accordance with all local codes and

ordinances.

WARNING – Improper connection of the

equipment-grounding conductor can

result in a risk of electric shock. Check with

a qualied electrician or serviceman if you

are in doubt as to whether the appliance is

properly grounded. Do not modify the plug

provided with the appliance – if it will not t

the outlet, have a proper outlet installed by

a qualied electrician.

3-prong

grounding

plug

3-prong groundingtype outlet

Power

supply cord

Grounding

prong

Page 5

Now start...

WARNING

Excessive Weight Hazard

Use two or more people to move

and install washer.

Failure to do so can result in back

or other injury.

Pull the strap completely

out of the washer.

1. Remove tape that covers

shipping strap. Pull to completely

remove the shipping strap with

2 cotterpins from the inside

of the washer.

Shipping

tape

Use new hoses and washers that came

with your Whirlpool washer.

Replace inlet hoses after 5 years of use

to reduce the risk of hose failure.

Inspect and replace inlet hoses if

bulges, kinks, cuts, wear, or leaks are

found. When replacing your inlet hoses,

mark the date of replacement on the

label with a permanent marker.

Coupling

Washer

2.Insert a at washer into each end

of the inlet hoses. Check that washers

are rmly seated in couplings.

Inlets are plastic.

Do Not strip or

crossthread.

Cold

water

inlet

valve

Hot water

inlet valve

3.Attach hose to bottom inlet

valve opening rst. Then second hose

to top inlet. Tighten couplings by

hand; then use pliers to make an

additional two-thirds turn.

5.Place hose clamp over washer

drain connector. Push drain hose onto

washer connector. Use pliers to open

clamp and slide clamp over drain

hose. Check for good t.

16"

(406 mm)

6.Measure and mark a point

approximately 16 inches (406 mm)

from the plug end of the shipping

strap. Cut this shipping strap at this

point.

Check that hose is not

twisted or kinked and is

securely in place.

Put “hook” end of drain

hose into standpipe.

Tightly wrap the shipping

strap around the

standpipe. Push plug into

the nearest hole in the

shipping strap.

7.

Before

attaching water

inlet hoses, run

water through

both faucets into

a bucket. This will

get rid of particles

in water lines that

might clog hoses.

Mark which is the hot water faucet.

Pull rmly to remove the end of

shipping strap from the back of the

washer. The shipping strap plug must

be completely removed from the

washer for the self-leveling legs to

be released.

Save the shipping strap for use in

Step 6.

4.Move washer close to nal

position. Put “hook” end of drain hose

into standpipe. Estimate length of

drain hose needed when washer is in

nal position. Hose must be cut

exactly to length so “hook” end is

held tightly over edge of standpipe. If

drain hose is too long, cut straight end

of hose. (Do Not cut “hook” shaped

end of drain hose.)

DO NOT FORCE EXCESS LENGTH OF

DRAIN HOSE DOWN THE STANDPIPE.

THIS COULD CAUSE SIPHONING. See

Step 6.

8.Attach bottom hose (inlet

marked “H”) to hot water faucet.

Attach top hose (inlet marked “C”) to

cold water faucet. Tighten coupling

to faucet by hand; then use pliers to

make nal two-thirds turn.

9.Stack two corner posts on top of

each other. Tilt washer backwards and

insert corner posts 3 inches (76 mm) in

from one side of washer as shown.

Repeat with other corner posts on other

side of washer.

5

Page 6

Base

1/2"

(13 mm)

NOTE: If the coin slide mechanism has

already been installed, skip this step

and proceed to Step 16.

20.Plug power supply cord into

grounded outlet.

Nut

10.Use legs and nuts from parts

package. Screw nut down to within

1/2 inch (13 mm) of

base.

11.

Insert legs into correct

holes at each front corner

of washer until nuts touch washer.

Do Not tighten nuts until Step 14.

12.Tilt washer backward and

remove corner posts. Gently lower

washer to oor.

Move washer to its permanent

location. Remove cardboard or

hardboard from under washer.

15.Remove the service door of

the meter case. Lift the service door

up at the back and remove. Install

money accepting device (refer to

manufacturer’s instructions for proper

installation). For washers using coin

slides, use adapter kit (provided with

washer). Replace meter case service

door.

16 .CHECK ELECTRICAL

REQUIREMENTS. BE SURE YOU HAVE

CORRECT ELECTRICAL SUPPLY AND

RECOMMENDED GROUNDING

METHOD.

21.

Only. Check the wash cycle time. The

washer has a 9-minute wash in the

Normal Cycle. Remove the timer from

the meter case of the washer to

manually start the timer. Start the

washer and allow it to complete the

Normal cycle.

Rotate

counterclockwise

only.

Timers can be started by turning the

clutch assembly counterclockwise

until the washer starts to ll with water.

Electromechanical Models

Timer "off" position

Timer-front view

13.

back legs 1 inch (25 mm) o of oor.

To adjust rear self-leveling legs, gently

lower washer to oor. Check levelness

of the washer by placing a

carpenter’s level on top of the

washer, rst side to side; then front to

back.

Tilt washer forward raising

14.If washer is not level, adjust

the front legs up or down. Make nal

check with level.

When washer is level, use wrench

to turn nuts on front legs up tightly

against washer base. If nuts are not

tight against washer base, the washer

may vibrate.

6

17.

installed.

is an extra part, go back through steps

to see which step was skipped.

Check that all parts are now

See parts list, Page 4. If there

18.Turn on water faucets and

check for leaks. Tighten couplings if

there is leaking. Do Not overtighten;

this could cause damage to faucets.

19.Check that you have all of

your tools. Check that the shipping

strap was removed from the back of

the washer and used to secure the

drain hose.

If entire strap is not removed, washer

may vibrate and be noisy.

22.If the washer fails to start or

does not give the proper washer

cycle time, the clutch assembly of the

timer can be adjusted. Remove the

timer from the meter case. Adjust the

clutch assembly screw clockwise if

the washer does not start after the

coin slide mechanism has been fully

actuated in or out. Adjust the clutch

assembly counterclockwise if the

washer segment of the Normal cycle

was less than 9 minutes.

Timer clutch

adjustment screw

Page 7

Additional features

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

To reduce the risk of re, electric shock, or injury to persons

when using your washer, follow basic precautions, including the following:

SAVE THESE INSTRUCTIONS

• Read all instructions before using

the washer.

• Do not wash articles that have

been previously cleaned in,

washed in, soaked in, or spotted

with gasoline, dry-cleaning

solvents, other ammable or

explosive substances as they give

o vapors that could ignite or

explode.

• Do not add gasoline, dry-cleaning

solvents, or other ammable or

explosive substances to the wash

water. These substances give o

vapors that could ignite or

explode.

• Under certain conditions,

hydrogen gas may be produced in

a hot water system that has not

been used for 2 weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been

used for such a period, before

using a washing machine, turn on

all hot water faucets and let the

water ow from each for several

minutes. This will release any

accumulated hydrogen gas. As

the gas is ammable, do not

smoke or use an open ame

during this time.

• Do not allow children to play on or

in the washer. Close supervision of

children is necessary when the

washer is used near children.

• Before the washer is removed from

service or discarded, remove the

lid.

• Do not reach into the washer if the

tub or agitator is moving.

• Do not install or store this washer

where it will be exposed to the

weather.

• Do not tamper with controls.

• Do not repair or replace any part

of the washer or attempt any

servicing unless specically

recommended in the Owner's

Manual or in published user-repair

instructions that you understand

and have the skills to carry out.

• See Page 4 of this booklet for

recommended grounding

instructions.

Check list for washer

operation

Check the following if the washer is

not operating properly:

1. Power supply cord is plugged in.

2. Circuit breaker is not tripped or fuse

blown.

3. Timer has been advanced to start

of a cycle.

4. Water faucets are turned on.

5. Inlet and drain hoses are not

kinked.

6. Washer lid is closed.

7. Inlet valve is frozen if not sheltered

from the weather.

8. Suds level. Excess suds will slow

the spin and cause poor rinsing.

Operate the washer through a

complete cycle with no detergent.

Use less detergent or a controlled

suds type detergent in future loads.

Additional features

Disconnect power before making

electrical connections.

Failure to do so can result in death

or electrical shock.

Electrical Shock Hazard

WARNING

For WARM RINSE (where applicable):

• Remove screws from each end

of the console bottom.

• Pull the console bottom forward;

lift and tilt back.

• Connect J1 to J2

To SAVE WATER (where applicable):

• Locate water level switch on

back of washer. (See Back Page.)

• Turn shaft 45° counterclockwise.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

To reduce the risk of re, electric shock, or injury to persons

when using your washer, follow basic precautions, including the following:

SAVE THESE INSTRUCTIONS

• Read all instructions before using

the washer.

• Do not wash articles that have

been previously cleaned in,

washed in, soaked in, or spotted

with gasoline, dry-cleaning

solvents, other ammable or

explosive substances as they give

o vapors that could ignite or

explode.

• Do not add gasoline, dry-cleaning

solvents, or other ammable or

explosive substances to the wash

water. These substances give o

vapors that could ignite or

explode.

• Under certain conditions,

hydrogen gas may be produced in

a hot water system that has not

been used for 2 weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been

used for such a period, before

using a washing machine, turn on

all hot water faucets and let the

water ow from each for several

minutes. This will release any

accumulated hydrogen gas. As

the gas is ammable, do not

smoke or use an open ame

during this time.

• Do not allow children to play on or

in the washer. Close supervision of

children is necessary when the

washer is used near children.

• Before the washer is removed from

service or discarded, remove the

lid.

• Do not reach into the washer if the

tub or agitator is moving.

• Do not install or store this washer

where it will be exposed to the

weather.

• Do not tamper with controls.

• Do not repair or replace any part

of the washer or attempt any

servicing unless specically

recommended in the Owner's

Manual or in published user-repair

instructions that you understand

and have the skills to carry out.

• See Page 4 of this booklet for

recommended grounding

instructions.

WARNING

Electrical Shock Hazard

Disconnect power before making

electrical connections.

Failure to do so can result in death

or electrical shock.

For WARM RINSE (where applicable):

• Remove screws from each end

of the console bottom.

• Pull the console bottom forward;

lift and tilt back.

• Connect J1 to J2

To SAVE WATER (where applicable):

• Locate water level switch on

back of washer. (See Back Page.)

• Turn shaft 45° counterclockwise.

Check list for washer

operation

Check the following if the washer is

not operating properly:

1. Power supply cord is plugged in.

2. Circuit breaker is not tripped or fuse

blown.

3. Timer has been advanced to start

of a cycle.

4. Water faucets are turned on.

5. Inlet and drain hoses are not

kinked.

6. Washer lid is closed.

7. Inlet valve is frozen if not sheltered

from the weather.

8. Suds level. Excess suds will slow

the spin and cause poor rinsing.

Operate the washer through a

complete cycle with no detergent.

Use less detergent or a controlled

suds type detergent in future loads.

If you need

assistance…

The Whirlpool Commercial Laundry Trade

Partner Support Center will answer any

questions about operating or maintaining

your washer not covered in the Installation

Instructions. The Whirlpool

Laundry Trade Partner Support Center is

available by dialing 1-800 NO BELTS

(1-800-662-3587) — the call is free.

When you call, you will need the

washer model number and serial

number. Both numbers can be found

on the serial-rating plate located on

your appliance.

®

®

Commercial

7

Page 8

Typical full load sizes

Load Type Loading Suggestion Load Type Loading Suggestion

Load Loading Load Loading

Type SuggestionType Suggestion

Mixed Load 3 double sheets

Mixed 3 double sheets Heavy 3 pair pants

Load4 pillowcases work 3 shirts

Permanent Press 2 double or

Permanent2 double or Knits3 blouses

Press 1 king size sheet 4 slacks

4 pillowcases

6 pair shorts

8 T-shirts

2 shirts

6 pair shorts clothes 1 coverall

2 blouses

8 handkerchiefs

2 blouses

1 king size sheet

8 handkerchiefs

1 tablecloth

1 dress

1 blouse

2 slacks

3 shirts

2 pillowcases

2 slacks

3 shirts

2 pillowcases

Heavy work clothes 3 pair pants

3 shirts

1 coverall

4 pair jeans

1 overall

snaej riap 4strihs-T 8

llarevo 1strihs 2

Knits 3 blouses

4 slacks

6 shirts

4 tops

4 dresses

strihs 6htolcelbat 1

spot 4sserd 1

sesserd 4esuolb 1

Operating Tips

WARNING

Fire Hazard

Never place items in the washer

that are dampened with gasoline or

other flammable fluids.

No washer can completely remove

oil.

Do not dry anything that has ever

had any type of oil on it (including

cooking oils).

Doing so can result in death,

explosion, or fire.

It is recommended that berglass

items not be washed in coinoperated washers. If these items are

washed in the washer, run the washer

through a complete cycle to rinse

any residue away that might be left

in the washer.

Moving the washer to

a new location...

Wedge blanket

between tub ring

and cabinet top.

Remove front legs.

Tape rear

legs in “up”

position.

• Remove the front legs from the

base of the washer.

• Place both rear leveling legs in the

upper position and tape securely.

• Apply tape to the side and bottom

of the cabinet near the rear.

• Open washer lid, wedge a blanket

between the tub ring and the

cabinet top restricting the tub

movement.

• Handle washer gently. Do Not

drop washer while using hand truck.

Tape 2

sides.

Note: Do Not

place blanket

in this area.

8

Page 9

1-1/2"

(40 mm)

7"

(180 mm)

Cold

Hot

Power supply cord

Water level

switch and

shaft

43"

(1.09 m)

38-1/8"

(970 mm)

35"

(890 mm)

27-3/4"

(705 mm)

25-1/2"

(650 mm)

1"

(25 mm)

Water

inlets

5-1/4"

(133 mm)

Label

Drain hose

connector

7"

(180 mm)

5"

(127 mm)

27"

(685 mm)

9

Page 10

Part No. 8524739C

Power supply cord

1-1/2"

(40 mm)

Cold

Hot

25-1/2"

(650 mm)

Drain hose

connector

7"

(180 mm)

43"

(1.09 m)

1"

(25 mm)

38-1/8"

(970 mm)

5-1/4"

(133 mm)

35"

(890 mm)

27"

(685 mm)

27-3/4"

(705 mm)

Water

inlets

5"

(127 mm)

7"

(180 mm)

Label

Water level

switch and

shaft

WHIRLPOOL® COMMERCIAL LAUNDRY WARRANTY:

CAM2752, CAM2762, CED8990, CEM2750, CEM2760, CEW9100, CGD8990, CGM2751, CGM2761, CGW9100,

CHW8990, CHW9900, CSP2760, CSP2761, QCAM2730, YCED8990, YCEM2760, YCEW9100, YQCEM2730

LIMITED WARRANTY (PARTS ONLY – LABOR NOT INCLUDED)

For three years from the original date of purchase, when this commercial appliance is installed, maintained, and operated according

to instrucons aached to or furnished with the product, Whirlpool Corporaon (hereaer “Whirlpool”) will pay for factory specied

replacement parts to correct defects in materials or workmanship that existed when this commercial appliance was purchased.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THE LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. Whirlpool

recommends that you use an “in network” service provider to diagnose and repair your Commercial Laundry product. Whirlpool will

not be responsible under this warranty to provide addional replacement parts as a result of incorrect diagnosis or repair by “out of

network” service company. This limited warranty is valid in the United States or Canada and applies only when the major appliance

is used in the country in which it was purchased. This limited warranty is eecve from the date of the original consumer purchase.

Proof of original purchase date is required to obtain service under this limited warranty.

ITEMS EXCLUDED FROM WARRANTY

This limited warranty does not cover:

1. All other costs including labor, transportaon, shipping, or custom dues for covered parts.

2. Factory specied replacement parts if this commercial appliance is used for other than normal, commercial use or when it is used

in a manner that is inconsistent to published user or operator instrucons and/or installaon instrucons.

3. Service calls to correct the installaon of your commercial appliance, to instruct you how to use your commercial appliance,

to replace or repair fuses, or to correct external wiring or plumbing.

4. Service calls to repair or replace appliance light bulbs, air lters, or water lters. Consumable parts are excluded from warranty

coverage.

5. Damage resulng from improper handling of product during delivery, the, accident, alteraon, misuse, abuse, re, ood,

acts of God, improper installaon, installaon not in accordance with local electrical or plumbing codes, or use of products

not approved by Whirlpool.

6. Pickup and Delivery. This commercial appliance is designed to be repaired on locaon.

7. Repairs to parts or systems resulng from unauthorized modicaons made to the commercial appliance.

8. The removal and reinstallaon of your commercial appliance if it is installed in an inaccessible locaon or is not installed

in accordance with published installaon instrucons.

9. Damage resulng from exposure to chemicals.

10. Changes to the building, room, or locaon needed in order to make the commercial appliance operate correctly.

11. Factory specied replacement parts on major appliances with original model/serial numbers that have been removed, altered,

or cannot be easily determined.

12. Discoloraon, rust, or oxidaon of stainless steel surfaces.

13. Factory specied replacement parts as a result of incorrect diagnosis or repair by an “out of network” service company.

The cost of repair or replacement under these excluded circumstances shall be borne by the customer.

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO THREE YEARS OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and

provinces do not allow limitaons on the duraon of implied warranes of merchantability or tness, so this limitaon may not apply

to you. This warranty gives you specic legal rights, and you also may have other rights that vary from state to state or province to

province.

Whirlpool makes no representaons about the quality, durability, or need for service or repair of this major appliance other than

the representaons contained in this Warranty. If you want a longer or more comprehensive warranty than the limited warranty

that comes with this major appliance, you should ask Whirlpool or your retailer about buying an extended warranty.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

WHIRLPOOL SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow

the exclusion or limitaon of incidental or consequenal damages, so these limitaons and exclusions may not apply to you. This

warranty gives you specic legal rights, and you also may have other rights that vary from state to state or province to province.

If you need service, please contact your authorized Whirlpool® Commercial Laundry distributor. To locate your authorized Whirlpool®

Commercial Laundry distributor, call 1-800-662-3587, or for web inquiries, visit www.WhirlpoolCommercialLaundry.com.

© 2011 Whirlpool Corporation

All rights reserved.

DISCLAIMER OF IMPLIED WARRANTIES

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

For wrien correspondence:

Whirlpool® Commercial Laundry Service Department

Benton Harbor, MI 49022-2632 USA

Prepared by Whirlpool Corporation

Benton Harbor, Michigan 49022

® Registered Trademark/TM Trademark of Whirlpool, U.S.A., Whirlpool Canada LP Licensee in Canada

2000 N M 63

12/11

12/11

Printed in U.S.A.

Page 11

Instructions d’installation

IMPORTANT:

Lire et conserver

ces instructions.

IMPORTANT:

Installateur:Remettre la brochure des instructions

d’installation au propriétaire.

Propriétaire: Conserver la brochure des instructions

d’installation pour référence ultérieure.

Conserver les instructions d’installation pour

consultation par l’inspecteur local des installations

électriques.

www.whirlpoolcommerciallaundry.com

N°de pièce 8524739C

LAVEUSE

COMMERCIALE

Modèles 120 volt, 60 Hz

®

PRODUIT DE

BUANDERIE

COMMERCIALE

Page 12

Robinets d’eau chaude et d’eau

froide : Ces robinets doivent être

situés à moins de 1,22 m (4 pi) de

l’arrière de la laveuse; la pression de

l’eau à la sortie des robinets doit être

2

Avant de commencer. . .

Nous donnons de nombreux

messages de sécurité importants

dans ce manuel et sur votre appareil

ménager. Assurez-vous de toujours

lire tous les messages de sécurité et

de vous y conformer.

Voici le symbole d’alerte de

sécurité.

Ce symbole d’alerte de

sécurité vous signale les dangers

potentiels de décès et de blessures

graves à vous et à d’autres.

Tous les messages de sécurité

suivront le symbole d’alerte de

sécurité et le mot “ DANGER” ou

“ AVERTISSEMENT ”. Ces mots

signifient:

Tous les messages de sécurité

vous diront quel est le danger

potentiel et vous disent comment

réduire le risque de blessure et ce

qui peut se produire en cas de nonrespect des instructions.

Risque possible de décès ou de

blessure grave si vous ne suivez

pas immédiatement

les instructions.

Risque possible de décès ou de

blessure grave si vous ne suivez

pas les instructions.

DANGER

Votre sécurité et celle des autres est très importante.

AVERTISSEMENT

Si vous avez besoin

d’assistance…

Le Centre d’assistance de associé

de commerce de buanderie commercial

question sur le fonctionnement

ou l’entretien de la laveuse non

couverte dans les instructions

d’installation. Le Centre d’assistance

de associé de commerce de buanderie

commercial de Whirlpool® est disponible

en composant sans frais le 1-800-662-3587.

Lors de votre appel, vous aurez

besoin des numéros de modèle et de

série de la laveuse. Les deux numéros

se trouvent sur la plaque signalétique

xée à votre appareil.

de Whirlpool® répondra à toute

AVERTISSEMENT : Pour réduire les risques d’incendie, de choc électrique ou

de blessures lors de l’utilisation de la laveuse, suivre les précautions

fondamentales dont les suivantes :

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

Lire toutes les instructions avant

•

d’utiliser la laveuse.

Ne pas laver des articles qui ont

•

été nettoyés ou lavés avec de

l’essence ou imbibés d’essence,

solvants de nettoyage à sec, ou

autres substances inammables ou

explosives; ces substances

peuvent émettre des vapeurs

susceptibles de s’enammer ou

d’exploser.

Ne pas ajouter d’essence, solvant

•

de nettoyage à sec ou autre

produit inammable ou explosif

dans l’eau de lavage. Ces

substances peuvent émettre des

vapeurs susceptibles de

s’enammer ou d’exploser.

Dans certaines conditions, de

•

l’hydrogène gazeux a pu se former

dans un circuit d’eau chaude qui

n’a pas été utilisé pendant 2

semaines ou plus. LE GAZ

HYDROGÈNE EST EXPLOSIBLE. Si le

circuit d’eau chaude n’a pas été

utilisé pendant une telle période,

avant d’utiliser la laveuse, ouvrir

tous les robinets d’eau chaude et

laisser l’eau s’écouler pendant

plusieurs minutes par chaque

robinet. Ceci permettra

l’évacuation de l’hydrogène

gazeux accumulé. Comme ce gaz

est inammable, ne pas fumer ni

utiliser une amme nue au cours

de cette période.

CONSERVEZ CES INSTRUCTIONS

12

• Ne pas laisser des enfants jouer sur

ou dans la laveuse. Bien surveiller

les enfants lorsque la laveuse est

utilisée à proximité d’enfants.

• Avant de mettre la laveuse au

rebut ou hors de service, enlever le

couvercle.

• Ne pas tenter d’atteindre un

article à l’intérieur de la cuve de la

laveuse lorsque la cuve ou

l’agitateur est en mouvement.

• Ne pas installer ni remiser cette

laveuse à un endroit où elle serait

exposée aux intempéries.

• Ne pas modier les organes de

commande.

• Ne pas réparer ni remplacer un

composant quelconque de la

laveuse, ni entreprendre une

opération de service, si ce n’est

spéciquement recommandé

dans le manuel du propriétaire ou

dans un manuel d’instructions de

réparations destiné à l’utilisateur; il

est alors essentiel que la personne

concernée comprenne ces

instructions et soit compétente

pour les exécuter.

• Pour les instructions de liaison à la

terre, voir la page quatre dans cette

brochure.

Page 13

eau de 48,9 ºC (120 ºF).

un tuyau de décharge de 50 mm (2 po)

tuyau de décharge doit être situé à au

moins 99 cm (39 po) au-dessus du fond

potentiels de décès et de blessures

graves à vous et à d’autres.

Tous les messages de sécurité

suivront le symbole d’alerte de

Tous les messages de sécurité

vous diront quel est le danger

pas les instructions.

Hot and cold water faucets: Must be

within 4 feet (1.2 meters) of the back

of the washer and provide water

pressure 10 - 100 PSI (69-690 kPa). A

pressure reduction valve should be

used in the supply line where inlet

pressure entering the building

exceeds 100 PSI (690 kPa) to avoid

damage to the washer mixing valve.

Grounded

electrical outlet

is required. See

Electrical

requirements.

Water heater: Set to

deliver 120°F (49°C)

water to the washer.

Standpipe drain system: Needs a two-

inch (50 mm) minimum carry-away

capacity of 17 gallons (64.4 liters) per

minute. Top of standpipe must be at

least 39 inches (990 mm) high and no

higher than 72 inches (1.83 m) from

bottom of washer.

IMPORTANT: Floor must be sturdy

enough to support loaded washer

weight of 315 pounds (143 Kg).

sécurité et le mot “ DANGER ” ou

“ AVERTISSEMENT ”. Ces mots

signifient :

Inspecter l’emplacement où la laveuse

sera installée. Assurez-vous d’avoir tout

le matériel nécessaire pour la

réalisation d’une installation correcte.

C’est au propriétaire de l’équipement

qu’incombe la responsabilité d’une

installation correcte.

Ne pas entreposer ni utiliser la laveuse

à une température inférieure à 0 ºC

(32 ºF) (un peu d’eau peut rester dans

la laveuse).

Ôter les rubans

adhésifs et ouvrir le

couvercle de la

laveuse. Ôter les

paquets de pièces

et tuyaux de

l’intérieur de la

laveuse.

potentiel et vous disent comment

réduire le risque de blessure et ce

qui peut se produire en cas de non-

respect des instructions.

Pour l’installation

d’une seule laveuse,

une section de tuyau

vertical d’au moins

300 mm (12 po) est

nécessaire; ceci

constitue un tampon

d’air et évite le bruit

et la détérioration

des robinets.

Une prise de

courant

électrique reliée

à la terre est

nécessaire. Voir

d’installation

électrique.

Robinets d’eau chaude et d’eau

froide : Ces robinets doivent être

situés à moins de 1,22 m (4 pi) de

l’arrière de la laveuse; la pression de

l’eau à la sortie des robinets doit être

de 69-690 kPa (10-100 lb/po

Lorsque la pression d’entrée d’eau à

690 kPa (100 lb/po

d’installer un robinet de réduction de

pression dans la conduite

d’alimentation pour éviter que les

valves de mixage de la laveuse

subissent des dommages.

Conduit de décharge à l’égout : Utiliser

2

), il convient

Chauffe-eau : Régler le

alimente la laveuse en

2

).

®†

Vis Torx

nº T20

On peut accéder par l’avant à la

zone de la pompe après avoir ôté

les deux vis Torx

panneau avant.

IMPORTANT : Observer toutes les

dispositions des codes et règlements

en vigueur.

PAGE 2

®†

nº T20 et le

Plancher horizontal : Pente

maximale de 25 mm (1 po) sous

la laveuse.

Un siphon de plancher devrait

être disponible sous la caisson.

Utiliser un caisson préfabriqué

avec prises de courant

électrique, conduits d’arrivée

d’eau et conduite de décharge

à l’égout, seulement lorsque le

code local le permet.

®† Torx est une marque déposée de Saturn Fasteners, Inc.

de diamètre minimum, avec une

capacité d’évacuation de 64,4 litres

(17 gallons) par minute. Le haut du

de la laveuse et à au plus 1,83 m (72 po)

au-dessus du fond de la laveuse.

IMPORTANT : Le plancher doit être

le poids de la laveuse et de sa

charge, soit 143 kg (315 lb).

† ® TORX est une marque déposée

de Saturn Fasteners, Inc.

13

Page 14

s

Instructions pour

l’installation dans

une cavité encastrée

Il est possible d’installer cette laveuse dans

une cavité encastrée ou dans un placard.

Les dimensions d’installation indiquées

correspondent à l’espacement minimum

admissible. Considérer de laisser des

espaces plus grands pour faciliter

l’installation et l’entretien. Si la porte du

placard est installée, veiller à aménager

des passages d’air de dimensions

adéquates en haut et en bas. L’utilisation

de portes à jalousie avec ouvertures de

passages d’air en haut et en bas est

acceptable. Tenir compte des dimensions

d’un autre appareil installé à proximité, le

cas échéant.

Dimensions minimales de séparation

Vue avant

2

3,10 m

(48 po2)

2

1,55 m

2

)

(24 po

Vue avant

(porte non illustrée)

430 mm

(17 po)

0 mm

(0 po)

Vue latérale

2

3,10 m

(48 po2)

2

1,55 m

2

)

(24 po

14

Porte de

placard

Porte de placard

350 mm

(14 po)

max.

25 mm (1 po)

min.

76 mm

(3 po)

76 mm

(3 po)

0 mm

(0 po)

100 mm

(4 po)

min.

Outillage nécessaire

pour l’installation :

Niveau

Couteau

utilitaire

Clé à

molette

Ciseaux

Pince

Tournevis à

lame plate

Pièces fournies pour

l’installation :

Retirer les pièces de l’emballage.

Vérier que toutes les pièces sont

incluses.

1 bride pour tuyau

2 tuyaux d’arrivée d’eau

4 joints plats pour tuyaux d’arrivée d’eau

2 pieds avant avec écrou, pour mise

d’aplomb

1 tuyau de décharge

Installation électrique

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles

reliée à la terre.

Ne pas enlever la broche de liaison

à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions

peut causer un décès, un incendie

ou un choc électrique.

Si les codes le permettent et un l

séparé de liaison à la terre est

employé, il est recommandé qu’un

électricien qualié détermine que

l’acheminement vers la terre est

adéquat.

Ne pas relier le l à la terre à un tuyau

de gaz.

Vérier avec un électricien qualié si

vous avez des doutes à savoir si la

laveuse est bien reliée à la terre.

Ne pas utiliser un fusible dans un

circuit neutre ou un circuit relié à la

terre.

L’appareil doit être alimenté par un

circuit de 120 V CA seulement, 60 HZ, 15

à 20 ampères, protégé par fusible. On

recommande l’emploi d’un fusible

temporisé ou d’un disjoncteur. Il est

préférable que l’appareil soit alimenté

par un circuit distinct, n’alimentant que

cet appareil.

Méthode de

raccordement à la

terre recommandée

Il faut que cet appareil soit relié à la

terre. Advenant une anomalie de

fonctionnement, la liaison à la terre

réduira le risque de choc électrique

en procurant un itinéraire de moindre

résistance pour le courant électrique.

Cet appareil est muni d’un cordon de

branchement comportant un

conducteur de liaison à la terre, qui

est doté d'une che de branchement

comportant une broche de liaison à

la terre. Brancher la che sur une prise

de courant de conguration

correspondante, convenablement

installée et reliée à la terre

conformément aux prescriptions des

codes et règlements locaux.

AVERTISSEMENT: Le raccordement

incorrect de cet appareil au

conducteur de liaison à la terre peut

susciter un risque de choc électrique.

En cas de doute quant à la qualité de

la liaison à la terre de l’appareil,

consulter un électricien ou technicien

d’entretien qualié. Ne pas modier

la che de branchement fournie avec

l’appareil – si la che ne correspond

pas à la conguration de la prise de

courant, demander à un électricien

qualié d’installer une prise de

courant convenable.

Prise de courant à

3 alvéoles, reliée à

Fiche de

branchement à

3 broches

Cordon

d’alimentation

la terre

Broche de

liaison à la terre

Page 15

Vérier que le tuyau exible n’est pas tordu

Commencement. . .

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes

pour déplacer et installer la laveuse.

Le non-respect de cette instruction

peut causer une blessure au dos ou

d’autre blessure.

Ruben adhésif

d’expédition

Retirer complètement la

sangle de la laveuse.

1.Ôter le ruban adhésif qui

recouvre la sangle d’expédition.

Retirer complètement la sangle

d’expédition avec les 2 goupilles

de l’intérieur de la laveuse.

Tirer fermement pour séparer l’extrémité

de la sangle de l’arrière de la laveuse.

Pour la libération des pieds arrière qui

assurent la mise à niveau de la laveuse,

il faut que le bouton de la sangle soit

totalement retiré de la laveuse.

Conserver la sangle d’expédition pour

utilisation à l’étape 6.

Utiliser les tuyaux d’arrivée d’eau et

joints neufs fournis avec la laveuse

Whirlpool.

Remplacer les tuyaux exibles

d’alimentation d’eau après 5 ans

d’utilisation pour réduire le risque d’un

bris de tuyau. Inspecter les tuyaux

d’alimentation d’eau et les remplacer si

des renements, déformations,

PAGE 4

coupures, signes d’usure ou fuites

apparaissent. Lors du remplacement des

tuyaux d’alimentation d’eau, inscrire la

date de remplacement sur l’étiquette

avec un marqueur indélébile.

Raccord

Joint

2.Insérer un joint dans chaque

raccord des tuyaux d’arrivée d’eau.

Vérier que les joints sont bien placés

au fond des raccords.

Les raccords

d’entrées sont en

plastique; veiller à

ne pas dégarnir

ou croiser le

letage.

Entrée

d’eau

froide

Entrée d’eau

chaude

3.Connecter d’abord un tuyau

d’arrivée d’eau à l’entrée inférieure;

connecter ensuite le deuxième tuyau à

l’entrée supérieure. Serrer les raccords à la

main; utiliser ensuite une pince pour serrer

les raccords de deux tiers de tour de plus.

4.Rapprocher la laveuse de son

emplacement nal. Placer l’extrémité

recourbée du tuyau d’évacuation dans

le conduit de décharge à l’égout.

Estimer la longueur du tuyau

d’évacuation nécessaire lorsque la

laveuse est à l’emplacement nal. Le

tuyau doit être coupé exactement à la

longueur de telle sorte que l’extrémité

recourbée soit maintenue solidement sur

le bord du conduit de décharge à

l’égout. Si le tuyau d’évacuation est trop

long, couper l’extrémité rectiligne du

tuyau. (Ne pas couper l’extrémité

recourbée du tuyau).

NE PAS FAIRE DESCENDRE DE FORCE

L’EXCÈS DU TUYAU D’ÉVACUATION DANS

LE CONDUIT DE DÉCHARGE À L’ÉGOUT,

CE QUI POURRAIT DONNER LIEU À UN

EFFET DE SIPHON. Voir l’étape 6.

5.Placer la bride pour tuyau sur le

raccord d’évacuation de la laveuse.

Pousser le tuyau d’évacuation sur le

raccord de la laveuse. Utiliser une

pince pour ouvrir la bride et la glisser

sur le tuyau d’évacuation. S’assurer

qu’elle est bien serrée.

406 mm

(16 po)

6.Mesurer et marquer un point à

environ 406 mm (16 po) de l’extrémité de

la sangle d’expédition. Couper la sangle à

ce point.

ou déformé et qu’il est bien immobilisé en

place.

Placer l’extrémité

recourbée du tuyau exible

dans le conduit de

décharge à l’égout. Bien

serrer la sangle d’expédition

autour du conduit de

décharge à l’égout.

Enfoncer le bouton dans le

trou le plus proche de la

sangle d’expédition.

7. Avant de

connecter les tuyaux

d’arrivée d’eau,

laisser l’eau couler

dans un seau à partir

des deux robinets

d’alimentation, pour

éliminer les particules solides

présentes dans les conduites

d’arrivée d’eau qui pourraient

obstruer les tuyaux. Identier le

robinet d’eau chaude.

8.Relier le tuyau inférieur (entrée

marquée “H”) au robinet d’eau

chaude. Relier le tuyau supérieur

(entrée marquée “C”) au robinet

d’eau froide. Serrer les raccords à la

main, puis utiliser une pince pour le

serrage nal de deux tiers de tour.

9.Mettre deux cornières l’une par-

dessus l’autre. Incliner la laveuse vers

l’arrière et insérer les cornières à 76

mm (3 po) de chaque côté de la

laveuse. Répéter avec d’autres poteaux

faisants le coin de l’autre côté de la

laveuse.

15

Page 16

13 mm

(1/2 po)

Base

Écrou

10.Utiliser les pieds et les écrous

fournis dans le sachet

de pièces. Visser

l’écrou jusqu’à

environ 13 mm

(1/2 po) de la

base.

11.

les pieds dans le trou

convenable à chaque

angle avant de la laveuse, jusqu’à ce

que l’écrou soit en contact avec la

base de la laveuse. Ne pas serrer les

écrous avant l’étape 14.

Insérer

REMARQUE :Si le mécanisme de la

coulisse a déjà été installé, sauter

cette étape et passer à l'étape 16.

15.Ôter le panneau d’accès au

mécanisme de paiement. Soulever le

panneau d’accès à l’arrière et le

retirer. Installer le mécanisme de

paiement (consulter les instructions du

fabricant pour une installation

adéquate). Pour les laveuses utilisant

un mécanisme de paiement à plaque

coulissante, utiliser le nécessaire

d’adaptation (fourni avec la

laveuse). Réinstaller le panneau

d’accès au mécanisme de paiement.

Soulever le panneau d’accès.

20.Brancher la che sur une prise

de courant reliée à la terre.

21.MODÈLES

ÉLECTROMÉCANIQUES SEULEMENT :

Vérier le temps de programme de

lavage. La laveuse a un lavage

pendant 9 minutes dans le

programme normal. Enlever la

minuterie du boîtier de compteur de

la laveuse pour mettre la minuterie en

marche manuellement. Enlever la

case du compteur de la laveuse pour

mettre en marche manuellement la

minuterie. Mettre en marche la

laveuse et puis permettre de

compléter le programme normal.

Tourner dans le sens

antihoraire seulement

Position d’arrêt de

la minuterien

12.Incliner la laveuse vers l’arrière

de la base et ôter les cornières. Abaisser

doucement la laveuse sur le plancher.

Faire glisser la laveuse jusqu’à son

emplacement permanent. Enlever la

feuille de carton ou le panneau de bois

dur de dessous la laveuse.

13.Incliner la laveuse vers

l’avant pour soulever les pieds arrière

de 25 mm (1 po) au-dessus du

plancher. Laisser la laveuse

redescendre doucement jusqu’au

plancher. Vérier l’aplomb de la

laveuse transversalement et de

l’avant à l’arrière (des deux côtés)

avec un niveau.

14.Si la laveuse n’est pas

d’aplomb, visser les pieds avant vers

le haut ou vers le bas pour réaliser

l’aplomb. Exécuter le contrôle nal

avec un niveau.

Lorsque la laveuse est d’aplomb, faire

tourner les écrous des pieds avant

avec une clé à molette pour les

mettre en contact avec la base de la

laveuse. Si les écrous ne sont pas en

contact étroit avec la base de la

laveuse, elle pourrait vibrer.

16 .CONTRÔLER LES

CARACTÉRISTIQUES DE L’ALIMENTATION

ÉLECTRIQUE. VÉRIFIER QUE LES

CARACTÉRISTIQUES DU CIRCUIT

D’ALIMENTATION CORRESPONDENT À

CELLES DE LA LAVEUSE, ET QU’ELLE EST

CONVENABLEMENT RELIÉE À LA TERRE.

17.Vérier que toutes les pièces

sont installées. Voir la liste des pièces à

la page 4. S’il y a une pièce

additionnelle, examiner

successivement toutes les étapes pour

identier quelle étape a été omise.

18.Ouvrir les robinets d’eau et

inspecter pour rechercher les fuites; le

cas échéant, resserrer les raccords.

NE PAS SERRER EXCESSIVEMENT; ceci

pourrait faire subir des dommages

aux robinets.

19.Vérier que tous les outils

nécessaires sont présents. Vérier que

la sangle d’expédition a été retirée à

l’arrière de la laveuse et utilisée pour

l’immobilisation du tuyau

d’évacuation.

Si la sangle n’a pas été entièrement

retirée, la laveuse peut vibrer et faire

du bruit.

Vue avant de la minuterie

Les minuteries peuvent être mises

en marche en tournant dans le sens

antihoraire le montage de

l’engrenage jusqu’à ce que la

laveuse commence à se remplir

d’eau.

22.Si la laveuse ne démarre pas

ou ne donne pas le temps de

programme approprié de lavage, le

montage de l’engrenage de la

minuterie peut être ajusté. Enlever la

minuterie de sa case du compteur.

Ajuster dans le sens horaire la vis de

montage de l’engrenage si la

laveuse ne se met pas en marche

après que le mécanisme de fente à

sous a été complètement activé ou

désactivé. Ajuster le montage de

l’engrenage dans le sens antihoraire

si le secteur de la laveuse du

programme normal était moins de 9

minutes.

Vis d’engrenage de

la minuterie

16

Page 17

Caractéristiques

ANTES INSTRUCTIONS DE SÉCURITÉ

Pour réduire les risques d’incendie, de choc électrique ou

de blessures lors de l’utilisation de la laveuse, suivre les précautions

• Ne pas laisser des enfants jouer sur

ou dans la laveuse. Bien surveiller

les enfants lorsque la laveuse est

utilisée à proximité d’enfants.

• Avant de mettre la laveuse au

rebut ou hors de service, enlever le

couvercle.

• Ne pas tenter d’atteindre un

article à l’intérieur de la cuve de la

laveuse lorsque la cuve ou

l’agitateur est en mouvement.

• Ne pas installer ni remiser cette

laveuse à un endroit où elle serait

exposée aux intempéries.

• Ne pas modier les organes de

commande.

• Ne pas réparer ni remplacer un

composant quelconque de la

laveuse, ni entreprendre une

opération de service, si ce n’est

spéciquement recommandé

dans le manuel du propriétaire ou

dans un manuel d’instructions de

réparations destiné à l’utilisateur; il

est alors essentiel que la personne

concernée comprenne ces

instructions et soit compétente

pour les exécuter.

• Pour les instructions de liaison à la

terre, voir la page quatre dans cette

brochure.

supplémentaires

AVERTISSEMENT

Risque de choc électrique

Déconnecter le courant avant de

faire des connexions électriques.

Le non-respect de cette instruction

peut causer un décès ou un choc

électrique.

Pour LE RINCAGE TIÈDE S'il y a lieu :

• Enlever les vis de chaque bout du

bas du tableau de

commande.

• Tirer vers le bas du tableau de

commande; soulever et incliner

vers l’arrière.

• Connecter J1 à J2

Pour ÉCONOMISER DE L’EAU S'il y a lieu :

• Repérer le sélecteur de niveau

d’eau à l’arrière de la laveuse.

(Voir la couverture arrière.)

• Tourner la tige de 45° dans le sens

antihoraire.

Liste de contrôle —

fonctionnement de la

laveuse

Si la laveuse ne fonctionne pas

correctement, contrôler ce qui suit :

1. Cordon d’alimentation branché.

2. Disjoncteur ouvert ou fusible grillé.

3. La minuterie a été avancé au point

de départ du programme.

4. Robinets d’arrivée d’eau ouverts.

5. Tuyaux d’arrivée d’eau et tuyau de

décharge déformés.

6. Couvercle de la laveuse fermé.

7. Valve d’admission congelée si elle

n’est pas abritée des intempéries.

8. Niveau de mousse. Une quantité

excessive de mousse ralentit

l’essorage et provoque un rinçage

médiocre. Faire exécuter un

programme complet par la laveuse,

sans détergent. Utiliser moins de

détergent ou utiliser par la suite un

détergent à mousse contrôlée.

Si vous avez besoin

d’assistance…

Le Centre d’assistance de associé

de commerce de buanderie commercial

de Whirlpool® répondra à toute

question sur le fonctionnement

ou l’entretien de la laveuse non

couverte dans les instructions

d’installation. Le Centre d’assistance

de associé de commerce de buanderie

commercial de Whirlpool® est disponible

en composant sans frais le 1-800-662-3587.

Lors de votre appel, vous aurez

besoin des numéros de modèle et de

série de la laveuse. Les deux numéros

se trouvent sur la plaque signalétique

xée à votre appareil.

IMPORT

AVERTISSEMENT :

fondamentales dont les suivantes :

Lire toutes les instructions avant

•

d’utiliser la laveuse.

Ne pas laver des articles qui ont

•

été nettoyés ou lavés avec de

l’essence ou imbibés d’essence,

solvants de nettoyage à sec, ou

autres substances inammables ou

explosives; ces substances

peuvent émettre des vapeurs

susceptibles de s’enammer ou

d’exploser.

Ne pas ajouter d’essence, solvant

•

de nettoyage à sec ou autre

produit inammable ou explosif

dans l’eau de lavage. Ces

substances peuvent émettre des

vapeurs susceptibles de

s’enammer ou d’exploser.

Dans certaines conditions, de

•

l’hydrogène gazeux a pu se former

dans un circuit d’eau chaude qui

n’a pas été utilisé pendant 2

semaines ou plus. LE GAZ

HYDROGÈNE EST EXPLOSIBLE. Si le

circuit d’eau chaude n’a pas été

utilisé pendant une telle période,

avant d’utiliser la laveuse, ouvrir

tous les robinets d’eau chaude et

laisser l’eau s’écouler pendant

plusieurs minutes par chaque

robinet. Ceci permettra

l’évacuation de l’hydrogène

gazeux accumulé. Comme ce gaz

est inammable, ne pas fumer ni

utiliser une amme nue au cours

17

Page 18

Taille typique des charges complètes

Type de charge Suggestion de

Type de Suggestion de Type de Suggestion de

charge chargement charge chargement

Charge mixte 3 draps (lit à 2 places)

Charge 3 draps (lit à 2 Vêtements 3 pantalons

mixte places) de travail 3 chemises

Pressage permanent 2 draps (lit à 2 places)

Pressage 2 draps (lit àTricots 3 chemisiers

chargement

4 taies d’oreiller

6 shorts

8 T-shirts

4 taies d’oreiller très sales 1 combinaison

2 chemises

2 chemisiers

8 mouchoirs

2 chemises

2 chemisiers

ou

8 mouchoirs

1 drap (lit très grand)

1 nappe

1 robe

1 chemisier

1 drap (lit très grand)6 chemises

2 pantalons

3 chemises

2 taies d’oreiller

Type de charge Suggestion de

Vêtements de travail

très sales

Tricots 3 chemisiers

1 chemisier

2 pantalons

2 slacks

3 chemises

2 taies d’oreiller

Conseils de

fonctionnement

Déplacement de la

laveuse vers un nouvel

emplacement…

chargement

3 pantalons

3 chemises

1 combinaison

4 jeans

1 salopette

snaej 4strohs 6

ettepolas 1strihs-T 8

4 pantalons

6 chemises

4 tricots

4 robes

snolatnap 4uo )secalp 2tnenamrep

stocirt 4eppan 1

sebor 4ebor 1

WARNING

Risque d’incendie

Ne jamais mettre des articles

humectés d’essence ou d’autres

fluides inflammables dans la

laveuse.

Aucune laveuse ne peut

complètement enlever l’huile.

Ne pas faire sécher des articles qui

ont été salis par tout genre d’huile (y

compris les huiles de cuisson).

Le non-respect de ces instructions

peut causer un décès, une explosion

ou un incendie.

On recommande de ne pas laver

dans une laveuse commandée par

pièces de monnaie des articles

contenant de la bre de verre. S’il est

nécessaire de laver de tels articles

dans la laveuse, faire exécuter un

programme complet à vide pour

éliminer les résidus qui pourraient être

restés dans la laveuse.

18

Coincer une

couverture entre

l’anneau de la

cuve et le haut

de la caisse.

Ôter les pieds avant.

Pieds

arrière

maintenus

relevés

avec du

ruban

adhésif

• Ôter les pieds avant de la laveuse.

• Ramener les deux pieds arrière de la

laveuse à la position relevée;

immobiliser ces pieds à l’aide de ruban

adhésif.

• Placer du ruban adhésif sur les côtés et

sous la caisse, près de l’arrière.

• Ouvrir le couvercle de la laveuse;

coincer une couverture entre l’anneau

de la cuve et le haut de la caisse pour

empêcher tout mouvement de la cuve.

• Manipuler la laveuse doucement.

Ne pas laisser la laveuse tomber lors

de l’utilisation d’un chariot manuel.

Ruban

adhésif

des

deux

côtés

Remarque : Ne pas

placer la couverture

dans cette zone.

Page 19

40 mm

(1-1/2 po)

180 mm

(7 po)

Froid

Chaud

Cordon d’alimentation

Interrupteur

et arbre de

niveau

d’eau

m

970 mm

(38-1/8 po)

890 mm

(35 po)

(27-3/4 po)

705 mm

650 mm

(25-1/2 po)

25 mm

(1 po)

Entrées

d’eau

133 mm

(5-1/4 po)

Étiquette

Raccord du

tuyau de

vidange

180 mm

(7 po)

127 mm

(5 po)

685 mm

(27 po)

19

Page 20

Cordon d’alimentation

40 mm

(1-1/2 po)

Froid

Chaud

650 mm

(25-1/2 po)

Raccord du

tuyau de

vidange

180 mm

(7 po)

1,09 m

(43 po)

25 mm

(1 po)

970 mm

(38-1/8 po)

133 mm

(5-1/4 po)

890 mm

(35 po)

685 mm

(27 po)

705 mm

(27-3/4 po)

Entrées

d’eau

127 mm

(5 po)

180 mm

(7 po)

Étiquette

Interrupteur

et arbre de

niveau

d’eau

GARANTIE DE LA BUANDERIE COMMERCIALE WHIRLPOOL® :

CAM2752, CAM2762, CED8990, CEM2750, CEM2760, CEW9100, CGD8990, CGM2751, CGM2761, CGW9100,

CHW8990, CHW9900, CSP2760, CSP2761, QCAM2730, YCED8990, YCEM2760, YCEW9100, YQCEM2730

GARANTIE LIMITÉE (PIÈCES UNIQUEMENT - MAIN-D’OEUVRE NON COMPRISE)

Pendant les trois années à compter de la date d’achat inial, lorsque cet appareil commercial est installé, ulisé et entretenu conformément aux

instrucons jointes à ou fournies avec le produit, Whirlpool Corporaon (ci-après désignée “Whirlpool”) paiera pour les pièces de rechange spéciées

par l’usine pour corriger les vices de matériaux ou de fabricaon qui étaient déjà présents lorsque cet appareil commercial a été acheté.

LE SEUL ET EXCLUSIF RECOURS DU CLIENT DANS LE CADRE DE LA PRÉSENTE GARANTIE LIMITÉE CONSISTE EN LA RÉPARATION PRÉVUE PAR LA

PRÉSENTE. Whirlpool recommande que l’ulisateur emploie les services d’une agence “sous réseau” pour diagnosquer et réparer le produit de

buanderie à usage commercial concerné. Whirlpool ne sera pas responsable de l’obtenon de pièces de rechange supplémentaires dans le cadre de

la présente garane suite à un diagnosc erroné ou à une réparaon eectuée par un service de dépannage “hors réseau”. Cee garane limitée est

valide uniquement aux États-Unis ou au Canada et s’applique exclusivement lorsque le gros appareil ménager concerné est ulisé dans le pays où il a

été acheté. La présente garane limitée est valable à compter de la date d’achat inial par le consommateur. Une preuve de la date d’achat inial est

exigée pour obtenir un service dans le cadre de la présente garane limitée.

ÉLÉMENTS EXCLUS DE LA GARANTIE

La présente garantie limitée ne couvre pas :

1. Tout autre coût y compris la main-d’œuvre, les frais de transport, d’expédion, ou les frais de douanes pour les pièces sous garane.

2. Les pièces de rechange spéciées par l’usine lorsque l’appareil commercial est ulisé à des ns autres que l’usage commercial normal, ou lorsque

les instrucons d’installaon et/ou les instrucons de l’opérateur ou de l’ulisateur fournies ne sont pas respectées.

3. Les visites de service pour recer l’installaon de l’appareil commercial montrer à l’ulisateur comment uliser l’appareil commercial, remplacer

ou réparer des fusibles ou recer le câblage ou la plomberie du domicile.

4. Les intervenons de dépannage pour réparer ou remplacer les ampoules électriques, les ltres à air ou les ltres à eau de l’appareil. Les pièces

consompbles ne sont pas couvertes par la garane.

5. Les dommages imputables à : manipulaon incorrecte du produit au cours de la livraison, vol, accident, modicaon, usage impropre ou abusif,

incendie, inondaon, actes de Dieu, installaon fauve ou installaon non conforme aux codes d’électricité ou de plomberie locaux, ou l’ulisaon

de produits non approuvés par Whirlpool.

6. Le ramassage et la livraison. Cet appareil commercial est conçu pour être réparé sur place.

7. Les réparaons aux pièces ou systèmes résultant d’une modicaon non autorisée faite à l’appareil commercial.

8. La dépose et la réinstallaon de votre appareil commercial si celui-ci est installé dans un endroit inaccessible ou n’est pas installé conformément

9. Les dommages dus à l’exposion à des substances chimiques.

10. Les modicaons apportées au bâment, à la pièce ou aux lieux an de permere à l’appareil commercial de fonconner correctement.

11. Les pièces de rechange spéciées par l’usine pour les gros appareils ménagers dont les numéros de série et de modèle originaux ont été enlevés,

aux instrucons d’installaon fournies.

modiés ou qui ne peuvent pas être facilement idenés.

12. La décoloraon ou l’oxydaon des surfaces en acier inoxydable ou encore l’apparion de rouille sur ces surfaces.

13. Les pièces de rechange spéciées par l’usine suite à un diagnosc erroné ou à une réparaon eectuée par un service de dépannage “hors réseau”.

Le coût d’une réparaon ou d’un remplacement dans le cadre de ces circonstances exclues est à la charge du client.

LES GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES IMPLICITES APPLICABLES DE QUALITÉ MARCHANDE OU D’APTITUDE À UN USAGE PARTICULIER,

SONT LIMITÉES À TROIS ANS OU À LA PLUS COURTE PÉRIODE AUTORISÉE PAR LA LOI. Certaines juridicons ne permeent pas les limitaons de la durée des

garanes implicites de qualité marchande ou d’aptude à un usage parculier, de sorte que cee limitaon peut ne pas s’appliquer dans votre cas. Cee

garane vous confère des droits juridiques spéciques et vous pouvez également jouir d’autres droits qui peuvent varier d’une juridicon à une autre.

EXONÉRATION DE RESPONSABILITÉ DANS LES DOMAINES NON COUVERTS PAR LA GARANTIE

Whirlpool décline toute responsabilité au tre de la qualité ou de la durabilité de l’appareil, ou en cas de dépannage ou de réparaon nécessaire sur ce gros

appareil ménager autre que les responsabilités énoncées dans la présente garane. Si vous souhaitez une garane plus étendue ou plus complète que la garane

limitée fournie avec ce gros appareil ménager, adressez-vous à Whirlpool ou à votre détaillant pour obtenir les modalités d’achat d’une garane étendue.

LE SEUL ET EXCLUSIF RECOURS DU CLIENT DANS LE CADRE DE LA PRÉSENTE GARANTIE LIMITÉE CONSISTE EN LA RÉPARATION PRÉVUE CI-DESSUS.

WHIRLPOOL N’ASSUME AUCUNE RESPONSABILITÉ POUR LES DOMMAGES FORTUITS OU INDIRECTS. Certaines juridicons ne permeent pas l’exclusion

ou la limitaon des dommages fortuits ou indirects, de sorte que ces exclusions ou limitaons peuvent ne pas s’appliquer dans votre cas. Cee garane

vous confère des droits juridiques spéciques et vous pouvez également jouir d’autres droits qui peuvent varier d’une juridicon à une autre.

Si vous avez besoin de service, veuillez contacter votre distributeur de buanderie commerciale Whirlpool® autorisé. Pour localiser votre

distributeur de buanderie commerciale Whirlpool® autorisé, composez le 1-800-662-3587, ou pour toute queson par Internet, consultez

www.WhirlpoolCommercialLaundry.com.

N° de pièce 8524739C

© 2011 Whirlpool Corporation

Tous droits réservés.

CLAUSE D’EXONÉRATION DE RESPONSABILITÉ AU TITRE DES GARANTIES IMPLICITES

LIMITATION DES RECOURS; EXCLUSION DES DOMMAGES FORTUITS OU INDIRECTS

Pour toute correspondance écrite :

Whirlpool® Commercial Laundry Service Department

Benton Harbor, MI 49022-2632 USA

Préparé par Whirlpool Corporation

® Marque déposée/TM Marque de commerce de Whirlpool, U.S.A.,

emploi sous licence par Whirlpool Canada LP au Canada

Benton Harbor, Michigan 49022

2000 N M 63

12/11

12/11

Imprimé aux E.-U.

Loading...

Loading...