Cron HDI-600, HDI-920, HDI-1600 User Manual

USER MANUAL

High-precisionDigital Imager

Hangzhou CRON Machinery & Electronics Co., Ltd.

Jinyi Road 875, Xiaoshan Economic & Technological

Development Zone Hangzhou, 311215, P.R.China

TEL:0571-82838989 FAX:0571-82838877

1 / 55

Revision History Version: A1 Date: 2017-11-12

Version: A2 Date: 2018-4-19

2 / 55

Contents

Chapter 1:About this manual ............................................................................................. 4

Chapter 2:Overview ........................................................................................................... 4

2.1 Overview ...........................................................................................................................5

2.2 System dimension& weight...............................................................................................6

2.3 Power requirement ...........................................................................................................6

2.4 Power connection & wiring ...............................................................................................6

2.5 Safety & Cautions labels ....................................................................................................7

2.6 Safety Information ............................................................................................................9

Chapter 3:Installation Site and Environmental Requirements ........................................... 10

3.1 Space requirement ..........................................................................................................10

3.2 Flooring & hallway access ...............................................................................................10

3.3 Environmental requirement ............................................................................................10

Chapter 4:Offloading, Unboxing and Installing ................................................................. 11

4.1 On-site conditions during handling .................................................................................11

4.2 Shipment packing ............................................................................................................11

4.3 Loading & unloading equipment .....................................................................................11

4.4 Installation personnel......................................................................................................11

4.5 Offloading, unboxing and installation .............................................................................12

Chapter 5:Operation Instructions ..................................................................................... 17

5.1 Turning onthe device ......................................................................................................17

5.2 Connecting to computer .................................................................................................17

5.3 Laboo-HDI installation & startup.....................................................................................17

5.4Create work template ......................................................................................................22

Chapter 6:SystemMaintenance ........................................................................................ 35

6.1Equipment internal cleaniness check...............................................................................35

6.2 Daily routine maintenance ..............................................................................................40

Chapter 7:Abnormal Problems Analysis and Handling

7.1 Error message and handling suggestions

7.2

Common plate-making problems and causes ..................................................................44

7.3Common instruments used for plate testing process ......................................................45

Chapter 8: Consumables Parts and Spare Parts

8.1 HDI-600bundled parts list ............................................................................................45

8.2 HDI-920bundled parts list ............................................................................................48

8.3 HDI-1600bundled parts list ..........................................................................................49

Chapter 9:Appendixes–Wiring Diagrams

........................................................................41

................................................................. 45

........................................................................... 50

....................................................... 41

3 / 55

About this manual

Chapter 1: About this manual

This document describes how to install and use the high-precision digital flexo imager HDI-600/920/1600

series

————————————————————————————————

Contents

The High-precision Digital Imager user's manual contains the following chapters:

Chapter 2: Overview

Chapter 3:Installation site and environmental requirements

Chapter 4:Offloading, unboxing and installing

Chapter 5:Operation instruction

Chapter 6:System maintenance

Chapter 7:Abnormal problems analysis and handling

Chapter 8:Vulnerable consumables and spare parts

Chapter 9:Appendixes

Typographic conventions

This document uses the following typographical conventions:

Calibri(Bold) Noun first defined and emphasis is indicated in bold

Calibri Represents the computer display of text and system items

————————————————————————————————

CRON welcomes any valuable comments and suggestions:

CRON welcomes your comments and suggestions on this document, and it’s our sincere commitment to provide upmost

relevant detail in this document to meet your requirements.

To send in any comments or suggestions, please visit http://www.cron.com.cn.

When submitting comments and suggestions, attach the titleof the document, indicates page number and any comments, errors

or suggestions for improvement found in this document.

If you want to know the upgrade items during production,please refer to the announcements by our company

Overview

Chapter 2: Overview

2.1 Overview

a)High-precision Digital flexo Imager is a laser imaging technology,that directly applies high-precision

bitmap information imaging on digital flexo plates by using thermal laser ablation

technique.Generally it consists of flexo plate mounting drum, optical imaging system, laser driver

system, scanning device, plate mounting and releasing mechanism, vacuum adsorption, dedusting

device, the overall control system and other components.

b) Available flexographic precision resolution: 4000DPI、4800DPI、5080DPI、9600DPI.

Productivity >1.2m2/h, Dot reproduction: 1%-99%。

c) Format: HDI-600(660mm X 560mm), HDI-920(920mm X 675mm), HDI-1600(1524mm X 1200mm).

d)Materialsused are selection of environmentally friendly materials and comply with environmental

laws and regulations. We avoid using hazardous materials in the device and strong abide to

environmental protectionrequirements.

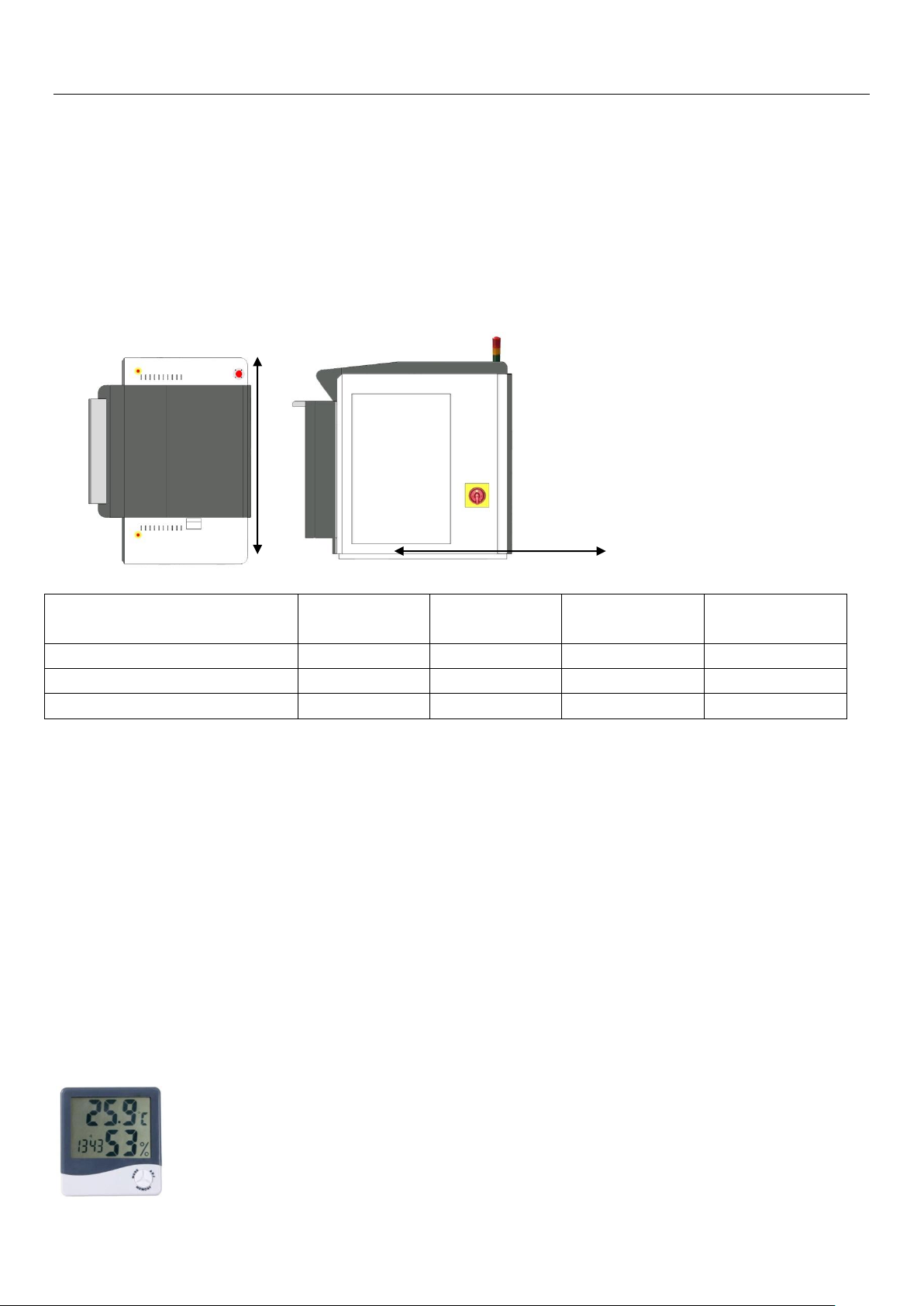

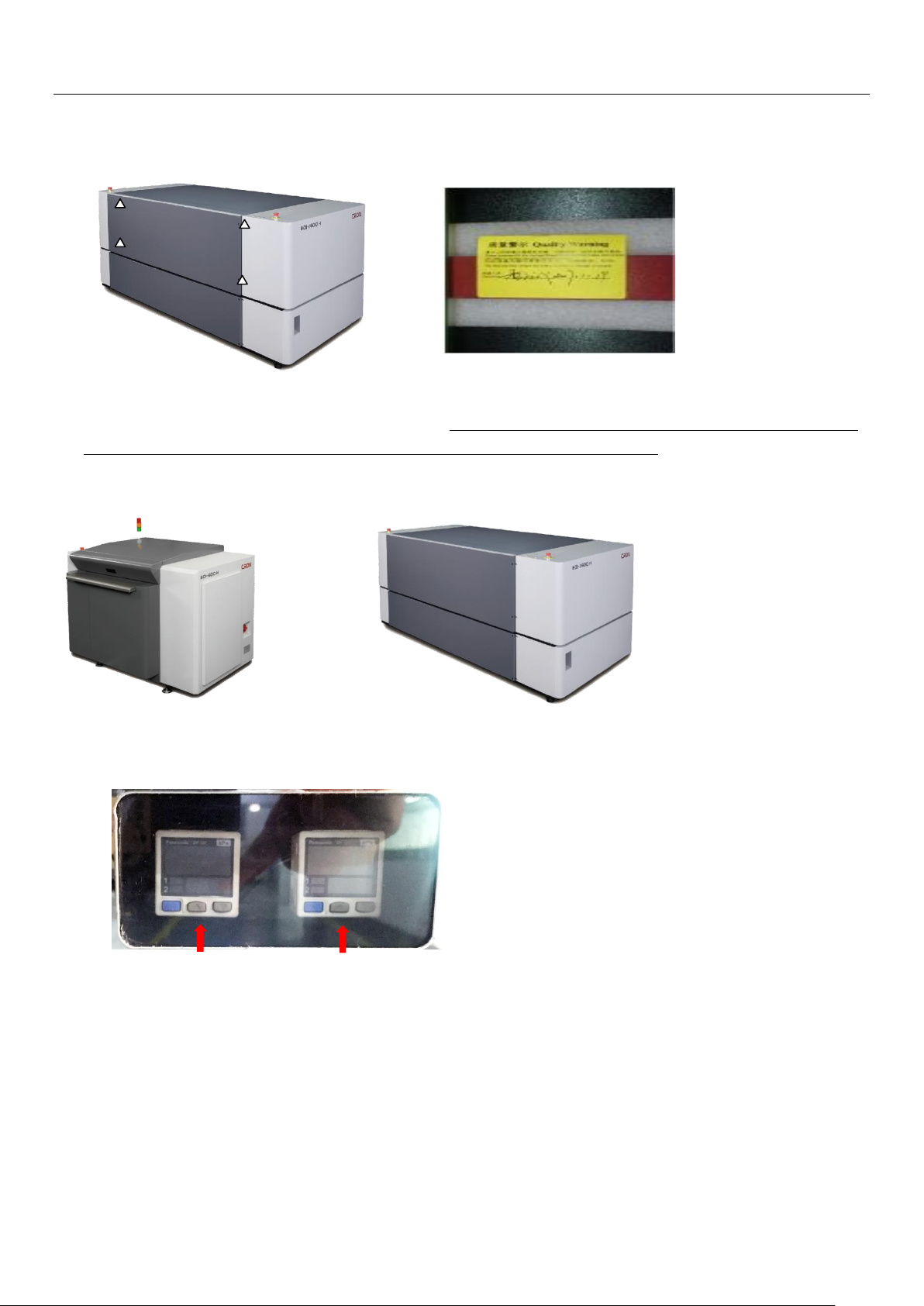

Figure illustration as shown Pictures 2-1, 2-2:

Picture 2-1: HDI-600、HDI-920

Picture 2-2: HDI-1600

5 / 55

Overview

Device Model

W(cm)

L(cm)

H(cm)

Weight(kg)

HDI-600**

140

118

105

780

HDI-920**

170

130

110

880

HDI-1600**

232

115

118

1480

Device Model

Rated power (kW)

Power supply requirements

HDI-600**

5.1

200~240V 23A

HDI-920**

5.6

200~240V 25A

HDI-1600**

6.0

200~240V 27A

2.2 System dimension & weight

Table 2-1:System equipment size, weight table

Remark:System equipment, size, weight will be vary depends on required configurations

2.3Power requirement

Table 2-2:Power requirements of the system

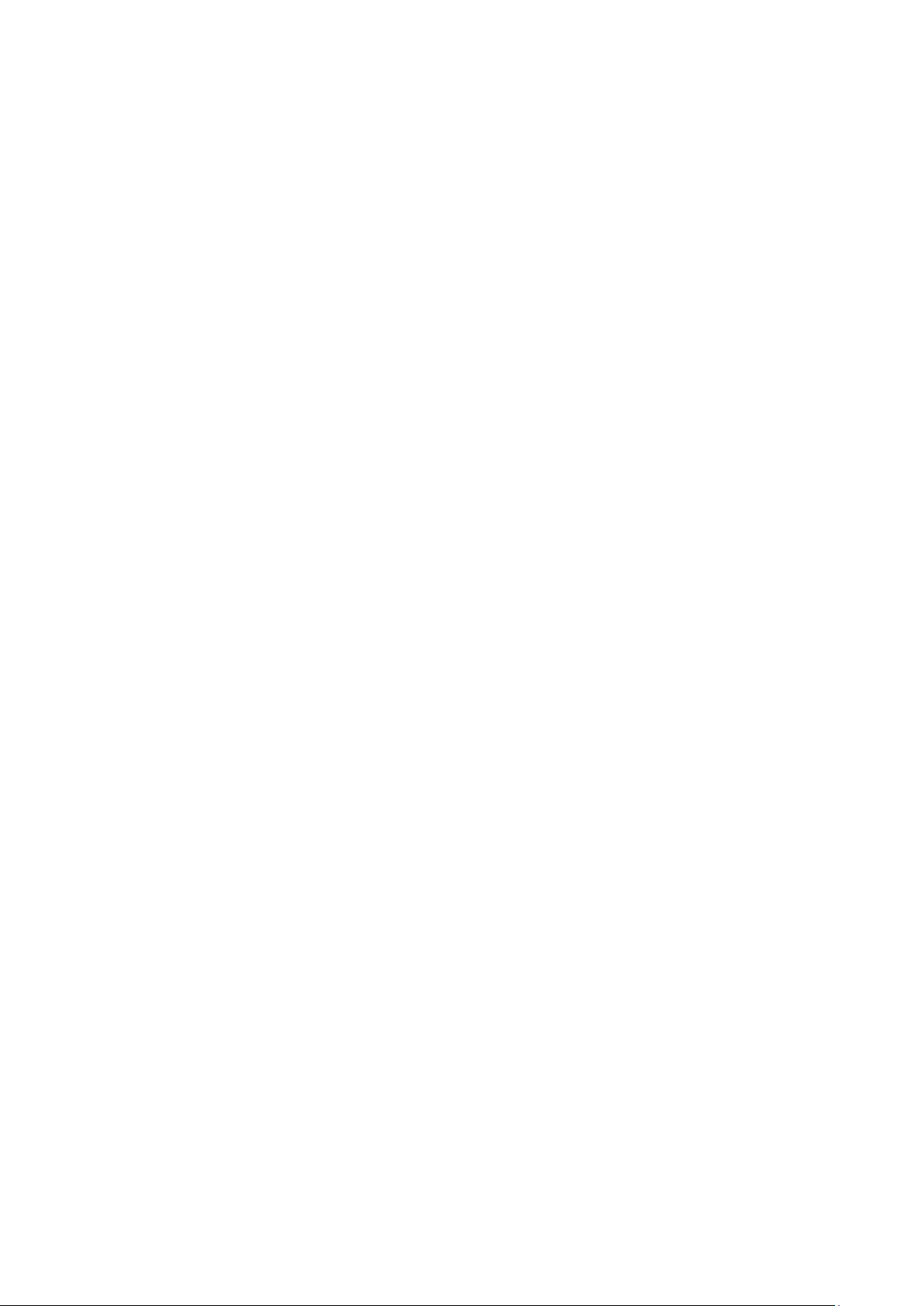

2.4Power connection & wiring

Preparation of the wires, sockets, open empty, etc. (if necessary, an UPS is required too)

Instruction:Required voltage must be stable. Grounding must be good (with galvanized metal diameter of

not less than 10mm, buried 1.5m below).

Equipment must be having ground resistance ≤ 0.5Ω.

Picture 2-4:power wiring diagram

6 / 55

Overview

2.5Safety and Caution labels

In the use of this device, please strictly comply with the requirements of the warning signs in the device!

WARNING!

Before using the High-precision Digital flexo Imager, please read carefully and understand the manual

content.Strictly follow all safety rules and regulations process while operating the equipment.Failure to

follow the safety precautions will not only damage the equipment but may even result in personal injury.

DANGER!

Unauthorized attempts of disassembling or alteration, and/or misuse, inappropriate operation of the

equipment hardware or modification of its circuitry may result in serious damage or malfunction to the

imager.

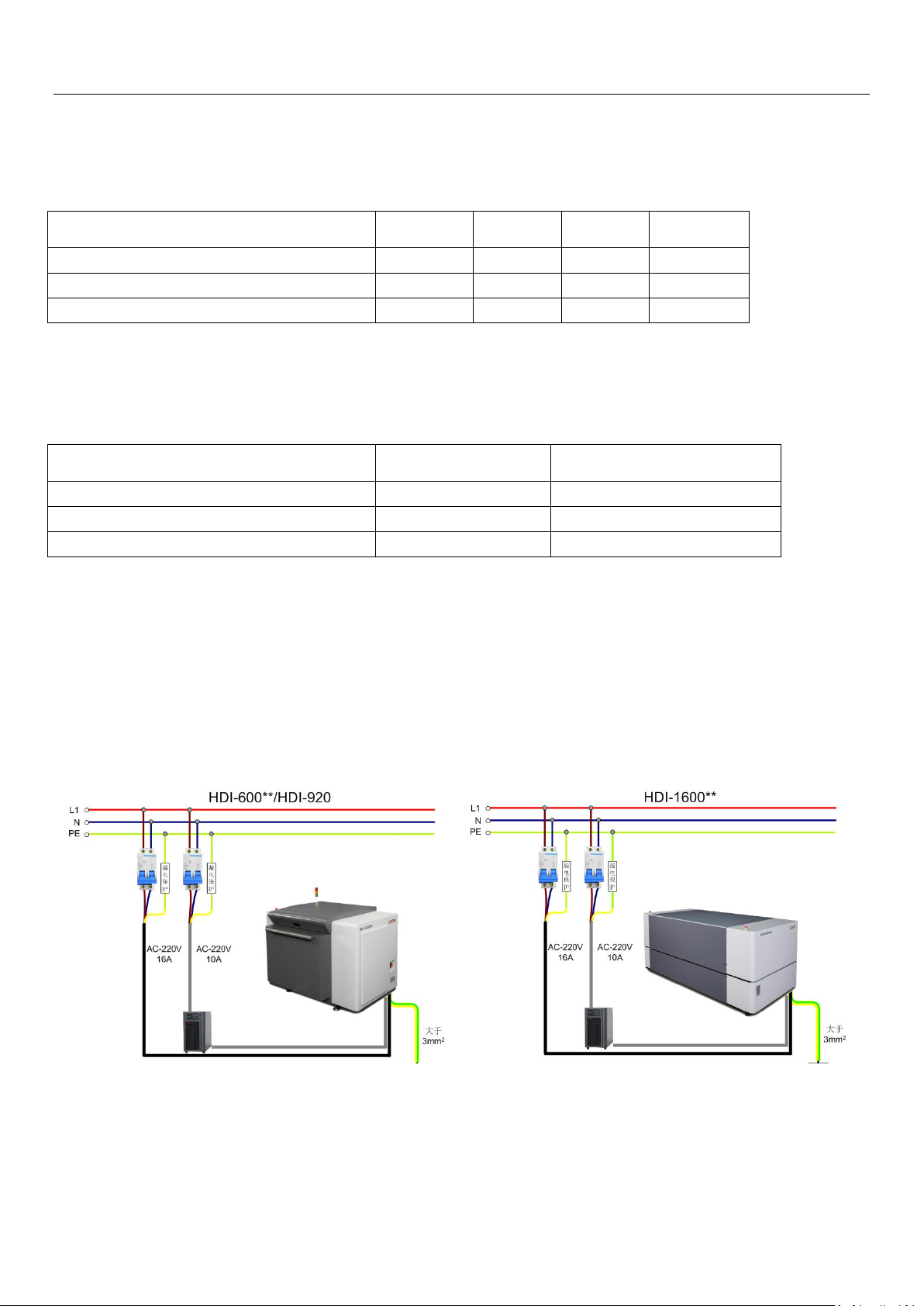

Caution Electricity!

Do not allow the body to come into contact with life current flowing parts of the

device.Put on anti-static gloves to prevent static or power surge when handling

with electronic or electrical components.Do not touch the power cord areas and

other electrical components with bare hands.Do not operate or turn on switch with

wet hands.

Overhead obstacle!

Equipment cover opening or closing, be carefulof head collision.

Do not look straight intothe laser beam!

Looking directly into the laserbeam is strictly prohibited. This would cause

damagesto your eyes.

7 / 55

Overview

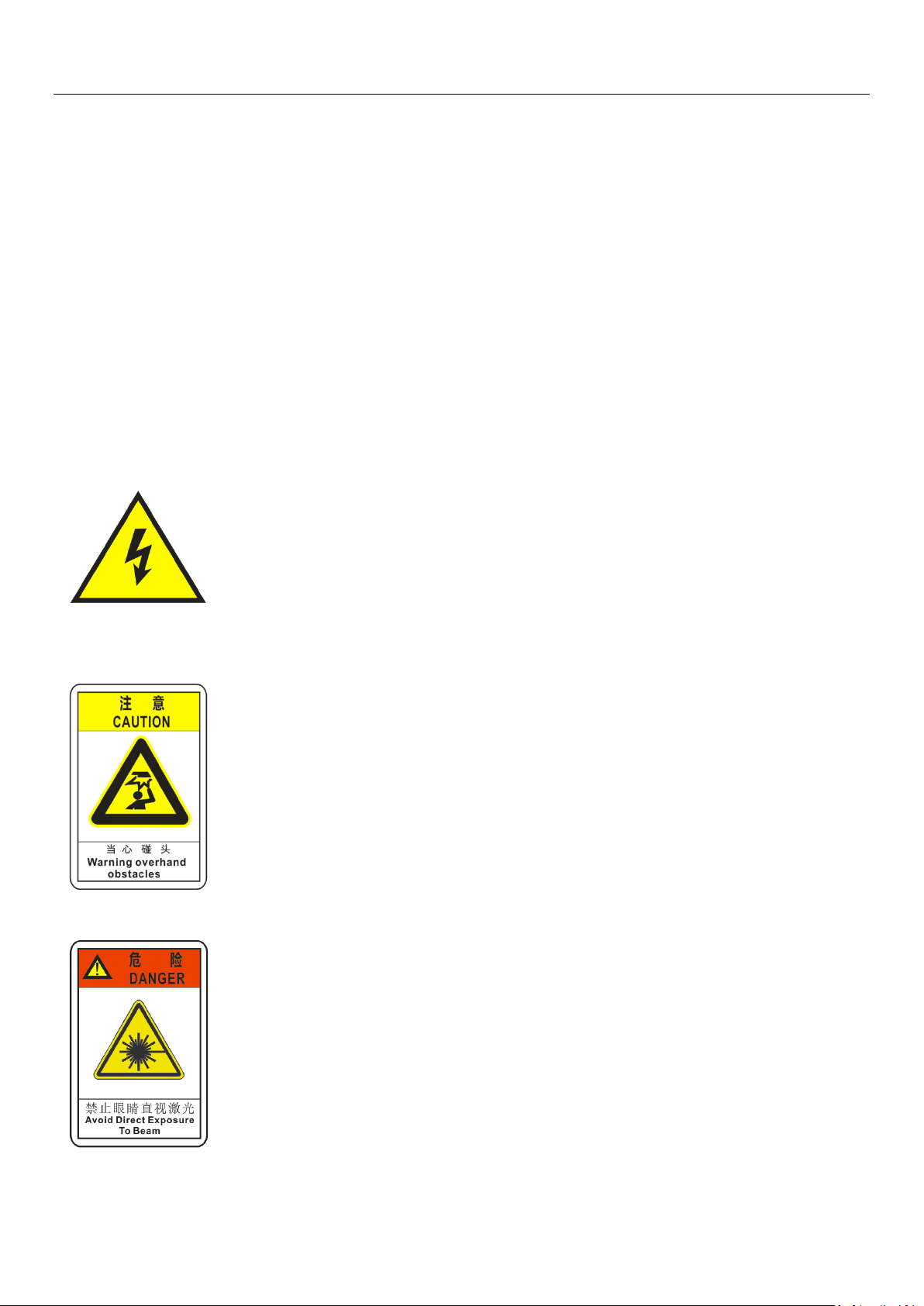

Beware of hand crush!

Please open or close the lead cover slowly, and avoid hands being crushed.

Drum is rotating! Do not touch!

Do not touch the drum while it is rotating the drum, it will cause injury!

Caution hot surface!

Do not touch the high temperature working part of equipment directly,

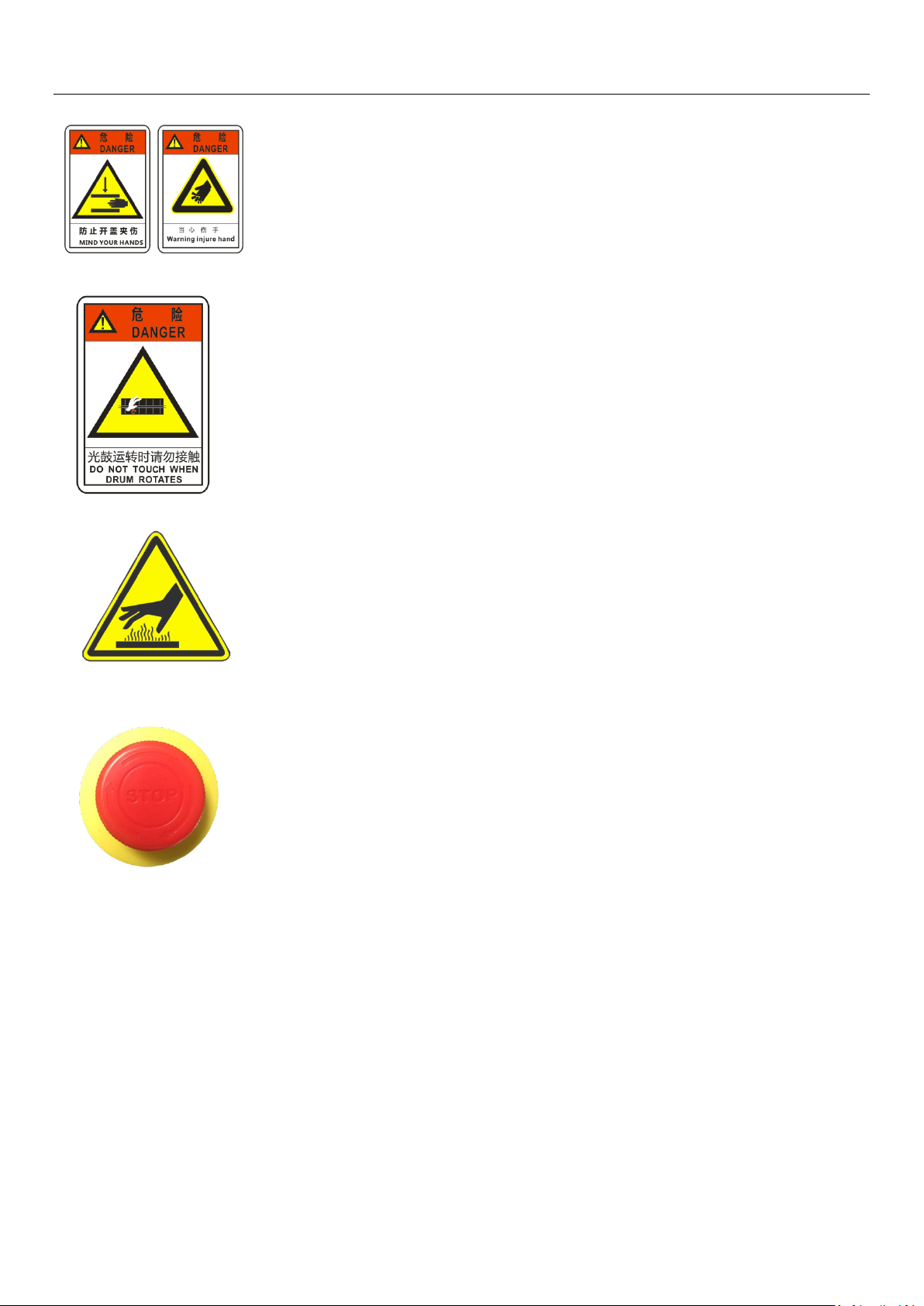

Emergency stop switch

Emergency stop switch is a safety measure function; when in an emergency

situation, where emergency stop switch is pressed to quickly get the drum stop

rotating.This switch is located on the side of the device top casing. Under

normal operation mode, make sure the emergency stop switch is disengaged or

released.

A. Rotate the switch in the direction of the arrow to dis-engage (working mode) the emergency

switch.

B. When the device appears abnormal, press the emergency stop switch, identify the cause and

problemhandling before reopening the emergency stop switch;

C. Emergency stop switch is only used when the equipment is found functioning abnormally.

Pleasedo not press it arbitrarily, so as not to cause unnecessary troubleto operator.

Note!

Emergency stop switch does not have the function of cutting off the current

power, make sure to turn off the power of the equipment before system

maintenance.

8 / 55

Overview

2.6Safety Information

Electrical Safety

◆Equipment must be grounded effectively;

◆To protect the equipment and personal safety, it is recommended to install indoor lightning arresting rod;

◆All maintenance work on the equipment must be carried out with the power off;

◆When the equipment is working, do not touch the moving parts of the machine with your hands or fingers.

Mechanical safety

◆Only under the circumstances necessary to dismantle the device casing;

◆Be attention to the machinery operation, always wear gloves, tools and parts must be placed in an orderly

manner;

◆Do not perform any maintenance or modifications to the equipment system that is not authorized by CRON.

◆Do not place any foreign objects on the device;

◆In non-emergency situations, it is strictly prohibited to press the emergency stop button;

◆In the operation of mechanical parts, always wear gloves, so as to avoid rusting parts; tools and parts should

be placed in order;

◆ Avoid overhead collision during equipment operation.

Other safety aspects

◆This device is not intended to be used in an explosive or potentially explosive atmosphere.

◆Fireworks is prohibited near the occasion of this device;

◆Prevent water or other liquids from flowing into the interior of the device;

◆Debris, scrap or residue generated from the use of this equipment must be handled in accordance with the

laws and regulations of the hazardous material management authority in the country / region in which it is

used.

Policy of equipment requirements

◆To ensure that customer’s installation site, environment and conditions, are able to meet and comply to the

equipment operational requirements.

9 / 55

Installation site and environment requirements

Device Model

Equipment Size

W(cm)

Equipment Size

L(cm)

Installation Space

W(cm)

Installation Space

L(cm)

HDI-600**

140

120

340

320

HDI-920**

170

130

370

330

HDI-1600**

232

115

430

315

L

W

Chapter 3: Installation Site and Environmental Requirements

—————————————————————————————————

3.1 Space requirement

Refer to Table 3-1, given the size of the machine and consider the space needed, minimum distance

between wall and machine is 100cm, sizes of the room(space) needed for the machine installation can be

determined. It is also advisable to reserve some room space close to the installed machine for placement

of plates and media too.

Table 3-1: System equipment size and installation space required

3.2 Flooring & hallway access

Doors and corridors at the installation site must be wide enough ( ≧ 145cm) so that the machine can be

pushed into the room.Floor level should be maintained at ± 4mm. If installation to be done above ground

floor, this requires an industrial elevator that have can load more than 2000kg. After the machine is in

place, the machine requires leveling by using a level gauge.

3.3 Environmental requirement

Working room temperature: 18°C ---- 28°C

Environment humidity: 40% ---- 60%, Non-condensing

Air quality: should meet international quality standards, that is, API value is less than or equal to 100;

Other installations for indoor: Air-condition, Dehumidifier/humidifier, air purifier.

Picture 3-1: Multi-function environment measurement (Temperature Humidity Hygrometer Tester)

Operation Instructions

Device Model

W(cm)

L(cm)

H(cm)

Weight(kg)

HDI-600**

170

136

140

850

HDI-920**

190

150

137

950

HDI-1600**

260

170

147

1600

Chapter 4: Offloading, Unboxing and Installing

—————————————————————————————————

4.1On-site conditions during offload handling

Customer needs to provide handling equipment and tools to ensure the safe handling of the machine to

the installation site.In the meantime, CRON engineers will assist with the handling and uncrating on site.

4.2Shipment packing

A High-precision Digital flexoImagerunit is usually packed in a wooden crate box for easy shipping and

handling. The following table lists the package sizes and weight of different models of HDI.

Table 4.1: Packing size and weight

4.3 Loading &unloading equipment

Customers must provide forklift or crane with minimum load-bearing for more than 2000kg. Forks length

must be more than 150cm. If necessary, lengthen the span of two forks according to the wooden box and

the structure of the machine to adjust to the corresponding width.

Picture 4-1: Forklift

4.4 Installation personnel

CRON advised customer to provide professional handling personnel to move the machine to the premises

of installation and unpack the crate, with CRON professionals work together on site.

Operation Instructions

HDI-600

Uncrate the box

Remove accessories

Lifting & positioning

Remove aluminium foil

Device levelling

Remove fixing bracket

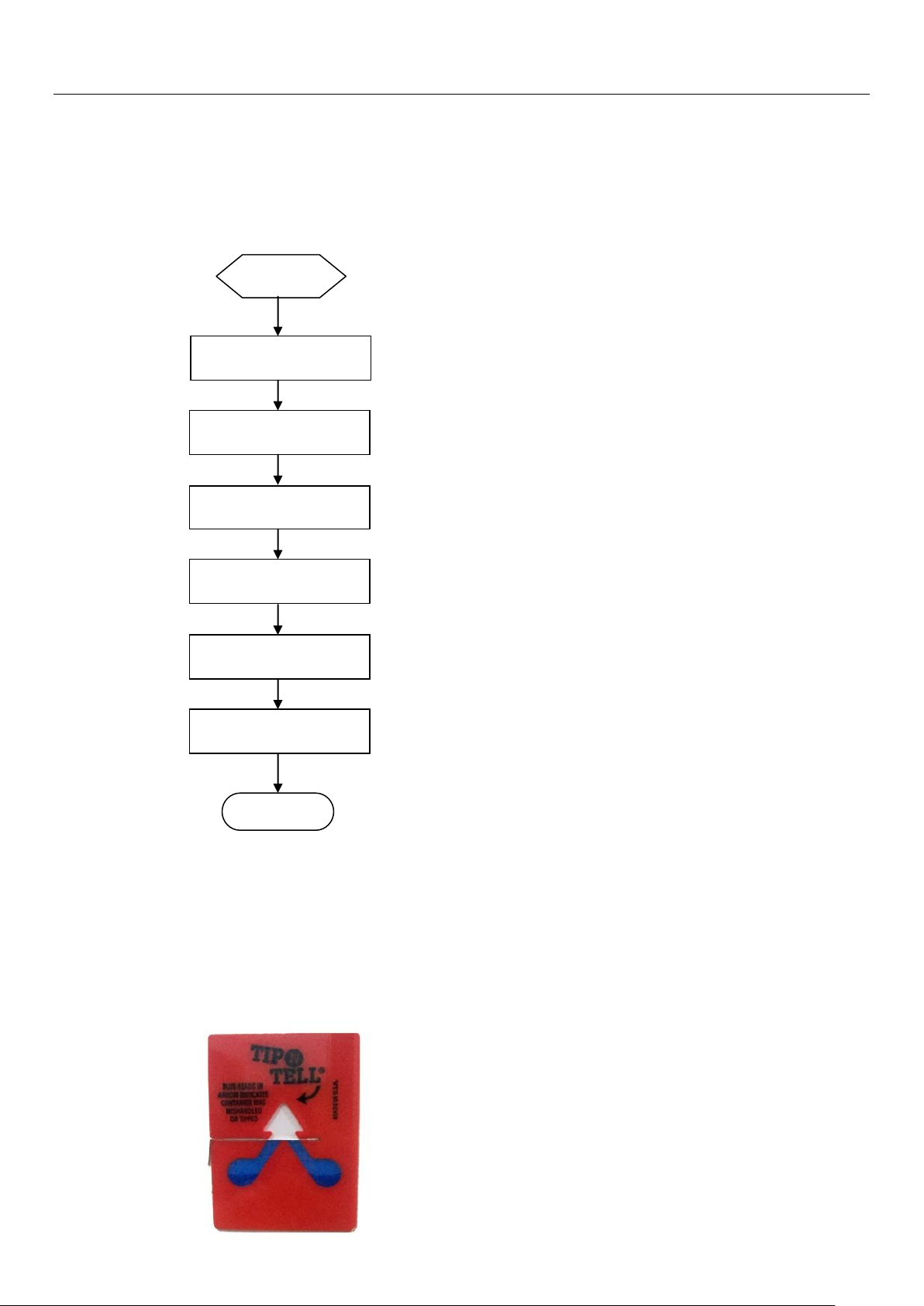

4.5Unboxing, fixing and installing

4.5.1 High-precision Digital flexo Imager unboxing flow chart:

4.5.2Unboxing preparation

First of all, check the crate box is intact, tilt indicator whether has any toner presence of overflow

beyond the guide line. Ifproblems are found, they should be documented and feedback to CRON

immediately.

Picture 4-2: Tilt indicator

12 / 55

Operation Instructions

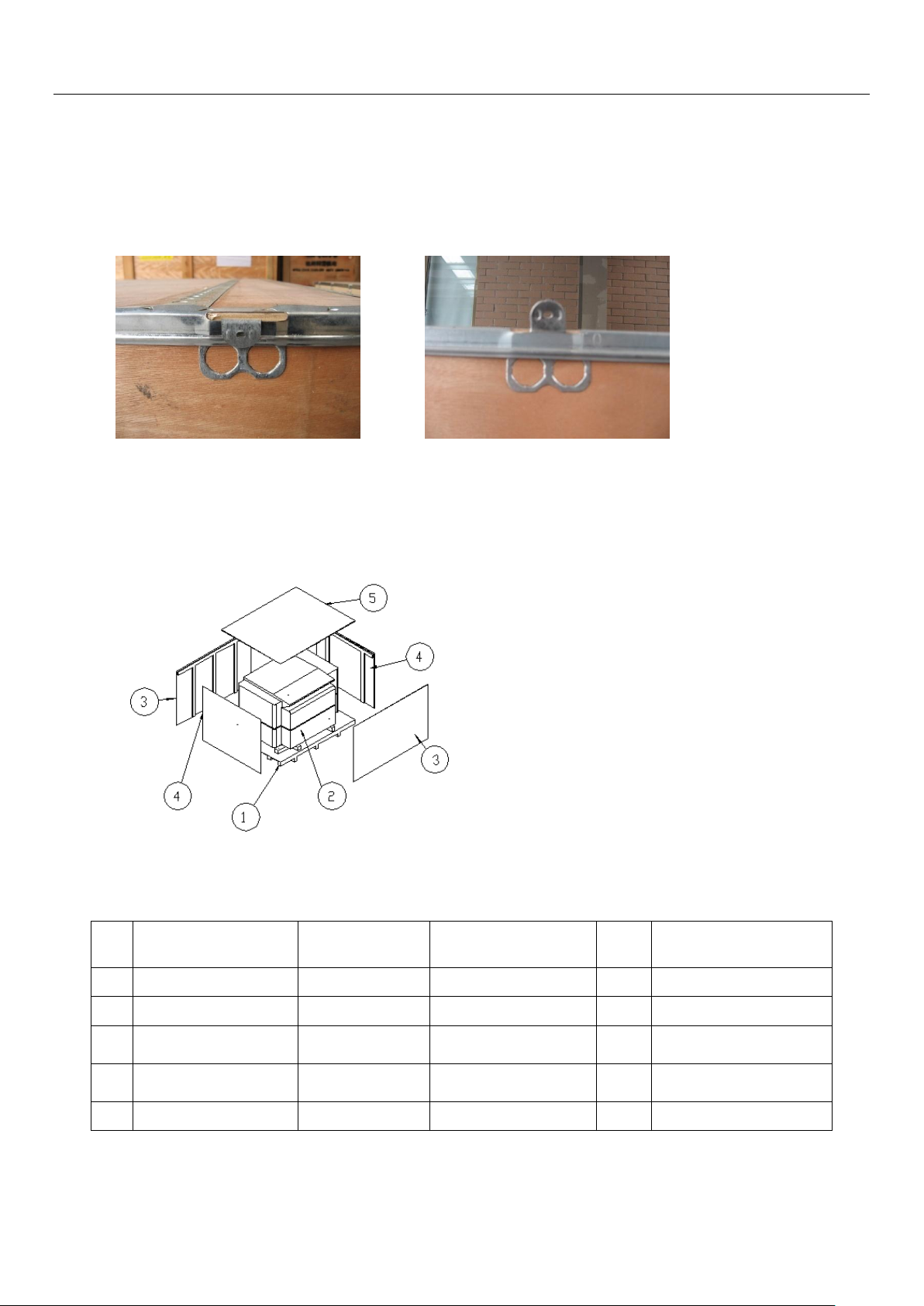

No

Description

Figure/Model

No.

Material/

Specification

Qty

Note

1

Wooden box pallet

Wood layers

1

2

Equipment

1

3

Wooden box side

panels

Wood layers

2 4

Wooden box end

panels

Wood layers

2

5

Wooden box cover

Wood layers

1

4.5.3 Uncrate the box:

Use long-nose pliers to loosen the wooden case lock;

A) locked stage B)unlocked stage

4.5.4 Follow the steps to remove the wooden box cover, side panels and pallet base(shown in Figure 3

and Table 1);

Figure 3: Panels removal instructions

Table 1:Wooden crate panels list

13 / 55

Operation Instructions

4.5.5Removal of aluminium foil:

Cut the foil bag at the bottom in circle, then remove foil bag (Figure 4).Be careful not to scratch the

equipment while cutting the foil bag.Then unscrew the hex screws 8-M6 * 10, unscrew the nut

4-M10,remove the fixing brackets(Figure 4);

Note: Depends on season and modes of transportation, method of packing could be done either

withwrapping bag, and/or aluminum foil bag. The description here refers of an aluminum foil bag as

an example;

Figure 4: Aluminium foil and equipment fixing brackets figures

4.5.6 Remove of bundled accessories:

Find the opening and remove of stretch film, remove the equipment spare parts and accessories and

keep it in a safe place for later use.

4.5.7Device lifting and positioning:

While using a forklift to lift up the HDI device, length of folds should be beyond the center gravity of the device,

and forks tips should be kept out of the wooden pallet base. Keep attention and maintain stable while shovel

and lifting the device. Moves the device to the installation location and carefully lower it down onto the ground.

4.5.8 Device level adjustment / power on

a)Adjust the device’s 3 support legs so that the legs are evenly weight down, and having the

transporting wheels levitated.At the same time adjust the overall level of device;

b) Connect the device power according to the power connection requirements;

14 / 55

Operation Instructions

4.5.9Connecting USB communication cable to the computer

a) HDI-600** /HDI-920**uses a separate external USB cable to connect the device and the computer.

The cable is located above the right side of the housing, and it is fastened tight to ensure reliable

connection;

b)HDI-1600**using an external USB interface cable to connect device and computer, the cable is

located in the lower right side of the enclosure, and it is fastened to ensure reliable connection;

4.5.10 Removal of the device’s “scanning platform fixation bracket”:

a-1) HDI-600 ** / 920 ** Model Scanning Platform fixation bracket is located inside the device. When

removing, open the device upper cover and remove the limit screws;

a-2) Move the top cover forward, notice that the "scanning platform fixation bracket" (in RED color)

inside the right sideof the device;

15 / 55

Operation Instructions

b-1)HDI-1600 ** Model’s scanning platform fixation bracket is located inside the device. After

removing the upper cover of the device, you can notice the scanning platform unit.

c) Use a hex wrench to remove the fixing screws of the "Scanning Platform Fixation Bracket" of the

device and pay special attention when removal; Handle with care and avoid scratches to the Encoder

Strip(gold color) that attached at the side of the panel along the guide rail.

4.5.11Putting back device covers

4.5.12Pressure window: through the pressure window, you can obtain current dedustingvacuum

pressure value, drum vacuum pressure value and the pressure sensor output status;

Dedusting vacuum Drum vacuum

16 / 55

Operation Instructions

Chapter 5: Operation Instructions

—————————————————————————————————

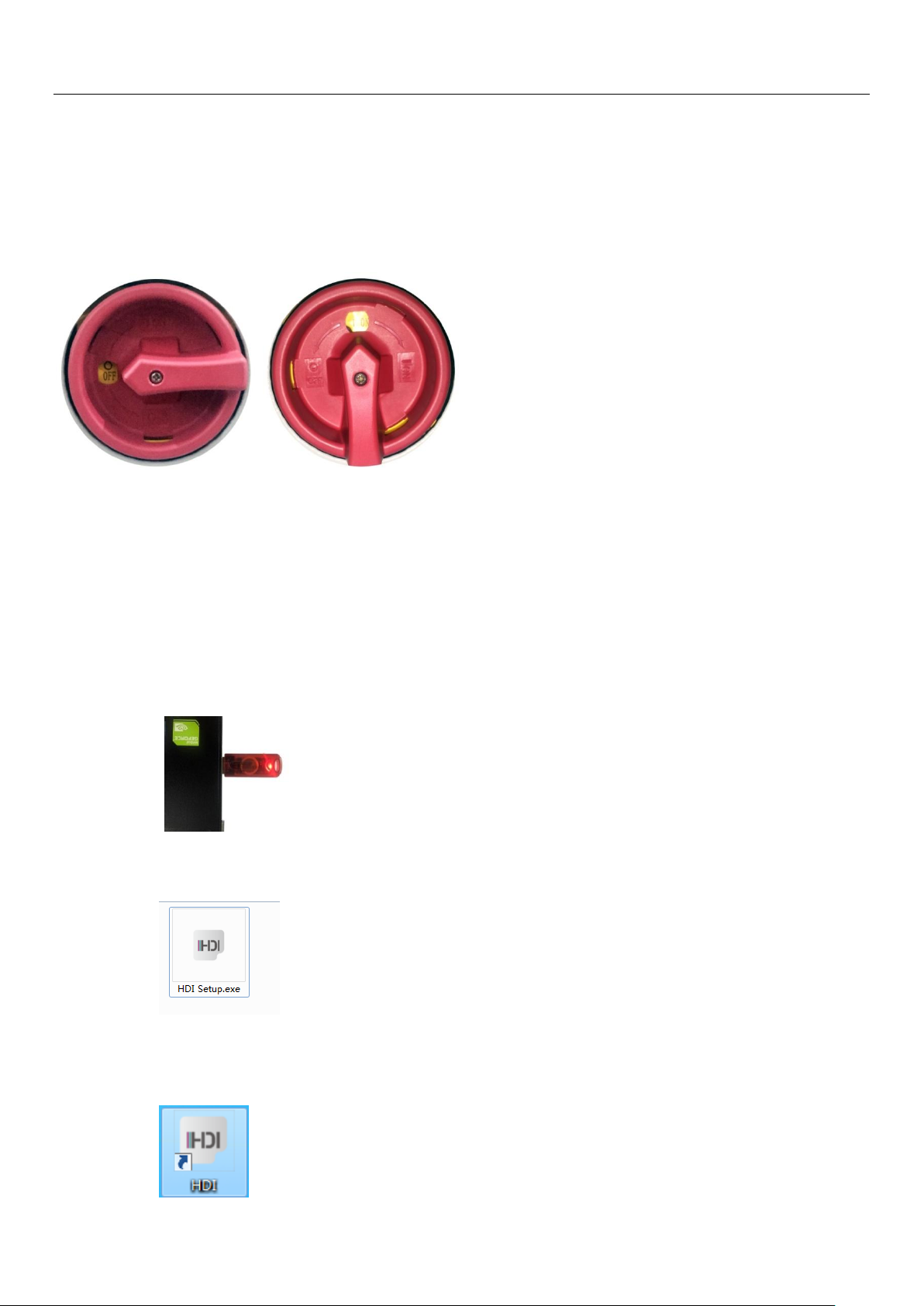

5.1 Turning on device

A) Open the circuit breaker(at the rear of the device) to the ON position. Then turn the cam switch to the

ON position to allow power supply access to the device.

5.2 Connecting to computer

Refer to 4.6.7, connect the computer USB port

5.3 Laboo-HDI installation & startup

5.3.1Connecting the Dongle and install LaBoo-HDI software

a) Remove the supplied dongle from the LaBoo software box and plug it into the USB port of the

computer;

b) Inserts theLaBoo software installation disk(provided in the Laboo software box) and insert it into

your computer's CD-ROM drive and run the "HDI Setup.exe" file;

c) Follows the software installation steps to install the LaBoosoftware and dongle driver.After

installation is completed successfully, the computer desktop will have the following icon shown as

below:

17 / 55

Loading...

Loading...