Page 1

Emotron M20

Shaft Power Monitor

Instruction manual

English

Page 2

Contents

1 Inside the Box............................................................................. 3

2 Safety .......................................................................................... 4

3 Description.................................................................................. 5

4 Getting Started ........................................................................... 7

4.1 Please note ................................................................................................. 7

4.2 Connection and set-up before first start ................................................... 7

4.3 First start ..................................................................................................... 8

4.4 Manual setting of alarm levels, alternative A ........................................... 9

4.5 Manual setting of alarm levels, alternative B ........................................ 10

4.6 Manual setting of alarm levels, alternative C ........................................ 10

5 Wiring ........................................................................................ 11

5.1 Alternative example for single-phase connection ................................. 13

5.2 Example - digital input ............................................................................. 14

6 Selection of Current Transformer ........................................... 14

6.1 Motors less than 100 A........................................................................... 14

6.2 Motors greater than 100 A ..................................................................... 17

7 Operation .................................................................................. 19

7.1 Overview ................................................................................................... 19

7.2 Window menu .......................................................................................... 20

7.3 How to change a value ............................................................................ 21

8 Programming ............................................................................ 22

8.1 Set measurement unit, kW or HP ........................................................... 22

8.2 Setting rated motor power and current (window 41 and 42) ............... 24

8.3 Setting number of phases (window 43) ................................................. 25

8.4 Monitor function (window 05)................................................................. 25

8.5 Setting the Start Delay (window 31)....................................................... 27

Emotron AB 01-2151-01r4 1

Page 3

8.6 Setting alarm levels with Auto set ........................................................... 28

8.7 Setting the Response Delay (windows 32 and 34)................................ 29

9 Advanced Features .................................................................. 31

9.1 Setting alarm levels manually (windows 11-14) .................................... 31

10 Troubleshooting ....................................................................... 41

11 Technical Data ......................................................................... 43

12 Parameter List.......................................................................... 47

13 Service ...................................................................................... 50

2 Emotron AB 01-2151-01r4

Page 4

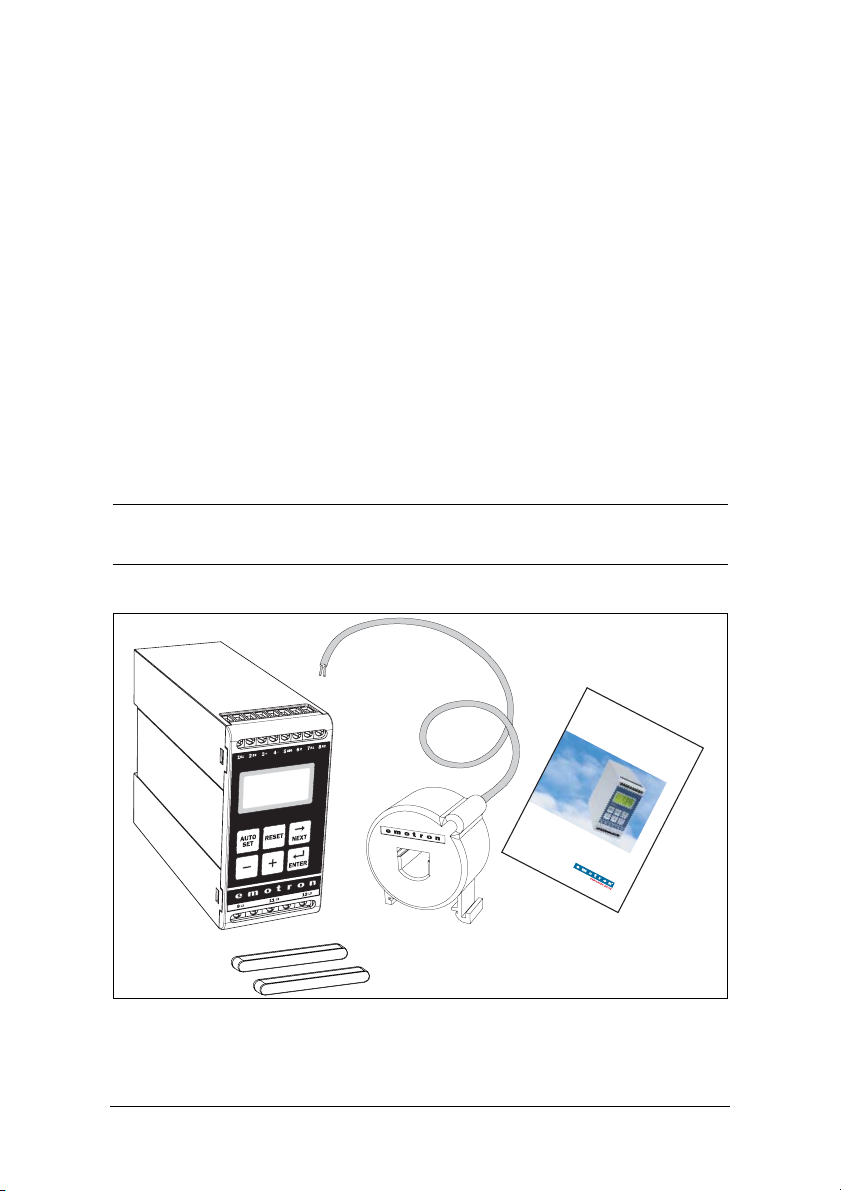

1 Inside the Box

Please check the delivery. Despite the fact that all products from Emotron are

carefully inspected and packed, transport damage may occur:

• Your shipment should contain the Emotron M20 shaft power monitor,

a current transformer, 2x terminal covers (option*) and this instruction

manual.

• Check carefully that the equipment ordered complies with the motor’s input

voltage and that the current transformer rating is as stated on the delivery

packaging.

• Check that the contents have not been damaged during shipping.

• If something is missing, or has been damaged, contact the supplier as well as

the forwarding agent within 48 hours of receipt.

NOTE: If in doubt contact your supplier before installing or commissioning

the product.

Shaft P

Emotron M20

ower Monitor

M20

In

s

tr

u

c

t

io

n

m

a

n

u

E

a

n

l

glish

*)

Emotron AB 01-2551-01r4 Inside the Box 3

Page 5

2Safety

• Study this manual thoroughly before installing and using the monitor.

• The monitor must be installed by qualified personnel.

• Always disconnect supply circuits prior to installing.

• The installation must comply with standard and local regulations.

• Pay special attention to the information in this chapter and the parts marked

CAUTION in the Operation and Programming chapters.

• Check that the monitor and the equipment are correctly connected before it

is taken into use.

• Should questions or uncertainties arise, please contact your local sales outlet

or see chapter 13, Service.

• Faults that arise due to faulty installation or operation are not covered by the

warranty.

NOTE: Removing or tampering with the seal on the housing will invalidate

the warranty.

4Safety Emotron AB 01-2551-01r4

Page 6

3 Description

This instruction manual describes the installation and commissioning of the

Emotron M20 shaft power monitor. The Emotron M20 supervises induction

motor driven equipment and provides warnings when abnormal conditions are

detected. It protects for example, pumps and other equipment. The M20’s ability to provide reliable monitoring and protection ensures that production equipment is optimized and expensive breakdowns and interruptions are minimized.

The Emotron M20 uses the motor as its own sensor and no external sensors or

extra cabling are required. Due to the special method of subtracting motor

power losses, the monitor is able to accurately measure the shaft power supplied

by the motor to the application. This advanced technique allows the M20 to

monitor only the “application” load rather than the “total” motor load, which

includes the varying motor losses.

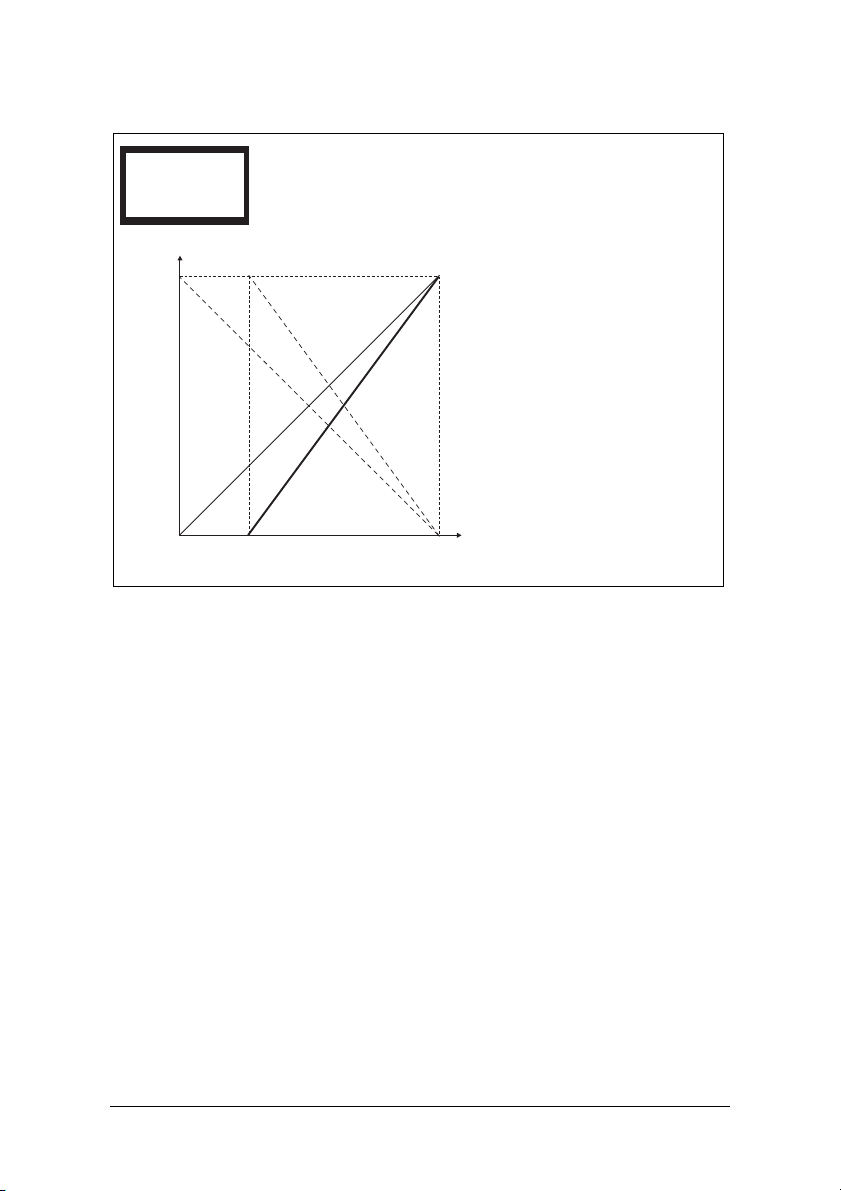

The shaft power is calculated by measuring motor input power, and subtracting

the motor power loss calculated using a unique principle. The shaft power output is indicated on the monitor display in kW or HP, or as a percentage of rated

power. Calculating shaft power gives more reliable supervision than non-linear

techniques, such as current and phase angle measurements. Current measurement is only sufficient at high motor loads and phase angle only at low loads.

Input power is sometimes called true or real power. Input power is linear, but

ignores motor power loss.

The M20’s analogue output and two relay outputs allow the combination of

direct and indirect control. The unit offers high accuracy in the event of very

small load variations. The analogue output signal can be used to scale the

machine load to represent the actual working range.

The monitor is very easy to install and set up and should be mounted on a

standard DIN rail. It is also very easy to use. The “Auto set” function makes it

possible to adjust the monitor automatically by pressing just one key.

The M20 provides complete flexibility in terms of the type of protection

required for your application. You may select either overload and underload

protection or simply overload with pre-alarm or underload with pre-alarm.

Independent response delays can be selected for both overload and underload

protection. Additional flexibility is provided in the form of programmable output relays, number of start attempts, number of reversing attempts etc.

Emotron AB 01-2551-01r4 Description 5

Page 7

The Emotron M20 shaft power monitor offers advanced multi-function monitoring and a display for load indication and parameter setting. It is ideal for

protecting many different applications including pumps in general, centrifugal

pumps, magnetic pumps, screw and impeller pumps, mixers, scrapers, crushers,

conveyor systems, etc.

For further information, please see www.emotron.com.

6Description Emotron AB 01-2551-01r4

Page 8

4 Getting Started

NEXT

ENTER

NEXT

4.1 Please note

1. Pay special attention to the safety section in this manual and parts marked

CAUTION.

2. Check that motor/supply voltage corresponds to values on the monitor

product label at the side of the unit.

3. Make a note of the motor’s rated power and full load amps from its nameplate. Confirm that the current transformer supplied is of the correct size

according to tables 1 and 2 in chapter 6 of this manual.

4.2 Connection and set-up before first start

1. Connect the Emotron M20 according to chapter 5 and Fig. 1.

2. Make sure all safety measures have been taken and switch on the supply

voltage.

3. Use the key to scroll through the menu. Press and hold the key and

ENTER

press the key to scroll back.

4. Set rated motor power and current in windows 41 and 42. Additional settings to be programmed are discussed in chapter 8.

5. Set monitor function in window 05, overload and underload or only underload or only overload. See chapter 12, Parameter list, for range and default

values.

6. Set start delay and response delay in window 31 and 32/34.

7. Compare all set values with the parameter list in chapter 12 to confirm that

all relevant values are set. Advanced features will be found in chapter 9.

Emotron AB 01-2551-01r4 Getting Started 7

Page 9

4.3 First start

SET

AUTO

CAUTION: Make sure that all safety measures have been taken before

switching on the supply voltage and starting the motor/machine in order to

avoid personal injury.

1. Start the motor/machine and let it run at normal load, until the Start Delay

has expired.

AUTO

2. Press for 3 seconds.

Hint!

Short-circuit the output relays during the set-up; this prevents the equipment

from stopping unintentionally.

More Hints!

The monitor can be set in three different ways:

1. Automatically by pressing the Auto set key as described above. The Auto set

2. If Auto set is used as above, the margins can be re-adjusted manually (win-

SET

function performs a measurement (momentarily) of the actual load and sets

relevant alarm levels for this actual load plus/minus the “margins” (Default;

Max +16% and Min -16%).

dows 21-24). When the margin values are changed a new Auto set must

always be performed to activate the changes and the new margins. More

information is provided in chapter 9, Advanced Features.

3. Manual setting of alarm levels (windows 11-14). The alarm levels can be set

manually, without using the Auto set. See sections Manual setting of alarm

levels, alternative A, B and C.

NOTE: If any window parameter is manually adjusted, the display will flash

the new value to indicate that a change has been made. The Enter key must

be pressed for the M20 to accept this new value.

8 Getting Started Emotron AB 01-2551-01r4

Page 10

4.4 Manual setting of alarm levels,

alternative A

Running and setting at normal load

• Start the motor/machine or pump and let it run at normal load, until the

Start Delay (window 31) has expired.

• Read off the load on the monitor display, e.g. 65%, window 01

(or kW/HP).

• Set the max. main alarm level to something between e.g. 70-85% in window

11. This must be set to the actual application requirements, maximum load

for machine/process.

• Set the min. main alarm level to something between e.g. 60-45% in window

14. This must also be set to the actual application requirements.

See also Fig. 7 in section 8.4, Over- and underload monitor.

Emotron AB 01-2551-01r4 Getting Started 9

Page 11

4.5 Manual setting of alarm levels,

alternative B

Running and setting at maximum load as well as at

minimum load

• Start the motor/machine or pump and let it run at maximum load, until the

Start Delay has expired. E.g. fill the conveyor with maximum allowed goods.

• Read off the load on the monitor display, e.g. 85% (window 01).

• Set the max. main alarm level to something between e.g. 90-95% in window

11. This must be set to the actual application requirements, maximum load

for both machine and processes.

• Then run the motor/machine and let it run at minimum load, e.g. idling,

until the Start Delay has expired.

• Read off the load on the monitor display, e.g. 30%.

• Set the min. main alarm level to something between e.g 25-20% in window

14. This must also be set to the actual application requirements.

See also Fig. 7 in section 8.4, Over- and underload monitor.

4.6 Manual setting of alarm levels,

alternative C

It is also possible to approximately calculate or estimate the alarm levels. If e.g.

the motor used is 22 kW, 22 must be set in window 41. This means that each

percentage point corresponds to 220 W (22 kW/100 = 220 W), and the alarm

limits in window 11- 14 can be set in steps of 220 W. If the max. alarm level is

set to 80% in this example, the monitor will emit an alarm and stop the

machine at approx. max. 17.6 kW shaft output power.

NOTE: If the pre-alarm is not used, the values for Min. pre-alarm and Max.

pre-alarm can be set to 0 (window 13) and 125% (window 12) respectively.

This will eliminate pre-alarm warning indications in the monitor display

when not in use.

See also Setting alarm levels manually in chapter 9, Advanced Features.

10 Getting Started Emotron AB 01-2551-01r4

Page 12

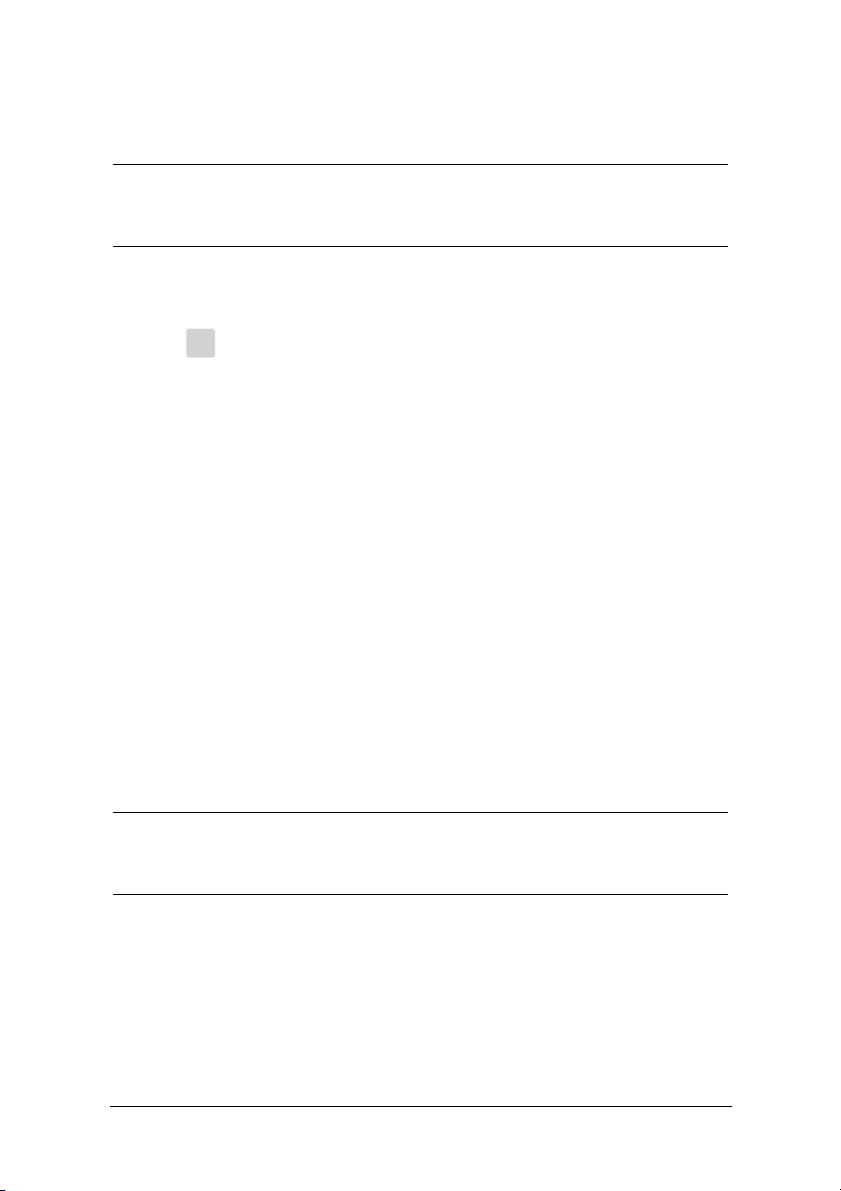

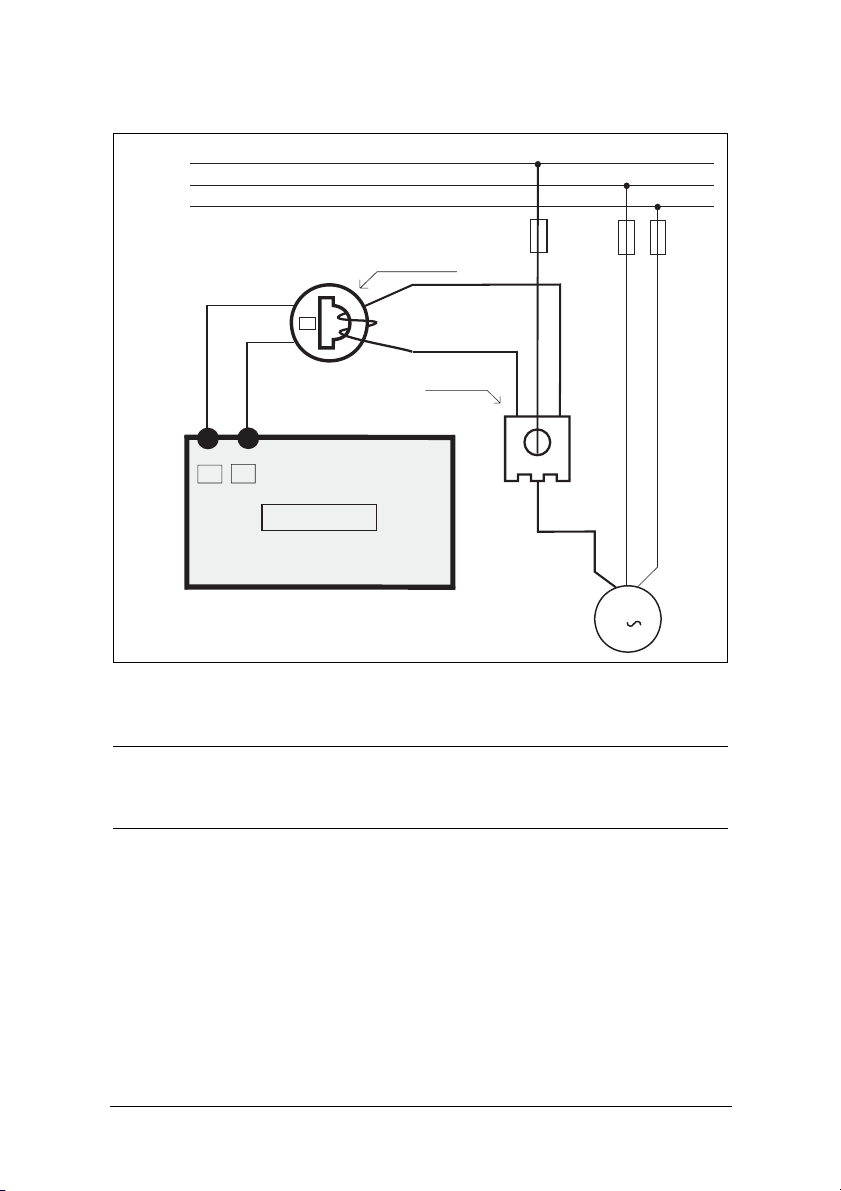

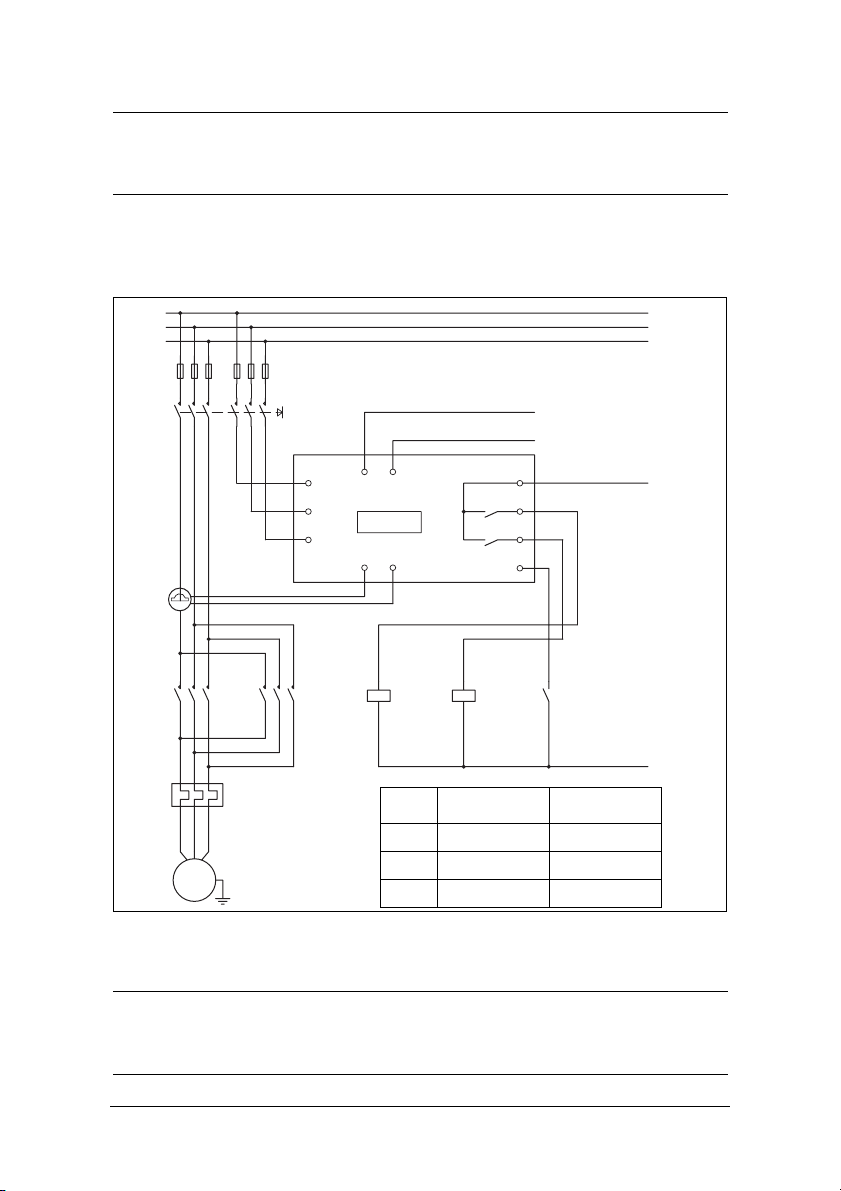

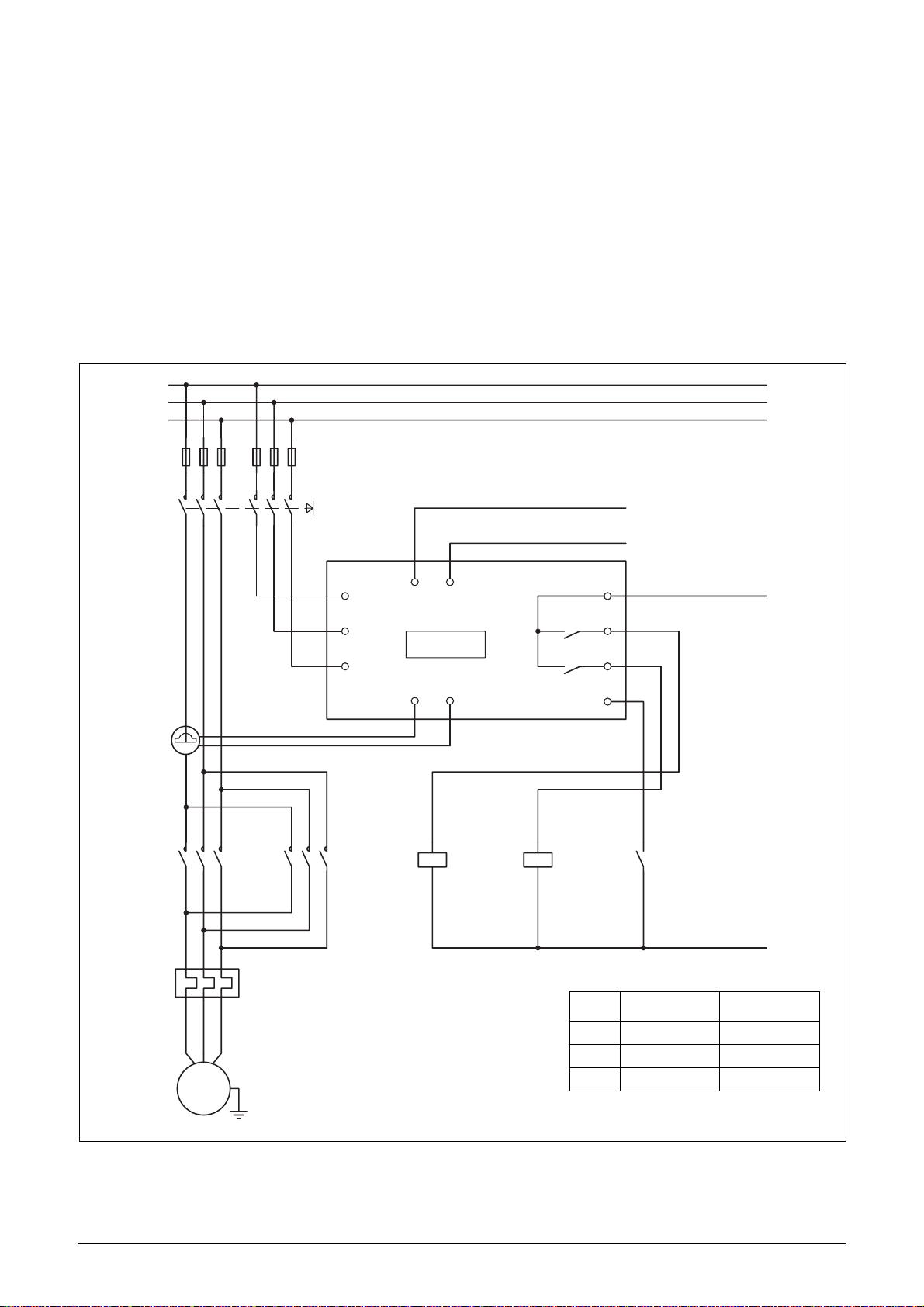

5 Wiring

The following wiring diagram provides an example of how the M20 can be connected to control the start/stop circuit of a three-phase motor, Fig. 1. Co nnections to a single-phase motor are described later in this manual (Fig. 2) as are the

programming changes necessary for such applications. The default setting for

the M20 is 3-phase.

1. The current transformer CTMxxx must be placed in the same phase that is

connected to terminal 9, phase L1, see Fig. 1. Failure to follow this requirement will result in the monitor failing to function.

2. For single-phase connection see fig 2.

When using DC voltage, terminal 6 should be connected to negative polarity

(ground) and terminal 5 to positive polarity (max. 48 VDC). See also Alternative auxiliary circuit (Fig. 16) in chapter 9.

Note: The current transformer (CTMxxx) must be placed in the same phase

that is connected to terminal 9, phase L1, see Fig. 1.

Emotron AB 01-2551-01r4 Wiring 11

Page 13

L1

L2

L3

NOTE: In power

down, both relays

are always N.O.

9

3

4

L1

A+ A-

11

L2

M20

13

L3

S2S1

1

2

6

C

7

R1

8

R2

5

DIG

Max. 240 VAC (alt. 0 VDC-)

CTMxxx

Please see CTM

K1

UVW

information

on Page 11.

NOTE: Monitor

voltage see

Note below.

-Reset

-Auto set

- Block

K1

{

PREALARM

Stop

Start

K1

N (alt. 48 VDC+)

M

Fig. 1 Connection example

NOTE: If the START/STOP is connected as per Fig. 1, it is recommended that

terminals 6 and 7 be bypassed during programming. After the programming

is completed the bypass must be taken out. Make sure that the monitor

voltage range e.g. 3x380-500 VAC matches the connected motor/line

voltage, e.g. 3x 400 V.

Please use the enclosed plastic (rubber) insert (if ordered, optional) to cover the

monitor terminals.

12 Wiring Emotron AB 01-2551-01r4

Page 14

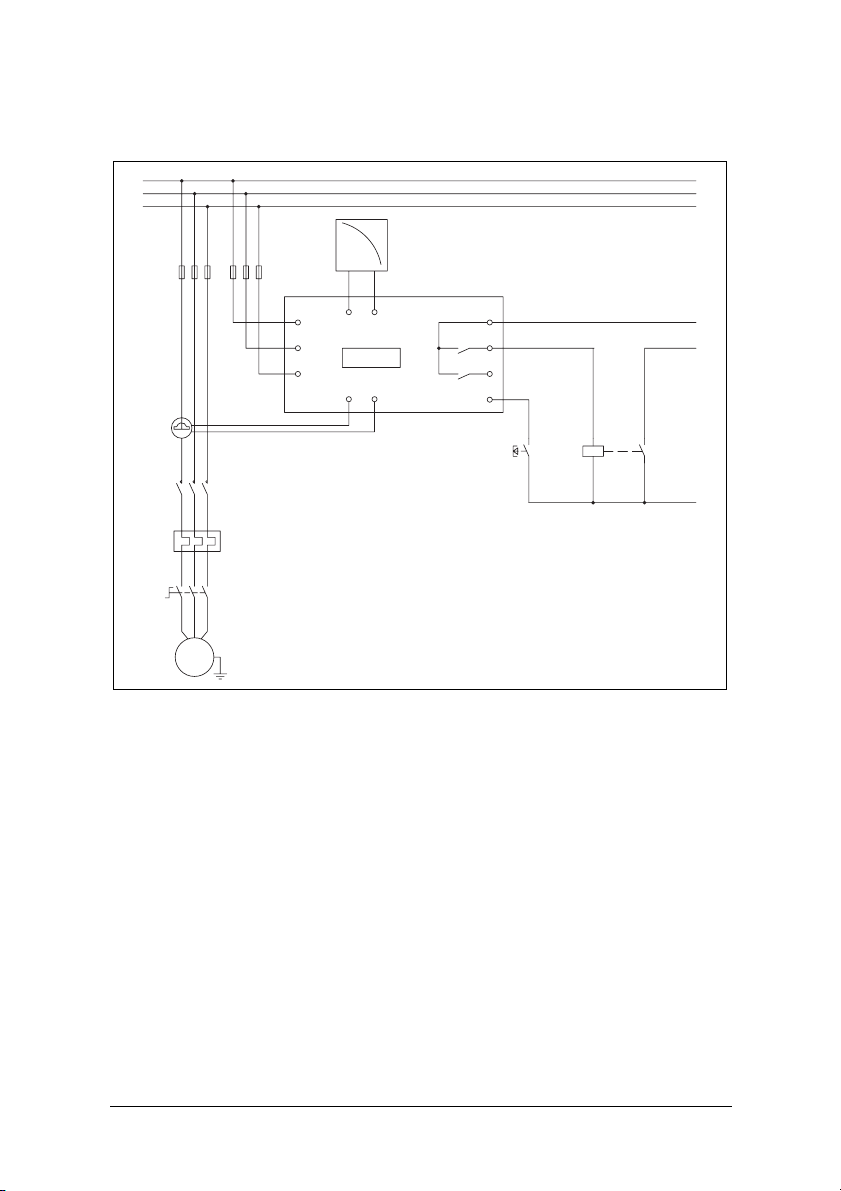

5.1 Alternative example for single-phase

connection

This wiring example shows the connections required for single-phase applications.

Refer to Fig. 1 for the remaining wiring.

L1

N

CTMxxx

K1

9

3

M20

S1 S2

1

4

C

A-A+

R1

R2

2

L1

11

L2

13

L3

NOTE: Monitor

DIG

6

7

8

5

voltage, see

note below.

L

N

M

Fig. 2 Single-phase connection example.

NOTE: In Fig. 2 make sure that the monitor voltage range e.g. 1x100-240 VAC

matches the connected motor/“line – neutral” voltage, e.g. 1x 230 V.

Emotron AB 01-2551-01r4 Wiring 13

Page 15

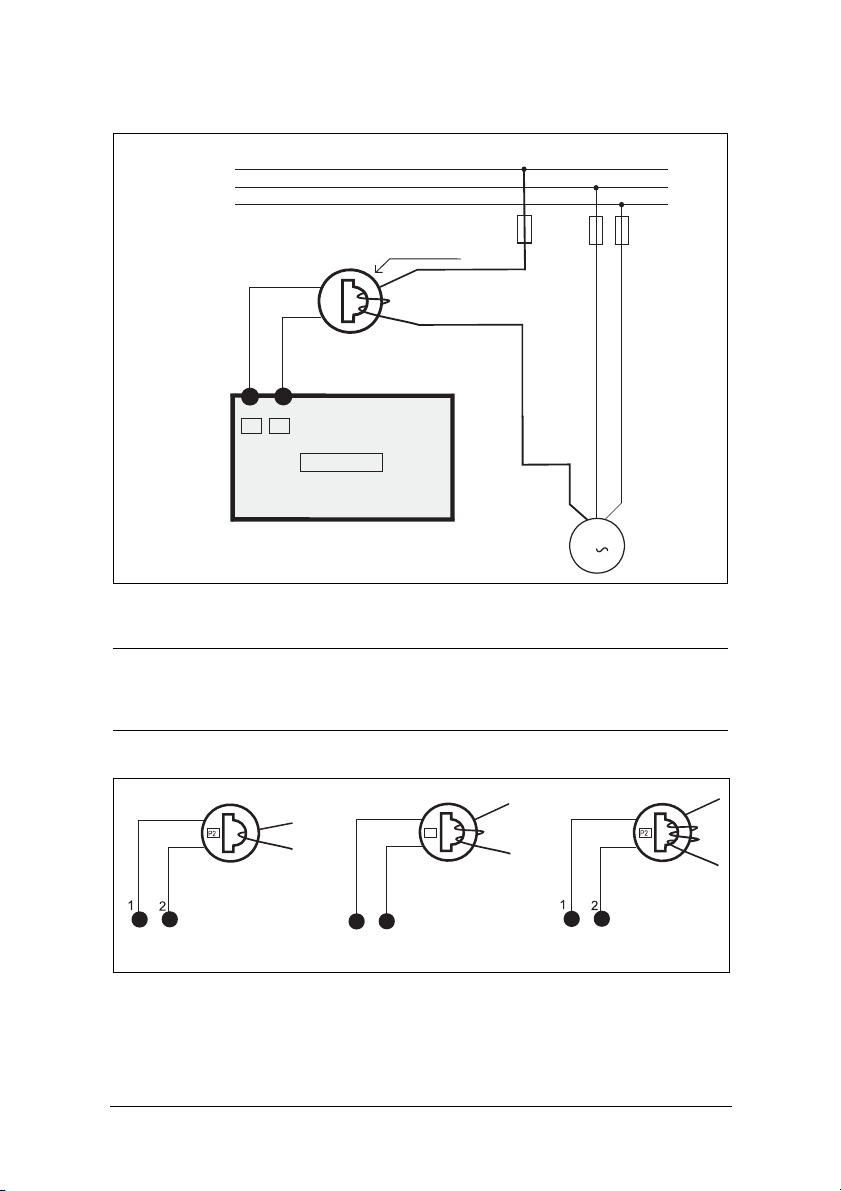

5.2 Example - digital input

The digital input uses terminals 5 (DIG) and 6 (C - reference). Either a VAC or

a VDC signal may be used. Connect + to terminal 5 (DIG) and - to terminal 6

for VDC signal. Please note the polarity when DC voltage is used. See also

Fig1

and terminal 6: Max. 240 VAC (or 0 VDC-) and on terminal 5: N

(or 48 VDC+).

VAC VDC

M20 M20

See also chapter 9, Advanced Features.

6

C

DIG

5

~

Max 240 VAC

~

DIG

6

C

5

-

Max 48 VDC

+

Note polarity!

Fig. 3 Wiring example for digital input.

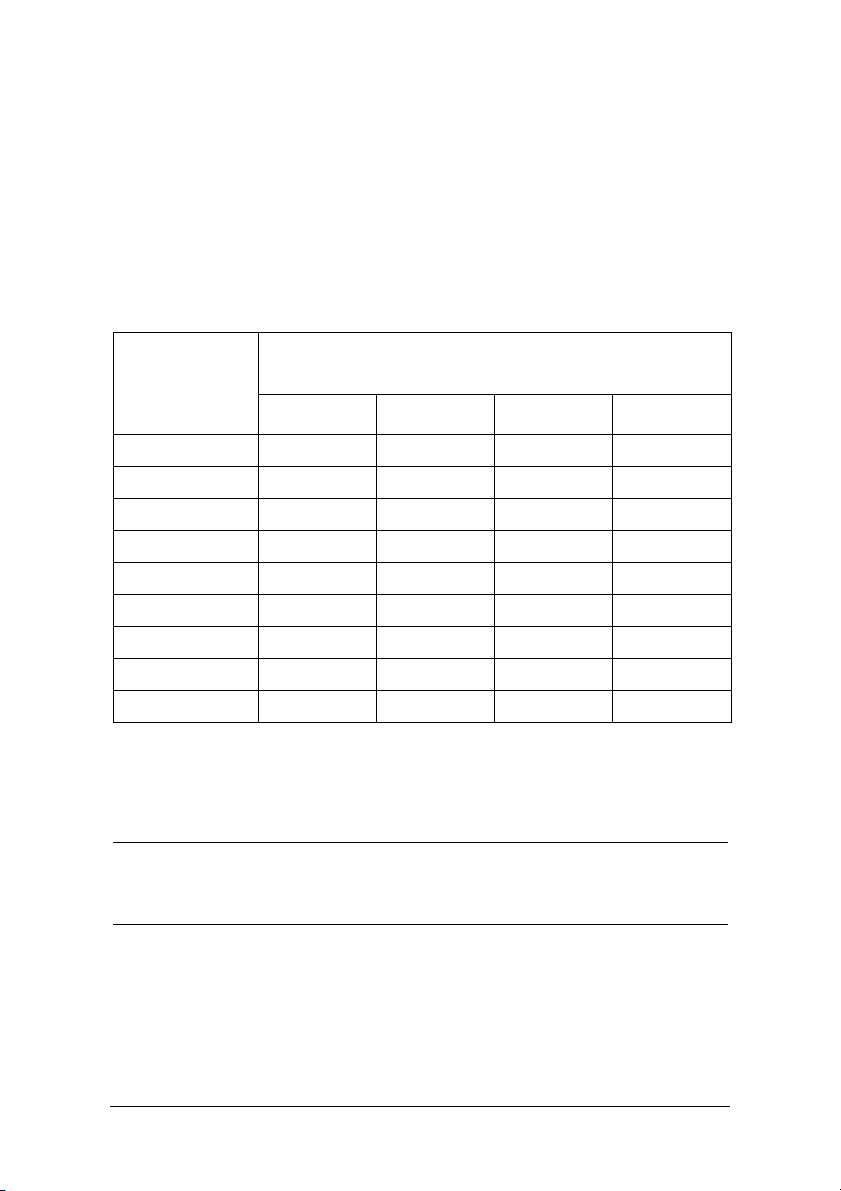

6 Selection of Current Transformer

6.1 Motors less than 100 A

1. Check the rated motor current on the motor plate.

2. Compare this value with the current in Table 1.

3. From Table 1, select the current transformer and the appropriate number of

windings.

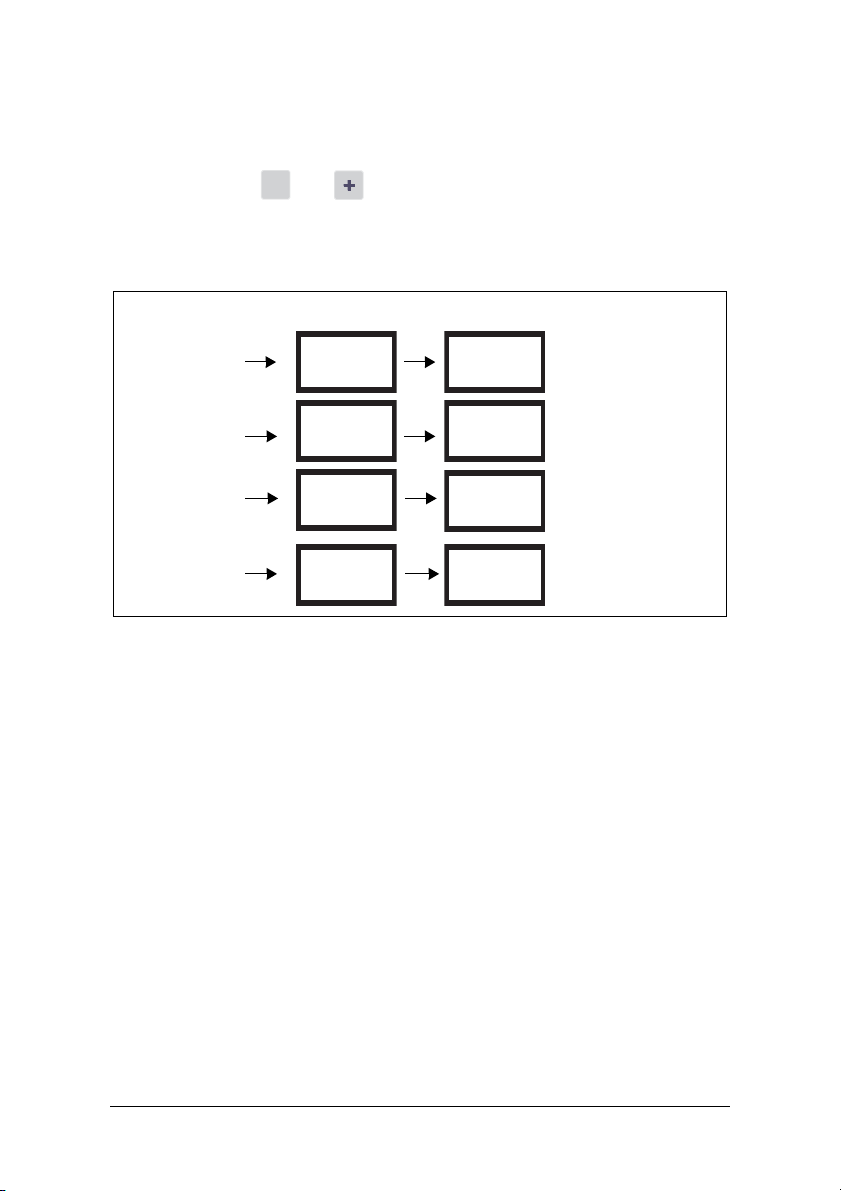

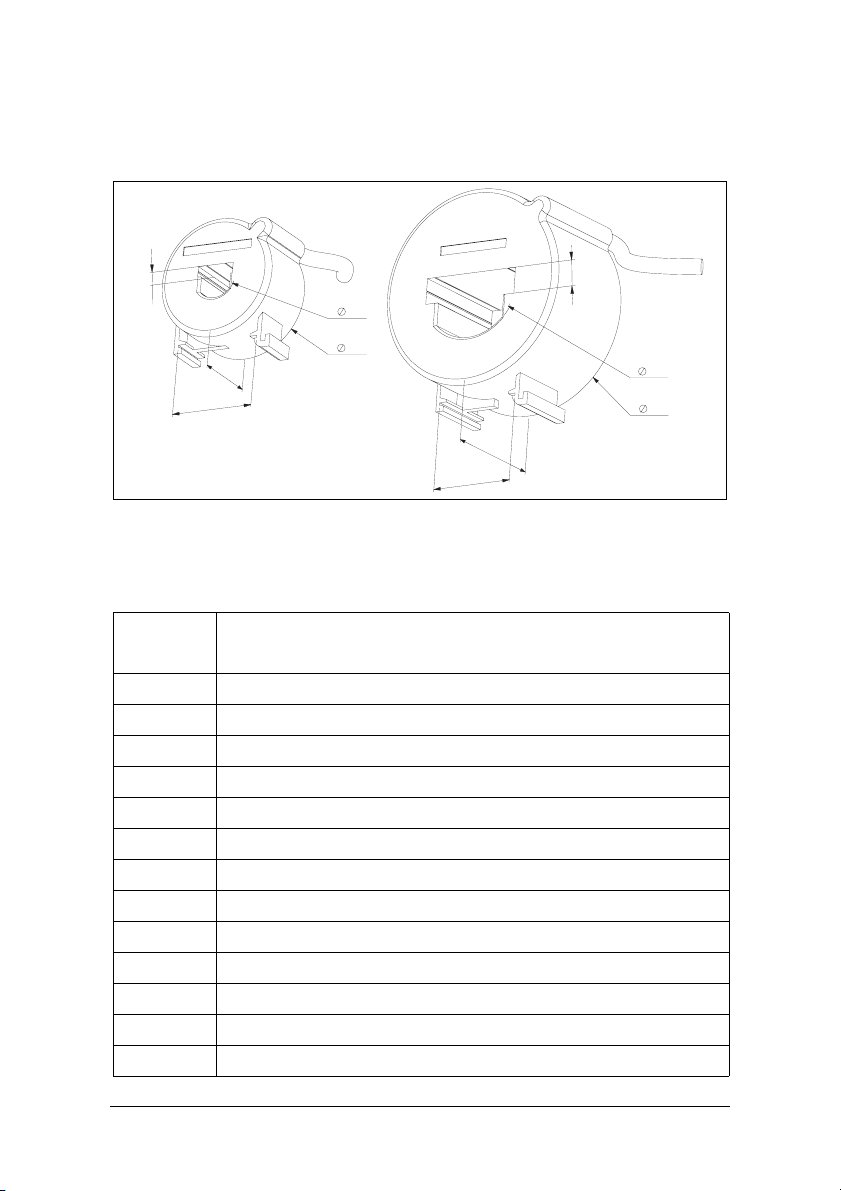

Fig. 5 shows the different types of current transformer (CT) windings. In Fig.

5:1 the motor wire is just drawn through the CT, in the text and tables below

this is described as 1 (one) winding. Fig. 5:2 shows a CT with 2 windings and

Fig. 5:3, 3 windings. In other words the number windings is equal to the

number of times the motor wire “L1” is drawn through the hole of the current

transformer.

NOTE: Maximum length of the CTM cable is 1 m (39 inches).

14 Selection of Current Transformer Emotron AB 01-2551-01r4

Page 16

Example

• Rated motor current = 12 A.

• Select 10.1-12.5 A from the first column in Table 1.

• This gives:

CTM025 with 2 windings (the motor wire is drawn through the CT’s hole

twice).

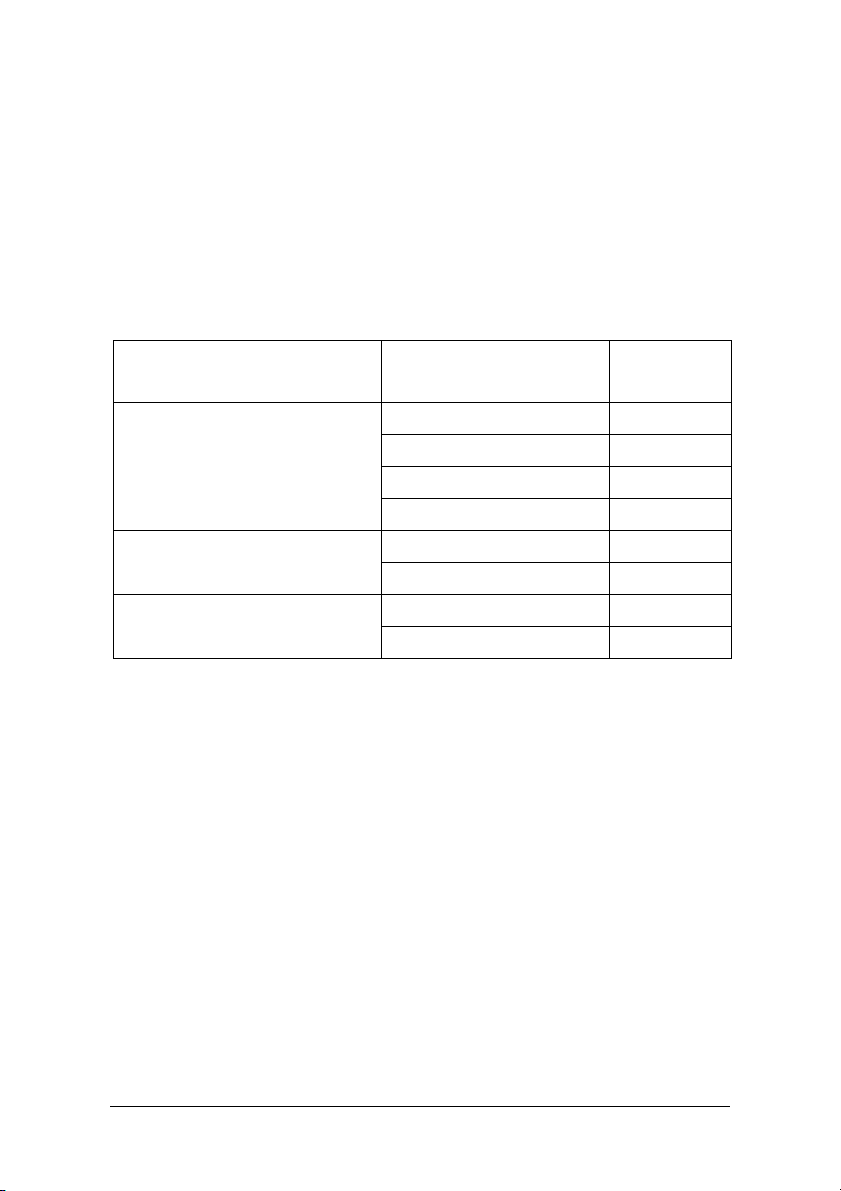

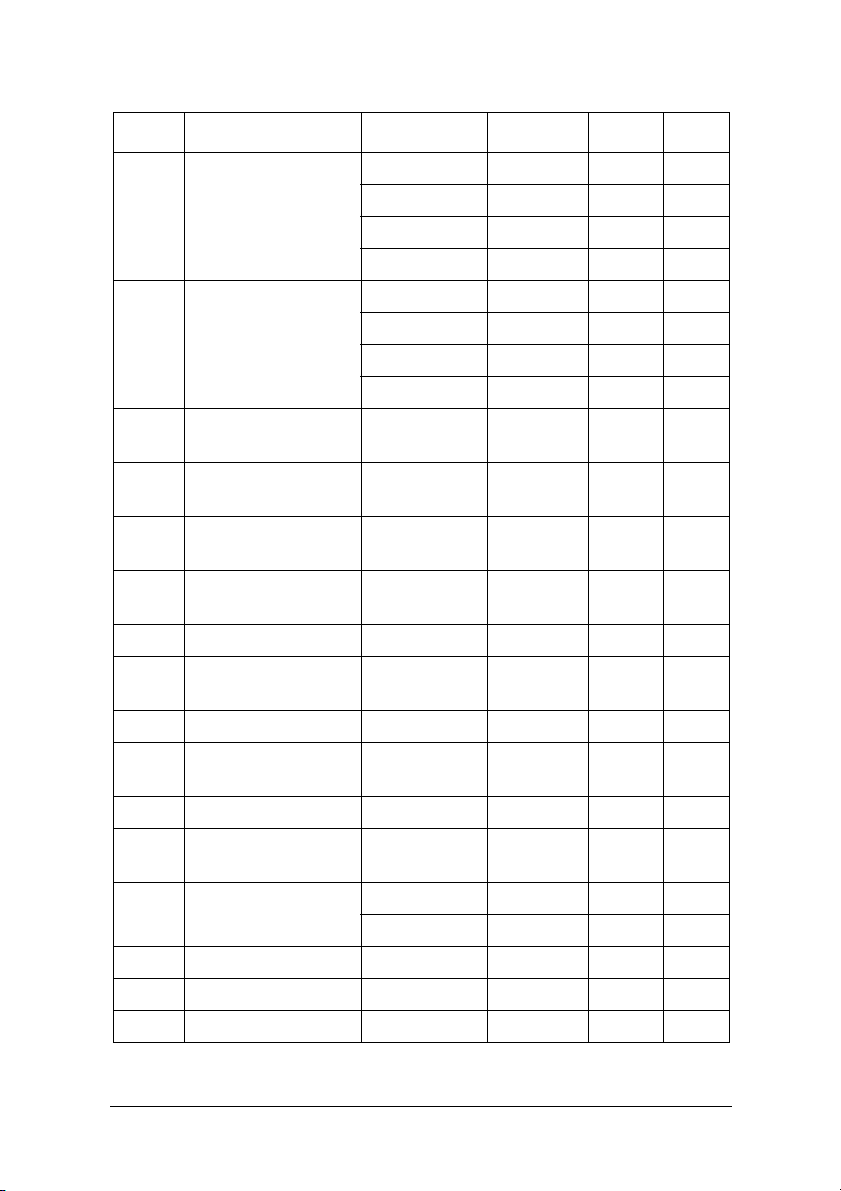

Table 1 Motors and CT less than 100 A

CURRENT TRANSFORMER TYPE and

RATED MOTOR

CURRENT [A]

CTM 010 CTM 025 CTM 050 CTM 100

0.4 – 1.0 10

1.01 – 2.0 5

2.01 – 3.0 3

3.1 – 5.0 2

5.1 – 10.0 1

10.1 – 12.5 2

12.6 –25 1

26 – 50 1

51 – 100 1

NUMBER OF WINDINGS

In order to ensure an accurate calibration of the M20, it is essential that you use

the correct CTM and apply the exact number of windings in accordance with

the above table.

NOTE: Normally the appropriate Current Transformer will have been ordered

and shipped with the M20. Check that this is the case; contact the supplier

if in doubt.

Emotron AB 01-2551-01r4 Selection of Current Transformer 15

Page 17

L1

L2

L3

CTM025

1

S1

P2

2

S2

M20

2 windings

M

3

Fig. 4 Example CTM 025 with 2 windings for a 12 A motor

NOTE: The current transformer connection and orientation are not polarity

sensitive, but must be connected to the same phase that is being

referenced for terminal 9 of the M20.

P2

1

2

5:1 5:2 5:3

Fig. 5 Example 1, 2 and 3 windings.

16 Selection of Current Transformer Emotron AB 01-2551-01r4

Page 18

6.2 Motors greater than 100 A

1. Check the rated motor current on the motor plate.

2. Compare this value with the current in Table 2.

3. Select the primary and secondary current transformer and the appropriate

number of windings from the columns in Table 2.

Please note that the ratio of the primary transformer must be exactly as provided

in the table below, otherwise the monitor power calculations will be inaccurate.

This will affect power readings, settings etc.

Example

• Rated motor current = 260 A.

• Select 251-500 A from the first column in Table 2.

• This gives:

- Primary transformer 500:5, 1 winding. (The motor wire is drawn through

the primary transformer once).

- CTM010 with 2 windings. (The wire from the primary transformer is

drawn through the hole in the CT, "CTM10", twice).

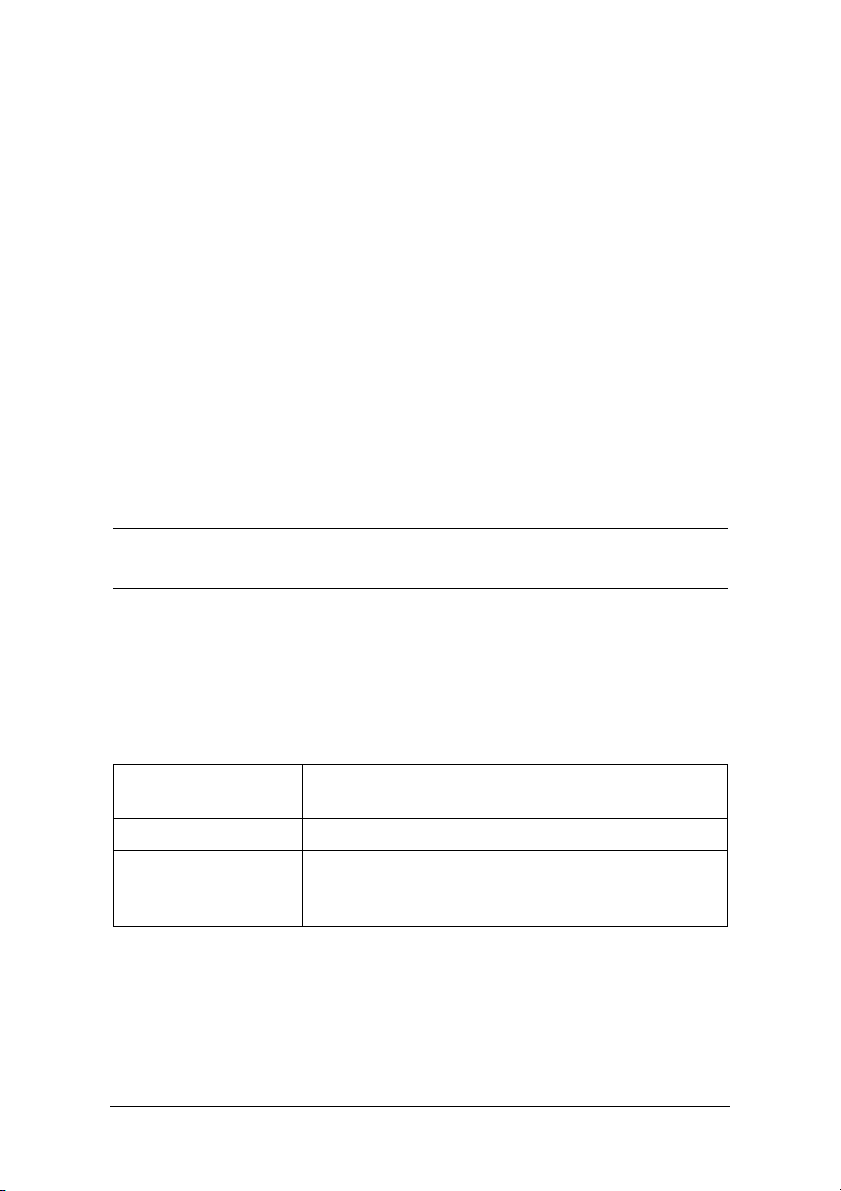

Table 2 CT greater than 100 A.

RATED MOTOR

CURRENT [A]

101 – 150

151 – 250

251 – 500

501 – 999

NOTE: Check that the appropriate Current Transformers has been ordered

and shipped with the M20. Contact the supplier if in doubt.

Emotron AB 01-2551-01r4 Selection of Current Transformer 17

CURRENT TRANSFORMER TYPE and

NUMBER OF PRIMARY WINDINGS

150:5 + CTM 010

1+ 2

250:5 + CTM 010

1+ 2

500:5 + CTM 010

1+2

1000:5 + CTM 010

1+ 2

Page 19

L1

L2

L3

CTM010

1

S1

P2

2

S2

2 windings

1 winding

S1 S2

500:5

M20

M

3

Fig. 6 Example of a CTM 010 with 2 windings and a primary transformer

500:5 with 1 winding for a 260 A motor.

NOTE: The transformer connection and orientation are not polarity sensitive, but must be connected to the same phase that is being referenced for

terminal 9 of the M20.

18 Selection of Current Transformer Emotron AB 01-2551-01r4

Page 20

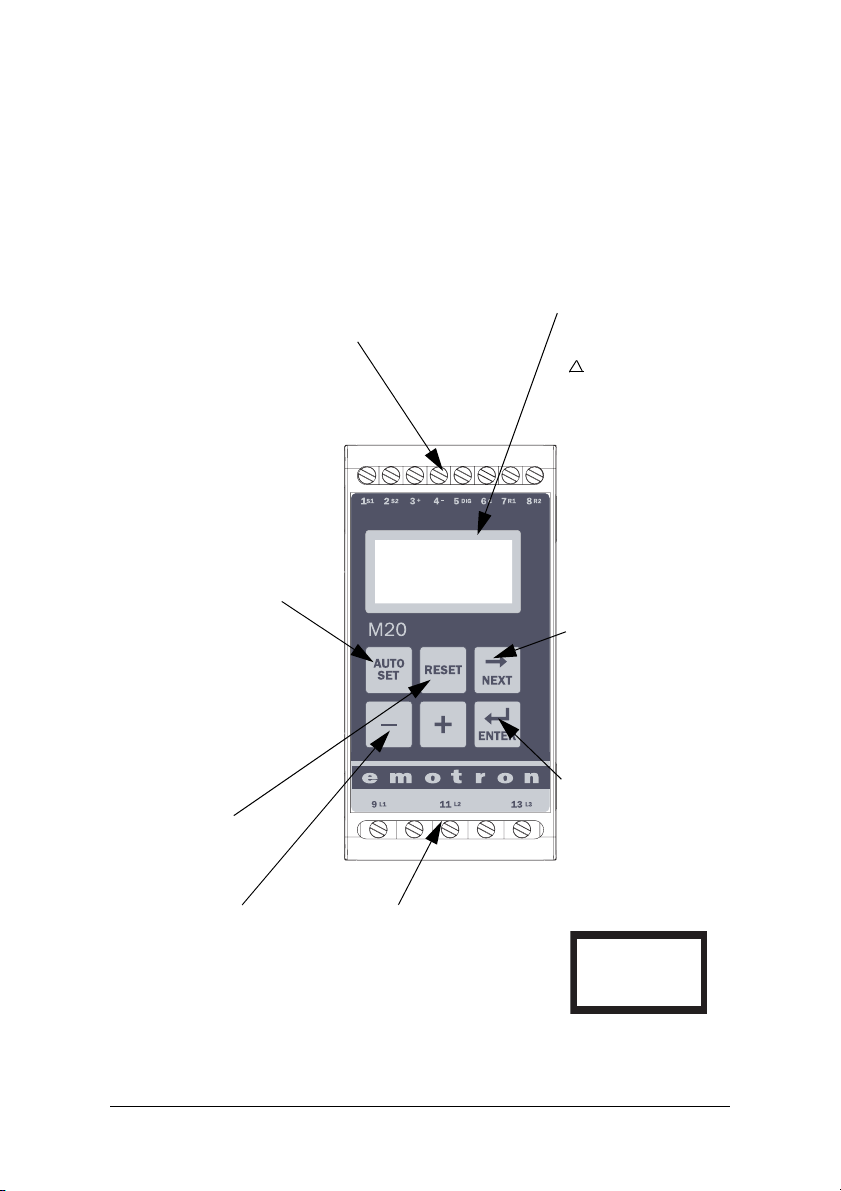

7 Operation

2123

Make sure the enclosed plastic (rubber) insert (if ordered, optional) covers the

monitor terminals before you start programming.

7.1 Overview

Control Terminals

1 S1 Current transformer input

2 S2 Current transformer input

3 + Analogue output

4 - Analogue output

5 DIG External RESET or AUTO SET

or Block Pre-Alarm

6 C Common: RELAY, DIG

7 R1 Main Alarm Relay 1*

8 R2 Pre-Alarm Relay 2

AUTO SET Key

Press for 3 seconds during

normal and stable load to

apply the automatic setting of

the alarm levels. Not available if Parameter Locked.

12

123

%

Display

Function (window) number

1

Function Value

!

Warning signal

Start, response delay or

block timer active

Parameter locked

VVoltage indicator

A Current indicator

mA Milliampere indicator

kW Kilowatt indicator

SSecond indicator

% Per cent indicator

NEXT Key

Proceeds to next window. If no

key is pressed for 1 minute the

display returns to window 01

automatically. Scroll back by

pressing and holding ENTER at

the same time as the NEXT key

is pressed.

ENTER Key

RESET Key

To r es et ALA RM

+/- Keys

For increasing and

decreasing value

Monitor Supply Terminals

9 L1 Motor phase

11 L2 Motor phase

13 L3 Motor phase

* For alternative relay function, see Special functions

in chapter 9.

Confirm (save) changes.

After Power up window 01

appears, the actual load value

is shown.

Default view (example shows

54% load):

01

54

%

Use the NEXT key to scroll

through the function menu.

Emotron AB 01-2551-01r4 Operation 19

Page 21

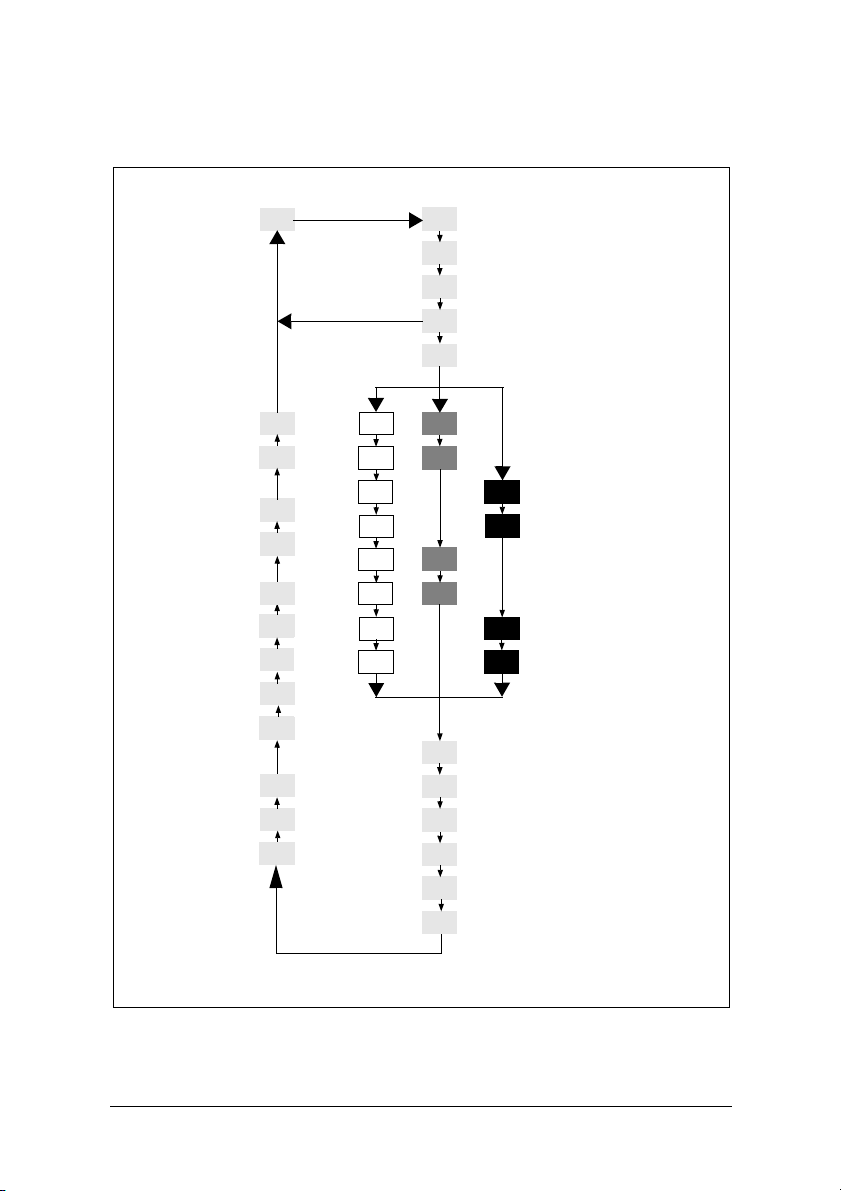

7.2 Window menu

Alarm indication

00

Start window

01

02

03

04

05

Measured shaft power

Measured line voltage

Measured current

Parameter Lock

Monitor Function

Factory defaults

Analogue Output

99

91

11

12

11

12

13

Block Timer

Digital Input

Relay function

Pre-Alarm Relay 2

Main Alarm Relay 1

Alarm at no motor

current

Main Alarm Latch

82

81

65*

64

63

62

61

14

21

OVER- and UNDERLOAD

22

21

OVERLOAD

22

UNDERLOAD

23

24

31

Number Of Phases

Rated Current

Rated Motor Power

43

42

41

32

33

34

35*

36*

* See Special functions in chapter 9, Advanced Features

MAX Main Alarm

MAX Pre-Alarm

13

MIN Pre-Alarm

MIN Main Alarm

14

MAX Main Alarm margin

MAX Pre-Alarm margin

MIN Pre-Alarm margin

23

MIN Main Alarm margin

24

Start Delay

Response Delay Max

Hysteresis

Response Delay Min

Pause/Reverse time

Autoreset (start attempts)

20 Operation Emotron AB 01-2551-01r4

Page 22

• The Alarm window only appears if an Alarm output is active.

NEXT

ENTER

NEXT

NEXT

ENTER

NEXT

• The Actual Load window appears after power up.

00

01

• Use the key to scroll through the menu. Scroll back by pressing and

holding at the same time as the key is pressed.

ENTER

• The Actual Load window (or alternative alarm window) will appear automatically if no keys are pressed for longer than 1 minute.

• If the Parameter Lock is on, only windows (if alarm active)

020403

01

• Window selects the monitor function, see section 8.4.

05

are visible.

00

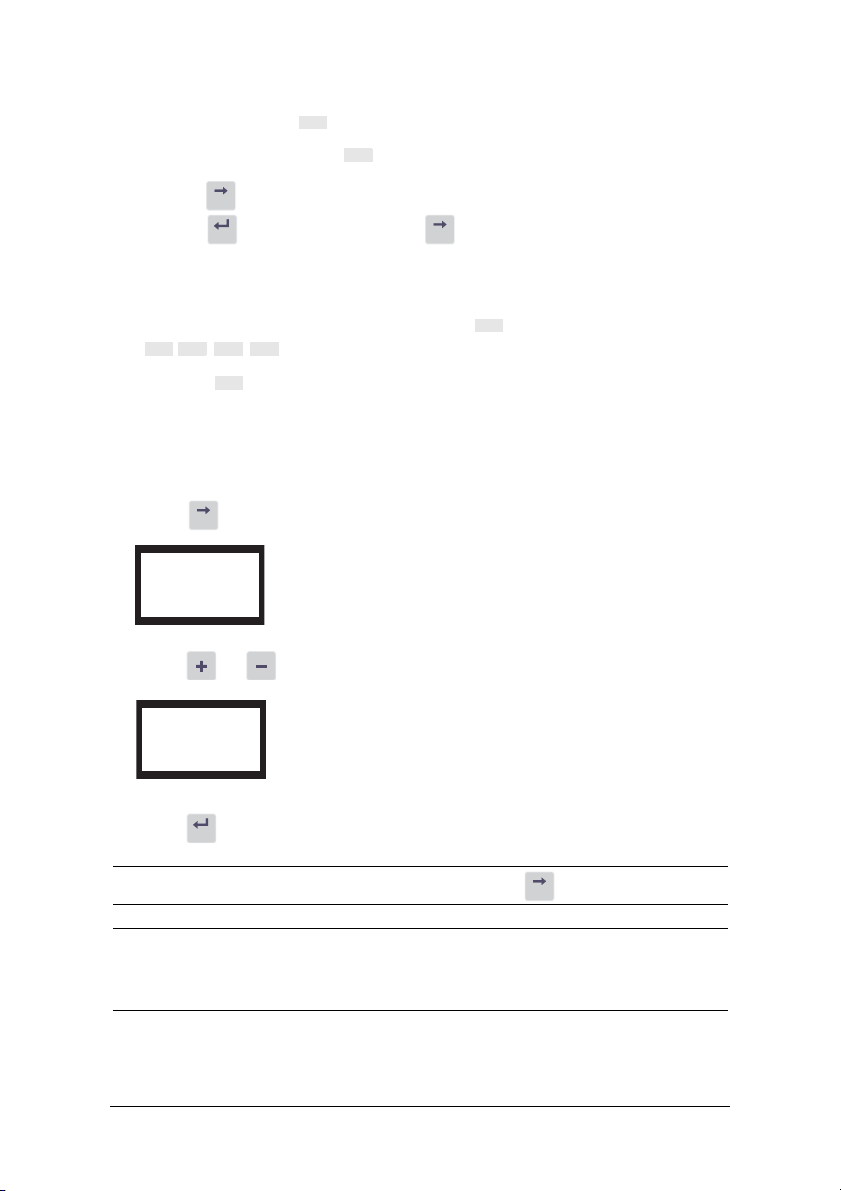

7.3 How to c hange a value

Example: setting the rated motor current in window 42.

1. Press until the window number 42 appears.

42

5.6

A

2. Press or until the desired value is reached (e.g. 23 A), value flashes.

42

23

A

3. Press to confirm and save the change, value stops flashing.

NOTE: If the value is NOT to be changed, press the key.

CAUTION: In order to avoid personal injury, make sure that all safety

measures have been taken before switching on the supply voltage and

starting the motor/machine.

Emotron AB 01-2551-01r4 Operation 21

NEXT

Page 23

8Programming

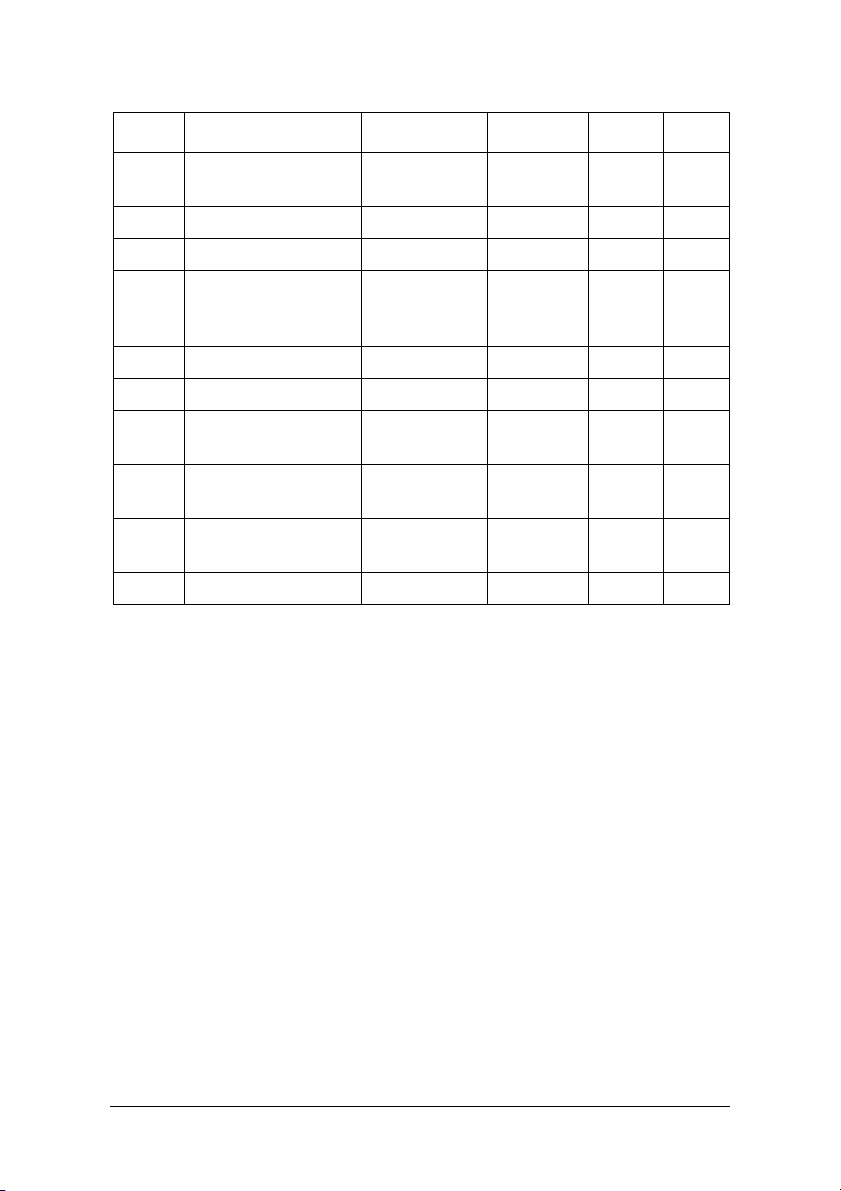

8.1 Set measurement unit, kW or HP

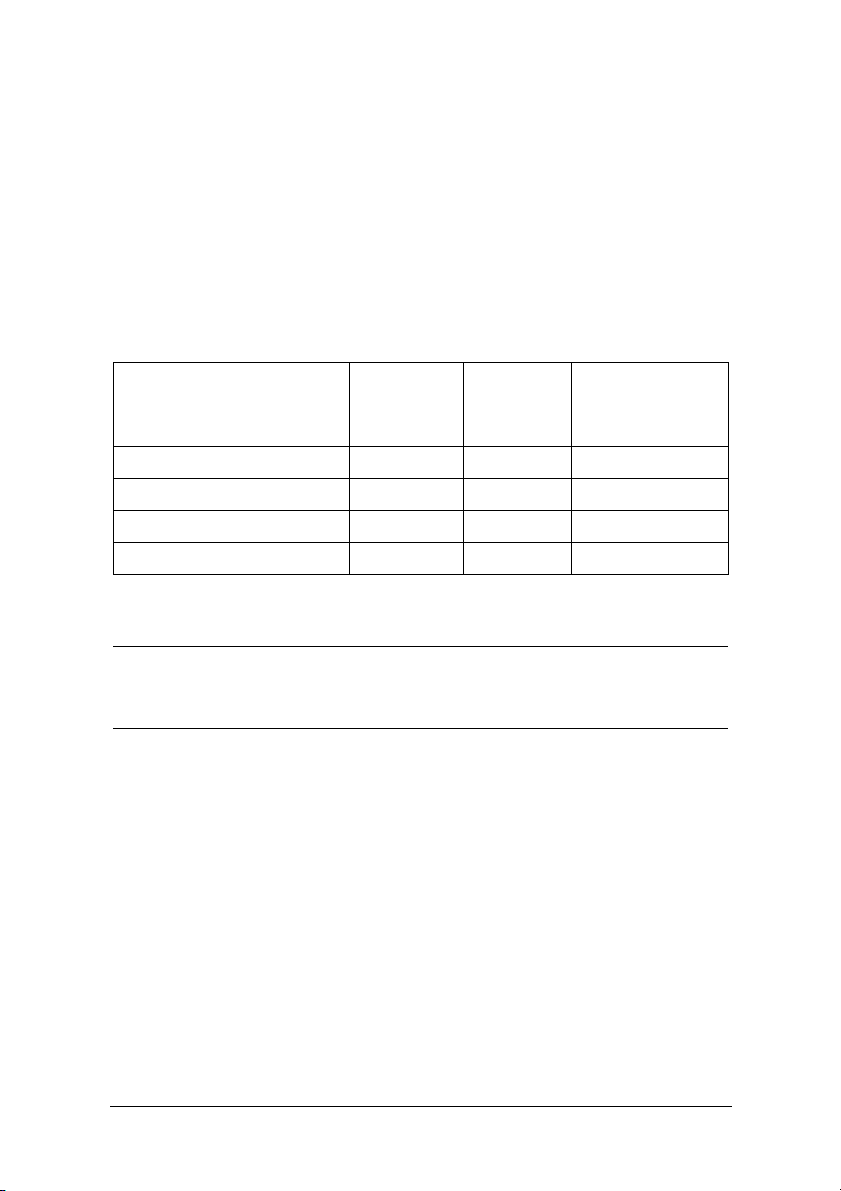

8.1.1 Selecting the unit of measurement

The unit of measurement can be set to kilowatts or horsepower both as absolute

or relative values. This setting is valid for the alarm levels, rated motor power

and the actual load read-out in window 01.

Measurement

unit

Kilowatt relative value (def.)* % kW %

Horsepower absolute value HP HP HP

Horsepower relative value* % HP %

Kilowatt absolute value kW kW kW

Read-out

load

window 01

Rated power

window 41

Alarm levels

windows

11, 12, 13, 14

* Measured shaft power as % of rated power.

CAUTION: In order to avoid personal injury, make sure that all safety

measures have been taken before switching on the supply voltage and

starting the motor/machine.

22 Programming Emotron AB 01-2551-01r4

Page 24

Programming

RESET

1. Go to window 01.

2. Press and hold and simultaneously for 3 seconds.

3. The next unit of measurement is set and appears for 2 sec (see examples).

Repeat to select the desired measurement unit according to the table.

Horsepower:

absolute value

RESET

For 2 seconds Read-out example

HP

01

3.52

Horsepower:

relative value*

Kilowatt:

absolute value

Kilowatt:

relative value*

(default)

HP

kW

kW

%

* Measured shaft power as % of rated power.

01

01

01

12

%

4.62

kW

12

%%

Emotron AB 01-2551-01r4 Programming 23

Page 25

8.2 Setting rated motor power and current

ENTER

ENTER

(window 41 and 42)

The rated motor power and the rated motor current must be set in windows 41

and 42.

Example motor plate:

TYPE: T56BN/4 NR: 948287 Prot. IP: 54

Serv: S1 Cos ϕ: 0.78 Is. Cl:F

V:Y/Δ Hz HP kW RPM A:Y/Δ

240/415 50 3 2.2 1400 5.6/9.4

260/440 60 3 2.2 1680 5.8/9.1

ASYNCHRONOUS THREE-PHASE MOTORS

8.2.1 Programming

1. Go to window 41 (default = 2.2 kW).

2. Press or to set the rated motor power as indicated on the motor

plate (see example).

3. Press to confirm the change.

4. Go to window 42 (default = 5.6 A).

5. Press or to set the rated motor current as indicated on the motor

plate (see example).

6. Press to confirm the change.

24 Programming Emotron AB 01-2551-01r4

Page 26

8.3 Setting number of phases (window 43)

ENTER

The number of phases must be set according to the number of motor phases.

Default is 3 phases, see also chapter 5, Wiring.

8.3.1 Programming

1. Go to window 43 (default = 3PH).

43

3PH

2. Press or to set the number of phases to 1 if a single-phase motor is

used.

3. Press to confirm the change.

43

1PH

8.4 Monitor function (window 05)

Monitor

(Protection)

OVER- and UNDERLOAD (default)

OVERLOAD

UNDERLOAD

If separate output relays are required for overload and underload alarms, please

refer to chapter 9 and chapter 12.

Emotron AB 01-2551-01r4 Programming 25

Indication in

window 05

Alarm

MAX Main Alarm Relay 1 (NC): 6-7

MAX Pre-Alarm Relay 2 (NO): 6-8

MIN Pre-Alarm Relay 2 (NO): 6-8

MIN Main Alarm Relay 1 (NC): 6-7

MAX Main Alarm Relay 1 (NC): 6-7

MAX Pre-Alarm Relay 2 (NO): 6-8

MIN Pre-Alarm Relay 2 (NO): 6-8

MIN Main Alarm Relay 1 (NC): 6-7

Output Relay

(default)

Page 27

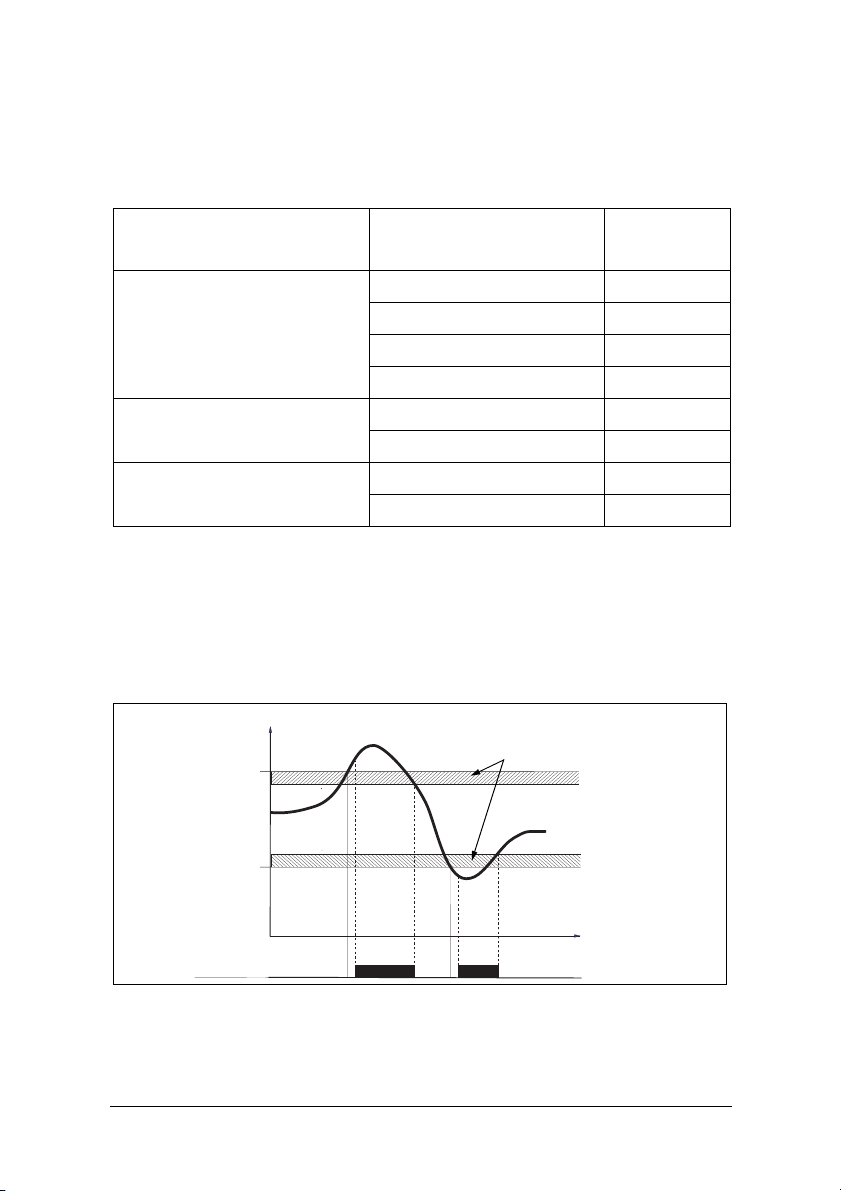

Overload and underload Monitor

ENTER

P/%

START UNDERLOAD OVERLOAD

MAX Main alarm

[11]

MAX Pre-alarm

[12]

OPERATION AREA

Auto set level

Normal load

MIN Pre-alarm

[13]

MIN Main alarm

[14]

Start delay [31]

Relay 1

Main alarm

Relay 2

Pre-alarm

Fig. 7 Overload and underload monitor.

Response

delay

[34] [32]

MAX Main

MAX Pre-alarm

margin [22]

MIN Pre-alarm

margin [23]

Main Alarm latch=ON [61]

alarm margin

[21]

MIN Main

alarm margin

[24]

t/s

Programming

1. Go to window 05. The default selection is Overload and Underload

monitor.

2. Press or to select underload or overload monitor.

_

05

_

OVER- and UNDERLOAD UNDERLOAD

3. Press to confirm the change.

26 Programming Emotron AB 01-2551-01r4

05

_

OVERLOAD

_

05

Page 28

8.5 Setting the Start Delay (window 31)

ENTER

To avoid false alarms during start up a Start Delay must be set to allow the

motor and machine to speed up and to allow the power in-rush currents.

Programming

1. Determine in seconds how long it takes for the motor and machine to reach

speed and for the power in-rush to pass. This will be the Start Delay.

2. Go to window 31 (default = 2.0 s).

3. Press or to set the determined Start Delay time in seconds.

4. Press to confirm the change.

If the monitor is being used on a self-priming pump, it may also be necessary to

set the Start Delay long enough to allow the pump to become fully primed.

Example: Start Delay 2.0 s

31

2.0

S

Fig. 8 Start Delay.

P

t

Start Delay [31]

Emotron AB 01-2551-01r4 Programming 27

Page 29

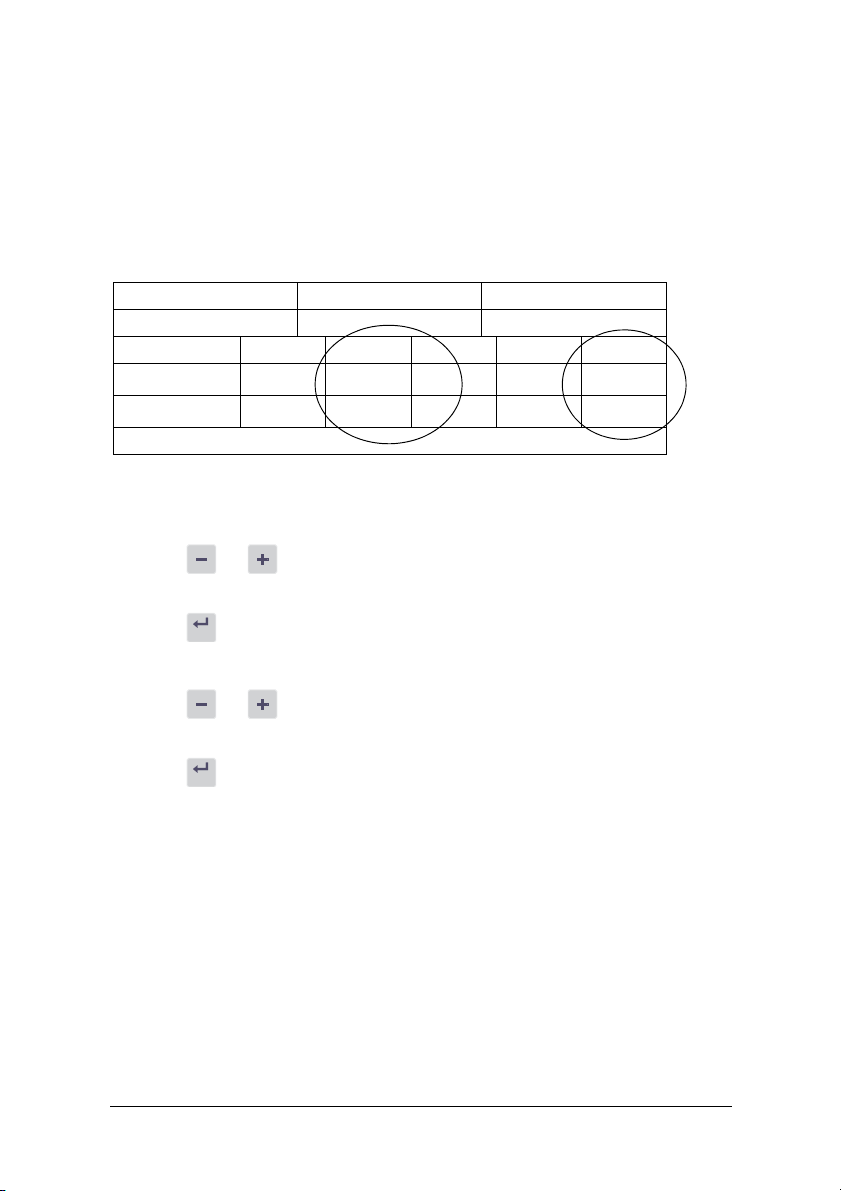

8.6 Setting alarm levels with Auto set

SET

AUTO

The Auto set command performs a measurement (momentarily) of the actual

motor load and automatically sets the relevant alarm levels depending on the

selected monitor function.

Protection

(Monitor

function

window 05)

OVER- and

UNDERLOAD

(Default)

OVERLOAD

UNDERLOAD

Alarm

MAX Main

Alarm

MAX PreAlarm

MIN PreAlarm

MIN Main

Alarm

MAX Main

Alarm

MAX PreAlarm

MIN PreAlarm

MIN Main

Alarm

Margin

Value

(Default

margins)

16%

8%

8%

16%

16%

8%

8%

16%

Margins

(Windows)

21: MAX Main

Alarm margin

22: MAX PreAlarm margin

23: MIN PreAlarm margin

24: MIN Main

Alarm margin

21: MAX Main

Alarm margin

22: MAX PreAlarm margin

23: MIN PreAlarm margin

24: MIN Main

Alarm margin

Alarm Level at

Auto set

Normal machine

load + Window 21

Normal machine

load + Window 22

Normal machine

load - Window 23

Normal machine

load - Window 24

Normal machine

load + Window 21

Normal machine

load + Window 22

Normal machine

load - Window 23

Normal machine

load - Window 24

Programming

1. Start the motor and let it run at the normal machine load until the Start

Delay has expired.

AUTO

2. Press for 3 seconds. This can be done in any window.

SET

28 Programming Emotron AB 01-2551-01r4

Page 30

3. The display shows “SEt”, to confirm that the Auto set level has been meas-

SET

AUTO

ENTER

ured and the alarm levels have been set. The display reverts to window 01.

3 seconds

AUTO

SET

SEE

01

40

%

4. If the alarm levels are too high or too low, readjust the appropriate MARGINS (see table) and perform a new Auto set. Alternatively, alarm levels can

be set manually, see chapter 9.

8.7 Setting the Response Delay (windows 32

and 34)

A Response Delay allows the machine to remain in an over- or underload condition for a specific time before the alarm relays are activated. Set the response

delay for the overload condition in window 32 (max.), and set the response

delay for the underload condition in window 34 (min.). The default value for

both windows are 0.5 s. The valves may be adjusted upwards to avoid triggering

a “false alarm”.

Programming

1. Determine in seconds the response delay required for both overload and

underload conditions. This is normally determined by the unique properties

and behaviour of each application.

2. Go to window 32 (overload, default = 0.5 s).

3. Press or to set the determined Response Delay time in seconds.

4. Press to confirm the change.

The response delay for the underload condition (min.) is set in window 34 in a

similar way.

Emotron AB 01-2551-01r4 Programming 29

Page 31

Example: Response Delay

32

0.5

S

P

Alarm level

34

0.5

S

Alarm

Fig. 9 Response Delay.

Response Delay [32]

t

30 Programming Emotron AB 01-2551-01r4

Page 32

9 Advanced Features

9.1 Setting alarm levels manually (windows

11-14)

The alarm levels can be set manually, without using the Auto set. These levels

can also be readjusted, e.g. for fine-turning, after an Auto set has been performed. See also section 4.3 to 4.6.

Protection (Monitor function

window 05)

OVER- and UNDERLOAD

(Default)

OVERLOAD

UNDERLOAD

Alarm levels (Window) Default

11: MAX Main Alarm 100%

12: MAX Pre-Alarm 100%

13: MIN Pre-Alarm 0%

14: MIN Main Alarm 0%

11: MAX Main Alarm 100%

12: MAX Pre-Alarm 100%

13: MIN Pre-Alarm 0%

14: MIN Main Alarm 0%

Emotron AB 01-2551-01r4 Advanced Features 31

Page 33

Setting margins (windows 21-24)

The margins for the Auto set can be changed manually. After the adjustment,

the Auto set action must be performed again.

Protection (Monitor function

window 05)

Window Default

21: MAX Main Alarm margin 16%

OVER- and UNDERLOAD

(Default)

22: MAX Pre-Alarm margin 8%

23: MIN Pre-Alarm margin 8%

24: MIN Main Alarm margin 16%

OVERLOAD

UNDERLOAD

21: MAX Main Alarm margin 16%

22: MAX Pre-Alarm margin 8%

23: MIN Pre-Alarm margin 8%

24: MIN Main Alarm margin 16%

Setting hysteresis (window 33)

The hysteresis of an alarm level prevents the alarm relay “chattering” if the load

fluctuates even in a normal “stable” condition. This also applies to a pre-alarm.

This feature is normally only used if the main alarm latch (window 61) is set to

Off. Default = 0%.

P/%

MAX Main Alarm level [11]

Hysteresis [33]

MIN Main Alarm level [14]

t/s

Relay 1 MAIN Alarm

Fig. 10 Hysteresis

32 Advanced Features Emotron AB 01-2551-01r4

Page 34

Setting main alarm latch (window 61)

The main alarm latch keeps the main alarm output active, even if the alarm condition has been removed. A latched alarm output can be reset by:

•The reset key

• External reset via digital input (see window 81).

• Switching off the power to the monitor (see also Wiring).

Default = Off.

Setting alarm at no motor current (window 62)

The alarm at no motor current gives an alarm if the motor current goes down to

zero (62 = on). Default = Off (No alarm at no motor current).

Setting relay output (window 63 and 64 alt. 65)

The relay outputs R1 and R2 can be set to NO or NC contacts.

NOTE: If the power to the load monitor is switched off, the relay contacts

are always in position NO.

If separate output relays are required for overload (max., relay R1) and underload (min., relay R2), see Special functions in chapter 9 and chapter 12.

Setting digital input (window 81)

The digital input can be set for:

RES: External RESET

(Default)

AU: External Auto set To perform an Auto set with an external signal.

bLo: Block Pre-Alarm

Emotron AB 01-2551-01r4 Advanced Features 33

To reset an alarm.

To block the Pre-Alarm function and start the Block

timer. If the input is high a Pre-Alarm is blocked, i.e. it is

neglected. See also window 82.

Page 35

Setting block timer (Window 82)

To set the timer for the blocking time after the Block command is released (see

also window 81). Default = 0.0 sec.

P/%

MAX Main Alarm level [11]

MAX Pre-Alarm level [12]

Auto set level

t/s

Relay 1 Main alarm

Relay 2 Pre-alarm

Pre-Alarm Blocked

Block signal high on terminal 5 DIG [81] Block timer [82]

Fig. 11 Block timer

Setting analogue output (window 91)

The analogue output provides an analogue signal of either 0-20 mA or 4-20 mA

which represents the motor shaft power. The signal can be inverted (20-0 or 204 mA). Full scale: rated motor power, see Fig. 12. To set P-span/scaling (full

scale) see Fig. 13.

34 Advanced Features Emotron AB 01-2551-01r4

Page 36

91

P

SHAFT

100%

4.20

20.4

20.0

0.20

0%

Fig. 12

4.20

04 20

Output

mA

Emotron AB 01-2551-01r4 Advanced Features 35

Page 37

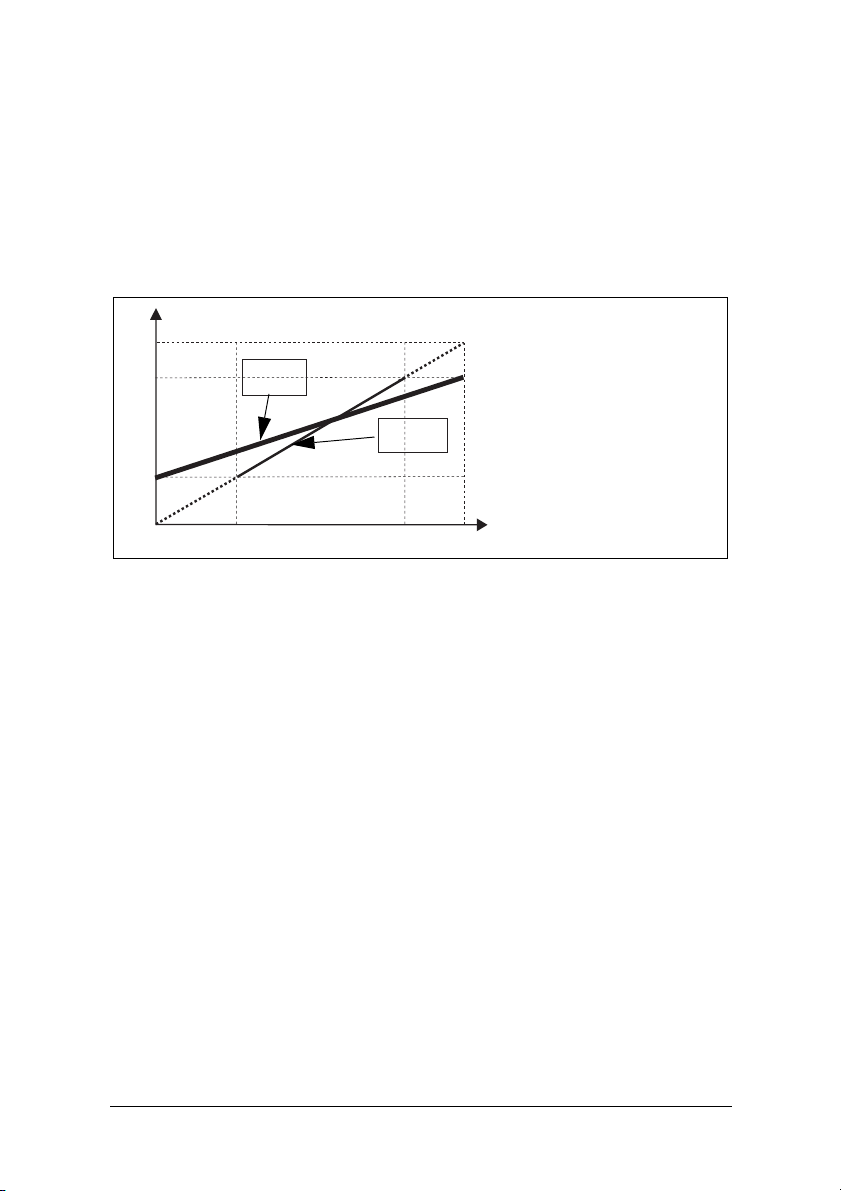

Setting analogue output load range: P-span (window

92-93)

With windows 92 and 93 the full scale of the analogue output can be set according to the minimum and maximum load (P-span).

1. In window 91, press RESET and + for two seconds until “on” shows. Windows 92 and 93 are now active.

P shaft

100%

70%

20%

92= 20%

93= 70%

92= 0%

93= 100%

0

0

6

14

20

Output

mA

Fig. 13

2. Set the lowest load value in window 92 (e.g. 20%)

3. Set the highest load value in window 93 (e.g. 70%)

The full scale of the analogue output is now set between 20% and 70% load.

See Fig. 13. To deactivate: Press RESET and + for two seconds until “Off”

shows in window 91.Windows 92 and 93 are now inactive.

Locking parameters (window 04)

To avoid the parameter settings being changed unintentionally, the programming can be locked by entering the code “369” in window 04. Now only Load

[01], Voltage [02] and Current [03] can be checked. Follow the same procedure

to unlock the monitor. The Auto set key is disabled when parameters are locked.

Auto set via digital input is always active if window 81 is set to AU (Auto set).

36 Advanced Features Emotron AB 01-2551-01r4

Page 38

01

24

%

NOTE: The symbol appears in all windows.

Resetting to factory defaults (window 99)

The factory defaults are reset by entering “dEF” in window 99. If window 99

shows “USr” it indicates that the settings have been changed to user specific settings.

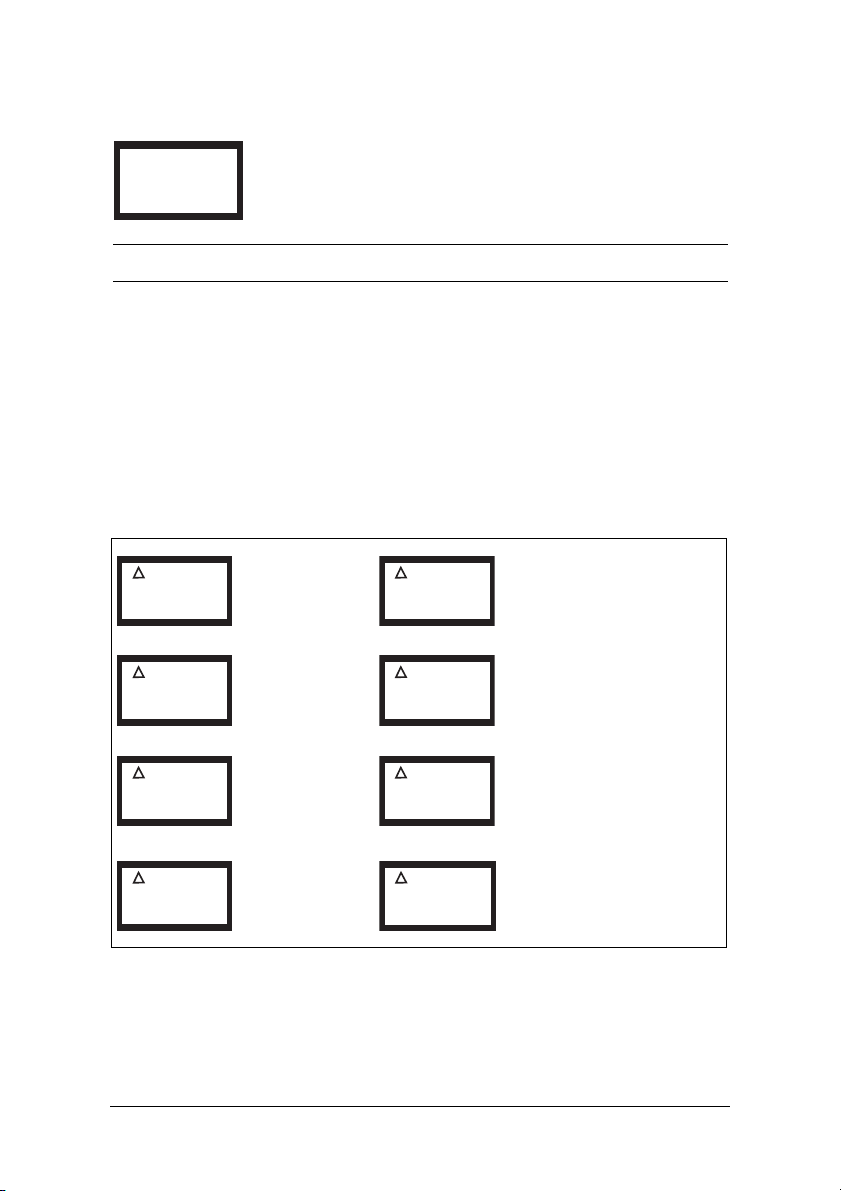

View alarm message (window 00)

In an alarm condition, the window 00 appears automatically. The window indicates the following alarm conditions. Window 00 flashes at all times.

Undervoltage,

switch off the

supply!

Overvoltage,

switch off the

supply!

No motor current

Window 62 = on

00

00

00

!

F

!

F

!

FO

^

^

Pre-Alarm MAX

level reached

Alarm MAX

level reached

Pre-Alarm MIN

level reached

00

00

00

!

LU

!

0U

!

F0

Out Of Range. This message

appears only in window 01 (actual

load) or 03 (actual current)

00

!

FO

Alarm MIN

level reached

01

!

OOO

When the monitor is switched on (power up), the voltage on phases L1, L2 and

L3 is checked. If the wrong voltage is detected, an LU (undervoltage) or OU

(overvoltage) alarm is generated. No relay alarm will be indicated or activated.

Emotron AB 01-2551-01r4 Advanced Features 37

Page 39

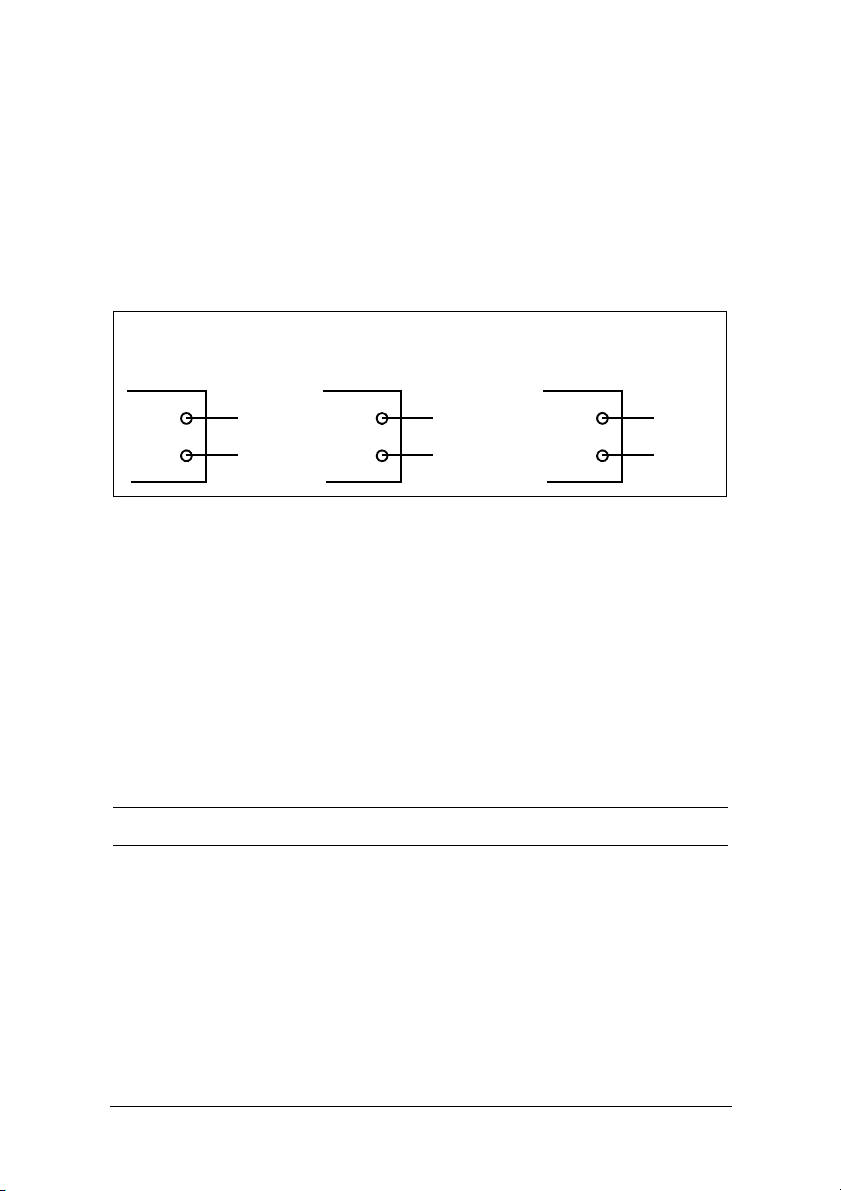

Special functions (windows 35, 36 and 65)

Special functions are separate relays for overload and underload alarm/stop, start

attempts and a reverse function with start attempts:

• Window 65 = 0, Normal M20

• Window 65 = 1, Separate relays for overload and underload alarm (DLM)

• Window 65 = 2, Reverse function

Window 65 = 0

“Normal M20”

R1

R2

Max/Min

Main alarm

Max/Min

Pre-alarm

Window 65 = 1

“Separate relays

over-/underload

alarm” (max/min)

R1

R2

Max

Main alarm

Min

Main alarm

Window 65 = 2

“Reverse function”

R1

R2

Forward

Reverse

Fig. 14 Window 65 and relay functions

In all three cases the number of start attempts after a main alarm may be set in

window 36. The pause time between start attempts may be set in window 35.

This time is also used as the time to run the motor in the reverse direction when

window 65=2.

The reverse function can be used to reverse e.g. a screw conveyor or pump when

a “jam” occurs. Reversing the motor may remove the blockage. Should one

reverse cycle not be enough to release the material, the M20 will repeat this

operation up to a maximum of 5 cycles (window 36, 0-5 start attempts). Relay

R1 = forward, relay R2 = reverse.

NOTE: For special handling of analogue output in reverse mode, see below.

The analogue output will go to its maximum e.g. 20 mA when the number of

allowed start attempts has elapsed.

Resetting an alarm

A reset will cause the start attempt counter to be reset (new start attempts may

be performed).

38 Advanced Features Emotron AB 01-2551-01r4

Page 40

NOTE: In order to accomplish the above result, it will be necessary for a

forward and reversing motor starter to be installed. See Fig. 15 Example of

connection with a forward and reversing motor starter (contactor).

For more information contact your local sales outlet or visit us at:

www.emotron.com

L1

L2

L3

Alarm/Stop

20 mA

}

(Blocking)

Max 240 VAC (alt. 0 VDC-)

6

7

8

5

CTMxxx

9

3

M20

S1 S2

1

4

A-A+

2

L1 C

11

L2

13

L3

R1

R2

DIG

K1

K2

UVW

M

K1 K2 Reset

FWD

Window Function Range

35 Reverse time 3-90 s

36 Star t attempts 0-5

65 Relay function 2=reverse

REV

N (alt. 48 VDC+)

Fig. 15 Example of connection with a forward and reversing motor starter (contac-

tor).

NOTE: In Fig. 15, R1 and R2 (K1 and K2) must not be energized/on at the

same time as this will generate a short circuit. Therefore it is important

that window 65 = 2 before the relays are connected to the contactors.

Emotron AB 01-2551-01r4 Advanced Features 39

Page 41

Alternative auxiliary circuit

L1

L2

L3

CTMxxx

UVW

9

3

4

L1

A+ A-

11

L2

M20

13

L3

1

C

R1

R2

S2S1

2

DIG

6

7

8

5

0VDC-

OUT

24VDC+

M

Fig. 16 Example of auxiliary circuit when VDC is used.

The example above can be used when a high VDC signal output is required.

40 Advanced Features Emotron AB 01-2551-01r4

Page 42

10 Troubleshooting

Ensure that the installation has been correctly carried out, e.g. check the terminals and that the cables are properly stripped. The monitor is maintenance-free.

However, you should regularly check wirings and terminals etc.

Problem Solution

- Check the connection of the current

transformer(s).

Window 01 always

shows zero load, even if

the motor is running

Window 01 shows an

improper power value

when the motor is running

Window 03 shows an

improper value for the

phase current

The monitor never gives

an alarm

- Check that the value of the rated motor power in

window 41 is the same as the rated motor power on

the motor plate.

- Check that window 03 shows a phase current

value that agrees with with the rated motor

current.

- Check that the motor is not oversized for its application, check power transmission and gear ratio.

- Check that there is a load on the motor during

normal operation.

- Check that the change in motor load is greater than

about 3% (window 01).

- Check that the current transformer is connected in

phase L1.

- Check that the current transformer has been

selected as per Tables 1 and 2.

- Check that the number of windings is as per Tables

1 and 2.

- Check that the value of the motor current in

window 42 is the same as the value of the motor

current on the motor plate.

- Check that window 01 shows a value greater than

zero.

- Check the alarm levels in windows 11 to 14. If incorrect readjust the levels or perform an Auto set.

Emotron AB 01-2551-01r4 Troubleshooting 41

Page 43

Problem Solution

- Check the alarm levels in windows 11 to 14.

If incorrect readjust the levels or perform an

The monitor always

gives an alarm

Window 00 shows “LU”

or “OU”. Under- or overvoltage alarm.

Window 01 shows

“oor”. “Out Of Range”

alarm.

Window 03 shows

“oor”. “Out Of Range”

alarm.

Over and undervoltage

is not detected

The alarm relays are not

switching

Not all windows are

shown

Auto set.

- Check if the monitor is programmed for “latched

alarm” (window 61=on). If so reset the monitor by

pressing the reset key.

Switch off the supply:

- Check that the supply voltage agrees

with the voltage range on the monitor type plate.

- The measured shaft power is higher than 125% of

the rated motor power programmed in window 41.

- The measured motor current is higher than 125%

of the rated motor current programmed in window

42.

This is only detected at monitor power up and not during continued operation. The relays will not trip, only

indication in the display.

- Check that the wire links between terminals 6

and 7 are removed as per “Wiring”.

When the special functions are used (windows 35, 65

etc.) blocked windows for settings are not shown.

42 Troubleshooting Emotron AB 01-2551-01r4

Page 44

11 Technical Data

45x90x115 mm (1.77" x 3.54" x 4.53")

Dimensions

35mm

(WxHxD)

45mm (1.77’‘)

(1.38)’‘

26mm

(1.02)’‘

115mm(4.53) ’‘

Mounting 35 mm DIN rail 46277

Weight 0.30 kg (10.5 oz)

Supply voltage

(±10%)

1x100-240 VAC, 3x100-240 VAC, 3x380-500 VAC or 3x525690 VAC

Frequency 50 or 60 Hz

Current input

Power consumption

Current transformer; CTM 010, 025, 050 and 100. Input 055 mA. (>100 A extra transformer needed)

Max. 6 VA

Start-up delay 1-999 s

Hysteresis 0-50% of rated motor power

Response delay

max

Response delay

min

0.1-500 s

0.1-500 s

Relay output 5 A/240 VAC Resistive, 1.5 A/240 VAC Pilot duty/AC12

Analogue output Max. load 500 ohm

Digital input

Max. 240 VAC or 48 VDC. High: ≥24 VAC/DC,

Low: <1 VAC/DC. Reset >50 ms

Fuse Max. 10 A

2

single core

Terminal wire size

Use 75°C copper (CU) wire only. 0.2-4.0 mm

(AWG12). 0.2-2.5 mm

2

flexible core (AWG14), stripped

length 8 mm (0.32")

’‘

90mm(3.54)

Emotron AB 01-2551-01r4 Technical Data 43

Page 45

Ter minal tig htening torque

Accuracy

Repeatability ±1 unit 24h; +20°C (+68°F)

Temperature tolerance

Operating temperature

Storage temperature

Protection class IP20

RoHS directive 2002/95/EC

Approved to CE (up to 690VAC), UL and cUL (up to 600 VAC)

0.56-0.79 Nm (5-7 lb-in)

±2%, ±1 unit cos phi>0.5; excl. current transformer; +20°C

(+68°F)

max 0.1%/°C

-20 to +50°C (-4°F to +122°F)

-30 to +80°C (-22°F to +176°F)

Article

number

01-2520-20 Emotron M20 1x100-240/3x100-240 VAC

01-2520-40 Emotron M20 3x380-500 VAC

01-2520-50 Emotron M20 3x525-690 VAC

Designation

Technical Data for Current Transformer (CT)

Type

CTM 010 27 (35) x Ø48 mm 0.20 kg 35mm DIN rail 46277

CTM 025 27 (35) x Ø48 mm 0.20 kg 35mm DIN rail 46277

CTM 050 27 (35) x Ø48 mm 0.20 kg 35mm DIN rail 46277

CTM 100 45 (58) x Ø78 mm 0.50 kg 35mm DIN rail 46277

44 Technical Data Emotron AB 01-2551-01r4

Dimensions

(WxØ)

Weight* Mounting

Page 46

* Weight including 1m (39 inch) cable. Please note that max. length of the

CTM cable is 1 m and this cable cannot be extended.

4.3

17

27

35

48

45

35

Fig. 17 Current Transformer CTM xxx.

Accessories and documentation

Article

number

01-2471-10 Current Transformer (CT) CTM010, max. 10 A

01-2471-20 Current Transformer (CT) CTM025, max. 25 A

01-2471-30 Current Transformer (CT) CTM050, max. 50 A

01-2471-40 Current Transformer (CT) CTM100, max. 100 A

01-2368-00 Front Panel Kit 1 (2x terminal covers included)

01-4136-01 2x Terminal covers

01-2551-00 Instruction manual (Swedish)

01-2551-01 Instruction manual (English)

01-2551-02 Instruction manual (German)

01-2551-03 Instruction manual (Dutch)

01-2551-04 Instruction manual (Spanish)

01-2551-08 Instruction manual (French)

01-2551-09 Instruction manual (Russian)

Designation

10.3

42

78

Emotron AB 01-2551-01r4 Technical Data 45

Page 47

Dismantling and disposal

The product is designed to comply with the RoHS directive, and shall be handled and recycled in accordance with local legislations.

EU (European Union) specifications

EMC EN 61000-6-3, EN 61000-6-2

EN 61000-4-5

Electrical safety EN 60947-5-1

Rated insulated voltage 690 V

Rated impulse withstand voltage 4000 V

Pollution degree 2

Terminals 3, 4, 5, 6, 7 and 8 are basic insulated from the line.

Terminals 3 and 4 are basic insulated from terminals 5, 6, 7 and 8.

US specifications

FCC (Federal Communications Commission). This equipment has been tested

and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference, in which case the user will be required to correct the interference at their own expense.

Canadian specifications

DOC (Department of Communications). This digital apparatus does not

exceed the Class A limits for radio noise emissions from digital apparatus as set

out in the Canadian Interference-Causing Equipment Regulations. Le présent

appareil numérique n'ément pas de bruits radio-électriques dépassant les limites

applicables aux appareils numériques de la Classe A prestite dans le Régelement

sur le brouillage radioélectrique édicté du Canada.

46 Technical Data Emotron AB 01-2551-01r4

Page 48

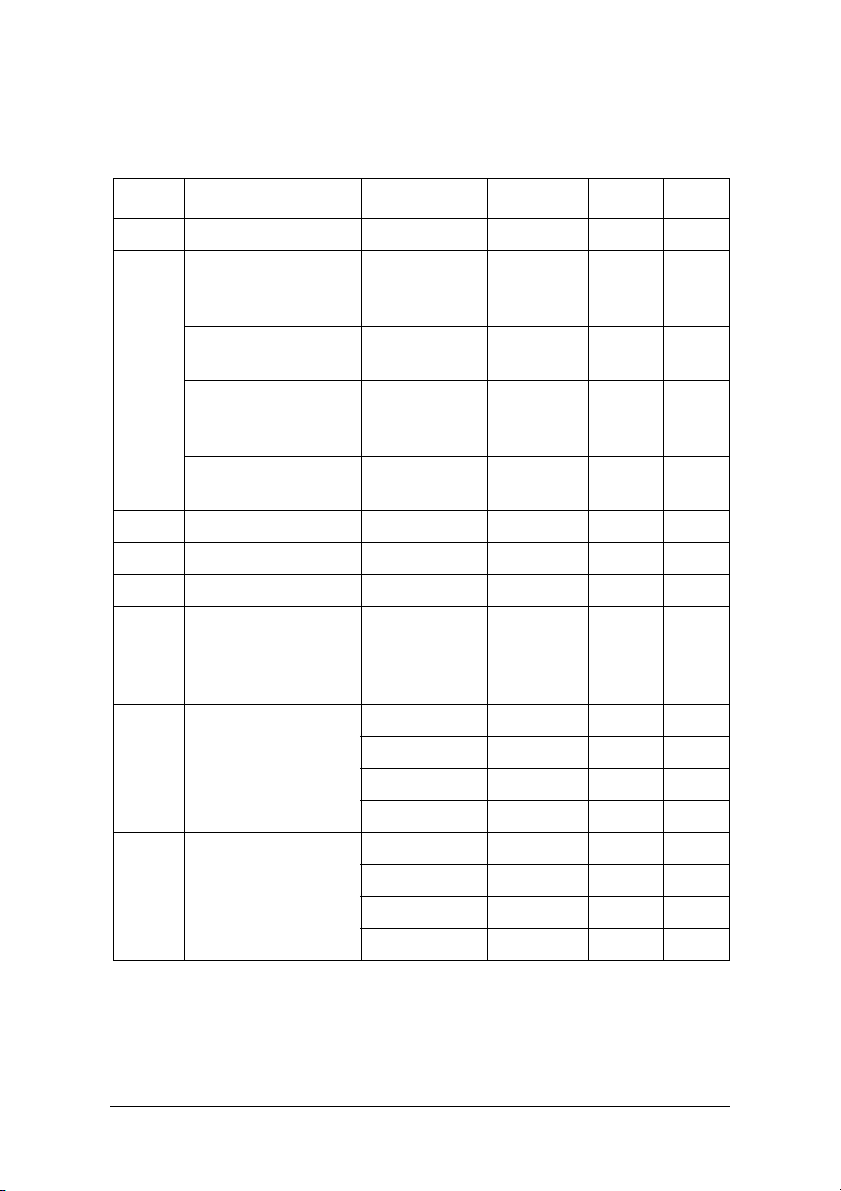

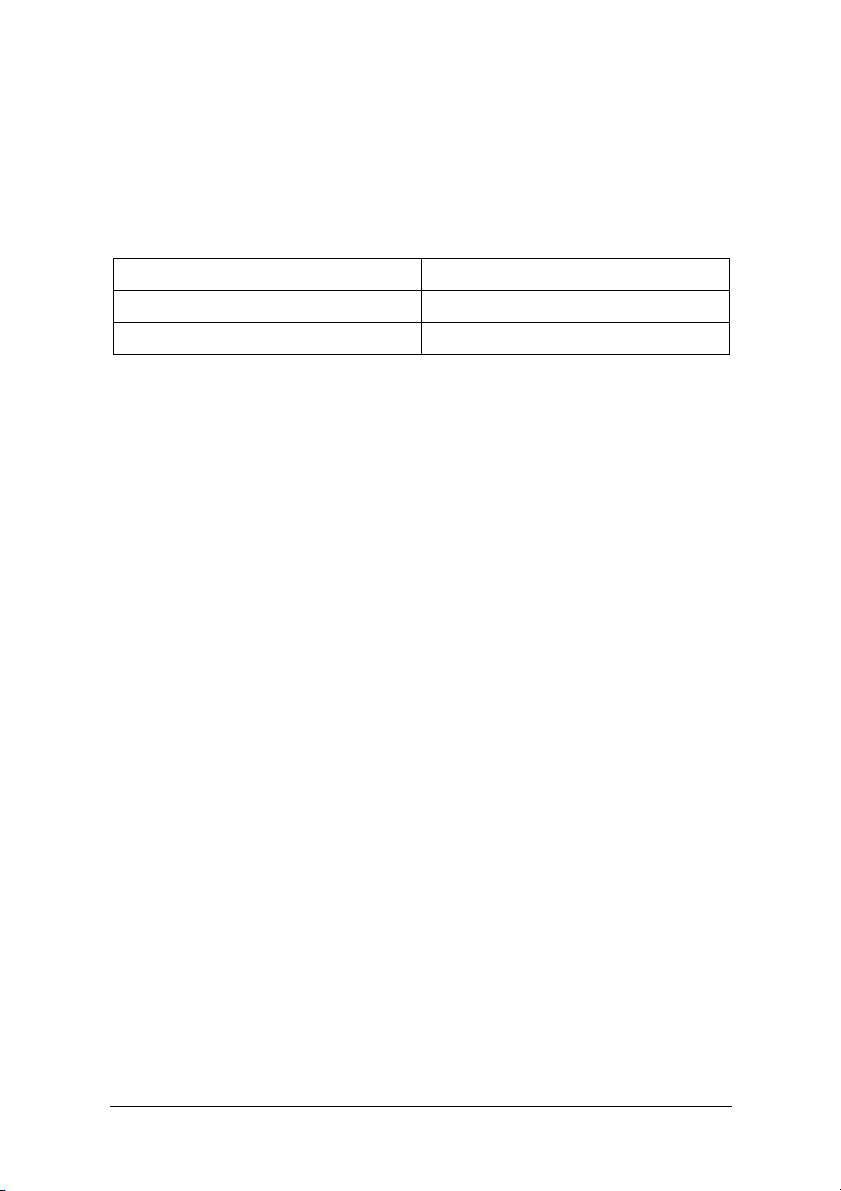

12 Parameter List

Window Function Range Default Custom Symbol

00 Alarm indication

Measured shaft

power in % of rated

power

Measured shaft

01

02 Measured line voltage 90-760 V V

03 Measured current 0.00-999 A A

04 Parameter lock 0-999

05 Monitor function

11

12

power in kW

Measured shaft

power in % of rated

power

Measured shaft

power in HP

MAX Main Alarm (relay

R1)

MAX Pre-Alarm (relay

R2)

0-125 %

0-745 kW

0-125 %

0-999

OVER- and

UNDERLOAD,

OVERLOAD,

UNDERLOAD

0-125 100 %

0-745 2.2 kW

0-125 100 %

0-999 3

0-125 100 %

0-745 2.2 kW

0-125 100 %

0-999 3

OVERLOAD

and UNDERLOAD

Emotron AB 01-2551-01r4 Parameter List 47

Page 49

Window Function Range Default Custom Symbol

0-125 0 %

13

14

21

22

23

24

31 Star t d el ay 1-999 2 s

32

33 Hysteresis 0-50 0 %

34

35* Pause/Reverse time 3-90 5 s

36*

41 Rated m oto r po wer

42 Rated current 0.01-999 5.6 A

43 Number of phases 1PH/3PH 3PH

61 Main alarm latch on/OFF OFF

MIN Pre-Alarm (relay

R2)

MIN Main Alarm

(relay R1)

MAX Main Alarm

margin

MAX Pre-Alarm

margin

MIN Pre-Alarm

margin

MIN Main Alarm

margin

Response delay overload

Response delay

underload

Autoreset (start

attempts)

0-745 0 kW

0-125 0 %

0-999 0

0-125 0 %

0-745 0 kW

0-125 0 %

0-999 0

0-100 16 %

0-100 8 %

0-100 8 %

0-100 16 %

0.1-500 s 0.5 s

0.1-500 s 0.5 s

0-5 0

0.10-745 2.2 kW

0.13-999 3

48 Parameter List Emotron AB 01-2551-01r4

Page 50

Window Function Range Default Custom Symbol

62

63 Main Alarm relay R1 nc/no nc

64 Pre-Alarm relay R2 nc/no no

65* Relay function

81 Digital input rES/AU/bLo rES

82 Block timer 0.0-90 0.0 s

91 Analogue output

92**

93**

99 Factory defaults dEF/USr dEF

Alarm at no motor

current

Analogue output low

value

Analogue output high

value

on/OFF OFF

0 = M20

1 = DLM

2 = Reverse

0.20/4.20/

20.0/20.4

0-100

0-125

0

0.20

* See Special functions in chapter 9.

** See Set analogue output range in chapter 9.

Emotron AB 01-2551-01r4 Parameter List 49

Page 51

13 Service

This manual is valid for the following model:

Emotron M20 (from software version R3b)

Document number: 01-2551-01

Document version: r4

Date of release: 2008-05-15

Emotron AB reserves the right to alter product specifications without prior

notification. No part of this document may be reproduced without permission

from Emotron AB.

For more information contact your local sales outlet or visit us at:

www.emotron.com

Protected by utility patents EP 1027759 and US 6879260

50 Service Emotron AB 01-2551-01r4

Page 52

Emotron AB, Mörsaregatan 12, SE-250 24 Helsingborg, Sweden

Tel: +46 42 16 99 00, Fax: +46 42 16 99 49

E-mail: info@emotron.se

Internet: www.emotron.com

Emotron AB 01-2151-01r4 2008-05-15

Page 53

Emotron M20

Reverse function

Addendum

English

Page 54

Emotron M20 Shaft Power Monitor

Special functions (windows 35, 36

and 65) ”Reverse function”

This instruction is valid for Emotron M20, 01-2551-01,

(from software version R3B).

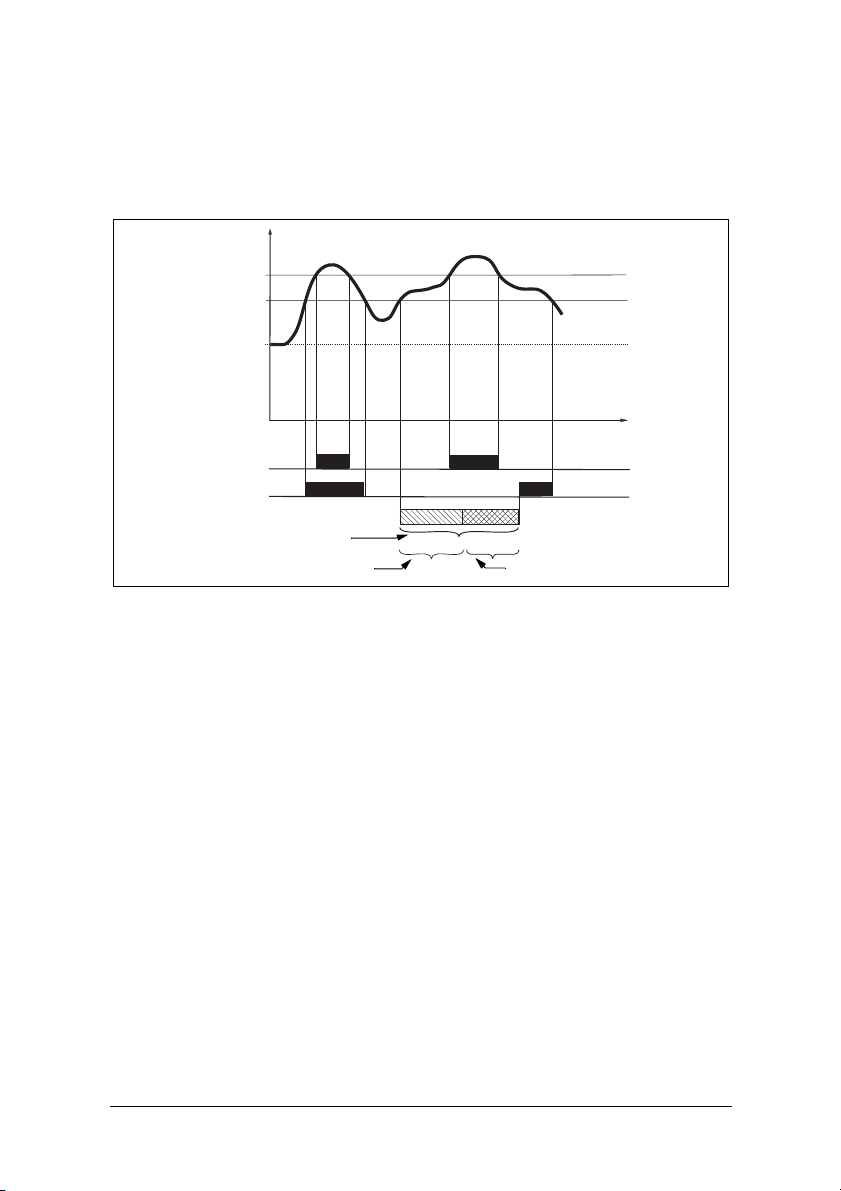

The reverse function can be used to reverse (drive backwards) motor driven equipment such as e.g. a screw conveyor when a “jam” occurs. With this function the M20 can

be used to prevent expensive stops and breakdowns in

machinery for example; blocked chip feeder, jammed lime

feeder, blocked slurry pump or in other similar applications.

In the case of a screw conveyor or chip feeder, for instance,

when an overload or jam-up occurs, the Emotron M20

reverses the “conveyor” automatically. Normally this would

clear the jammed material and then enable the conveyor to

feed forward again.

Should one reverse cycle (drive backwards) not be enough to

release the material, the monitor will repeat this operation

up to a maximum of five start attempts. If the conveyor is

still jammed, the monitor stops the conveyor motor/

machine from any further operation and an alarm is given.

The conveyor would then have to be cleaned manually and

the monitor reset. The number of start attempts and the

reverse time can be set. If set number of start attempts is

enough to release the material the conveyor will feed forward

again, and reset the previous number of start attempts, but

only after the conveyor has fed forward for least 60 seconds

if the selected start and response delay time has elapsed.

and

Wiring, Programming and Operation

CAUTION: Study thoroughly section 2 Safety in the Emotron

M20 Instruction manual before installing and using the

monitor. Please note that the machine starts and stops

automatically during set-up and running when the reverse

function is used!

For wiring, programming and operation see the corresponding sections in the Installation manual for the M20. See also

under 9 Advanced Features and the headline Special functions (windows 35, 36 and 65) as well as the special connection example in Figure 1 (this example can also be found at

the end of this instruction).

NOTE:

To implement the above Reverse function, it will be

necessary for a forward and reversing motor starter

(contactors) to be installed.

Relay R1 and R2 (K1 and K2) must not be energized/on at

the same time as this will generate a short circuit.

Therefore it is important that window 65 = “2” before the

relays are connected to the contactors and it is also

recommended that the Forward and Reverse contactors

are also electrically interlocked.

The output relay contacts, terminals 6, 7 and 8 connect to

the motor control circuit and to the respective contactor; i.e.

terminal 7 to K1 (R1) = Forward and terminal 8 to K2 (R2)

= Reverse (see fig. 1). Terminal 5 can be used for external

reset and has the same function as the reset button on the

front of the monitor.

Analogue output

In this Reverse function application the analogue output will

go to its maximum 20 mA when the number of allowed start

attempts has elapsed. The output signal can for example be

used as an input to PLC´s or similar equipment to handle

the alarm etc. If a potential free relay contact is required, the

following external relay is recommended as an accessory:

• Schrack / Tyco RT174012 12 VDC (10A 250VAC)

• Camden DIN-rail relay socket C 250 3P

Please note that an external alarm relay connected to the

analogue output must be specified as the above relay coil

voltage, resistance, power etc to ensure correct operation

and life time.

Set the monitor as follows

(First perform settings according to the applicable parts of

the M20 Monitor installation manual):

1. In this application it is unusual that both overload and

underload monitoring is used and unless the underload

is required in some other function window 5 should be

-

set to monitor overload only (

).

2. Start the motor/machine and let it run at normal load

until the start delay has elapsed - the machine load is

shown in the monitor display.

3. Press the “Auto set” button for 3 seconds.

4. Adjust start attempts (window 36), start delay (window

31), response delay (window 32, alt 34 at min), reverse

time (window 35) etc. as required.

It is also possible to set the alarm level manually, see the

manual and chapter 4 Getting Started.

Operation – Alarm

When an overload occurs for longer than the selected

response delay (window 32), the following sequence takes

place if there are still some start attempts available:

1. Motor is switched-off and stands for 3 seconds.

2. Motor is reversed during chosen reversal time, window

35 (If the monitor senses an overload during reversal the

motor will stop).

3. Once again, the motor is switched-off and stands for 3

seconds.

4. Motor re-starts automatically in forward mode.

For a prolonged jam-up, the monitor will carry out the maximum of reverse cycles set in window 36. If this does not

clear the blockage, the motor is switched-off and the analogue output will go to its maximum 20 mA “permanent”

stop and alarm. When this occurs, the conveyor/machine

must be cleaned manually and the monitor reset, either by

1 Emotron AB 01-4481-01r1

Page 55

the reset button or by the digital input. When reset, the

monitor can once again perform the number of reverse

cycles set in window 36.

Reset of the monitor can be done in three ways:

• Reset button

• Digital input, set for “rES”, window 81

• Switch-off the supply voltage, 3-phase.

Important! If the monitor senses an overload during reversal,

after start and response delay has elapsed, the motor will be

stopped immediately even if the reversal time is set for a

longer time. The monitor will then try to run in the forward

direction again. If the load returns to a normal running level

before the start delay has elapsed (i.e. the jammed material

L1

L2

L3

clears), the monitor will reverse the motor/feeder until the

selected time has concluded.

If the reversal time is set to a shorter time period than the

start and response delay together, the reverse mode will be

completed after the selected reverse time has concluded,

independently of the set response delay. In this case the

response delay only has an effect on forward running.

When the conveyor has fed forward for at least 60 seconds

with normal conditions and no alarm, the previous number

of start attempts (reverse cycles) are reset automatically

although only if selected start and response delay time has

concluded.

Alarm/Stop

20 mA

}

(Blocking)

CTMxxx

K1

UVW

M

K2

9

11

3

L1 C

4

A-A+

L2

M20

13

L3

S1 S2

2

1

K1 K2 Reset

FWD

R1

R2

6

7

8

5

DIG

REV

Window Function Range

35 Reverse time 3-90 s

36 Start attempts 0-5

65 Relay function 2=reverse

Max 240 VAC (alt. 0 VDC-)

N (alt. 48 VDC+)

Fig. 1 Example of connection with a forward and reversing

motor starter (contactor).

Emotron AB 01-4481-01r1 2

Page 56

Emotron AB, Mörsaregatan 12, SE-250 24 Helsingborg, Sweden

Tel: +46 42 16 99 00, Fax: +46 42 16 99 49

E-mail: info@emotron.se

Internet: www.emotron.com

Emotron AB 01-4481-01r1 06-30-2008

Loading...

Loading...