Page 1

Crompton

INTEGRA 1530, 1560, 1580

Communications Guide

Crompton Instruments

Freebournes Road

Witham

Essex

CM8 3AH

England

Tel: +44 (0) 1376 509 509

Fax: +44 (0) 1376 509 511

E-Mail: crompton.info@tycoelectronics.com

Integra Comms Issue 1 Jan 2006

Page 2

Contents Page

1 Modbus

tm

4

1.1 Modbus tm Overview 4

1.2 Input Registers 5

1.3 Modbustm Holding Registers and Integra set up 7

1.4 Analogue Output setting via Modbus 11

2 RS485 Implementation of Johnson Controls Metasys 13

2.1 Application details 13

2.2 Metasys release requirements 13

2.3 Support for Metasys Integration 13

2.4 Support for Crompton Integra operation 13

2.5 Design considerations 13

2.6 METASYS N2 Integra Point Mapping table 14

3 Integra Profibus Interface 16

3.1 GSD file 16

3.2 Floating Point Format 16

3.3 Single Parameter access 16

3.4 Functionality of the PLC Function Block 16

3.4.1 Reading 16

3.4.2 Writing 17

3.5 Common Pro b l ems 17

4 The LonWorks Interface 18

4.1 XIF File 18

4.2 Overview and Device Functional Profile 18

4.3 Node Object 19

4.3.1 Network Variables 19

4.3.2 Object Status 19

4.3.3 Configuration Properties 19

4.4 Voltmeter Functional Profile 19

4.4.1 Voltmeter Network Variables 20

4.5 Ammeter Functional Profile 21

4.5.1 Ammeter Network Variables 21

4.5.2 Ammeter Configuration Properties 22

4.6 Energy Meter Functional Profile 23

4.6.1 Energy Meter Network Variables 23

4.6.2 Energy Meter Configuration Properties 23

4.7 Power Meter Functional Profile 25

4.7.1 Power Meter Network Variables 25

4.7.2 Power Meter Configuration Properties 26

4.8 Demand Ammeter Functional Profile 27

2 Integra Comms Issue 1 Jan 2006

Page 3

Contents Page

4.8.1 Demand Ammeter Network Variables 27

4.8.2 Demand Ammeter Configuration Properties 27

4.9 Demand Power Meter Functional Profile 28

4.9.1 Demand Power Meter Network Variables 28

4.9.2 Demand Power Meter Configuration Properties 29

4.10 Power Quality Meter 30

4.10.1 Power Quality Network Variables 30

4.10.2 Power Quality Meter Configuration Properties 31

4.11 Common Pro b l ems 31

Integra Comms Issue 1 Jan 2006 3

Page 4

1 Modbus

1.1 Modbus tm Overview

This section pr ovides basic info rmation for interfacing the Integra to a Modbus

information or more details of the Integra implementation is required please refer to our “Guide to RS485

Communications and the Modbus

supplier.

Integra offers the option of an RS485 communication facility for direct connection to SCADA or other

communications systems using the Modbus

format for the master's query by placing into it the device address, a function code defining the requested

action, any data to be sent, and an error check ing fie ld . The slave's re spon se me ssage is also

constructed using Modbus

returned, an d an error-checking field. If an er r or occurs in receipt of the message, Integra will ma ke no

response. If the I ntegra is unable to p erform the requested action, it will constr uct an error message and

send it as it’s response.

The electrical interface is 2-wire RS485, via 3 screw terminals. Connection should be made using twisted

pair screened cable (Typically 22 gauge Belden 8761 or equivalent). All "A" and "B" connections are

daisy chained together. The screens should also be connected to th e “Gnd” terminal. To avoid the

possibility of loop currents, an Earth connection should be made at only one point on t he network.

Line topology may or may not require terminating loads depending on the type and leng th of cable used.

Loop (ring) topology does not require any termination load.

The impedance of the termination load should match the impedance of the cable and be at both ends of

the line. The ca ble should be terminated at each end with a 120 ohm (0.25 Watt min.) resistor.

A total maximum length of 3900 feet (1200 metres) is allowed for the RS485 network. A maximum of 32

electrical nodes can be connected, including the controller.

The address of each Integra can be set to any value between 1 and 247. Broadcast mode (address 0) is

not supported .

The maximum latency time of an Integra is 150ms i. e. this is the amount of time that can pass before the

first response ch aracter is output. The supervisory programme must allow t his period of time to elapse

before assuming that the Integra is not going to respond.

The format for each byte in RTU mode is:

Coding System: 8-bit per byte

Data Format: 4 bytes (2 regist ers) per parameter.

Error Check Field: 2 byte Cyclical Redundancy Check (CRC)

Framing: 1 start bit

Data Transmission speed is selectable between 2400, 4800, 9600 and 19200 baud.

tm

tm

network. If background

tm

Protocol”, available on our CD catalogue or from any recognised

tm

RTU slave protocol. The Modb ustm protocol establishes the

tm

protocol. It contains fields confirming the action taken, any data to be

Floating point format ( to IEEE 754)

Most significant register first (Default). The default may be changed if required See Holding Reg ister "Register Order " parameter.

8 data bits, least significant bit sent first

1 bit for even/odd parity or no parity

1 stop bit if parity is used; 1 or 2 bits if no parity

4 Integra Comms Issue 1 Jan 2006

Page 5

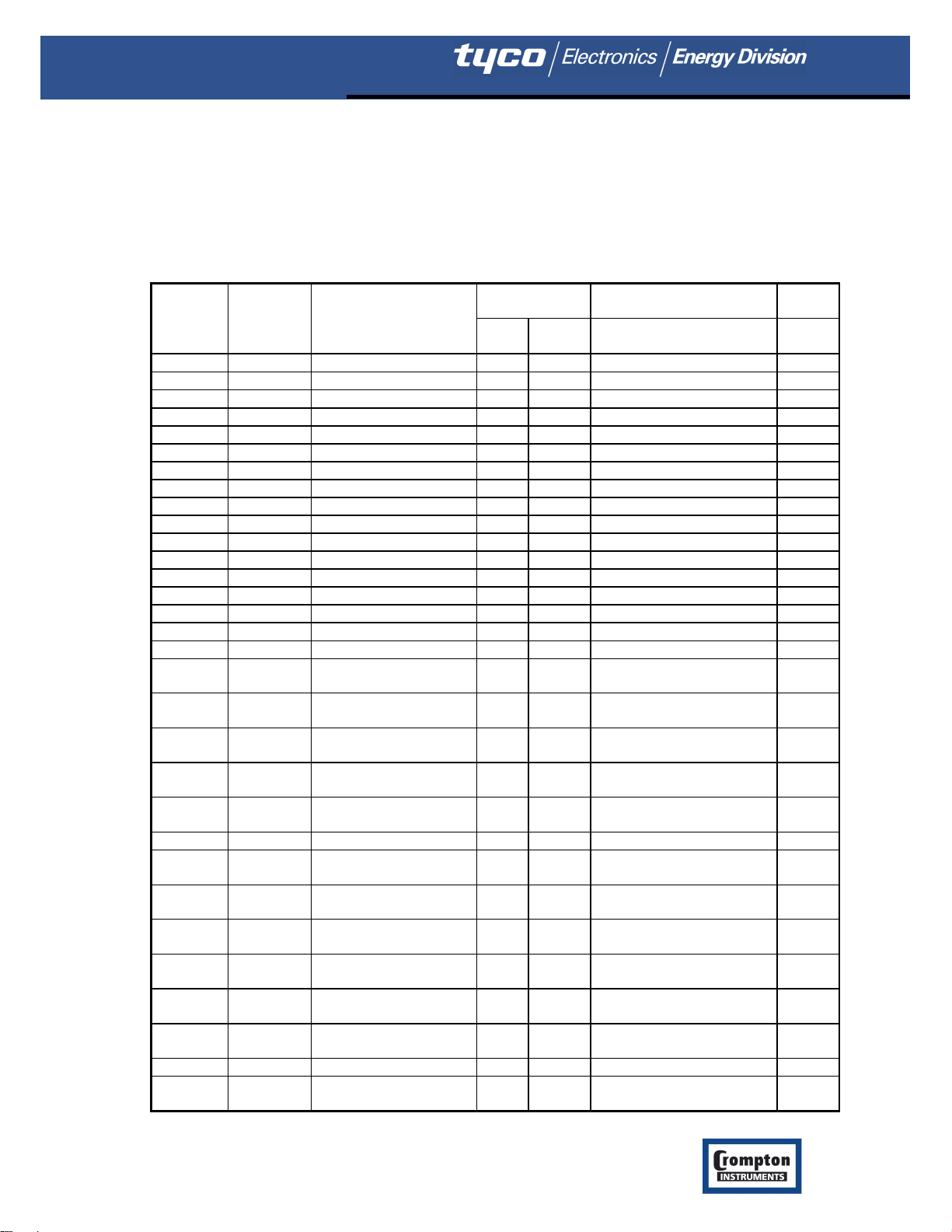

1.2 Input Registers

Input register s are used to indicate the present values of the measured an d calculated electrical

quantities.

Each parameter is held in two consecutive 16 bit registers. The following table details the 3X re gister

address, and the va lues of the address bytes within the message. A tick (√) in the column indicates that

the parameter is valid for the particular wiring system. Any parameter with a cross (X) will return the value

Zero.

Each parameter is held in the 3X registers. Modbus

.

For example, to request: Amps 1 Start address = 0006

No of registers = 0002

Amps 2 Start address = 0008

No of registers = 0002

Each request for data must be restricted to 40 parameters or less. Exceedi ng the 40 parameter limit will

cause a Modbus

tm

exception code to be returned.

tm

Function Code 04 is used to access all para meters

Integra Comms Issue 1 Jan 2006 5

Page 6

–

00

02 X

–

00

04 X X

00

06

00

08 X

00

0A X X

00

0C

00

0E X X

00

10

X

00

12

00

14 X X

00

16

X

00

18

00

1A X X

00

1C

X

00

1E

00

20 X X

00

22

X

00

24

00

26 X X

00

28

X

00

2A

00

2E

00

30

00

34

00

38

00

3C

00

3E

00

42

00

46

00

48

00

4A

v

a

00

4C

00

4E

00

50

00

54

00

56

00

68

00

6A

00

C8 X X

00

CA

X

00

CC

X

00

CE X X

00

E0

00

EA

00

EC X

00

EE X X

00

F0

00

F2 X

00

F4 X X

00

F8

00

FA

-

C

00

FE

Address

(Register)

Parameter

Number

Parameter

Modbus

Address Hex

High Byte

tm

Start

Low Byte

3 Ø 3 Ø 1 Ø 1 Ø

4 W 3 W 3 W 2 W

30003 2 Volts 2 (L2 – N 4W or L2

30005 3 Volts 3 (L3 – N 4W or L3

30007 4 Current 1

30009 5 Current 2

30011 6 Current 3

30013 7 W Phase 1

30015 8 W Phase 2

30017 9 W Phase 3

30019 10 VA Phase 1

30021 11 VA Phase 2

30023 12 VA Phase 3

30025 13 var Phase 1

30027 14 var Phase 2

30029 15 var Phase 3

30031 16 Power Factor Phase 1

30033 17 Power Factor Phase 2

30035 18 Power Factor Phase 3

30037 19 Phase Angle Phase 1

30039 20 Phase Angle Phase 2

30041 21 Phase Angle Phase 3

30043 22 Volts Ave

30047 24 Current Ave

30049 25 Current Sum

30053 27 Watts Sum

30057 29 VA Sum

30061 31 var Sum

30063 32 Power Factor Ave

30067 34 Average Phase Angle

30071 36 Frequency

30073 37 Wh Import

30075 38 Wh Export

30077 39

30079 40 varh Export

30081 41 VAh

30085 43 W Demand Import

30087 44 W Max. Demand Import

30105 53 A Demand

30107 54 A Max. Demand

30201 101 V L1-L2

30203 102 V L2-L3

30205 103 V L3-L1

30207 104 Average Line t o Line Volts

30225 113 Neutral Current

30235 118 THD Volts 1

30237 119 THD Volts 2

30239 120 THD Volts 3

30241 121 THD Current 1

30243 122 THD Current 2

30245 123 THD Current 3

30249 125 THD Voltage Mean

30251 126 THD Current Mean

30255 128 Power Factor (+Ind/

rh Import

L3 3W)

L1 3W)

X

X X

X

X X

X

X X

X

X X

X

X X

X X

X X

X

ap)

6 Integra Comms Issue 1 Jan 2006

Page 7

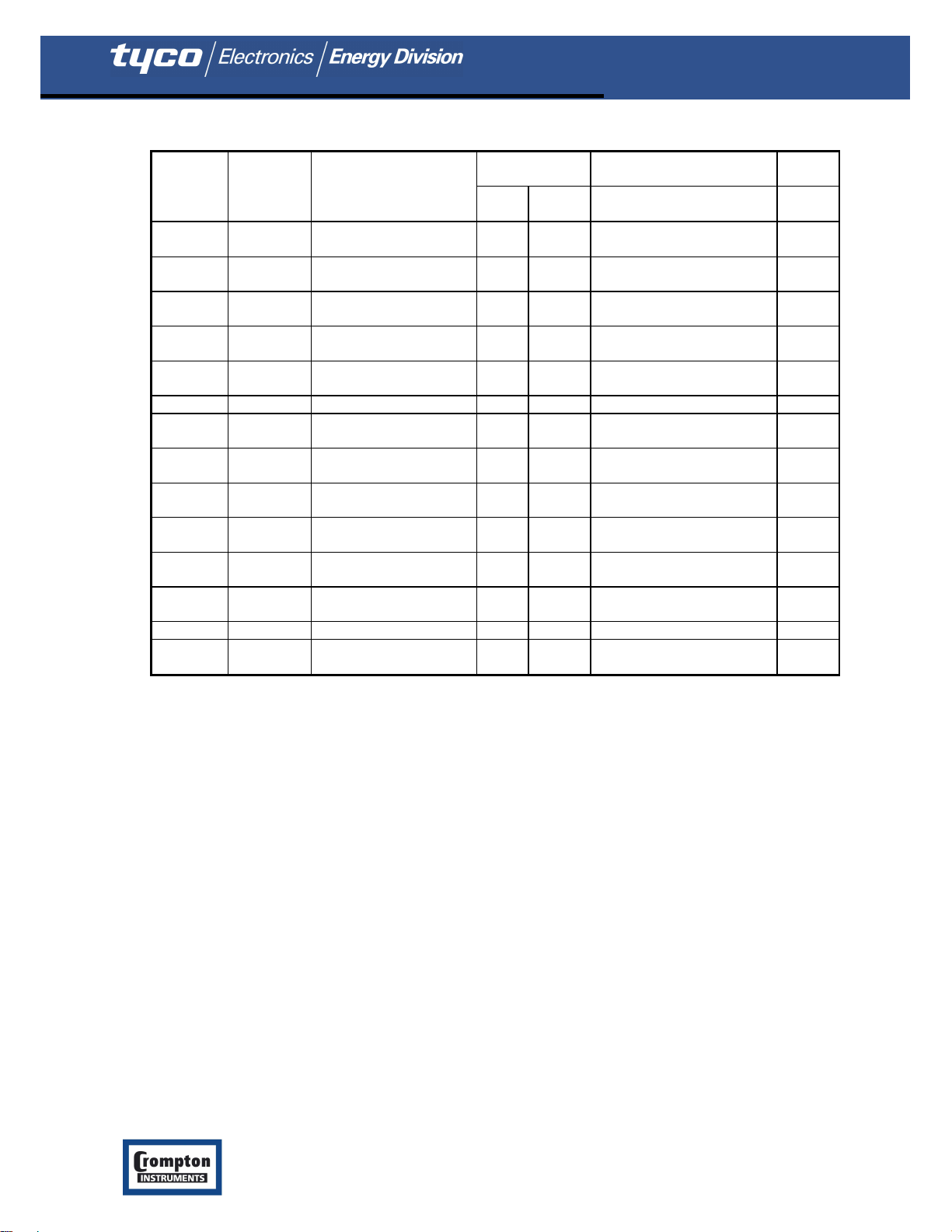

1.3 Modbustm Holding Registers and Integra set up

Holding regis ters are used to store and display instrument configuration settings. All holding registers not

listed in the ta ble below should be considered as reserved for manufacturer use and no attempt should be

made to modify their values.

The holding register parameters may be viewed or changed using the Modbus

parameter is held in the 4X registers. Modbus

Function Code 16 is used to write.

Address

(Register)

Parameter

Number

Parameter

tm

Function Code 03 is used to rea d the para m et er and

Modbus

Address Hex

High

Byte

tm

Start

Low

Byte

Valid range

40001 1 Demand Time 00 00 Write: 0 but see * below r/w

40003 2 Demand Period 00 02 8,15,20,30, 60 minutes. r/w

40007 4 System Voltage 00 06 1V - 400kV r/wp

40009 5 System Current 00 08 1-9999 A r/wp

40011 6 System Type 00 0A See below for values r/wp

40013 7 Relay Pulse Width 00 0C 3,5, 10 (x20mS) r/w

40015 8 Energy Reset 00 0E 0 only wo

40019 10 RS485 set-up code 00 12 See table below r/ w

40021 11 Node Address 00 14 1-247 r/w

40023 12 Pulse Divisor 00 16 1,10,100,1000 r/w

40025 13 Password 00 18 0000-9999 r/w

40037 19 System Power 00 24 ro

40041 21 Register Order 00 28 2141.0 only R/w

40299 150 Secondary Volts 01 2A Min Vin-Max Vin r/wp

40307 154 Max Energy Co unt 01 32 6,7,8 digits r/wp

40309 155 Analogue Hardware Max 01 34 ro

40311 156 Analogue Hardware Min 01 36 ro

40313 157

40315 158

40317 159

40319 160

40321 161

Analogue 1 Out put

Parameter

Analogue 1 Parameter

Max

Analogue 1 Parameter

Min

Analogue 1 Reading

Top

Analogue 1 Reading

Bottom

01 38

01 3A ro

01 3C ro

01 3E Analogue 1 Parameter Max r/wp

01 40 Analogue 1 Parameter Min r/wp

See table below

(section1.4)

40323 162 Analogue 1 Output Top 01 42 Analogue Hardware Max r/wp

40325 163

40329 165

40331 166

40333 167

40335 168

40337 169

Analogue 1 Out put

Bottom

Analogue 2 Out put

Parameter

Analogue 2 Parameter

Max

Analogue 2 Par ameter

Min

Analogue 2 Reading

Top

Analogue 2 Reading

Bottom

01 44 Analogue Hardware Min r/wp

01 48

See table below

(section1.4)

01 4A ro

01 4C ro

01 4E Analogue 2 Parameter Max r/wp

01 50 Analogue 2 Parameter Min r/wp

40339 170 Analogue 2 Output Top 01 52 Analogue Hardware Max r/wp

40341 171

Analogue 2 Out put

Bottom

01 54 Analogue Hardware Min r/wp

tm

protocol. Each

Mode

r/wp

r/wp

Integra Comms Issue 1 Jan 2006 7

Page 8

Modbustm Start

Address

(Register)

40345 173

40347 174

40349 175

40351 176

40353 177

40355 178 Analogue 3 Output Top 01 62 Analogue Hardware Max r/wp

40357 179

40361 181

40363 182

40363 182

40361 181

40361 181

40361 181 Analogue 4 Output Top 01 68 Analogue Hardware Max r/wp

40361 181

r/w = read/write r/wp = read and write with password clearance ro = read only wo = write onl y

Some registers marked wo above may in fact be read, but the value returned is not valuable.

It is perfectly feasible to change Integra set-up using a general purpose Modbus

easier to use the Integra disp lay or Integra configurator software. The Integra configurator software has

facilities to store configurations to disk for later retrieval and rapid set up of similarly configur ed products.

Password Settings marked r/wp require the instrument password to have been entered into the

Password register before changes will be accepte d. Once the instrumen t configuration has been

modified, the password should be written to the pa ssword register again to protect the configuration from

unauthorised or accidental cha nge. Power cycling also restores prot ection. Reading the Password

register retur ns 1 if the instrument is unprotected and 0 if it is protected from changes.

* Demand Time

accomplish this. Writing any other value will cause an error to be retu r ned. Reading this register after

instrument restart or resetting demand period gives the number of minutes of demand data up to a

maximum of the demand period setting. For example, with 15 minute demand period, from reset the

value will increment from zero every mi nute until it reaches 15. It will remain at this value until a

subsequent reset occurs.

Demand Period

Writing any other value will caus e an error to be returned.

System Voltage in a PT/VT connected system represents the PT/VT primary voltage. In a direct

connected (i.e. no PT.VT) system this param eter should be set the same as secondary volts.

System Current

Parameter

Number

Analogue 3 Out put

Parameter

Analogue 3 Parameter

Max

Analogue 3 Parameter

Min

Analogue 3 Reading

Top

Analogue 3 Reading

Bottom

Analogue 3 Out put

Bottom

Analogue 4 Out put

Parameter

Analogue 4 Parameter

Max

Analogue 4 Parameter

Min

Analogue 4 Reading

Top

Analogue 4 Reading

Bottom

Analogue 4 Out put

Bottom 01 68 Analogue Hardware Min r/wp

is used to reset the demand period. A va lue of zero must be wr itten to this register to

represents demand time in m inutes. The value written must be one of 8,15, 20 or 30,.

is the CT primary current.

Parameter

Address Hex

High

Byte

01

01

01

01

01

01

01

01

01

01

01

Low

Byte

58

60 ro

62 ro

64 Analogue 3 Parameter Max r/wp

60 Analogue 3 Parameter Min r/wp

64 Analogue Hardware Min r/wp

68

70 ro

70 ro

68 Analogue 4 Parameter Max r/wp

68 Analogue 4 Parameter Min r/wp

Valid range

See table below

(section1.4)

See table below

(section1.4) r/wp

tm

master, but oft en

Mode

r/wp

8 Integra Comms Issue 1 Jan 2006

Page 9

System Type

single phase 3 wire.

Relay Pulse Width

ms), 5 (100 ms) or 10 (200 ms) are supported. Writing any other value will cause an error to be returned.

Reset Energy is used to reset the Energy readings. A value of zero must be written to this register to

accomplish this. Writing any other value will cause an error to be retur ned.

RS485 Set-Up Code

Baud Rate Parity Stop Bits Decimal

19200 NONE 2 30

19200 NONE 1 14

19200 ODD 1 13

19200 EVEN 1 12

9600 NONE 2 26

9600 NONE 1 10

9600 ODD 1 9

9600 EVEN 1 8

4800 NONE 2 22

4800 NONE 1 6

4800 ODD 1 5

4800 EVEN 1 4

2400 NONE 2 18

2400 NONE 1 2

2400 ODD 1 1

2400 EVEN 1 0

Codes not listed in the table above may give rise to unpredi ctable results inc luding loss of

communication. Exercise caution when attempting to change mode via direct Modbus

display or the Integra configurator software is recommended.

Node Address

can be set.

Pulse Rate Divi s or supports only values o f 1,10,100 or 1000. Writing any other value will c ause an error

to be returned.

System Power

system current.

Register Order

or reversed register order. In normal mode, the two registers that make up a floating point number are

sent most signifi cant bytes first. In reversed register mode, the two registers that make up a floating point

number are sent least significant bytes first. To set the mode, write the value '2141.0' into this register the instrument will detect the or der used to send this value and set that order for all Modbus

transactions involving floating point numbers.

Secondary Volts

the value of System Volts . The value of this register c an be set to between the minimum and max i mum

instrument input voltage.

Maximum Energy Count

before they roll over (i.e. resets to zero). The values of 6, 7 or 8 can be written to thi s register to indicate

the number of digits to use. Other values will be rejected.

Analogue Hardware Minimum

is set to '1' fo r single phase 2 wire, '2' for 3 Phase 3 Wire, '3' for 3 Phase 4 Wire or 4 for

is the width of the relay pulse in multip les of 20 ms. However, only values of 3 (60

Value

tm

writes. Use of a

is the Modbus

tm

or JC N2 slave addr ess for the instrument. Any value between 1 and 247

is the maximum system power based on the values of system type, system volts and

controls the order in which the Integra receives or sends floating-point numbers: - normal

tm

indicates the voltage on the VT secondary when the vo ltage on the Primary is equal to

controls the number of digits the energy (kWh and kvarh) counters can use

Analogue Hardware Maximum

and

indicate res pectively the minimum

Integra Comms Issue 1 Jan 2006 9

Page 10

and maximum outp ut currents that the instrument analogue output hardware is capable of.

Analogue 1 Output Parameter indicates the number o f the input parameter that is to be ou tput on

analogue output 1. A value of zero signifies the analogue output is unused.

Analogue 1 Parameter Maximum

Analogue 1 Parameter Minimum

Analogue 1 Reading Top

can range between Parameter Minimum and Parameter Maximum.

Analogue 1 Reading Bottom

value can range between Parameter Minimum and Parameter Maximum.

Analogue 1 Output Top

reading reaches Reading Top. The value of Output Top must be between Analogue Hardware Minimum

and Analogue Hardware Maximum.

Analogue 1 Output Bottom

parameter reading reaches Reading Bottom. The value of Outpu t Bottom must be between Analogu e

Hardware Minimum and Analogue Hardw are Maximum.

Analogue 2, 3 and 4

to the relevant analogue channel. Analogue 3 and 4 are only relevant for the 1560/1580. Consult the

1560/80 manual for det ails of auto conf ig ure oper at ion , w hich in some cir cumstances overrides user

settings.

Note: Analogue Hardwar e Maximum and M inimum refer to the fact ory build hard ware limits. It is the

same for all analogue channels on a particular instrument.

represents the upper limit of the parameter value that will be output. This value

represents the analogue output level that will be achieved when the parameter

set up values function in the same way as Analogue 1, except of course, they refer

is the maximum value that the selected input parameter c an r each.

is the minimum value that the selected input parameter can r each.

represents the lower limit of the parameter value that will be outp ut. This

represents the analog ue outp ut level th at will be ac hieve d when the

10 Integra Comms Issue 1 Jan 2006

Page 11

1.4 Analogue Output setting via Modbus

This section summarises Modbus co ntrol of analogue outputs. A more detai led explanation of analogue

operation and user settings to achieve the desired output ranges is included in the Integra Installation and

Operating Instructions. Review of the relevant section of the Integra instructions i n conjunction with the

description here may be helpful.

When the values of Output Top is greater than Output Bottom, the analogue output will operate in a

conventional n on-inverting mode . That is, when the selected metered value increases the analogue

output will increase.

When the value of Output Top is le ss than Output Botto m, the analogue output will operate in inverting

mode. That is, as the selected meter ed value increase s the analogue output will decrease. This can also

be achieved by reversing Reading Top and Reading Bottom values. Reversing both will self cancel.

When the value of Reading Top is equal to Reading Bottom, the analogue output will operate in

Threshold mode, the threshold being the value of Reading Top and Bottom. When the selected metered

value rises above the threshold the analogue output w ill switch to Output To p. When the selected

metered value falls below the thresh old the analogue output will switch to Ou tput Bottom.

When Output To p is set to the same value as Output Bottom the analogue out put will be fixed at the

specified value, effectively turning the output into a constant current generator.

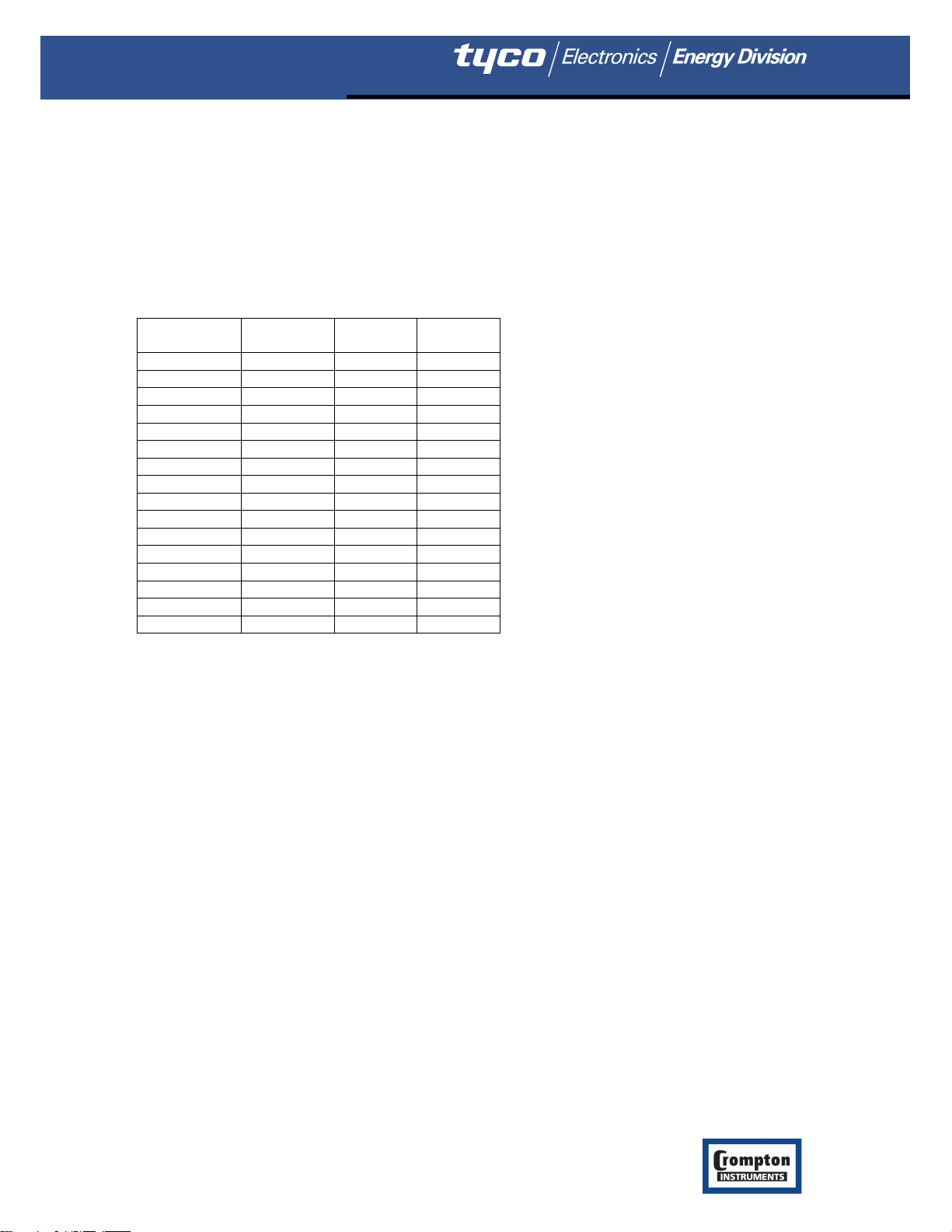

The parameters in the table following (next page) may be selected to be r epresented as analogue

outputs. The ranges shown are the limit values for Reading Top and Reading Bottom.

When analogu e outputs are used t o r epresent either individual or average power factor, parameters have

slightly different meanings.

The sign of the power factor when defining reading top and reading bottom is the sign of the active power

: +ve for active power (watts) i mp ort and -ve for act ive power (wat ts) export.

The reading span which the analogue output represents always includes unity (active power import, zero

vars), but subject to this, the range span may be set as desired, using Reading Top and Reading Bottom.

Reading Top value sets the limit va lue in the "export var" quadrants

Reading Bottom value sets the limit value in the "import var" quadrants

The direction the output moves depends on the Output Top and Output Bottom values.

If Output Top is greater than Output Bottom, then the analogue output value increases as the power

factor moves from the "export var" quadrants to the "import var" quadrants. This is the convention

normally adopted in European technically influe nced areas of the world.

If Output Top is less than Output Bottom, then the anal ogue output value decreases as the power factor

moves from the "export var" quadrants to the "import var" quadrants. This is the convention normally

adopted in Nort h American technically influenced areas of the world.

Integra Comms Issue 1 Jan 2006 11

Page 12

Parameter System Type

No. Name 3 Ø 4 wire 3 Ø 3 wire 1 Ø 3 wire 1 Ø 2 wire

1 Volts 1 0 – 1.2 * Vs 0 – 1.2 * Vs 0 – 1.2 * Vs 0 – 1.2 * Vs

2 Volts 2 0 – 1.2 * Vs 0 – 1.2 * Vs 0 – 1.2 * Vs

3 Volts 3 0 – 1.2 * Vs 0 – 1.2 * Vs

4 Current 1 0 – 1.2 * Is 0 – 1.2 * Is 0 – 1.2 * Is 0 – 1.2 * Is

5 Current 2 0 – 1.2 * Is 0 – 1.2 * Is 0 – 1.2 * Is

6 Current 3 0 – 1.2 * Is 0 – 1.2 * Is

7 W 1 ± 1.44 * Vs * Is ± 1.44 * Vs * Is ± 1.44 * Vs * Is

8 W 2 ± 1.44 * Vs * Is ± 1.44 * Vs * Is

9 W 3 ± 1.44 * Vs * Is

10 VA 1 0 – 1.44 * Vs * Is 0 – 1.44 * Vs * Is 0 – 1.44 * Vs * Is

11 VA 2 0 – 1.44 * Vs * Is 0 – 1.44 * Vs * Is

12 VA 3 0 – 1.44 * Vs * Is

13 var 1 ± 1.44 * Vs * Is ± 1.44 * Vs * Is ± 1.44 * Vs * Is

14 var 2 ± 1.44 * Vs * Is ± 1.44 * Vs * Is

15 var 3 ± 1.44 * Vs * Is

16 Power Factor 1 ± 1 ± 1 ± 1

17 Power Factor 2 ± 1 ± 1

18 Power Factor 3 ± 1

19 Phase Angle 1 deg. ± 180 ± 180 ± 180

20 Phase An gle 2 deg. ± 180 ± 180

21 Phase An gle 3 deg. ± 180

22 Voltag e ( A ver age) 0 – 1.2 * Vs 0 – 1.2 * Vs 0 – 1.2 * Vs 0 – 1.2 * Vs

24 Current ( Average) 0 – 1.2 * Is 0 – 1.2 * Is 0 – 1.2 * Is 0 – 1.2 * Is

25 Current (Sum) 0 – 3.6 * Is 0 – 3.6 * Is 0 – 2.4 * Is 0 – 1.2 * Is

27 W (Sum) ± 4.32 * Vs * Is

29 VA (Sum) 0 – 4. 32 * Vs * Is

31 var (Sum) ± 4. 32 * Vs * Is

32 Power Factor (Average) ± 1 ± 1 ± 1 ± 1

34 Phase Angle (Avg) deg. ± 180 ± 180 ± 180 ± 180

36 Frequency Hz 40 – 70 40 – 70 40 – 70 40 – 70

43 Import Power Demand 0 – 4. 32 * Vs * Is

44 Import Power Max. Dem. 0 – 4. 32 * Vs * Is

53 Current Demand 0 – 3.6 * Is 0 – 3.6 * Is 0 – 2.4 * Is 0 – 1.2 * Is

54 Current Max. Demand 0 – 3.6 * Is 0 – 3.6 * Is 0 – 2.4 * Is 0 – 1.2 * Is

101 Volts L1-L2

102 Volts L2-L3

103 Volts L3-L1

104 Volts Line-Line (Avg)

113 Neut ral Current 0 – 1.2 * Is 0 – 1.2 * Is 0 – 1.2 * Is

118 THD Va % 0 – 100 0 – 100 0 – 100 0 – 100

119 THD Vb % 0 – 100 0 – 100 0 – 100

120 THD Vc % 0 – 100 0 – 100

121 THD Ia % 0 – 100 0 – 100 0 – 100 0 – 100

122 THD Ib % 0 – 100 0 – 100 0 – 100

123 THD Ic % 0 – 100 0 – 100

125 THD Voltage (Avg) % 0 – 100 0 – 100 0 – 100 0 – 100

126 THD Current (Avg) % 0 – 100 0 – 100 0 – 100 0 – 100

Vs = System Volts, Is = System Current.

0 – 1.2 * √3 * Vs

0 – 1.2 * √3 * Vs

0 – 1.2 * √3 * Vs

0 – 1.2 * √3 * Vs

± 1.44 * √3 * Vs * Is

0 – 1.44 * √3 * Vs * Is

± 1.44 * √3 * Vs * Is

0 – 1.44 * √3 * Vs * Is

0 – 1.44 * √3 * Vs * Is

0 – 2.4 * Vs

0 – 2.4 * Vs

± 2.88 * Vs * Is ± 1.44 * Vs * Is

0 – 2.88 * Vs * Is 0 – 1.44 * Vs * Is

± 2.88 * Vs * Is ± 1.44 * Vs * Is

0 – 2.88 * Vs * Is 0 – 1.44 * Vs * Is

0 – 2.88 * Vs * Is 0 – 1.44 * Vs * Is

12 Integra Comms Issue 1 Jan 2006

Page 13

2 RS485 Implementation of Johnson Controls Metasys

These notes briefly explain Met asys and Crompton Instruments Inte gra integration. Use these notes with

the Metasys Technical Manual, whic h provides information on installing and commissioning Metasys N2

Vendor devices.

2.1 Application details

The Integra is a N2 Vendor device that connects directly with the Metasys N2 Bus. This implementation

assigns 54 k ey electrical parameters to ADF points, each with ov erride capability.

Components requirements

• Integra with RS485 card and N2 port available.

• N2 Bus cable.

2.2 Metasys release requirements

•

Metasys OWS so ftware release 7. 0 o r higher.

•

Metasys NCM311. NCM360.

2.3 Support for Metasys Integration

Johnson Control Systems

System House, Randalls Research Park,

Randalls Way, Leatherhead,

Surrey, KT22 7TS

England

2.4 Support for Crompton Integra operation

This is available via local sales and service centre.

2.5 Design considerations

When integrat ing the Crompton equipment into a Metasys Network, keep the follow ing considerations in

mind.

• Make sure all Crompton equipment is se t up, started and running properly before attempting to

integrate with the Metasys Network.

• A m aximum of 32 devices can be connected to any one NCM N2 Bus.

Vendor Address

Port Set-up

Baud Rate* 9600

Duplex

Word Length

Stop Bits*

Parity* None

Interface

* The user should ensure these values are set as shown on the Integra for compatibility with the N2

network.

Half

1

RS485

1-247 (Limited by co-re sident Modbus

8

tm

protocol)

Integra Comms Issue 1 Jan 2006 13

Page 14

2.6 METASYS N2 Integra Point Mapping table

Address Parameter Description Units

1 Voltage 1 Volts

2 Voltage 2 Volts

3 Voltage 3 Volts

4 Current 1 Amps

5 Current 2 Amps

6 Current 3 Amps

7 Voltage average Volts

8 Current average Amps

9 Power (Watts) Sum KW

10 VA Sum kVA

11 var Sum kvar

12 Power Factor average

13 Frequency Hz

14 Active Energy (Import) (6 digits max) kWh

15 Reac tive Energy (Import) (6 digits ma x) kvar h

16 Watts Demand (Import) kWatts

17 Maximum Watts Demand (Import) kWatts

18 Amps Demand Amps

19 Maximum Amps Demand Amps

20 Voltage L1-L2 (calculated) Volts

21 Voltage L2-L3 (calculated) Volts

22 Voltage L3-L1 (calculated) Volts

23 Neutral Current Amps

24 Active Energy (Import) (les s par a m 1A) GWh

25 Reactive Energy (Import) (less param 15) Gvarh

26 THD V1 %

27 THD V2 %

28 THD V3 %

29 THD I1 %

30 THD I2 %

31 THD I3 %

32 THD Vmean %

33 THD Imean %

34 Power (Watts) 1 kW

35 Power (Watts) 2 kW

36 Power (Watts) 3 kW

37 VA 1 kVA

38 VA 2 kVA

39 VA 3 kVA

40 var 1 kVAr

41 var 2 kVAr

42 var 3 kVAr

43 PF 1

44 PF 2

14 Integra Comms Issue 1 Jan 2006

Page 15

45 PF 3

46 PA 1 degrees

47 PA 2 degrees

48 PA 3 degrees

49 A Sum amps

50 VLL Ave volts

51 Exp W h ( 6 digits max) kWh

52 Exp Wh ( less par am 51) GWh

53 Exp VArh (6 digits max) kVArh

54 Exp VArh (less param 53) GVArh

55 Command Register See note below

56 VAh (6 digits max) kVAh

57 VAh (less param 56) GVAh

Command Register: The command regi ster is used to clear ener gy registers by override with 156001.0

and clear dema nd r egisters by over r ide with 156002.0

Energy registers: Principal energy registers are repor ted in pairs – the one showing the least significant 6

digits and the other showing the ov erflow, or more significant digits. The total energy since the last reset

is found by combining both these r egisters appropriately. This allows energy register rollover to be

postponed, and maintains consistency.

Register pairs are:

14 and 24 (active impor t ener gy)

15 and 25 (reactive import energy)

51 and 52 (active expor t ener gy)

53 and 54 (reactive export energy)

56 and 57 (apparent energy)

Integra Comms Issue 1 Jan 2006 15

Page 16

3 Integra Profibus Interface

The Integra Profibus interface implements a “modular” slave, in which the I/O set is not fixed but allows

modules, real or virtual, to be selected (“plugged in”) at configuration time. The configuration tool will be

specific to the manufacturer of the Profibus network Class-1 Master unit. However, the slave device GSD

file provides the data to the configuration tool that will associate a module type (e.g. “VA Phase 1”) with

configuration data.

3.1 GSD file

A copy of the GSD file may be accessed via the website : www.crompton-instruments.com

page as Integra instruction and operation manua ls.

3.2 Floating Point Format

As with Modbus, data transfer occurs using IEEE floating point format.

The convention for the four bytes of floating-point data is to transmit and receive it in Big Endian format,

that is, the most significant byte is in Data0 and the least significant byte is in Data3.

3.3 Single Parameter access

The system des cribed doesn’t allo w access to all the Integra parameters simultaneously, as onl y 5 0

parameters ar e available in the configuration tab le for the Integra. Since the configuration is fixed in

operation, modules can’t be swapped in and out dynamical ly to gain access to addition parameters. So in

addition to th e regular parameter modules, a ‘Control’ module has been defined. Through the use of its

I/O area a single parameter read or wr ite facility is available.

Note: that only one instance of a ‘Control’ module can be used in an Integra con figuration and the module

must be placed after other configured modules in the table.

In order to reference the parameters, the Modbus numbering con vention is used. These are shown in

section 1.3.

The table below illustrates the contents of the I/O area of the Control module.

Output Bytes Input Bytes

Command Echo command

Modbus address hi Echo address hi

Modbus address lo Echo address lo

Data0 write Data0 read

Data1 write Data1 read

Data2 write Data2 read

Data 3 write Data3 read

Status Status/error

3.4 Functionality of the PLC Function Block

, on the same

The PLC programmer will need to implement a function block that can fulfil the following requirements.

3.4.1 Reading

In order to execute a read of parameter values from the Control module of the Integra, the sequence of

events is as follows:

The Command should initially be null (i.e. zero). The Modbus Address is written into the output fields,

then the ‘Read floating-poin t value from an input r egister” (the val u e 4), or read flo ating-point valu e from a

16 Integra Comms Issue 1 Jan 2006

Page 17

holding register’ (the value 3) is written to the command field.

The slave checks for a change in the command field as ind ication that there is a command to action and

that the rest of the fields are valid and ready for use.

The slave will r eturn the appr opriate value in the data field, together with a confirmation/rej ection value in

the status field. The master checks for the command field to be echoed in the input data as indication that

the rest of the fields are valid, and ready for reading. A zero in the status field indicates the command

completed correctly. A non-zero value indicates an error has occurred.

The sequence is completed by outputting the null-command (zero) and awaiting confirmation (zero) from

the echo-command byte.

This last step is important since Profibus transmits t he I/O data continuously and repeat edly, so the slave

device looks for the change in the command field to initiate the action. If this step is omitted, even though

the data field may have been changed the slave will take no action unless it detects a change in the

command field.

3.4.2 Writing

In order to write parameter values using the Control module, the se quence of events is as follows:

The Command should initially be null (i.e. zero). The Modbus Address is written into the output fields,

then the value to be writte n is placed in the dat a fie ld . Th e next ite m to be put into the d ata area is the

command ‘Write floating point value to Holding Register’ (the value 16), written to the command field.

The slave checks for a change in the co mmand field as indication that there is a command to action and

that the rest o f the fields are valid and ready for use.

The slave will r eturn the appr opriate value in the data field, together with a confirmation/rej ection value in

the status field. The master checks for the command field to be echoed in the input data as indication that

the rest of the fields are valid, and ready for reading. A zero in the status field indicates the command

completed correct ly. A non-zero value i ndicates an error has occurred.

The sequence is completed by outputting the null-command (zero) and awaiting confirmation (zero) from

the echo-command byte.

This last step is important since Profibus transmits t he I/O data continuously and repeat edly, so the slave

device looks for the change in the command field to initiate the action. If this step is omitted, even though

the data field may have been changed the slave will take no action unless it detects a change in the

command field.

3.5 Common Problems

The most common r easons why a single parameter read or w rite fails are:

The Command field contains a value not supported by the module. (Va lues 0, 3, 4, and 16 are

permissible).

The Modbus Address is incorrect. Correct Modbus address values can be found in the table of available

parameters co n ta i ned in this guide.

A parameter is being written to that requires the password to be entered in the password register before it

can be changed.

Integra Comms Issue 1 Jan 2006 17

Page 18

The LonWorks Interface

4

This section details the LonMark Objects that make up the network interface of the Integra

1530/1560/1580 Meter or transducer.

The Implementation contains eight objects: Voltmeter, Ammeter, Power meter, Energy Meter, Demand

Ammeter, Demand Po wer, Power Quality and Bus Generator . In addition, ther e is a ninth object known as

the Node obje ct which is used by network manage me nt tools and/or cu stomised device plug-ins

(Windows app lication) to manage the eight pri mary objects.

4.1 XIF File

A copy of the XIF file may be accessed via the website : www.crompton-instruments.com

page as Integra instruction and operation manua ls.

4.2 Overview and Device Functional Profile

A device using these object profiles will typically be used in industrial power and energy metering

applications.

, on the same

Device Functional Profile

18 Integra Comms Issue 1 Jan 2006

Page 19

4.3 Node Object

4.3.1 Network Variables

Object Request

network input SNVT_obj_request nviRequest

Refer to the L

4.3.2 Object Status

network output SNVT_obj_status nvoStatus

Refer to the L

4.3.3 Configuration Properties

Device Label

network input config SNVT_str_ascii nciDeviceLabel

This configuration property can optionally be used to provide more descriptive physical location

information t han can be provided by the Neuron Chip’s 6-byte location string.

Valid Range: Any NUL terminated ASCII string less than 31 bytes total in length.

Default Value: The default value is an ASCII string containing all zeroes.

SCPT/UCPT Ref erence: SCPTloc ation (17)

4.4 Voltmeter Functional Profile

ONMARK

ONMARK

Application Layer Interoperability Guidelines for definition.

Application Layer Interoperability Guidelines for definition.

Integra Comms Issue 1 Jan 2006 19

Page 20

4.4.1 Voltmeter Network Variables

Voltage Between Phases (Corresponds to Modbus register 101,102,103,1,2,3)

network output SNVT_volt_f nvoVoltsL12

This output network variable reports the voltage measured from phase L1 to phase L2 in a 3 phase

power system.

network output SNVT_volt_f nvoVoltsL23

This output network variable reports the voltage measured from phase L2 to phase L3 in a 3 phase

power system.

network output SNVT_volt_f nvoVoltsL31

This output network variable reports the voltage measured from phase L3 to phase L1 in a 3 phase

power system.

network output SNVT_volt_f nvoVoltsL1

If applicable based on PT Connection Type, this output network variable reports the voltage measured

from phase L1 to the Neutral conductor in a 3 phase power system.

network output SNVT_volt_f nvoVoltsL2

If applicable based on PT Connection Type, this output network variable reports the voltage measured

from phase L2 to the Neutral conductor in a 3 phase power system.

network output SNVT_volt_f nvoVoltsL3

If applicable based on PT Connection Type, this output network variable reports the voltage measured

from phase L3 to the Neutral conductor in a 3 phase power system.

Valid Range: -1E38…1E38 (Volts)

Default Service T ype : Ack now ledge d

Voltage Average (Corresponds to Modbus register 22)

network output SNVT_volt_f nvoVoltsAve;

This output net work variable is used to report the average voltage across all of the Phases.

Valid Range: -1E38…1E38 (Volts)

Default Service T ype : Ack now ledge d

Voltage Frequency (Corresponds to Modbus register 36)

network output SNVT_freq_f nvoFreq;

This output network variable, if provided, is used to report the nominal fundamental frequency of the

voltage in the Power Sys tem.

Valid Range: -1E38…1E38 Hertz

Default Service T ype : Ack now ledge d

Voltmeter Configuration Properties

PT Connection Type (Corresponds to Modbus holding register 6)

network input config UCPTptConnType nciPTConnType

This input network configuration variable is used to describe the connection arrangement of the

Potential Transformers used to connect 3 phase voltage to the meter.

Valid Range: The valid range is specified by the enumer ation list,

UNKNOWN : 0

SINGLE_PHASE : 1

THREE_PHASE_THREE_WIRE : 2

THREE_PHASE_FOUR_WIRE : 3

Default Value: The default value is UNKNOWN (0). The gateway will update this configuration property

when it has

extracted th e contents of Modbus Holding register #6 from the connected meter.

SCPT/UCPT Reference: UCPTptConnType (10)

Voltage Send on Delta

network input config UCPTsendDeltaVolts nciSendOnDeltaV

Specifies the maximum amount that any of the retrieved Voltme ter points of SNV T type

SNVT_volts_f c an change without an update occurring on the associated network var iable.

Valid Range: -1E38…1E38 (Volts)

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaVolts (01)

Frequency Send on Delta

network input config UCPTsendDeltaFreq nciSendOnDeltaF

Specifies the maximum amount that any of the retrieved Voltmeter points of SNVT type SNVT_freq_f

can change with out an update occurring on the associated network var iable.

Valid Range: -1E38…1E38 (Hertz)

20 Integra Comms Issue 1 Jan 2006

Page 21

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaVolts (02)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value : The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

4.5 Ammeter Functional Profile

4.5.1 Ammeter Network Variables

Current (Corresponds to Modbus register– 4, 5, 6)

network output SNVT_amp_f nvoCurrentL1

This output network variable reports the current measured flowing on phase L1 in a 3 phase power

system.

network output SNVT_amp_f nvoCurrentL2

This output network variable reports the current measured flowing on phase L2 in a 3 phase power

system.

network output SNVT_amp_f nvoCurrentL3

This output network variable reports the current measured flowing on phase L3 in a 3 phase power

system.

Integra Comms Issue 1 Jan 2006 21

Page 22

Valid Range: -1E 38… .1E 38 (Amperes)

Default Service T ype : Ack now ledge d

Average Current (Corresponds to Modbus register– 24)

network output SNVT_amp_f nvoCurrentAve;

This output network variable, if provided, is used to report the average of the three phase currents

(IL1, IL2, & IL3) in the Power System.

Valid Range: -1E 38… .1E 38 (Amperes)

Default Service T ype : Ack now ledge d

Neutral Current (Corresponds to Modbus register 113)

network output SNVT_amp_f nvoCurrentNt;

This output network variable reports the current measured flowing with respect to Neutral.

Valid Range: -1E 38… .1E 38 (Amperes)

Default Service T ype : Ack now ledge d

4.5.2 Ammeter Configuration Properties

Voltage Send on Delta

network input config UCPTsendDeltaAmps nciSendOnDeltaA

Specifies the maximum amount that any of the retrieved Ammeter points can change without an

update occurring on the associated network variable.

Valid Range: -1E38…1E38 (Amperes)

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaAmps (03)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value: The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

22 Integra Comms Issue 1 Jan 2006

Page 23

4.6 Energy Meter Functional Profile

4.6.1 Energy Meter Network Variables

Energy Import (Corresponds to Modbus register 37)

network output SNVT_elec_whr_f nvoWhrImport

This output net work variable reports the 3 phase Energy Import measured in a 3 phase pow er system.

Energy Export (Corresponds to Modbus register 38)

network output SNVT_elec_whr_f nvoWhrExport

This output net work variable reports the 3 phas e Energy Export measured in a 3 phase power system.

Reactive Energy Import (Corresponds to Modbus register 39)

network output SNVT_elec_whr_f nvoVarhImport

This output net work variable reports the 3 phas e Reactive Energy Import measured in a 3 phase power

system.

Reactive Energy Export (Corresponds to Modbus register 40)

network output SNVT_elec_whr_f nvoVarhExport

This output network variable reports the 3 phase Reactive Energy Export measured in a 3 phase power

system.

Real Energy (Corresponds to Modbus register 41)

network output SNVT_elec_whr_f nvoVAh

This output network variable reports the total 3 phase Real Energy measured in a 3 phase power

system.

Valid Range: 0 t o 1E38 (Watt-hour)

Default Service T ype : Ack now ledge d

Amphours (Corresponds to Modbus register 42)

network output SNVT_amp_f nvoAhr

This output network variable reports the current consumption in Amps.

Valid Range: -1E38 .. 1E38 Amps

Default Service T ype : Ack now ledge d

4.6.2 Energy Meter Configuration Properties

Energy Send on Delta

network input config UCPTsendDeltaVolts nciSendOnDeltaV

Specifies the maximum amount that any of the retrieved Energy Meter points of SNVT type

Integra Comms Issue 1 Jan 2006 23

Page 24

SNVT_elec_whr_f can change without an update occurring on the associated network variable.

Valid Range: 0 to 1E38 (Watt hour)

Default Value: The default value is 0.

SCPT/UCPT Ref erence: UCPTsendDeltaWhr (04)

Current Send on Delta

network input config UCPTsendDeltaAmp nciSendOnDeltaF

Specifies the maximum amount that any of the retrieved Energy Meter points of SNVT type

SNVT_amp_f ca n change without an update occurring on the associated network variable .

Valid Range: -1E38…1E38 (Hertz)

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaAmp (03)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value : The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

24 Integra Comms Issue 1 Jan 2006

Page 25

4.7 Power Meter Functional Profile

4.7.1 Power Meter Network Variables

Watts Sum (Corresponds to Modbus register 27)

network output SNVT_power_f nvoWattSum

This output net work variable reports the total 3 phase instantaneous real power measured in a 3 phase

power system.

VA Sum (Corresponds to Modbus register 29)

network output SNVT_power_f nvoVASum

This output network variable reports the total 3 phase instantaneous power measured in a 3 phase

power system.

VAr Sum (Corresponds to Modbus register 31)

network output SNVT_power_f nvoVArSum

This output network variable reports the total 3 phase Instantaneous reactive power measured in a 3

phase power system.

Valid Range: -1E38 .. 1E38 watts

Default Service T ype : Ack now ledge d

Watts L1, L2, L3 (Corresponds to Modbus register 07, 08, 09)

network output SNVT_power_f nvoWattL1

This output network variable reports the instantaneous real power measured on Phase 1 of a 3 phase

power system.

network output SNVT_power_f nvoWattL2

This output network variable reports the instantaneous real power measured on Phase 2 of a 3 phase

power system.

Integra Comms Issue 1 Jan 2006 25

Page 26

network output SNVT_power_f nvoWattL3

This output network variable reports the instantaneous real power measured on Phase 3 of a 3 phase

power system.

Power Factor L1.L2,L3 (Corresponds to Modbus register 16, 17, 18)

network output SNVT_pwr_fact_f nvoPwrFactL1

This output network variable reports the Power Factor measured on Phase 1 of a 3-phase power

system.

network output SNVT_pwr_fact_f nvoPwrFactL2

This output network variable reports the Power Factor measured on Phase 2 of a 3-phase power

system.

network output SNVT_pwr_fact_f nvoPwrFactL3

This output network variable reports the Power Factor measured on Phase 3 of a 3-phase power

system.

Average Power Factor (Corresponds to Modbus register 32)

network output SNVT_pwr_fact_f nvoPwrFactr

This output network variabl e reports the total 3 phase true power factor measured in a 3 phase power

system.

Valid Range: -1.0 .. 1.0 (0.00005)

Default Service T ype : Ack now ledge d

Reset Totals (Corresponds to Modbus holding register 8)

network input SNVT_lev_disc nviResetTotals

This input network variable r esets all accumulated power readings when the value of zer o ( 0) is

written to it.

Valid Range: 0

Default Service T ype : Ack now ledge d

4.7.2 Power Meter Configuration Properties

Power Send on Delta

network input config UCPTsendDeltaPwr nciSendOnDeltaP

Specifies the maximum amount that any of the retrieved Power meter points of SNVT type

SNVT_power_f can change with out an update occurring on the associate d network variable.

Valid Range: -1E38…1E38 (Volts)

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaPwr (05)

Power Factor Send on Delta

network input config UCPTsendDeltaPwrFact nciSendOnDeltaPF

Specifies the maximum amount that any of the retrieved Power meter points of SNVT type

SNVT_pwr_fact_f can change without an update occurring on the associated network variable.

Valid Range: -1 to 1

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaPwrFact (06)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value : The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

26 Integra Comms Issue 1 Jan 2006

Page 27

4.8 Demand Ammeter Functional Profile

4.8.1 Demand Ammeter Network Variables

Demand Current (Corresponds to Modbus register 53)

network output SNVT_amp_f nvoADemand

This output network variable reports the demand current

Valid Range: -1E38 .. 1E38 Amps

Default Service T ype : Ack now ledge d

Maximum Demand Current (Corresponds to Modbus register 54)

network output SNVT_amp_f nvoAMaxDemand

This output network variable reports the maximum demand current

Valid Range: -1E38 .. 1E38 Amps

Default Service T ype : Ack now ledge d

4.8.2 Demand Ammeter Configuration Properties

Current Send on Delta

network input config UCPTsendDeltaAmps nciSendOnDeltaA

Specifies the maxi mum amount that any of th e r et r ieved Demand Ammeter points can change without

an update occurring on the associated network variable.

Valid Range: -1E38 to 1E38

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaPwrFact (06)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value : The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

Integra Comms Issue 1 Jan 2006 27

Page 28

4.9 Demand Power Meter Functional Profile

4.9.1 Demand Power Meter Network Variables

Power Demand (Corresponds to Modbus register 51)

network output SNVT_power_f nvoVAdemand

VA demand.

Power Max Demand (Corresponds to Modbus register 52)

network output SNVT_power_f nvoVAMaxDmnd

VA Maximum demand.

Valid Range: -1E38 .. 1E38 watts

Default Service T ype : Ack now ledge d

Reactive Power Demand (Corresponds to Modbus register 47)

network output SNVT_power_f nvoVarDmdImp

VA Maximum demand.

Reactive Power Max Demand (Corresponds to Modbus register 48)

network output SNVT_power_f nvoVarMaxDmdImp

VA Maximum demand.

Valid Range: -1E38 .. 1E38 watts

Default Service T ype : Ack now ledge d

Watts Demand (Modbus input 43)

network output SNVT_power_f nvoWDemand

This output network variable reports the three phase total real power demand.

Watts Max Demand (Modbus input 44)

network output SNVT_power_f nvoWMaxDemand

This output network variable reports the peak three phase total real power demand which has occurred

since peak demand was last reset.

Valid Range: -1E38… .1E38 ( Watt s )

Default Service T ype : Ack now ledge d

Reset Demand Period (Modbus holding – 1)

network input SNVT_lev_disc nviRstDemandP

Writing the proper value to this input network variable causes the demand period t o be reset.

28 Integra Comms Issue 1 Jan 2006

Page 29

Valid Range: 0

Default Service T ype : Ack now ledge d

4.9.2 Demand Power Meter Configuration Properties

Demand Period (Modbus holding – 2)

network input config UCPTdemandPeriod nciDmdPeriod

This input network configuration variable spec ifies the time interval used when cal cu lating the power

demand.

Valid Range: 8, 15, 20 or 30 minute s

Default Value: The default value is 30 minutes

SCPT/UCPT Ref erence: UCPTdema ndPeriod(09)

Power Send on Delta

network input config UCPTsendDeltaPwr nciSendOnDeltaP

Specifies the maxi mum amount that any of the r et r ieved Demand Power meter points can change

without an update occurrin g on the associated network var i able.

Valid Range: -1E38 to 1E38

Default Value: The default value is 0.

SCPT/UCPT Reference: UCPTsendDeltaPwr (05)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value : The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

Integra Comms Issue 1 Jan 2006 29

Page 30

4.10 Power Quality Meter

4.10.1 Power Quality Network Variables

Quality of Phase Voltages (Corresponds to Modbus register 118, 119, 120)

network output SNVT_lev_percent nvoQV1

This output network variable reports the Total Harmonic Distortion (THD) of the voltage on Ph ase 1

in a 3 phase power system.

network output SNVT_lev_percent nvoQV2

This output network variabl e reports the Total Harmonic Distortion (THD) of the voltage o n Phase 2

in a 3 phase power system.

network output SNVT_lev_percent nvoQV3

This output network variable reports the voltage measured from phase L3 to phase L1 in a 3 phase

power system.

Valid Range: 0% .. 100% (0.5%) the SNVT has a range of - 163.84% .. 163. 83% (0.005%)

Default Service T ype : Ack now ledge d

Quality of Phase Currents (Corresponds to Modbus register 121, 122, 123)

network output SNVT_lev_percent nvoQA1

This output network variable reports the Total Harmonic Distortion (THD) of the current on Phase 1 in

a 3 phase power system.

network output SNVT_lev_percent nvoQA2

This output network variable reports the Total Harmonic Distortion (THD) of the current on Phase 2 in

a 3 phase power system.

network output SNVT_lev_percent nvoQA3

This output network variable reports the Total Harmonic Distortion (THD) of the current on Phase 3 in

30 Integra Comms Issue 1 Jan 2006

Page 31

a 3 phase power system.

Valid Range: 0% .. 100% (0.5%) the SNVT has a range of -163.84% .. 163.83% (0.005%)

Default Service Type: Acknowledged

Quality of Current to Neutral (Corresponds to Modbus register 124)

network output SNVT_lev_percent nvoQANt

This output network variable reports the Total Harmonic Distortion (THD) of the current with respect

to Neutral.

Quality of Average Voltage (Corresponds to Modbus register 125)

network output SNVT_lev_percent nvoQVave

This output network variable reports the Total Harmonic Distortion (THD) of the average voltage.

Quality of Average Current (Corresponds to Modbus register 126)

network output SNVT_lev_percent nvoQAave

This output network variable reports the Total Harmonic Distortion (THD) of the average current.

Valid Range: 0% .. 100% (0.5%) the SNVT has a range of -163.84% .. 163.83% (0.005%)

Default Service T ype : Ack now ledge d

4.10.2 Power Quality Meter Configuration Properties

Quality Send on Delta

network input config UCPTsendDeltaQlty nciSendOnDeltaQ

Specifies the maximum amount that any of the retrieved Quality meter points c an change without an

update occurring on the associated network variable.

Valid Range: -163.84% to 163.83%

Default Value: The default value is 0.

SCPT/UCPT Ref erence: UCPTsendDeltaQlty (07)

Minimum Send Time

network input config SNVT_time_sec nciMinSendTime;

Indicates the minimum period between output network variable transmissions.

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 allows

the maximum refresh according to t he SendOnDelta value.

Default Value: 1 second.

SCPT/UCPT Ref erence: SCPTmin S endTime (52)

Maximum Send Time (Heartbeat)

network input config SNVT_time_sec nciVMaxSendTime;

This input configuration network variable defines the maximum period of time that expires before an

automatic update oc curs on the network varia bl es .

Valid Range: The valid range is an y value between 0.0 seconds and 6553.4 seconds . Setting the valu e to

0 disables

the automatic update mechanism.

Default Value : The default value is 1800.0 seconds (30 minutes)

SCPT/UCPT Reference: SCPTmaxSendTime (49)

4.11 Common Problems

If the LonW orks interface is not functioning corr ectly, confirm that communications parameters are set

currently in the Integra. This topic is co ver ed in the Integra Installation manua l. This manual also gi ves a

guide to the ser v ice indicator LED, and status indication of the LonW orks interface.

Integra Comms Issue 1 Jan 2006 31

Loading...

Loading...