Crompton integra 1530, integra 1560, integra 1580 Communications Manual

Crompton

INTEGRA 1530, 1560, 1580

Communications Guide

Crompton Instruments

Freebournes Road

Witham

Essex

CM8 3AH

England

Tel: +44 (0) 1376 509 509

Fax: +44 (0) 1376 509 511

E-Mail: crompton.info@tycoelectronics.com

Integra Comms Issue 1 Jan 2006

Contents Page

1 Modbus

tm

4

1.1 Modbus tm Overview 4

1.2 Input Registers 5

1.3 Modbustm Holding Registers and Integra set up 7

1.4 Analogue Output setting via Modbus 11

2 RS485 Implementation of Johnson Controls Metasys 13

2.1 Application details 13

2.2 Metasys release requirements 13

2.3 Support for Metasys Integration 13

2.4 Support for Crompton Integra operation 13

2.5 Design considerations 13

2.6 METASYS N2 Integra Point Mapping table 14

3 Integra Profibus Interface 16

3.1 GSD file 16

3.2 Floating Point Format 16

3.3 Single Parameter access 16

3.4 Functionality of the PLC Function Block 16

3.4.1 Reading 16

3.4.2 Writing 17

3.5 Common Pro b l ems 17

4 The LonWorks Interface 18

4.1 XIF File 18

4.2 Overview and Device Functional Profile 18

4.3 Node Object 19

4.3.1 Network Variables 19

4.3.2 Object Status 19

4.3.3 Configuration Properties 19

4.4 Voltmeter Functional Profile 19

4.4.1 Voltmeter Network Variables 20

4.5 Ammeter Functional Profile 21

4.5.1 Ammeter Network Variables 21

4.5.2 Ammeter Configuration Properties 22

4.6 Energy Meter Functional Profile 23

4.6.1 Energy Meter Network Variables 23

4.6.2 Energy Meter Configuration Properties 23

4.7 Power Meter Functional Profile 25

4.7.1 Power Meter Network Variables 25

4.7.2 Power Meter Configuration Properties 26

4.8 Demand Ammeter Functional Profile 27

2 Integra Comms Issue 1 Jan 2006

Contents Page

4.8.1 Demand Ammeter Network Variables 27

4.8.2 Demand Ammeter Configuration Properties 27

4.9 Demand Power Meter Functional Profile 28

4.9.1 Demand Power Meter Network Variables 28

4.9.2 Demand Power Meter Configuration Properties 29

4.10 Power Quality Meter 30

4.10.1 Power Quality Network Variables 30

4.10.2 Power Quality Meter Configuration Properties 31

4.11 Common Pro b l ems 31

Integra Comms Issue 1 Jan 2006 3

1 Modbus

1.1 Modbus tm Overview

This section pr ovides basic info rmation for interfacing the Integra to a Modbus

information or more details of the Integra implementation is required please refer to our “Guide to RS485

Communications and the Modbus

supplier.

Integra offers the option of an RS485 communication facility for direct connection to SCADA or other

communications systems using the Modbus

format for the master's query by placing into it the device address, a function code defining the requested

action, any data to be sent, and an error check ing fie ld . The slave's re spon se me ssage is also

constructed using Modbus

returned, an d an error-checking field. If an er r or occurs in receipt of the message, Integra will ma ke no

response. If the I ntegra is unable to p erform the requested action, it will constr uct an error message and

send it as it’s response.

The electrical interface is 2-wire RS485, via 3 screw terminals. Connection should be made using twisted

pair screened cable (Typically 22 gauge Belden 8761 or equivalent). All "A" and "B" connections are

daisy chained together. The screens should also be connected to th e “Gnd” terminal. To avoid the

possibility of loop currents, an Earth connection should be made at only one point on t he network.

Line topology may or may not require terminating loads depending on the type and leng th of cable used.

Loop (ring) topology does not require any termination load.

The impedance of the termination load should match the impedance of the cable and be at both ends of

the line. The ca ble should be terminated at each end with a 120 ohm (0.25 Watt min.) resistor.

A total maximum length of 3900 feet (1200 metres) is allowed for the RS485 network. A maximum of 32

electrical nodes can be connected, including the controller.

The address of each Integra can be set to any value between 1 and 247. Broadcast mode (address 0) is

not supported .

The maximum latency time of an Integra is 150ms i. e. this is the amount of time that can pass before the

first response ch aracter is output. The supervisory programme must allow t his period of time to elapse

before assuming that the Integra is not going to respond.

The format for each byte in RTU mode is:

Coding System: 8-bit per byte

Data Format: 4 bytes (2 regist ers) per parameter.

Error Check Field: 2 byte Cyclical Redundancy Check (CRC)

Framing: 1 start bit

Data Transmission speed is selectable between 2400, 4800, 9600 and 19200 baud.

tm

tm

network. If background

tm

Protocol”, available on our CD catalogue or from any recognised

tm

RTU slave protocol. The Modb ustm protocol establishes the

tm

protocol. It contains fields confirming the action taken, any data to be

Floating point format ( to IEEE 754)

Most significant register first (Default). The default may be changed if required See Holding Reg ister "Register Order " parameter.

8 data bits, least significant bit sent first

1 bit for even/odd parity or no parity

1 stop bit if parity is used; 1 or 2 bits if no parity

4 Integra Comms Issue 1 Jan 2006

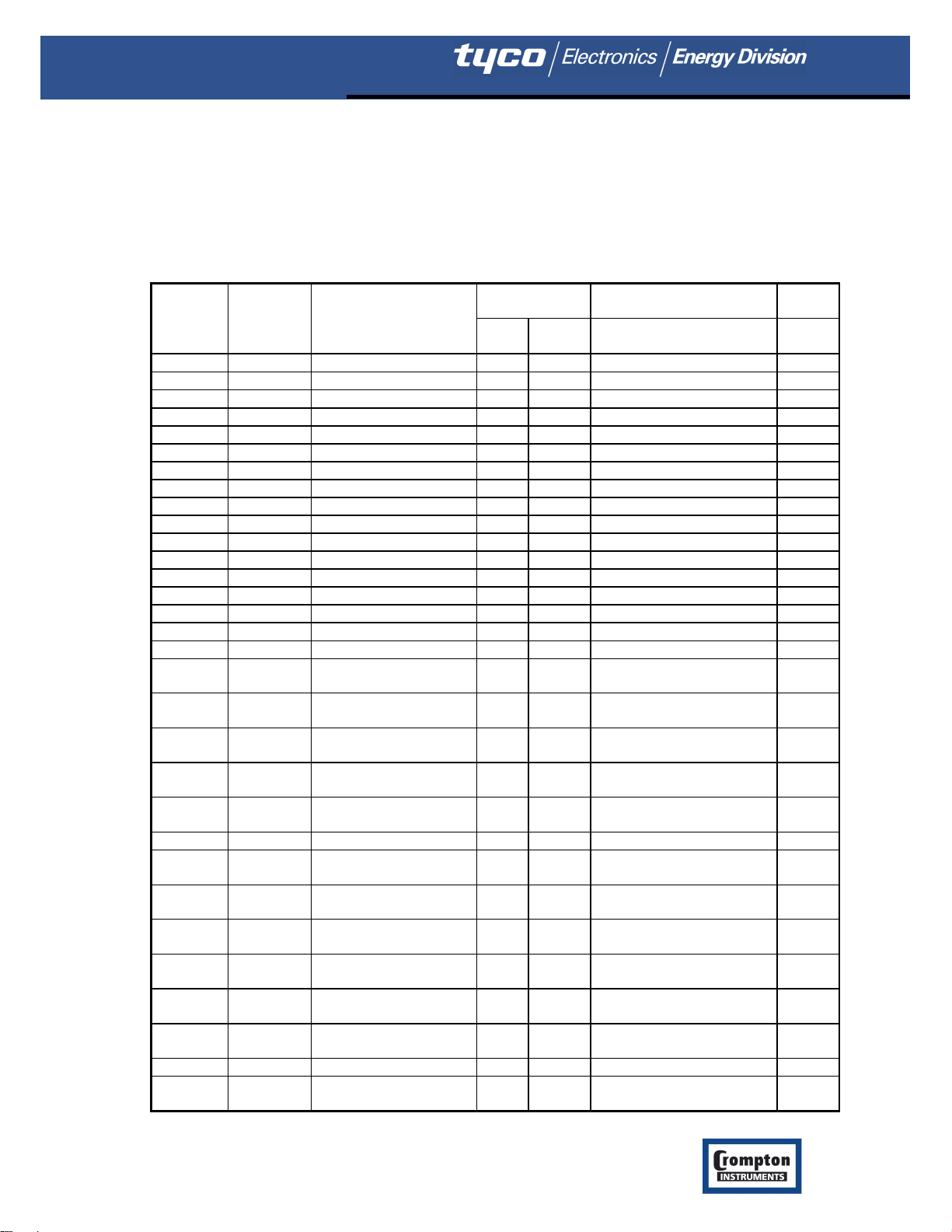

1.2 Input Registers

Input register s are used to indicate the present values of the measured an d calculated electrical

quantities.

Each parameter is held in two consecutive 16 bit registers. The following table details the 3X re gister

address, and the va lues of the address bytes within the message. A tick (√) in the column indicates that

the parameter is valid for the particular wiring system. Any parameter with a cross (X) will return the value

Zero.

Each parameter is held in the 3X registers. Modbus

.

For example, to request: Amps 1 Start address = 0006

No of registers = 0002

Amps 2 Start address = 0008

No of registers = 0002

Each request for data must be restricted to 40 parameters or less. Exceedi ng the 40 parameter limit will

cause a Modbus

tm

exception code to be returned.

tm

Function Code 04 is used to access all para meters

Integra Comms Issue 1 Jan 2006 5

–

00

02 X

–

00

04 X X

00

06

00

08 X

00

0A X X

00

0C

00

0E X X

00

10

X

00

12

00

14 X X

00

16

X

00

18

00

1A X X

00

1C

X

00

1E

00

20 X X

00

22

X

00

24

00

26 X X

00

28

X

00

2A

00

2E

00

30

00

34

00

38

00

3C

00

3E

00

42

00

46

00

48

00

4A

v

a

00

4C

00

4E

00

50

00

54

00

56

00

68

00

6A

00

C8 X X

00

CA

X

00

CC

X

00

CE X X

00

E0

00

EA

00

EC X

00

EE X X

00

F0

00

F2 X

00

F4 X X

00

F8

00

FA

-

C

00

FE

Address

(Register)

Parameter

Number

Parameter

Modbus

Address Hex

High Byte

tm

Start

Low Byte

3 Ø 3 Ø 1 Ø 1 Ø

4 W 3 W 3 W 2 W

30003 2 Volts 2 (L2 – N 4W or L2

30005 3 Volts 3 (L3 – N 4W or L3

30007 4 Current 1

30009 5 Current 2

30011 6 Current 3

30013 7 W Phase 1

30015 8 W Phase 2

30017 9 W Phase 3

30019 10 VA Phase 1

30021 11 VA Phase 2

30023 12 VA Phase 3

30025 13 var Phase 1

30027 14 var Phase 2

30029 15 var Phase 3

30031 16 Power Factor Phase 1

30033 17 Power Factor Phase 2

30035 18 Power Factor Phase 3

30037 19 Phase Angle Phase 1

30039 20 Phase Angle Phase 2

30041 21 Phase Angle Phase 3

30043 22 Volts Ave

30047 24 Current Ave

30049 25 Current Sum

30053 27 Watts Sum

30057 29 VA Sum

30061 31 var Sum

30063 32 Power Factor Ave

30067 34 Average Phase Angle

30071 36 Frequency

30073 37 Wh Import

30075 38 Wh Export

30077 39

30079 40 varh Export

30081 41 VAh

30085 43 W Demand Import

30087 44 W Max. Demand Import

30105 53 A Demand

30107 54 A Max. Demand

30201 101 V L1-L2

30203 102 V L2-L3

30205 103 V L3-L1

30207 104 Average Line t o Line Volts

30225 113 Neutral Current

30235 118 THD Volts 1

30237 119 THD Volts 2

30239 120 THD Volts 3

30241 121 THD Current 1

30243 122 THD Current 2

30245 123 THD Current 3

30249 125 THD Voltage Mean

30251 126 THD Current Mean

30255 128 Power Factor (+Ind/

rh Import

L3 3W)

L1 3W)

X

X X

X

X X

X

X X

X

X X

X

X X

X X

X X

X

ap)

6 Integra Comms Issue 1 Jan 2006

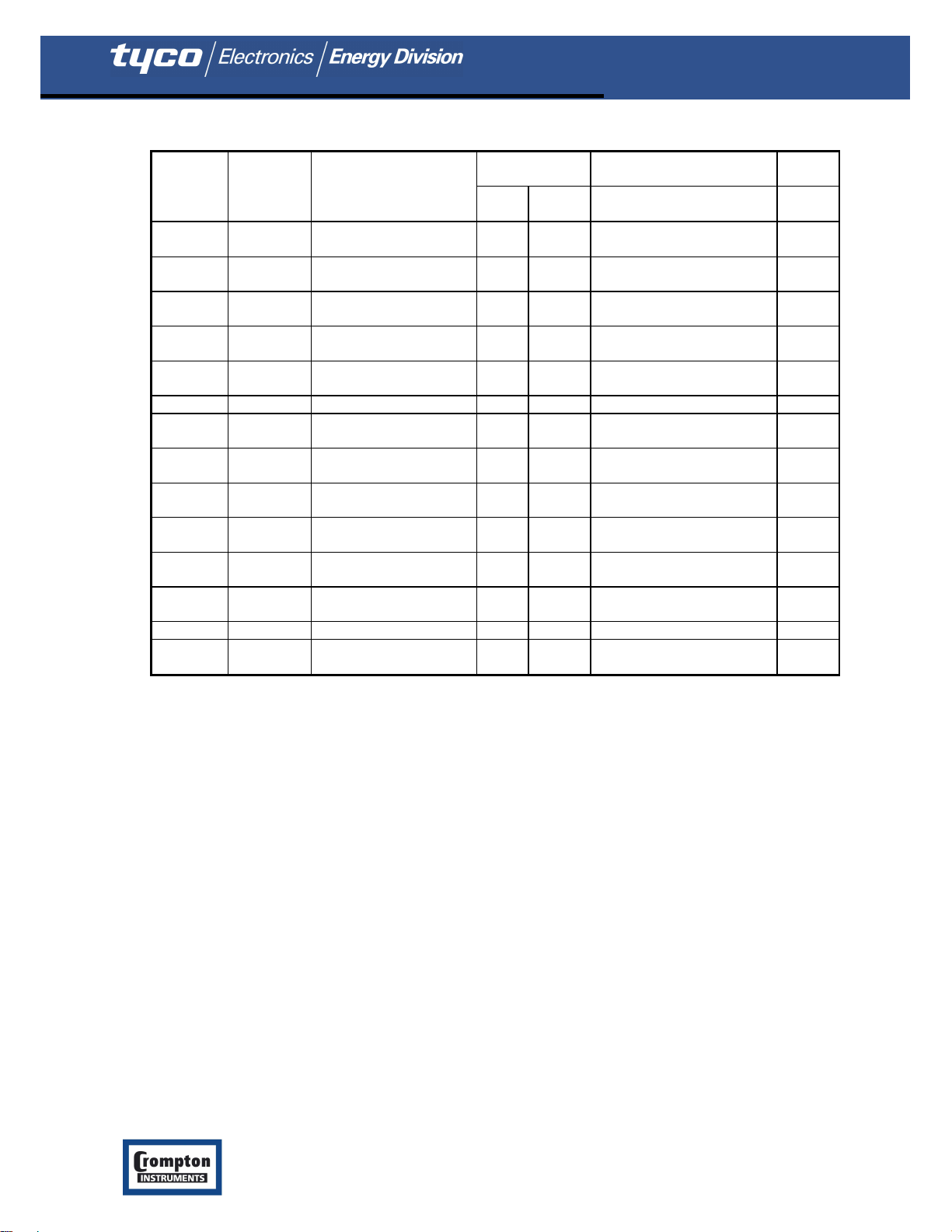

1.3 Modbustm Holding Registers and Integra set up

Holding regis ters are used to store and display instrument configuration settings. All holding registers not

listed in the ta ble below should be considered as reserved for manufacturer use and no attempt should be

made to modify their values.

The holding register parameters may be viewed or changed using the Modbus

parameter is held in the 4X registers. Modbus

Function Code 16 is used to write.

Address

(Register)

Parameter

Number

Parameter

tm

Function Code 03 is used to rea d the para m et er and

Modbus

Address Hex

High

Byte

tm

Start

Low

Byte

Valid range

40001 1 Demand Time 00 00 Write: 0 but see * below r/w

40003 2 Demand Period 00 02 8,15,20,30, 60 minutes. r/w

40007 4 System Voltage 00 06 1V - 400kV r/wp

40009 5 System Current 00 08 1-9999 A r/wp

40011 6 System Type 00 0A See below for values r/wp

40013 7 Relay Pulse Width 00 0C 3,5, 10 (x20mS) r/w

40015 8 Energy Reset 00 0E 0 only wo

40019 10 RS485 set-up code 00 12 See table below r/ w

40021 11 Node Address 00 14 1-247 r/w

40023 12 Pulse Divisor 00 16 1,10,100,1000 r/w

40025 13 Password 00 18 0000-9999 r/w

40037 19 System Power 00 24 ro

40041 21 Register Order 00 28 2141.0 only R/w

40299 150 Secondary Volts 01 2A Min Vin-Max Vin r/wp

40307 154 Max Energy Co unt 01 32 6,7,8 digits r/wp

40309 155 Analogue Hardware Max 01 34 ro

40311 156 Analogue Hardware Min 01 36 ro

40313 157

40315 158

40317 159

40319 160

40321 161

Analogue 1 Out put

Parameter

Analogue 1 Parameter

Max

Analogue 1 Parameter

Min

Analogue 1 Reading

Top

Analogue 1 Reading

Bottom

01 38

01 3A ro

01 3C ro

01 3E Analogue 1 Parameter Max r/wp

01 40 Analogue 1 Parameter Min r/wp

See table below

(section1.4)

40323 162 Analogue 1 Output Top 01 42 Analogue Hardware Max r/wp

40325 163

40329 165

40331 166

40333 167

40335 168

40337 169

Analogue 1 Out put

Bottom

Analogue 2 Out put

Parameter

Analogue 2 Parameter

Max

Analogue 2 Par ameter

Min

Analogue 2 Reading

Top

Analogue 2 Reading

Bottom

01 44 Analogue Hardware Min r/wp

01 48

See table below

(section1.4)

01 4A ro

01 4C ro

01 4E Analogue 2 Parameter Max r/wp

01 50 Analogue 2 Parameter Min r/wp

40339 170 Analogue 2 Output Top 01 52 Analogue Hardware Max r/wp

40341 171

Analogue 2 Out put

Bottom

01 54 Analogue Hardware Min r/wp

tm

protocol. Each

Mode

r/wp

r/wp

Integra Comms Issue 1 Jan 2006 7

Modbustm Start

Address

(Register)

40345 173

40347 174

40349 175

40351 176

40353 177

40355 178 Analogue 3 Output Top 01 62 Analogue Hardware Max r/wp

40357 179

40361 181

40363 182

40363 182

40361 181

40361 181

40361 181 Analogue 4 Output Top 01 68 Analogue Hardware Max r/wp

40361 181

r/w = read/write r/wp = read and write with password clearance ro = read only wo = write onl y

Some registers marked wo above may in fact be read, but the value returned is not valuable.

It is perfectly feasible to change Integra set-up using a general purpose Modbus

easier to use the Integra disp lay or Integra configurator software. The Integra configurator software has

facilities to store configurations to disk for later retrieval and rapid set up of similarly configur ed products.

Password Settings marked r/wp require the instrument password to have been entered into the

Password register before changes will be accepte d. Once the instrumen t configuration has been

modified, the password should be written to the pa ssword register again to protect the configuration from

unauthorised or accidental cha nge. Power cycling also restores prot ection. Reading the Password

register retur ns 1 if the instrument is unprotected and 0 if it is protected from changes.

* Demand Time

accomplish this. Writing any other value will cause an error to be retu r ned. Reading this register after

instrument restart or resetting demand period gives the number of minutes of demand data up to a

maximum of the demand period setting. For example, with 15 minute demand period, from reset the

value will increment from zero every mi nute until it reaches 15. It will remain at this value until a

subsequent reset occurs.

Demand Period

Writing any other value will caus e an error to be returned.

System Voltage in a PT/VT connected system represents the PT/VT primary voltage. In a direct

connected (i.e. no PT.VT) system this param eter should be set the same as secondary volts.

System Current

Parameter

Number

Analogue 3 Out put

Parameter

Analogue 3 Parameter

Max

Analogue 3 Parameter

Min

Analogue 3 Reading

Top

Analogue 3 Reading

Bottom

Analogue 3 Out put

Bottom

Analogue 4 Out put

Parameter

Analogue 4 Parameter

Max

Analogue 4 Parameter

Min

Analogue 4 Reading

Top

Analogue 4 Reading

Bottom

Analogue 4 Out put

Bottom 01 68 Analogue Hardware Min r/wp

is used to reset the demand period. A va lue of zero must be wr itten to this register to

represents demand time in m inutes. The value written must be one of 8,15, 20 or 30,.

is the CT primary current.

Parameter

Address Hex

High

Byte

01

01

01

01

01

01

01

01

01

01

01

Low

Byte

58

60 ro

62 ro

64 Analogue 3 Parameter Max r/wp

60 Analogue 3 Parameter Min r/wp

64 Analogue Hardware Min r/wp

68

70 ro

70 ro

68 Analogue 4 Parameter Max r/wp

68 Analogue 4 Parameter Min r/wp

Valid range

See table below

(section1.4)

See table below

(section1.4) r/wp

tm

master, but oft en

Mode

r/wp

8 Integra Comms Issue 1 Jan 2006

System Type

single phase 3 wire.

Relay Pulse Width

ms), 5 (100 ms) or 10 (200 ms) are supported. Writing any other value will cause an error to be returned.

Reset Energy is used to reset the Energy readings. A value of zero must be written to this register to

accomplish this. Writing any other value will cause an error to be retur ned.

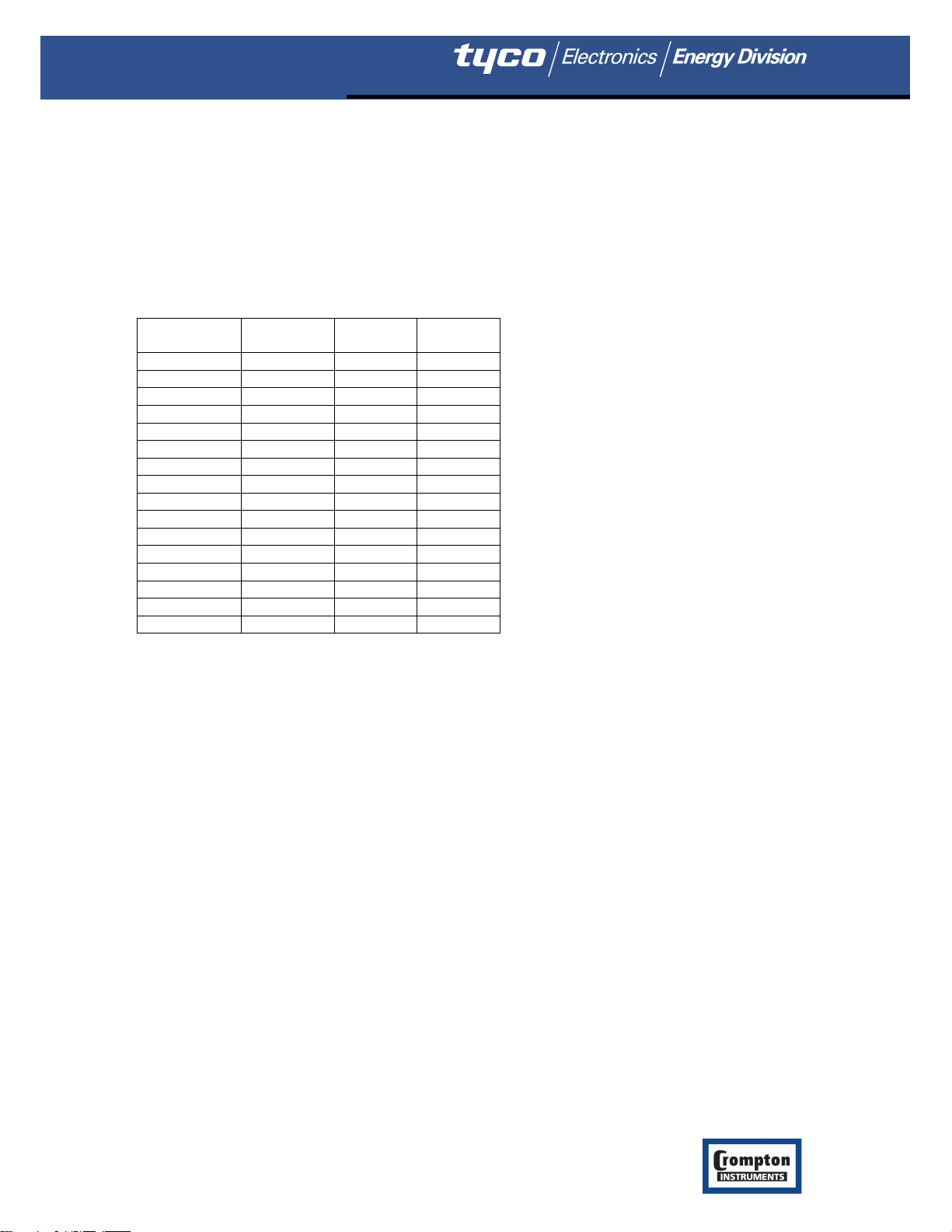

RS485 Set-Up Code

Baud Rate Parity Stop Bits Decimal

19200 NONE 2 30

19200 NONE 1 14

19200 ODD 1 13

19200 EVEN 1 12

9600 NONE 2 26

9600 NONE 1 10

9600 ODD 1 9

9600 EVEN 1 8

4800 NONE 2 22

4800 NONE 1 6

4800 ODD 1 5

4800 EVEN 1 4

2400 NONE 2 18

2400 NONE 1 2

2400 ODD 1 1

2400 EVEN 1 0

Codes not listed in the table above may give rise to unpredi ctable results inc luding loss of

communication. Exercise caution when attempting to change mode via direct Modbus

display or the Integra configurator software is recommended.

Node Address

can be set.

Pulse Rate Divi s or supports only values o f 1,10,100 or 1000. Writing any other value will c ause an error

to be returned.

System Power

system current.

Register Order

or reversed register order. In normal mode, the two registers that make up a floating point number are

sent most signifi cant bytes first. In reversed register mode, the two registers that make up a floating point

number are sent least significant bytes first. To set the mode, write the value '2141.0' into this register the instrument will detect the or der used to send this value and set that order for all Modbus

transactions involving floating point numbers.

Secondary Volts

the value of System Volts . The value of this register c an be set to between the minimum and max i mum

instrument input voltage.

Maximum Energy Count

before they roll over (i.e. resets to zero). The values of 6, 7 or 8 can be written to thi s register to indicate

the number of digits to use. Other values will be rejected.

Analogue Hardware Minimum

is set to '1' fo r single phase 2 wire, '2' for 3 Phase 3 Wire, '3' for 3 Phase 4 Wire or 4 for

is the width of the relay pulse in multip les of 20 ms. However, only values of 3 (60

Value

tm

writes. Use of a

is the Modbus

tm

or JC N2 slave addr ess for the instrument. Any value between 1 and 247

is the maximum system power based on the values of system type, system volts and

controls the order in which the Integra receives or sends floating-point numbers: - normal

tm

indicates the voltage on the VT secondary when the vo ltage on the Primary is equal to

controls the number of digits the energy (kWh and kvarh) counters can use

Analogue Hardware Maximum

and

indicate res pectively the minimum

Integra Comms Issue 1 Jan 2006 9

and maximum outp ut currents that the instrument analogue output hardware is capable of.

Analogue 1 Output Parameter indicates the number o f the input parameter that is to be ou tput on

analogue output 1. A value of zero signifies the analogue output is unused.

Analogue 1 Parameter Maximum

Analogue 1 Parameter Minimum

Analogue 1 Reading Top

can range between Parameter Minimum and Parameter Maximum.

Analogue 1 Reading Bottom

value can range between Parameter Minimum and Parameter Maximum.

Analogue 1 Output Top

reading reaches Reading Top. The value of Output Top must be between Analogue Hardware Minimum

and Analogue Hardware Maximum.

Analogue 1 Output Bottom

parameter reading reaches Reading Bottom. The value of Outpu t Bottom must be between Analogu e

Hardware Minimum and Analogue Hardw are Maximum.

Analogue 2, 3 and 4

to the relevant analogue channel. Analogue 3 and 4 are only relevant for the 1560/1580. Consult the

1560/80 manual for det ails of auto conf ig ure oper at ion , w hich in some cir cumstances overrides user

settings.

Note: Analogue Hardwar e Maximum and M inimum refer to the fact ory build hard ware limits. It is the

same for all analogue channels on a particular instrument.

represents the upper limit of the parameter value that will be output. This value

represents the analogue output level that will be achieved when the parameter

set up values function in the same way as Analogue 1, except of course, they refer

is the maximum value that the selected input parameter c an r each.

is the minimum value that the selected input parameter can r each.

represents the lower limit of the parameter value that will be outp ut. This

represents the analog ue outp ut level th at will be ac hieve d when the

10 Integra Comms Issue 1 Jan 2006

Loading...

Loading...