Page 1

V1000

V1000

V1000

V1000

INVERTER SERIES

V1000

E N

DE

ES

FR

IT

Page 2

2

YASKAWA V1000

Content

Contents

V1000

YASKAWA INVERTER DRIVE TECHNOLOGY

Page 2

Experience & Innovation

A leader in Inverter Drives

technology

V1000 – Easy and cost-saving

handling through all kinds of

applications

Page 3

”One for all“ –

Multiple Applications

Page 4/5

Specifications

Page 6

Connection Diagram

Page 7

Content

V1000 Dimensions

Experience & Innovation

For more than 90 years YASKAWA has

been manufacturing and supplying

mechatronic products for machine

building and industrial automation. Its

standard products as well as tailor-made

solutions are famous and have a high

reputation for outstanding quality and

durability.

A leader in Inverter Drives

technology

Extensive research and development has

allowed YASKAWA to remain at the forefront

of motion control and automation technology. This technological leadership has helped

to modernise industries such as mining,

steel, pulp and paper, chemical, automotive,

packaging, machine tool and semiconductor.

focuses on all aspects of application,

installation, operation and maintenance.

Safety Integrated

YASKAWA V1000 is one of the first general

purpose compact drives with built-in two

channel hardware base block input. It already

meets international safety standards and

thereby supports machine builder to apply

to international machine directives.

Finless Type

YASKAWA has as one of the first

manufacturers promoted the development

of finless type inverters for the European

and international markets. Consequently the

V1000 is available as finless version for

applications with an external cooling system.

YASKAWA V1000 Features

Page 8

V1000 Finless Version

Dimensions

Page 9

V1000 IP66 Dimensions

Page 10

Options

Page 11

Ratings & Type Descriptions

incl. finnless

In 2007 YASKAWA produced its 10 millionth

inverter in the new inverter plant in

Yukuhashi, Japan. By this YASKAWA is

probably the biggest inverter manufacturer in

the world.

The 10 millionth inverter was a V1000, the

latest inverter developed by YASKAWA.

Awarded by IEN magazine as being the

‘most innovative product 2007’ at Hanover

Fair Industry 2007 the V1000 has raised the

bar in the market in terms of usability and

reliability.

V1000 – Easy and cost-saving

handling through all kinds of

applications

This powerful little helper sets standards

in terms of user friendliness and process

orientation. The development of the V1000

Dual Safety Input, safety category 3

(EN954-1) and stop category 0

(EN60204-1) and IEC-61508 SIL2

In normal duty (120% overload) one

frame size larger motor can be driven

Standard AC Motor and PM motor control

V/f and open-loop current

vector control

One of the smallest inverter drives

in the world

Side-by-side mounting

Icon-based programming

Designed for 10 years of

maintenance-free operation

Page 3

3

“One for all” – Multiple Applications

YASKAWA V1000 is a general purpose inverter drive covering the demands of a wide field of applications.

Simple duties as well as requirements of complex systems need a higher level of functionality, reliability and easy handling,

which are provided by the V1000.

For energy saving, permanent magnet motor control is possible

Selectable control method: open-loop current vector or V/f

Small Design – Big Power: 150% overload in heavy duty service is possible. For applications with low overload

requirements the drive can be operated with 120% overload in normal duty service. Consequently you can use a drive of

smaller size to do the work of a bigger one.

Worldwide specification CE, UL, cUL, RoHS (TÜV safety approved)

High flux braking reduces braking time to the half

Easy Installation

YASKAWA V1000 reduces installation time and costs. Installable in tight

spaces it requires a minimum of set-up time and provides you all the

comfort of a modern up-to-date inverter drive.

One of the smallest inverter drives in the world saves mounting

space and cost by side-by-side mounting

Application parameter pre-settings shorten set-up time

Same handling and parameter structure for all YASKAWA inverters

DriveWorksEZ visual programming tool. Simply drag and drop icons

to customize your drive. Create special sequences and detection

functions, then load them onto the drive.

Quick Maintenance

YASKAWA V1000 is an inverter drive which adapts to user demands and provides

maintenance functions that ensure quick replacement and minimize down time.

Removable terminal board with parameter memory for quick and easy maintanance

Screwless control terminal saves setup time

Reliable Operation

The V1000 continues the tradition of YASKAWA by being the reliable

link in your production chain.

Designed for Long Performance Life (10 years 24 h per day at 80%

nominal load.)

Quick response on load and speed changes improves your

machine performance

Online Auto-Tuning to optimise for improved motor performance at

low speed

Optional external 24 VDC-supply assures communication and data

flow in any power-down situation

Dual safety input: safety category 3 (EN954-1), stop category 0 and

IEC-61508 SIL2

Page 4

4

YASKAWA V1000

Specifications

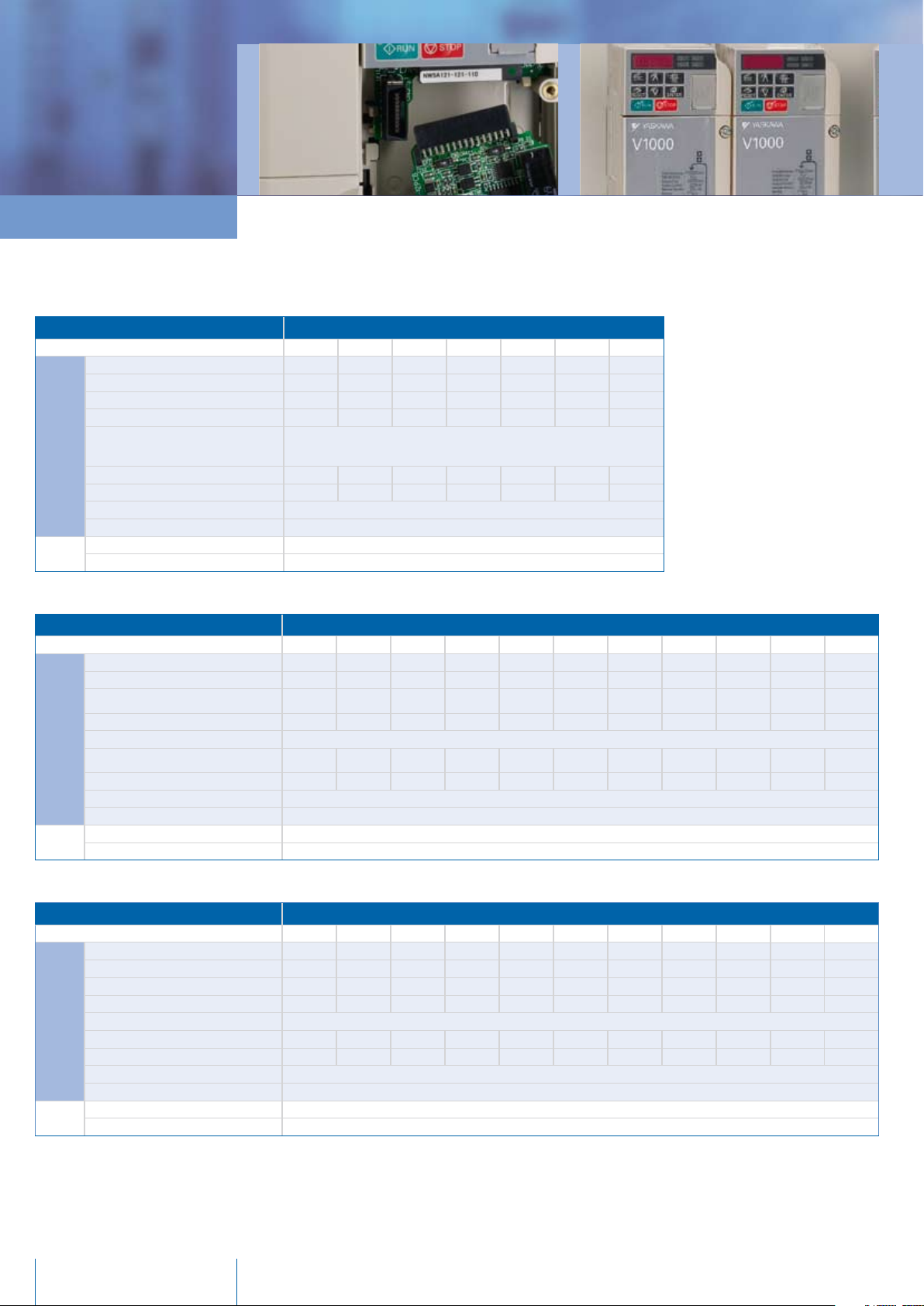

Voltage class Single-phase 200 V

Inverter model CIMR-VCBA*

Motor output kW at normal duty*

Motor output kW at heavy duty *

Rated output current at normal duty [A]*

Rated output current at heavy duty [A] 0.8*

Overload

Rated output power at normal duty [kVA]* 0.5 0.7 1.3 2.3 3.7 4.6 -

Inverter output

Rated output power at heavy duty [kVA]* 0.3 0.6 1.1 1.9 3.0 4.2 6.7

Max. output voltage Three-phase 200 to 240 V (proportional to input voltage)

Max. output frequency 400 Hz

Inverter

* based on input voltage 220 V

Inverter

* based on input voltage 220V

Rated input voltage Single-phase 200 to 240 V, -15% to +10%

input

Rated input frequency 50/60 Hz, ±5%

Voltage class Three-phase 200 V

Inverter model CIMR-VC2A 0001 0002 0004 0006 0010 0012 0020 0030 0040 0056 0069

Motor output kW at normal duty*

Motor output kW at heavy duty*

Rated output current at normal duty [A]*

Rated output current at heavy duty [A] 0.8*

Overload 120% for 60 sec at normal duty, 150% for 60 sec at heavy duty from inverter rated output current

Rated output power at normal duty [kVA]* 0.5 0.7 1.3 2.3 3.7 4.6 7.5 11.4 15.2 21.3 26.3

Inverter output

Rated output power at heavy duty [kVA]* 0.3 0.6 1.1 1.9 3.0 4.2 6.7 9.5 12.6 17.9 22.9

Max. output voltage Three-phase 200 to 240 V (proportional to input voltage)

Max. output frequency 400 Hz

Rated input voltage Three-phase 200 to 240 V, -15% to +10%

input

Rated input frequency 50/60 Hz, ±5%

1

2

2

0001 0002 0003 0006 0010 0012 00018*

0.18 0.37 0.75 1.1 2.2 3.0 –

0.1 0.18 0.55 0.75 1.5 2.2 4.0

3

1.2 1.9 3.3 6 9.6 12 –

4

1.6*

4

3.0*

4

5.0*

4

8.0*

5

11.0*517.5*

6

5

125% for 60 sec normal duty, 150 % for 60 sec

at heavy duty from inverter rated output current

2

2

0.18 0.37 0.75 1.1 2.2 3.0 5.5 7.5 11.0 15.0 18.5

0.1 0.2 0.4 0.75 1.5 2.2 4.0 5.5 7.5 11.0 15.0

3

1.2 1.9 3.5 6.0 9.6 12.0 19.6 30.0 40.0 56.0 69.0

4

1.6*

4

3.0*

4

5.0*

4

8.0*

5

11.0*517.5*525.0*533.0*547.0*560.0*

5

Voltage class Three-phase 400 V

Inverter model CIMR-VC4A 0001 0002 0004 0005 0007 0009 0011 0018 0023 0031 0038

Motor output kW at normal duty*

Motor output kW at heavy duty*

Rated output current at normal duty [A]*

Rated output current at heavy duty [A]*

2

2

0.37 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15.0 18.5

0.18 0.37 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11.0 15.0

3

1.2 2.1 4.1 5.4 6.9 8.8 11.1 17.5 23.0 31.0 38.0

5

1.2 1.8 3.4 4.8 5.5 7.2 9.2 14.8 18.0 24.0 31.0

Overload 120% for 60 sec at normal duty, 150% for 60 sec at heavy duty from inverter rated output current

Rated output power at normal duty [kVA]* 0.9 1.6 3.1 4.1 5.3 6.7 8.5 13.3 17.5 23.6 29.0

Inverter output

Rated output power at heavy duty [kVA]* 0.9 1.4 2.6 3.7 4.2 5.5 7.0 11.3 13.7 18.3 23.6

Max. output voltage Three-phase 380 to 480 V (proportional to input voltage)

Max. output frequency 400 Hz

Inverter

* based on input voltage 400 V

*1 Drives with a single-phase power supply input have three-phase output. Single-phase motors cannot be used.

*2 The motor capacity (kW) refers to a YASKAWA 4-pole, 60 Hz, 200 V motor. The rated output current of the drive output amps should be equal to or greater than the motor rated current.

*3 at 2 kHz carrier frequency without derating

*4 at 10 kHz carrier frequency without derating

*5 at 8 kHz carrier frequency without derating

*6 only heavy duty available

Rated input voltage Three-phase 380 to 480 V, -15% to +10%

input

Rated input frequency 50/60 Hz, ±5%

Page 5

5

Rotational Auto-Tuning must be performed to achieve the performance described with Open Loop Vector Control.

Specifications

Control methods Open Loop Vector Control (Current Vector), V/f Control, PM Open Loop Vector Control (for SPM and IPM motors)

Frequency Control Range 0.01 to 400 Hz

Frequency Accuracy

(Temperature Fluctuation)

Frequency Setting

Resolution

Output Frequency

Resolution

Frequency Setting

Resolution

Starting Torque

Digital input: within ±0.01% of the max. output frequency (-10°C to +50°C))

Analog input: within ±0.1% of the max. output frequency (25°C ±10°C)

Digital input: 0.01 Hz

Analog input: 1/1000 of max. frequency

20 bit of maximum output frequency (parameter E1-04 setting)

Main frequency reference: 0..10 V (20 kΩ) 10 bit, 4..20 mA (250 Ω) or 0..20 mA (250 Ω) 9-bit

Main speed reference : Pulse Train Input (max. 32 kHz)

200% / 0.5 Hz (assumes Heavy Duty rating AC Motor of 3.7 kW or less using Open Loop Vector Control),

50% / 6 Hz (assumes PM Open Loop Vector Control)

Speed Control Range 1:100 (Open Loop Vector Control), 1:20 to 40 (V/f Control), 1:10 (PM Open Loop Vector Control)

Speed Control Accuracy ±0.2% in Open Loop Vector Control (25°C ±10°C) *

Speed Response 5 Hz in Open Loop Vector (25°C ±10°C) (requires Rotational Auto-Tuning)

Control Functions

1

Torque Limit Open Loop Vector Control allows separate settings in four quadrants

Accel/Decel Time 0.0 to 6000.0 s (4 selectable combinations of independent acceleration and deceleration settings)

2

: over 150% for 0.1/0.2 kW motors, over 100% for 0.4/ 0.75 kW motors, over 50% for 1.5 kW motors, and over 20% for

2.2 kW and above motors (overexcitation braking/High-Slip Braking: approx. 40%)

3

: 10% ED, 10 s, internal braking transistor)

Braking Torque

q Short-time decel torque*

w Continuous regen. torque: approx. 20% (approx. 125% with dynamic braking resistor option*

V/f Characteristics User-selected programs, V/f preset patterns possible

Momentary power loss ride-thru, Speed search, Overtorque detection, Torque limit, 17-step speed (max), Accel/decel time switch, S-curve accel/decel,

Main Control

Functions

3-wire sequence, Auto-tuning (rotational, stationary tuning for resistance between lines), Dwell, Cooling fan on/off switch, Slip compensation, Torque

compensation, Frequency jump, Upper/lower limits for frequency reference, DC injection braking at start and stop, Overexcitation braking, High slip

braking, PID control (with sleep function), Energy saving control, MEMOBUS comm. (RS-485/422 max, 115.2 kbps), Fault restart, Application presets,

DriveWorksEZ (customized function), Removable terminal block with parameter backup function...

Motor Protection Motor overheat protection based on output current

Momentary Overcurrent Protection Drive stops when output current exceeds 200% of Heavy Duty Rating

Overload Protection Drive stops after 60 s at 150% of rated output current (Heavy Duty Rating)*

Overvoltage Protection

Undervoltage Protection

200 V class: Stops when DC bus exceeds approx. 410 V

400 V class: Stops when DC bus exceeds approx. 820 V

Stops when DC bus voltage falls below the following levels:

Three-phase 200 V class: approx. 190 V, single-phase 200 V class: approx. 160 V, three-phase 400 V class: approx. 380 V, three-phase 380 V class:

approx. 350 V

4

Momentary Power Loss Ride-Thru Stops after approx. 15 ms (default). Parameter settings allow the drive to continue running if power loss lasts for up to approx. 2 s *

Heatsink Overheat Protection Protection by thermistor

Protection Function

Braking Resistance Overheat

Protection

Overheat sensor for braking resistor (optional ERF-type, 3% ED)

Stall Prevention Separate settings allowed during acceleration, and during run. Enable/disable only during deceleration.

Ground Fault Protection Protection by electronic circuit *

6

Charge LED Charge LED remains lit until DC bus has fallen below approx. 50 V

Area of Use Indoors

Ambient Temperature -10°C to +50°C (open chassis), -10°C to +40°C (NEMA Type 1)

Humidity 95 RH% or less (no condensation)

Storage Temperature -20°C to +60°C (short-term temperature during transportation)

Altitude Max. 1000 m (output derating of 1% per 100 m above 1000 m, max. 3000 m)

Shock 10 to less than 20 Hz (9.8 m/s2) max., 20 to 55 Hz (5.9 m/s2) max.

Operating Environment

Safety Standard UL508C, EN954-1 Cat. 3, IEC/EN61508 SIL2

Protection Design IP20 open-chassis, NEMA Type 1 enclosure

*1 Speed control accuracy may vary slightly depending on installation conditions or motor used.

*2 Momentary average deceleration torque refers to the deceleration torque from 60Hz down to 0 Hz. This may vary depending on the motor.

*3 If L3-04 is enabled when using a braking resistor or braking resistor unit, the motor may not stop within the specifi ed deceleration time.

*4 Overload protection may be triggered at lower levels if output frequency is below 6 Hz.

*5 Varies by drive capacity. Drives smaller than 7.5 kW (CIMR-VA2A0004/CIMR-VA4A0023) require a separate Momentary Power Loss Recovery Unit to continue operating during a momentary power loss of 2 s.

*6 Protection may not be provided under the following conditions as the motor windings are grounded internally during run:

• Low resistance to ground from the motor cable or terminal block.

• Drive already has a short-circuit when the power is turned on.

5

Page 6

6

YASKAWA V1000

Connection Diagram

Power

Supply

Fuses

Main

Switch

Multi-function

digital inputs (default

setting)

Filter

Forward / Stop

Reverse / Stop

External fault

Fault reset

Multi-speed step 1

Multi-speed step 2

DC reactor

(option)

Link

DIP

switch S3

Shield ground

terminal

Pulse Input

(max. 32 kHz)

Analog input power supply

+10.5 max. 20 mA

Multi-function analog input 1

0 to +10 V (20 kΩ)

Multi-function analog input 2

0 to +10 V (20 kΩ)

0/4 to 20 m A (250 Ω)

Thermal

SINK

SOURCE

t

relay

Braking resistor

(option)

Shielded

Cable

Ground

Fault

During run

Frequency agree

Photocoupler

output common

Pulse train output

(max. 32 kHz)

(Output frequency)

Analog output

0 to +10 VDC (2 mA)

(Output frequency)

Multi-function relay output

250 VAC / 30 VDC (10 mA to 1 A)

(default setting)

Multi-function photocouplee output

48 Vdc, 2 to 50 mA

(default setting)

Monitor outputs

(default setting)

Multi-function pulse / analog inputs

(default: frequency reference)

Use twisted pair cables.

Use shielded twisted pair cables.

Indicates a main circuit terminal.

Indicates a control circuit terminal.

Safe Disable

inputs

Terminal resistance

(120 Ω, 1/2 W)

MEMOBUS comm.

RS-485/422

max. 115 kBps

Page 7

7

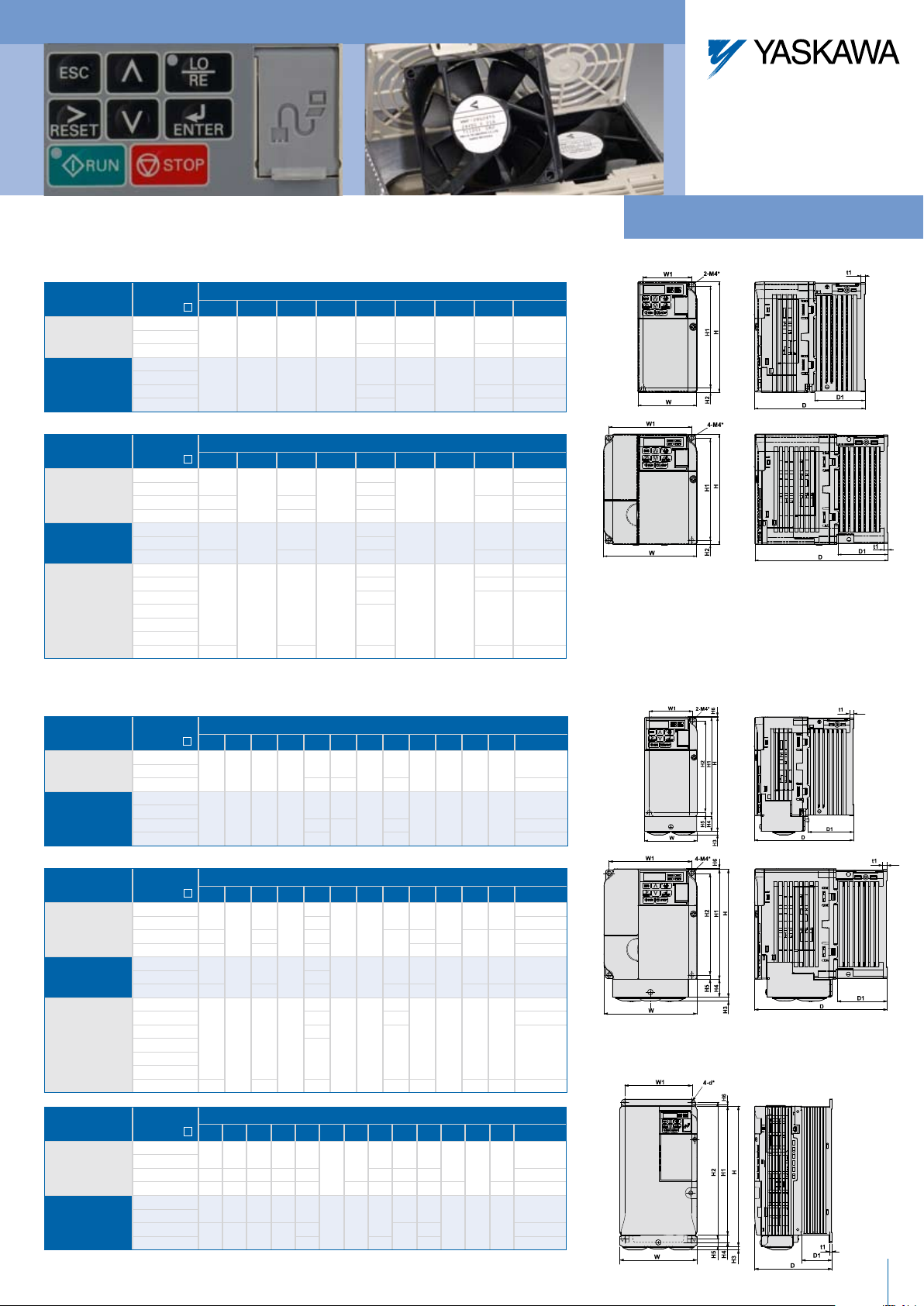

IP20/Open-Chassis (without an EMC filter)

V1000 Dimensions

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

Three-Phase

400 V Class

Drive Model

CIMR-VC

BA0001B

BA0002B

BA0003B 118 5 38.5 1.0

2A0001B

2A0002B

2A0004B 108

2A0006B 128 58.5 1.1

W1 H1 W H D t1 H2 D1

56 118 68 128

56 118 68 128

Drive Model

CIMR-VC

BA0006B

BA0010B 154 1.8

BA0012B 128 140 163

BA0018B 158 170 180 3.0

2A0010B

2A0012B 137.5

2A0020B 128 140 143 65 2.4

4A0001B

4A0002B 99 28 1.2

4A0004B 137.5

4A0005B

4A0009B

4A0011B 128 140 143 65 2.4

W1 H1 W H D t1 H2 D1

96

96

96

118

118

118

108

108

108

Dimensions in mm

76 3

76 3

Dimensions in mm

137.5

128

129

128

81

128

1544A0007B

IP20/NEMA Type 1 (without an EMC filter)

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

Drive Model

CIMR-VC

BA0001F

BA0002F

BA0003F 118 5 39 1.2

2A0001F

2A0002F

2A0004F 108

2A0006F 128 59 1.3

W1 H2 W H1 D t1 H5 D1 H H4 H3 H6

56 118 68 128

56 118 68 128

Dimensions in mm

76 3

76 3

5

6.5

5

6.5

5

Weight (kg)

6.5 0.6

5

6.5 0.6

5

5

38.5 0.9

Weight (kg)

1.7

5 5

5 5

5 5

58

2.4

65

58 1.7

10 1.0

58 1.7

Weight (kg)

149.5

20 4 1.5

149.5

39 1.1

20 4 1.5

0.8

0.8

* inner

diameter

for M4

screws

* inner diameter for M4 screws

* inner

diameter

for M4

screws

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

Three-Phase

400 V Class

Voltage Class

Three-Phase

200 V Class

Three-Phase

400 V Class

Drive Model

CIMR-VC

BA0006F

BA0010F 154 2.0

BA0012F 128 140 163

BA0018F 158 170 180 171 38 3.3

2A0010F

2A0012F

2A0020F 128 140 143 65 153 4.8 5 2.6

4A0001F

4A0002F 99 28 1.4

4A0004F

4A0005F

4A0009F

4A0011F 128 140 143 65 153 4.8 5 2.6

W1 H2 W H1 D t1 H5 D1 H H4 H3 H6

96

96

96

118

118

118

108

108

108

128

128

128

Drive Model

CIMR-VC

2A0030F

2A0040F

2A0056F 160 284 180 270 163 75 290 15 5.5

2A0069F 192 336 220 320 187 22 78 350 15 7 M6 9.2

4A0018F

4A0023F

4A0031F

4A0038F 163 75 13 5.5

W1 H2 W H1 D t1 H5 D1 H H4 H3 H6 d

122 248 140 234 140

122 248 140 234 140

160 284 180 270

Dimensions in mm

137.5

5 5

129

137.5

5 5

81

137.5

5 5

1544A0007F

Dimensions in mm

5

5 13

143

58

149.5

20

153

65

149.5

58

10

58 1.9

55 254 13

13

254 13

55

290

20

149.5

20

6

6 1.5 M5

15 5.2

Weight (kg)

4 1.5

4.8 5

4 1.5 1.9

4 1.5

Weight (kg)

M5

1.5

1.9

2.6

1.2

3.8

3.8

* inner diameter for M4 screws

* inner

diameter

for M5/M6

screws

Page 8

8

YASKAWA V1000

V1000 Finless Version Dimensions

… for Models BA0001~2A0006

Voltage Class

Single-Phase

200 V Class

Drive Model

CIMR-VC

W H D W1 H1 H2 t1

BA0001

BA0002

68 128

BA0003 81 0.8

2A0001

Three-Phase

200 V Class

2A0002

2A0004

68 128 71 56 118 5 3

2A0006

… for Models BA0006~4A0009

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

Three-Phase

400 V class

Drive Model

CIMR-VC

BA0006

BA0010 91

W H D W1 H1 H2 t1

108 128

2A0008

108 128

2A0012 79.5

4A0001

4A0002

4A0004 79.5

4A0005

108 128

4A0009

Dimensions in mm

71

Dimensions in mm

79.5

71

71

964A0007

Weight (kg)

56 118 5 3

0.6

0.6

0.7

Weight (kg)

96 118 5 4 1.1

96 118 5 4 1.02A0010

0.9

96 118 5 4

1.0

1.1

* inner

diameter

for M4

screws

* inner

diameter

for M4

screws

… for Models BA0012~4A0011

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

Three-Phase

400 V class

Drive Model

CIMR-VC

W H D W1 H1 H2 t1

BA0012 140 128 98 128 118 5 4 1.4

2A0018

2A0020

140 128 78 128 118 5 4 1.3

4A0011 140 128 78 128 118 5 4 1.3

… for Models 2A0030~4A0038

Voltage Class

Three-Phase

200 V Class

Three-Phase

400 V Class

Drive Model

CIMR-VC

2A0030

2A0040

W H D W1 H1 H2 H3 H4 H5 d t1

140 260 145 122 248 6 234 13

2A0056 180 300 147 160 284 8 270

2A0069 220 350 152 192 336 7 320 M6 7.0

4A0018

4A0023 3.2

4A0031

4A0038 4.6

140 260 145 122 248 6 234 13

180 300 147 160 284 8 270 15

Dimensions in mm

Dimensions in mm

15

M5

5

5 M5 5

Weight (kg)

Weight (kg)

5

3.2

4.6

3.1

4.3

* inner

diameter

for M4

screws

* inner

diameter

for M5/M6

screws

Page 9

9

V1000 IP66 Dimensions

H1

W1

H

H2

.

W

Ø

IP 66

V1 000

6.5

D

t1

Inverter model

CIMR-VC

W H D W1 H1 H2 t1

BA0001

BA0002

BA0003

BA0006

262 340 173.5 214 321 9 2

BA0010

BA0012

BA0018 under development

2A0001

2A0002

2A0004

2A0006

262 340 173.5 214 321 9 2

2A0010

2A0012

2A0020

2A0030

2A0040

2A0056

2A0069

4A0001

4A0002

4A0004

4A0005

262 340 173.5 214 321 9 2

4A0007

4A0009

4A0011

4A0018

4A0023

4A0031

4A0038

Data and Dimensions are preliminary and subject to be changed at any time.

Dimensions in mm

under development

under development

Page 10

10

YASKAWA V1000

Options

Name Purpose Model, Manufacturer

1-phase 200 V Filter:

CIMR-VCBA0001 FS23638-10-07

CIMR-VCBA0002 FS23638-10-07

CIMR-VCBA0003 FS23638-10-07

CIMR-VCBA0006 FS23638-20-07

CIMR-VCBA0010 FS23638-20-07

CIMR-VCBA0012 FS23638-30-07

CIMR-VCBA0018 FS23638-40-07

3-phase 200 V Filter:

CIMR-VC2A0001 FS23637-8-07

CIMR-VC2A0002 FS23637-8-07

CIMR-VC2A0004 FS23637-8-07

CIMR-VC2A0006 FS23637-8-07

CIMR-VC2A0010 FS23637-14-07

Input noise filter

Braking resistor Used to shorten the deceleration time by dissipating regenerative energy through a resistor (3% ED). ERF-150WJ series

24 V power supply

USB copy unit

(RJ-45/USB compatible plug)

Support tools (DriveWizard Plus)

cable

LCD operator

LCD operator extension cable Cable for connecting the LCD operator.

MECHATROLINK-2

Communication

interface

unit

Momentary power loss recovery unit Ensures continued drive operation for a power loss of up to 2 s.

Attachment for external heatsink

Screw-type terminal board Control terminal board with screw-type terminals. Available soon

Plus operator mounting kit

Note: contact the manufacturer in question for availability and specifications of non-YASKAWA products.

CC−link SI-C3/V

DeviceNet SI-N3/V

PROFIBUS−DP SI-P3/V

CANopen SI-S3/V

Reduces noise from the line that enters into the drive input power system.

Should be installed as close as possible to the drive.

Provides power supply for the control circuit and option boards. Note: Parameter settings cannot be

changed when the drive is operating solely from this power supply.

Adapter for connecting the drive to the USB port of a PC. (e.g. for Support Tool Drive Wizard Plus)

Can copy parameter settings to be later transferred to another drive.

Connects the drive to a PC for use with DriveWizard. WV103

For easier operation when using the optional LCD operator. Allows for remote operation. Includes a

Copy function for saving drive settings.

Allows control of the drive via a fieldbus network.

Mechanical kit to install the drive with the heatsink out of the cabinet.

Note: current derating must be considered when this installation method is used.

For the use with holes through the panel. 100-039-992

For the use with panel mounted threaded studs. 100-039-993

CIMR-VC2A0012 FS23637-14-07

CIMR-VC2A0020 FS23637-24-07

CIMR-VC2A0030 FS23637-52-07

CIMR-VC2A0040 FS23637-52-07

CIMR-VC2A0056 FS23637-68-07

CIMR-VC2A0069 FS23637-80-07

3-phase 400 V Filter:

CIMR-VC4A0001 FS23639-5-07

CIMR-VC4A0002 FS23639-5-07

CIMR-VC4A0004 FS23639-5-07

CIMR-VC4A0005 FS23639-10-07

CIMR-VC4A0007 FS23639-10-07

CIMR-VC4A0009 FS23639-10-07

CIMR-VC4A0011 FS23639-15-07

CIMR-VC4A0018 FS23639-30-07

CIMR-VC4A0023 FS23639-30-07

CIMR-VC4A0031 FS23639-50-07

CIMR-VC4A0038 FS23639-50-07

PS-V10S

PS-V10M

JVOP-181

JVOP-180

WV001: 1 m

WV003: 3 m

SI-T3/V

P0010 type (200 V class)

P0020 type (400 V class)

(Please contact your YASKAWA

representative)

Page 11

11

Ratings & Type Descriptions

CIMR- V C B A 0001 B A A

Inverter Series Revision

V1000 V 1st A

Specification Coating Specification and Protection

Japanese spec. A Standard A

Chinese spec. B Moisture (humidity)/Dust-proof M

European spec. C Oil-proof N

USA spec. U Salt-proof C

Asia spec. T Vibration-proof S

Input Voltage Oil and vibration-proof Q

Single-phase 200 VAC B Gas-proof + vibration-proof B

Three-phase 200 VAC 2 Oil-proof double coating D

Three-phase 400 VAC 4 Moisture double coating E

Customer Specification Enclosure

Standard A Fin Filter Protection level

Standard No IP00 A

Standard No IP20 without top cover B

Standard No IP20 with top cover C

Standard No NEMA 1 (IP20) F

Gas-proof K

Moisture/Dust and vibration-proof P

Built in

No No Finless (IP20) J

IP66 H

Single-phase 200 VAC

0001 1.2 A 0.18 kW 0.8 A 0.1 kW

Rated output current Max. applicable motor Rated output current Max. applicable motor

0002 1.9 A 0.37 kW 1.6 A 0.18 kW

0003 3.3 A 0.75 kW 3.0 A 0.55 kW

0006 6.0 A 1.1 kW 5.0 A 0.75 kW

0010 9.6 A 2.2 kW 8.0 A 1.5 kW

0012 12.0 A 3.0 kW 11.0 A 2.2 kW

0018 – – 17.5 A 4.0 kW

Rated output current Max. applicable motor Rated output current Max. applicable motor

0001 1.2 A 0.4 kW 0.8 A 0.1 kW

0002 1.9 A 0.37 kW 1.6 A 0.2 kW

0004 3.5 A 0.75 kW 3.0 A 0.4 kW

0006 6.0 A 1.1 kW 5.0 A 0.75 kW

0010 9.6 A 2.2 kW 8.0 A 1.5 kW

0012 12.0 A 3.0 kW 11.0 A 2.2 kW

0020 19.6 A 5.5 kW 17.5 A 4.0 kW

0030 30.0 A 7.5 kW 25.0 A 5.5 kW

0040 40.0 A 11.0 kW 33.0 A 7.5 kW

0056 56.0 A 15.0 kW 47.0 A 11.0 kW

0069 69.0 A 18.5 kW 60.0 A 15.0 kW

Rated output current Max. applicable motor Rated output current Max. applicable motor

0001 1.2 A 0.37 kW 1.2 A 0.2 kW

0002 2.1 A 0.75 kW 1.8 A 0.4 kW

0004 4.1 A 1.5 kW 3.4 A 0.75 kW

0005 5.4 A 2.2 kW 4.8 A 1.5 kW

0007 6.9 A 3.0 kW 5.5 A 2.2 kW

0009 8.8 A 4.0 kW 7.2 A 3.0 kW

0011 11.1 A 5.5 kW 9.2 A 4.0 kW

0018 17.5 A 7.5 kW 14.8 A 5.5 kW

0023 23.0 A 11.0 kW 18.0 A 7.5 kW

0031 31.0 A 15.0 kW 24.0 A 11.0 kW

0038 38.0 A 18.5 kW 31.0 A 15.0 kW

Normal duty Heavy duty

Three-phase 200 VAC

Normal duty Heavy duty

Three-phase 400 VAC

Normal duty Heavy duty

Page 12

V1000

YASKAWA Electric Europe GmbH

Hauptstr. 185

65760 Eschborn

Deutschland /Germany

+49 6196 569-300

@yaskawa.de

info

www.yaskawa.eu.com

Specifications are subject to change without notice

for ongoing product modifications and improvements.

© YASKAWA Electric Europe GmbH. All rights reserved.

Literature No. YEG_INV_V1000_EN_v3_1109

Printed in Germany November 2009

Loading...

Loading...