Page 1

This is

Crompton Controls

Crompton Controls

Installation and Maintenance

Instructions

S10 & Smooth-BRAKE

DC Injection Brake Modules

LT011 Issue 1

Tel: +44 (0)1924 368251

Page 2

DC Injection Brake Module

Installation and Maintenance Document

S10 and Smooth-BRAKE

Warranty

All goods are guaranteed for one year from the date of purchase. This does not affect the

statutory rights of the user.

Safety warning

Important Safety Information

All electrical equipment for operating on low voltages contain devices which are capable of

causing serious or fatal injuries.

Any person involved in installation or maintenance of this equipment should be ful ly

competent to conduct the work.

Such persons should be familiar with the Health and Safety at Work Act, Electricity at

Work Regulations and have a working knowledge of the IEE Wiring Regulations.

If in doubt please contact,

Crompton Controls Ltd Tel: +44 (0)1924 368 251

General Description of the equipment

Crompton Controls DC injection Braking starters are suitable for controlled

stopping of induction motors.

When the machine starter is de energised the brake timer senses the break in supply and

applies a DC voltage to the motor windings to provide a controlled braking force for a

timed duration.

NOTE:

DC injection braking is a PUWER

motors and requires the mains supply to be present to operate correctly.

98 approved method of stopping AC electric

Induction motors

Induction motors can be braked to standstill, by injecting a DC current into the winding,

this creates a stationary field and any shaft rotation will produce a braking torque.

Braking from full speed an induction motor behaves as a twice speed generator, the

generated currents help to stop the motor and full load braking torque requires a DC

current of approx 2 to 2.5 times motor full load current. The DC is produced using a

thyristor with controlled half rectification and a diode is connected across the motor to

rectify the generated current, without the diode the motor would not brake. The externally

applied dc current will rise as the machine brakes to a halt. Motor noise is normal when

using phase angle control due to the nature of the unsmoothed dc waveform.

The DC current produces magnetic flux in the motor air gap, current can increase but

there is a saturation effect that means flux and braking torque will increase with current

up to saturation after which high currents will not produce much extra braking.

Most braking systems provide a voltage to apply to the windings, at standstill the current

will be determined by ohms law, current=voltage/winding resistance.

Part Numbers Rated operational voltages

BR011 S10/400 400 volt 50Hz 25 Amp brake module

BR016 S10/240 240 volt 50Hz 25 Amp brake module

BR021 S10/110 110 volt 50Hz 25 Amp brake module

BR025 Smooth-Brake 400 volt 50Hz 60 Amp brake assembly

BR026 Smooth-Brake 400 volt 50Hz 90 Amp brake assembly

BR024 Smooth-Brake Control Module

2

Page 3

Electrical Specification

Conforming to Standards BS/EN60947

DC CURRENT: S10 25A nominal current flows through L1, L2, M1 & M2

Smooth-BRAKE 60 Amp or 90 Amp high current connections directly

to thyristor diode module.

FREQUENCY: The unit is for rated 50 Hz.

DWELL TIME: From operating main contactor to closing DC contactor:

S10 0.5 seconds

Smooth-BRAKE 1 second

TIME RANGE: S10 braking time range is 0.1 to 12.7 seconds

(270° rotation linear potentiometer)

Smooth-BRAKE 0.2 to 50 seconds

(270° rotation linear potentiometer)

DC VOLTAGE: The voltage range is up to approx. 160 volts, with the minimum

oltage dependent on thyristor latching current.

v

DUTY CYCLE: S10 Limited by software to 10%. For every second of braking 10 is

added to a register. For every second not braking 1 is subtracted.

Restart is inhibited if the register is above a value of 250.

Note: if the unit will not start it will be waiting for this register to count

down below 250. The maximum dela

y is approx. 2 minutes.

Smooth-BRAKE No software limitation of duty cycle. Heat sink rated

for 10 off equally spaced 35 second stops per hour maximum at stated

current.

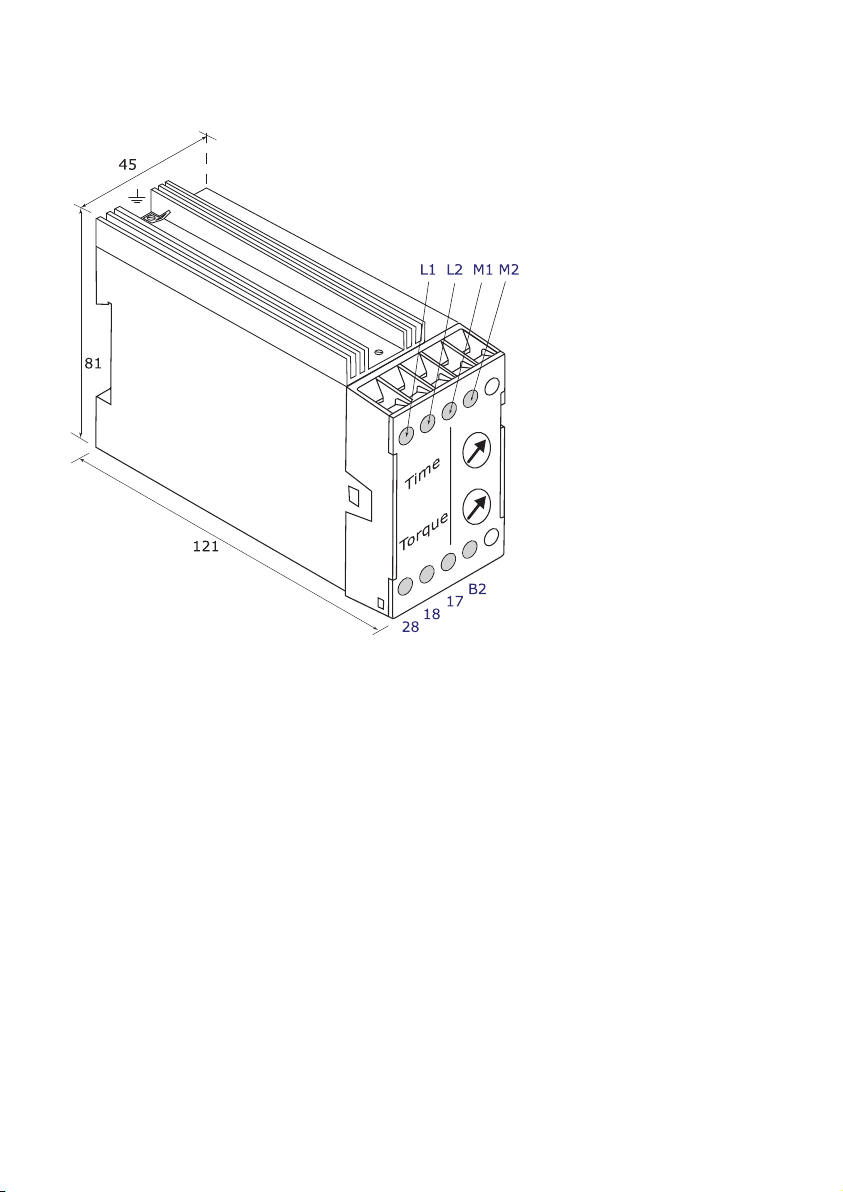

DIMENSIONS: S10 81H x 45W x 121D (mm) - DIN Rail mounting

TERMINALS: S10 2 times 2.5mm

Smooth-BRAKE 100H x 160W x 125D (mm)

2

max

Smooth-BRAKE main terminals M5 screw

control terminals 2 times 2.5mm2max

WEIGHT: S10 200g

Smooth-BRAKE 1.0kg

HUMIDITY: 85% non condensing

AMBIENT TEMP: Operating -10 to +40C Storage -20 to +70C

PROTECTION: IP code IP20

RELAYS: RL1 Internal 8A rated contacts, 440Vac max breaking voltage.

RL2 The relay terminals 17 18 28 are volt free and can be wired in a control

circuit at lower voltage.

The rela

y contacts can be protected with a 4 Amp Control fuse.

BRAKE FUSE: Semiconductor fuse

S10

30A (10mm x 38mm) FL078 740 A

2

sec

Ferraz 660gRB10-30 A070gRB30T13 ref M330015 or equivalent.

Diode 40EPS12 800 A2sec

Thyristor 40TPS12 1250 A

2

sec

Smooth-BRAKE

60 Amp SKNH56 or IRKN56 8000 A2sec

FE100 semiconductor fuse 1800A

2

sec

NSD 32 3000 A2sec approx 60A 100 sec trip point

NSD 40 6000 A2sec approx 100A 100 sec trip point

90 Amp SKNH91 or IRKN91 15000 A2sec

FE120 semiconductor fuse 1900A

2

sec

ESD 50 8700 A2sec approx 120A 100 sec trip point

ESD 63 13300 A2sec approx 150A 100 sec trip point

3

Page 4

S10 Module Terminals Identification and marking

Part Numbers

BR011 400v

BR016 240v

BR021 110v

L1 Common phase connection

L2 Phase connection - connected to M2

M1 Motor connection

M2 Motor connection - connected directly to L2

B2 Voltage sense input

17 Relay input - common to RL1 and RL2

18 RL1 Rela

28 RL2 Relay output connects to brake contactor

The B2 terminal to signal the unit to brake requires the full operating voltage of the

module applied.

L1 is common internally so a normally open auxiliary contact on the main contactor is

used to pro

y output - motor contactor via stop start circuit

vide a signal on B2 from L2.

4

Page 5

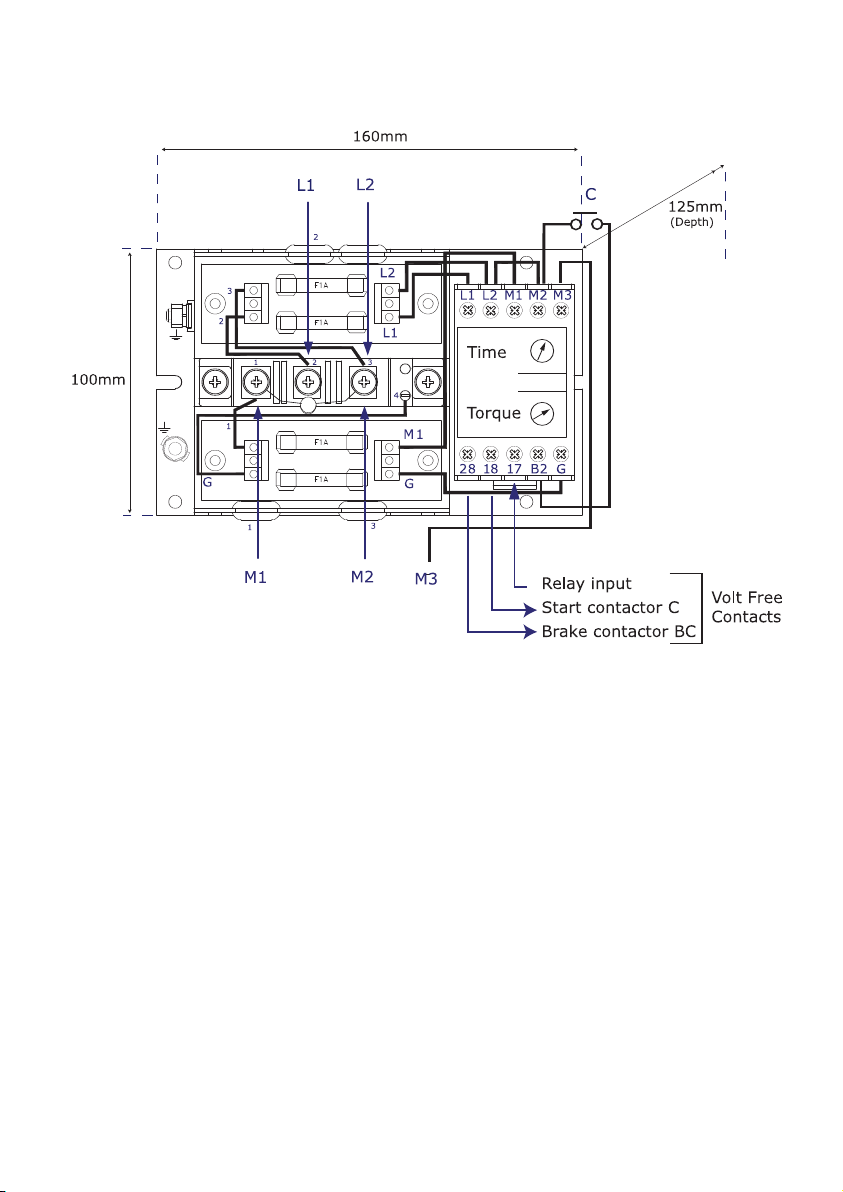

Smooth-BRAKE Module Terminals Identification and marking

Outline and Mounting Dimensions

Part Numbers

BR025 400v 60A

BR026 400v 90A

Terminal Description

L1 Common phase connection to thyristor terminal 2

L2 Phase connection to thyristor terminal 3

M1 Motor connection to thyristor terminal 1

M2 Motor connection also to thyristor terminal 3

M3 Motor connection - generated voltage

B2 Voltage sense input relative to L1

17 Relay input common to RL1 and RL2

18 RL1 Relay output - motor contactor via stop start circuit

28 RL2 Relay output connects to brake contactor

G Gate to connect to external thyristor

NOTE: A V

oltage Dependant Resistor – VDR is fitted across the M1 M2 motor terminals

to protect the diode.

Terminal covers not shown - MUST be fitted.

PCB fuse rating - 500V, 1A, quick blow, 6.3mm x 32mm ceramic tube, eg SIBA

ref: 70-065-63 1 Amp or equivalent.

5

Page 6

Description of operation

Both S10 and Smooth-BRAKE units are powered at operational voltage on L1 and L2. L1

is connected internally to the PCB OV common. A secure connection to the incoming supply

must be made at all termination and switching points. The voltage sensing input to B2 is

measured relative to L1. At power on there is a short initial delay and RL1, one of the two

internal relays, is energized giving an output on terminal 18, provided terminal 17 has a

supply. This output is wired to the main start contactor which can be energized to start

the motor; an auxiliary terminal on this contactor is used to connect a voltage to the B2

sensing input. When voltage is applied to B2 nothing happens, until on removal of this

oltage when the timing sequence starts:-

v

1 25mS dwell, then re-check no voltage on B2 – to prevent the startup voltage drop

causing dc injection

2 RL1 opens removing the feed to 18 preventing the main contactor from operating

3 500mS dwell period to allow the contactor arcs and motor EMF to decay – the setting

potentiometers are also read at this time.

4 RL2 is then energized to bring in the external brake contactor, connecting terminals

M1 and M2 directly to the motor

5 This enables DC to be injected for the time and voltage as set on the potentiometers.

(Smooth brake without M3 connected).

The DC is increased progressively to the set value to avoid mechanical shock.

6 RL2 is then de-energized after turning off the DC

7 Dwell period to allow the DC to decay

8 RL1 is then re-energized to allow the motor to be started again.

.

NOTE:

DC injection braking is a PUWER

motors and requires the mains supply to be present to operate correctly.

98 approved method of stopping AC electric

S10 and Smooth-BRAKE (without M3 connection)

Basic setting procedure

A Braking Time Setting (0-100% S10 0.1- 12.7 sec Smooth Brake 0.2 to 50 sec)

1. From minimum, turn the Braking Time Pot slightly clockwise.

2. Start the motor.

3. Stop the motor and check the time the brake contactor energises for.

4. Repeat steps 1 – 3 until the required time is reached (10 seconds or less).

B Braking Torque Setting (0-100% - approx 160v dc)

1. From minimum, turn the Braking Torque Pot slightly clockwise.

2. Start the motor.

3. Stop the motor and measure the time tak

4. If the motor continues to rotate after the Braking Time (contactor) has lapsed repeat

steps 1 – 3 until there is sufficient braking to stop the motor within the required time.

en to stop.

6

Page 7

Description of operation

100%

20%

0%

Speed

Reducing

Voltage &

Braking

100%

50%

25%

Voltage from motor

100%

20%

0%

Speed

Reducing

Voltage &

Braking

100%

50%

25%

100%

50%

Stage 1

Stage 2

Stage 3

Time set on pot

Timeout

Stage 2

Stage 3

Voltage from motor

Smooth-BRAKE with M3 connected

Controlled Stopping with feedback from motor

The M3 terminal provides voltage feedback from the motor during braking. The basic

setting is as page 6 but the braking torque setting will become the main adjustment and

switch the unit off a few seconds after coming to rest. The time setting needs to be long

enough to allow this to happen. Removal of the wire from the M3 terminal will remove the

voltage signal and braking will be to the torque and time settings only.

Operation with voltage feedback i.e. M3 connected

A three stage stop utilizing the v

oltage generated by the motor during braking as a speed

signal. The amount of voltage varies with the speed and amount of DC injection. With

high levels of DC and the motor spinning fast there is a strong signal.

Stage 1 The unit brakes at full until this signal reduces to approx 18%.

Stage 2 Then the braking strength is reduced.

There is an increase in v

oltage as standstill is approached to trigger the switch

to stage 3.

After this the voltage is too low to provide an accurate signal.

Stage 3 A low lev

NOTE: The Time potentiometer provides an ov

el of DC for a time is then used to bring the shaft to rest.

erriding switch off point adjustment from

0.2 to 50 sec.

Stages 2 and 3 have inbuilt timeouts dependent on the length of time in stage 1.

Stage 2 timeout equals two times the stage one time plus 2 sec.

Stage 3 timeout equals one times the stage one time plus 3.5 sec.

Braking Strength

7

Page 8

Typical Direct on Line DC brake retro fit

NOTE: M3 connection only applies to Smooth-BRAKE modules.

See page 3 for BF1 and BF2 Brake Fuse rating.

The Brake Contactor, ‘BC’ should be sized to cover the relative braking current.

8

Page 9

Direct on Line starter with S10 Brake Module

3 phase

9

Page 10

Direct on Line starter with S10 Brake Module

1 phase

NOTE: On braking there is a diode in the brake circuit connected directly across the motor.

Single phase induction motors have capacitors, permanent capacitors can be dc injected

and the diode needs to be rated for the discharge currents of the motor capacitors this

current can also produce a torque pulse on the shaft.

The capacitance in circuit prolongs the decay of electrical energy in the motor so a longer

dwell time is required from pressing the stop button to connecting the brake.

Capacitors can be short time rated and if so it is better to remove them from circuit

during braking.To remove the capacitors during braking use a normally closed auxiliary

contact on the brake contactor.

Aux contacts normally carry a 10 Amp rating and this may not be sufficient for the start

winding current for some single phase motors. The normally closed contact allows the

capacitor energy to discharge through the motor wining as normal otherwise a bleed

resistor would be needed.

10

Page 11

Separate control supply version

11

Page 12

Star Delta starter with S10 Brake Module

12

Page 13

Star Delta Starter with Smooth-BRAKE Assembly

13

Page 14

Fault finding

Initially check for loose connections and physical damage

Not Starting

Brake contactor

not operating

Brake Contactor

operating

but not braking

Module tracks

can be damaged

Check power to L1 L2 supply to module - volt meter check 1.

Supply to terminal 17 control fuses and wiring - volt meter check 2.

Relay closed internally linking 17 to 18 module fault if doesn’t close

- volt meter check 3.

Check voltage signal to B2 – fed from auxiliary contact block on the

main contactor - volt meter check 4.

Application of voltage causes no change however removal of voltage

triggers the braking.

Check voltage on 28 to ensure internal relay operating - volt meter

check 5.

Wiring from M1 M2 to motor – Isolate supply test with meter on

resistance across M1 M2 when operating the BC brake contactor by

hand should be able to measure the winding resistance - resistance

check 6.

Motor connections for star delta.

DC injection fuse.

Faulty contactor.

Wiring fault.

Module fault.

If semiconductor fuses are not fitted and high currents result from

earth faults.

If voltage setting is too large for the motor impedance.

If Interlocks incorrectly wired and AC and DC contactors operate at

the same time.

14

Page 15

Interlocks

The two internal relays controlling the starting (RL1) and braking (RL2) provide in initial

degree of interlocking. The normally closed on the first relay feeds the common on the

second so the outputs 18 and 28 cannot be on at the same time. Electrical interlocks are

also used on the main and DC contactors. However if the interlocking is bypassed for

some reason then the AC and DC contactors energised together put a direct short circuit

across two phases and supply fuse size will determine the amount of damage.

If several brake modules are used with a common control circuit it is important to

maintain interlocks across all the units. Use volt free relay contacts in the common circuit

from relays connected to terminal 18 on each module.

General Notes

• Star Delta run up times of approx 15 sec or more could result in the overload tripping.

• Star Delta connections are important easy to have the motor start and run but not dc

inject if the 6 leads are not correctly marked or wired.

• Inertia can result in the need to increase the amount of dc current. E.g. Disc sanders,

band saws, and high-speed routers.

• Mechanical damage can occur with very high levels of dc injection.

• The motor resistance will change with temp up to 30% from cold to hot, reducing

braking as the motor warms.

• Bad connections can cause severe damage to contactors –old machines have old

motors, wiring and starters. Sawdust and woodchips inside contacts is a prime cause of

bad connections.

• More than one motor can be dc injected using the same thyristor/diode power assembly

if all can be stopped together.

• Multi motor machines (tennoners) can have individual start buttons but one common

stop which will dc inject all motors running or stationary.

• Aux block on the main contactor has to be moved to allow the starter to be wired. If

not put back in place this may result in no braking i.e. the brake contactor doesn’t

operate.

• Check connections to the motor if the brake contactor is operating but the motor is not

braking.

This can be quickly done by measuring the winding resistance across the diode M1 to

M2 while operating the brake contactor by hand to make the circuit.

15

Page 16

BS EN ISO 9001:2000

All information contained in this publication is, as far

as possible, correct at the time of going to print.

However, due to our policy of continued improvement,

we reserve the right to alter specifications and prices

without prior notice.© 2008 Crompton Controls Ltd.

All rights reserved.

AUTOMATION

INSTRUMENTATION & CONTROL

LABORATORY TECHNOLOGY

Crompton Controls Ltd

Monckton Road,

Wakefield,

West Yorkshire WF2 7AL UK

Tel: +44 (0)1924 368251

Fax: +44 (0)1924 367274

E-mail: sales@cromptoncontrols.co.uk

www.cromptoncontrols.co.uk

Printed in England j4design.co.uk Part No: LT011 PC/A/10/08

Loading...

Loading...