Crommelins CFGKUB Operation & Instruction Manual

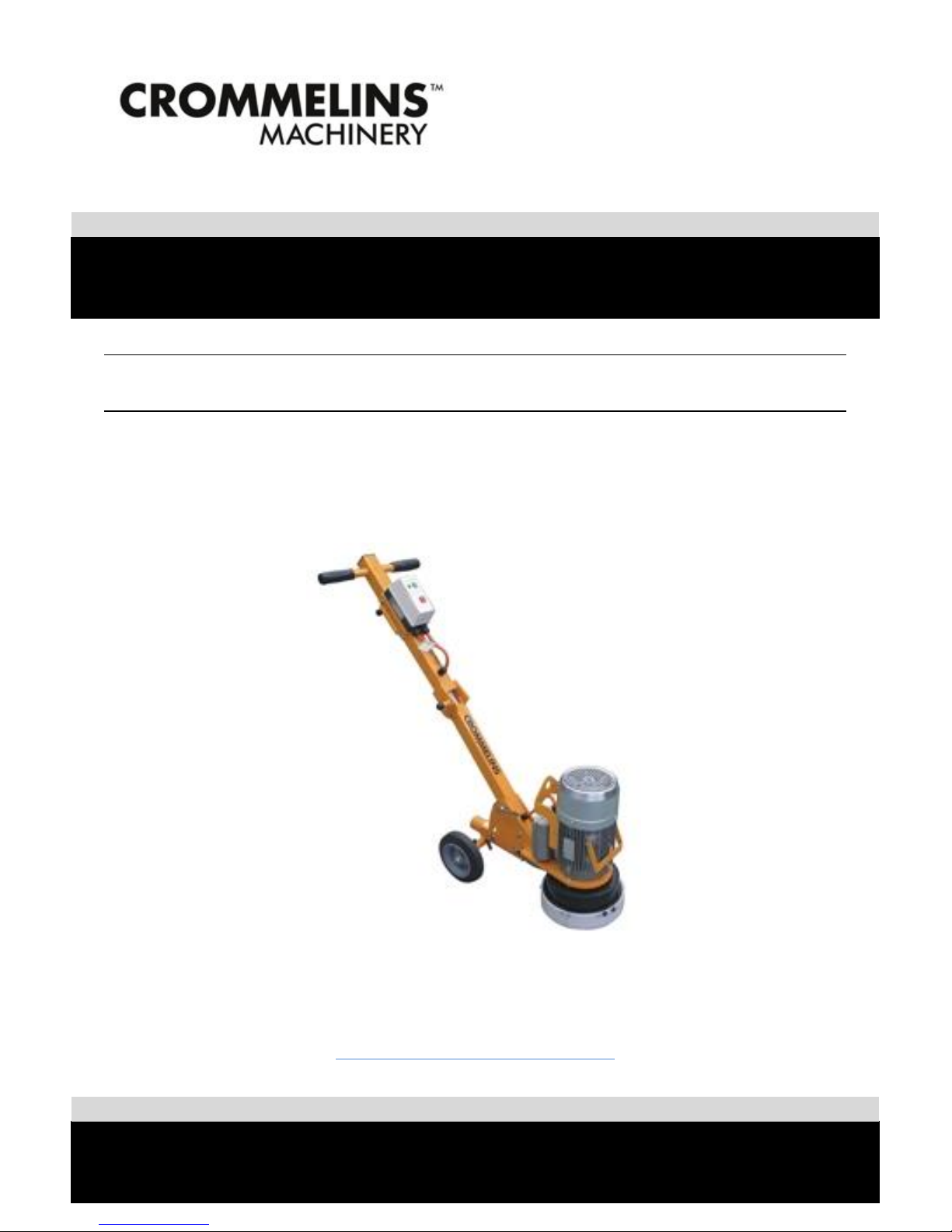

10” CROMMELINS™ FLOOR GRINDER

Thank you for your selection of an 10” CROMMELINS™ Floor Grinder. This

Operation Manual explains its use, installation, checking and maintenance. We

highly recommend that you retain this manual for ready reference regarding

proper handling of the 10” CROMMELINS™ Floor Grinder.

Spare Parts & Service

Phone: 1300 554 524

Freecall Fax: 1800 636 281

spareparts@crommelins.com.au

www.crommelins.com.au

WA Metro 9350 5588

WA Regional 1800 655 588

East Coast 1300 650 659

email@crommelins.com.au

OPERATION & INSTRUCTION MANUAL

2

Thank you very much for purchasing a 10” CROMMELINS™ FLOOR GRINDER. This manual

covers operation and maintenance of the 10” CROMMELINS™ FLOOR GRINDER.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures in order to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at anytime.

Due to constant efforts to improve our products, certain procedures and specifications

are subject to change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference.

CONTENTS

Introduction & Contents ..................................................................................... 2

General Safety Rules .......................................................................................... 3

General Information .......................................................................................... 4

Operating Floor Grinder ..................................................................................... 5

Maintenance ..................................................................................................... 6

Parts Diagram ..................................................................................................... 7

Parts List .......................................................................................................... 8

Warranty ........................................................................................................... 9

SERIAL NO.

MODEL NO.

3

GENERAL SAFETY RULES

This manual contains important information on how to use the following floor grinder

model CFGKUB correctly and safely. Please read through this manual before you attempt to

operate the machine.

This floor grinder is designed to give safe and dependable service if operated according to

the instructions.

1. Do not use the grinder for longer than prescribed in your local environment

working regulations, as the noise load from extensive daily use may result in

hearing defects.

2. Do not modify the grinder in any manner, or use a machine that has been modified

by anyone other than the manufacturer or authorised dealers.

3. Do not add weight to the machine to make the grinder work harder. Instead

reduce the number of segments on the grinding plates to increase the

performance.

4. Make sure that re-tipped plates and new grinding plates are balanced properly.

5. Do not run the grinder with the grinding head raised higher than necessary, i.e.

tipped back on the handle.

6. Always make sure that the folding handle latch is secure and has not vibrated loose

after use.

7. When grinding the machine is exposed to high vibration. Occasionally check the

machine if any nut or bolt has loosened due to the vibration.

8. Do not allow water or cotton to enter the interior of the motor.

To prevent injury wear the following protective items: Ear plugs/muffs, safety glasses, work

boots and any other protective item required by job conditions.

4

GENERAL INFORMATION

The floor grinder is a sturdy, reliable and easy to use machine.

The floor grinder is fitted with 2.2kW single phase motor. This motor offers direct drive to

the grinding plate with the incorporation of a flexible coupling between the motor and the

plate.

The shroud system is unique in design, automatically adjusting to suit segment height and

floor angle. This shroud system when used in conjunction with an appropriate industrial

vacuum unit eliminates dust loss during grinding. The shroud has 2 removable sections to

enable the operator to grind close up to the wall etc. Please note dust loss is possible when

this section is removed.

The floor grinder comes complete with a water connection for wet grinding should this be

required. There is also a ball valve which allows the operator to regulate the water supply

to obtain the best grinding results.

The floor grinder has a foldable handle which makes it easily transportable in any small

vehicle. The rear wheels can be extended outwards should the operator require more

stability from the grinder. This requires the use of an 8mm Allen key. The operator can also

raise and lower the height of the handle to maximise their comfort during their use of the

grinder.

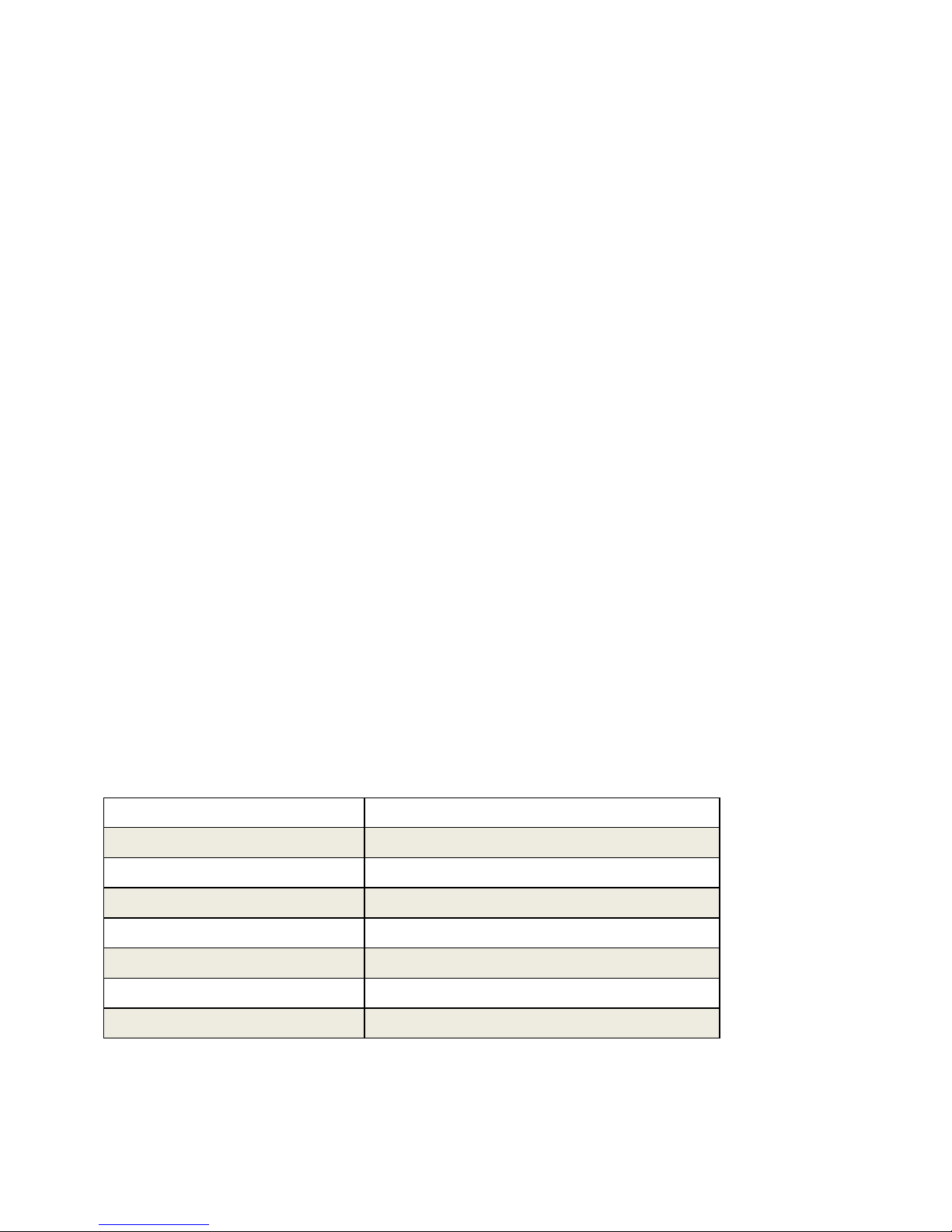

TECHNICAL DATA

Motor HP

3 HP

Motor KW Rating

2.2 kW

Motor RPM

1450 rpm

Unit Weight

45 kg

Plate Type

Standard 250mm plate or K-Kub shoes

Plate Bolt Types

M12x25 countersunk socket bolts

M8 x 16 mm Hex head engineers bolt

Main Construction

Powder coated steel

Loading...

Loading...