Page 1

r @ e # @ ''

2 9 9 8 D IS K D R IV E

T E C H N I C A L M A N U A L

C R O M E M C O . Inc .

2 8 O B e rn a rd o A v e nu e

M o un ta in V ie w , C A 9 4 0 4 3

P art N 0 .0 2 3 - 6 0 0 0 A p ril 1 9 8 1

C opyright (C) 19 8 0

B y C R O M E M C O , lnc .

A L L R IG H T S R E S E R V E D

Page 2

FUNCT ION OF H ICROPROCESSOR IN 299 6

Tbe m icroprocessor implementation on 299 B performs three malor functlons .

T he se a re se rvo con t ro l, read y s ta tus , and e ra se de lay t im ing . The pro ce sso r

co nt inuo us ly execu tes a sequence o f ro ut ine s wh lch t rack the statu s o f ready

and se rve fun c t ion s , an d tes t the co nd lt ion o f th e se lec t l ine s to d e te rm ine

w he the r to o utp ut suc h sta tus . Beca use se e k ing a nd w r lt ing a re mu tua lly ex -

c lu s îve fu nc t io n s . T he p roc es so r a lso ha s t im e to ca lcu la te e ra se t lm ing .

Se rvo Co n t ro l

R he n the po s it po ne r 7s bo ld ing o n t rac k , the p ro ce sso r is ou t o f the se rvo

loo p , a llow ing 1' F INE PO S IT IO N SENS E '' to ke e p t he po s ît io ne r Cn p lace . khe n

seek ing to a track , the p roce sso r outputs a ve loc ity va lue wh ic h d ire ct ly co n-

tro ls the po s it io ne r w h ile co un t lng ste p an d de ten t p ulse s . Th e p roce sso r also

de te rm lne s w he n to sw itch itse lf into and o ut o f the feed bac k loo p . To e nsu re

m in im um re spo nse time to ch a nge s in se rvo sta tu s , b0 th ET EP p u lse s and DET ENT

pu lse s a re t ied to the INTE RRUP T inpu t o f the proce sso r . Th us , wh ene ve r a

st im u lus îs re ce ive d , the p roc e sso r sto ps w ha te ve r it w a s do ing a t the t /me ,

ide nt if ies the sou rce o f the in te r rup t , and tre a ts it app ro p ria te ly . T he ve l-

oc ity fo r the se rvo is de pend en t upon th e d istan ce re m a in in: to t rave l , a nd a

va lue for each ha lf-track of rem a ln ing d istance up to 63 tracks is sto red

in a look-up tab le ln memory . For greater than 6) tracks the max imum ve loc ity

b ou tp ut . T he D IRE CT IO N l ine ls sam p led a t the sta rt of a se ek and sto red fo r

the d u ra t io n o f tha t see û . lt is o u tp u t to th e D to A c on ve rte r a s the m o s t s ig -

nificant bit or slgn bit. By inlecting a current equal to one half the full

scale output through R1O3 and R10ù înto the D-A co nve rte r outpu t , a un i-po la r

dev lce ca n be use d to pro v ide s ig n ed d ua l po lar ity o u tpu t .

Upo n reach lng a d lf fe ren ce o f ze ro be twee n ste ps and d e ts n ts , the se rvo îs

sw itched to the HO LD mode fo r f lna l se tt ling to t rack . The proce sso r clea ns up

reglsters and track counters, and samples TKCENT (track center) and TKJ; (track

zero), storing them for future outgut conditîonal on selected status.

T he p roce s so r a lso co n t ro ls the RE ST OR E fu nc t îon . REST OR E ma y be în it ia te d

by the ho s t v la the RE STO RE inp u t , o r w il l o cc u r if a n il leg a l se e k is com -

manded ltoo many step pulses) or Cf a detent is received while hold in: on track.

Page 3

The bu ilt- in exe rciser on the 29j 8 automatica lly w r ite-protects tbe drive

by ho ld ing SEEK COMPL ETE fa lse in the e xe rc zse r mo de .

Re ad y Sta tus

The proce sso r wa tc he s the fou r index lln e s fo r change s . A com ple te low -h igh -

1ow se que nce be lng de te cted o n e ithe r d lske tte sta rt s a t im e r fo r tha t d iske tte .

The coun t ls te sted f requen tly , a nd shou ld 2Q0m S e la pse be fo re anothe r index

pulse is sensed , the d iskette îs logged no t ready . In 299 B it is stored

Inte rna l ly and o u tput on ly fo r the se lecte d d iske tte . Tw o -s zded inde x is sam p led

whe n '' EITHER INDEX 11 is h lg h and sto red fo r ou tpu t to the ho st .

E ra se De la y T im ing

Th e use o f tunne l-e ra se head s ma nda tes a de lay c ha nge s in % R IT E G AT E and

ERASE GATE. The processor allows a refinement of this delay by adlustlng it

acco rd ing to the t rac k loca t ion . T he INT ERRU PT c lrcu it is co nf lgu red such tha t

either edge of WRITE GATE (turn-on or turn-off) causes an lnterrupt. When thls

inte rrupt is lden t if îed , R R IT E GAT E ST AT U S is te ste d a nd the a pp ro pr îa te d e lay

Is ge ne ra ted ; longe r de lay s fo r tu rn -o ff and va ry lng length s depe nde nt upon the

track loca tlon . De nse r fo rmats tha n w e re ava ilab le w ith fixes de lay s can be

o bta lne d .

Page 4

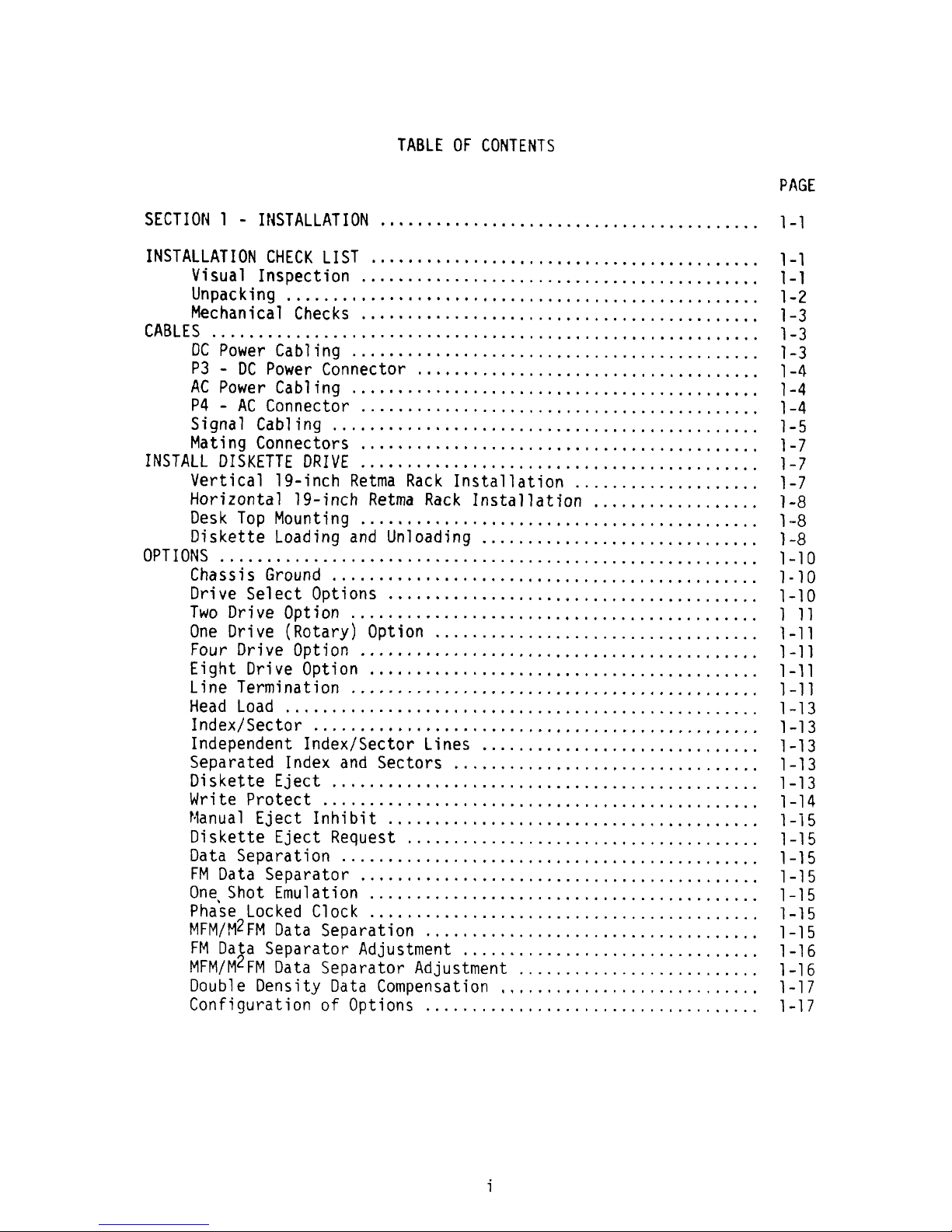

TABLE O F CONTENTS

PAGE

SECT IOK 1 - INSTALLAT ION ...............................

. . . . . . . . . . 1-1

INSTALLAT ION CHECK LIST .................,......

. . . . . . . . . . . . . . . . . .

1-1

14 i s u a 1 I n s ;) (, c 1; 1- () n . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

1 - 1

hltl C h a n 1* (: a 1 C h (, c k S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

1 - 3

1::1 (512 1::1 1::j lkhdr 152! 14*% 1::2 iilk I1:i *1 -1' 4'11 !g4l . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

-1 --- 111:

P3 - DC power Connecto r ...............................

. . . . . .

1-4

/1 C P 0 k:e r C a b ) 1 n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

) - 4

? 4 - /$ C C 0 n n e C t 0 r . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . .

. . . . . . . . .

1 - 4

S 1- g n a 1 C a b l 1- n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - . . . . . . . .

. . . . . .

1 - S

h1 ; t 1- n g C 0 n n e C t O r S . . . . . . . . . . * . . . . . . . . . . . . . . , . . . . . . . .

. . . . . . . . .

1 - 7

INSTALL D ISKETTE DR IVE .................................

. . . . . . . . . .

)-7

Vert ical lg-inc h Retma Rac k Installat ion ..............

. . . . . .

1-7

Ho rizontal 19- 1'nch Retma Rack lnstallat l'on ............

. . . . . .

1-8

E) (! S k 17 () p h1 () u n t i n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

1 - E$

Diskette Load ing and onload p'ng ........................

. . . . , .

1-8

ChaSSI'S Ground ...................................,.........

. 1-10

Drive Select Options .......................................

.

1-10

17 kk () () r 1- v t! () p t )- () n - . . - . . - . . . . . . . . . . . . . . . . . . - . . . . . . . . . . . . . . . . . . ) 1 )

0ne Drive (Rotary) Option ................................... 1-11

F () u r () r 1- v i? () p t 1- () n . - . . . . . . . . . . . . . . . . . . - . . - . . . . . . . . . -

. . . . . . . . .

1 - 1 1

E 1- g h t D 4% 7- v (, () p t 1 o n . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . 1 - 1 1

L 7- n (, lr (, ywrr 1- n a t 1- () n . . . . . . - - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

) - 1 1

lndex/sector ................................................ 1-13

Independent Index/sector Lines .............................. 1-13

Sepa ra ted Inde x and Sec to rs . ,. .... .,., ... ...

. . . . . . . . . . . . . . . .

1-13

(2h 1* 1; $( (, 1: 17 (? !! J- (! (2 1: . . . . . . . . . . . , . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 1 -- 1 :$

l!1 k, 1* 1) (! F' ke (:p 1: (, (: 1: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

1 -- 1 dl

l'la n u al E je c t I n hi bi t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -1 5

Di s k e t t e Eje c t Re q u e s t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . 1 -1 5

Da t; Se P; r; t1'0 9 ... .. .... .... .. .. .... .. .... .. .... ..

. . . . . . . . . . 1 -1 6

FM Da ta Se pa ra t0 r ....... ...... ........ ... .. ........ ...... ..

.

1 - 1 S

0n e

.

ShO t Em ul a t ion ..... ...... .... ....... ... .... ...... .... ... 1 -1 5

P ha Se L0C ked C1 Oc k ........ ... ....... ...... -.......

. . . . . . . . . .

1 -1 5@

FH Data Se paration ..........................

. . . . . . . . , .

1-15MFH/H

FR Data Separator Adjustment ..........................,..... 1-162

FM Data Separator Adjustment ....................,..... 1-16HFM/M

Do ub le De nsity Data Com pensat l'o n .....,.........,...,........ 1-17

Configu rat ion o f Opt ion s ... ................................. 1-17

1

Page 5

TABLE 0F CONTENTS (Continued)

PAGE

SECT ION 2 - HAINTENANCE

PREVENT IVE HA INTENANCE SCHEDULE

kuarterly Cleanl'ng ..,....................................... 2-1

DriMe Sy stem Test ......................,.................... 2-1

FREkENT IVE HA INTENANCE PROCEDURES .......,........................ 2-1

Splndle Dr ive Sy stem ........ ............,.............. ..... 2-1

Drive Belt Tens l'on .......................................... 2 -2

Read/krl'te Data Amplitude ....,.............................. 2-2

MA INTENANCE PROCEDURES ........................................... 2-2

Tools and Test Eqe l'pment ..............,..................... 2-2

JACQS and P1u9S ............................................. 2-3

Drive Elect'ronl'cs PCB ....................................... 2-4

PCB Replacement .......................................,..... 2-4

Voltage Adjustment .......................................... 2-4

Drive H otor and Belt Checks .................,............... 2-6

Drive Belt Tenslon Adjustment ............,.................. .2-6

Drive Belt Replacement ...................................... 2-7

lndex Transducer and Logic Checks ........................... 2-7

lrldex T ransducer A ll'gnment .................................. 2-8

Index Transducer Replacement ................................ 2-9

Spind le Cone Check .......................................... 2-10

Sp indle Cone Replacement .................................... 2-12

Positl'on ing Sy stem .......................................... 2-12

Positioner Servo Check .,.................................... 2 -12

Head Assembly Track A ll'gnment and Haciine Azimuth ........... 2-13

Positioner Servo Adjustment ........,...,..........,......... 2-16

prell'minary Adjustments ............................,..,..... 2-16

Final Adjustments ...............................,........... 2-17

Head Assem bly T rac k and Head Azimuth A ll'gnment Side 2 ....... 2-18

Head A ssembly Track and Head Azimuth Allgnment S ide 1 ....... 2-19

Load Cam Shutter Al ignment .................................. 2-19

Eject Motor Cam Allgnment Check ............................, 2-20

Crank Cam Alignment Check ................................... 2 -20

Crank Cam Alignment procedure ............................... 2-21

DISKETT E DRIVE EïERC ISER ..............

.

. . . . . . . . . . . . . . . . . . . . . , . . . . .

2-22

Contrcls , Indicators. and Test Po 'lnts ..............,....,... 2-22

D r aw 1- n g s a n d Ha t e r 1 a 1 L 1 s t s

1 1

Page 6

LISI 0 F ILLUST RAT IONS

FIGURE T ITLE PAG E

1- 1 Diskette Drive Shipplnq Con flguration .................... 1-2

l-2 Prope r Load ing of Dlskette ............................... 1-3

)-3 Slide Hountinq Dlmenspons ..... ,......................... 1-7

1-4 Ve rt ical Retma Rac k Hount lng .. .............. ............ 1-9

1-5 Hor izon ta l Retma Rack Mountinq ........................... 1-9

1 -6 Outl ine o l'men sïo ns - .. .. .... - .. ... .... ....... ... ... ... . . 1 -1 0

1 -7 H r l'te ? rotec t Notc h Loca t ion .- ..... . ... .. .... .... ., .... . 1 -1 4

2-1 P1 ug s and Jac ks Id en t î fl ca tion .....,... .. ..... ... .

. . . . . . . 2- 5

2-@ Dr1've S# StQm .................. ......... ............ .

. . . .

2-6

2-3 Index Pu lse and lata Bu rst .... ...... ... ... .. ... ... ... .. 2-8

2-4 Index Transduc er and Coce A ssem bly ................

. . . . . , .

2-10

2-5 Exam ple of Good Cone ......... ....... ........,........... 2-11

2-6 T rac k A lïjnm en t ..... .................................

. . . .

2- 13

2-7A Head Assem bly Hount qnç Sc rew s S lde 2 .... ............

. . . . .

2-14

2-78 Head Assem bly Mount lnj Screw s S lde 1 .............

. . . . . . . .

2-14

2-7C Cat Ey es and Head Azimuth D isplay ................

. . . . . . . .

2-15

2-7D Head Az l'm uth Alignment ..................................

.

2-1 5

2-8 Dr ive Elect ronl'cs PC8 ... ................................

. 2- 16

2-9 Load Cam Shutter A lignm ent ......... ..................

. . . . 2-20

2-10A Eject Motor Cam Alignment Check-carrier Open ............. 2-21

2-10B Eject Hotor Cam Alignment Check-carrier Clnsed ........... 2-21

2-11 Cran k Cam Alignment Check .........................

. . . . . . .

2-22

2-12 Control panel , D iskette Exerc iser , Model 499 ............

. 2 -23

LIST OF TA8LES

NUH8Eq T ITLE FAGE

7-1 Installat ion Check Llst ........ ..........

. . . . . . . . . . . . . .

1- 1

l-2 Inte rface P 1n Connect l'ons ......,.... .......

. . . . . . . . . . . . . .

1-6

1-3 Binary Se lectlon of Four Dr q'ves . ......... ..

. . . . . . . . . . . . . .

1-12

1-4 B inary Selection of Elçht Drives ........

. . . . . . . . . . . . . . . . .

1-12

l-5 Opt ion Com ponents , Jum pers , and I race Cuts

. . . . . . . . . . . . . . .

1-18

2 - 1 J a c k S a n d P 1 u g S . . . . . . . . . . . . - . . . . .

. . . . . . . - - . . . . . . . . . . . . . .

2 - 3

2-2 Po sit ione r Servo Prelim lnary Adlustments .

. . . , . . . . . . . . . . . .

2-17

2-3 Exe rc iser Sw itch , lnd icator and Test Po int Functions

. . . . .

2-24

7 1 1

Page 7

SECT ION )

IhSTALLAT ION

This sec tion contains procedu res to verîfy the operat ional integrity nf

the d iskette dr ive pr ior to on-line oper at ion .

INSTALLAT IOh CHECK LIST

The insta llation chec k llst , Table 1-1 , is desijned for trained personne l

to use as a guide in performing installation checks necessart for proper

operat ion . If more de ta qled insta llation info rmat ion is de slred . refer

to the appropr iate paragraph in this sect ion .

TABLE 7-1 . INSTA LLAT ION CHE CK LIST

Visual In spectlon

a . Remo ve a1l pac king m aterial .

b . Chec k packing l ist .

c . Check for shlppins dam age .

d . Remove carriage restra int inserted in S ide 1 .

Hec han ical Chec ks

a . Chec k that carrïage dssem bly moves free ly over entlre stroke .

Cable s

a . Fabricate DC and sig nal cables .

b. Check pin to pin resistance (a11 cables).

c. Check pin to conductor continuity (a11 cables).

d. Check for prcper pin alignments (a11 cables).

Houn ting

a . Insta ll d iskette dr ive ,

b . Connect ca bles to d iskette dr ive .

Chec kout

a. Operational checkout with exerciser (optional).

b . Ope ra tiona l c hec kout w ith sy stem .

kisua l In spec tio n

The d iskette drive is packaged to ensure adequate pro tect îon for shipp ing

and handling (See Figure 1-1).

1-1

Page 8

ûUTSIOE CARDBOARD B0 X - -

%

%

x e N x

8 CORNER BLOCKS .-

l

%. I

l

*

-

*

I

I I l

1 --

INNER

CARDBOARD

-

B0XN

x N -DRIVE

CARRIAGE

RESTRA INT - e

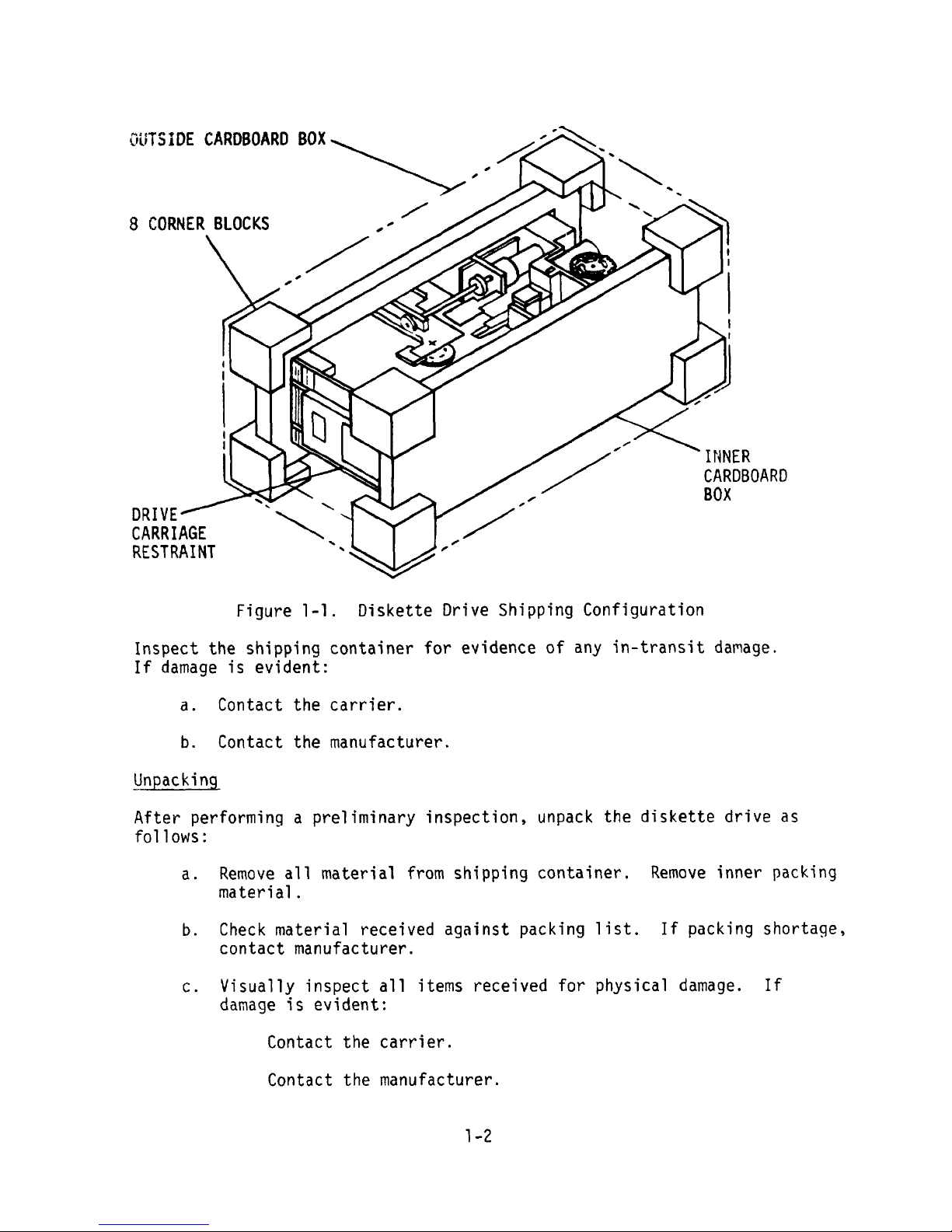

Figure 1-1 . Diskette Drive Shipping Configuration

Inspect the shiqping container for evidence of any in-transit damage.

If damage is evlten t :

a . Contact the carrier .

b . Contact the manu facturer .

Unpac king

After performing a prel îm inary inspect ion , unpack the dîskette drive a s

fo llow s :

a . Remcve a11 material from shipping container . Remove inner pac king

materlal .

b . Check m ateria l rece ived against packîng list . If pack ing shortage ,

con tac t ma nufactu rer .

c. kîsually insqect a11 items received for physical damage. lf

dam age qs ev lden t :

Contact the carrier .

Co ntact the manufacturer .

1-2

Page 9

- , '

A

x

LA BEL

d

!

N

<

HEAD SLOT

FORHARD

INDEï HO LE

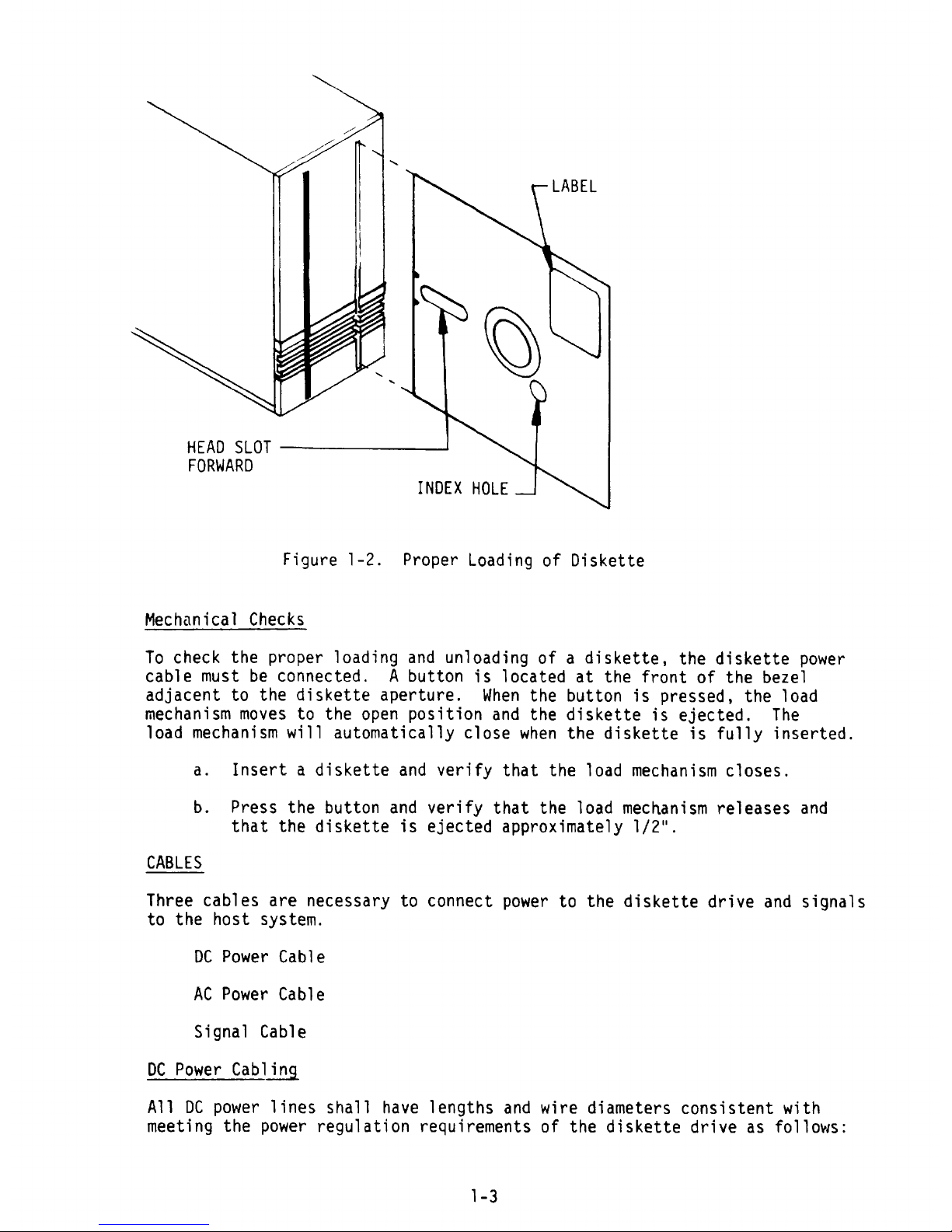

Fijure 1-2 . pro per Load ing of Diskette

Mechcnlcal Checks

To chec k the proper loading and unload ing of a diskette , the d iske tte pow er

cable must be connected . A button is located at the front of the beze l

adjacent to the diskette aperture. Hhen the button is pressed, the load

mechanism moves to the open position and the diskette is ejected. The

load mechanism w ill automatically close when the d iskette is fully inserted .

a . Inse rt a d iskette and ver ify that the load mechan ism clo se s.

b . press the button and Mer ify that the load mecNan ism releases and

that the diskette is ejected approximately 1/2'%

CABLES

Three cables are necessary to connect power to the d iskette d rive and signals

tn t he host sy stem .

DC Power Cable

AC Power Cable

Slgnal Cable

DC power Cabling

A11 DC pow er llne s shall have lengths and w ire d iameters consistent w ith

meeting the power regulation reguirements of the d iskette dr ive as fcllows :

1-3

Page 10

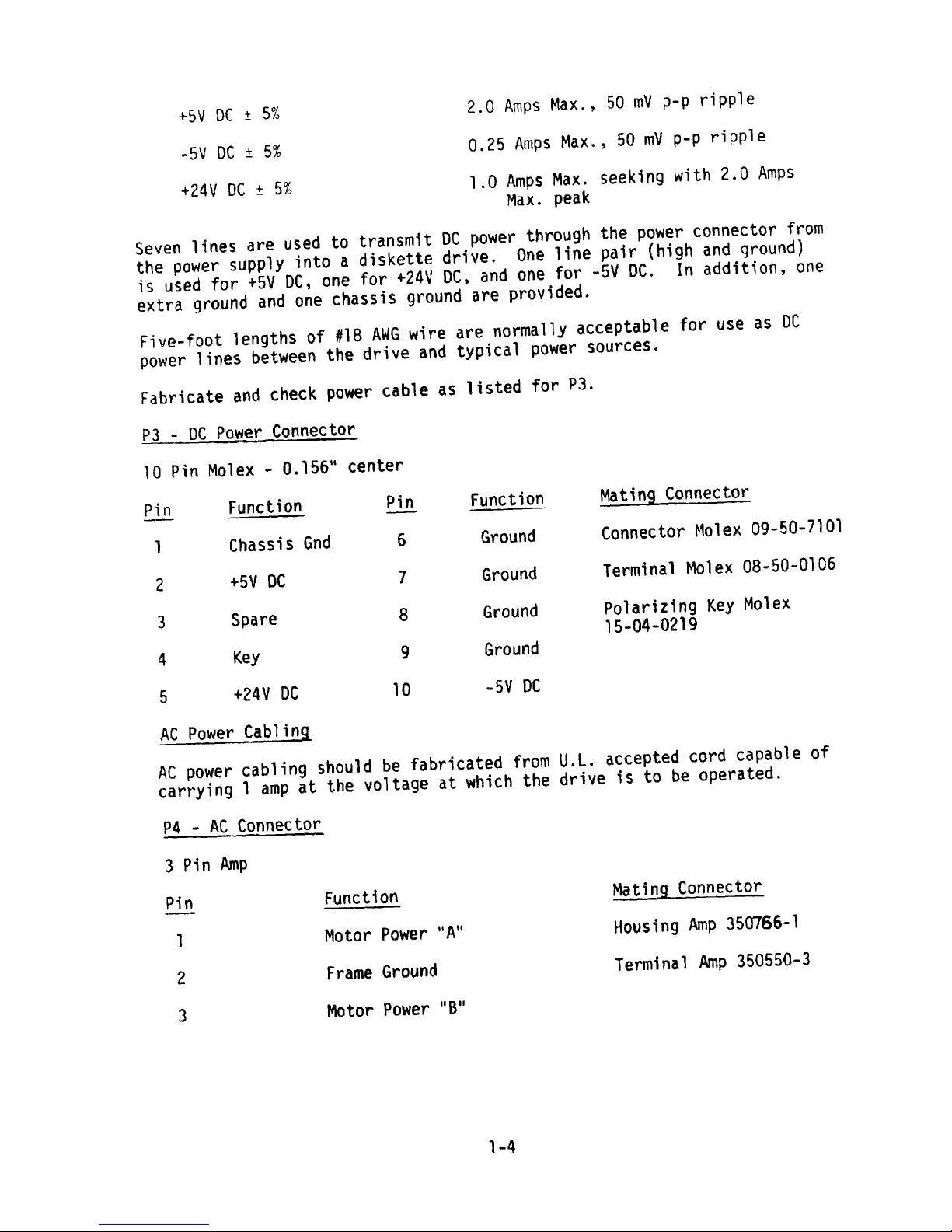

15V DE l 5% 2 .0 Am ps Max ., 50 mv p-p ripple

-

5k DC à 5% 0 .25 Amps M4x ., 50 mv p-p ripple

+24/ DC 1 5% 1 .0 Am ps Yax . seekinj w ith 2 .0 Amps

Max . peak

Seven lines are used to transmit DC power throu:h the power connector from

the power supply into a diskette drive. Qne lqne palr (high and ground)

is used for +5V DC , nne for +24V DC . and one for -5V DC . Iq addltïon , one

extra ground and one chassls :round are provsded .

Five-foot lengths of 418 AHG w ire are normally acceptable for use as DC

power lines between the drive and ty pical pcwer Gources.

Fabricate and check pcwer cable as listed f0r ?3 .

P3 - DC Pow

-

e r

-

connectp r

10 Pin Molex - 0 .156'' center

Pin Func tion Pin Functlon Mating

-

c

-

c nce cto r

1 Chassis Gnd 6 Ground Connector Molex 09-50-3101

2 +5V DC 7 Grcqnd Termlnal Molex 08 -50 -0106

3 Spare 8 Ground Polarizinq Key Holex

15-04-0219

4 Key 9 Ground

5 +24: DC 10 -5V DC

AC Power Cabling

AC power cabling should be fabricatrd from U.L. accepted ccrd capable Qf

carry ing 1 amp at the Moltage at w hlch the drive is to be operated .

P4 - AC Connector

3 P1 n Amp

Pin Funct fon Ha ti nq Connector

1 Motor Power ''A'' Houssng Amp 35076 6-1

2 Frame Groepd Termlnal Amp 350550 -3

3 Ho tor Power ''B ''

1-4

Page 11

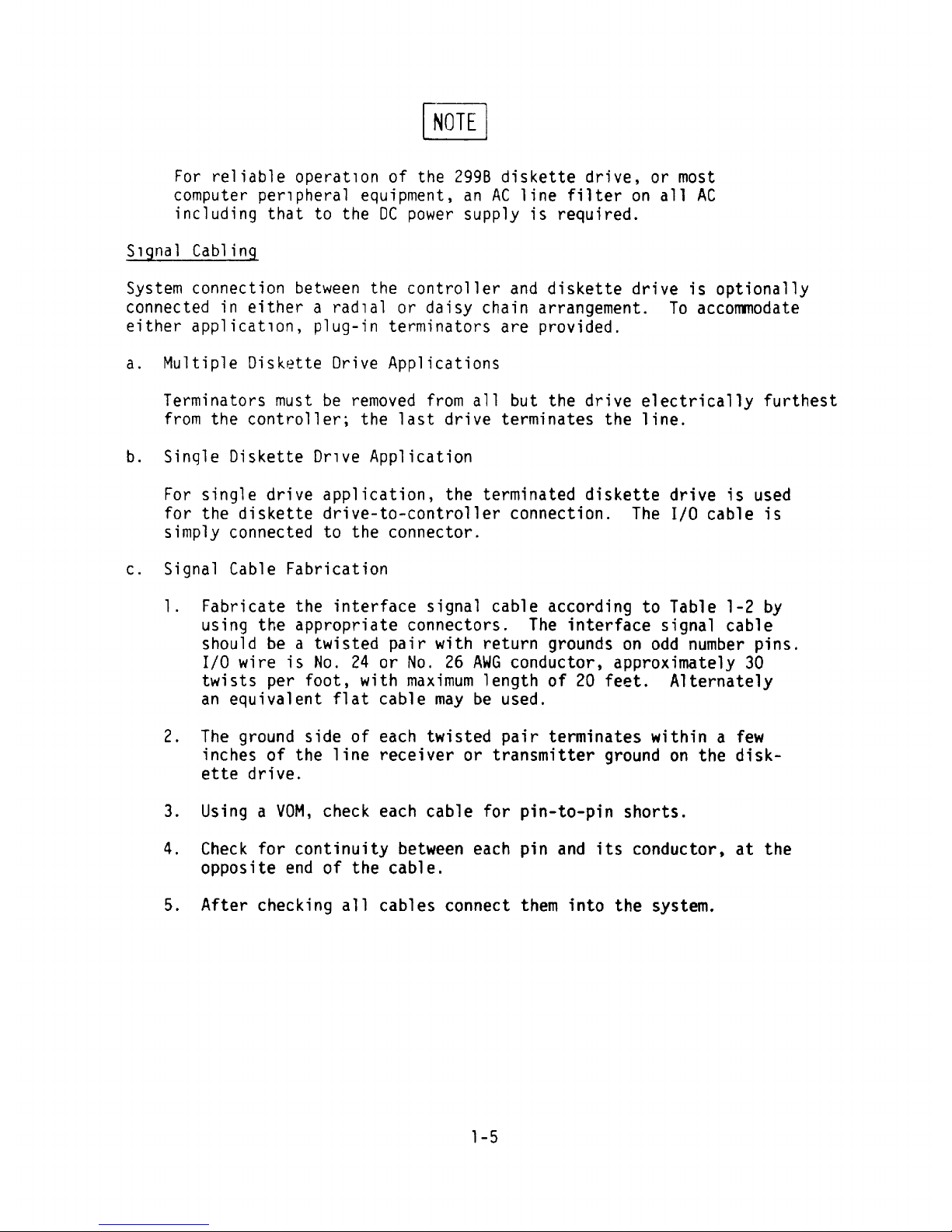

AOTE

For re liab le ope rat po n of the 2998 d is kette d rive , o r mo st

com puter pe rlpheral equ ipme nt . an AC l ine filter o n a11 AC

inc lud ing that to the OC power supply is requ ired .

S lgna l Cabl ing

Sy stem con nec tlo n be twee n the con tro lle r and d iske tte dr ive is opt iona lly

co nnected in e ither a rad lal or da isy cha in arrangement . T0 accommodate

eithe r app licatlon , plug-in te rm inato rs are prov ided .

a . Hu lt iple Dis kette Dr ive A pplicat ion s

Term ina to rs must be remo ved from a 11 but the dr ive electr ically furthest

from the controller ; the last d rive te rm înate s the l ine .

b . S inq le Diskette Drlve Appl ica tion

For single drive apqlication, the terminated diskette drive is used

for the diskette drlve-to-controller connection. The I/0 cable is

sim ply c onnected to t he co nne cto r .

c . S igna l C able Fabr icat io n

1. Fabr icate the interface s ignal cable accord ing to Table 1-2 by

using tbe appropriate connectors . T he interface s ignal cable

shou ld be a twisted pa ir w ith return grounds on odd num ber p ins .

I/0 wire is No . 24 or No. 26 AHG conductor. approximately 30

tw ists per foot . w ith max imum length of 20 fee t. Alternately

an eq uivalent flat cable may be used .

2 . T he g round side of each tw isted pa ïr term inate s w it hin a few

inc he s o f the line rece iver or tra nsm itter ground on the d isk-

ette dr îve .

3 . Usinj a V0H . check each cable for pin-to-pin shorts .

4 . Check for continu ity between each p in and its conductor , at the

oppos ite end o f the cab le .

5 . A fter che cking a11 cables co nnect them into the sy stem .

1-5

Page 12

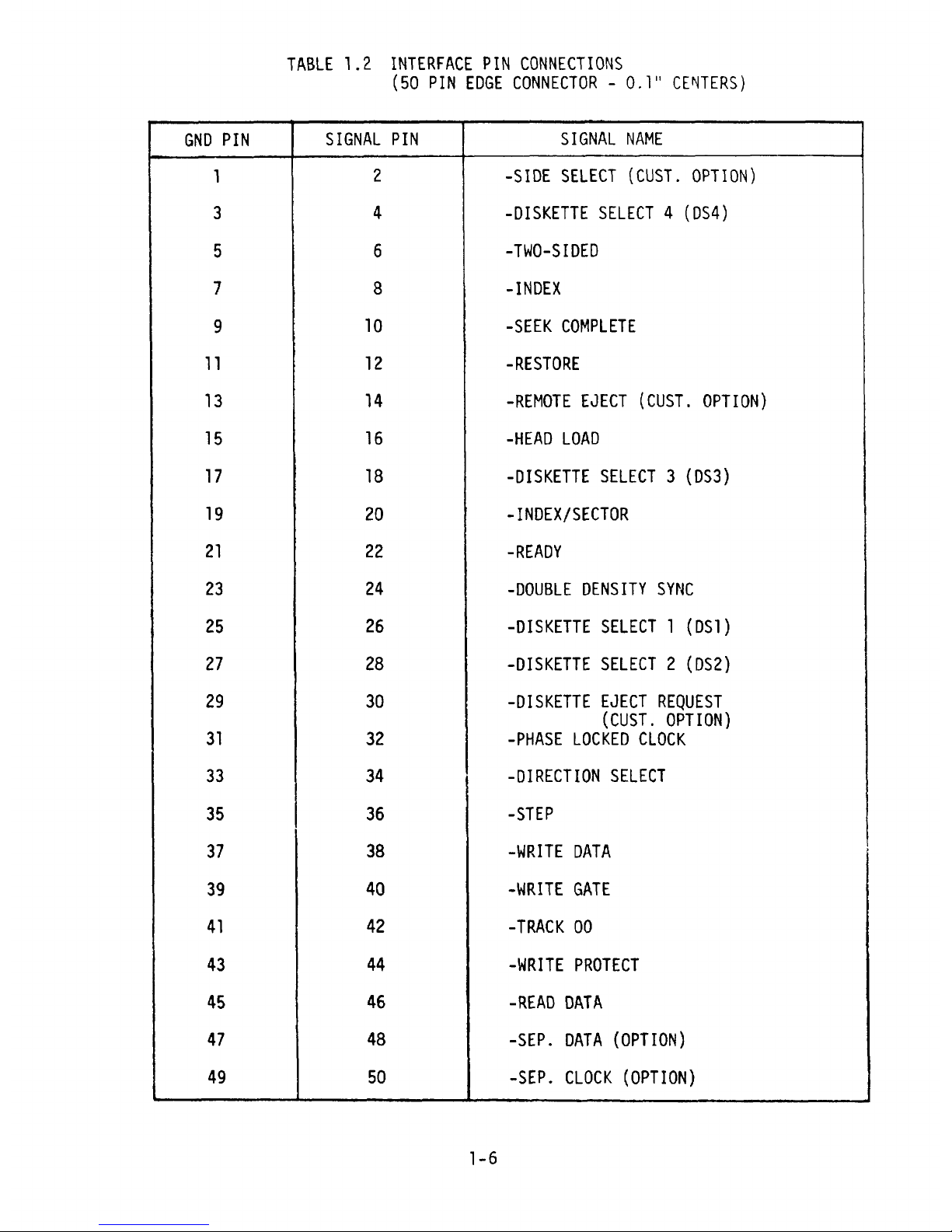

TABLE 1 .2 INTERFACE P IN CONNECT IONS

(50 P1N EDGE CONNECTOR - 0.1.' CENTERS)

GND P IN S IGNAL P IN SIGNAL NAH E

1 2 -SIDE SELECT (CUST. OPTION)

3 4 -DISKETTE SELECT 4 (9S4)

5 6 -THO-S IDED

7 8 -INDEX

9 10 -SEEK COHFLETE

11 12 -RESTORE

13 14 -REMOTE EJECT (CUST. OPTION)

15 16 -H EAD LOA D

17 18 -DISKETTE SELECT 3 (DS3)

19 20 -INDEX/SECTOR

21 22 -READ?

23 24 -DOUBLE DENS ITY S/NC

25 26 -DISKETTE SELECT 1 (DS1)

27 28 -DISKETTE SELECT 2 (DS2)

29 30 -DISKETTE EJECT RECUEST

(CUST. OPTION)

31 32 -PHASE LOC KED CLOCK

33 34 -DIRECT ION SELECT

35 36 -STE?

37 38 -HR ITE DATA

39 40 -HRITE GATE

41 42 -TRAC K 00

43 44 -HRITE PROT ECT

45 46 -READ DATA

47 48 -SEP. DATA (0pTI0N)

49 50 -SEP. CLOCK (0PTl0N)

1-6

Page 13

Ha ting Connecto rs

Vend or

kendor Part N

-

um ber com ment

Scotch Flex 3415-0000 Flat Cable

T & B Ansley 609-5005 Flat Cable

Viking 3VH25/1JN-5 Solder

Texas Instruments H312125 Solder

INSTALL D ISKETTE DRIVE

There are two methods of installing the diskette dr ive in a lg- inch Retma

rac k ;

Vert ical - 4 maximum

Horizon tal - 2 max imum

a . kertica l 19-înch Retma Rack Installation

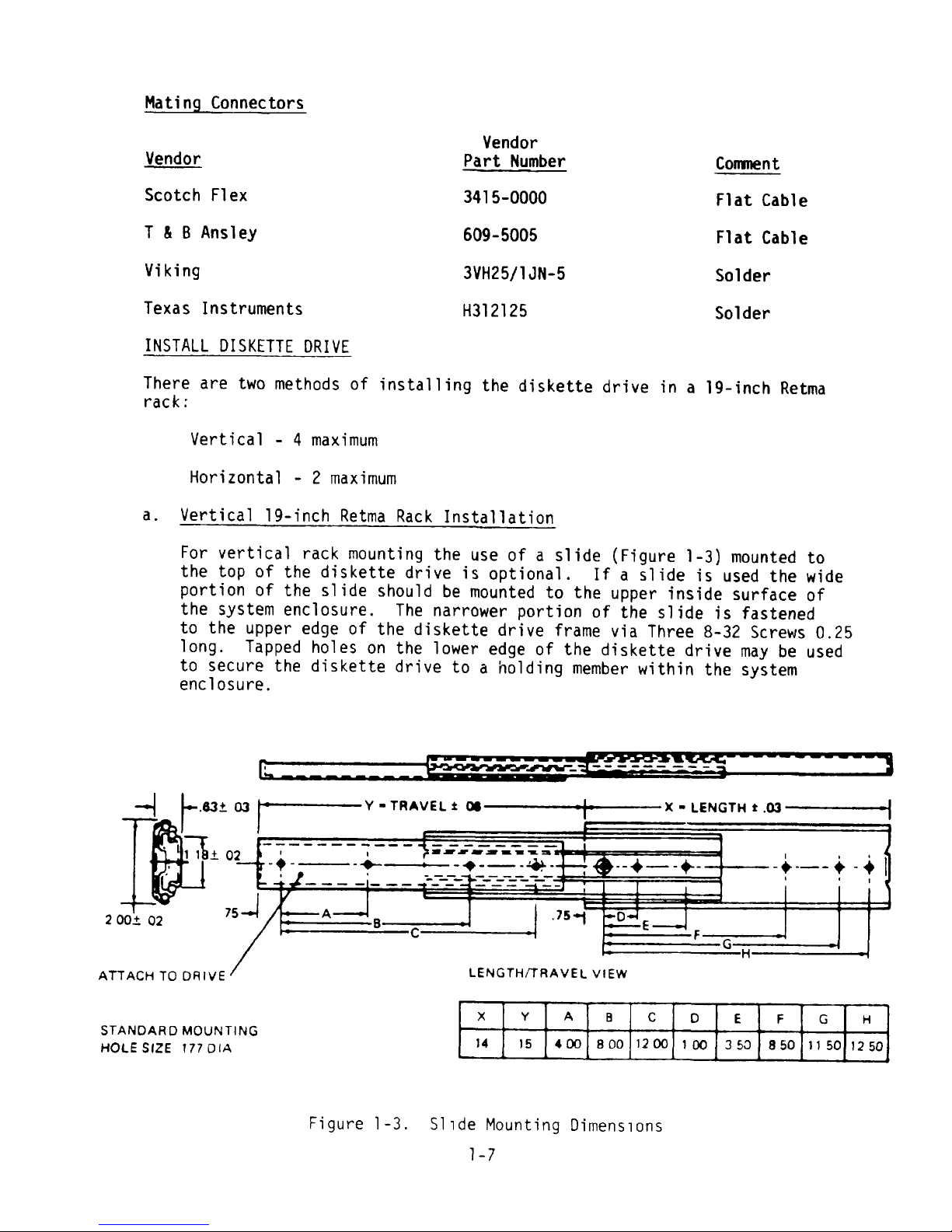

For vertical rack mounting the use of a slide (Figure 1-3) mounted to

the top o f the d is kette drive is o pt iona l . If a sl ide is used t he w ide

portion of the slide should be m ounted to the uppe r inside surface of

the system enclosure . The narrcwe r port ion o f the slide is fastened

to the uppe r edge of the d iskette d rive frame v ia Three 8-32 Screw s 0

.

25

long . Tapped ho les on the lower ed ge of the diske tte d rive m ay be used

to secure the d iskette dr ive tn a hold ing m ember w ith in the system

enc lo sure .

V .0â. û3 Y - TRAVEL à œ X - LENGTH 1 .X

'

1 1 .t 02 ' ç . VK* ** R-Q Q < l '

-

# - - - -. + . -+ - - - + - +- - + --- - Y - # j

= - - . .

.

r .c - - . . l

i A j . 75M D q752 X.t Q2 B c

- F G

H

c L E N G T H JT q A V E L v lEwA U A C H T O D 8 IV

x Y A B C () E F G 8

STA N D A R (7 M O U N T IN G

14 1 s 4 a ) 8 00 1 2 (% 1 (m a 6,3 8 50 1 1 50 1 2 508 O LE S 4Z E ! 77 (3 IA

Fi gure 1 -3 . S 1 1 de Hount i ng Di men s 1 o ns

1 - 7

Page 14

Alternatively îf a slide is not used , ''skid rails'' w ithin the system

enclosure may be used . Up to four dr ives m ay be moqnted vertically

in a lg-inch Retma rack. (Flgure 1-û.) The vertical orientation of

the diskette drive must be as shnwn . Vertical mounting of the diskette

drive is preferred over horizontal mounting .

b . Hor izontal lg-inch zetm

-

a R

-

ac k Insta

.

llat îon

If two drïves are mounted horizontally, ''sk#d Rails'' must be used as

there is insufficïent space to use slldes . lf a sfngle d iskette drive

is mounted hor izonta lly s tw0 slides , cne on each side o f the d fske tte

frame , shou ld be used . The w ide porticn o f the sllde should be fastened

t: the system enclcsure and the narrow portion to the d iskette frame .

The hor izontal orientaticn of the drive is shown in Figure 1-5 .

Powe r and signal cables may be c onnected to the drive prior to slld ing

into the system enc losure provid ing there ls enough service loop . or

if there is r ear access to the system enclo sure , the power and slgna!

cables can be installed after the d bskette drlve is mounted .

Dr ive assembly hea t dissipation under maximum seek activity is 291

BTU/hr (85 watts). To limit the maximum allowable operating tempera-

ture of the media to 125 F (46.1 C). an unrestrlcted flow of 30 cubic

feet per minute (CFH) cooling eir is reqoired.

Desk Top M ount ing

The dbskette d rlve may be desk top mounted , i .e ., Positioner Vertical .

Proper compensation is automatically made for the ma ss of the carriage

assem blies .

Diskette Load inq and Unlo.ad ïng

Prope r load ing of the diskette is vital to the operat ion of the d iskette

dr ive . Figure 1-2 show s the proper loca tion of the diske tte open inj for

lo ad ing .

Procedure for loading/unlcading the diskette is ûs fcllows :

a . lnsert the d iskette into t he desired side Df the diskette drive such

tha t the lab el is a t the oppos ite end of the slot from the pushbu tton

eject switch. A sensing devïce in the drbve will automatically close

the carrier when the d ïskette ïs inserted . D iskette 1 is on the left

side of an observer fac ing the dr ïve w hich is mounted such tha t the

slot ïs vert ïcal . Dïskette 2 ïs then on the r îght side .

b . To remo ke the d iske tte , press the pushbutton located nea r the slo t con -

taining the dïskette. The diskette w111 be ejected to where dt can

easily be remc ved from the d rive .

1-8

Page 15

@ *

* *

@ *

ê *

* #

. *

. @

@ @

Flgure 1-4 . Vertlcal Retma Rack Mountlng

e @

@ .

: @

11

@ @

Fi gure 1 -5 . Hor i zontal Retma Rac k Hount i ng

l - 9

Page 16

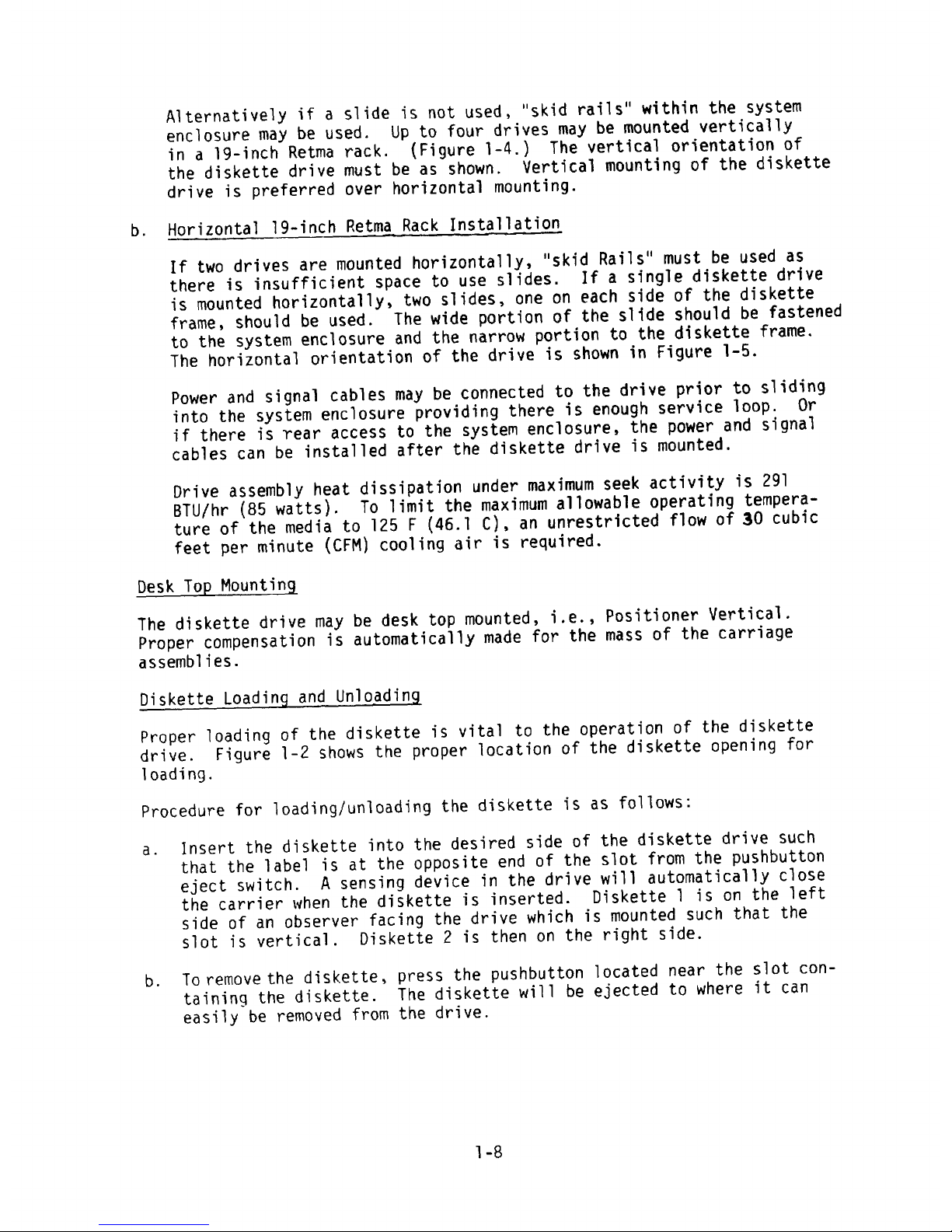

SLIDE MTG .

8 .00 .80 opy loNAk

2 MTG . HOLES Typ

98-32. .38 DEEP 2.19 j--

'

! !I

1

'

#

'

1

1

1

l

l

O 8 54

1 I I $

l : DIs- rIs-

4 HOLES *8-32 , .38 DEEP KETTE xgyyE

4 .00 ) ?0N 4

. 00 CE8TERS TYP

15 .00 u .2s = 4 .38

Figure 1-6 . Outline D imensions

OPTIONS

ln ork er to meet varying requïrements of different customers , persc i provides

the follow ing Customer-lnstallable Optîons:

Chassis Ground

Chassi! grcund is bcnnected tc signal grqund near the power ccnnector on

the drlve electronlcs PCB . This connectpon îs easily broken by cutting

trace cut A . Trace cut A îs located near the chassis ground inj lead . If

this trace cut is made , P 1n 1 of the power connec tor become s a chassis ground

line only .

Drive S elec

-

t Options

Fcur d iskette select inputs and a side select input are provided . T he

normal configurat icn uses Diskette Se lect 1 and 2 to select the d iskette .

and side se lect to select the side o f the diskette . Side se lect high w ill

select the normal side of the d iskette . and 10W the reverse side .

1-10

Page 17

Two Drive Option

Th is nc rma l conf igura tïon is de fïned as Dr ive 1 o f 2 dr ïves

.

To ope ra te

two dr ives in parallel , one drive must be this No rma l 1 o f 2

, a nd the

other m ust be c on figured a s Drive 2 of 2 d rives . Dr ive 2 uses oiskette

Selec t 3 and D iskette Sele ct 4 to se lect the d ïske tte a nd s ide se lec t f0r

the side Gf that diskette . Drive 2 of 2 d rives is option 2

. Re fer to

Tab le 1-5 for the connections regu ired for these configura tions

.

One Drive (Rotary) Option

The one drive (rotary) option uses the 4 diskette select lines to select

the d iskette and s ide of the d iskette . The side se lect line m ust be le ft

hig h o r open for th is co nfigura tion .

Diskette select 1 (DS1) selects Diskette 1 Side 0 (normal), DS2 selects

Diskette 1 Side 1 (reverse), DS3 selects Diskette 2 Side 0 (normal)! and

DSô selects Diskette 2 Side 1 (reverse). This configuration is Optlûn

3 , and may be im pleme nted by ma klng the connect bons found Jn Table 1

-

5 .

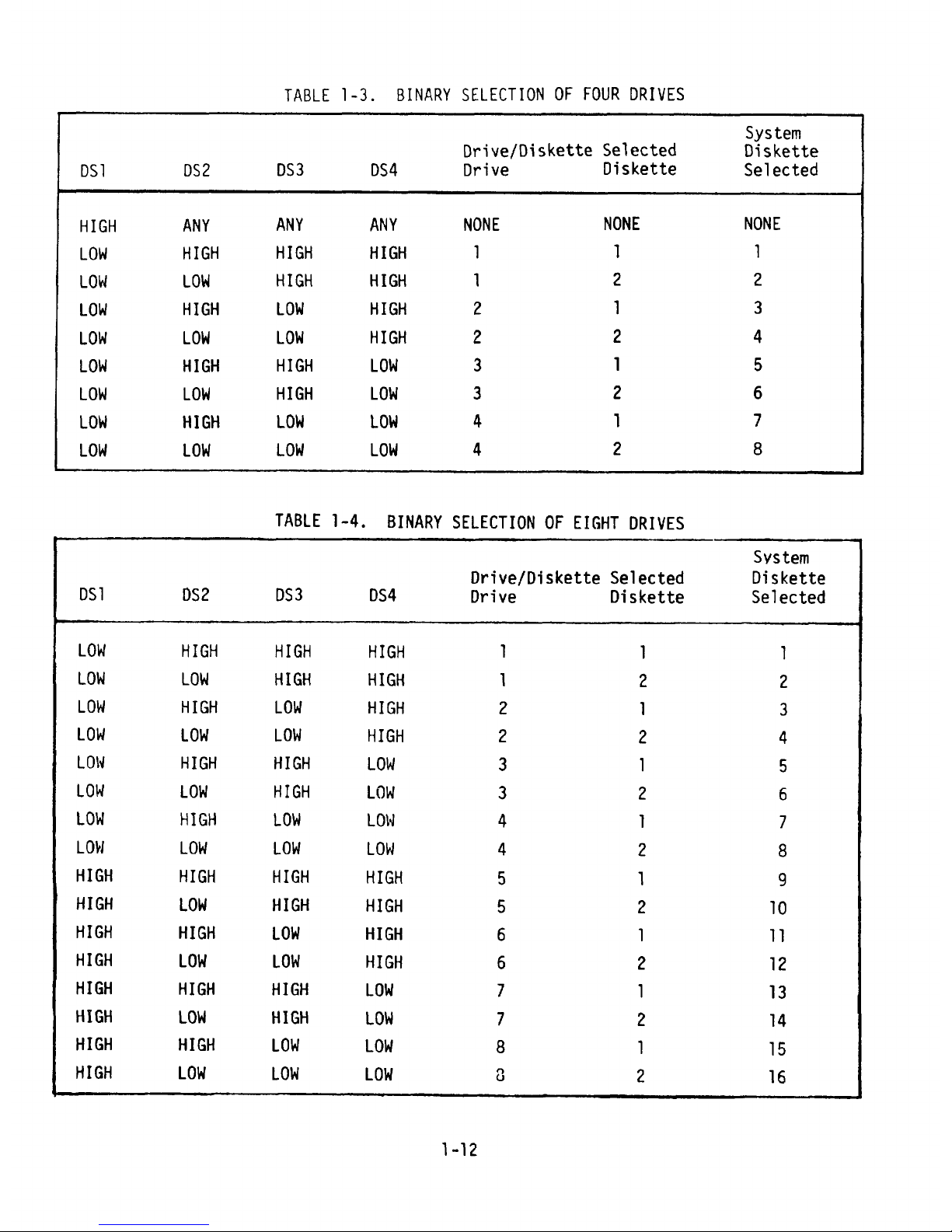

Four Drive Option

Four drives may be operated in parallel using the diskette select linesi

n a binary code to se lect each of the 8 d iskettes and slde se lect to

obta in two-sided record ing . ln this mode cf operation , DS1 is u sed as

un enable line . 1ow to enable ; and DS2 , DS3 . and DS4 are decoded ln a

binary fashion . Diskettes are selected according tn Table 1-3

.

Bina ry

Selection nf 4 Drives. This confisuratinn is option 4 . and can be im ple-

mented by referring to Table 1-5 to determine the connections required by

each o f the 4 d rives .

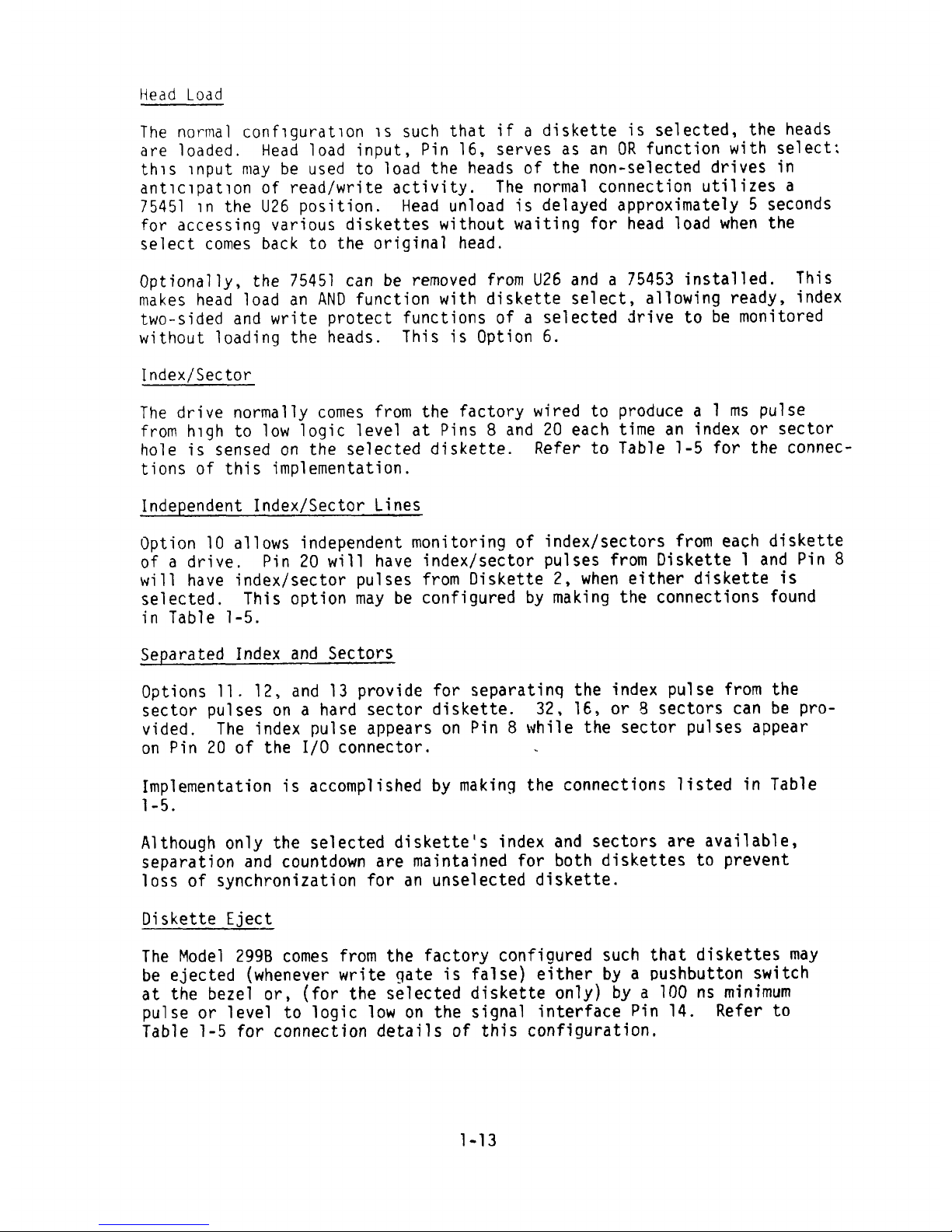

Eight Drtve Opt

-i-

o n

Eight d rives m ay be operated in para llel usic: the four d iskette select

lines in a b inary code . See Table 1-4 . If a 11 e fght dr fves are used

.

n o

state will be available f0r a11 d rives to be de-selected

.

i.e ., there w i11

alway s be one drive selected . This conflguratbon ls optson 5 and can be

implemented by making the requ ired connectfons as defined by Table 1-5

.

Line Term ination

A 220/330 chm resistor pack is iqstalled in U8. This kûck is used to match

the impedance of the input sijnal line pairs. Mhen drlves are used ln

parallel , this resistor pack must be removed from a11 drives but the 0ne

electrically farthest from the controller. The 220/330 ohm resistor pack

must be left in the drive electrically farthest from the controller to

maintain proper line term inat ion .

1-11

Page 18

TABLE 1-3 . BINARY SSLECT ION 0 F FOUR DRIVES

System

Drjve/Diskette Sllected Dqskette

DS l DS2 DS3 DS4 Dr lve Dlskette Se lected

HIGH ANY ANY ANY NONE hONE NONE

L0H H IGH H IGH H IGH 1 1 1

L0H L0% H IGH H IGH 1 2 2

L0k HIGH L0% H IGH 2 1 3

L0H L0k L0% HIGH 2 2 4

L0% HIGH H IGH L0% 3 1 5

L0H L0H H IGH L0% 3 2 6

L0k H IGH L0k L0% 4 1 7

L0M L0H L0H L0H 4 2 8

TA BLE 1-4 . BINARY SELECT ION 0F EIGHT DR IVES

Svstem

orive/Diskette Selected Diskette

DS 1 :S2 DS3 DS4 pr ive Diskette Selected

L0H H IGH H IGH H IGH 1 1 1

L0H L0H HIGH H IGH 1 2 2

L0H H IGH L0H H IGH 2 1 3

L0H t0% L0% H IGH 2 2 4

L0N H IGH H IGH L0H 3 1 5

L0H L0H H IGH L0H 3 2 6

LO% H IGH L0% L0l4 4 1 7

L0H L0M L0H L0H 4 2 8

H IGH H IGH H IGH H IGH 5 1 9

H IGB L0H H IGH HIGH 5 2 10

H IGH H IGH L0% H IGH 6 1 11

HIGH L0: L0: HIGB 6 2 12

H IGH H IGH H IGH L0% 7 1 13

H IGH L0% B IGH L0% 7 2 14

HIGH H IGH L0M L0H 8 1 15

HIGH L0M L0% L0H 0 2 16

1-12

Page 19

He ad Load

The noçm al co nf7gurat qon ls suc h that if a diskette is selected . the heads

are loaded . Head load input , P in 16 . serve s as an OR funct ion w ith select ;

th ls lnput may be used to lo ad the heads of the non -selec ted dr ives in

antlclpatlon of read/wrïte activïty . The normal connection utilizes a

75451 ln the U26 qosition. Head unload ls delayed approximately 5 seconds

for accessin: varlous diskettes without W ait ing fcr head 7oad when the

Se lec t comes bac k to the orïg ina l head .

Optbona lly , the 754 51 can be removed from U26 and a 75453 installed . This

makes head load an AND function With diskette select, allowing ready, index

two -sided and write protect funct ion s of a selec ted drive to be m on ltored

w ithout load ing the heads . This is Opt ion 6 .

lndex/sector

The drive norma lly com es from the facto ry w ired to prcduce a 1 ms pulse

from h lgh to 1ow logic leve l at Pins 8 and 20 each t ime an index or sector

hole is sensed on the selected dJskette . Refer to Table 1-5 for the connec-

tions o f th is implemen tat ion .

Independent Index/sector Lines

Optjon 10 allows independent monitoring Qf index/sectors from each diskette

of a drive. Pin 20 will have index/sector pulses from Diskette 1 and Pin 8

wil) have index/sector pulses from Diskette 2 . When either diskette is

selected . This option may be configured by m akin: the connect ion s found

ïn Table 1-5 .

Sepa ra ted Index and Sectors

Opticns 11 . 12 . and 13 prov ide for separatinq the index pulse from the

sector pulses on a hard sector d iskette . 32 . 16 . or 8 sectors can be pro-

vided . The lndex pulse appears on p in 8 wh ile the sector pulse s appear

on Pin 20 of the I/0 connector . -

lm plementat ion is accomplîshed by making the connection s listed in T able

1-5 .

Although only the selected diskette 's index and sectors are availab le .

sepa ratlon and countdown are ma întained for both d iskettes to prevent

loss o f synchro nizat ion for an unse lec ted d iskette .

Diskette Eject

The Model 2998 comes from the factory confijured such that diskettes may

be ejected (whenever write gate is false) elther by a nushbutton switch

at the bezel or. (for the selected diskette only) by a 100 ns minimum

pulse o r level to log ic 1ow on the ssgnal interface P in 14 . Refer to

Table 1-5 for connec tion de ta ils of th is configuratlon .

1-13

Page 20

I II()E' ï HOt E

v = 6 . 175 z . 005 ( 1 56 . 8 :!: . l nml ( S INGLF S I DE.D )

x = . 1 50 :t . 005 ( 3 .81 0 :t . 1 mm)

Y = . 200 :!: . 01 0 ( 5. 080 :!: . ?50 mm) INDEï HOLE

( DUAL S I DED )

Z = .075 :f .005 ( : .905 :f . 1 mm) O

Z

HEAD ACCESS

OPEN ING

Y

.

= k > - 't y

Figure 1-7. Vrite Protect Notch Lccation

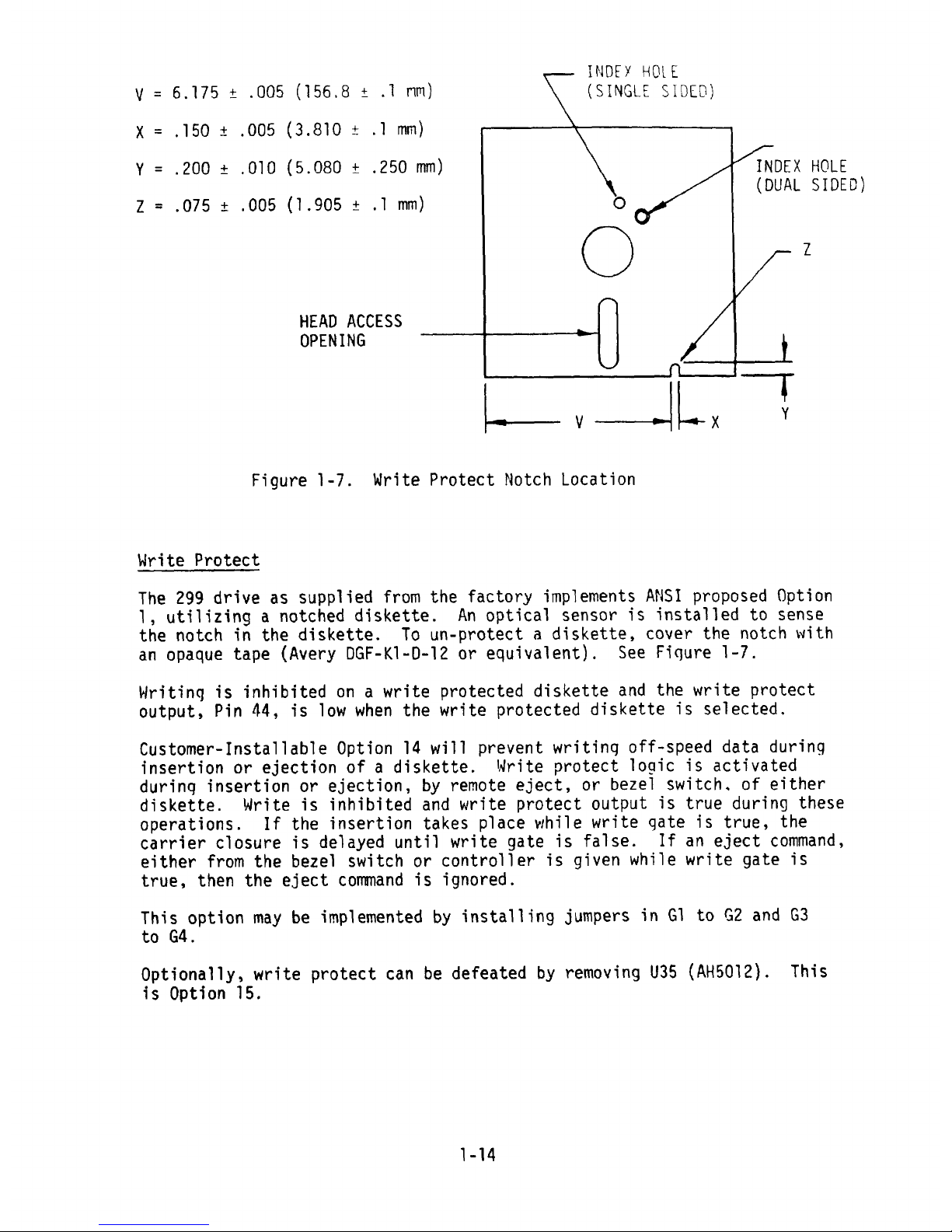

kr ite Pro tect

The 299 drive as supplied from the facto ry implements ANS I proposed Optlon

1 , utilizing a nctched d iskette . An optical sensor is installed to sense

the notch in the diske tte . Tc un-prc tect a d iskette s cover the no tc b w ith

an opaque tape (Avery DGF-KI-D-IZ or equivalent). See Fiqure 1-7.

Hritinq is inhibited on a w rite protected diskette and the w rite protect

output . Pin 44 , îs 1ow when the w rite pro tected diskette is selected .

Cu stomer- lnstallable Opt ion 14 Will prevent writlng o ff-speed data dur ing

însertion or ejection of a diskette. lkrite protect logic is actîvated

durinq insertion or ejection, by remote eject, or bezel switch. of eîther

d iskette . Hrite is inhib ited and Wr ite protec t output ls true turinj these

operat ion s. lf the insert ion takes place w hile W rite qate is true , the

carrier closure Js depayed until write gate is false. lf an eject command,

either from the bezel sw itch or controller is gqven wh ile w rite gate is

true, then the eject coFmand is ignored.

This option may be implemented by installing jumpers in G1 to G2 and G3

to G4 .

Optionally, write protect can be defeated by removing U35 (AH5072). This

is Optlon 15 .

1-14

Page 21

Hanual Eject lnhibit

Optîon 9 is the manual eject inhiblt option. Rith this configuration a

logic 1ow on Pin 30 of the signal înterface will prevent ejecticn by the

bezel pushbutton ; allow ing the controlle r to loc k in a d iskette until

reat/write operatjons in prcgress (i.e., closing files) are complete.

Refer to Tab le 1-5 for con nection deta ils .

Diskette Eject Request

Hhen Opt ion 8 is configured : the function of the bezel pu shbutton is

changed from ejecting the dlskette to prcducin: a logic 1ow at Pin 30.

The controller can then recognize this signal and issue an eject command

when a11 processinj is finished . Re fer to Table 1-5 for connection deta ils .

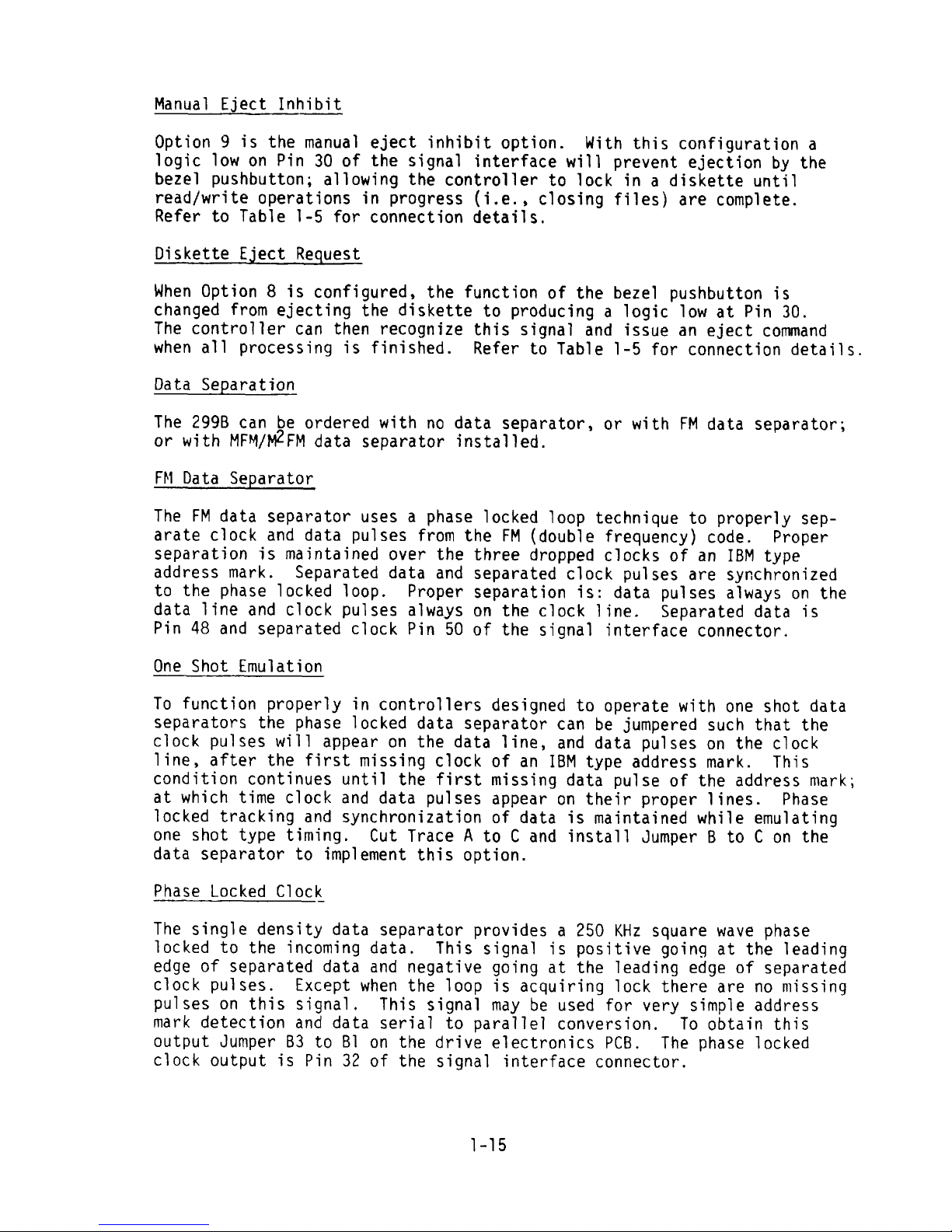

Data Sepa rat ion

The 2998 c an be ordered W ith no data se parator . or w ith FM data sepa rator ;

or with HFM/MZ FM data separator installed

.

Fh1 Data Se pa rato r

The FH data Separator use s a p hase loc ked loop techn ique to pro pe rly sep-

arate clock and data pulses from the FH (double frequency) code. Proper

se parat ion is ma inta ined over th e three dropped c locks o f an IBH type

address m ark . Separated data and separated clock pulses are sycchron ized

to the phase loc ked loop. Froper separation is : data pulses alway s on the

data l ine and clock pu lses a lway s on the c loc k line . Sep arated data is

?in 48 and se parated cloc k P in 50 of the signal interface connec tor .

0ne Shot Emu lat ion

To funct ion pro per ly in con trolle rs de signed to opera te w ith one shot data

separators the phase locked data separator can be jumpered such that the

cloc k pu lses w ill appear on the d ata line , and data pul ses on the cloc k

line ! after the first m issing cloc k o f an IBH type addre ss mark . Th is

condltion continues until the first misslng data qulse of the address mark;

at w hich time cloc k and data pulse s appear on the lr proper l ine s . Phase

locked tracking and synchron izat ion of data is ma ïnta ined While emulating

one sho t ty pe t iming . Cut Trace A to C and install Jum per B to C on the

data separator to implement this o pt ion .

phase Locked Clocq

The single den sîty data separator provides a 250 KHz square w ave phase

loc ked to the incom ing d ata . T his signa l is pos itive go in; at the lead ing

edge of separated data and negat ive go ïng at the le ad ing edge of separated

cloc k pulses . Except w hen the loop is acquiring lock there are no m issing

pulse s on this signal , T his signal m ay be used for very simple address

mar k de tect ion and da ta serial to para llel conversïo n . To obtaïn this

output J um per B3 to B1 on the dr ive e lectron ics PCB . The phase locked

cloc k output is Fin 32 of the sîgna l interface connector .

1-15

Page 22

MFM/H2FH Data separation

A data sepa rator is ava ilab le wh ich may be used for both of these codes .

A pulse appears cn the separated data l ine . Pin 48 of the signal interface ,

for each data pu lse in the cnde . These pulse s are synchron #zed to the phase

locked loop such that timing jbtter due to density effects is fîltered.

A reccnstructed c loc k derived from the phase locked loop appears on the

separated c lock line , Pin 50 o f the sîgnal in terface connec tor .

The HFH/M2FM data separatcr reguires a synchronizing pulse at the beginning

of eac h field independently w ritten on the d isk . In a hard sectored system

where sec tors are separated and co unted in the 2998 : Jum perïng B3 to B4

w ill prc vide this . o the rw ise , Jumpering B3 to B2 w 171 connect the sync

line to Pin 24 of the s igna l inter face connector .

FH Data Separator Adjustment

The FH data separator was adjusted at the factory. and normally needs no

maintenance. The only adjustment is the VC0 center frequency. This may

be adjusted wîth potentiometer R-12. Adjust while installed usinq the

fo llow in g proced ure :

1. Observe the sawtooth VC0 at T?1 (Approxïmately 4.4V p-p). Observe the

kC0 control koltage (range +0.4V to -0.4V) at T?2. The oscilloscope

sround s m ay ba connecte d to TP5 or T P6 .

2. Hrîte a dîsk using either a 4998 exerciser (STD. pattern) or the host

system for the drlve. (An a11 0's FH pattern gives least phase Jltter.)

Read this d isk fo r data input to the data separato r.

3. Adjust R12 until the system locks the saWt0oth to read data with the

sawtooth at Approximately 500 KHz. (Actual frequency is determined

by data frequency , : 2% average.)

4. Sontînue to adjust R12 such that the average value at TP2 is 0k t 50 mv

while locked at 500 KHz . rlote that ISV W ill cause this voltage to

oscillate about qround as the loo p tracks drive spee d .

MFM/MZFH Data Separator Adjustment

The MFM/HZFM data separator was adjusted at the factory o it normally requires

no malntenance. There are three adjustments; sync pulse. frequency, and

phase .

Sync pulse 7s adjusted With 229, frequency with Rl6, and phase With R4.

Adgust w ith the fo llow ing procedure W ith da ta separato r insta lled .

1. Prepare a disk of al1 0's using either a 4998 exercîser OIFM pattern)

or the ho st sy stem . Read this disk fo r da ta to the da ta separa tor .

1-16

Page 23

2 . Adgust the sy nc pulse at T ?8 to 2 5 0 pseconds us ïng R?9 . If necessary ,

trlgjer this pulse by temporarily Jumpering B3-B4 on the drive elec-

tronlcs PCB. (0r jumpering Pin 24 to Pin 20 at the signal interface

connector.) This is a negatsve golng TTL level pulse.

3 . O bserve the VC0 saw tooth at TP3 and the kC0 co ntrc l vo lta ge at T P2 .

Oscilloscope jround is available at T?1. Adjust R16 to lock the VC0

to the data Wpth the VC0 at 1 NHz. Continue to adjust R16 to center

the VC0 control voltage about ground (â 50 mk) while maintaining lock

at 1 HHz .

4. Observe the read data pulse at TP7 and the data/clock window at TP6 .

Adg ust the pba se contro l , R4 ! to cente r the tra iling edge of the read

data pu lse between the po sitlve go ïng edge and negatlve qo lng ed qe of

the data/clock window . Attempt to make this average setting within

à 20 n seco nd s .

Doub le Dens îty Data Compensat jon

The 2998 comes supplied from the factory to read 'IFN or M? Fn coted diskettes

that are w rjtten w ïthout w rite precompensation . The read electron ics may be

mod ified for optimum perfo rmance , when used w ith diskettes written y ith

Write precom pensation s by configuring Optîon 416 . Refer to Table 1-5 fo r this

con nec t pon .

Conflguration of O pt ions

ln the following table, the items listed unded ''Connectinns'' are jumqer

point s or 1C 's located on the drive electronics PC8 . IC 's are identlfied

by a ''U'' number and ''Type'' number. The jumper points listed affect the

particular function in that section only . An ''*'' under the jumper points

indicates that an ''ETSHED'' jumper exists and must be cut to produce an

open cond it ïon .

A ''J'' under a jumper point means that the tWo points HUST by jumpered,

An ''0'. means that the two points HUST be open. IC's will be fqllowed by

USE o r Oh11T . T hese cond it ions MUST be m et for any of the conflguration s

to func t ion pro pe rly .

1-77

Page 24

TAB LE 1-5 .

OPT ION COMPON ENTS , JUHPERS , AND T RA CE CUTS

FUNCT ION OPT ION # CON FIGURAT ION CONNECT ION

SELECT cl C3 c4 c 5 c7 c9 C 11

T0 T0 T0 T0 TO T0 T0

C2 64 C5 C6 C8 C 10 C 12

* * * * *

NO RMAL D R IVE 1 0F 2 0 J 0 J J J J

2 DRIVE 2 OF 2 J J 0 d J J 0

**3 1 DRIVE/NO SS J J 0 J J J J

4 4 DRIVES/8 -- -- -- -- -- -- -- X

DISKETTES

4-1 DR IVE 1 OF 4 J 0 J O J 0 O

4-2 DR IVE 2 0F 4 0 0 J 0 J O J

4-3 DR IVE 3 O F 4 J 0 J 0 J 0 J

4-4 DR IVE 4 0F 4 0 0 J 0 J J 0

5 8 9R1VES/16 '

DISKET T ES -- -- -- - - -- -- --

5-1 DRIVE 1 0 F 8 J 0 J 0 J 0 0

5-2 DRIVE 2 0F 8 0 0 J 0 J 0 J

**A lsc known a s ro tary select

.

Page 25

TABLE 1-5 .

OPTION COHPONENTS, JUHPERS, AND TRACE CUTS (Continued)

FUNCT ION OPTION # CONFIGURAT ION CONNECT ION

SELECT C1 C3 C4 C5 C7 C9 C11

T0 T0 T0 T9 T0 T0 T0

C2 C4 C5 C6 C8 C10 C12

* * * * *

5-3 DR IVE 3 0F 8 0 0 J 0 J 0 J

5-4 DR IVE 4 OF 8 0 0 0 0 J J 0

J5

-

5 DRIVE 5 OF 8 J 0 J 0 0 0 0

5-6 DRIVE 6 O F 8 0 0 J 0 0 0 J

5-7 DR IVE 7 OF 8 J 0 0 0 0 0 J

5-8 DR IVE 8 O F 8 0 0 J 0 0 0 0

HEAD NO RHA L DISKETTE SELECT OR

LOAD HEAD LOAD 1/0 U26 = 75451

6 D ISKETTE SELECT

AND HEAD LOAD I/0 U26 = 75453

Page 26

TABLE 1-5 .

OPTION COMPONENTS, JUHPERS, AND TRACE CUTS (Continued)

FUNCT ION OPT ION # CONFIGURAT ION CONNECT ION

D IS KETT E

EJ ECT D1 D3 D5 D7 U2? U2 3 U28

)5454 yy45y75453T0 T0 T0 T0

D2 94 D6 D8

* * * * *

NORHAL BEZEL SH ITCH J J J J OH IT OH IT USE

OR REMOT E EJECT

7 8 EZE L SM ITCH ONLY

OMIT OHIT 0H1T X(N0 REMOTE) J J J J

8 EJECT REOUEST 0 J J 0 USE 0H1T USE

9 EJ ECT INH IBIT J 0 0 J 0H 1T USE USE

Page 27

TAB LE 1-5 .

OPTION COMPONENTS, JUHPERS. AND TRACE CUTS (Continued)

FUN CT ION OPT ION CONFIGURAT ION CONNECT ION

INDEX/ SIDE 1 S IDE 2

SECTORS A2 A 1 A 5 A4 A7 A 9 A7 A9 B 5 E1 E3 C C U2 U3

7474 7474T0 T0 T 0 T0 T0 T0 T0 TO T0 T0 T0 T0 T0

A3 A3 A6 A6 A8 A10 A 10 A11 B6 E2 E4 -- --

+ * * * * *G WG

NORMAL COHHON I/O J 0 J 0 J J 0 0 J 0 0 J - G J - G OMIT OHIT

10 INDEPENDENT I/O 0 J 0 J 0 0 J J 0 0 0 J - G J - G 0H 1T OH IT

11 32-SECT0R5 J 0 J 0 J J 0 0 0 J J J - 32 J - 32 OMIT 0M1T ç

(SEPARATED) '=

12 I6-S ECTO RS J 0 J 0 J J 0 0 0 J J J - 16 J - 16 0!1lT USE

(SEPARATED)

13 8-SECTORS J 0 J 0 J J 0 0 0 J J J - 3 J - 8 US E USE

(SEPARATED)

HR ITE G) yg Ga G a Tg G4 r 3 s

.

A: 50)2PROTECT

NORMAL M R ITF PROT ECT 0 0 US6

F0 R SEL ECT DISK

14 MR ITE FROT ECT J J USE

NORMA L PL U S

DU R ING EJECT

IS N0 H RITE -- -- OM IT

PROTEST

Page 28

TA B LE 1-5 .

OPTION COHPONENTS, JUHPERS, AND TRACE CUTS (Continued)

FUNCT ION OPTION CONFIGURAT ION CONN ECT ION

DAT A ELEST RON ICS H1 T0 H2 H3 T0 H4

CO H P ENSA T ION +

NORHAL USE RITH %; HRITE J 0

PRECOHPENSAT ION

16 USE H ITH : RITE 0 J

PRECOHPENSAT ION

DOU8LE DENS IT? B3 T0 B 2 B3 T0 B4

DATA S EPARATOR NORHAL EXTERNAL SYNC J 0

SYNC (SOFT SECTORED) k

.

117 SECTOR SYNC 0 J

(HARD SECTORED)

S ING LE DENS ITY B3 T0 B1

PHASE LO CKE D 18 P

HASE LOC KED CLOC K 0CLOCK

FROH F/M DATA

SEPA RATOR

Page 29

SECT ION 2

HA INTENANCE

This section cnntains the follow ing :

Preventive ma intenance schedule and procedure s.

Maintenance check, adjustment and replacement procedures.

Diskette Dr ive Exerc iser . o pera ting procedures and replacement ,

FREkENT IVE HA INTENANC

-

E

- -

S

- -

CHE

-

DULE

kuarterly Cleaning

a . Cleac inte rior and exter ior surfaces w ith damp c loth using a

solut ion of non-abrasive c leaner . C lean d rive be lt . d rbke and

driven pulley s w ith alcoho l.

b. Cpean positioner scale surfaces using lint-free c10th (dry) and

vîsually exam ine fQ r fore ign partîcles after c leaning . Foreign

pa rt icles on the clear area of the ve loc ity wedges , even m inu te

ones. are part icularly de trimen tal to po sitio ner performance .

c . Clean positioner gu ide ra il with dry . lint-free c 10th .

d. Clean read/write head using alcohol.

Drive System Te st

a . Run available diagnostic test to verify proper operatinn of

d iskette drive .

PREVENT IVE HA INTENANCE FROCEDURES

Spind le D rive Sy stem

a . Remo ve the d rive be lt and engage both cones by manually depressing

Side l and Side 2 load cam shutter . H ith bo th cones engaged . the

dr fve be lt removed . and no med îa pre sent . the hub a ssembly shou ld

rotate virtually frict ïon-free . lf frict ion is detected then

either tbe hub or cone bearings are wo rn . The prob lem c an be

iso lû ted by rcta ting tbe hub se parately s then en gaging the cones

separately .

b . Rotate dr ive mo tor sha ft and check for uniform ity of torque .

A non-un iform rotaticcal torque may be due to worc bearings .

2-7

Page 30

Drive Be lt Tens ion

a . Drive be7t tension ïs measured by applying a side force to the

belt at the center of span between the crowned idler pu lley and

hub and measuring the deflection . place a scale a t the center

of span norma l to the belte Apply a 1 1b . force to the be lt us bng

a cantilever type fcrce jage and measure the resultant belt de-

flection . Belt tension ls correct when the deflection is .1 à

.

02 jnc he s .

Read/krite Data Amplitude

a . Diskette opera tinnal , drive ready .

b. Uslng a new 1BM Diskette 2, write an a11 ones pattern (FH) at

Track 76 . observe read data differentially at TF77 and 18 , ground

scope at T P8 o r TP14 .

c . Output must be at least 200 m v p-p.

d . lf the proper reading cannot be p btained , the possible problem

a r e a s a r e :

1 . Defective w rite drivers.

2 . Defective med ia . Repeat test w ith a d ifferent d iskette to

îso late problem .

3. Defective read/write head.

MA INTENANCE PROCEDURES

The maintenance procedures are divided as follows :

Chec k

Adjustment

Replacem ent

Tools a nd Test Eq uîpm en t

The follow ing material is required to perform the ma lntenance procedure s :

Com mon hand too ls

Fla shligh t

lnspec tion m ir ro r

Cotton-tipped swabs (k-Tips)

95% Iso prophy l alco hol

6-ïnch steel scale, l/loths

0 -1 oz . or 0 -30 gm . fo rce gage

1-1b . fo rce sa je

Al ignmen t Dis kette - DYHE K 80 2-11

Osc illo sco pe , Te ktron lx 465 or eq uîva len t

Drive Exe rc iser - Fersc i Mode l 4998

Kimw ipe s

2-2

Page 31

The cogn izant maintenance personnel should

read the entlre check , adjustment or replace-

ment procedu re prior to pe rform ing the rout ine .

Je

-

cks and Plugs

The interconnectïng plujs and jacks are listed ïn Table 2-1 and fdentifled

in Figure 2-1 . The connector pins should be checked for cleanliness and

tota l co ntac t if interm ittent problem s are encountered .

TAZLE 2-1 . JACKS AND PLUGS

ASSEHBL? CONNECTOR

Drive Elec tronics P1 Customer S ignal Interface

PCB 02 Voice Co il Motor Assem bly

03 DC power lnput

04 Eject and Harness PCB

15 Servo Lam p Assem bly

06 Hask Assemb ly

J7 Data Separator

08 Read Hrite Era se PCB

Read Hrite Erase J1 D iskette 1 Heads

PC8 02 Diskette 2 Heads

J3 Drive Electron ics PCB

Data Separator J 1 Drive Electronîcs FCB

PC8

Eject and Harness J1 Drive Electronics PCB

?CB 1 J2 Dïsektte 1 Eject Motor

J3 Carrier Sw itch 1 , Bezel Switch 1

Ac tivity Light l s lndex Sensor 1

04 Head Load Hechan ism l s Hrite Protect 1

2- 3

Page 32

TABLE 2-1. JACKS AND PLUGS (Continued)

ASSEHBLY CONNECTOR FUNCT ION

Eject and Harness J1 Drive Electronics PCB

PCB 2 J2 Di

skette 2 Eject Hotor

J3 Carrier Switch 2

,

Bezel Sw itch 2

Activity Light 2 , Index Sensor 2

04 Head Load Mechan #sm 2

,

Hr ite P rotec t 2

05 Index Light Sou rce

Deck J4 Sp indle Xo tor AC

Drive Elz ctronics PCB

The diskette electronîcs PCB contains the the customer 's l/0 connector

,DC power inqut connector and most of the electronics. lt also serves as

a d istributlon and gathering po int for a 11 nther sub-assem blies

y e xceptth

e spind le motor .

PCB Re placem ent

a . Disconnect a71 the connectors along the upper board edge

.

b . Rem ove the screw holdîng the lower board etge to the d iskette frame

.and re lease the catch

.

c . Remove three screws hold ing the PCB hinges to the FCB

.

d . Install replacement ?C8 by reverse procedure

.

e . A lignm ent o f re placem en t FCB to low er mount ing po ints is ach seved by

slac ken îng three screws ho lding hînges to PC8

.

Voltage Adjustment

No adjustments are provïded for voltage levels. If any voltage îs out of

tolerance . chec k fcr internal lc ad ing by d isccnnecting d iskette drive and

chec king levels at controlle r

.

If leve ls are co rrec t , check out cable or

iso la te a defect ive compo nent or as sem bly a t the dr ive e lectronics PCB

.If necessary . replace the PCB

.

2-4

Page 33

=

,

q a 'P A5 A4 j

ja2 os

DATA SEPARATOR PCB READ/HRITE HODULE PCB

J 2 J 4 2 5 J l

A l A z

: 3 J3

J I J 2 J4

EJECT AND HARNESS S IDE 1 PC2 EJECT AND HARNESS SIDE 2 PCB

= M =

J : :7 :6 J J# g

J 3

A I

l

lP1

l

l

DRIVE ELECTRON ICS PCB

Figure 2-1. P1Q9s and Jacks ldentificat ion

2-5

Page 34

D R I V E

M Q TQ R

O

5 * +

# 4 -4 0 SO C K Q T H EA D

A OJ U S F M E N T SC R E W

l I l l

'

O t ,! $

/ /

J ?

A

zz

> . . .

M

.

e

. . . .' e

T E N S lO N A D J U S T

ID t E 9

Figure 2-2 . Dr lve Sy stem

Dr îve Motor and Belt Cbecks

a. Set d iske tte power off .

b . Inspect d rive be lt fo r wear , pa rt icularly fray ing of the ed ges .

c . Hanua lly rotate dr ive m oto r. lf b ind ing is ev ident , re place moto r.

d . Verify belt ten sion .

e . Verify drive belt tracks in center o f both d rive and d riven pulley s ;

retrac k be lt if necessary .

Drive Belt Tension Adjustment

To adjust drive belt tension, proceed as follow:

a . Set d iskette power o ff.

b. Loosen idler shaft screw. (Figure 2-2.)

c . Slide id ler shaft away from d rive mo tor so as to tension be lt .

d . T ighten idler shaft screw and check belt tens ion .

e . Belt tension is correct when the belt deflect ion at the center of

span ls .1 à .02 inche s .

2-6

Page 35

Drlve selt Replacement

a . Se t d iskette powe r off .

b . Slac ken id ler pul ley shaft screw and slide shaft tcwards drive mo to r.

c . Remo ve m o to r .

d . Remove belt .

e . Clean mo tor and spind le pulley surfaces , w ipïng spar ing ly w ith alcoho l .

f. Install replacement belt and motor , carefully placing belt around moto r

pulley .

ç . Re -tens ion belt .

Ind ex T ransd ucer and Loqic Checks

The procedure for checkinç index transducer is the same for Side 1 as Side

2 . only the te st points and potentiometer s used are d ifferent .

a . Se t d isket te pow er on .

b . If the drive is of ''norma l'' configurat ion as defined in the options

sec tion , a 1 ms à 15% pulse occurring once each 166 .7 m s 1 2% w ill

occur at Pin 8 and Pin 20 w hen a ''soft sector'' d iskette is inse rted

and se lected. Check with Diskette 1 selected and w îth D iskette 2

selected . For both sides, check that extra pulses do not occur When

a d iskette is inserted . Chec k that pulses do n0t occer when the selected

diskette is removed (both sides). lf optional interfaces are used

refer to the options section to determine index/sector output character-

istics .

If the drive is beîng used as a soft sectored driye. only Steps a and b

above are requ ired . The follow ing steps are regulred only lf the drive

is to be used in a hard secto red env ironment .

c . Index transducer al ignment is c hec ked usïng a DYHEK 802 -11 a lignment

d iskette . Fo r its u se read the procedure sh ipped With each d iskette .

Determ ine if the drive is being used w ith single sided Qr two sided

tiskettes . If used w ith single sided d iskette . cover the index hole

furthest from d iskette center line w ith a write protect tab or an cpaque

tape . If it is to be used w ith a tw0 sided diskette . cover the m iddle

index hole . If both ty pe s o f d iskettes are to be used the al bgnment

must be perform ed each way .

d . Insert DYMEK alignment Diskette 802-11 into S ide 1.

e . Access Track 73 and load head assembly S ide 1 and select Head 1.

f. Monïtor read data at TP13 on the d rïve e lectron ics board ground ïng

the probe at T P14 ,

2-7

Page 36

g . Sy nc to lead inj edg e c f lndex qu lse a t ? in 20 o f 81 o n the dr lve elec -

tro nic s board .

PROG : INDEX TRANS DUCER

SYhC : EXT CH 2 NEG

CH 1 : .SV/DIV A .C .

NODE : CH 1 50 gSEC .

h. T he sta rt of the data burst should 1a9 t he ne ga tive go ing edge of the

inde x pu lse by 2O0 psec à 100 psec .

- - - - - . - . - - - - -

,

I jj' ' ' I t ' II

I

il

- .e. 1* ,1 j , j ,' j sc v s Ec/nl v

1 t. I

Figure 2-3 . Index Fulse and Data Burst

i. T hss is true for bo th T rack 73 and T rack 1 . Any d qffere nce ln reading

between these two tracks is due to machîne az imut h ; az im uth should

be checked before aligning the îrdex transducer .

j. Variaticns in reading will occur with successive insertions of the

diskette and an average read lnq shou ld be taken . Excessive var lations

w ith d iske tte inse rt ion , i .e ., greate r than 1 50 p sec , indica te a

med ia concentric ity or registration problem . lf this occurs , perform

the spindle cone check outlined on page 2-10 . T he timlng should remain

be tween 1 0 0 p sec and 30 0 gsec fo r a11 ca se s .

k. T o chec k index Side 2 load DtHEK alignm ent d iskette into S ide 2 and

select Bead 3. Leave scope probe at T?13 and repeat Steps e thru j.

Index Transduce r Alignment

This alignment is n0t required for dr

-

ive s u sed in soft sector env ironment .

To align the index-rransducer , sync from lead ing edge of index pulse and

monitor data burst on the DYHEK alignm ent dîskette 802-11 as described

in the index tra nsducer check procedure .

a . Alternately access Tracks 1 and 73 .

b. Observe time inte rval between negatïve edge of index pulse and data

burst .

2-8

Page 37

c. Adjust R4 until time interval is 200 : lû 0 psec fcr siqgle slded disk-

ettes . and R8 until t ime interva l is 200 : 1 o o psec for two sided d isk-

ette adjustment at Track 1. (Use R12 and q15 for Sfde 2 adjustments.)

Verbfy that it is 200 zl 00 psec at Track 73 .

d . Chec k w ith successive insertions of diskette that time interval remains

200 à l o û gsec at Track 7 .

e . lf this time interva) cannot be achieved by adjustment of the photo-

sense electronics . then prcceed as fcllow s:

1 . Po siticn the phcto sen se as c lose to the correct po sition w ithout

losing sijnal .

2 . Remcve d iskette .

3 . Hanually load the cone by pressinq the carrier in and observe the

alignment between the photosense and lamp modupe .

4 . Slacken two screws holdin: photnsense assembly to deck plate and

reposltion sach that the photosecse and lamp :re cpposite each

othe r .

5 . Insert d lskette and proceed w ith alignment frcm Step ; .

Index Transduce r Rep lacement

The ïnde x transducer consbsts o f two elem ents - the photosense assem bly

ant a common lam p assem bly .

Tc replace the photosen se assembly proceed as follow s :

a . Set d iske tte powe r off .

b . Unsolder the yellow . blue . and green lead s at the pho tosense assembly

observing lead pnlarity .

c . Remove Nc . 4 allen cap screws Securing photosense assem bly to carrier

and insta ll replacem ent a ssembly .

d . Snlder lead s, observing same polarbty as on the replaced assembly .

e . Perform index al ignment procedure .

To replace the lam p assembly proceed as follow s ;

a. Disconnect P5 from eject and harness PCB 2.

b . Remove two screw s securing lamp assembly to deck plqte . beiog careful

n0t to d ïsturb lens al ignment .

c . Remo ve lamp assembly and insta ll replacemen t assem bly .

d . Check ind ex aljgnment .

2-9

Page 38

l l F 1 1 R j N g

(3 PLACES) '

SHAFT

j2 pH0T0sENsE

CARRIER , '' ASSEXBLY

' %.9

l

.

09 : .01

. Aqayrq

I CLOSED

%ASHER

- . -

'

I LAMP

THRUST

BEARIN

ASSEPBLY

1

CONE FLANGE I

CONE SPRING

j

CONE

1

I

Figure 2-4 . Index Transducer and Ccne Assembly

Sp indle Cone Check

a . Connec t the Channel 1 scope prcbe to T?l3 on the diskette electron ics

PCB and ground at TP14 and the tr igger probe to ?1-20 . Set the sccpe

controls as follow s :

MODE : CH 1

VOLTS/DIk: 0.2 (10y probes) AC

SECONDS/DIV: 20 mS

TR IGGER SOURCE : EyT

TRIGGER COUPLE ; AC , NORM

TRIGGER SLOPE: (-)

2-10

Page 39

1 p

! , . 1 I

Peaks = 1 .2 V ' ' I

1 I ! '

f

Hndulation s drop ' I

zff to 1.1 vi *- i'

Reference

Peaks = ) .1 V

Mndu lations d op zff

to 1.0 V

1

After Reinserting

Figure 2-5 . Example of Good cone

I.1 = 92% peaks 1 '0 = 9q: yoduqat jons

1.2 1 .7

b. Insert an 1BN D iskette 1 or D iskette 2 w hich is known to have a good

center hole . position to Track 0 . select Side 1, and write a 1 's pat-

tern and O 's patte rn .

c . Carefu lly notice the am plitude cf the signal and the modulat ion char-

acteristics . Y ou w ill be looking fnr changes in amplitude and modula -

tion charac teristics , so study them before proceed ing .

d. Eject the disk, then reinsert it. D0 N0T HRITE again. Look for lower

amplitude or increased modulat ion . If the am pl itude of the en tire

signal or if any modulation decrea ses by 10% or more . the cone is bad .

Eject then reinsert the dlsk ten times. lf the cone looks bad any

one of the ten times , it 's bad and mu st be replaced .

e . Repeat a thru d for Side 2 .

2-11

Page 40

Sp lndle Cone Replacement

The cone assem bly engages the med ia w ith the drive hub . T he cone a ssem blies

for Slde 1 and Side 2 are the same and the replaceme nt procedures are the

same . To replace the cone o r any o ther part w ith in the assembly , proceed

as follows :

a . Set d iskette power o n .

b. Hanually depress the optical load shutter , thus engag ing the cone with

the hub .

c. Remove E ring holding the cone assembly to the carrier. (Fiçure 2-4.)

d. Press the eject button, i.e., carrier in disengaged pcsition.

e . Remove cone assembly , com pression spring , and shim washer , between the

spring and carrier .

f. D ismantle co ne assem bly by removîng E ring next to the thrust bearing .

g . Install replacement cone and assemble by reverse procedure .

Positioning System

The qositioner servo comprises a voice coil actuator, optical transducers,

carrAage essembly :nd the e7ectroqics requ ired to control the system .

Positioner circuits are located on the drive electronic PCB. (See Figure

2-6.)

Positioner

-

Se rvo Check

Using the osc illosco pe . observe the po sit îon tran sduce r output at T FC .

A signal sw ing of 3 .25 à .25V p-p is expected . Ground the o sc illoscope

at TP2 . Sy nc hron ize the osc illosco pe to the pos itive golng edge of seek

complete , ava ilable at a test point of the 4998 exerc iser or at ?1 ? in

10 s the signal interface connector to the dr ive .

After connecting the osc illo scope , alte rna tely see k between Trac k 00 and

Trac k 76 , us ing the tis ket te drive exerc iser in SL mode . ke rify that each

see k requires 100 ms k 5 ms : that the positioner transducer output is

3 .25 à .25V p-p m inimum durlng see k and that the po sitione r transducer sig-

na1 is balanced w ithin à 100 m t about ground . Observe at 0 .5V per d iv qsion

on the o scîlloscope .

Ste p sequent ially from trac k to trac k w ith the d iskette exerc iser . u sing

step m ode . Ver ify that the posit ioner settqes within O .5 d ivisions within

10 m s , and that there are no overshoots greate r than 0 .5 d ivision s.

(Observe at 0.5% per dbvision.)

See k in crescendo mode ! automatic , w ith t he exerc iser f0r at least two

cycle s to ver ify settl qng to e ach trac k from a h igh speed seek .

2-12

Page 41

Head Assem bly Track A lignmen t and H ac hine Azimuth

a . Se t d is ke tte pow e r on .

b . Lcad DYHEK alisnment d iskette 802-11 into Side 1 .

c . Acce ss Trac k 76 and load head assem bly Side 1.

d . Hon itor read data Head 7 .

PROG : TRACK ALIGNHENT SIDE 1

SYNC: EXT INDEX PULSE NEG. (PIN 20)

CH 1: 50 mV/DIV A.C.

MODE: CH 1. 20 mSEC/DIV

Scope probe CH 1 to TP13 o n data and interface PCB . Hoo k probe

gro und to T Pl4 .

e . lf track alignm ent is perfect the am plîtudes of the cat 's ey e pattern

will be equal. A 30% amplitude difference represents a 1% m i1 position

error. (Figure 2-6 ) 1% mi1 îs the maximum tolerable error.

Machine az imuth is important to , and need nn ly be chec ked for . hard sec tor

dr ive s . De lete tests f, g , h , and ï f0r soft secto r dr ive s.

f. Access Trac k 73 and load head s assembly Side 1 still usinj alignment

diskette . Set up as în ''Index Transducer and Logic Checks'' Fage 2-7 .

g. Observe time bnterval between sync and data burst. (Figure 2-3.)

h . Acc ess Trac k l and observe a ny change in this time interval .

j 1 . dl l '

4

1 j I !

j

l i ! . ' ' j,' 1, /1 I .1J ' ' ' ' '- 1. .! 1 . t

I

l , i li - #( $ j $s , jl

-

r I ,I

I

EkEN AHFLITUDE 100% 0N TRACK 70% AYPLITUDE 1% HIL 0FF TRACK

Figure 2 -6 . Track A lignment

i. If mach ine az imuth is correct the time inte rva l shou ld be the same

with in 100 psec .

2-13

Page 42

HEï S0 C BUTTON HD SCRE: HEX S0C HD CAP SCREHS

4-40 ï 1/4 LG (RECESSED) 4-40 / 1/2 LG

C C

: O

Z

@

HEX S0C HD CAP SCRE%S

4-40 X 5/8 LG

Figure 2-7A . Head A ssem bly Mountîng Screws Side 2

HEX S0C HD CAP SCREHS HEX S0C BUTTON H D SCRE% S

4-40 i 1/2 LG 4-40 X 1/4 LG (RECESSED)1

O O

@ o

o

HEï S0C HD CAP SCREHS

4-40 ï 5/8 LG

Figure 2-7B. Head A ssem bly Hounting Screw s Side 1

2-14

Page 43

20 mS/Dlk DELAtED SHEEP

I

I

l

1 mS/DIV

Figure 2-7C . Cat Eyes and Head Azimuth Display

-

12 M INTUES 0F ANGLE

+)2 MINUTES 0 F ANGLE

0 M INUTES OF A8GLE

Figure 2-7D . Head A zimuth A lijnment

2-15

Page 44

j. Select Side 1 and repeat Steps c throuçh i.

k. Repeat Steps c through j except with the 802-11 alignment diskette ln

Dïskette 1 pnsition and taking the index pulse from Pl Pin 8. (1f

separated index option, take index at Pin 20.)

Positioner Servo Adjustment

lf the positioner servo d id nct pass the check of the preceed inj section ,

alignment m ïght be requïred .

prelimlpary Adjustments

The positioner servo adjustments are located on the drive electronics PCB.

(Figure 2- 8 ) Before perfcrming the preliminary adjustments, unplug P2

from 22 on the drive epectron ics PC8 .

&

e % œ Q : j : 2 . t 1 œœ œ œ œ œ œ = = œ 3 œ œ

N :2

Y 9* 4

i

l

P l 1

TP5 !

rP4 l

T P 1

T P 2 I

T P 5

<Pl4 TP2

TPIS

Flgure 2-8 . Drlve Electronscs PCB

2-16

Page 45

TABLE 2-2 . FOS ITIONEE SERVO FREL IM INARY ADJUSTHENTS

TEST

FU8CT ION CONT ROL PO INT ADJUSTHENT S

Lamp voltage is normally only adjusted on installtion of new lamp. These

two settings are servn cqctrolleö to compensate fcr temperature and age;

they normally vary from lnitial setting - D0 N0T RESET IF OTHER SETTINGS

ARE CORRECT .

Lam p Vo ltage R-28 TP1 Set to 2 .5V à .1V

R-18 T?1 Hove positione r back and forth

over the fu ll stroke and set

R-2 fo r m in imum var iat ion in

lam p vo ltage . Expect to obtain

less than 50 m v var iation over

the stroke . Re set R-28 fc r

2 .54 1 .lV at TPI .

Velocïty R-33 TP3 Adjust for a 1.25k Dc-swinq over

Gain the full stro ke . Should be more

negative toward Track 76 .

Fine R-67, R-68 Tp4 Adjust fcr 3.25V p-p 1 .25V

position balanced about ground as posi-

tioner mo ved back and fo rth by

hand . R-67 is balance and R-68

is ga in .

Track Sense R-72, R-73 TP5 Adjust the bottom of sawtooth

wave form to .0V à .1V at T rac ks

2 through 76 (wi11 be triangle

Wave approximately .5V p-p).

and -1.25k à .1V at Track -1.

N ith servo co il connected , se t

TK 00 voltaçe at .754 A .05V and

ma ke sure the bo ttom o f saw too th

waveforms are st ill at 0k . R-72

is ba lance and R-73 is gain .

Osc ïllo scope TP2

Gro und

Fïnal Adjustments

The adjustments of the preceeding sections should be suffïcient for opera-

tïon , but for attainlng spec ïfied pe rfo rmance levels trac k sense and speed

should be adlusted tynamîcallt. Also. forward and reverse speed is balanced

by adjustinq R-l03 on the posptioner servo FCB.

2-17

Page 46

Move the o sclllo scope probe to TF4 , and oscillo sco pe ground to T?? on the

diskette electronics board. Alternately seek from Track 64 to Track 1.

Stnchronize the oscilloscope to the posltive edge of the ''seek complete''

sljnal found at a test po int on the exe rciser or at P1-10 on the da ta and

înterface PCB. Adjust R-103 for best symmetry between forward and reverse

see ks .

Sync On the negative edge of ''seek complete '' TP on the 4998 exerc iser or

P)-10 of the drive electronics PCB . Alternate seeks between Track 0Q and

Trac k 76 . keeping oscilloscope funct sons as they were , except fo r time .

Adgust R-10 such that the time f0r the longer seek (forward or reverse)

to settle w ithin .25V of ground is 95 to 100 ms . This com pletes the

adjustment of positioner servo.

Mead Assembly Track and Head Azimuth A lignment Sïde 2

a . Use a wr ite grotect labe l o r equ ïvalent to cove r the d ua l sided ïndex

ape rture on a DYHEK 802 -11 alignment d iskette ,

b. Loosen 4 -40 X 1/4 recessed screw holding Side 2 head assembly to carriage.

c . #ccess Track 76 .

d . Insert a lignm ent d iske tte Side 2 .

e . Hon îto r read data at TP13 , using a Te ktronix 465 or equivalent scope

Wh ich has a m ixed sw eep feature . T rigger scope ex te rnal negat lve off

index. Set main time base to 200 msec/div and delayed time base to

1.0 msec/div. Select Head 4 (fixed button bead).

f. Loosen two 4-40 1/2 cap screws holding Side 1 head assembly to carriage.

See Figure 2 -7A .

g . Adg ust assem bly for correct head az imuth . See Figu re 2-7C . Hea d az imuth

is witbin acceptable tole ranc e when the data bursts see n on the delay ed

tïme ba se lnd icate the head is W ith in t 12 m inutes of true position .

How ever , head az imut h interûc ts w ith machine az imuth : the refore ! for

head sector drïves best resu lts are obta ïned by setting head azlm uth

ds close a s fea slb le . Th is gives b est tolerance of param eter var iatio n .

lf necessary , to m eet mach ïne az imuth t ïm ing by cance lling to le rances ,

head azim uth may be re lax ed to à 12 minutes o f arc .

h. Tighten two 4-40 j 1/2 cap screws.

1. Remo ve d iske tte .

J . Tlghten 4-40 X 1/4 recessed screw .

k. Re -insert al ignment d iskette and chec k head az im uth .

2-18

Page 47

1. Adzust track alignment by loosening twc 4-40 cap screws holding the

position transducer to the ma in casting . Rad ial trac k alignment is

correct when the lobes Qf the cat's eyes seen on the main time base

are equa l or w ith in 70: of each other 's am pl itude ,

m . T ighten two 4-40 cap screw s.

IOTE

The posîtion transducer îs used to set rad ïal track alignment 0n

Head 4 only . After this has been set the transducer should n0t be

mo ved .

n . Loosen two 4-40 X 5/8 cap screws holding Head 3 to Head 4 .

o . Mon itor read data qead 3 .

p . lnsert alignment dqskette and access Track 76 .

q. Adjust head for correct ratial track and head azlmuth allqnment.

r. Tighten tw0 4 -40 ï 5/8 cap screws and check alignments.

Head Assem bly Track and Head Azimuth Aliç nm

-

ent

-

s

-

ide 1

8OTE

Side 2 head assem bly must be properly aligned before Side 1 can be

al igned .

The procedure for alignment is the same as Side 1 except thit radial a7ign-

ment of Head 1 (fixed button head) ïs accomplished by movlng the assembly

rad ially rather than movîng the transducer assembly .

Load Cam Shutter Al ign

-

m en t

a . Set d iskette power on .

b . Hanually depress the load cam shutter to allow the carrïer to c lose .

c . Depress the elect button on the bezel to allow the carr ier to open .

d . Observe how the pin frcm the top o f the shu tter r ide s on ûnd com es

to rest on the motor cam w hen the carrier is fully open .

e . The shu tte r pin should be parallel to the flat on the cam , în this open

posïtion. (See Figure 2- 9.)

f . Loosen the 4-40 sictted sc rew on the bo ttom of the casting and near the

fro nt of the egect and harness PCB . p ivct t he board in o r o ut sl ightly

to adgust the shu tter to cam t ïm ïng . Re-t ighten the 4-40 screw to secure

the PCB .

q. Repeat Steps b through e to check the adjustment.

2-19

Page 48

P I N

S H U T TER C A M

#

I !I

,

C R E W PC O4

-

4 0 S

Figure 2-9 . Load Cam Shutter Alignment

Eject Motor C

-

a m

.

A1 ignment

- .

chec k

a . Se t d is kette power o n .

b. Hanua lly depress the load cam shutte r.

c . Observe the crank cam moves to a bottom dead center position relative

to the carr ier plane , i .e ., maximum pene trat ion o f cone assemb ly into

hub. (See F igu r e 2- 1 0B .)

d. Depress eject button on bezel and observe the crank cam rotate to a point

where the bearlnç follower is just clear of impactqng the carrier plane ,

i.e ., 0 - .03.'. Once the carrier is open there must be no further contact

between the bearing follower and carrier. (See Fig ure 2-l0A .)

T h i s c h e c k d o e s n o t a p p l y to d r lv e s w i th S .N . a b o v e 5 35 0 0 .

C ra n k C a m A l ig n m ên t C h ec k

T h e c ra n k c am a n g u l a r a l lg nm en t i s d e te rm i na t ed by th e m o to r

c am a l i g nm en t . T o c h e c k f o r c am p e n e t ra ti o n p r o c e e d a s

f o l l ow s :

a . S e t d i s ke t te p ow e r o n .

b . M an u a l l y d e p r e s s t h e l o a d c am sh u t t e r .

c . O b s e rv e t h e g a p b e tw e en t h e E r in g w h lc h h o l d s t h e c o n e

a s sem b ly t o th e c a rr i e r a n d th e c o rr e s p on d in g c a rr i e r

surfac e . (See Figu re 2- 11 .)

d . W i t h th e c a rr i e r in th e l o a d e d p o s i t io n th e g a p s h o u l d

b e .0 3 5 ï .û 0 1 5 œ .

2-20

Page 49

Cran k Cam Al ignment Prccedure

-

a . Slac ken two Nc . 8 slntted screws securing motor bracke t to deck cast-

ing flange .

b. Set d iskette power on .

c . Manually depress the load cam shutter and observe 9ap described in

Paragraph c nf check procedure .

d . lf incorrect , slacken two N0 . 4 slotted screws holding motor shaft sup-

port to deck casting flange .

e . Displace arm . tighten screw s and cieck alignment .

f. Repeat until desired alignment is achieved .

g . T ighten 2 motor brac ket screw s a fte r al ign ins support arm .

h . After align ing the crank cam chec k the space betweec the phctc seq se

assembly on the carrier and the lamp assembly on the deck plate . H ith

the carrier in the loaded position this should be .09 à .01'% lFigure

2-4.) There is no adjustment for this. If the dimension is incorrect,