Critikon Dinamap IR Modul Service Manual

INVASIVE PRESSURE MODULE

INTRODUCTION

This area contains service information about the

Model 7330 Invasive Pressure (IP) Module. The

Module can monitor two channels of invasive

pressure derived from resistive bridge pressure

transducers. Monitored blood pressure typically

includes pulmonary artery pressure or central

venous pressure. Heart rate values are also

determined by a weighted average formula that is

applied to pulse rate data obtained from a pulsatile

invasive pressure.

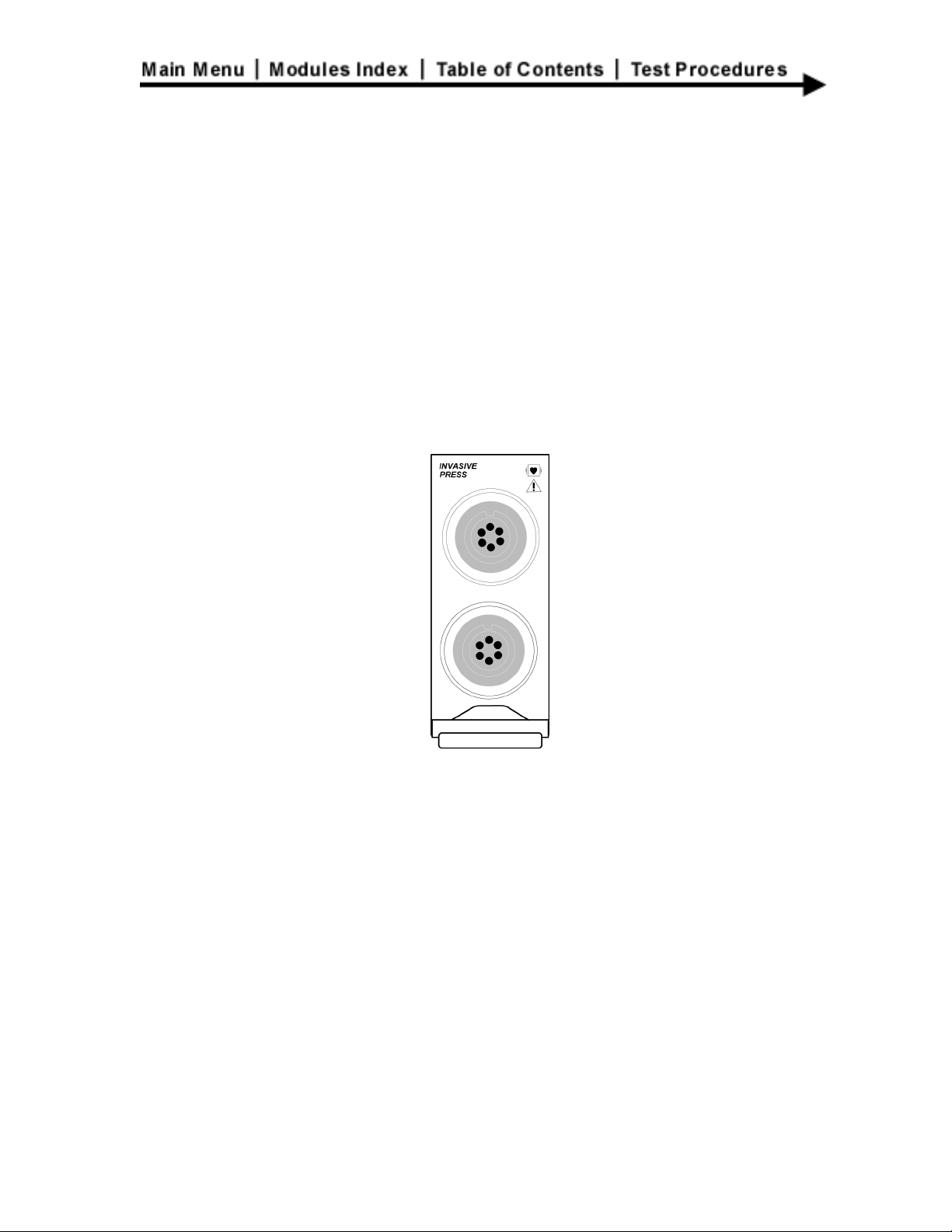

PHYSICAL

DESCRIPTION

The IP module, shown in FO-6B, occupies a single

parameter slot. The circuitry is contained on a

single, 6-layer PWA. The module contains a front

panel with connectors for one or two resistive bridge

pressure transducers. A flex circuit PWA transfers

the signals from the connectors to the rigid PWA.

The two layers of the flex circuit act as a shield for the

inner signal traces. Removable metal cans cover

the top and bottom of the PWB isolated circuitry. The

two side insulators (item 13) insulate isolated

circuitry from non-isolated circuitry, and thus ensure

compliance with patient safety requirements.

FUNCTIONAL

PRINCIPLES OF

OPERATION

Isolated Circuits

A functional block diagram of the IP Module is shown

in FO-6A. The diagram is divided into isolated

circuitry and non-isolated circuitry. The isolated

circuitry includes the EMI filters, IP front end

amplifiers and filters, A/D conversion, and isolated

control. The ISO interface and DC-DC converter

isolate this circuitry from the non-isolated core logic.

The core logic provides communication between the

system host and module through the PNet

synchronous serial interface. It also controls data

acquisition and data processing functions for the

pressure channels.

Isolated circuits are shown in the top half of FO-6A.

Signals from pressure transducers at two patient

connections are received through the module front

panel connectors and are connected to the circuit

board via a flex circuit. IP1 and IP2 are then filtered

and applied to the IP front end.

The IP front end supplies ratiometric excitation

(IPEX) to the transducers via the EMI filter and

amplifies the IP1 and IP2 input from the pressure

transducer bridge. Disconnect signals (DIS_CON)

are used to determine when a transducer has been

plugged in.

The A/D Conversion block samples analog data IP1

and IP2. A buffered version of the A/D reference is

used for transducer excitation. This allows the

readings to be isometric. The A/D converter is

controlled by the isolated control FPGA.

The ISO control FPGA receives serial commands

from the CPU and reports status and sends data

back to the CPU through the ISO interface. The ISO

interface provides an isolated asynchronous serial

communication channel between the core logic and

the isolated control FPGA.

Non-Isolated Circuits

The isolated power block consisting of +9V, +5V, -9V,

and -5V power supplies provides isolated power to

the patient connected circuitry.

Non-isolated circuits are shown in the bottom half of

FO-6A. Functional blocks include the PNet interface,

reset/failsafe, 68302 microprocessor, 8 bit memory,

and logic analyzer/test interface.

Power for the core logic (+12V and +5V), is received

through J1. The +12V is applied to the DC-to-DC

converter which powers the isolated power block.

The +5V supplies power to all non-isolated core

logic. The -12V and +3.3V power supplies are not

used on this Module.

The Module will not be damaged when plugged into

a live slot. Core logic power inputs to a module are

limited to a peak inrush current during hot-plugging.

Within 2 seconds the module responds to

identification and wakes up in a minimized power

state until registered with the system.

The PNet interface allows asynchronous and

synchronous data transfer between the core logic

and the external devices. Synchronous operation is

always used in MPS systems. Asynchronous

operation is for test and development only. The

reset/failsafe logic provides power-on reset,

processor reset and halt, and failsafe if a problem

occurs with the microprocessor. The

microprocessor controls and transfers data within

the core logic. The program memory is a FLASH

device that can be loaded with program information

from the PNET interface or the logic analyzer

interface. Data memory temporarily stores status

and monitoring data for processing.

COMPONENT

PRINCIPLES OF

OPERATION

EMI Filtering

IP Module PWA schematic SC315-447 and IP Flex

PWA schematic SC313-104 are contained here. The

first two sheets of SC315-447 show an overall block

diagram of the IP PWA.

The EMI filter circuit is shown on sheet 3 of the

schematic. Transducer signals are received on front

end connector J100 (sheet 1) with the following

pinout:

PIN NAME PIN NAME

1 IPEX2-_RAW 5 IP1+_RAW

2 IP2+_RAW 6 IPEX1-_RAW

3 IP2-_RAW 7 IPEX1+_RAW

4 IPEX2+_RAW 8 IP1-_RAW

The transducer plug shield is connected to shield

ground (SGRD). SGRD is terminated to ground (IG)

by a 10KΩ resistor. Filtering on all transducer

signals is accomplished by a ferrite core encircling

the flex, providing common mode filtering. Also,

1000 pf bypass capacitors C149 through C152 and

C154 through C157 decouple each signal to the

internal shield. These signals are clamped at ±9V

by CR13 and CR14. As shown on sheet 4, the input

signals IP1+/- and IP2+/- have additional lower

frequency common mode filtering through C125,

C126, C130, and C131, and differential mode

filtering through C122 and C147.

IP Front End

The IP front end amplifies and filters the input from

the pressure transducer bridge. The IP front end is

shown on sheet 4 of the schematic.

Pressure Channels

Excitation drivers U124-5,6,7 and U123-1,2,3 buffer

and scale AD_REF from the A/D converter to provide

a nominal transducer voltage excitation of +4.97V

(IPEX1+ and IPEX2+) for both pressure transducers.

This gives a nominal scale of 24.85 µV/mmHg at the

input, for a transducer which has a gain of

5µV/V/mmHg. Since the excitation is derived from

the A/D reference, the system is ratiometric and

variations in the reference cancel. R174, C141 and

R173 and C142 provide lead compensation for the

excitation driver.

The bridge outputs from the transducers are

received differentially through instrumentation

amplifiers U100 and U101. The dynamic range of

the channel is nominally an input pressure of ±500

mmHg. The instrumentation amplifiers have a gain

of 100. The pressure channels (IP1 and IP2) are

then passed through 4-pole, low pass, 40 Hz

Butterworth anti-aliasing filter U119, with an

additional gain of 1.638. The two pressure channels

(IP1 and IP2) are then multiplexed and buffered

where they are presented to the A/D for conversion.

An IP1 or IP2 output of ≈800 mV is equivalent to 200

mmHg.

Disconnect Detection Circuitry

DIS_CON_1 and DIS_CON_2 are buffered versions

of the common mode transducer bridge voltages.

When an IP cable is disconnected, this voltage is

pulled to the negative supply (-5V) via 10 MΩ pull-

down resistors R187 and R189. Pull-down resistors

are used on both the positive and negative inputs of

the instrumentation amplifiers to minimize errors

due to offsets currents through the transducer.

When a transducer is plugged in, the common mode

voltage is pulled up to half of the excitation voltage

(+2.5V). Disconnect signals DIS_CON_1 and

DIS_CON_2 are monitored via an A/D converter. A

disconnected cable gives a full scale A/D reading of -

2.048V, while a connected transducer is ≈ 2V.

Test/Calibration Interface

U112 consists of two double-pole double-throw

analog switches are used in front of instrumentation

amplifiers U100 and U101. These switch in

calibration signals for channel gain and offset. The

control for these signals is provided by the Isolated

Control section. With IPTESTZERO-0 low, asserting

IPTEST1-0 and/or IPTEST2-0 pulls both inputs of the

instrumentation amplifiers to ground allowing the

channel zero to be read. Releasing IPTESTZERO-0

turns on Q102 and Q103, and provides

approximately 5 mV at the junction of voltage dividers

R148-R146 and R154-R155. This voltage is applied

through the analog switches to instrumentation

amplifiers U100-3 and U101-3 when IPTEST is

selected. This voltage is equivalent to 199.8 mmHg

and used for a calibration signal. This allows the

gain of the channels to be calibrated. Additionally,

anti-aliasing filter U119 response may be checked

by using the Service Mode facility to input a step

function and monitor the transient response of the

filter output.

A/D Conversion

The A/D conversion block samples the analog data

under control of the isolated control block. This

circuit is shown on sheet 5 of the 315-447

schematic.

Reference

The reference AD_REF at TP100 for the A/D is the

4.096V internal reference provided by the MAX191

A/D converter U111. The A/D reference, scaled and

buffered at U123 and U124, provides the reference

for the transducer excitation for both pressure

transducers.

Multiplexer Control

The two pressure channels (IP1 and IP2) are

multiplexed by U102 and buffered by U122 where

they are presented to the A/D for conversion.

Clamping diodes before the A/D buffer keep the

input to the A/D within a diode drop of the supplies

(±5V). The 8-to-1 multiplexer U102 controls channel

selection of IP1, IP2, DIS_CON_1, DIS_CON_2, and

resistor networks R108-R113. The resistor

networks allow the A/D converter to monitor ±9 and 5V power supplies. The select signals, MUX0,

MUX1, and MUX2 are controlled by the isolated

control section. The isolated control section

controls the switching of the select signals, and

takes into account the acquisition and settling times

needed between A/D conversions.

Isolated Power and

Interface

Converter Characteristics

A filtered version of digital power supply +5VD (+5VA)

is used to power the A/D converter U111. The A/D is

a bipolar 12-bit sampling converter with full scale

ranging from ±2.048V. This yields approximately 4

LSBs/mmHg for the pressure channels. Digital data

is output (DOUT) serially and formatted in 2’s

complement. The conversion rate is determined by

the AD_CLK (SCLK) frequency, normally 410 kHz.

Conversion Control

Conversion is initiated by the assertion of AD_CS

and the next falling edge of the clock (AD_CLK).

These control signals are derived from the isolated

control section. Data (AD_DATA) is valid on the

AD_CLK rising edge.

The isolated power block is shown on sheet 6 of the

schematic. It provides power to the patient

connected circuitry which is isolated from earth

ground for patient safety. The isolated

communication interface is shown on sheet 7 of the

schematic. It provides an isolated asynchronous

serial communication channel between the core

logic and the isolated circuitry.

Isolated Power

The isolated power section provides patient isolation

from earth ground (compliant with UL 2601 and IEC

601) by isolating the power for the patient connected

circuitry.

DC-to-DC converter PM100 provides isolated,

unregulated power outputs of ±12VDC (+VS and -VS)

derived from the system non-isolated +12VDC

supply. L1 provides common mode filtering to

reduce noise generated by the DC-to-DC converter.

Voltage regulators driven from the isolated supply

provide regulated +5VDC, +9VDC, -5VDC, and 9VDC supplies for the isolated circuitry.

The positive regulated supplies provide open

collector PWR_OK signals which are ORd together.

A logic low signal indicates that one of the regulator

outputs has dropped by more than 5%.

The +9VDC, -9VDC and the -5VDC supplies are

scaled and monitored through the A/D converter

(R108-R111 on sheet 5).

The isolated power supply is turned on when Port A

bit 6 from the CPU (ISO_POWER_ON-0) is enabled

(active low).

Isolated Interface

Opto-couplers U105 and U106 provide a full duplex,

isolated serial channel between the non-isolated

core logic and the isolated circuitry. The isolated

control block receives data through opto-coupler

U105 and transmits on U106. Opto-coupler U107

transmits the baud clock (16x baud rate) which

provides the clock (ISO_CLK, normally 830 kHz) to

the Isolated Control. Q100, Q101, and Q105 buffer

the signals to the opto-couplers.

Isolated Control

The isolated control block is shown on sheet 8 of the

schematic. The isolated control block accepts

commands from the core logic, provides the control

for the isolated circuitry, reads input data, outputs

data, and commands a/d conversion. Sampled data

is passed back to the core logic through this

interface.

The isolated control is implemented with a fieldprogrammable gate array (FPGA) U104. EPROM

U103 stores the configuration data for FPGA U104.

This data is downloaded to U104 on power up. The

function of the isolated control block is to accept

serial commands from microprocessor U10 via the

ISO Interface and output the appropriate control

signals, AD_CS, AD_CLK, and MUX 0-3 to the

analog circuitry and to transmit sample data

(AD_DATA) and status back to the microprocessor.

This controls the MUX channel selection, the

operation of the A/D converter, and the IPTEST

signals.

Core Logic

The core logic is shown on sheets 9 through 13 of

the schematic. The core logic provides

communication between the system host and

module through the PNet synchronous serial

interface. It also controls data acquisition and data

processing functions for the pressure channels.

The module is an 8-bit version of the core logic with

one 128Kx8 RAM and 128Kx8 ROM device. The

microprocessor runs at 9.966 MHz.

PNet Interface

The PNet interface, shown on sheet 10 of the

schematic, provides the following functions:

• RS485 drivers (U7 and U8) for serial data and

clock,

• Module select and presence detection (U2),

• Module reset (U6 and U9), and

• Module synchronization.

Core signals are received on PNet connector J1

(sheet 2) with the following pin-out:

PIN NAME PIN NAME

1A,1B +5V 6B M_SELECT

2A DATA+ 7A M_PRESENT

2B DATA- 7B TXOC-0

3A,3B +3.3V 8A M_SYNC-0

4A CLK+ 8B -12V

4B CLK- 10A,10B +12V

5A,5B GROUND 1,2 GROUND

6A M_RESET

The IP module is designed to be hot-plugged, or

inserted and removed from powered systems.

Ground pins 1 and 2 are longer than the other

connector pins, thus they make first and break last to

protect circuitry. Protective impedance located on the

system backplane, in series with the modules +5V

and +12V power, limits inrush current on hotplugging or live insertion. Series impedance on

PNet control lines also limits inrush and protects

logic devices from excessive currents during a hotplug power up.

The PNet protocol defines two modes of operation:

synchronous and asynchronous. The normal mode

of operation is synchronous, with half duplex

transmitted and received data on differential signals

DATA+ and DATA-. The device transmitting the serial

data also generates differential clock signals CLK+

and CLK-. Transceiver direction for data and clock

are controlled by the 68302 processor-generated

TX_EN-0 (low true transmit enable) signal through

U2. In the synchronous mode, both data and clock

transceivers U7 and U8 are set to receive (i.e.,

transmit disabled) when fail-safe signal FS-0 is

asserted.

The alternate serial mode, full duplex asynchronous,

is entered by asserting processor generated control

bit ASYCH_EN. This mode transmits data onto the

differential signals CLK+ and CLK-, and receives

data from the differential signals DATA+ and DATA-.

The transmitter in the module is disabled unless the

module has been commanded to transmit per the

PNet protocol. The module transmitter is

immediately disabled after the last character of a

transmission has been sent.

The module select input (M_SELECT, hi true)

instructs the module to respond to identification

requests. When both M_SELECT input and

M_RESET input (hi true) are asserted, a module

performs a hardware reset.

The module present output, M_PRESENT is

connected to M_SELECT through diode CR1 to allow

a means of determining if the module is plugged

into an instrument. When M_SELECT is asserted

(pulled hi) M_PRESENT is hi true.

A low true open collector signal TXOC-0 from Q1

signifies the module transmitter is enabled. Serial

data is then transmitted in the synchronous mode.

M_SYNC is a signal used for timing purposes that

require shorter latency time than supported by the

serial data protocols. M_SYNC is not asserted by a

Module unless enabled to do so by the host. At the

time of publication, the IP Module does not drive

M_SYNC.

Reset Logic

The reset logic is shown on sheet 11 of the

schematic. Power on reset is generated by U9 when

the unit is powered up. Processor reset (RESET-0)

and halt (HALT-0) are generated by the system.

RESET-0 AND HALT-0 signals remain low for

minimum of 130 msec after all logic rail is in

specification.

External reset, processor reset, and halt signals are

low for minimum of 24 clocks when external reset

asserted. Power monitoring, processor reset, and

halt signals low when logic rail drops below

specification. they remain low for minimum of 130

msec after logic rail returns to specified range.

The reset circuit (U6-4,5,6; U6-11,12,13) provides

open drain outputs to the processor bi-directional

reset and halt signals.

Fail-Safe Logic

Fail-safe latch (U6-1,2,3; U6-8,9,10 on sheet 11)

ensures that the module enters a safe state should

the processor fail to operate correctly. The latch is

set by a low true output from the processor watchdog

timer (WDOG-0). The data transmitter is disabled

and module remains in a safe state until the latch is

cleared by a power on or external reset.

Microprocessor

The core logic design is based around the 68302

microprocessor (U10) shown on sheet 12 of the

schematic. The 68302 combines a 68000 core with

a three channel communication processor, and

system integration circuits.