Critical Environment Technologies GEM-II Operation Manual

Operation Manual

www.critical-environment.com

GEM-II Self Contained Gas Detector

Rev. E | 2014.10

2 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

TABLE OF CONTENTS

1 POLICIES .................................................................................................................. 5

1.1 Important Note ..............................................................................................................5

1.2 Warranty Policy ..............................................................................................................6

1.3 Service Policy .................................................................................................................6

1.4 Copyrights ......................................................................................................................7

1.5 Disclaimer ......................................................................................................................7

1.6 Revisions ........................................................................................................................8

2 INTRODUCTION ..................................................................................................... 9

2.1 General Description .......................................................................................................9

2.2 Key Features...................................................................................................................9

2.3 Model Designations .....................................................................................................10

2.3.1 Type A – Single Channel ............................................................................................... 10

2.3.2 Type B – Single Channel Controller ............................................................................... 11

2.3.3 Type D – Dual Channel .................................................................................................. 12

2.3.4 Type E– Dual Channel ................................................................................................... 13

3 INSTRUMENT SPECIFICATIONS .........................................................................13

3.1 Technical Specications................................................................................................13

3.2 Standard Enclosure Dimensions ...................................................................................16

3.3 Watertight Enclosure Dimensions ................................................................................16

4 SENSOR SPECIFICATIONS ...................................................................................17

4.1 Sensor Specications ...................................................................................................17

4.2 Remote Sensor Specications ......................................................................................18

4.3 Calibration Extending Firmware (CEF) and Sensor Aging .............................................18

5 FEATURES & FUNCTIONS ....................................................................................19

5.1 Standard Exterior Enclosure .........................................................................................19

5.2 Watertight Exterior Enclosure ......................................................................................20

5.3 Interior System Layout .................................................................................................21

6 INSTALLATION ...................................................................................................... 22

6.1 AC and DC Wiring .........................................................................................................22

6.1.1 Wiring Example 1 .......................................................................................................... 22

6.1.2 Wiring Example 2 .......................................................................................................... 23

© 2014 All rights reserved. Data subject to change without notice. 3

Rev. E | 2014.10 GEM-II - Operation Manual

6.1.3 Wiring Example 3 - INCORRECT ..................................................................................... 23

6.1.4 Wiring Example 4 .......................................................................................................... 24

6.1.5 Wiring Example 5 (J2 Removed) ................................................................................... 24

6.1.6 Wiring Example 6 (J2 Removed) ................................................................................... 25

6.2 Sensor Mounting Heights ............................................................................................25

6.3 Standard Enclosure Mounting Components .................................................................26

6.3.1 Enclosure Base .............................................................................................................. 26

6.3.2 Enclosure Top ................................................................................................................ 26

6.3.3 Enclosure Bottom ......................................................................................................... 27

6.4 Remote Sensor Connection ..........................................................................................27

6.5 Wiring Connections ......................................................................................................28

6.5.1 Types A, B and D ............................................................................................................ 28

6.5.2 Type E............................................................................................................................ 28

6.6 Important Notes for Wiring ..........................................................................................29

6.7 System Installation ......................................................................................................29

6.7.1 Low Voltage Power ........................................................................................................29

6.7.2 Wiring to Remote Sensor .............................................................................................. 30

6.7.3 Voltage to Remote Sensors ........................................................................................... 30

6.7.4 Relay Connections......................................................................................................... 30

6.8 Installation Examples ...................................................................................................31

6.8.1 Type A with Internal Sensor and Enclosed Transformer ................................................. 31

6.8.2 Type B with Remote Sensor or Analog Transmitter ........................................................ 32

6.8.3 Type D with One Internal & One Remote Sensor ............................................................ 33

6.8.4 Type E with Two Internal Sensors .................................................................................. 34

7 OPERATION ...........................................................................................................34

7.1 System Operation ........................................................................................................34

7.2 Test Functions ..............................................................................................................35

7.3 Dip Switch Package ......................................................................................................36

7.4 Internal Audible Alarm Operation ................................................................................37

7.5 Jumpers .......................................................................................................................37

7.6 Adjusting Alarm Set Points ..........................................................................................39

7.6.1 Voltage Reference Table for Alarm Settings ................................................................... 41

7.7 Time Delays for Relay Operations .................................................................................42

7.7.1 Procedure for Setting Time Delays .................................................................................44

7.8 Temperature Display - Unit of Measure ........................................................................45

4 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

7.9 Latching Relay Functions .............................................................................................45

7.10 LED Digital Display .....................................................................................................46

8 CALIBRATION ........................................................................................................47

8.1 Calibration Specications .............................................................................................47

8.1.1 Gas ................................................................................................................................ 47

8.1.2 Exception ...................................................................................................................... 47

8.1.3 Regulators & Flow ......................................................................................................... 47

8.1.4 Adapters ....................................................................................................................... 47

8.2 Calibrating Sensors ......................................................................................................48

8.2.1 Calibration Frequency ................................................................................................... 48

8.3 Calibration Procedure ...................................................................................................48

8.4 Calibrating the Internal Sensor ....................................................................................49

8.4.1 Setting Span Gas Value ................................................................................................. 49

8.4.2 Calibrating the Null (Zero) Value ................................................................................... 49

8.4.3 Calibrating the Span Gas ............................................................................................... 50

8.5 Calibrating Second Internal Sensor ..............................................................................51

8.6 Calibrating Remote Sensor ..........................................................................................51

8.6.1 Setting Span Gas Value for Remote Sensor ................................................................... 51

8.6.2 Calibrating the Null (Zero) Value ................................................................................... 51

8.6.3 Calibrating the Span Gas ............................................................................................... 52

8.7 Calibrating 4-20 mA for Incoming Analog Transmitter ................................................53

8.7.1 Using a Current Source to Calibrate the Null .................................................................. 53

8.7.2 Using a Current Source to Calibrate the Span ................................................................ 53

8.7.3 Using a CETCI Analog Transmitter to Calibrate the Null .................................................. 54

8.7.4 Using a CETCI Analog Transmitter to Calibrate the Span ................................................ 54

8.8 Forcing Calibration ......................................................................................................55

9 ACCESSORIES .......................................................................................................56

9.1 Calibration Kit ..............................................................................................................56

9.2 Metal Protective Guard ................................................................................................56

10 MAINTENANCE ..................................................................................................57

© 2014 All rights reserved. Data subject to change without notice. 5

Rev. E | 2014.10 GEM-II - Operation Manual

1 POLICIES

1.1 Important Note

Read and understand this manual prior to using this instrument. Carefully read the warranty

policy, service policy, notices, disclaimers and revisions on the following pages.

This product must be installed by a qualied electrician or factory trained technician and

according to instructions indicated in this manual. This instrument should be inspected and

calibrated regularly by a qualied and trained technician. For more information, refer to Sections

8 Calibration and 10 Maintenance of this manual.

This instrument has not been designed to be intrinsically safe. For your safety, do not use it in

classied hazardous areas (explosion-rated environments).

INSTRUMENT SERIAL NUMBER:

__________________________________________________________

PURCHASE DATE:

__________________________________________________________

PURCHASED FROM:

__________________________________________________________

6 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

1.2 Warranty Policy

• Disconnect power before servicing

• Caution: More than one live circuit

• Supply: 24 V (nominal, 50 or 60 Hz)

• Certied for electrical shock and electrical re hazard only

Critical Environment Technologies Canada Inc. (CETCI), also referred to as the manufacturer,

warrants this instrument, (excluding sensors, battery packs, batteries, pumps and lters) to be

free from defects in materials and workmanship for a period of two years from the date of

purchase from our facility. The sensors have a warranty period of one year on a pro-rated

basis from the date of purchase from our facility. If the product should become defective

within this warranty period, we will repair or replace it at our discretion.

The warranty status may be aected if the instrument has not been used and maintained per

the instructions in this manual or has been abused, damaged, or modied in any way. This

instrument is only to be used for purposes stated herein. The manufacturer is not liable for

auxiliary interfaced equipment or consequential damage.

Due to ongoing research, development, and product testing, the manufacturer reserves the

right to change specications without notice. The information contained herein is based on data

considered accurate. However, no warranty is expressed or implied regarding the accuracy of this

data.

All goods must be shipped to the manufacturer by prepaid freight. All returned goods must be

pre-authorized by obtaining a Returned Merchandise Authorization (RMA) number. Contact the

manufacturer for a number and procedures required for product transport.

1.3 Service Policy

CETCI maintains an instrument service facility at the factory. Some CETCI distributors / agents

may also have repair facilities; however, CETCI assumes no liability for service performed by

anyone other than CETCI personnel.

Repairs are warranted for 90 days after date of shipment (sensors have individual warranties).

Should your instrument require non-warranty repair, you may contact the distributor from

whom it was purchased or you may contact CETCI directly.

© 2014 All rights reserved. Data subject to change without notice. 7

Rev. E | 2014.10 GEM-II - Operation Manual

Prior to shipping equipment to CETCI, contact our oce for an RMA #. All returned goods must

be accompanied with an RMA number.

If CETCI is to do the repair work, you may send the instrument, prepaid, to:

Attention: Service Department

Critical Environment Technologies Canada Inc.

Unit 145, 7391 Vantage Way

Delta, BC, V4G 1M3

Always include your Returned Merchandise Authorization (RMA) number, address, telephone

number, contact name, shipping / billing information, and a description of the defect as

you perceive it. You will be contacted with a cost estimate for expected repairs, prior to the

performance of any service work.

For liability reasons, CETCI has a policy of performing all needed repairs to restore the instrument

to full operating condition.

Pack the equipment well (in its original packing if possible), as we cannot be held responsible for

any damage incurred during shipping to our facility.

1.4 Copyrights

This manual is subject to copyright protection; all rights are reserved. Under international and

domestic copyright laws, this manual may not be copied or translated, in whole or in part, in any

manner or format, without the written permission of CETCI.

1.5 Disclaimer

Under no circumstances will CETCI be liable for any claims, losses or damages resulting from or

arising out of the repair or modication of this equipment by a party other than CETCI service

technicians, or by operation or use of the equipment other than in accordance with the printed

instructions contained within this manual or if the equipment has been improperly maintained

or subjected to neglect or accident. Any of the foregoing will void the warranty.

Under most local electrical codes, low voltage wires cannot be run within the same conduit as

line voltage wires. It is CETCI policy that all wiring of our products meet this requirement.

It is CETCI policy that all wiring be within properly grounded (earth or safety) conduit.

8 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

1.6 Revisions

This manual was written and published by CETCI. The manufacturer makes no warranty or

representation, expressed or implied including any warranty of merchantability or tness for

purpose, with respect to this manual.

All information contained in this manual is believed to be true and accurate at the time

of printing. However, as part of its continuing eorts to improve its products and their

documentation, the manufacturer reserves the right to make changes at any time without

notice. Revised copies of this manual can be obtained by contacting CETCI or visiting

www.critical-environment.com.

Should you detect any error or omission in this manual, please contact CETCI at the following

address:

Critical Environment Technologies Canada Inc.

Unit 145, 7391 Vantage Way, Delta, BC, V4G 1M3, Canada

Toll Free: +1.877.940.8741

Telephone: +1.604.940.8741

Fax: +1.604.940.8745

Email: marketing@cetci.com

Website: www.critical-environment.com

In no event will CETCI, its ocers or employees be liable for any direct, special, incidental

or consequential damages resulting from any defect in any manual, even if advised of the

possibility of such damages.

© 2014 All rights reserved. Data subject to change without notice. 9

Rev. E | 2014.10 GEM-II - Operation Manual

2 INTRODUCTION

2.1 General Description

Thank you for purchasing our GEM-II self-contained gas detector.

The GEM series gas detection systems are economical, self-contained, gas detectors for nonhazardous (non-explosion rated) commercial applications. They are available in two basic

congurations: one sensor models and two sensor models. The sensors can be congured as one

integral (A-type), one remote (B-type), one integral and one remote (D-type), or two integral

(E-type).

A basic system provides one set of LED indicating lights representing “Power”, “Fail”, “Low

(Warning) Gas Alarm”, ‘High Gas Alarm”, an integral audible alarm with door mounted silence

push-button, audible time delay, eld settable relay time delays and two alarm relays. In either

system, the LED lights provide visual indication of the status of each channel (Int = internal

sensor, Ext = external sensor or second channel).

Gas specic electrochemical sensors for toxic gases and Oxygen (O2) are available as are MOS

solid-state sensors for refrigerants and catalytic sensors for combustible gases. All GEM integral

sensors are packaged as plug-in “smart” sensor modules to reduce eld maintenance time.

If after reading through the manual, you have any questions, please do not hesitate to contact

our service department for technical support.

2.2 Key Features

• Single or dual channel

• Network multiple units

• Integral plug & play “smart” sensors or remote sensors

• 4 – 20 mA linear output signal

• Three conduit entry ports

• Thermal resetting fuse

• LED light indicators

• Two 5-amps SPDT relays

• RoHS compliant circuit boards

• CSA & UL certied

10 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

2.3 Model Designations

2.3.1 Type A – Single Channel

Choices for GEM-A:

• One integral electrochemical sensor.

NOTES: Optional LED digital display is shown in the photo.

Opening for integral sensor

(example: CO) to monitor

diused air and gas.

© 2014 All rights reserved. Data subject to change without notice. 11

Rev. E | 2014.10 GEM-II - Operation Manual

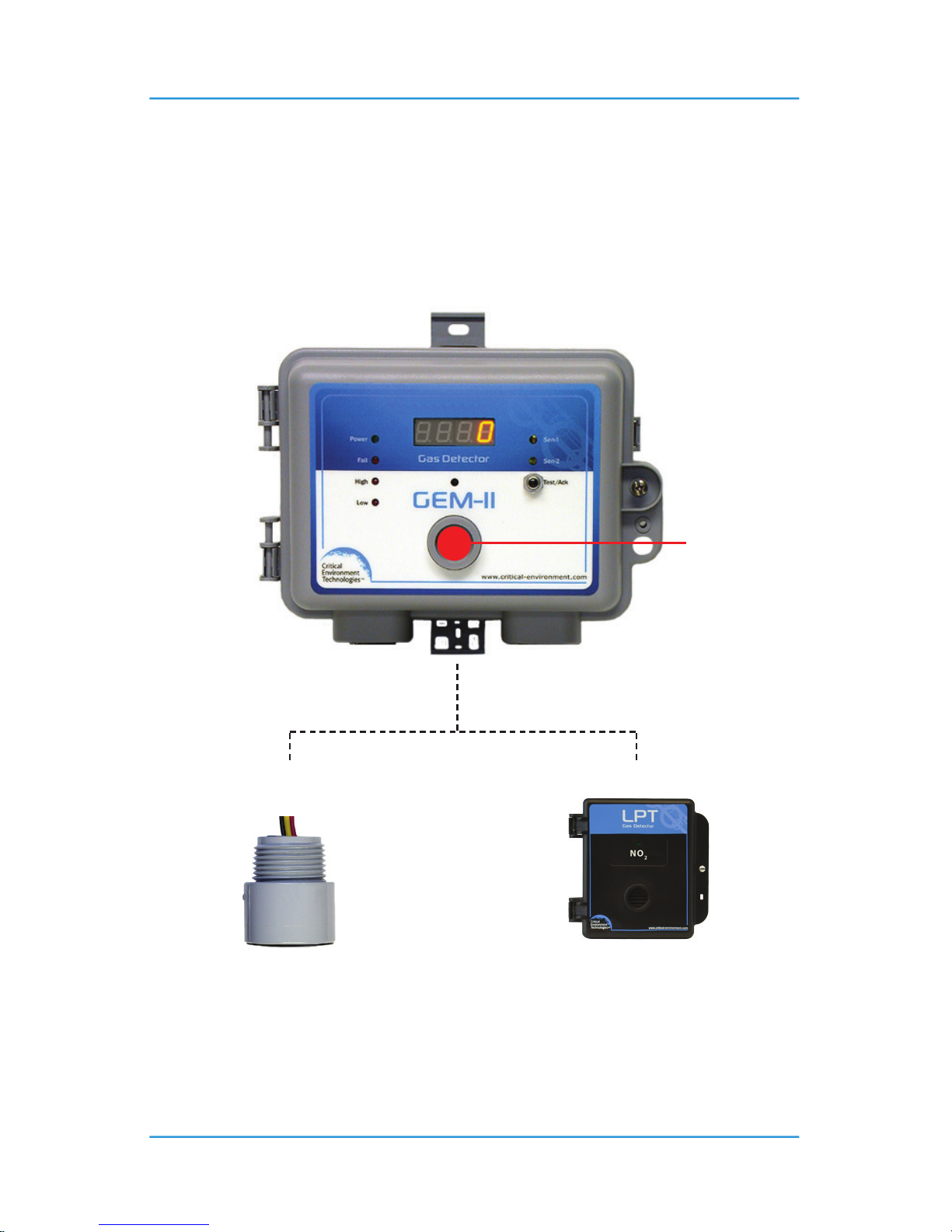

2.3.2 Type B – Single Channel Controller

Choices for GEM-B:

• One remote catalytic or solid state sensor

• One remote LPT-A or LPT series analog transmitter

NOTES: Optional LED digital display is shown in the photo.

Wiring requirements:

• 3-conductor, 18 gauge to remote sensor.

• 3-conductor shielded to remote analog transmitter.

Plug covering

sensor opening

Remote catalytic or

solid state sensor

Remote analog transmitterOR

12 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

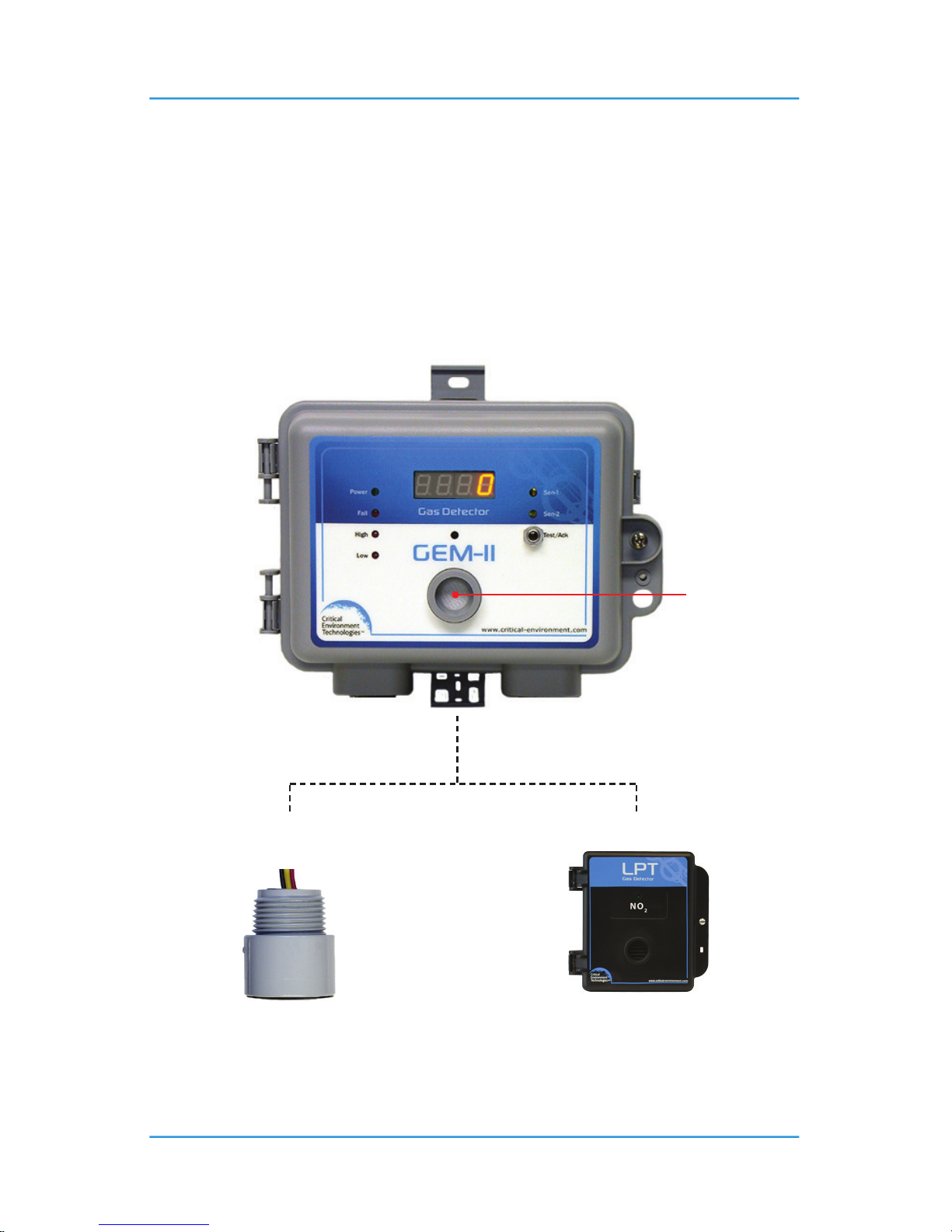

2.3.3 Type D – Dual Channel

Choices for GEM-D:

• One integral electrochemical sensor (Channel1) PLUS one remote catalytic or solid state

sensor (Channel 2).

• One integral electrochemical sensor (Channel1) PLUS one remote LPT-A or LPT series

analog transmitter (Channel 2).

NOTES: Optional LED digital display is shown in the photo.

Wiring requirements:

• 3-conductor, 18 gauge to remote sensor.

• 3-conductor shielded to remote analog transmitter.

Opening for

integral sensor

to monitor

diused by air

and gas.

Remote catalytic or

solid state sensor

Remote analog transmitterOR

© 2014 All rights reserved. Data subject to change without notice. 13

Rev. E | 2014.10 GEM-II - Operation Manual

2.3.4 Type E – Dual Channel

Choices for GEM-E:

• Two integral electrochemical sensors (Channel 1 & 2)

NOTES: Optional LED digital display is shown in the photo.

3 INSTRUMENT SPECIFICATIONS

3.1 Technical Specications

GAS TYPE

Carbon Monoxide (CO)

Combustible Gases (catalytic)

Hydrogen (H

2

), Methane (CH4), Propane (C3H8)

Nitrogen Dioxide (NO

2

)

Nitric Oxide (NO)

Oxygen (O

2

)

Refrigerants (solid state)

R22, R134A, R402A, R404A, R407C, R410A, R422A, R422D, R507A

Sulphur Dioxide (SO

2

)

TVOCs (solid state)

Opening for TWO integral

sensors to monitor diused

air and gas.

Common application is

engine exhaust: gasoline

or diesel sensors are both

integral in the GEM type E

version.

14 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

MECHANICAL

Standard Enclosure General purpose PVC

Standard Weight 600 g (1.2 lb)

Standard Size 5.3” x 6.8” x 2.6” (135 mm x 173 mm x 66 mm)

Watertight Enclosure Water / dust tight polycarbonate

Watertight Weight 700 g (1.4 lb)

Watertight Size 5.1” x 7.1” x 4.0” (130 mm x 181 mm x 102 mm)

ELECTRICAL

Power Requirement 15 - 30 VDC or 12 - 28 VAC

Current Draw Approximately 125 mA

Wiring

VDC three-conductor shielded

VAC four-conductor shielded

Circuit

Analog design with microprocessor and user settable time

delays, accessible with DIP switches on circuit board.

Fuse Automatic resetting thermal

INPUT / OUTPUT

Outputs Linear 4 - 20 mA (single)

Distance

Maximum 500 ft between controller and remote solid state

sensor using minimum 18 gauge wire.

Relays

Two S.P.D.T. dry contact relays, rated 5 amps @ 240 VAC.

NOTES:

1. System is congured such that all relays are “FAIL SAFE”

(relay coils are always energized in non-alarm state).

2. Relays are “common” to both channels (activated by either

channel).

USER INTERFACE

Display

Common set of LED indicating lights for “Power”, “Fail”, “Low

(Warning) Gas Alarm”, “High Gas Alarm”

© 2014 All rights reserved. Data subject to change without notice. 15

Rev. E | 2014.10 GEM-II - Operation Manual

Audible

Integral piezo audible alarm rated 80 dB @ 10’ c/w door mounted

silence push-button.

NOTES: Audible alarm & silence push-button are right side

mounted on water tight enclosure.

Time Delays

Delay “ON” (on make),

DIP switch

Delay “OFF” (on break),

DIP switch

Audible (on make),

DIP switch

Low alarm relay: 2 minutes

High alarm relay: 5 minutes

Also known as “minimum run time”

Low alarm relay: 10 minutes

High alarm relay: not available

10 minutes

NOTES: Time delays can be changed by user.

Reference Section 7 Operation. DIP switches are still used to

enable or disable time delays.

SENSOR

Enclosure Molded PVC

Integral

Electrochemical only

NOTES: All integral electrochemical gas sensors are packaged as

“smart” sensor modules.

Remote

Solid State sensor for refrigerants and TVOCs

Catalytic sensor for combustible gases

Analog transmitter, LPT-A or LPT (4 – 20 mA signal)

ENVIRONMENTAL (sensor dependant)

Operating Temperature -20°C to 50°C (-5°F to 120°F)

Operating Humidity 15 - 90% RH non-condensing

16 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

CERTIFICATION

CSA Certied

UL Certied

3.2 Standard Enclosure Dimensions

3.3 Watertight Enclosure Dimensions

5.25” (133 mm)

2.625” (67 mm) 6.75” (172 mm)

5.13” (130 mm)

7.13” (181 mm)4.0” (102 mm)

4.38” (102 mm)

© 2014 All rights reserved. Data subject to change without notice. 17

Rev. E | 2014.10 GEM-II - Operation Manual

4 SENSOR SPECIFICATIONS

4.1 Common Sensor Specications

Carbon Monoxide (CO)

Type Electrochemical

Response Time <30 seconds to 90% of signal response

Operating Temperature 0°C to 50°C (32°F to 120°F)

Repeatability ± 10% of set point

Life Span 3 years in air (under normal conditions)

Nitric Oxide (NO)

Type Electrochemical

Response Time <30 seconds to 90% of signal response

Operating Temperature 0°C to 50°C (32°F to 120°F)

Repeatability ± 10% of set point

Life Span 2 years in air (under normal conditions)

Nitrogen Dioxide (NO

2

)

Type Electrochemical

Response Time <30 seconds to 90% of signal response

Operating Temperature 0°C to 50°C (32°F to 120°F)

Repeatability ± 10% of set point

Life Span 3 years in air (under normal conditions)

Sulphur Dioxide (SO

2

)

Type Electrochemical

Response Time <30 seconds to 90% of signal response

Operating Temperature 0°C to 50°C (32°F to 120°F)

Repeatability ± 10% of set point

Life Span 2+ years in air (under normal conditions)

18 © 2014 All rights reserved. Data subject to change without notice.

GEM-II - Operation Manual Rev. E | 2014.10

Temperature (°C or °F)

Range -20°C to 40°C (-4°F to 104°F)

4.2 Remote Sensor Specications

1. Remote sensor module: The remote sensor housing accommodates one catalytic or one solid-

state sensor. 2. Any 4-20 mA analog transmitters manufactured by CETCI (LPT-A or LPT series).

Combustible Gases

Type Catalytic

Response Time <10 seconds to 90% of signal response

Operating Temperature -10°C to 50°C (14°F to 122°F)

Repeatability ± 10% of set point

Life Span 5 years in air (under normal conditions)

Typical Gas Examples Hydrogen (H

2

), Propane (C3H8), Methane (CH4)

Refrigerants

Type Solid state

Response Time <120 seconds to 90% of signal response

Operating Temperature 0°C to 40°C (32°F to 104°F)

Long Term Drift < 5% signal loss / month at ambient temperatures

Repeatability ± 10% of set point

Life Span 5 years in air (under normal conditions)

Typical Gas Examples

R11, R12, R22, R134A, R404A, R407C, R410A, R422A, R422D,

R438A, R507A

4.3 Calibration Extending Firmware (CEF) and Sensor Aging

GEM systems with integral electrochemical sensors have been programmed with our CEF

(Calibration Extending Firmware). This rmware takes into consideration the aging of the

electrochemical CO, NO and NO2 sensors so that less frequent calibrations are acceptable in

non-critical applications such as parking garages. The system tracks the age of the sensor and

automatically compensates for the degraded output of the sensor as it ages.

Loading...

Loading...