Page 1

Cricket

Robot

Documentation

Revision 1.0B Copyright 2015

Page 2

Contents

CRICKET THE ROBOT ...................................................................................................... 4

Description ....................................................................................................................... 4

Cricket Kit Contents ......................................................................................................... 5

Getting Started ................................................................................................................. 5

Using the Remote Control ................................................................................................ 5

Documentation ................................................................................................................. 7

Software and Download Cable ......................................................................................... 7

Cricket Features ............................................................................................................... 7

Top View .......................................................................................................................... 8

Bottom View ..................................................................................................................... 9

Front View ...................................................................................................................... 10

HOW CRICKET WORKS.................................................................................................. 11

How Does Cricket Walk? ............................................................................................... 11

Obstacle Avoidance ....................................................................................................... 11

Random Noises ............................................................................................................. 11

Flashing LED Eyes ........................................................................................................ 11

Remote Control .............................................................................................................. 11

PLAYING WITH CRICKET ............................................................................................... 12

ABOUT CRICKET’S HARDWARE ................................................................................... 13

Chassis .......................................................................................................................... 13

Legs ............................................................................................................................... 13

Servo Motors .................................................................................................................. 13

Arduino Controller .......................................................................................................... 14

Batteries ......................................................................................................................... 15

Speaker and Sound Generation ..................................................................................... 15

Infrared Remote Receive ............................................................................................... 15

Light Emitting Diodes ..................................................................................................... 16

Feeler Wires and Switches ............................................................................................ 16

Programming Connector, Cable and Software ............................................................... 17

Uploading an Arduino Program ...................................................................................... 18

Launch the Arduino Application ..................................................................................... 19

Open the blink Example ................................................................................................. 19

Select your Board .......................................................................................................... 19

Select your serial port .................................................................................................... 20

Upload the program ....................................................................................................... 20

2 – Cricket Robot Documentation

Page 3

ASSEMBLING CRICKET’S ARDUINO CONTROLLER BOARD .................................... 22

Tools Needed ................................................................................................................. 22

Parts Layout ................................................................................................................... 24

Installing the Parts ......................................................................................................... 25

Checkout and Cleanup................................................................................................... 32

ASSEMBLING CRICKET’S CHASSIS ............................................................................. 33

Tools Needed ................................................................................................................. 33

General Assembly Instructions ...................................................................................... 34

Assemble the Legs ........................................................................................................ 34

Assemble the Center Leg Beam .................................................................................... 36

Attaching the Servo Motor Mounts ................................................................................. 40

Install the PC Board Mounts .......................................................................................... 42

Assemble the Leg Control Arms .................................................................................... 46

Assemble the Sonar Bracket .......................................................................................... 47

ABS Parts of Chassis are Now Complete ...................................................................... 51

Installing the Servos into the Chassis ............................................................................ 52

Installing Cricket’s Legs ................................................................................................. 54

Installing the Leg Control Arms ...................................................................................... 58

Installing the Battery Holder ........................................................................................... 62

Installing the Speaker .................................................................................................... 64

Completing the Feelers .................................................................................................. 65

Installing the Feelers ...................................................................................................... 66

Centering the Servos ..................................................................................................... 72

Installing the Servo Horns .............................................................................................. 72

Installing the Sonar Module ............................................................................................ 78

Cleaning Up the Wiring .................................................................................................. 81

Final Checkout ............................................................................................................... 84

TROUBLESHOOTING ..................................................................................................... 88

APPENDIX A – SCHEMATICS ........................................................................................ 90

APPENDIX B - PARTS LIST ............................................................................................ 92

APPENDIX C - PC BOARD LAYOUT .............................................................................. 93

3 – Cricket Robot Documentation

Page 4

Cricket the Robot

Congratulations on the purchase of your Cricket Robot Kit. Cricket is a unique walking

robot. You will find that he is also a powerful programmable robot.

Cricket has:

Arduino based

Programmable Controller

Sturdy Laser Cut Body

construction

3 Hitec Servos to control six

legs

Sonar with Hitec scan servo

2 LED Eyes for visual

effects

Speaker to make sound

effects

2 Bump Feelers

IR Remote Control

Documentation

Cricket comes preprogrammed and ready to go. As you become more familiar with his

capabilities you can easily modify his control program to add or change his behaviors.

Programming Cricket requires just the standard Arduino Environment and a USB down

load cable.

Description

Cricket is a six-legged walking robot. He uses three motors to make the six legs walk in a

tri-gate fashion. Tri-gate means that Cricket has three legs on the ground at any one time.

The three legs touching the ground form a triangle which is very stable. Cricket can walk

forward, backward, and turn right and left. Cricket can also make sounds, flash his LED

eyes, and detect obstacles with his sonar and feelers. The Arduino Uno compatible

controller operates all of Cricket’s capabilities. The controller can be easily programmed

using the standard Arduino environment. The Arduino libraries allow you to perform

things like making sounds, blinking lights, and controlling motors. The Arduino based

program is written on a PC and then is downloaded through the PC’s USB port.

4 – Cricket Robot Documentation

Page 5

Cricket Kit Contents

Cricket robots come in three variations. They are:

Fully assembled robot

Robot kit with fully assembled Arduino controller

Robot kit with Arduino controller as a kit for user assembly

If you received an assembled robot, you may review the assembly instructions if you

would like to become more familiar with how your robot is assembled. Otherwise just start

enjoying playing with your Cricket Robot

Getting Started

Cricket runs on 4 standard AA batteries. You may use rechargeable batteries or alkaline

batteries. Install the batteries while noting the correct orientation. Place Cricket on a level

service and push the slide switch at the back end of the controller board. Cricket will make

a series of chirping sounds, bring all his legs into a neutral position, pause for one second

and then begin walking. While walking around, Cricket will make chirping sounds at

random times, and he will blink his LED eyes. He will also make a series of sounds

whenever his antennae touch an object or when the sonar detects something. When

Cricket detects an obstacle, he will back up and then turn away from the obstruction and

keep wandering around. Cricket will continue to walk around until his battery becomes

weak. You can tell the battery is weak when the robot starts to act erratically. Replacing or

charging the batteries for a few hours will restore Cricket’s health.

Using the Remote Control

In addition to Cricket’s ability to wander around on his own, he will also respond to his

remote control. The remote is simply a Universal remote setup as a Sony TV/VCR

Combo. You may use your own remote or the one provided with Cricket.

The remote control will override whatever Cricket is doing and execute the following

actions:

Volume Up Cricket turns right.

Volume Down Cricket turns left

Channel Up Cricket moves forward at a fast walk

Channel Down Cricket backs up

Rewind Shake Left Legs

Fast Forward Shake Right Legs

Play Rock Back and Forth

Stop Cricket stops and holds his position

Pause Cricket freezes as long as button is held

Keys 0-9 Cricket makes different interesting sounds

Mute, On-Off Stop and center legs

Prev. CH, Record Dances the Cha-Cha

The sound keys 0-9 are fun to play with because Cricket can make a continuous stream of

various sounds and chirps while you hold one of these keys down. Pushing the Pause

button will cause Cricket to freeze for as long as you hold the button. Pushing Stop

Remote Control

5 – Cricket Robot Documentation

Page 6

causes Cricket to stop and hold his last position. Mute which is in the center of the round

volume and channel area causes Cricket to stop and center his legs.

IMPORTANT: If the remote fails to work, you may need to reset the remote operation

code. Use the following instructions for your remote. These instructions are also on the

battery door of your remote. If you have an older remote, the code may be different but

the instructions are the same.

The code is 0972 for GE 4 Device Remote (24993) as shown to the right.

To Reprogram for CRICKET:

Press and release the TV button.

Press and hold the setup button until the LED lights.

Then key in the three-digit code 0972 and the red LED will go out.

6 – Cricket Robot Documentation

Page 7

Documentation

This documentation includes information on using Cricket and how to assemble a Cricket.

This manual and assembly information and will be updated periodically.

Software and Download Cable

Some Cricket kits come with an optional USB/Serial programming cable. This cable can

be used to program the Arduino with the original Cricket software or to program Cricket

with your own custom version of the software. If you did not get a cable, you can purchase

SparkFun part number DEV-9716 or any similar 6 pin Arduino programming module.

https://www.sparkfun.com/products/9716

The Cricket program can be edited in the Arduino environment and the Arduino

reprogrammed. A new program will erase the current program. The original Cricket

program may be downloaded to restore Cricket’s original behavior.

Cricket may also be purchased with a Nano Arduino Module which can also be connected

to a USB port so that Cricket may be reprogrammed. Both the Arduino IC and the Nano

Module use the same control Sketch.

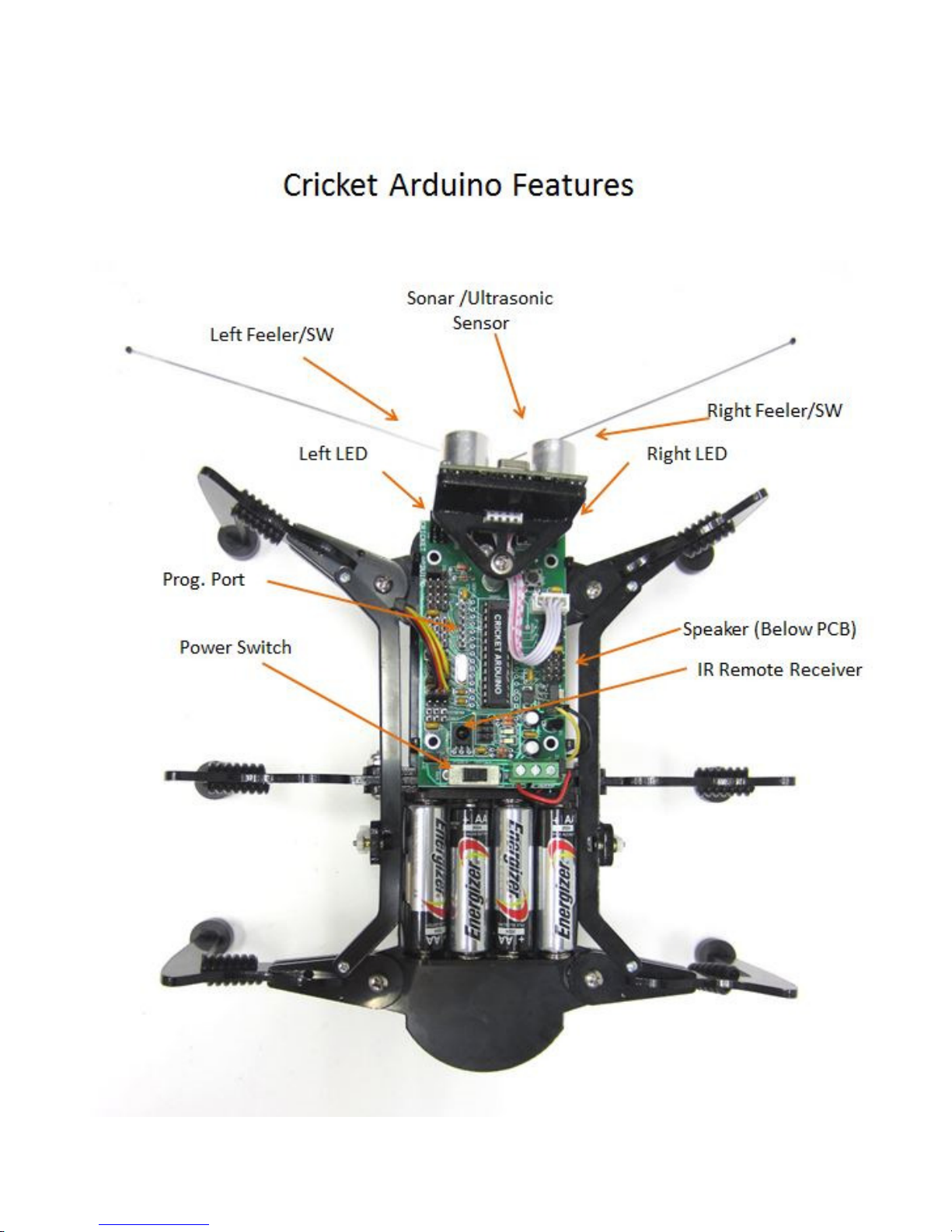

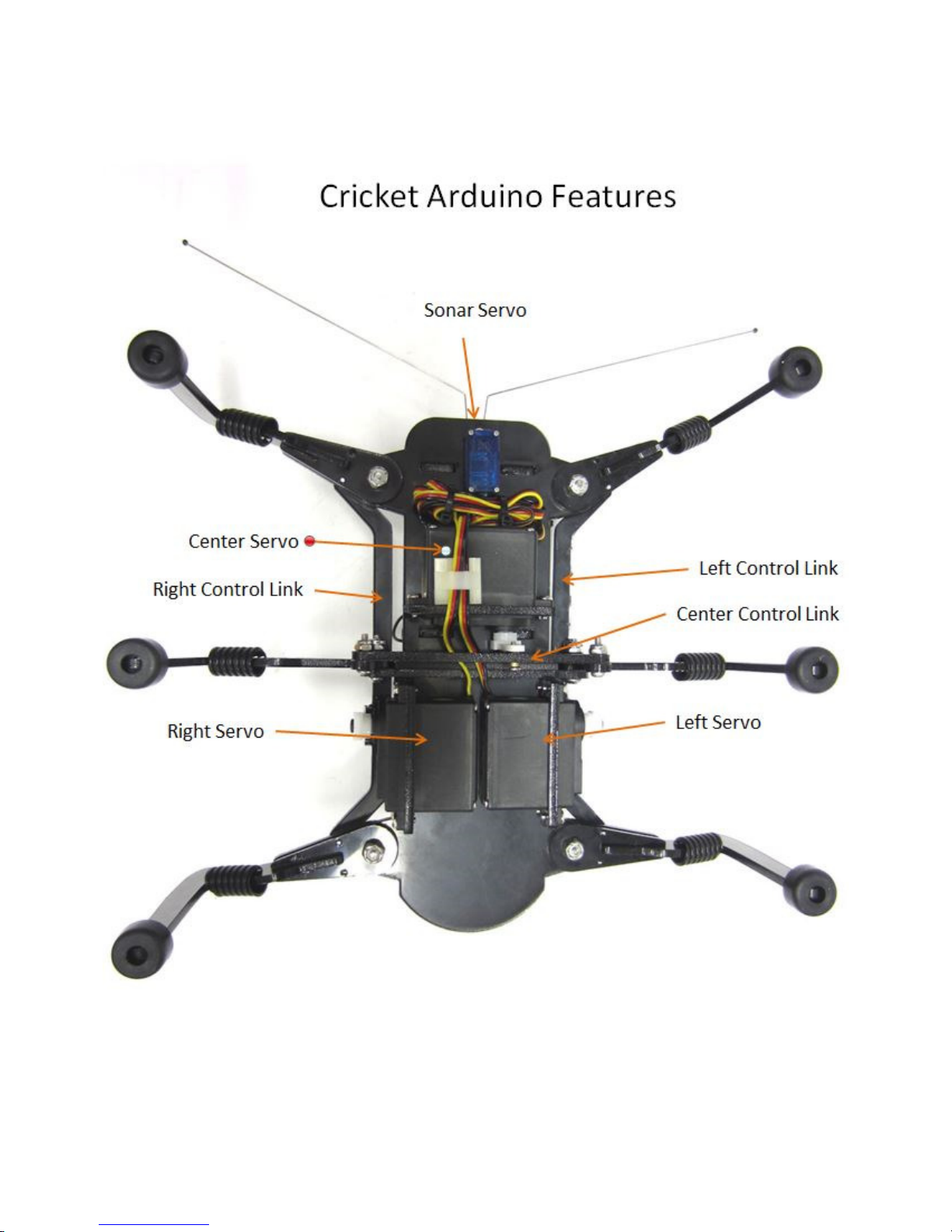

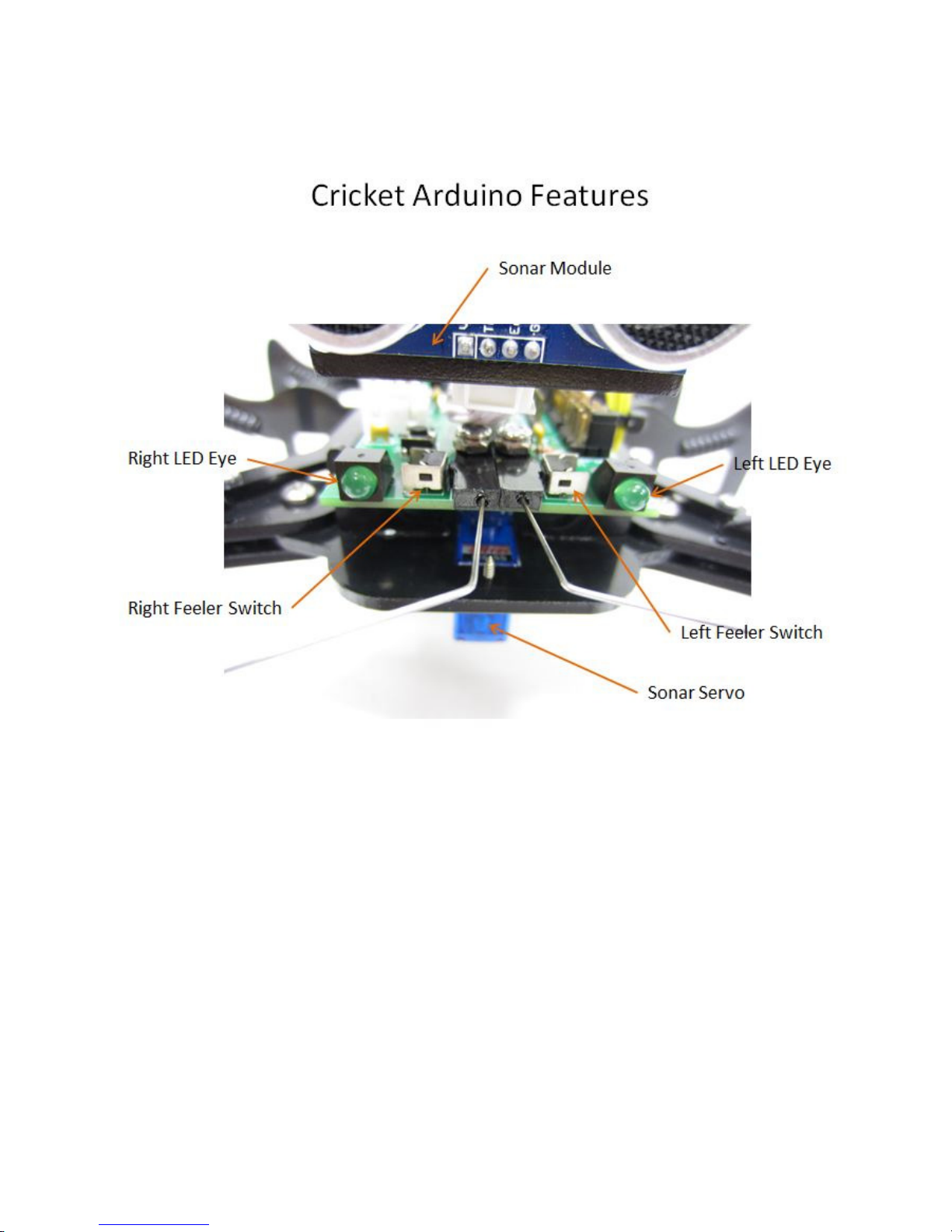

Cricket Features

The following photos show the layout of Cricket’s features including top, bottom, and front

views of the robot.

7 – Cricket Robot Documentation

Page 8

Top View

8 – Cricket Robot Documentation

Page 9

Bottom View

9 – Cricket Robot Documentation

Page 10

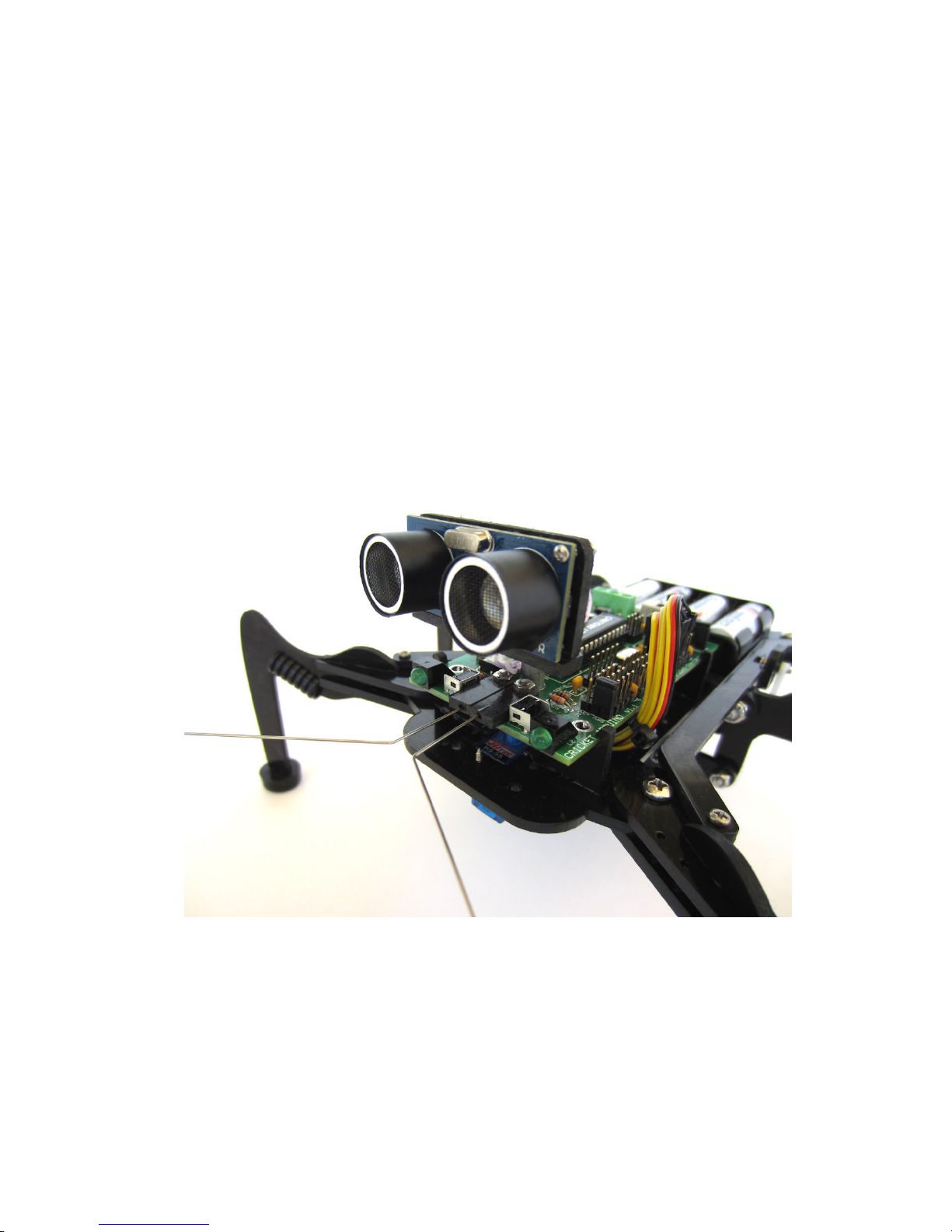

Front View

10 – Cricket Robot Documentation

Page 11

How Cricket Works

The following paragraphs explain how Cricket is able to walk, make sounds, and how his

various behaviors and features work.

How Does Cricket Walk?

Cricket uses what is called a tri-gate walk. Tri-gate walking is one of the most efficient

ways to implement a walking robot with a minimum number of motors. The right and left

servo motors move the right and left pairs of legs forward and backward. In order for this

leg movement to move the robot forward, the center legs rock the robot to one side so the

legs can move forward without touching the ground. When the legs are touching the

ground a backward movement pulls the robot forward one step. This stepping alternates

from one side to the other causing the robot to walk forward. Walking backward is the

same as forward except that the legs are off the ground when being moved backward and

touching the ground when being pulled forward. Watch the robot for a while and you will

begin to see how it works. Cricket executes a turn by stepping forward with one side

while the other side steps backwards.

Obstacle Avoidance

Cricket’s Arduino microcontroller is constantly monitoring his sonar and his feeler switches

to detect obstacles. When Cricket detects an object with his sonar or his feelers, he stops,

makes a noise, backs up three steps, scans the area in front of him for the best direction,

and then continues moving forward in the best direction. If either the feelers are bumped,

Cricket will also do a sonar survey of what is in front of him and select the best direction to

proceed. The best direction is the longest unobstructed distance he can measure.

Random Noises

You may notice that Cricket chirps from time to time but not always. Sometimes he will

chirp three or four times in a row. This random chirping is part of the Arduino program.

For every step the robot takes he looks up a random number. If the number is less than a

preset value, Cricket stays quiet, but if the number is larger than a preset value, Cricket

makes a chirp sound.

Flashing LED Eyes

Cricket has two LED eyes. After Cricket is powered up, the green LED eyes will light and

randomly turn on and off. These LEDs are all under the program control and are not just

blinking on their own. Cricket’s eyes will alternate turning on when he is sleeping. Try

pushing the mute button.

Remote Control

The square black module on the controller board is a TV remote receiver module, which

responds to the Remote Control by directing Cricket to actions other than his normal

automatic behavior. During each step Cricket takes, he also checks to see if any remote

control commands were received. The remote module receives the remote control signal

and the Arduino turns the information into commands which Cricket can use to perform

actions. Cricket is able to understand almost all of the keys on the remote.

11 – Cricket Robot Documentation

Page 12

Playing with Cricket

So that is enough of the details. Here’s what you can do with Cricket!

Put Cricket in an area with some obstacles and watch how he walks around them

detecting things in his way. Are there things that he doesn’t see? What would he

need to see things he currently misses

Use the Cha-Cha and side leg movements to choreograph a dance routine using

Cricket’s remote control. Here’s an example of the “Harlem Shake”

https://www.youtube.com/watch?v=9qCdq174cd8

And another one:

https://www.youtube.com/watch?v=L3Fsne3_BPk

Using the remote control, steer Cricket through an obstacle course.

Try the programming experiments in the manual “Cricket Programming”

After you tried the above, think about ways that you would improve your Cricket.

You could change the sounds, add unique leg movements that are different than

the Cha-Cha, or add crazy random behaviors to the things he does.

How would you make Cricket walk around a table without falling off?

Improve or modify Cricket and enter him in a Science Fair or County Fair. We have

already seen kids do this and win first place ribbons.

Cricket is a great way to learn new programming and robotic skills. Playing with him will

trigger ideas of how he could be made better. Using the Arduino environment and possibly

some other sensors, will allow you to make him even smarter.

12 – Cricket Robot Documentation

Page 13

About Cricket’s Hardware

The following paragraphs explain

each of Cricket’s components.

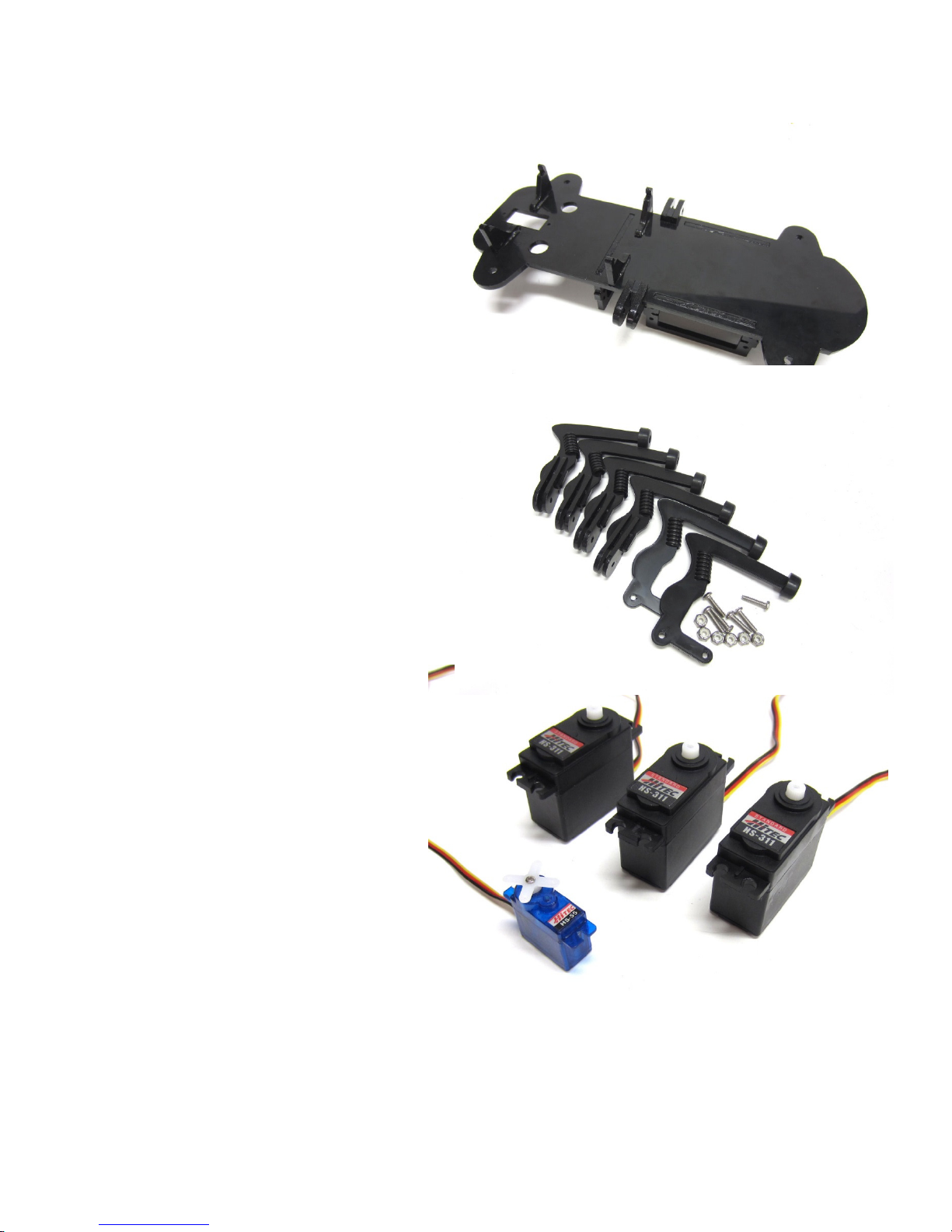

Chassis

The Cricket body is made from laser

cut ABS plastic. Motors, controller,

switches, and the battery pack are all

mounted on this chassis. This

chassis is strong and easy to

assemble.

Legs

Cricket’s legs are also made from

laser cut ABS plastic. The legs pivot on

a simple screw and a captive nut. The

legs have control arms that transfer the

rotary motion of the servos into linear

forward and backward motion or up and

down motion. Cricket’s foot pads are

made from rubber bumpers which are

attached to the end of the leg.

Servo Motors

Cricket uses three servo motors for

walking and one for the Sonar.

These motors are hobby servo

motors used for model airplanes and

cars. Each motor has three wires that

supply 6 volts (red), ground (black),

and the special controller signal

(yellow). The controller signal is a

special stream of pulses supplied by

the Arduino controller. These pulses

tell the motor what position to go to.

Normally a radio control receiver in a

model airplane or car would supply

this special signal but for Cricket, the

Arduino microcontroller generates

these signals. The motor on the

right side moves the right front and rear legs forwards and backwards. The motor on the

left side moves the left front and rear legs forwards and backwards. The center motor

pulls on the right and left center legs to make the robot lean from one side to the other.

The small blue motor runs the Sonar Sensor.

13 – Cricket Robot Documentation

Page 14

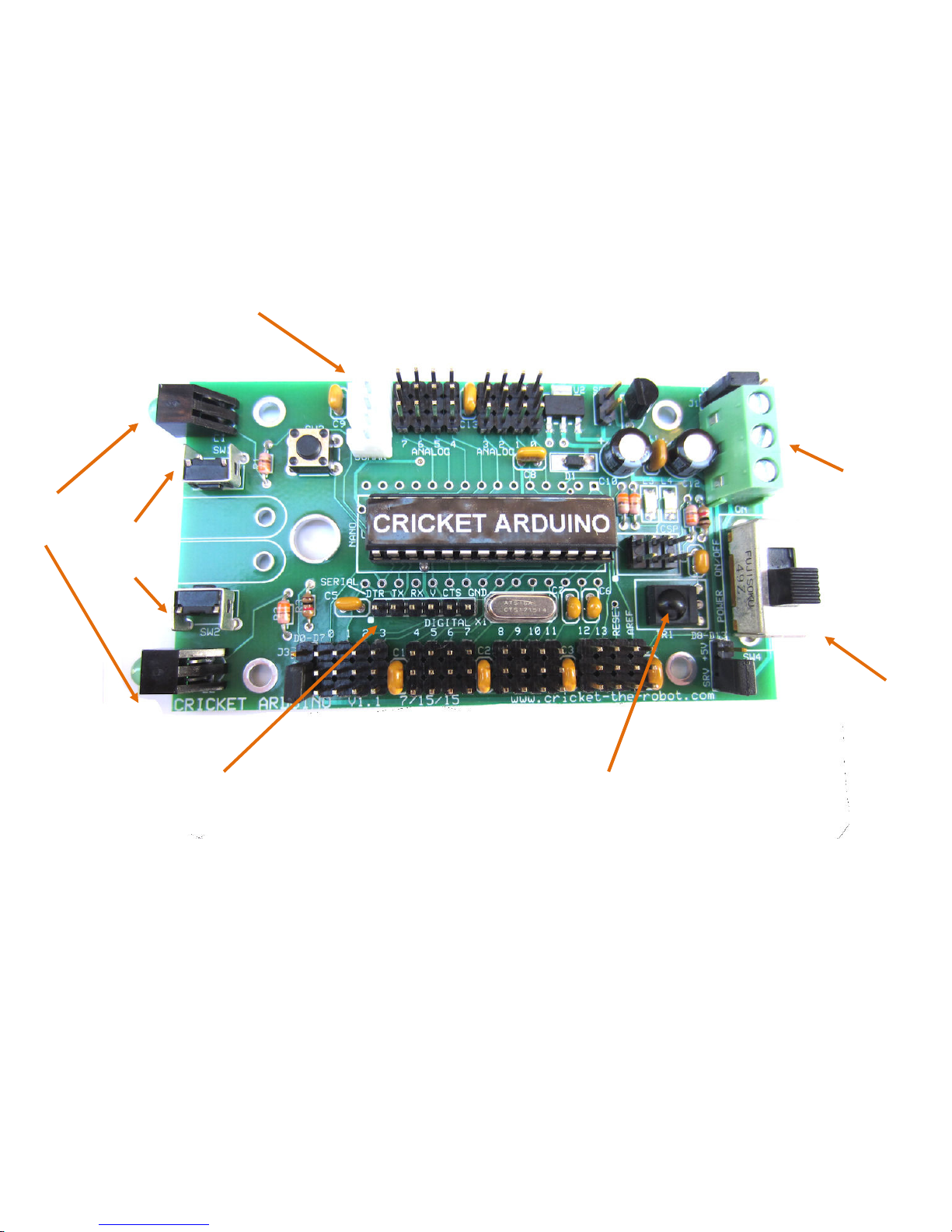

Arduino Controller

The Arduino microcontroller is mounted on a small circuit board along with the connectors

that go to the motors, feeler switches, and batteries. A download 1/8” phono connector on

the front left of the circuit board allows the Basic programs to be downloaded into the

Arduino. There is a small speaker for sounds and LEDs that can be blinked. The battery

pack powers the Arduino directly while a 5-volt regulator supplies power for the Arduino.

LED Eyes

Sonar Conn.

Analog Sensor

Connectors

Power

connector

Feeler

Switches

(pin 1 is leftmost pin)

Digital & Servo

Motor Connectors

Remote Sensor Programming Port

Power

Switch

14 – Cricket Robot Documentation

Page 15

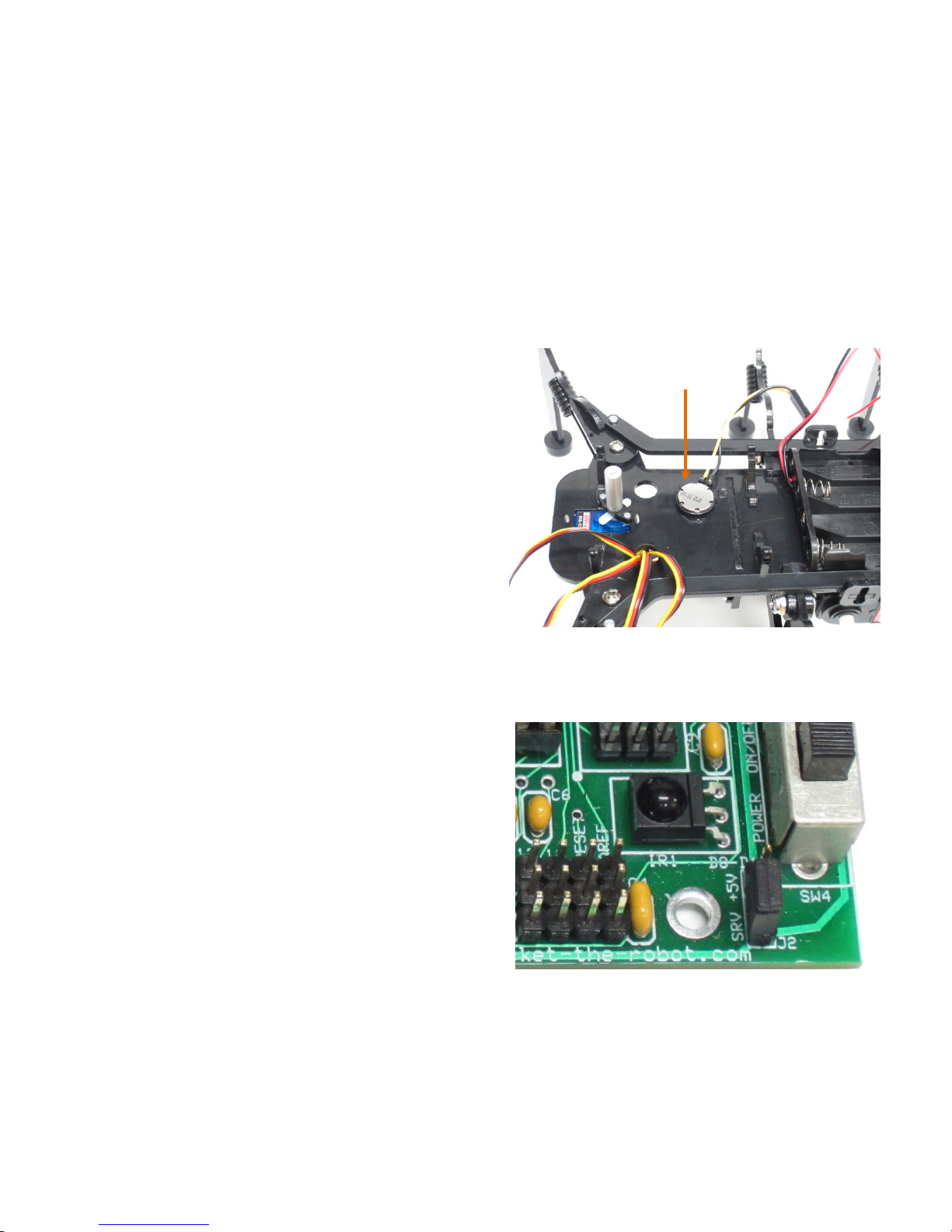

Batteries

Cricket uses standard AA batteries. The batteries will last about 1 -2 hours of operation

before needing to be replaced. Rechargeable batteries are an economical alternative to

alkaline cells. Battery power enters the controller board through a terminal block at the

rear of the controller. The on-off switch at the rear of the controller turns Cricket on and

off.

Speaker and Sound Generation

The Arduino microcontroller has the ability to

make sounds of various frequencies and

duration. The Cricket program makes

extensive use of this ability using a small

speaker to generate many different sound

effects. I would be an interesting experiment to

modify some of the “Sound” commands in the

Cricket program and see how it affects

Cricket’s voice. The speaker is glued to the

chassis face down which may seem odd but

the chassis acts as a sound board much like

the body of a guitar. If you follow the directions

you will be surprised how loud the Cricket sounds are.

Infrared Remote Receive

The remote control uses infrared light to

communicate with Cricket. The black part with a

bubble on the controller board (IR1) is an IR

receiver, which can detect the remote control

signals. The detected signal is converted into a

command which the program software uses to

override Crickets autonomous behavior.

Speaker

15 – Cricket Robot Documentation

Page 16

Light Emitting Diodes

Two green LEDs give Cricket the appearance of having eyes. These LEDs blink on and

off under program control. They may be controlled individually.

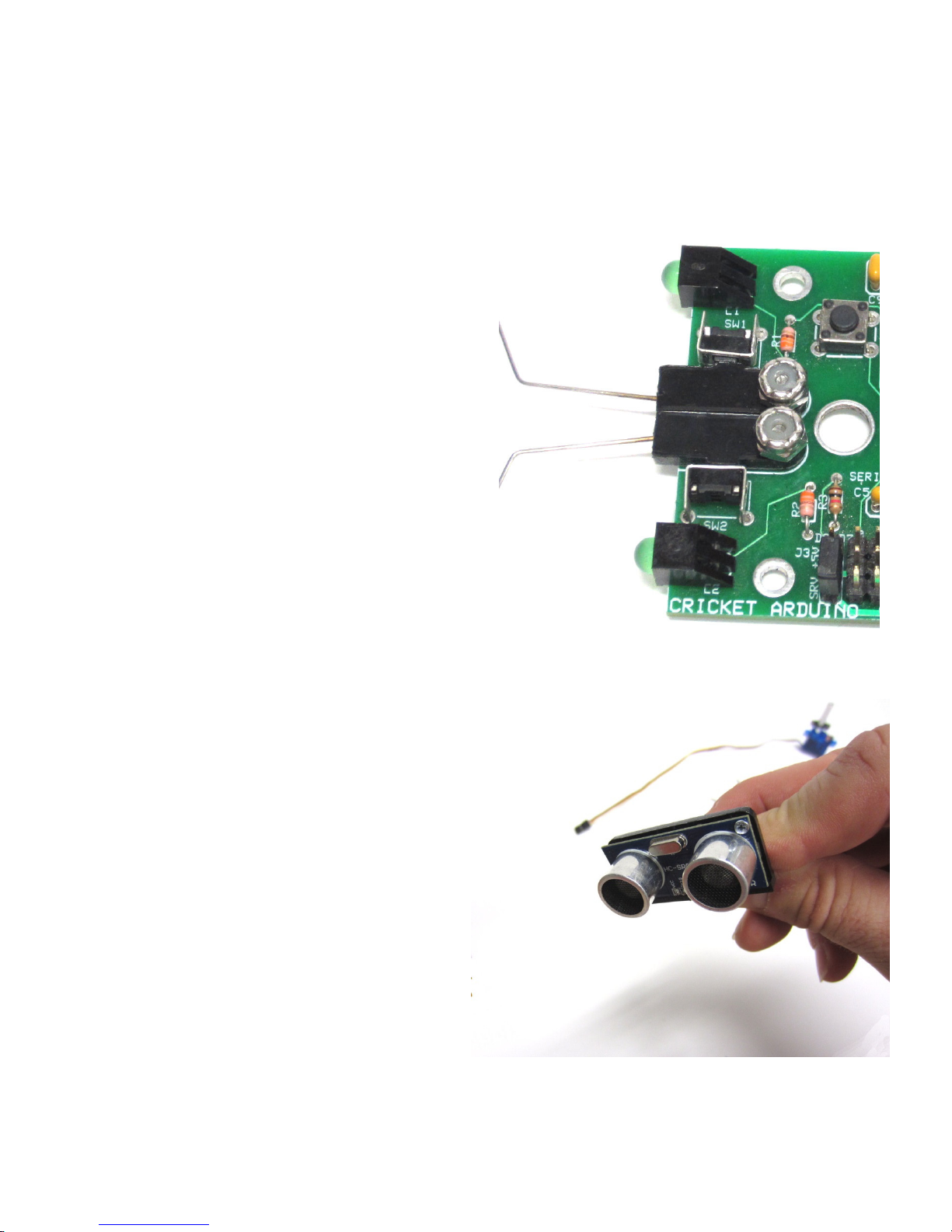

Feeler Wires and Switches

Once Cricket starts walking around, it doesn't

take long before he will run into something.

Without a way to detect an obstacle he would

get stuck. For this reason, Cricket has long

feelers much like a real cricket has. These

feelers are connected to small switches,

which turn on, when the feeler is pushed. The

Arduino controller checks the switches and if

they are closed, the robot backs up and turns

away from the obstacle. The feelers are quite

flexible and sensitive.

Sonar Sensor

Cricket has a sonar sensor which rotates

using a small hobby servo. Cricket takes

distance measurements in 7 directions.

These 7 measurements are then

compared to find the most unobstructed

direction for Cricket to head.

16 – Cricket Robot Documentation

Page 17

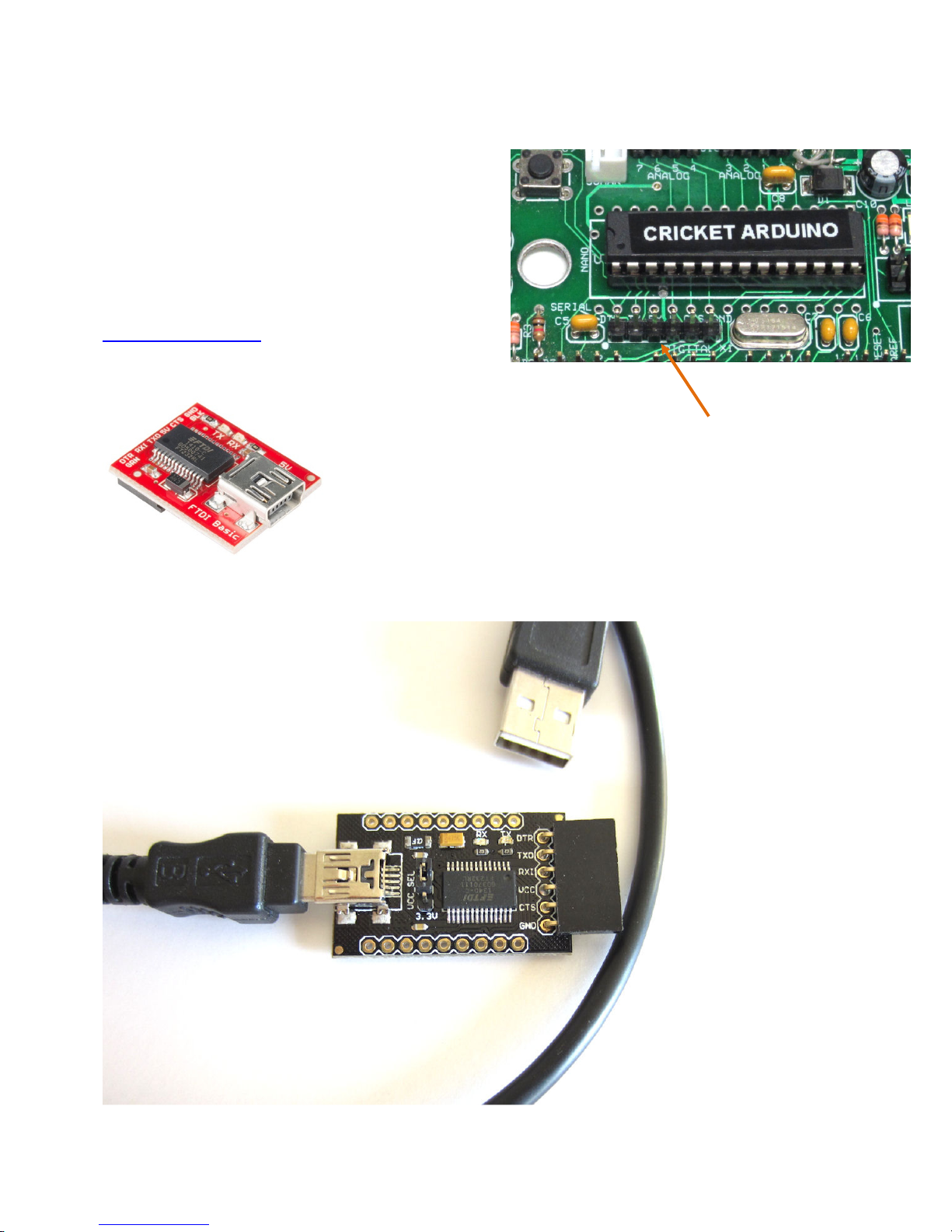

Programming Connector, Cable and Software

Cricket uses an Arduino Uno compatible

controller but this board does not have the USB

circuitry onboard. This was done to save cost.

If you want to program Cricket, you will need to

use a USB/Serial programming module that

plugs into the header just above the Digital I/O.

This module is an Arduino standard, is

inexpensive, and can be purchased from

multiple sources. SparkFun at

www.sparkfun.com carries the modules as part

number DEV-09716 for $14.95.

SparkFun DEV-09716

This module plugs

directly into the Serial

programming header on

the Cricket Controller.

You’ll also need a mini

USB cable.

Serial Program Port

17 – Cricket Robot Documentation

Page 18

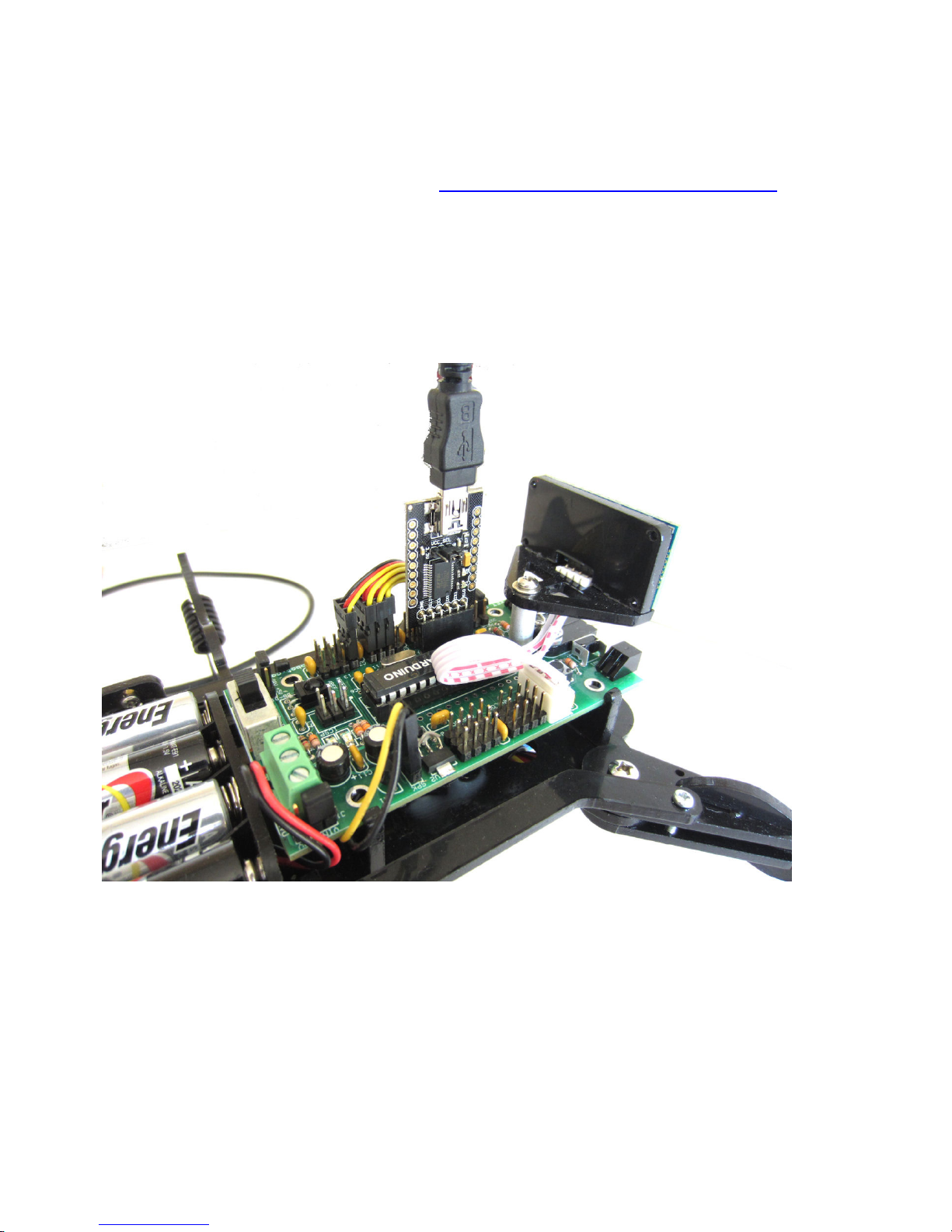

Uploading an Arduino Program

This procedure assumes that you have the Arduino software installed. If you don’t,

download the Arduino environment from https://www.arduino.cc/en/Main/Software and

install it using their instructions. The SparkFun USB/Serial module DEV-09716 will be

recognized with the Arduino drivers.

Once you have the Arduino software installed, connect the SparkFun or similar

USB/Serial cable to the Cricket Arduino Controller. Make sure to note pin 1 of the

USB/Serial module and plug it into the Cricket controller with the dot lining up with pin

one.

Cricket with Programming Cable Connected

18 – Cricket Robot Documentation

Page 19

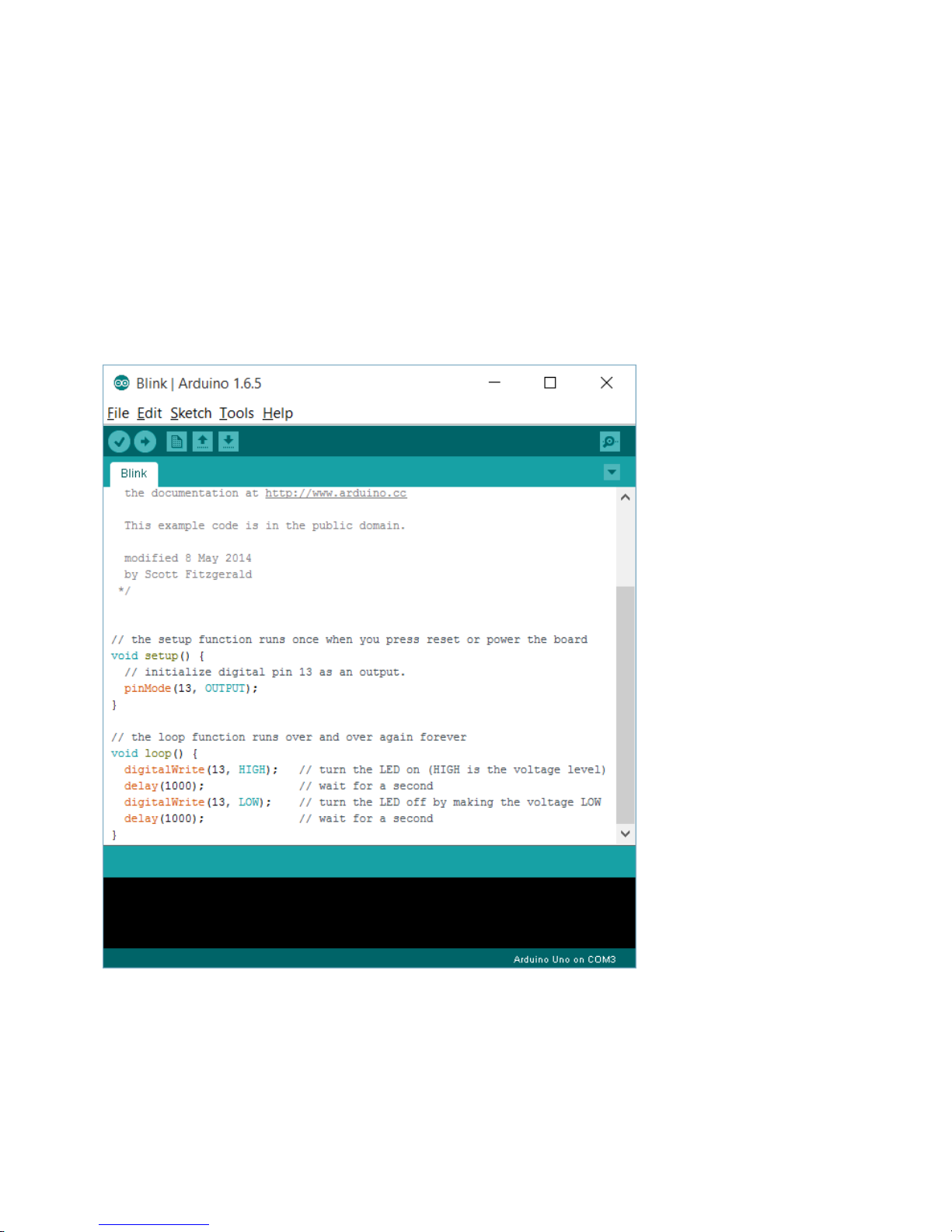

The following instructions are from the Arduino site

https://www.arduino.cc/en/Guide/Windows#toc1

Launch the Arduino Application

Double-click the Arduino application (arduino.exe) you have previously downloaded.

(Note: if the Arduino Software loads in the wrong language, you can change it in the

preferences dialog. See the Arduino Software (IDE) page for details.)

Open the blink Example

Open the LED blink example sketch: File > Examples >01.Basics > Blink.

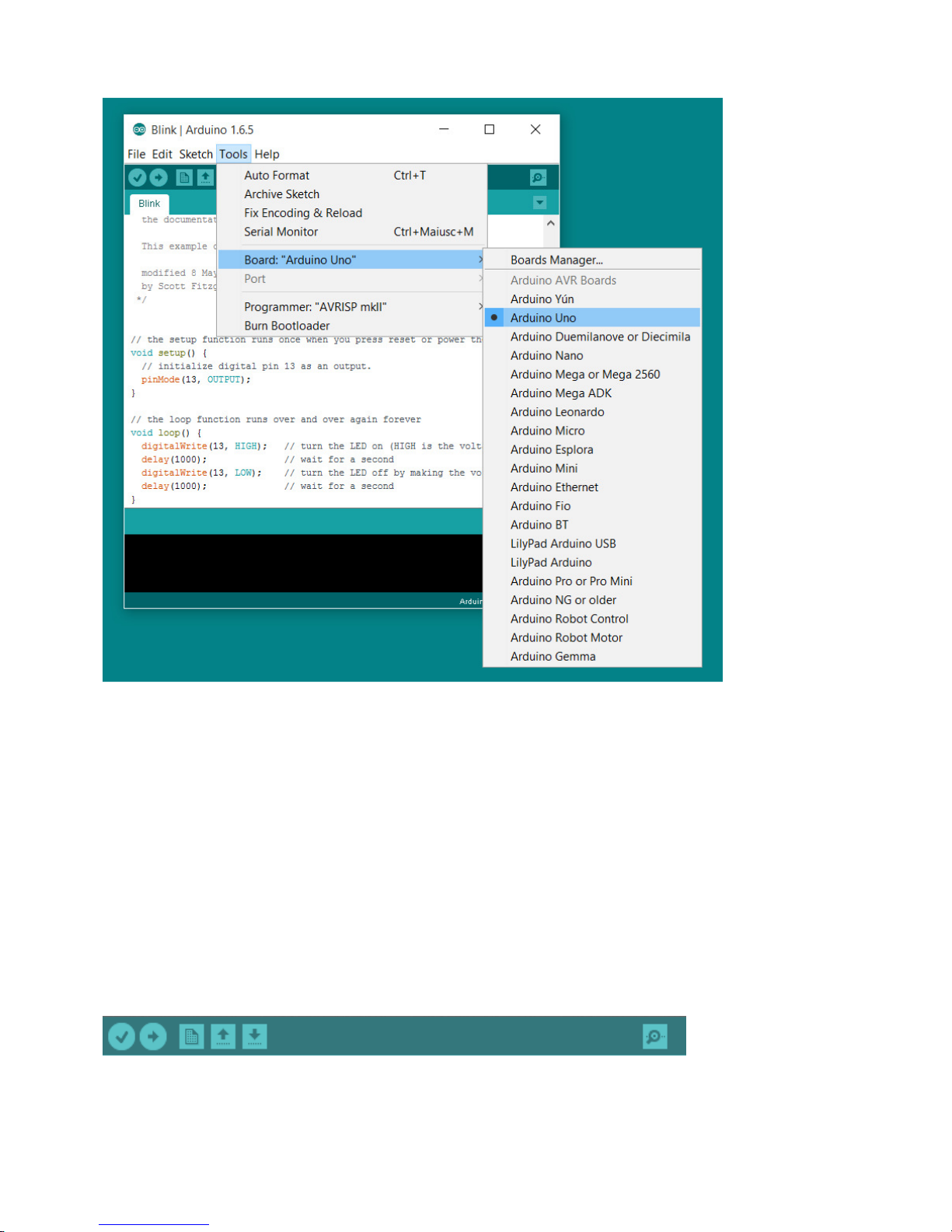

Select your Board

You'll need to select the entry in the Tools > Board menu that corresponds to your

Arduino. For Cricket the board is “Arduino Uno”

19 – Cricket Robot Documentation

Page 20

Selecting an Arduino Uno

Select your serial port

Select the serial device of the Arduino board from the Tools | Serial Port menu. This is

likely to be COM3 or higher (COM1 and COM2 are usually reserved for hardware serial

ports). To find out, you can disconnect your Arduino board and re-open the menu; the

entry that disappears should be the Arduino board. Reconnect the board and select that

serial port.

Upload the program

Now, simply click the "Upload" button in the environment. Wait a few seconds - you should

see the RX and TX LEDs on the SparkFun USB/Serial board flashing. If the upload is

successful, the message "Done uploading." will appear in the status bar.

20 – Cricket Robot Documentation

Page 21

A few seconds after the upload finishes, you should see the pin 13 LED on the board start

to blink (in red). If it does, congratulations! You've gotten Cricket Arduino up-and-running.

If you have problems, please see the troubleshooting suggestions.

You have programmed Cricket with a Sketch that only blinks the pin 13 LED. If you would

like to restore Cricket to his full operation, select the Cricket program from your CD under

“Software”. Select “Cricket_Arduino_1_0.ino. Do another download the same way you did

the “blink” download above. After the download, Cricket will straighten his legs and make

a couple of beeps. Your Cricket is now back to its normal operation.

21 – Cricket Robot Documentation

Page 22

Assembling Cricket’s Arduino Controller Board

If you received a Cricket kit with the Arduino Controller board already assembled, please

skip this section.

Assembling Cricket requires that you solder the parts onto the controller board and

assemble the robot chassis. I suggest that you assemble the controller first so you can

center the motors after mounting them in the chassis. The Cricket Arduino Controller uses

a printed circuit board (PC Board). The PC board has four surface mount components that

have been soldered in place for your convenience. You will solder the remaining

components. Follow the steps below to complete your controller.

Tools Needed

Soldering Iron

Rosin Core Solder (for electronics)

Small Diagonal Cutters

Small Needle Nose Pliers

Small straight blade screwdriver

Tooth Brush and Rubbing Alcohol (optional)

Multimeter to check voltages (optional and not shown)

22 – Cricket Robot Documentation

Page 23

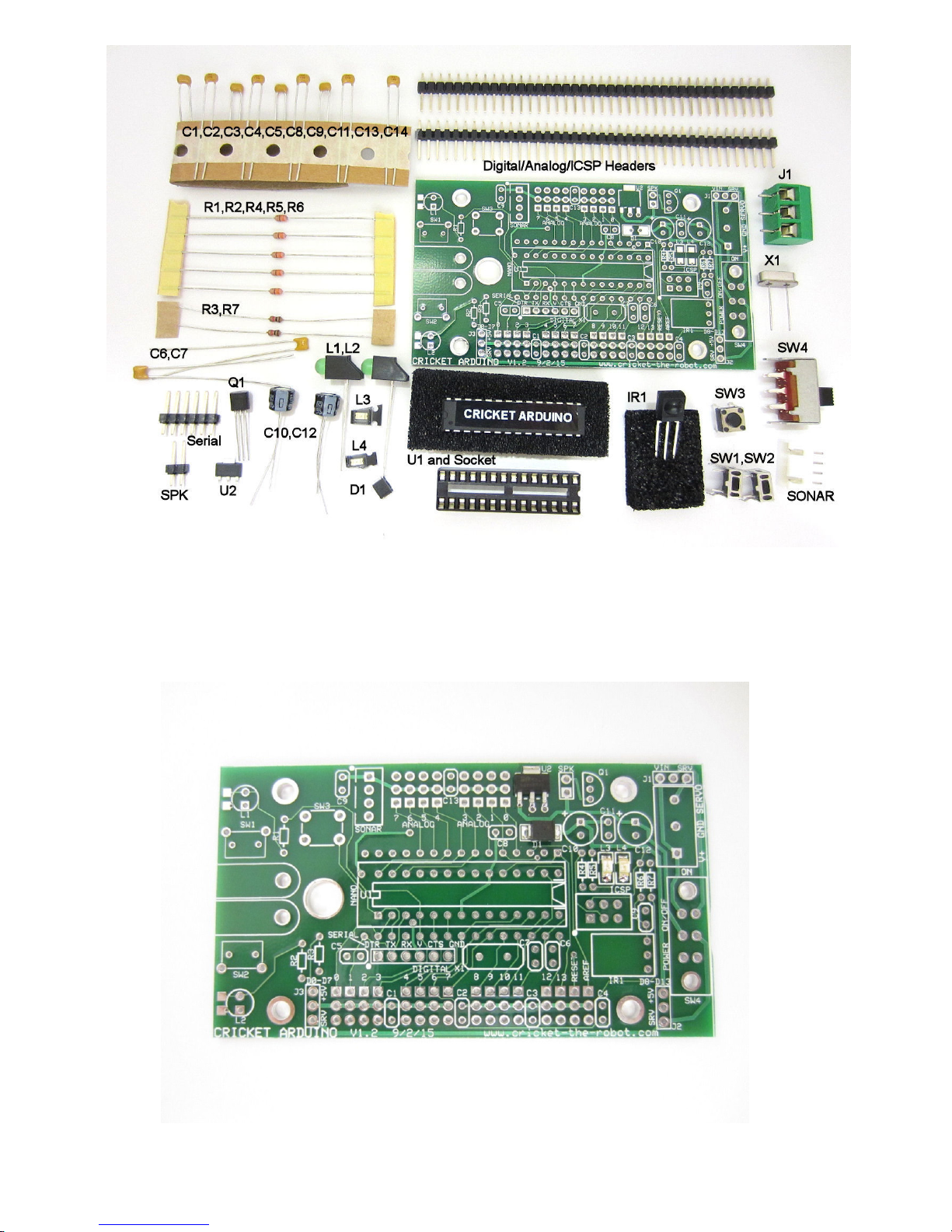

The PC Board and Parts

The PC Board is silkscreened with all of the part designations and outlines of the parts. Be

sure to note any parts that have a polarity or keyed direction before you install them. The

instructions will mention if a part has a polarity or direction. Your kit will have 4 surface

mount parts already installed on the PC board as show in the photo below.

23 – Cricket Robot Documentation

Page 24

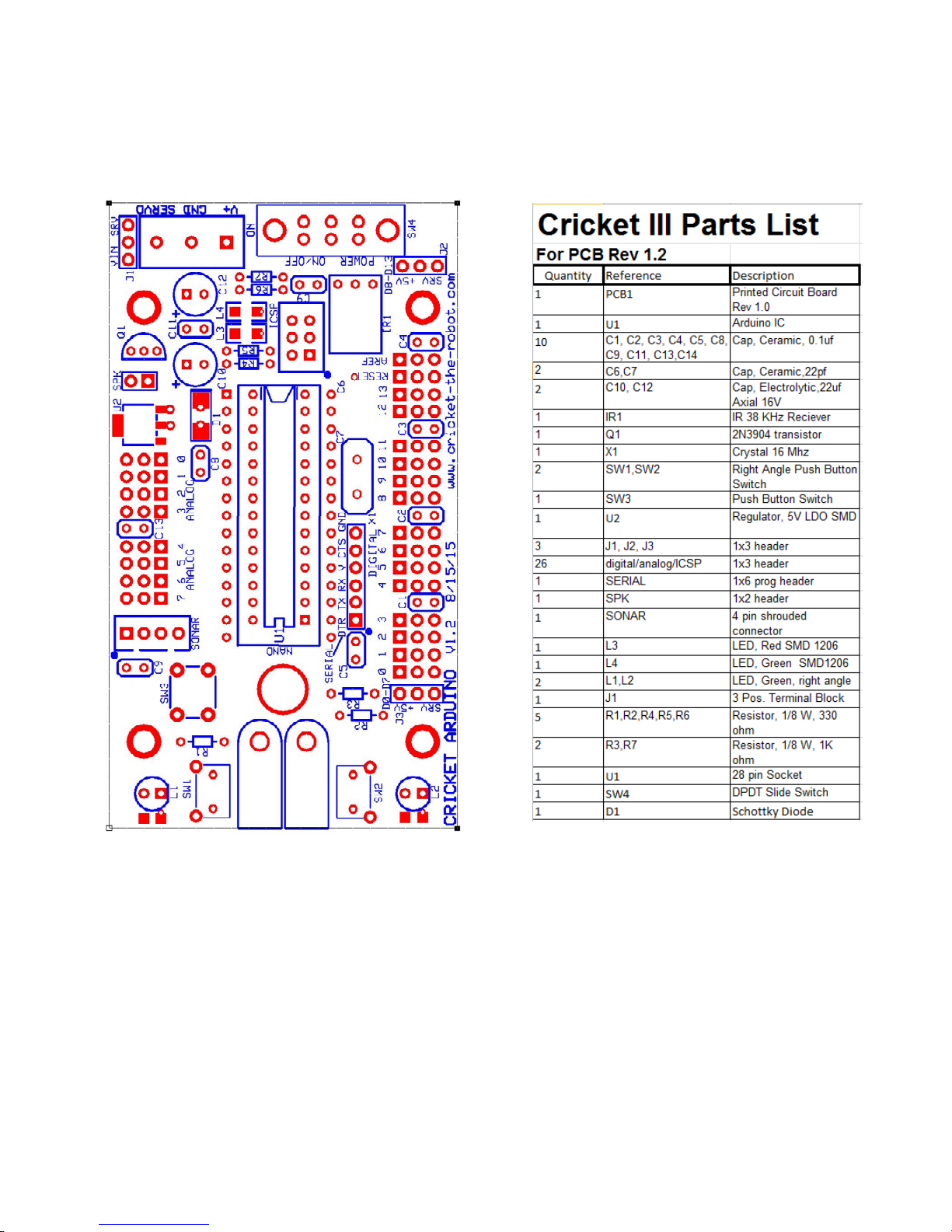

Parts Layout

Use this diagram to help you to locate where the parts are installed. Follow each of the

steps to complete your controller. All controller parts are listed in the parts table.

PC Board Parts Layout Parts List

24 – Cricket Robot Documentation

Page 25

Qty.

Location

Description

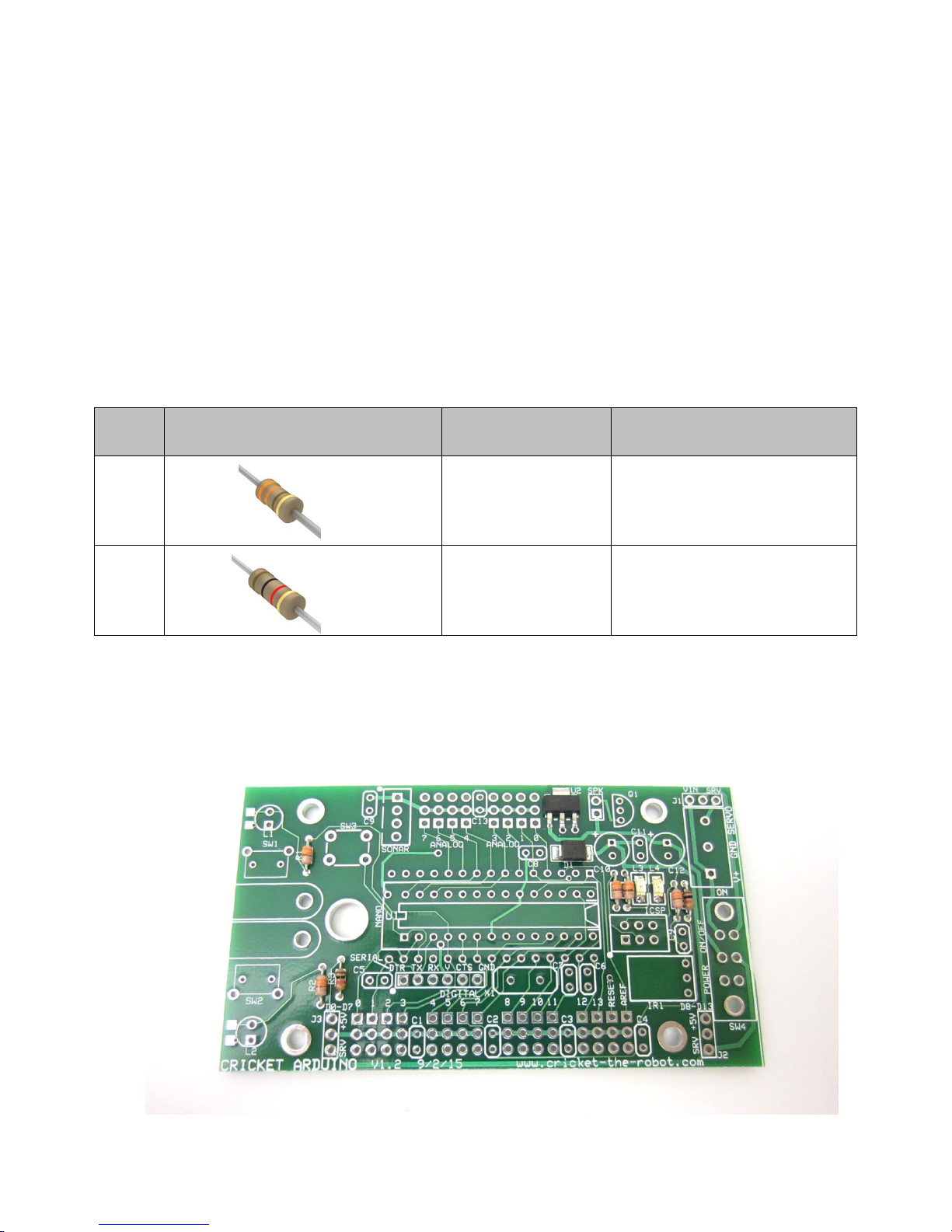

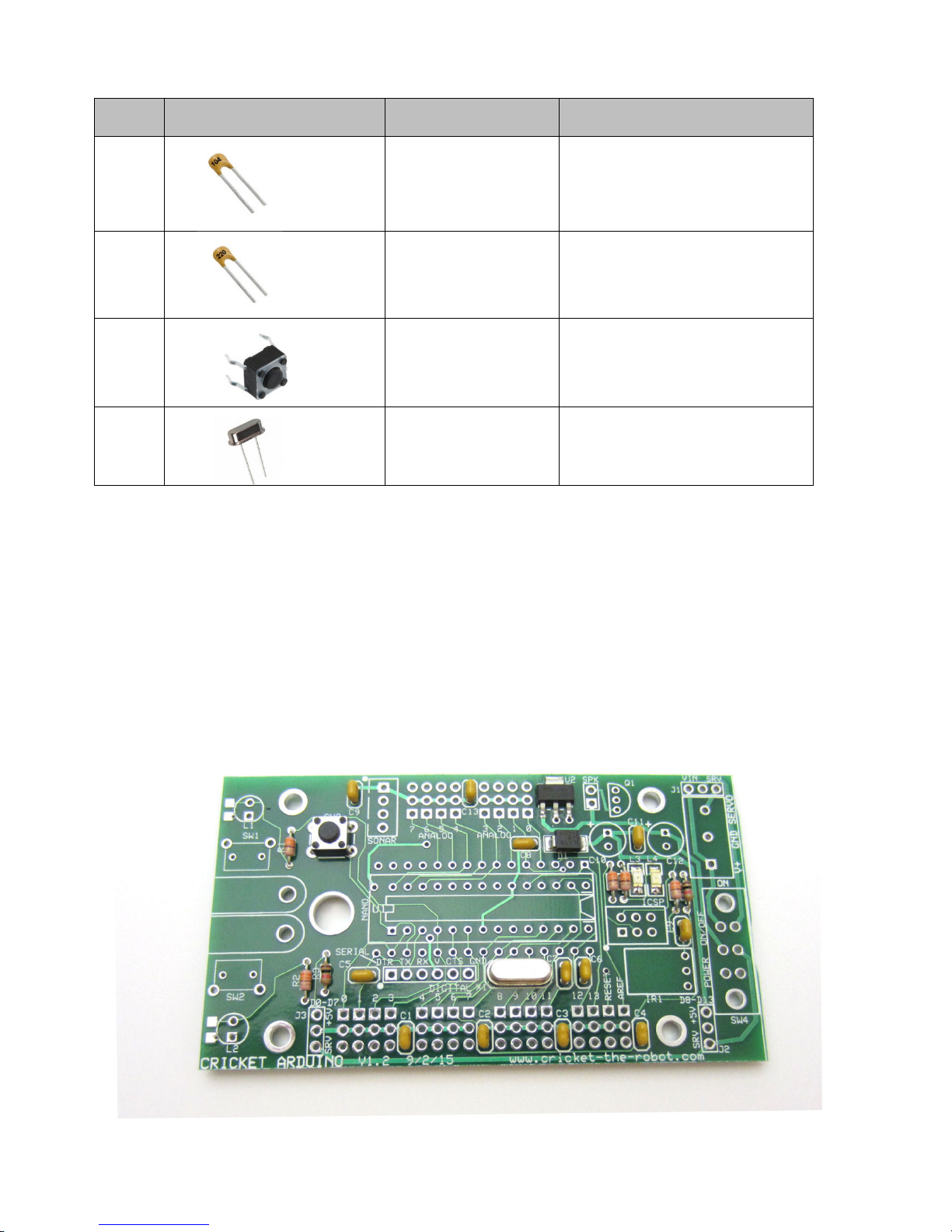

Installing the Parts

It’s best to install the low profile parts first. Each of the parts has a picture to help you

identify it. Start with the resistors followed by the capacitors. Resistors are color coded to

indicate their value of resistance. The ceramic capacitor’s value is designated by the

number 104 or 220 printed on the body. Look for the part that matches the picture and be

sure to note any parts that have a polarity which means that they can only be installed in

one direction (small “+” sign).

Install the resistors which each have a series of colored bands to indicate their value.

Bend the leads of each resistor so that they form legs which drop into the holes on the

board. You can install all the resistors at once or you can install and solder them one at a

time. Be sure that each resistor is low to the board and not up in the air. Solder each lead

from the back of the board and then clip the lead slightly above the solder joint.

5 R1,R2,R4,R5,R6 330 ohm resistor 1/8W

orange -orange-brown-gold

2 R3,R7 1K ohm resistor 1/8W

brown-black-red-gold

Install R1, R2, R4, R5, &R6. Solder the 2 leads and clip the excess lead.

Install R3 & R7. Solder the 2 leads and clip the excess lead.

25 – Cricket Robot Documentation

Page 26

Qty.

Location

Description

9

C1, C2, C3, C4,

C5, C8, C9,

Ceramic Capacitor

marked 104 0.1uf

C11, C13, C14

2

C6, C7 Ceramic Capacitor 220

0.1uf

1 SW3 Reset Push Button

1 X1 Crystal 16 MHz

Install the ten 0.1uf capacitors which all have the same marking of 104. No lead bending

is needed. They just drop in and there is no polarity. Solder the leads from the back of the

board and clip the excess lead length. Install the two 22 pf capacitors which both have the

same marking of 220. No lead bending is needed. They just drop in. Solder the leads and

clip the excess lead length.

Install the push button switch SW3 and solder the four leads. This part can fit in either of

two directions. Install connector X1 crystal making sure that it is flush to the PC board.

Solder the 2 leads on the back side of the board.

26 – Cricket Robot Documentation

Page 27

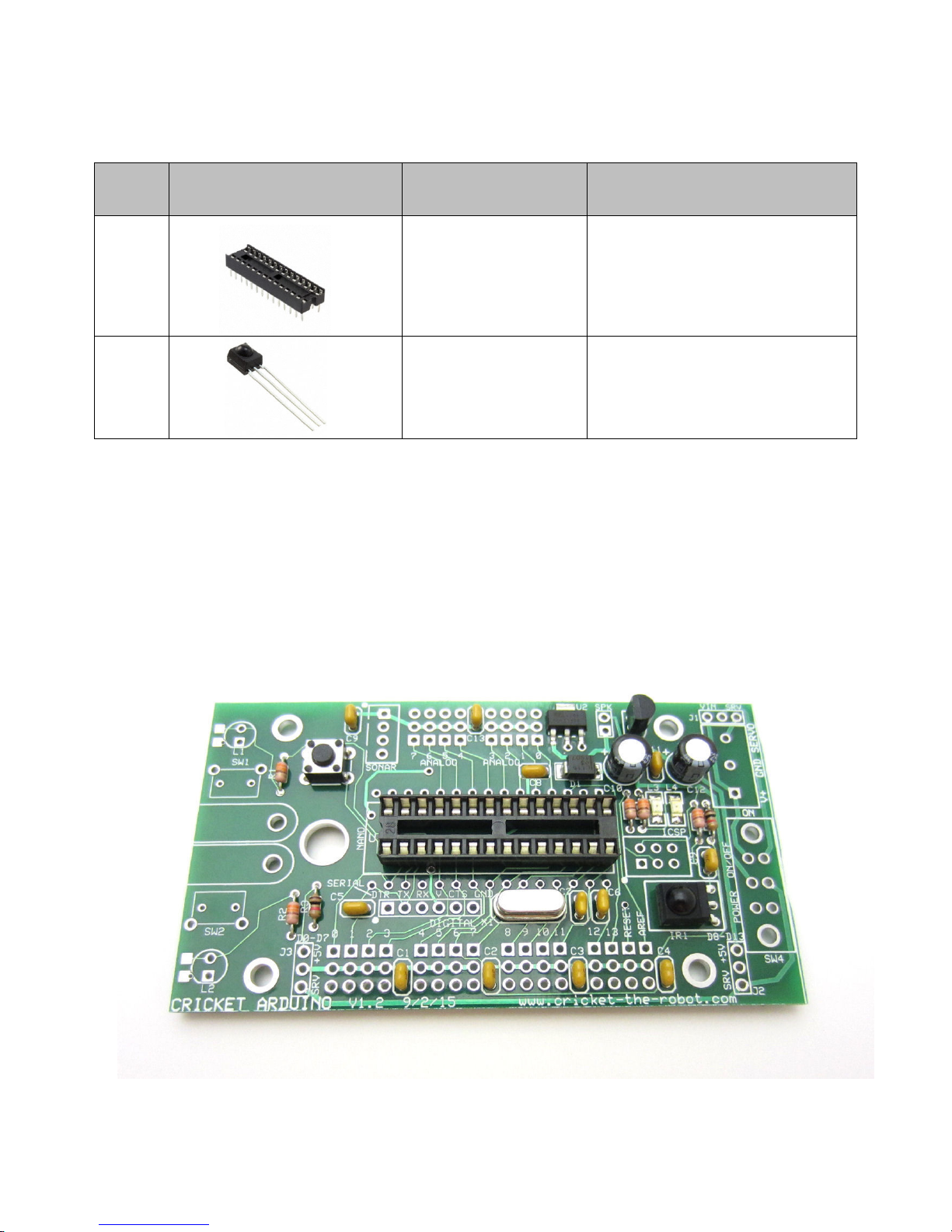

Qty.

Location

Description

1

Socket Socket for U1 Arduino IC

28 pins

1

Insert the socket for U1 making sure that the notch on one end matches the notch on the

PC Board designation (towards large 0.25” hole). Solder 2 corner pins and then make

sure the socket is flush to the board. Solder the remaining 28 pins.

Install IR1 which is IR Remote Control Sensor by first bending the leads down at 90

degrees at about ¼” from the body so that the part fits in its location on the board. The

bubble on IR1 faces up. Solder the 3 leads and clip the excess lead.

IR1 IR Remote Sensor

27 – Cricket Robot Documentation

Page 28

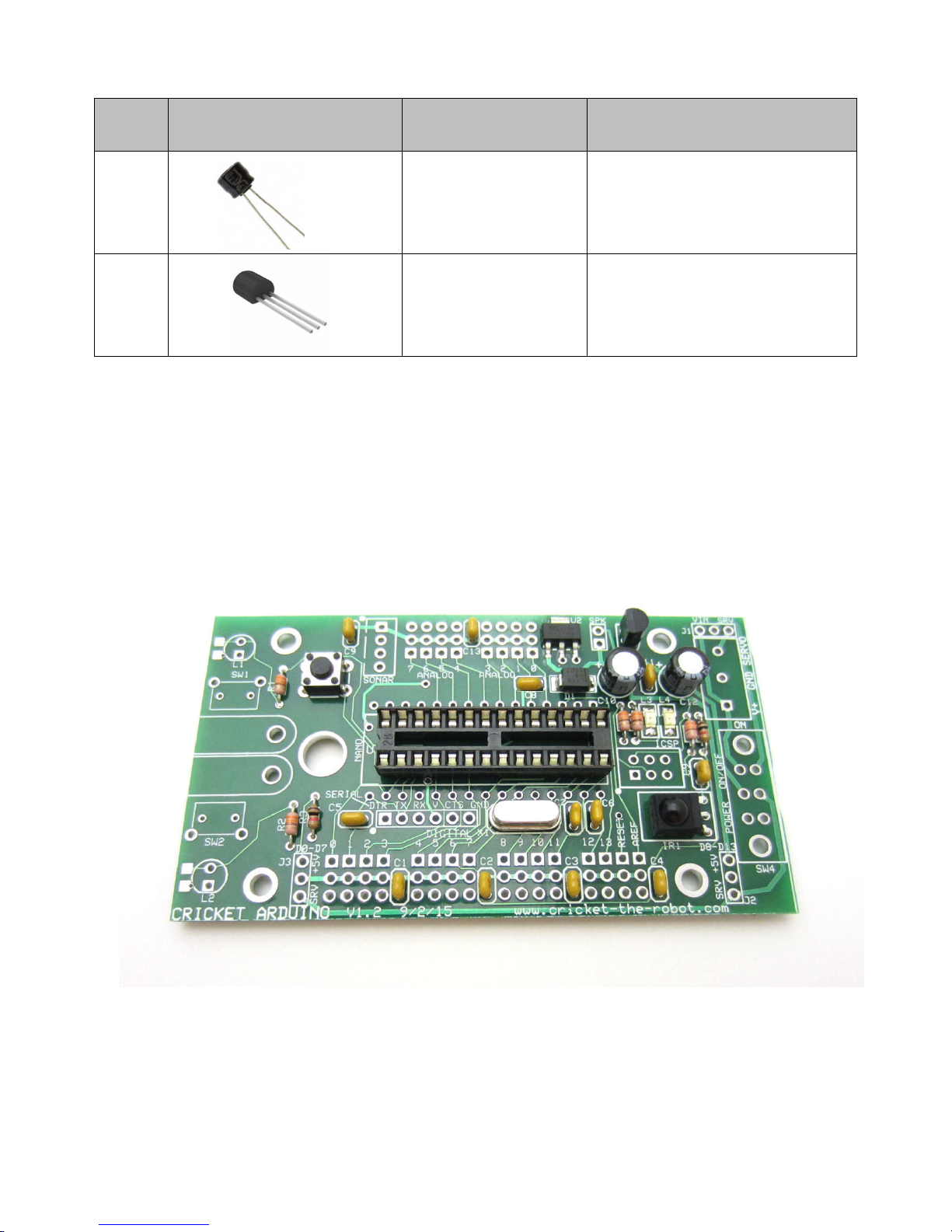

Qty.

Location

Description

2 C10, C12 22uf Electrolytic Capacitor

1 Q1 Transistor

Install C10 and C12 which are 22uf capacitors. Be sure to insert them with the “-” on the

part so that it lines up with the hole labeled with a “-”. There is no “+” marking on this part.

Solder and then clip the excess lead length.

Install transistor Q1 making sure the rounded side matches the silkscreen on the PC

board. You will have to slightly spread the leads and make sure the transistor is close to

the board as shown below. Solder and then clip the excess lead length.

28 – Cricket Robot Documentation

Page 29

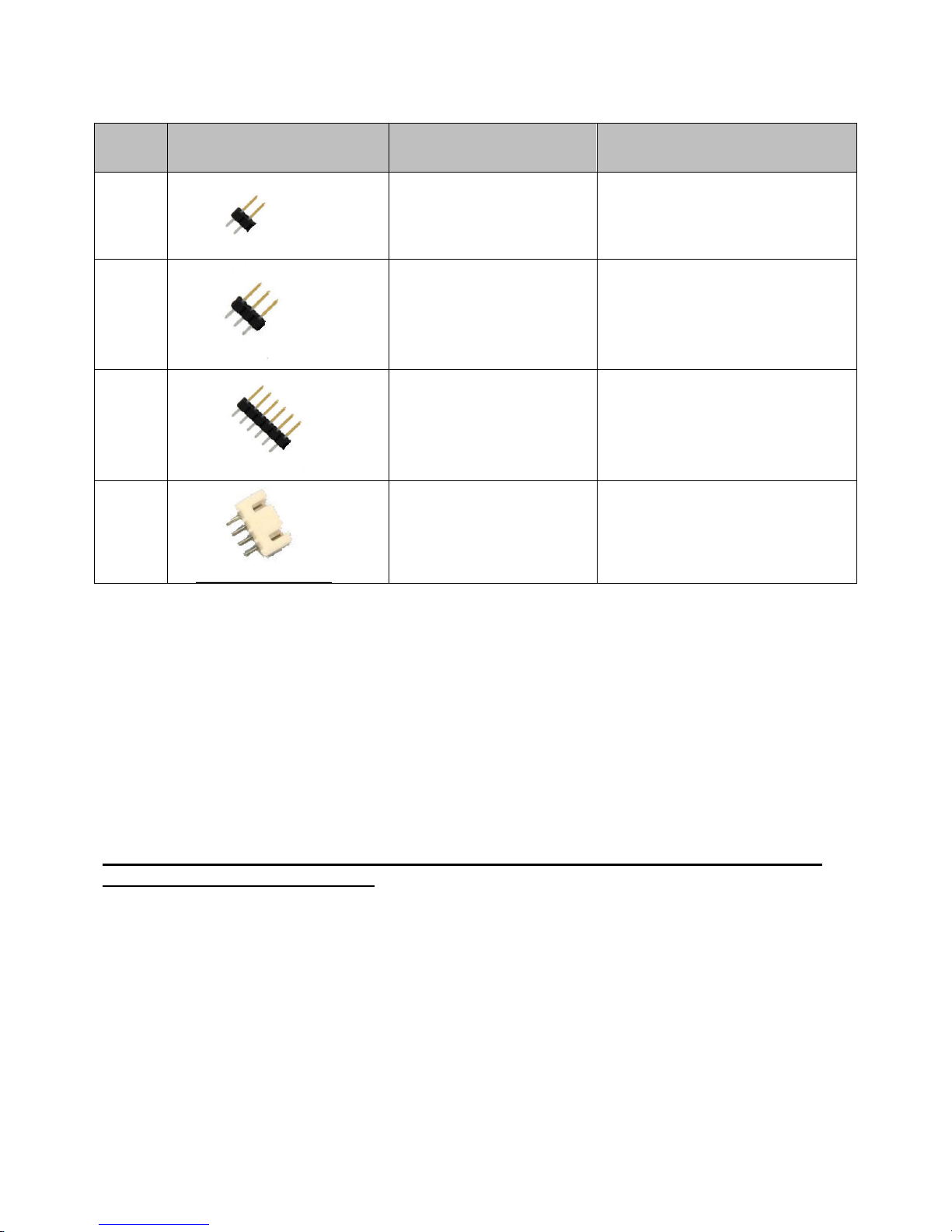

Qty

. Location

Description

1

29

SPK 2 Pin Header

Digital/Analog/ICSP

3 Pin Headers

J1, J2, J3

1 SERIAL 6 Pin Header

1

SONAR 4 Pin Connector

Your kit was supplied with two strips of pin headers. These headers are breakable using

your needle nose pliers. Break the strips into 26 three pin headers and one 2 pin header.

When installing these connectors it is very important that you install them flush and

vertical to the PC Board. They can be held in place with masking tape while you solder

them from the back side. Do not use plastic tape which will melt.

Install SPK which is a 2 pin connector. Solder only one pin, check that the connector is

straight up and down and flush with the board and then solder the other pin.

Connectors for Digital, Analog, and ICSP are three pin headers which were broken from a

long strips found in your kit. Carefully install and solder each connector.

Solder one pin, check that the connector is straight and flush with the board, and

then solder the other two pins. You may install these connectors in groups but be sure

they are straight and flush to the board, solder one pin, check them, and then solder the

remaining pins. You may use masking tape to hold the connector in position while you

solder the first pin.

Install SERIAL 6 pin connector. Solder one pin, make sure the connector is straight and

flush with the board and then solder the other 5 pins.

Install the SONAR connector. Make sure the side with 2 slots matches the silkscreen and

faces SW3 reset switch. Solder one pin, make sure the connector is straight and flush and

then solder the other 3 pins.

29 – Cricket Robot Documentation

Page 30

Qty

.

Location

Description

The above shows 3 pin connectors in the locations pointed to in the arrow. Leave these

connectors off. We will just solder a jumper at those locations rather than using a

connector.

2

2

30 – Cricket Robot Documentation

L1, L2 Right Angle Green LED

SW1, SW2 Feeler Switches

Page 31

Qty

.

Location

Description

Install LEDs L1 and L2 facing out. They are the right angle LEDs which mount on the

edge of the board. Make sure they are straight and flush to the board. Solder one pin,

make sure the LED is straight and flush and then solder the other pin.

Install the switches SW1 and SW2 which snap into place. Solder one lead, make sure the

switches are all the way flush with the board and then solder the remaining 3 leads. The

photo below shows 3 pin connectors in the locations pointed to by the arrows. Leave

these connectors off. We will just solder a jumper at those locations rather than using a

connector.

1 SW1 Slide Switch

1 J1 Terminal Block

1

Install the slide switch. The direction does not matter. The switch will work installed in

either direction. Make sure it is straight by soldering one pin first and the remaining seven

pins after checking it. The two large pins are mechanical mount points which should be

soldered.

U1 ARDUINO IC

31 – Cricket Robot Documentation

Page 32

Install the J1 terminal block by soldering one pin, checking that it is flush and straight and

then soldering the remaining two pins. Add three jumpers as indicated by the arrows.

These jumpers supply power to the Digital Connectors 0-13.

J2 and J3 should be jumpered from the center hole to the lower hole labeled “SRV”. J1

should be jumpered from the middle hole to the left hole labeled “VIN”. Any of the cutoffs

from your resistor installation can be used for these three jumpers.

Straighten the leads of your Arduino IC by bending them against a table top until they are

perpendicular. Do this on both sides. Insert the Arduino IC into the U1 socket noting that

the notch is facing the large 0.25” hole near the reset switch. Press firmly into place

Checkout and Cleanup

The board is now complete and should look like the picture above. If you would like to,

you may test the board by powering it with the battery holder from your kit. Connect the

red lead to V+ and the black lead to GND. When you turn it on, L4 should start blinking.

If you have a multi-meter, check the voltage at any of the center posts of the Analog

connectors.

You may optionally clean the flux residue caused by soldering using a toothbrush and

rubbing alcohol.

32 – Cricket Robot Documentation

Page 33

Assembling Cricket’s Chassis

Cricket’s Chassis is laser cut from ABS plastic. The parts fit together snuggly but still

require gluing to make the chassis strong and stiff. The assembly process is easy and

goes quickly. Just follow the rest of this section to build your Cricket Chassis.

The following diagram shows all of the plastic chassis parts for your Cricket Robot. Each

part is labeled with a letter which will be referred to during the assembly steps.

Tools Needed

ADD COMPLETE TOOLS PHOTO

Xacto Knife

File or Sandpaper (included)

Phillips #3, #2, and #1 screwdrivers

Pliers

Plastic Glue (included)

Spring Clamps or Masking Tape

33 – Cricket Robot Documentation

Page 34

General Assembly Instructions

Cricket’s chassis is made from ABS plastic. You will be gluing it together using plastic glue

which is provided. The supplied glue works well. You can also use Super Glue Gel if you

would like but I’ll warn you that it leaves a white residue which is difficult to clean off.

Otherwise the gluing process is the same. If you do use Super Glue Gel, I suggest that

you use soapy water and a tooth brush to remove any white residue caused by the Super

Glue. Use a minimal amount of glue when assembling the parts. Too much glue makes a

mess. If you do get glue squeezing out, leave it to dry and cut it off later with the Xacto

knife. If you try to wipe it, it will smear.

Cricket’s chassis is laser cut so the corners and notches are sharp. If you would like to

have an extra nice job, a little bit of filing of the corners and edges will make the parts fit

better however filing is optional except for few steps which are noted. On the sections

where filing is directed, you must remove the small ridge to allow the pieces to fit together

smoothly. Some of the part holes and notches may still have plastic slugs in them. You

need to knock these slugs out with a toothpick or other small instrument.

Assemble the Legs

Cricket’s outer four legs are identical

and are made up of 3 parts, the leg

(B) and two pivot pieces (C). These

pieces interlock by sliding C into the

notch on B. The parts must be glued

to assure the legs don’t come apart

with use.

34 – Cricket Robot Documentation

Page 35

Apply the glue sparingly

to the inner notch on

both the leg and the

pivots. Slide the pivots

all the way into the

notch. Slide one 6-32 x

5/8” screws through the

pivot hole to make sure

the holes line up. This is

very important so that

the legs move smoothly.

You may optionally

Clamp or tape each leg

to get a tight joint.

4 outer legs glued and

having a screw to make

sure the pivots are

aligned

35 – Cricket Robot Documentation

Page 36

Attach the rubber feet

part S to each of the 6

legs including the center

legs part D.

36 – Cricket Robot Documentation

Cut the bellow material

(T) into 6 parts with 7

segments each using an

Xacto knife or single

edge razor blade.

Page 37

Glue the bellows to each leg

on the underside near the

leg elbow on all 6 legs.

Note: The bellows are

cosmetic. They give the

legs the appearance of

having hydraulic cylinders. If

you don’t like them, they

may be left off or attached

in a different spot.

All 6 legs complete with

rubber foot pads and

bellows. Note the

location of the bellows.

After the legs are dry,

you may remove the

screws used to align the

pivots.

37 – Cricket Robot Documentation

Page 38

Assemble the Center Leg Beam

Locate two outside center beam plates (F) and one inside center beam plate (G). These

plates are glued together to create a strong center beam to support the center legs. The

laser cutting process leaves a minor ridge that keeps the center beam from being glued

together on flat faces. Use a file or some sandpaper to flatten the inner surfaces. Use 2

nails (provided) to line up the leg beam stack.

File off ridges so that the stack of

3 parts fit together flat. File both

sides of G and one side of each

F part.

Make sure that you apply glue to

both sides of the inside center

beam plate (G) and then add the

outer plates (F). Slide them over

the 16 GA nails supplied using

the small holes which will align

the whole assembly. Clamp or

tape the assembly together.

Allow this assembly to dry for a

while before attaching it to the

chassis body (A). Remove the

alignment nails before the

assembly dries but after you

have clamped/taped it.

38 – Cricket Robot Documentation

Page 39

Use the supplied nails to align

the center beam while clamping

it. The nails are discarded later

after the glue dries.

You may use spring clamps to

clamp the center beam.

OR you may use masking tape

to hold the beam while the glue

dries.

39 – Cricket Robot Documentation

Page 40

Sand the area where the center

beam will rest so that the glue

adheres better.

40 – Cricket Robot Documentation

After the center beam dries,

make sure the inside surface is

smooth using sandpaper, the file,

or the Xacto knife and that the

beam fits snuggly in the notch on

the chassis body. Once you have

checked the dry fit, apply glue to

the inner surface.

Page 41

Push the center beam firmly into

place on the body (A) making

sure that the surfaces mate. The

chassis body is completely

symmetrical so the beam can be

installed on either side.

Whichever side you install it on

becomes the bottom of the

Cricket Robot.

Use masking tape or spring

clamps to hold the beam in place

while the glue dries. This is now

the bottom of the robot.

41 – Cricket Robot Documentation

Page 42

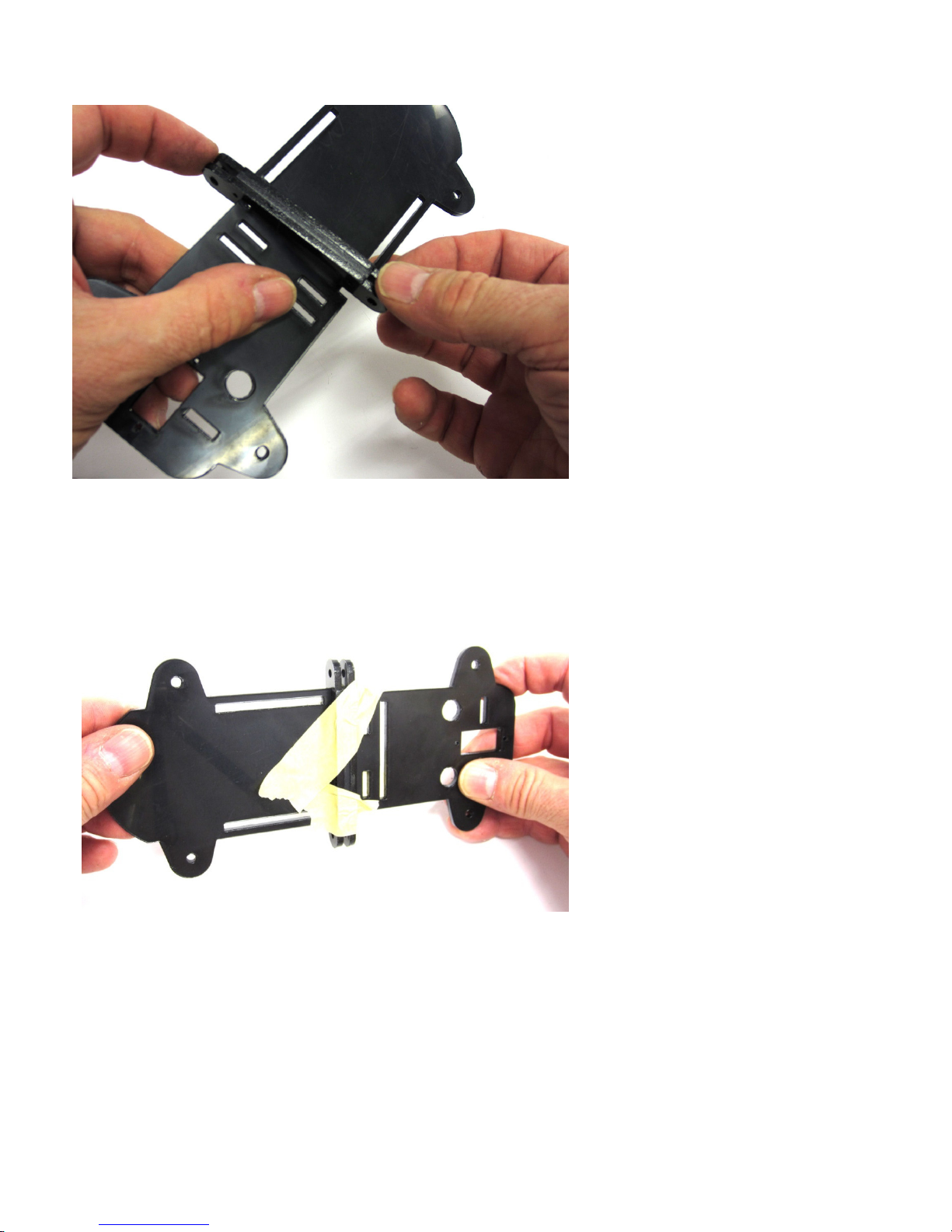

Attaching the Servo Motor Mounts

Find the 3 motor mounts (H). These parts will have a small ridge on the notched end that

slides into slots on the body (A). The motor mounts are symmetrical so they may be

inserted in either direction in the notch on the body (A). File or sand the ridge off and try

dry fitting them into the matching notches on the body (A). IMPORTANT: The motor

mounts (H) must be installed on the same side of the body (A) as the center beam (F & G)

was installed on. When you glue the motor mounts in place, don’t worry about a little glue

squeeze out. Cut it off with a Xacto knife after it dries. I suggest that you don’t try to wipe it

off because it makes a mess of the body.

File or sand off the small ridge

on each tab as shown.

42 – Cricket Robot Documentation

Apply glue sparingly on each

side of the tab.

Page 43

Left Motor Mount

Center Motor Mount

Right Motor Mount

Insert each of the three motor

mounts (H)

Make sure each of the three

mounts (H) are perpendicular to

the chassis body. You may tape

or clamp them if you like but they

should be OK just drying in

place.

43 – Cricket Robot Documentation

Page 44

Install the PC Board Mounts

Find the 4 PC Board mounts (N). The parts are used to mount the Arduino controller. The

mounts have a small ridge on the notched end that slides into 4 slots on the body (A). Be

sure to note the orientation of these mounts as they can be installed backwards. File or

sand the ridge off and dry fit them into the matching notches on the body (A) before gluing

them. IMPORTANT: The motor mounts (N) must be installed on the opposite side of the

body (A) as the center beam (F & G) was installed on.

File or sand the ridge so that the

mount (N) can slide easily into its

matching pocket. Dry test fit the

mounts in the 4 locations noted.

44 – Cricket Robot Documentation

Apply a small amount of glue to

each side of the tab and press

the mount into place. Make sure

it is fully seated and that the

small hooks point inward

Page 45

Installing the PCB mounts (N)

4 PCB mounts (N) installed. Note

that they are on the opposite

side of the body from the motor

mounts.

45 – Cricket Robot Documentation

Page 46

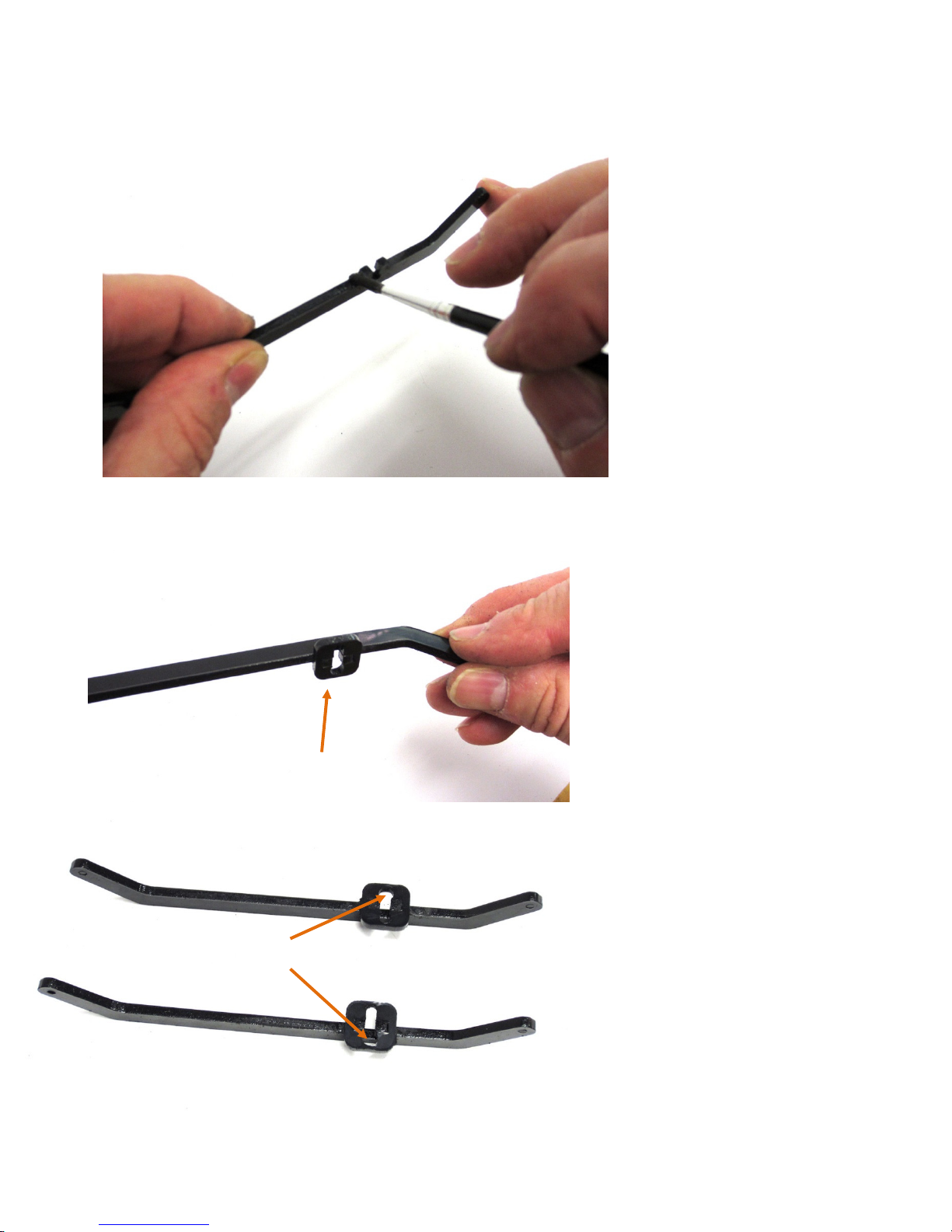

Assemble the Leg Control Arms

Find two leg control strips (J) and two retainers (K). Dry fit the retainer onto the strip. If the

retainer will not fit on the arm, use a file or sandpaper to lightly fit the parts. The two leg

control arms are mirror images for right and left sides. The retainer is attached to one side

with the small round circle pointing up and on the other Control Strip with the small round

circle pointing down. See the assembled photo if this is not clear.

Leg Control Arms (J)

Retainers (K)

Be sure to note the

orientation of the retainers in

following photos.

46 – Cricket Robot Documentation

If the retainers will not slide on,

file or sand the outside of the

notch.

Page 47

Apply a small amount of glue to

the mating surfaces and press

the retainers on each of the

Control Strips. Do not apply glue

to the inner notch which is where

the servo horn will ride.

Left Control Arm

Right Control Arm

Key holes facing outward

This shows the Left Control Arm

with keyhole facing down.

Hole

This shows both the Right Control

Arm and the Left Control Arm. The

holes at the end of the slot face

outward.

Left Control Arm

47 – Cricket Robot Documentation

Page 48

Assemble the Sonar Bracket

The Sonar mount bracket is made up of parts (L) and (M). The upright (L) has a tab that

must fit into a slot on the base (M). Check the fit and if it is tight, remove the ridge using a

file or sandpaper.

Check the fit and if it is tight,

remove the ridge using a file or

sandpaper.

Apply a small amount of glue to

each side of the tab.

Press the upright tab into the

base slot. Make sure it is fully

seated.

48 – Cricket Robot Documentation

Page 49

The Completed Sonar Bracket

Assemble the Sonar Servo Linkage with the servo horn adapter (R) the 4-40 round ¾”

standoff, 4-40 internal star washer, and a 4-40 x 3/8” flathead screw. These parts are

shown in the photo below.

4-40 flathead Adapter (R) star washer ¾” spacer

Push the flat head screw through the countersunk side of adapter (R). Place the star washer on the

screw. Add a small amount of glue to the screw and then tighten the spacer onto the screw using a

#1 Phillips screw driver.

49 – Cricket Robot Documentation

Page 50

Completed Sonar Servo Linkage

Attach the post to the Sonar Servo

horn using two #0 x 3/16" flathead

sheet metal screws

Tighten the screws with a #1 Phillips

screw driver.

50 – Cricket Robot Documentation

Page 51

Completed Sonar Servo with linkage

ABS Parts of Chassis are Now Complete

You have completed all of the ABS assembly. You should have the completed body, legs,

control arms and Sonar Bracket. The photo also shows a center control arm (right side)

which did not require any gluing. Let everything dry before assembling the legs and other

parts to the chassis body.

51 – Cricket Robot Documentation

Page 52

Installing the Servos into the Chassis

Remove your 3 Hitec servos from their boxes

and remove the standard control horn from

each servo by removing the center screw.

Label the servos “R”, “L”, and “C” on both the

body of the servo and its connector. A black

indelible ink pen works well. These labels

stand for right, left, and center and are

important because we will setup the servos

based on their position on the robot.

There are 12 #4 x 3/8” screws for mounting

the servos.

Install the left servo with the shaft

closer to the front of the robot and the

center beam

Attach the servo with four #4 x 3/8”

self-tapping screws using a #2

Phillips screw driver.

52 – Cricket Robot Documentation

Page 53

Left servo shown installed

Install the right servo the same way

with the shaft and wire towards the

front of the robot

Insert the center servo with the shaft

to the left side of the robot as shown.

Use only 2 screws because this servo

will be removed later.

Install with only 2 screws because

this servo will be removed later.

53 – Cricket Robot Documentation

Page 54

Install the sonar servo with the

linkage in the opening at the front of

the robot. The shaft should face the

center of the robot as shown.

Mount the sonar servo with the 2

screws from the supplied HS-55

accessories inside the box using a #1

Phillips screw driver.

The completed sonar servo

installation should look like this.

54 – Cricket Robot Documentation

Page 55

Verify your servo installation against

these photos. Route all servo wires

through the left access hole in the

body as shown

Your servo wires should be loosely

routed as shown. Later we will neaten

the wires up with wire ties

55 – Cricket Robot Documentation

Page 56

Installing Cricket’s Legs

We will now install the legs using six 6-32 x 5/8”

machine screws and six self-locking nuts.

Attach the 4 outer legs (B) by pushing

a 6-32 x 5/8” screw through the top of

the leg through the body. Do the

same on all four corners of the robot

6-32 x 5/8” Screw and

6-32 Self Locking Nut

Using a pliers and a #3 Phillips

screwdriver, tighten the 6-32 selflocking nut onto the screw from the

bottom of the robot. Tighten all the

way until the screw will not turn

anymore and then loosen one half

turn. Make sure the legs move freely.

If they do not, loosen the screws a

little more until they move freely.

56 – Cricket Robot Documentation

Page 57

Attach the 2 center legs (D) by

pushing a 6-32 x 5/8” screw through

the center beam and the leg. The

screw head should be closest to the

right and left servos.

6-32 x 5/8” Screw and

6-32 Self Locking Nut

Tighten all the way until the screw will

not turn anymore and then loosen

one half turn. Make sure the legs

move freely. If they do not, loosen the

screws a little more until they move

freely

57 – Cricket Robot Documentation

Page 58

Installing the Leg Control Arms

Locate the Leg Control Arms you

assembled earlier and four 2-56 x ½”

machine screws

Select the control arm for the right

side of the robot noting the round

keyhole pointing down as shown.

Insert the machine screw through the

arm and into the hole in the leg. The

screw will self-tap itself into the

plastic. Tighten the screw all the way

and then pack it off about one full

turn. Repeat on the front leg and then

make sure the legs on the right side

move freely. Repeat these steps on

the left side.

58 – Cricket Robot Documentation

Page 59

Your leg control arm on the left side

should look like this. Note the round

keyhole pointing down.

Your leg control arm on the right side

should look like this. Note the round

keyhole pointing down.

59 – Cricket Robot Documentation

Page 60

The center leg control arm (E) is

installed on the front of two posts

coming up from the center legs (D)

with the round Keyhole facing down

as shown.

60 – Cricket Robot Documentation

Add two 4-40 x ½” screws through the

center leg control arm as shown, Be

sure the arm is in front of the posts.

Page 61

Secure the center control arm

(E) to the center legs as

shown using two 4-40 x ½”

Screws and 4-40 Self

Locking Nuts. The keyhole in

the center control strip should

face with the round part of

the hole down.

Your robot should look like this photo

with all six legs installed. Make sure

all the legs move freely and loosen or

tighten the leg screws as needed.

61 – Cricket Robot Documentation

Page 62

Installing the Battery Holder

Clean the area on top of the robot

towards the back with rubbing alcohol

or water. Let it dry.

62 – Cricket Robot Documentation

Attach two strips of double sided tape to

the back of the battery holder by removing

one side of the protective paper.

(Only one tape is shown. There are two)

Page 63

Remove the protective paper on the

other side of the double sided tape

and press the battery holder into

place. The battery holder should be

placed all the way up to the center

brace and centered between the

servo control arms.

There should be a small amount of

space between the battery holder and

the rear leg pivots.

63 – Cricket Robot Documentation

Page 64

Installing the Speaker

The speaker is installed by gluing it

face down to the chassis body in

front of the center servo mount as

shown. Installing it face down may

seem wrong but the chassis acts

as a sound board with the sound

exiting the rear of the speaker.

64 – Cricket Robot Documentation

Glue the speaker by holding it

firmly in place and putting three

drops of glue evenly spaced

around the perimeter. Use a

spring clamp or tape to hold the

speaker in place while the glue

dries.

Page 65

Completing the Feelers

The feelers with feeler switch actuators have

been assembled for you. You must only add the

small glass bead and bend the feeler to shape.

The bead protects people and animals from

being poked by the sharp end of the feeler. You

may also bend the end of the feeler into a tiny

loop if you don’t want to use the bead.

Slide a supplied glass bead onto the feeler. Add a small drop of the supplied glue (or Crazy Glue) to

the end of the wire and then carefully slide the bead into the glue. Let this dry before handling further.

Note: The bead protects people and animals from getting poked by the sharp wire. As an

alternative you may simply bend a small loop into the end of the feeler wire.

65 – Cricket Robot Documentation

Page 66

Installing the Feelers

Using two 2-56 x ¼” machine screws and 2-56

self-locking nuts, attach the feelers to the control

board. The little nubs on the feeler switch

actuators (P) must face the switch button.

Tighten the screw with a #1 Phillips screw driver

and pliers until tight and then back off about a

half turn. Make sure the feelers operate the

switches smoothly

66 – Cricket Robot Documentation

Page 67

The feelers need to have a couple of

bends in them so that they point

outwards from Cricket’s body.

The first bend can be done with your

hands. Gently bend the two feelers

away from each other so there is about

½” to ¾” between them.

Next take a pair of pliers with the

Cricket controller lying on a table and

bend the feelers about 1” from the

switch actuators so they point outward

as shown. The bend angle is not

critical. The idea is for the feelers to

reach out past to body and touch

something before the robot crashes

into the object.

67 – Cricket Robot Documentation

Page 68

You may now install the controller on

your Cricket chassis. Make sure all of

your wires are exiting outward from the

chassis as shown. Carefully slide the

controller over the sonar post. When it

is resting on the four PCB mounts

carefully push down on it until it snaps

into place.

Connect the speaker to the

connector labeled “SPK: on

the PC board. The

connector is next to the

terminal block. The yellow or

red wire faces in towards the

center of the robot. The

black wire is near the edge.

68 – Cricket Robot Documentation

Page 69

Connect each of the service

noting the labels you added to

each connector. The connections

are show in the table below and

correspond to the numbers on

the connectors along the left side

of the robot. The yellow wire

faces in towards the center of the

robot. THIS IS IMPORTANT.

The photo at the left shows the

correct orientation for each servo

connector as you plug them in.

Plug the servos into your

controller using the following

connections:

Right Servo 9

Left Servo 10

Center Servo 11

Sonar Servo 12

69 – Cricket Robot Documentation

Page 70

Connect the battery holder to the

controller by connecting the red

and black wires. The photo

shows long wires but your wires

will already be cut to the correct

length.

The red wire goes to the terminal

labeled V+ which is the terminal

closest to the center of the

board.

The Black wire goes to the

terminal labeled GND which is

the center terminal.

Be sure you have these

connections correct so that you

don’t damage your controller.

You may have to loosen the

terminal with a straight blade

screw driver. Insert the wire and

then tighten the screw.

70 – Cricket Robot Documentation

Insert the AA batteries into the

holder noting the correct

polarities print on the bottom of

the holder. Be careful not to

pinch the battery leads.

Page 71

NOTE:

The Servo

yellow wire faces toward middle of the PC board.

Before you power your Cricket up for the first

time, verify that you have connected the motors

and battery as shown below.

SPK-speaker wire

No Connect

Black Battery

Red Battery

9-Right Servo

10-Left Servo 11-Center Servo

12-Sonar Servo

71 – Cricket Robot Documentation

Page 72

Centering the Servos

Your servos are now electrically connected and you have a battery connection. When the

controller is turned on, it will center each servo to its middle position. You have no

mechanical connection between the motors and the legs so the motors will turn without

moving anything. This allows the motors to be centered in the correct position before we

install the control arms that will move the legs. If the motors are not centered before the

mechanical connection is made, the legs might be forced into a bad position possibly

damaging the robot.

Turn on your controller using the switch next to the batteries and the controller will center

the servos, make a beep, and then pause for a couple of seconds. During that pause, turn

off the robot. If you miss the pause; just turn the controller off and then on again. When

you hear the first sound, turn the switch off. This procedure allows us to center the servo

shafts to the correct position before attaching the servo horns which will be used to move

the control arms.

Installing the Servo Horns

Inside the accessories package for the Hitec 311 servos are extra horns. Horns are the

plastic pieces that screw onto the servo shaft. We will not be using the default horn which

comes attached to the servo. Locate the horn and pieces shown in the photo below. Two

of the horns have an extra-large hole drilled in the end spot and the third horn has an

extra-large hole in the third spot. The ones with the hole in the end are the right and left

horns and the other is the center horn. Each horn has a serrated and a smooth side.

The accessories package also has four rivets which are normally used for mounting the

servo. We will be using one rivet as a bearing point for each horn. On the right and left

horns, place a rivet through the 2-56 x 3/8” machine screw and screw it into the first hole

on the serrated side of the horn. On the center horn, place a rivet through the 2-56 x 3/8”

machine screw and screw it into the third hole on the non-serrated side of the horn.

Horn Assembly Parts:

Horn, Rivet from

Servo kit, 2-56 x 3/8”

screw, and original

horn screw.

72 – Cricket Robot Documentation

Page 73

Right and left horns

Serrated side up

.

Center horn

Serrated side down

Here’s a photo showing the

completed servo horns

Horn adapter fits on

servo shaft.

Screw retains both

horn and horn adapter

to servo shaft.

Before you install the horns on

the right and left sides, make

sure the slot they ride in is free of

glue or plastic flash. Check that

the screw and rivet ride smoothly

in the slot.

73 – Cricket Robot Documentation

Page 74

Install the horn adapter in it most vertical

position. If you can’t find a shaft position

that is perfectly up and down, pick the

closest position to vertical. Be very careful

to not move the servo shafts as you install

each of the adapters. If you think you may

have moved the shaft, turn on the

controller to center the shaft and turn it off.

Once the adapter is in position, add the

horn. The serrations should be facing in

and mesh with serrations on the

adapter which keep it from sliding

around. Line up the bottom edge of the

horn with the adapter and screw the

assembly in place with a #1 Phillips

screwdriver.

74 – Cricket Robot Documentation

This photo shows the left side

horn in place. Repeat the

process on the right side

again making sure the adapter

is as vertical as possible.

Page 75

Remove the center servo

which was installed with just

two screws. Add the horn

adapter installing it in the most

vertical position you can find.

Once the adapter is in

position, add the horn. The

serrations should be facing in

and mesh with serrations on

the adapter which keep it from

sliding around. Line up the

bottom edge of the horn with

the adapter and screw the

assembly in place with a #1

Phillips screwdriver.

Reinstall the center motor

by tipping it through the

motor mount and inserting

the rivet and screw bearing

point through the center

keyhole.

75 – Cricket Robot Documentation

Page 76

Install all four screws

to retain the center

servo motor

76 – Cricket Robot Documentation

Check that your robot

center motor installation

looks like the photo at the

left. The rivet bearing point

should be poking through

the center control arm as

shown.

Page 77

Turn your robot over and he should look like the above photos. The wires are just

hanging at this point but we will neaten them up and use wire ties to hold them in place.

If you would like, you can turn your robot on and let him walk a bit. If you hear any

binding in the motors, you can remove the horns and repeat the centering procedure.

If the robot fails to walk correctly, recheck the motor connections. If the right, left, or

center motor connections are swapped, the robot will act very strange.

77 – Cricket Robot Documentation

Page 78

Installing the Sonar Module

Attach the sonar (ultrasonic module) to

your bracket with two #1 panhead

screws. You will need to slightly tip the

module to install it in the bracket. The

screws are at diagonal positions.

Note: The photo shows the sonar post

and screws which we already installed

on the servo. Please ignore

Sonar module and bracket with

screws installed

78 – Cricket Robot Documentation

Page 79

Locate your sonar cable, a 4-40 x 3/8”

panhead screw, a flat washer, an

external star washer, and an internal

star washer.

Internal

Washer

Screw

External

star

star

Connect the cable to your sonar

module with the ribbed side facing

as shown.

Place the flat washer on the screw and

push it through the hole in the sonar

bracket. Add the external star washer

and then the internal star washer.

Note: The external star grabs the

plastic of the bracket and the internal

star grabs the top of the post. This

keeps the sonar module from slipping.

Ribbed side

79 – Cricket Robot Documentation

Page 80

Without dropping the star

washers insert the screw and

bracket assembly onto the sonar

servo post and tighten it with a

#1 Phillips screwdriver. Try to

hold the post from turning so that

the servo maintains it center

position.

Note: Later if you find that the

sonar module does not face

straight forward you can loosen

the bracket, move it, and

retighten the screw.

80 – Cricket Robot Documentation

Plug the sonar module into

the controller board

Page 81

Cleaning Up the Wiring

Your robot will look nicer if

the wires are not hanging all

over the place.

Neaten up the four servo

wires by removing the slack

by pushing them through the

hole in the chassis.

Wire Tie

Use one of the supplied wire

ties to retain the four servo

wires from moving around.

Allow a little bit of slack in

case you need to disconnect

any of the servos

81 – Cricket Robot Documentation

Page 82

Wire Retainer

Attach the nylon wire retainer

on the side of the center servo

by peeling the backing off and

pressing it into place.

Route the right and left

servo wires through the

wire retainer. Make sure

there is some slack so

that the wires are not in

the way of the center

servo horn.

82 – Cricket Robot Documentation

Page 83

Fold the dangling wires

into a neat bundle and

tuck it between the sonar

and center servos.

Use two more wire ties to

retain the wire bundle in

place.

Note: There is a small

amount of slack one the

right and left servo wires

to clear the motion of the

center servo horn’s

movement.

83 – Cricket Robot Documentation

Page 84

Final Checkout

Your Cricket Robot should look like this photo from the top. Make sure your wires are not

hanging out. The legs should center as shown when turned on and the sonar should be

facing forward.

From the side, the right and left

motor horns should be vertical

and the horn should be flush

with the bottom of the horn

adapter.

84 – Cricket Robot Documentation

Page 85

Your sonar module

should face straight

forward and the

feelers should look

like the photo.

From the bottom, the

center servo horn should

be vertical and the wires

should be out of the way of

moving servo horns. Your

feelers should extend in

front of the robot so they

detect objects before the

leg runs into it.

85 – Cricket Robot Documentation

Page 86

Your sonar cable should exit

from the bottom of the sonar

module and bend through a

graceful loop into its

connector on the controller.

This bend allows for

movement of the wire as the

sonar module turns right and

left.

Recheck that your feeler

switches both click when

the feelers are pushed.

86 – Cricket Robot Documentation

Page 87

Beep Beep!!

Your Cricket Robot is complete. Place him in an open area and turn him on. He should start

walking around and avoiding obstacles. In most cases the sonar should detect an obstacle but

if it misses, the feelers will detect the obstacle. When Cricket detects something in the way, he

should back up, scan with the sonar and pick a way around the object. Cricket will make

random sounds while walking around. If you have problems with your Cricket, refer to the

troubleshooting section of this manual.

If you find that your Cricket does not walk in a straight line, try adjusting the horn alignment with

the horn adapter on the right and left servos. Moving the horn down on the serrated teeth

against the adapter will slow that side down.

87 – Cricket Robot Documentation

Page 88

You may override Cricket’s autonomous movement using the remote control. Try pushing

the right, left, up and down buttons to see how it affects Cricket’s motion. Pushing the up

button will make him walk forward faster. Right and left will make him turn that direction

and down will make him backup. Pushing the number 0-9 buttons will cause Cricket o

make various sounds. Try them out. The Prev. Chan/Record/Enter button makes Cricket

dance the Cha-Cha.

If you find anything is not as it should be, refer to the troubleshooting section of this

manual for tips on how to fix your Cricket.

Enjoy your Cricket Robot!!!

Troubleshooting

If you find that your Cricket isn’t acting like he should, here are some things to check:

Low Battery – A low or dead battery can exhibit all kinds of funny behavior. Cricket

could start chirping constantly, resetting repeatedly, or just stop walking. This

occurs because the Arduino controller can detect a brownout situation and will

keep trying to reset to recover. This causes the initial turn on chirping to keep

happening with no movement of the legs.

Remote Doesn’t Work - If the remote fails to work, it may need to be reset.

Press and release the TV button. See the section on reprogramming your remote

Legs Not Working – If any of Crickets legs appear to not be moving correctly, try

looking at the linkages. Something may have loosened. If a motor is not working at

all, check the wiring and make sure the motor connectors are seated. Check that

the joints on each leg are tight but not so tight that the leg can’t move freely. Make

sure if this is a newly built robot, that his motors are plugged into the correct

connector

Cricket pulls to one side or the other when walking straight – Adjust the alignment

of the right or left horn adapter to horn. Moving the horn down in the adapter slows

that side down.

Unexplained Erratic Operation – Sometimes fluorescent lights or camera flashes

can falsely trigger the remote control sensor. This should be very rare. Try running

Cricket in another location to test for this problem

Nothing happens at all – If Cricket completely stops working, the battery may have

gone dead or the Arduino controller may have a problem. If a multimeter is

available, check the power at the connector on the controller board. Also try

reloading the control program. If the Arduino software can’t recognize the hardware

there is a more serious problem.

88 – Cricket Robot Documentation

Page 89

If the Arduino Programming doesn’t recognize the Cricket Arduino, you've either

forgot to attach the cable, the battery is low or turned off, or a more serious

problem has occurred.

Sound is not very loud or non-existent. Check the speaker wiring and that the

speaker is tightly glued to the chassis

If you can’t figure the problem out, contact us. Replacement parts can also be purchased

from us. Documentation and program updates are available at:

http://www.cricket-the-robot.com

You can reach me through email at:

henryarnold@earthlink.net

89 – Cricket Robot Documentation

Page 90

Appendix A – Schematics

90 – Cricket Robot Documentation

Page 91

91 – Cricket Robot Documentation

Page 92

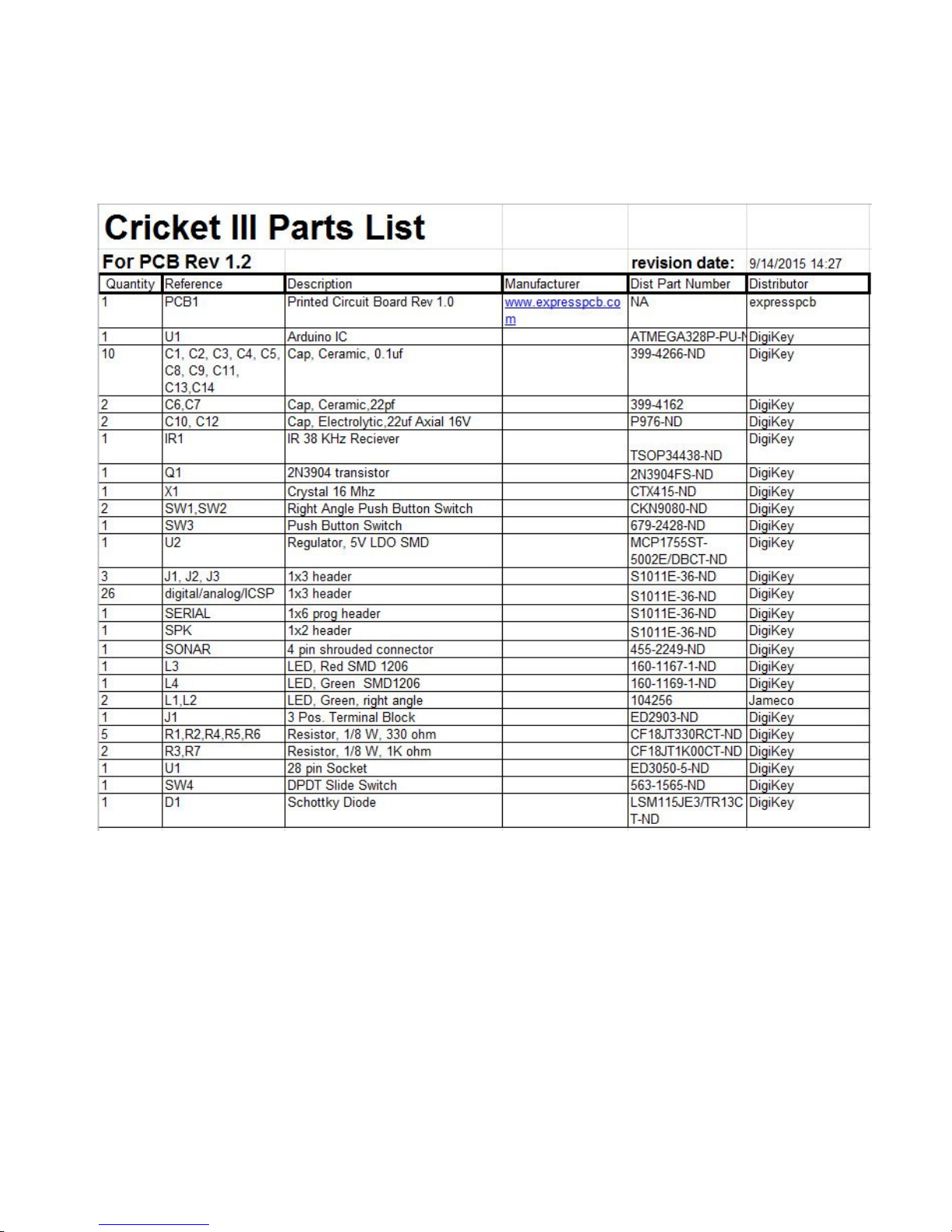

Appendix B - Parts List

92 – Cricket Robot Documentation

Page 93

93 – Cricket Robot Documentation

Page 94

Appendix C - PC Board Layout

All Layers

Parts Layout

94 – Cricket Robot Documentation

Loading...

Loading...