Page 1

TTK-MP/MPC/IPAC & SMK-MP/MPC/IPAC

TableTop and Swivel Mount Kits for MP, MPC, & IPAC

Installation Guide

Description

The Crestron® TTK-MP/MPC/IPAC tabletop kit provides a tabletop enclosure for any

MP series media presentation button panel, MPC and MPC3-302 series media

presentation controller, or IPAC integrated professional automated computer. The

device’s front panel is angled at a xed tilt of 45 degrees when installed in the enclosure.

The complete assembly may be placed on any at, level surface, with the option to install

the assembly to the surface permanently using screws.

The optional SMK-MP/MPC/IPAC swivel mount kit enables the enclosure to be

permanently mounted to a table, desk, or counter top surface, while retaining the ability

to rotate. The swivel range may be customized with optional limiting screws.

The installation procedures for both the TTK-MP/MPC/IPAC and SMK-MP/MPC/IPAC

are covered in this guide.

Additional Resources

Visit the product pages on the Crestron

website (www.crestron.com) for additional

information and the latest rmware updates.

Use a QR reader application on your mobile

device to scan the QR images.

TTK-MP/MPC/IPAC

SMK-MP/MPC/IPAC

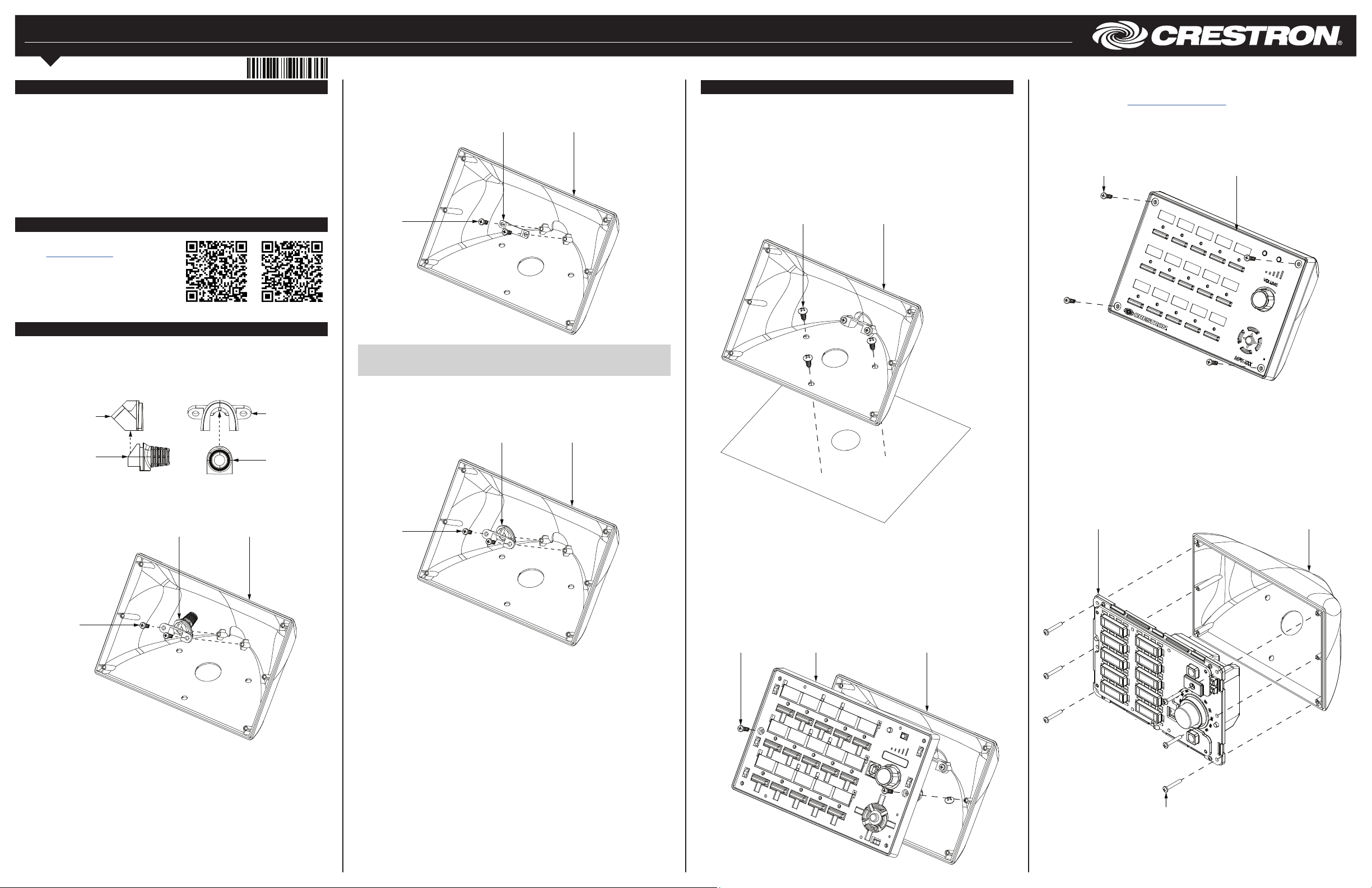

Prepare the TTK-MP/MPC/IPAC

The TTK-MP/MPC/IPAC provides two options for routing cables through the rear of the

enclosure and one option for routing cables through the bottom of the enclosure.

To route a single cable through the rear of the enclosure:

1. Join the plug insert (open rear) and rubber cable grommet.

Joining the Plug Insert and Cable Grommet

Plug insert

(side view)

Cable grommet

(side view)

2. Attach the joined assembly to the TTK-MP/MPC/IPAC with the two 4-20 x 1/2"

screws.

Attaching the Assembly to the TTK-MP/MPC/IPAC

Joined

assembly

Screw (2):

4-20 x 1/2"

TTK-MP/MPC/IPAC

enclosure

Plug insert

(rear view)

Cable grommet

(rear view)

To route multiple cables through the rear of the enclosure, attach the wire capture to the

TTK-MP/MPC/IPAC with the two included 4-20 x 1/2" screws.

Attaching the Wire Capture to the TTK-MP/MPC/IPAC

Wire

capture

Screw (2):

4-20 x 1/2"

NOTE: The illustration above shows the metal wire capture installed “bow” side up.

When fewer cables are routed through the rear of the TTK-MP/MPC/IPAC, install the

metal wire capture “bow” side down to better secure the cables.

To route one or more cables through the bottom of the enclosure, attach the plug insert

(closed rear) to the TTK-MP/MPC/IPAC with the two 4-20 x 1/2" screws.

Attaching the Plug Insert (Closed Rear) to the TTK-MP/MPC/IPAC

Plug insert

(closed rear)

Screw (2):

4-20 x 1/2"

TTK-MP/MPC/IPAC

enclosure

TTK-MP/MPC/IPAC

enclosure

Install the TTK-MP/MPC/IPAC

Attach the TTK-MP/MPC/IPAC to a Flat Surface

To permanently attach the TTK-MP/MPC/IPAC to a table top or other at surface:

1. If routing cables through the bottom of the TTK-MP/MPC/IPAC, cut an

appropriately sized hole in the surface using the hole in the bottom of the

TTK-MP/MPC/IPAC as a guide.

2. Use the three 8-16 x 1/2" screws to attach the TTK-MP/MPC/IPAC to the surface.

Ensure that the hole in the table is aligned with the hole on the bottom of the

TTK-MP/MPC/IPAC.

Attaching the TTK-MP/MPC/IPAC to a Flat Surface

Screw (3):

8-16 x 1/2"

Install an MP/MPC/IPAC Device into the TTK-MP/MPC/IPAC

To install an MP, MPC, or IPAC device into the TTK-MP/MPC/IPAC:

1. If the device’s front panel is still attached, remove the four 4-40 x 1/2" screws

holding the panel in place, and then detach the panel from the device assembly.

2. Route all necessary cables through the bottom or rear of the TTK-MP/MPC/IPAC,

and connect them to the rear of the assembly.

3. Insert two of the six 4-20 x 3/4" screws into the center screw holes on either side

of the assembly, and attach the assembly to the TTK-MP/MPC/IPAC.

Attaching the Assembly to the TTK-MP/MPC/IPAC

Screw (2):

4-20 x 3/4"

MP/MPC/IPAC

assembly

TTK-MP/MPC/IPAC

enclosure

TTK-MP/MPC/IPAC

enclosure

4. If necessary, attach or replace the button holders and button labels on the

assembly. For more information refer to the MP, MPC, or IPAC device’s

documentation at www.crestron.com/manuals.

5. Place the front panel back on the assembly.

6. Insert the four remaining 4-20 x 3/4" screws into the corner screw holes on either

side of the front panel, and secure the device to the TTK-MP/MPC/IPAC.

Attaching the Front Panel to the Assembly

Screw (4):

4-20 x 3/4"

Install an MPC3-302 Device into the TTK-MP/MPC/IPAC

To install an MPC3-302 device into the TTK-MP/MPC/IPAC:

1. If the device’s front panel is still attached, grasp both sides of the panel from the

bottom, and pull upward rmly until the bottom half of the panel detaches from the

assembly. Then, pull the top half of the panel upward rmly until it detaches from

the assembly.

2. Route all necessary cables through the bottom or rear of the TTK-MP/MPC/IPAC,

and connect them to the rear of the assembly.

3. Insert the six 4-20 x 3/4" screws included with the MPC3-302 into the screw holes

on either side of the assembly, and attach the assembly to the TTK-MP/MPC/IPAC.

Attaching the Assembly to the TTK-MP/MPC/IPAC

MPC3-302

assembly

MP/MPC/IPAC

front panel

TTK-MP/MPC/IPAC

enclosure

Screw (6):

4-20 x 3/4"

Page 2

4. If necessary, attach or replace the buttons and the button labels on the assembly.

For more information, refer to the MPC3-302 DO Guide (Doc. 8249) at

www.crestron.com/manuals.

5. Align the front panel with the assembly so that all of the buttons align with their

respective openings in the panel.

6. Press the front panel into the assembly until the panel snaps into place.

Attaching the Front Panel to the Assembly

MPC3-302 assembly

(in enclosure)

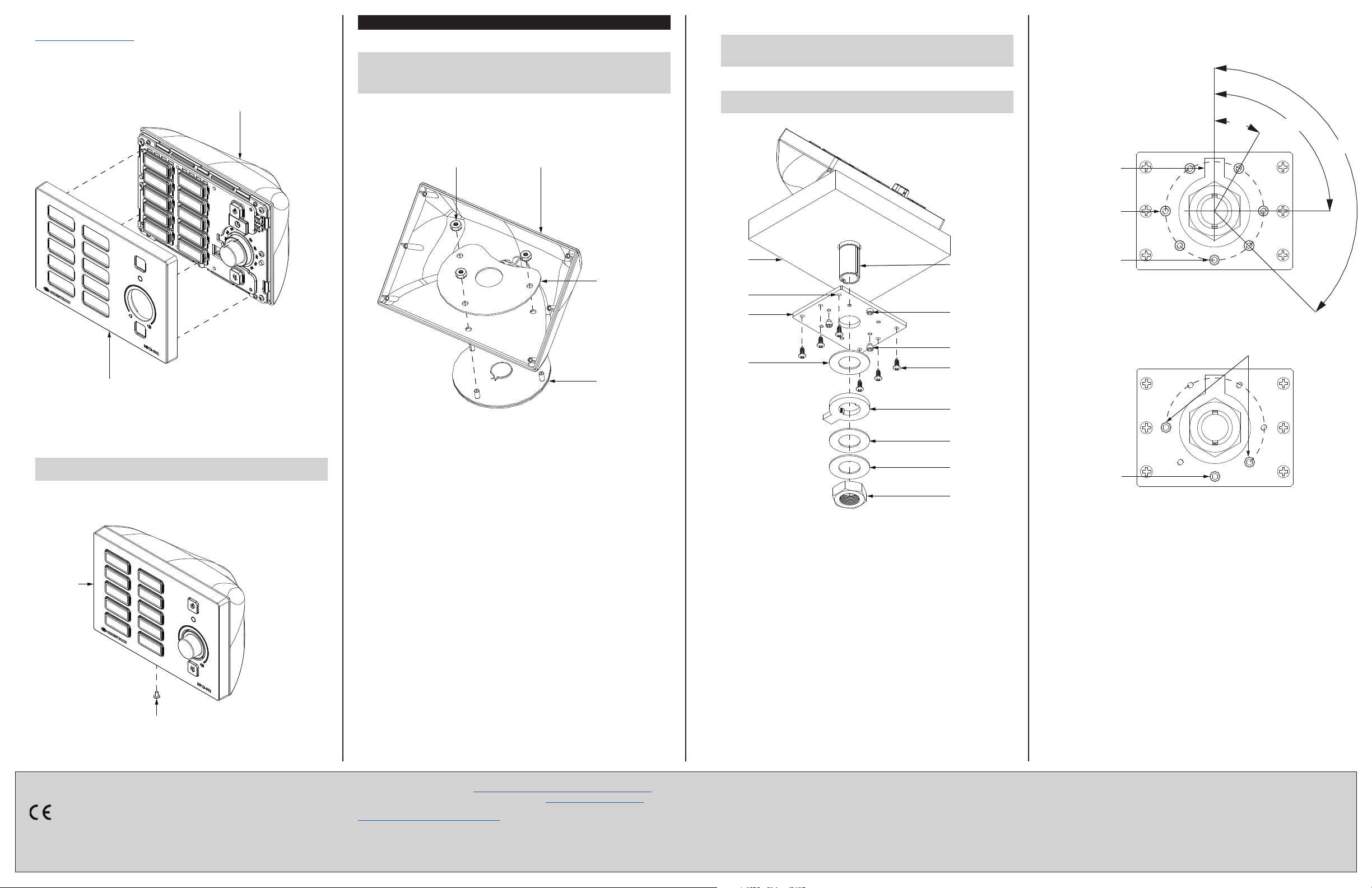

Install the SMK-MP/MPC/IPAC

Assemble the Swivel Mount

NOTE: If the SMK-MP/MPC/IPAC is being added to an existing TTK-MP/MPC/IPAC

installation, remove the device’s front panel and assembly from the

TTK-MP/MPC/IPAC enclosure, and then remove the three 8-16 x 1/2" screws securing

the enclosure to the surface.

To assemble the swivel mount:

1. Attach the top of the swivel mechanism tube to the bottom of the

TTK-MP/MPC/IPAC enclosure with the metal top plate and the three 8-32 nuts.

Attaching the Swivel Mechanism Tube

Nut (3):

8-32

TTK-MP/MPC/IPAC

enclosure

6. Slide the provided hardware up onto the swivel tube in the order shown in the

illustration following step 7.

NOTE: The keyed metal washer ts onto the swivel tube in one of two

orientations. Orient the tab on the washer to face away from the permanently

installed limiting screw in the swivel stop plate.

7. Tighten and adjust the 7/8"-14 nut onto the swivel tube to achieve the desired

resistance in swivel assembly motion.

NOTE: A at tool (such as a large at head screwdriver) may be placed in the

slot on the bottom of the swivel tube to hold the tube still while tightening the nut.

Completing the Swivel Mount Assembly

Customize the Swivel Range

Aside from the permanently installed limiting screw that is attached to the swivel stop

plate, two additional 8-32 x 1/8" limiting screws can be attached to the swivel mount

plate to set a custom range for swivel movement. Refer to the illustrations below.

Limiting Screw Locations in Swivel Stop Plate

30°

90°

135

Tab of keyed metal

washer where swivel

motion begins

Locations (6)

for additional

limiting screws

°

MPC3-302

front panel

6. Test the buttons to ensure that they can be pressed and released without

becoming impeded by the front panel, and test the volume knob by rotating it

gently. If any buttons are impeded or if the knob does not rotate easily, remove the

panel as described in step 1, adjust the button and front panel placement, and then

reattach the front panel.

CAUTION: Do not apply force when rotating the knob, and do not attempt to

pull the knob away from the assembly.

®

7. Using the drill bit included with the MPC3-302, screw the Torx

security screw

included with the MPC3-302 into the screw hole on the bottom of the front panel to

secure the panel to the assembly.

Attaching the Security Screw

MPC3-302

front panel

Metal top

plate

Swivel

mechanism

tube (top)

2. If cables are to be routed through the bottom of the TTK-MP/MPC/IPAC, feed the

full length of the cables through the swivel mechanism tube.

3. Prepare the mounting surface using the cutout template provided with the

SMK-MP/MPC/IPAC:

a. Ensure that the center hole diameter for the swivel mount is 7/8" minimum

(22 mm), 15/16" maximum (24 mm).

b. Position the template so that the edge indicated as the front end of the surface

aligns with the front position of the TTK-MP/MPC/IPAC.

c. Observe the dashed line indicating the front edge of the TTK-MP/MPC/IPAC to

ensure that the device does not overhang the mounting surface.

4. Using the six mounting holes on the swivel stop plate as a template, drill pilot holes

0.09" (2 mm) minimum, 0.12" (3 mm) maximum, and no deeper than 0.35" (9 mm)

in the bottom of the mounting surface.

5. Attach the swivel stop plate to the bottom of the mounting surface with the six

8-8B x 1/2" screws, then pass the swivel tube down through the mounting hole

and stop plate. Refer to the illustration following step 7.

Table

(bottom)

Mounting

holes (6)

Swivel stop

plate

Cork/rubber

washer

Swivel

mechanism

tube

Limiting

screw

Screw (2):

8-32 x 1/8"

Screw (6):

8-8B x 1/2"

Keyed metal

washer

Rubber

washer

Flat steel

washer

Nut: 7/8"-14

Permanent

limiting screw

Swivel Stop Plate with Additional Limiting Screws

8-32 x 1/8" limiting screws (2)

limit swivel to custom range

Permanent

limiting screw

Torx® security

screw

As of the date of manufacture, the product has been tested and found to comply with

specications for CE marking.

The product warranty can be found at www.crestron.com/legal/sales-terms-conditions-warranties.

The specic patents that cover Crestron products are listed at www.crestron.com/legal/patents.

Certain Crestron products contain open source software. For specic information, please visit

www.crestron.com/legal/open-source-software.

Crestron and the Crestron logo are either trademarks or registered trademarks of Crestron Electronics,

Inc. in the United States and/or other countries. Torx is either a trademark or a registered trademark of

Acument Intellectual Properties, LLC, in the United States and/or other countries. Other trademarks,

registered trademarks, and trade names may be used in this document to refer to either the entities

claiming the marks and names or their products. Crestron disclaims any proprietary interest in the

marks and names of others. Crestron is not responsible for errors in typography or photography.

This document was written by the Technical Publications department at Crestron.

©2018 Crestron Electronics, Inc.

Crestron Electronics, Inc. Installation Guide - DOC. 6782D

15 Volvo Drive, Rockleigh, NJ 07647 (2023116)

Tel: 888.CRESTRON 03.18

Fax: 201.767.7576 Specications subject to

www.crestron.com change without notice.

Loading...

Loading...