Page 1

CRESTRON

e-control™ Database

Manager

(SW-DBM)

version 1.4

© 1999 Crestron Electronics, Inc.

Page 2

Crestron e-control Database Manager SW-DBM

Contents

How to Use This Manual 3

A Note on Printing This Document................................................................................................... 3

Quick Start ........................................................................................................................................ 3

Section Summary .............................................................................................................................. 3

Quick Start Guide: Address Book (demo1) 5

Introduction 6

What is Crestron e-control™ Database Manager?............................................................................. 6

System Terminology and Topology .................................................................................................. 6

Leading Specifications ...................................................................................................................... 8

Requirements..................................................................................................................................... 8

Installation......................................................................................................................................... 9

Licensing........................................................................................................................................... 9

Basic Server Setup 11

Communications Setup.................................................................................................................... 12

Test Communications...................................................................................................................... 15

Additional Server Side Setup .......................................................................................................... 16

Server Configuration In Depth 16

Specifying a Configuration File ...................................................................................................... 16

Password Access ............................................................................................................................. 17

COM Settings Definition................................................................................................................. 18

Signal Block Definition................................................................................................................... 20

Server Windows and Menus............................................................................................................ 27

The Database File 32

Database Fundamentals................................................................................................................... 32

The Queries Table ........................................................................................................................... 35

Successive Queries.......................................................................................................................... 38

Operating on Database Tables......................................................................................................... 40

Demos 41

Demo 1 Database Browsing and Maintenance................................................................................ 42

Demo 2 Successive Query...............................................................................................................43

Demo 3: AutoPick........................................................................................................................... 45

Appendix A: Theory of Operation 48

Server Protocol................................................................................................................................48

Signal Block Definition / Activation............................................................................................... 48

Signal Block Enable / Disable......................................................................................................... 48

Signal Block Error Reporting.......................................................................................................... 48

Appendix B: Intersystem Communications and Signal Space Considerations 50

System Connections........................................................................................................................ 50

Appendix C: Signal Reference 54

Definition of Terms......................................................................................................................... 54

String Proxies.................................................................................................................................. 54

Bit Patterns...................................................................................................................................... 54

Error Reporting ............................................................................................................................... 55

Signal Summary.............................................................................................................................. 55

Signal Reference.............................................................................................................................. 58

ii •• Table of Contents Installation & Reference Guide — DOC. 5823

Page 3

Crestron e-control Database Manager SW-DBM

Crestron

e-control Database Manager

How to Use This Manual

A Note on Printing This Document

Adobe and Acrobat are

trademarks of Adobe Systems

Incorporated.

This Portable Document File (PDF) can be printed with Adobe Acrobat Reader.

Printing from a Windows 95 platform, version 4.0 or later, is strongly recommended

because the figures print poorly with earlier versions. The latest version is freely

available from Adobe at http://www.adobe.com/acrobat/.

Quick Start

To see an “out-of-the-box” demonstration of Crestron e-control™ e-Mail Instant

messaging as quickly as possible, turn to the Quick Start Guide(s) beginning on the

next page.

You will need:

• A Crestron CNMSX-PRO control system

• A touchscreen (LC-3000, CT-3000, CT-3500, or VT-3500); and

• A null-modem cable

Follow the instructions in the guides precisely in the order given and you should be

up and running in a matter of minutes.

NOTE: The demos included with this package are all compiled to two versions, a COM version for

use with an RS-232 serial connection, and a TCP version for use with an Ethernet connection (the

latter case requiring the CNX Gateway). The Quick Start Guides refer only to the COM versions of

these programs because setting up a serial connection is far simpler. We strongly recommend getting

at least one demo to work first using a serial connection. Once that works, try the TCP versions.

Instructions for setting up TCP/IP communications are provided below (see “Communications

Setup, Control System Side, TCP/IP,” page 14).

You do not need to license the software to try the demos provided you are still within

the 15-day free trial period.

Section Summary

For more information, start with “Introduction” on page 6.

3 •• How to Use This Manual Installation & Reference Guide — DOC. 5823

Page 4

Crestron e-control Database Manager SW-DBM

Detailed setup and configuration instructions and follow “Introduction”.

Then comes information about the database file format.

After that, the examples (demos) are described and illustrated in detail.

Appendices include Theory of Operation, along with a complete Signal Reference.

4 •• How to Use This Manual Installation & Reference Guide — DOC. 5823

Page 5

Crestron e-control Database Manager SW-DBM

Quick Start Guide: Address Book (demo1)

1 Install this package on your PC

Presumably, since you are reading this PDF file, you have already done this.

2 Connect a CNMSX-PRO (with touchscreen)

Connect a programming cable (a standard modem cable) from any COM port on

your PC to the COMPUTER port on the front or back of the CNMSX-PRO control

system. Connect a touchscreen to the control system set up for CRESNET ID 03.

3 Upload all control system software

The demo files can be found in the

demos folder (also accessible

through the Start Menu shortcut

e-control Database Manager

Demos)

Open the Crestron Viewport and establish communications with your control system.

If you have not already done so, use the FileTransfer | Send Touchpanel…

command to upload demoDBM.hex to the touchscreen at ID 03. Use the

FileTransfer | Send Program… command to upload the compiled SIMPL windows

file demo1COM.bin to the CNMSX-PRO. You may now close the Viewport.

4 Connect the null modem cable

Make sure pins 4, 5, and 6

are not connected.

Connect a null-modem cable from COM1 on the PC to COM A on the

CNMSX-PRO.

The installer sets the server to

use config file demoDBM.ini.

5 Run the “server”

Select shortcut e-control Database Manager Server from the Crestron folder in the

Windows Start Menu. If the title bar of the window does not read “e-control

Database Manager Demos,” use the File | Configuration file… command to

navigate to the demos folder and select the file demoDBM.ini.

6 Start the “server protocol”

Give the command Server | Start Server w/Signal Analyzer. (The Signal Analyzer

is good for demos because it shows you the various signals going back and forth.)

7 Start the demo

On the touchscreen, navigate through the setup instructions to the demo screen. This

final page-flip to the demo screen starts the demo.

8 Open a database record!

Make a selection on the touchscreen to open a record. A sample address book

containing Crestron offices around the world appears. When you select an office, its

address information is displayed. You can browse the database, add and delete

records, and modify information in a record. If you select an option that requires

entering information, a keyboard appears on the touchpanel so you can type the

necessary information.

5 •• Quick Start Guide: Address Book (demo1) Installation & Reference Guide — DOC. 5823

Page 6

Crestron e-control Database Manager SW-DBM

Introduction

What is Crestron e-control™ Database Manager?

Crestron e-control Database Manager (SW-DBM) empowers any Crestron control

system with database capability.

Simply by asserting specific signals, your control systems can send arbitrary text,

whole text files, canned messages, alerts, status updates, etc., to any e-mail address.

Messages can be sent to a control system for display and to assert specific signals.

The term “server” does not imply

a need for specialized hardware.

Any PC meeting the minimum

requirements on page 7 will

suffice to run swserver.exe.

The actual database access is not carried out by the control systems themselves, but

by the freely distributed Crestron e-control Software Server. SW-DBM is a

licensable component of this “server” application (swserver.exe) which is

hosted on a standard PC running Windows® 95 or Windows NT® and provides the

following core technologies:

• Signal-level communications with the control system

• Access to database tables

• Access to external services (such as e-mail servers) through the PC’s network

connection.

The server is connected to the control system via either a serial cable through an

RS-232 port or an Ethernet network through a LAN port. To effect the latter type of

connection, the control system relies on an intermediary, the Crestron CNX Gateway,

to translate communications protocols.

To aid in making all this clear, the following illustrated discussion of system

terminology and topology should prove useful at this point.

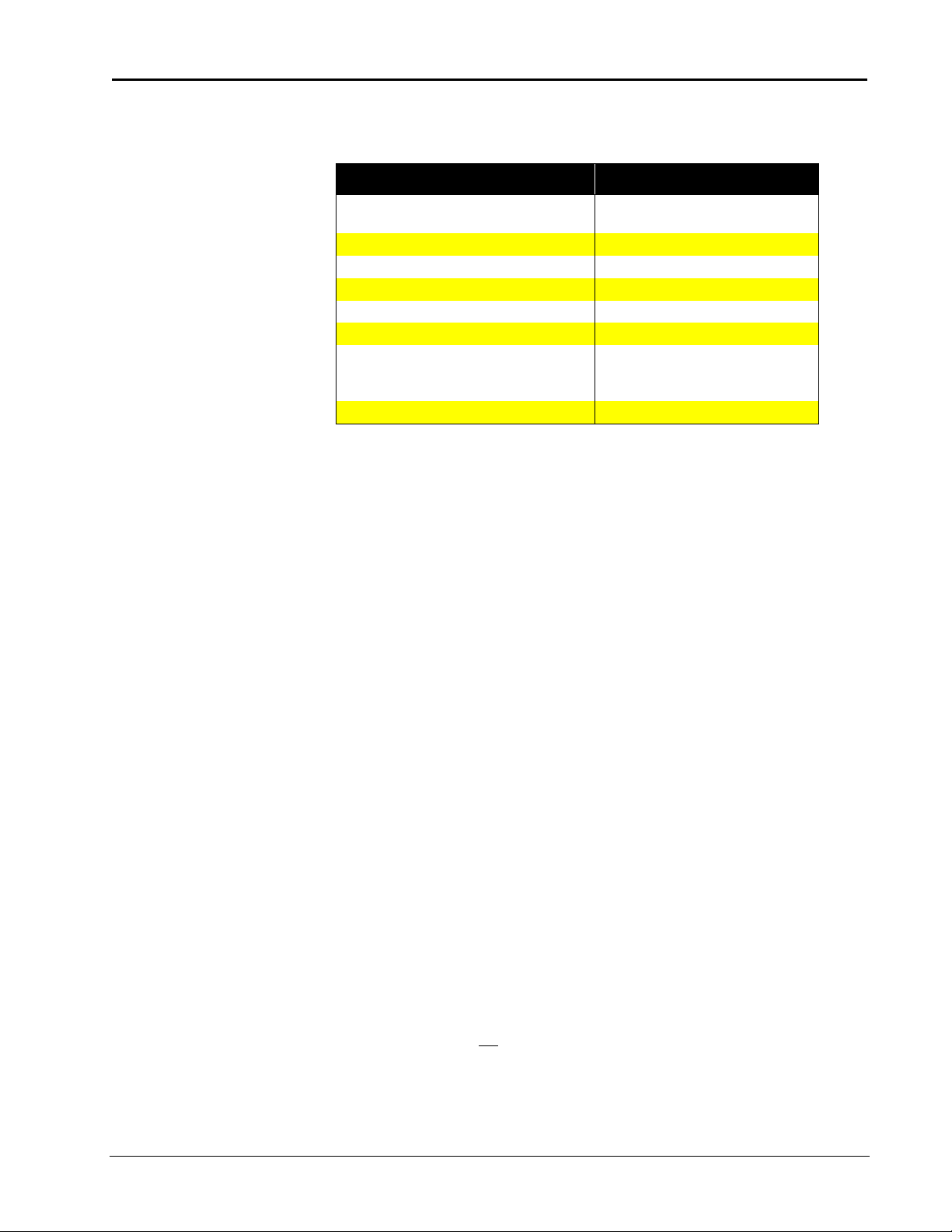

System Terminology and Topology

This manual simultaneously discusses several different inter-connected computer

systems. To reduce confusion, throughout the manual, these systems are referred to

using the terms in the following table. (Also refer to the diagrams on the next page.)

Term Explanation

The system

or the control system

The server

or the software server

The gateway

or the CNX Gateway

The control system(s) are connected to the server via direct RS-232 serial connection

or via TCP/IP to the gateway and thence via TCP/IP to the server.

One of a number of Crestron control

system(s), which may include any combination

of the following models: CNMS, CNRACK,

CNMSX-PRO, CNMSX-AV, and CNRACKX.

The Crestron Software Server,

swserver.exe, which runs on a PC under

Microsoft® Windows® 95 or Windows NT®.

A communications conduit that sits between

the server and the control system(s).

NOTE: “Connected via TCP/IP” means any node (computer) visible on the Local Area Network

(LAN). If the LAN is connected to the Internet, this could include any node visible anywhere on the

Internet. Since a node can also see itself, this implies that multiple services can run on the same

machine. For example, the gateway and the server can be “self-hosted” in this way.

6 •• Introduction Installation & Reference Guide — DOC. 5823

Page 7

Crestron e-control Database Manager SW-DBM

In the illustration that follows, the communication pathways are represented by the

arrows. The physical network is not represented, however.

System block diagram, showing communication pathways (all connections using TCP/IP):

Crestron

control

system

Crestron

CNX

Gateway

Crestron

VT-3500 VT-3500 VT-3500

Software

VT-3500 VT-3500 VT-3500

Server

Database

System block diagram, showing communication pathways

(curved arrows are RS-232 serial connections; straight arrows are TCP/IP):

Crestron

control

system

Crestron

control

system

Crestron

control

system

Crestron

VT-3500 VT-3500 VT-3500

Software

VT-3500 VT-3500 VT-3500

Server

Database

NOTE: The CNX Gateway is not necessary when using RS-232 serial communications.

TCP/IP connections between the server and the control systems require that each

side of the connection be provided with the IP address of the other. This kind of

connection also requires the use of the CNX Gateway which is separately licensed

software that facilitates communication between the server and the control system.

The CNX Gateway is typically installed on the server (when sufficient TCP/IP

sockets are available) or it can be installed on any computer visible (i.e., pingable) on

the TCP/IP network. There only needs to be one Gateway running on one computer

to service the needs of all the computers and CNX control systems on the network.

However, multiple Gateways are perfectly permissible as long as they are run on

different computers.

7 •• Introduction Installation & Reference Guide — DOC. 5823

Page 8

Crestron e-control Database Manager SW-DBM

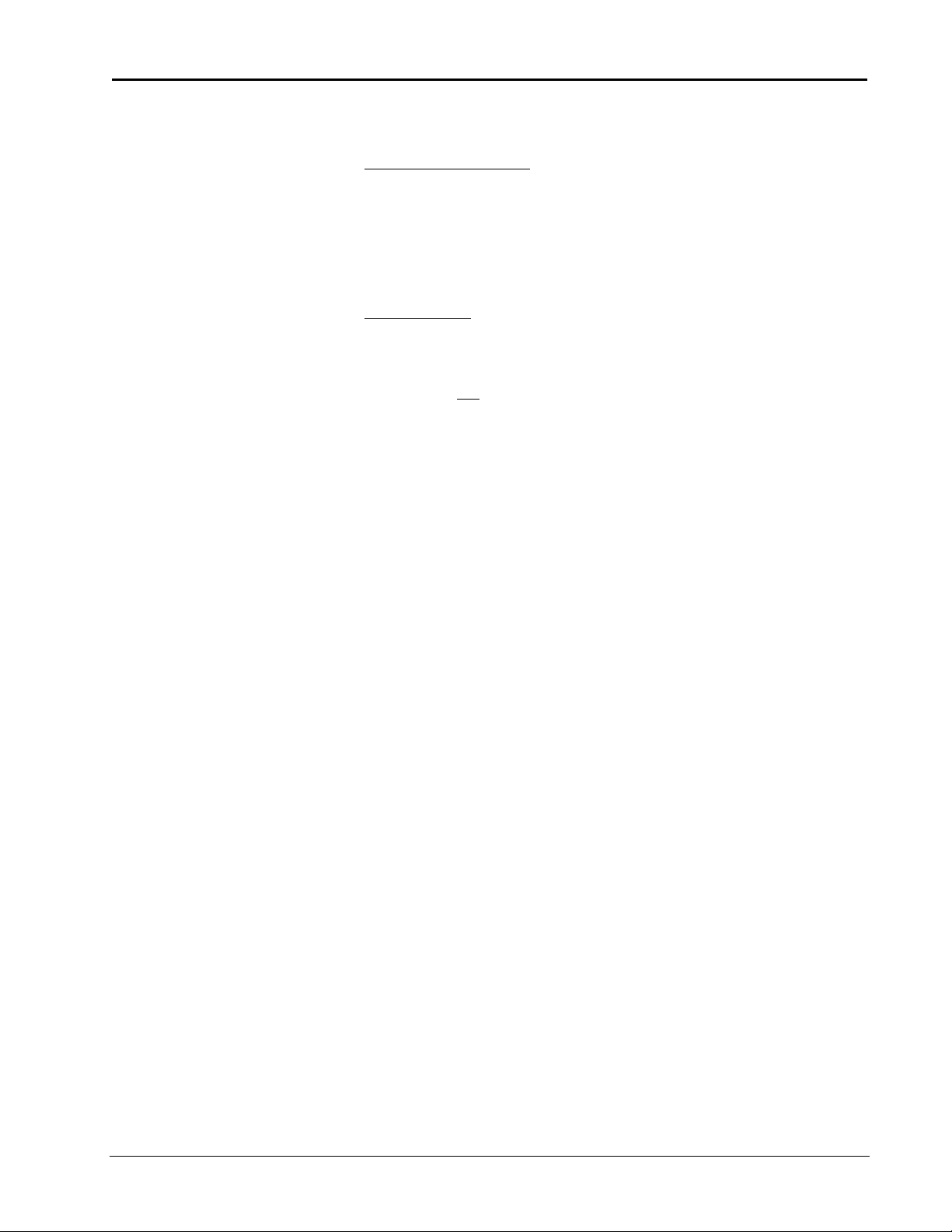

Leading Specifications

Specifications Table

SPECIFICATIONS DETAILS

SWSERVER.EXE

(included with this package)

CNMS/RACK Operating System Version 3.18.12 or later

CNMSX/RACKX Operating System Version 5.09.25 or later

CNMSX/RACKX Monitor Version 5.09.25 or later

CNMSX/RACKX TCP/IP Stack Version 5.09.10 or later

CNX Gateway Version 2.08.04 or later

SIMPL™ Windows®

VisionTools™ Pro (VT Pro-e) Version 2.0.8.2 or later

Version 1.4

Version 1.4 or later; or

Version 1.3 with Symbol Library

Update 067 or later

Requirements

The server should meet these minimum system requirements.

Windows 95/98/NT Operating System hardware requirements

32 MB RAM

100 MB hard drive space

133 MHz or faster Pentium processor

A faster processor is recommended for serving multiple connections

simultaneously

Precise CNSP-532 specs are

available in the Crestron Cable

Database.

800 x 600 or higher screen resolution

COM ports

Required to make serial (RS-232) connections to control systems (one

port per control system). (See Cable requirements below.)

Network Interface Card

Required to make TCP/IP connections to control systems.

TCP/IP sockets

(These are software constructs provided by your operating system. The

maximum number of sockets is operating system dependent.)

Server requires one socket per server–control system connection

Required for EtherNet control system connections only. The maximum

number of sockets is operating system dependent.

CNX Gateway (see below) requires one socket + one additional socket per

server–control system connection

Cables

Null modem cable, Crestron model CNSP-532 or equivalent

Required for serial control system connections only.

Warning: Do not use a generic null modem cable.

8 •• Introduction Installation & Reference Guide — DOC. 5823

Page 9

Crestron e-control Database Manager SW-DBM

Auxiliary software

CNX Gateway

Required for TCP/IP (EtherNet) connections between the server and

the control systems. Not required for serial connections.

SMTP Express

Recommended to reduce server overhead and improve server

responsiveness while e-mail is being sent.

Installation

As of this writing, the Crestron

Downloads page can be found at:

http://ftp.crestron.com/library/

A 15-day free trial follows initial

installation. If you are still within

the 15-day period, you have the

option to postpone licensing and

skip to the next section.

Server components are separately

licensed. A license for the e-mail

component must be obtained from

Crestron even if other components

are already in use.

To install the Software Server, first download the installer package from the

Crestron FTP site. To do this, first go to the Crestron website and select the

Downloads page. New users must register. Proceed to the ECONTROL Library.

Simply click on SW-DBM.EXE to start the download.

Once the install package arrives on your PC, double-click the icon to initiate the

install. Directions for the install are provided. The package is typically installed in

C:\Crestron\econtrol. During the install, the package reminds the user that a CNX

Gateway is required. (This is actually only true for TCP/IP connections. Direct

RS-232 connections do not require the CNX Gateway.)

Licensing

Both the Software Server and the CNX Gateway are a licensed products, which

means that although both software packages may be freely downloaded from the

Crestron FTP site, use of the software requires purchase of licenses from Crestron.

Each server running the Software Server must be individually licensed. In addition,

to use Ethernet, you must acquire a CNX Gateway license with sufficient

connections to accommodate all servers and control systems on your network.

Each package, once installed, generates a “Site Code” specific to the server on which

it is running. Upon being provided with these Site Codes, Crestron can issue the

appropriate “Site Keys,” which, once entered into each package’s licensing window,

enables the full functionality of the software.

9 •• Introduction Installation & Reference Guide — DOC. 5823

Page 10

Crestron e-control Database Manager SW-DBM

Obtaining a License

e-control Software Server – Upgrade/Transfer License window

showing “unlimited” database license — shown activated (checked)

You must use the Copy button to

copy the SITE CODE to the

clipboard. (Copying with Ctrl+C

does not work from this field.)

Open the server application. Select Server | License to open the e-control Software

Server – Upgrade/Transfer License window, shown above. The license can be

obtained over the phone or via e-mail. Call Crestron Customer Support with the

“Site Code” shown in the Site Code field. However, it is easier and far more reliable

to copy the “Site Code” into an e-mail message addressed to license@crestron.com.

Once received, Crestron Customer Support issues a “Site Key” which must either by

typed or pasted into the Site Key field of the window. Once entered, click on the

Update License button. If the key is valid, the licensed components appear in the list

above. Before closing the License Window, be sure to activate the components you

plan to use. In the above example, the user has checked the box next to SW-DBM.

It is permissible to exit the program while waiting for a “Site Key” to be issued. The

application can be restarted and the “Site Key” entered at a later time. The “Site

Key” issued is only valid on the same computer. It does not work on a different

computer.

The License Window of the CNX Gateway is almost identical to the above. See the

documentation that comes with the Gateway package for specific instructions.

Transferring an Existing License to Another Computer

As mentioned, a license is only valid on the computer for which it was obtained.

However, a license can be transferred from one computer to another without the need

to contact Crestron first. There are several reasons to transfer a license. The

application developer may set up the system off-site, then transfer the license to the

actual computer on-site when ready. Alternatively, if the hardware or operating

system on the computer where the server is licensed is upgraded, the license may

cease to be valid, but could be transferred to another computer before the upgrade

and then back to the original machine after the upgrade.

On both the source computer (where the license is currently valid) and the

destination computer (where the license is to be transferred), open the server

application. Select Server | License to open the e-control Software Server –

10 •• Introduction Installation & Reference Guide — DOC. 5823

Page 11

Crestron e-control Database Manager SW-DBM

Upgrade/Transfer License window (shown above). Make sure this window is active

on both computers.

Step 1. On the destination computer, create a preparation file on a diskette in the A:

drive by inserting a blank, formatted diskette and selecting Prepare Diskette. This

creates a file on the diskette which indicates who is receiving the license. A second,

backup copy of the file is also created. Alternatively, these files can be created on

another portable media (e.g. Zip disc) or a network drive by simply browsing for a

new file location in the save file window. If you plan to transfer via a network drive,

first make sure that both computers have the appropriate read/write access to the

drive and folder being used.

Step 2. After the above step has completed, remove the diskette from the drive and

insert it into the source computer’s floppy drive. Do not flip the write-protect tab; the

diskette must remain write-enabled. Click on the Transfer License button. The

source computer reads the preparation file to see which computer wants the license.

It encodes the license for the destination and writes it back to the same file on the

floppy diskette (or network drive). The source computer has now passed the license

to the file. Only the designated computer can use the license, so the server is no

longer licensed on the source computer.

NOTE: At this point in the transfer procedure the server license resides on a file on the diskette or

network drive, and not on the computer. If this file should become lost or damaged, the license is

lost as well. Because of this, please use the utmost care while performing this transfer.

Step 3. Bring the diskette back to the destination computer. Click on the Transfer

License button. The computer reads the license information off the diskette and

transfers the license to itself. The server is now licensed on this machine.

Basic Server Setup

This product requires a proper physical connection between both “sides” of the

system — the server and the control system. Furthermore, the software on both sides

must be properly configured. As previously discussed, the connection can be either

serial via RS-232 cable or Ethernet via Local Area Network (LAN). Choose your

mode of communication and refer to the following sections to make the proper

physical connections and to configure the software.

The following sections include specific notes in italics for setting up the server and

the control system to run the included demo programs. Although the focus is

therefore on the demos, the same basic procedures would be followed to ready the

system for any other programming as well.

The files for all three demos are in a folder called demos which can be located

through the following Start Menu shortcut:

Start Menu

Inside this folder there are three individual demo folders and support files:

demoDBM.vtp VisionTools touchscreen project file

demoDBM.hex compiled VisionTools file

demoDBM.ini Server’s Configuration Settings file which accommodates all three demos

DBMdemo.mdb Sample database file for use with all three demos

| Programs

| Crestron

| e-control Database Manager

| Database Manager Demos

demo1

demo2

demo3

11 •• Basic Server Setup Installation & Reference Guide — DOC. 5823

Page 12

Crestron e-control Database Manager SW-DBM

The installer registers demoDBM.ini as the currently selected Configuration

Settings file. (If the server’s title bar does not read “e-control Database Manager

Demos,” use the File | Configuration file… command to reset it.) This file

configures the server for all three demos.

Each demo folder contains the following files:

Demo?COM.smw SIMPL Windows project file (RS-232 version)

Demo?TCP.smw SIMPL Windows project file (TCP/IP version)

demo?COM.bin compiled SIMPL program code (RS-232 version)

demo?TCP.bin compiled SIMPL program code (TCP/IP version)

RS-232 is featured in the Quick

Setup Guide because it is easy to

set up. Because we anticipate

strong interest in TCP/IP, we have

pre-built both versions for your

convenience.

In the above, ? stands for the demo number. The two versions of the SIMPL

program for each demo, (COM and TCP) are almost identical, both being

configured for a CNMSX-PRO, using the front panel device and a touchpanel with

CRESNET ID = 03. Both versions have ports defined for both serial (RS-232)

communications via the CNMSX-PRO’s built-in COM A port (slot 4, port A), and

EtherNet (TCP/IP) communications via the LAN port on a CNXENET card installed

in the CNMSX-PRO’s DPA slot. In the COM versions, the TCP/IP port is

commented off while in the TCP versions, the RS-232 port is commented off. This

is the only difference between the two versions.

The following sections separately describe the setup procedures for connecting

multiple control systems via either RS-232 or TCP/IP connections. Actually, a

mixture of connections is permitted. For example, two control system might be

connected via RS-232 (using the COM1 and COM2 ports) while two more might be

simultaneously connected via the TCP/IP network connection.

In the following, the indented, italicized paragraphs contain advice on setting up the

server and a control system specifically to run the supplied demo files. You will find that

most of the steps have already been accomplished because they are specified by the

supplied demo configurations.

Communications Setup

Server Side

1. Run server application by selecting Database Manager from the Crestron

folder of your Start menu.

2. Select config file. Specify a Configuration Settings file (.ini file) by selecting

File | Configuration File…. Refer to “Specifying a Configuration File,” page

16.

The server is installed with a demomail.ini pre-selected as the default

configuration file. (This is intended to simplify the Quick Start Guide.)

Set communications mode. Select Server | Configure and enter a password to open the

Configuration Options window. (Refer to “NOTE: If the server cannot open a specified configuration

file, it uses default values for all options. If any changes are made, a new config file is created using

the specified pathname when the OK or the Apply buttons are actuated

3. Password Access,” page 16). Select the COM Settings tab. The settings for

each connection to a control system must match those on the other end (the

control system side) of the actual connections. Click on each connection in

turn, click the Modify… button, and choose either RS-232 (and select the port

and speed) or TCP/IP (and set the IP address and IP ID). Click OK to make

the changes for each connection.

The demos are pre-configured to use RS-232.

12 •• Basic Server Setup Installation & Reference Guide — DOC. 5823

Page 13

Crestron e-control Database Manager SW-DBM

Control System Side, RS-232

Serial communication requires wiring the server directly to the control system.

NOTE: Serial communications requires neither the CNX Gateway software nor the use of an

Ethernet network.

1. Connect PC for programming purposes. For each control system to be

connected to the server, temporarily connect the PC containing the control

system and touchscreen project files to the control system via a serial cable

between any available COM port of the server and the COMPUTER port of

the CNX control system. (This could be — but need not be — the same

physical machine that runs the Software Server.) Refer to the CNMSX manual

(latest revision of Doc. 8118) for instructions. This connection can be

removed once the control system is programmed.

2. Install control system program. Upload the compiled SIMPL Windows

program file (.bin file) to each control system.

As supplied, the demo programs are configured for a CNMSX-PRO control system.

For other models, using SIMPL Windows, convert the program as described below

and recompile.

3. Install touchpanel pages. Upload the compiled VT Pro-e project file (.hex

file) to each control system.

As supplied, the demo touchpanel file, which contains pages for all the demos, is

configured for a CT-3000 touchpanel; and the accompanying .hex file is compiled

for same. This file however also works fine with an LC-3000, CT-3500, and a

VT-3500. If you have one of these models, go ahead and upload the .HEX file as is.

If you are working with another panel, convert the file to your target panel and

recompile.

4. Connect to server. Connect null-modem cables (Crestron model CNSP-532)

from each control system to the server. Each connection requires its on COM

port on the server side. The port to use on the control system depends on the

specific model:

CNMSX-PRO. Use one of the built-in COM ports.

The demo files are all configured for a CNMSX-PRO using COM A (slot 4, port A).

CNMSX-AV. Use one of the built-in COM ports.

Use SIMPL Windows to convert the demo files. In the Configuration Manager, drag &

drop a CNMSX-AV system onto the CNMSX-PRO. The converted system does not have a

front panel, so compile “notices” appear — which can be ignored.

CNRACKX. Install a CNXCOM-2.

Use SIMPL Windows to convert the demo files. In the Configuration Manager, drag &

drop a CNRACKX system onto the CNMSX-PRO. The converted system has a

CNXCOM-2 card in slot 4; use Port A. The converted system does not have a front panel,

so compile “notices” appear — which can be ignored.

CNMS. Install a CNCOMH-2 card. Use of the built-in COM ports for the present

purpose is not recommended.

Use SIMPL Windows to convert the demo files. In the Configuration Manager, drag &

drop a CNMS system onto the CNMSX-PRO. The converted system has a CNCOMH-2

card in slot 5; use Port A. The converted system does not have a front panel, so compile

“notices” appear — which can be ignored.

CNRACK. Install a CNCOMH-2.

Use SIMPL Windows to convert the demo files. In the Configuration Manager, drag &

drop a CNRACK system onto the CNMSX-PRO. The converted system has a CNCOMH-2

card in slot 4; use Port A. The converted system does not have a front panel, so compile

“notices” appear — which can be ignored.

13 •• Basic Server Setup Installation & Reference Guide — DOC. 5823

Page 14

Crestron e-control Database Manager SW-DBM

Control System Side, TCP/IP

For more information on control

system TCP/IP setup, consult the

e-control Overview document,

overview.pdf, installed with

the CNX Gateway software; or the

SIMPL Windows release notes,

installed with SIMPL Windows.

TCP/IP communications requires a control system with a LAN/Internet port.

Therefore, a CNX generation control system is required (CNMSX-AV,

CNMSX-PRO, CNRACKX, or CNRACKX-DP). The CNX control system and the

server are both connected to the same network. This connection, once properly

configured, can then be used both for system communications (uploading, Test

Manager support, Viewport functions) and run-time server/client (server/control

system) communications as well. (The latter function however requires the addition

of the CNX Gateway software.)

1. Install Ethernet card. Install the CNXENET card into the Direct Processor

Access (DPA) slot of each CNMSX. Refer to the CNXENET manual (latest

revision of Doc. 8129) for instructions.

2. Connect server. Connect the CNX control system(s) to the server using one of

the following two methods:

(1) Connect the control system into the same LAN as the server. Use a

commercially available Ethernet hub to expand the number of connections

available by plugging in the LAN, the server, and the control system into the

same hub.

(2) Alternatively, make a two-device private network by connecting an

Ethernet “crossover” cable between the Ethernet port of the server’s Network

Interface Card and the LAN port of the CNX control system’s CNXENET card.

Do not attempt this with a regular Ethernet cable.

3. Connect PC for programming purposes. For each control system to be

connected to the server, temporarily connect the PC containing the control

system and touchscreen project files to the control system via a serial cable

between any available COM port of the server and the COMPUTER port of

the CNX control system. (This need not be the same machine that will run the

Software Server.) Refer to the CNMSX manual (latest revision of Doc. 8118)

for instructions. This connection can be removed once the control system is

programmed. Open the Viewport and issue the Setup | Communications

Settings… command to reconfigure communications for RS-232.

4. Check firmware versions. Before proceeding, however, verify that the CNX

control system has been loaded with the proper versions of firmware. Still in

the Viewport, select File Transfer | Update Control System to bring up a

window box containing the current versions of monitor, operating system, and

TCP/IP stack. Verify the versions per the

5. Leading Specifications (page 7).

In early versions of the CNMSX, it

may be necessary to upgrade to

an intermediate version of the

monitor first and then to the

required version of the monitor.

(The Viewport issues a notice if

this is necessary.)

To upgrade any of these files, retrieve a copy of the latest upgrade package

from the Crestron website (OPSYS Library). These files have an extension of

.upz which contains all three system components in one compacted file.

Once downloaded, browse for the appropriate file in the Update Control

System window. Click Send to upload the files to the control system. (When

upgrading the system in this manner, always send all three components to

avoid incompatibilities.)

6. Define control system IP address. Still in the Viewport, select Functions | Set

Control System IP Information. The Set Control System IP Address window

opens. Assign an IP address for the CNX control system. The address should

be obtained from the MIS department. The IP address has four fields

separated by periods (e.g. 192.168.2.3) and must be unique. Click OK.

7. Enter gateway address. Still in the Viewport, select Functions | Setup IP

Table to open the IP Table window. Click on the Retrieve Current IP Table

14 •• Basic Server Setup Installation & Reference Guide — DOC. 5823

Page 15

Crestron e-control Database Manager SW-DBM

from Control System button to display the current listing. Verify that the IP

address for the PC running the CNX Gateway (often but not necessarily the

server itself) appears with an IP ID of 03. If it does not appear, use the Add…

button to add an entry for IP ID 03. Then click the Send IP Table to Control

System button.

8. Switch to TCP/IP. Now that TCP/IP is properly configured, the Ethernet

connection can be used for all subsequent system communications (from

SIMPL Windows, Test Manager, Vision Tools Pro-e, and all Viewport

functions). See the section below titled Test Communications. Open the

Viewport and issue the Setup | Communications Settings… command to

reconfigure communications for TCP/IP. The serial cable can now be

removed.

9. Install control system program. Upload the compiled SIMPL Windows

program file (.bin file) to each control system.

As supplied, the demo programs are configured for a single CNMSX-PRO control

system. For other models, use SIMPL Windows to convert the program as follows

and recompile:

CNMSX-AV.

In the Configuration Manager, drag & drop a CNMSX-AV system onto the CNMSX-PRO.

The converted system does not have a front panel, so compile “notices” appear — which

can be ignored.

CNRACKX. Install a CNXCOM-2 card in slot 4 and use Port A.

In the Configuration Manager, drag & drop a CNRACKX system onto the CNMSX-PRO.

The converted system has a CNXCOM-2 card in slot 4; use Port A. The converted system

does not have a front panel, so compile “notices” appear — which can be ignored.

10. Install touchpanel pages. Upload the compiled VT Pro project file (.hex

file) to each control system.

As supplied, the demo touchpanel file, demomail.vtp (which contains pages for

all five demos), is configured for a LC-3000 touchpanel; and the accompanying

.hex file is compiled for same. This file however also works fine with an CT-3000,

CT-3500, and a VT-3500. If you have one of these models, go ahead and upload the

.hex file as is. If you are working with another panel, convert the file to your

target panel and recompile.

Test Communications

At this point, test your connections.

RS-232 Control Systems

Use the Viewport to verify communications between the server and the CNX control

system. Select Diagnostics | Establish Communications. If properly connected, the

PC responds with the COM port and baud rate.

TCP/IP Control Systems

First test the IP address of the CNX control system by “pinging” it. From a

networked PC bring up an MS-DOS prompt (Windows 95/98) or “Command

Prompt” (Windows NT) and type “ping <IP ADDRESS>”, as shown below. The

control system responds with several lines “Reply from address < IP ADDRESS >…”.

If no response is received from the “ping” to the IP address of the CNX control

system, repeat the procedure in “Control System Side, TCP/IP,” page 14.

C:\WINDOWS>ping 132.149.2.2

Pinging 132.149.2.2 with 32 bytes of data:

15 •• Basic Server Setup Installation & Reference Guide — DOC. 5823

Page 16

Crestron e-control Database Manager SW-DBM

Reply from 132.149.2.2: bytes=32 time=8ms TTL=60

Reply from 132.149.2.2: bytes=32 time=5ms TTL=60

Reply from 132.149.2.2: bytes=32 time=5ms TTL=60

Reply from 132.149.2.2: bytes=32 time=5ms TTL=60

Once a reliable connection is established, test that the CNX control system is

listening and responding properly. Reconfigure Viewport communications to use

TCP/IP by selecting Setup | Communications Settings. Once the Port Settings

window opens, select TCP/IP as the Connection Type. For IP Address, Click on

Fixed and enter the CNX control system IP address in the active field. Test the new

connection by issuing the Diagnostics | Check Operating System Version

command.

Additional Server Side Setup

In addition to properly setting up and testing communications with each connected

system, the following steps are also required to make the server operational:

1. Select database file. Supply the full pathname to the database under the

COM Settings tab. This file is the sole source of all database tables accessed

by all signal blocks. See “The Database File,” page 32, for additional

information.

The demos are pre-configured to point to the file DBMdemo.mdb in the demos

folder.

2. Indicate control system connection. Point each active signal block to a COM

Settings definition. (If you have not yet defined the connection through which

this signal block will communicate, you can leave this blank for the now.

However, the signal block cannot be activated until it references a COM

Settings definition.) See “COM Settings,” page 23, for a description of how to

point a signal block to a COM Settings definition.

All the signal blocks in the demo configuration already point to a COM Settings

definition.

Server Configuration In Depth

This section is a reference to all the options available in the Configuration Options

window. Changes to options in this window are saved to the current Configuration

Settings file when the OK or the Apply buttons are actuated. Therefore, it is

important to make sure you are operating on the appropriate Configuration Settings

file before opening the window.

Specifying a Configuration File

The installer registers the file demoDBM.ini as the current Configuration

Settings file. This file pre-configures the server for all three demos, and particularly

for use with the Quick Start Guide — which instructs you to load demo1.

You can use the File | Configuration file… command to select a Configuration

Settings file of your choice. The file pathname so specified is stored in the Windows

registry on your machine. In addition to specifying the configuration filename, this

command also instantly reconfigures the server based on the named file. This is a

very useful feature for the developer working on multiple projects.

NOTE: If the server cannot open a specified configuration file, it uses default values for all options.

If any changes are made, a new config file is created using the specified pathname when the OK or

the Apply buttons are actuated

16 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 17

Crestron e-control Database Manager SW-DBM

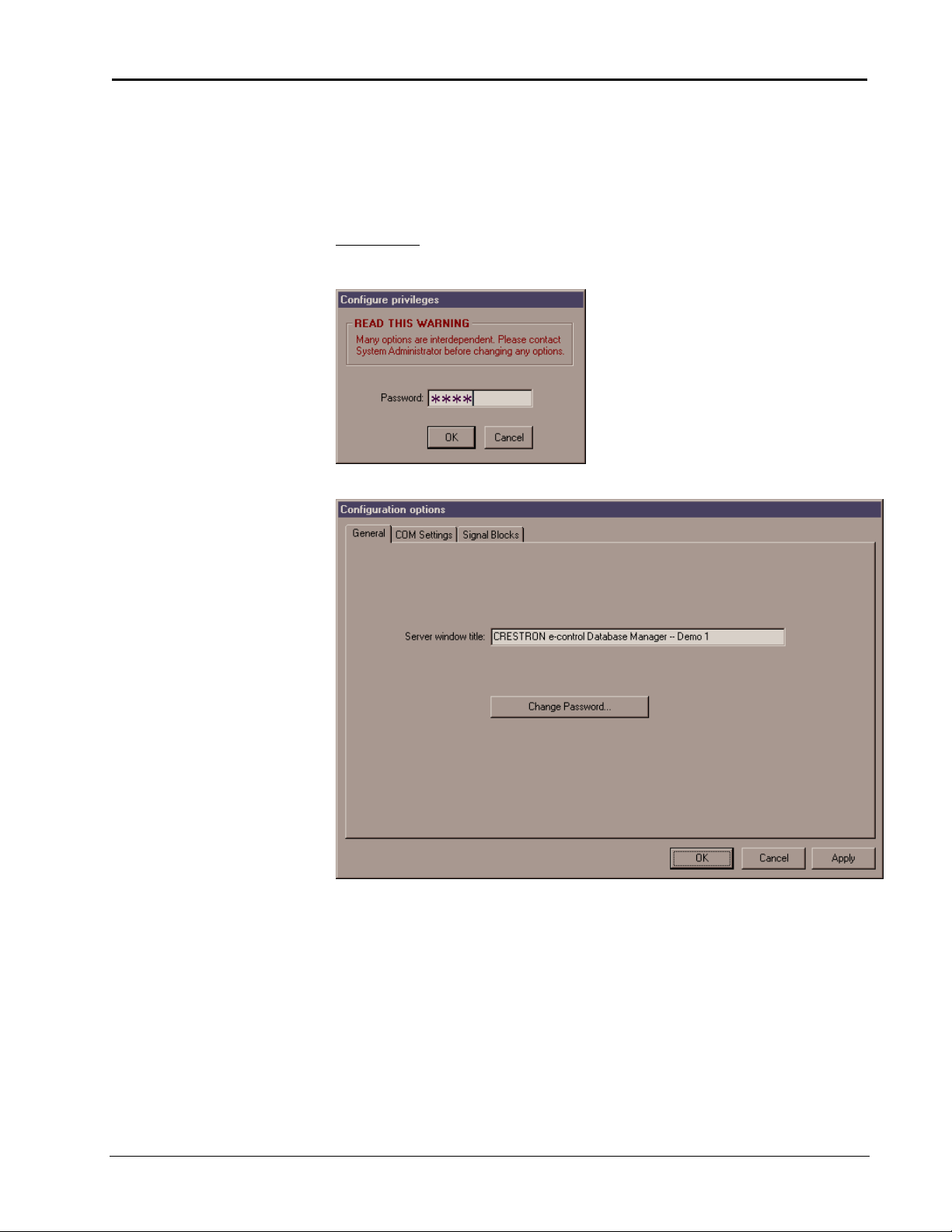

Password Access

Access to the server’s Configuration Options window is password-protected. This is

to prevent end-user meddling with the configuration options, which can very

possibly disable the server’s proper operation.

Select Server | Configure. The server prompts the user for a password. Enter

crestron2 which displays all tabs. Entering anything else displays the General

tab only.

The configuration password dialog — controls access to the Configuration Options window

The Configuration options window, General tab, showing all tabs (correct password entered).

Level 1 and 2 passwords may be changed from the General tab. Click on the Change

Password button to open the Change Password window. Enter the old password and

the new password twice. Click OK to complete the change.

Resetting the Configuration Password

In the event the password is misplaced, be aware that it is not stored in readable

form. Rather, values derived from the password is stored in the configuration files.

The password can effectively be reset by locating the configuration file and then

either deleting or editing it.

Use the File | Configuration file... command to note the pathname of the currently

selected configuration file. Exit the server.

17 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 18

Crestron e-control Database Manager SW-DBM

Deleting the file means that all configuration variables revert to their default values

the next time the server is run. The problem with this approach, of course, is that you

lose any settings already made.

To reset the password only (without affecting the rest of the configuration), edit the

.ini file using the Notepad application (Start | Programs | Accessories |

Notepad). Locate and delete the following key in the [GENERAL] section (the

value may differ):

privilegeLevel_2=180350152

Exit the Notepad application, saving the file.

The password is now reset to its default — which is “crestron2.”

Run the server again. Issue the Server | Options... command. Enter the default

password. You can now change the password to whatever you want by clicking the

Change Password button.

COM Settings Definition

A data structure called a “system” must be created for each connection you intend to

make to your control systems.

All active signal blocks (Signal Blocks tab) must reference such a structure. See

“COM Settings,” page 23, for instructions on defining such a reference for your

signal blocks.

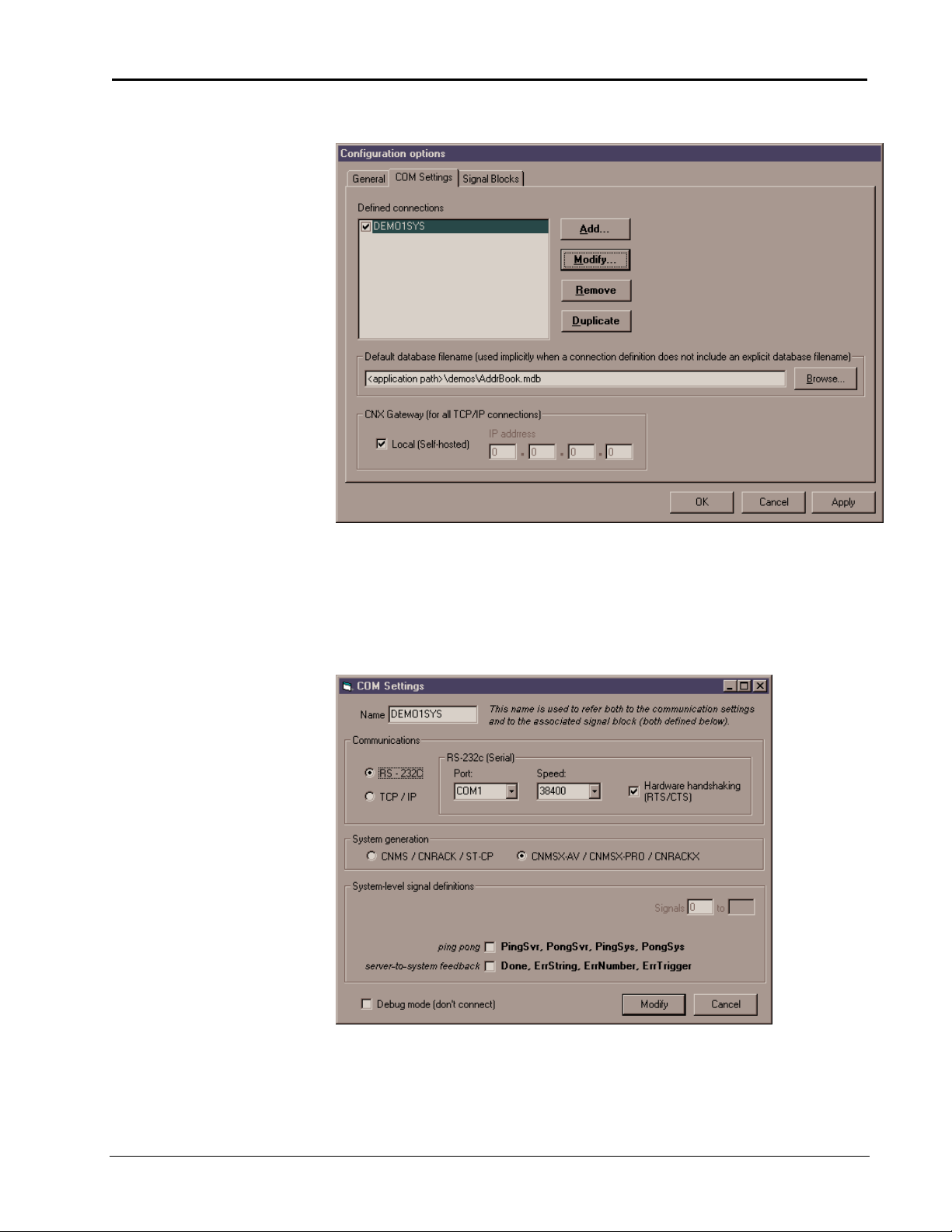

The COM Settings tab

The COM Settings tab of the Configuration Options window contains a list of data

structures called “COM settings definitions” which represent connections to control

systems. From this tab, you can activate and deactivate such definitions, and define

additional ones.

NOTE: Connections may be defined before or after signal blocks are defined. However, signal

blocks cannot be activated until they reference a defined connection.

Refer to the figure below.

To remove a COM settings definition, select it and click the Remove button.

To duplicate an existing definition, select it and click the Duplicate button. The new

definition differs from the original in that it is given a unique name which is derived

from the name of the original, incremented by one. (If the original did not end in a

number, the name of the duplicate is the name of the original with a “1” suffixed to

it.)

Click the Add… button to define an new connection; or select one of the definitions

already listed and click Modify… to modify it. The COM Settings window opens:

18 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 19

Crestron e-control Database Manager SW-DBM

The Configuration Options window, COM Settings tab, showing the only connection defined in the demo

configuration (selected).

COM Settings definitions (connections) can be active or inactive. A check in the box

next to the definition name indicates that the connection is activated. If not activated,

it is ignored when the server protocol is started.

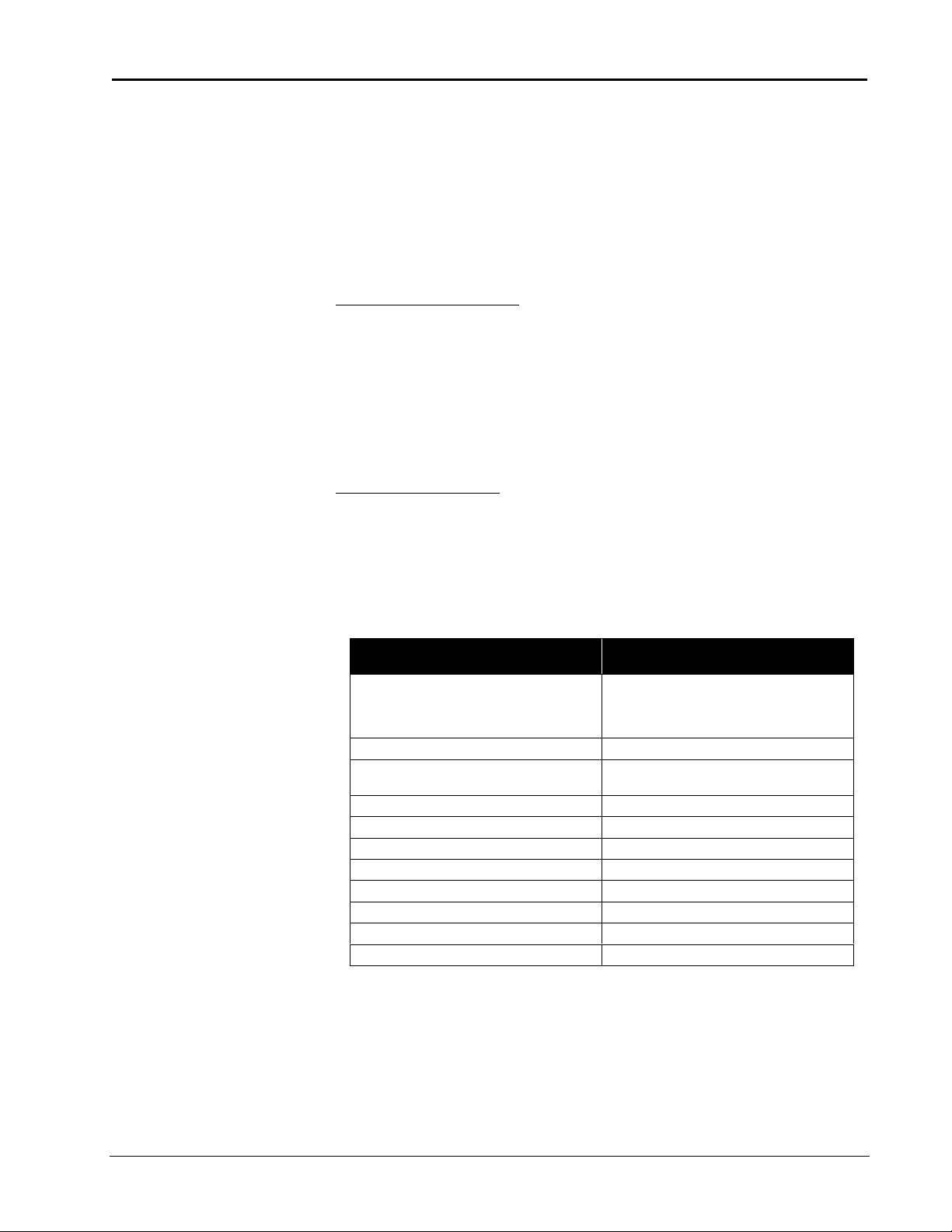

The COM Settings window

The COM Settings window for the connection defined in the configuration for demo 1, showing RS-232

communications selected …

19 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 20

Crestron e-control Database Manager SW-DBM

… and if TCP/IP communications were selected, it would look like this (fictitious IP address shown):

Definition name

Each COM Settings definition requires a unique name. A field for this data can be

found at the top left of the COM Settings window. We recommend choosing a name

that reflects either the location of the control system (such as SUITE3) or its function

(such as PHONEBOOK).

This name is used in the server’s user interface to identify the system data structure.

It is also sent along with error messages to the actual control system to identify the

source of an error resulting from processing one of the system-level signals defined

herein.

Control system generation

Here you specify the type of control system. The server uses this information to take

into account minor differences in the way the older generation of Crestron control

systems functioned in terms of timing and data capacity.

Communications mode

In this frame you choose RS-232 or TCP/IP connections. The details are described in

the Server Side configuration sections for RS-232 (page 13) and TCP/IP (page 14).

System-level signal definitions

In this window you can also define optional system-level signals by checking the

appropriate boxes. Doing so defines a special signal block which communicates with

its own Intersystem Communications symbol in your SIMPL Windows program.

In this case, you should also fill in the Signals field, as follows:

Signals

This is the offset of the Intersystem Communications symbol in your SIMPL

Windows program. The connection’s signal block must not overlap any other signal

block (channel 1 of) these COM settings or else the server protocol will not be able

to be started.

Refer to the “Signal Reference” section, which begins on page 58, for more

information on each of the signals listed in the window.

Signal Block Definition

Data structures called a “signal blocks” are created on the server, each

communicating with its own Intersystem Communications symbol on a control

system. Each active signal block must reference a “COM Settings” data structure

which defines a connection to a control system. See “COM Settings Definition,”

above.

20 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 21

Crestron e-control Database Manager SW-DBM

A “signal block” is a software

construct defined in the server

which communicates with

Intersystem Communications

(XSIG) symbols in the SIMPL

program running in your control

system.

The Signal Blocks tab (see below) displays a list of defined signal blocks. Two types

of signal blocks are available with an SW-DBM license:

Custom Scroller for interactive display and maintenance of an arbitrary

database table.

Standard Scroller a subset of the above; for interactive display of up to two

fields from a database table; typically used in support of a

separately licensed server component (such as SW-EMAIL)

(especially when not also licensed for SW-DBM);

conforms to SIMPL symbol Receive e-Mail.

Without an SW-DBM license, Standard Scroller signal blocks cannot be directly

enabled via a signal from a control system. In that case, they are only useful when

attached to another type of signal block designed to control scrollers. Examples of

such controlling signal blocks include, among others, the e-Mailer and e-Mailbox

signal blocks provided with an SW-EMAIL license. Such signal blocks can use

scrollers in support of their primary function. For example, an e-Mailer (e-mail

sender) can use scrollers to display an address book and prepared messages; an

e-Mailbox (e-mail receiver) can use them to display an IN box and a message. When

attached to a controlling signal block, a scroller is enabled automatically when the

controller is enabled.

With an SW-DBM license, a Standard Scroller can be enabled directly, and so can be

used on its own whenever the full functionality of a Custom Scroller is not called for.

Standard Scroller signal blocks are simpler, involving far fewer signals and options.

Their signal configuration is static and designed to interface with the included

Standard Scroller SIMPL Windows macro. (If you use a Custom Scroller, you

cannot use the macro.)

Specific differences between the two types of scroller signal blocks are summarized

in below:

Standard scroller options

no license required

Enable signal non-functional except in

simulation (from Signal Analyzer window).

Enabled signal sent by server as usual (but not

available through DBMScroller macro).

Maximum of 8 rows x 2 columns Any number of rows/columns in displayed list

e-Mail data echoed through e-Mailer signal

block only

Same Specify list fields, data fields, and SQL queries

Same Sort by list fields or ID field

N/A Modify any field(s) through Write signals

N/A Add new records

N/A Delete “picked” record

N/A Local error reporting signals

N/A Successive query signals

N/A Auto-pick feature

Custom scroller options

SW-DBM license required

Fully functional Enable and Enabled signals

Echo selection of fields from “picked” records

through Data signals

The Signal Blocks tab

The signal blocks tab contains a list of the currently defined signal blocks. Refer to

the figure below.

To remove a signal block definition, select it and click the Remove button.

21 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 22

Crestron e-control Database Manager SW-DBM

To duplicate an existing definition, select it and click the Duplicate button. The new

definition differs from the original in that it is given a unique name which is derived

from the name of the original, incremented by one. (If the original did not end in a

number, the name of the duplicate is the name of the original with a “1” suffixed to

it.)

New signal blocks can be added by selecting a signal block type from the New signal

block type list box and clicking the Add… button. Existing signal blocks can be

modified by highlighting the signal block in the Defined signal blocks list and

clicking the Modify… button.

The Configuration Options window, Signal Blocks tab, showing all the signal blocks defined in the demo

configuration. As shown, all three signal blocks are active (checked); and the custom scroller signal

block for demo1, ADDRBOOK, is selected.

Signal Blocks, once defined, can be active or inactive. A check in the box next to the

signal block name indicates that the signal block is activated. If a signal block

definition is not checked, it is ignored when the server protocol is started, neither

accepting nor responding to incoming signals in its range. Inactive signal blocks are

not considered for signal space conflicts with other signal blocks when the server

protocol is started.

NOTE: Signal Blocks may be defined before or after the COM Settings to which they need to refer

are defined. If the signal block is defined first, you will not be able to specify the COM Settings yet.

This is permitted. However, such signal blocks cannot be activated until they reference defined

COM Settings.

The server can have any number of signal blocks defined and active simultaneously.

Selecting a signal block from the list in the Signal Blocks tab and clicking the

Modify… button — or defining a new signal block with the Add… button — opens a

signal block definition window.

Such a window shows a particular signal block definition. The definition includes:

• Interface definition. The options across the top of the Signal Block Definition

window are common to all types of signal blocks and include the signal block’s

name, system connection, and signal offset. (The term interface refers to the

22 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 23

Crestron e-control Database Manager SW-DBM

server-signal block interface; i.e., information that all signal blocks must have to

be handled by the server as signal blocks.)

• Optional signal definitions. Words shown in the Signal Block Definition window

in bold case are names of optional signals implemented by the signal block.

These are included in the signal block definition (they are "defined") either by

checking the adjacent checkbox, or (in the case of a set of enumerated signals)

by supplying a non-zero number in the adjacent text field. Undefined signals do

not appear in the signal list and must not appear in the matching Intersystem

Communications symbol on the control system side. Be aware that there may

also be a number of non-optional signals which are not shown in the window.

• Behavior options. These have specific effects on signal block behavior when the

server protocol is running.

The highest numbered signal in the signal block’s input or output signal lists is

shown in the box in the upper-right corner. This is based on the signal offset entered

in the adjacent box and the current signal block definition. This value is updated

synchronously as the user interacts with the window. This box turns red when the

highest analog or serial signal number on either the input or the output lists exceed

1023; or should the highest digital signal number exceed 4095.

Interface Definition

All signal blocks require the following basic information. Fields for these data are

shown across the top of all Signal Block Definition windows.

Name

A unique signal block name is required here. This name is used in the server’s user

interface to identify the signal block. It is also sent along with error messages to the

control system to identify the source of the error. We recommend choosing a name

that reflects either the location of the control system (such as BOOTH3) or its

function (such as PHONEBOOK).

COM Settings

The COM Settings list box contains the names of all the COM Settings definitions

from the COM Settings tab. Point the signal block to a particular COM Settings

definition by selecting it from the list.

Each signal block must be associated with a control system. Control systems are

defined separately under the COM Settings tab. You may define the signal blocks

first if you like, then define the systems, and come back and make the associations

later. Note, however, that signal blocks cannot be activated without first associating a

system, through its COM Settings connection, with the signal block.

Channel

For systems with multiple Virtual COM Port channels defined, select a channel here.

Signal Offset

When a signal block shares a signal space (a channel) with another signal block, they

both cannot begin numbering their signals at 0. In such a case, supply values space

the signal blocks’ signals properly — such that they do not overlap with each other.

If any signal blocks’ signal spaces overlap, attempting to start the server protocol

results in an error.

Auto-enable

If this box is checked, the signal block is automatically enabled when the server

protocol is started.

23 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 24

Crestron e-control Database Manager SW-DBM

Standard Scroller Signal Block Definition

NOTE: The reader is urged to refer to the Signal Reference for more information about the signals

discussed in these sections.

A “standard” scroller is a very simplified form of the full-featured “custom” scroller

(described in the following section). The Standard Scroller features the following:

• A static signal block definition. That is, unlike the Custom Scroller, the

selection of signals that comprise the signal block of a Standard Scroller cannot

be changed. Certain options that control the behavior of the signal block can

however be changed (as described below).

• Conforms to the DBMScroller SIMPL macro. Due to the static definition, the

supplied macro can be used in your SIMPL programming.

• Useful for browsing a database table and selecting a record therein. Cannot

display the records, however.

• Scroller display is limited to 8 (rows) x 2 (columns), maximum.

• Does not require an SW-DBM license. If licensed for any other component that

can make use of interactive database table displays (such as SW-EMAIL, for

example), access is automatically conferred for creation and use of Standard

Scroller signal blocks. (If also licensed for SW-DBM, custom scrollers may be

used by such components.)

The Standard Scroller Signal Block Definition window looks similar to the Custom

Scroller Signal Block Definition window. The difference is that in the former,

optional signal definitions are disabled.

The Standard Scroller Signal Block Definition window, showing the definition

of a hypothetical 4-row x 1-column “standard” scroller.

24 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 25

Crestron e-control Database Manager SW-DBM

Default Query

This textbox contains the number of the query from the Queries table ID field

that this signal block performs when it is enabled.

List Rows and List Columns In Use

Sets the number of rows and columns in use by the scroller. These values must be

within the range of the number of rows and columns defined (see below, under

“Custom Scroller Options”).

Sort

Each scroller table must have an ID field. This number makes each row distinct from

every other row. To have the rows display in the order of this field, select the by ID

field option. If you want the rows to display sorted by the list fields you specified in

the Queries table, select the by list fields option.

To display the values from highest to lowest, check the Descending checkbox.

Scrollbar

If you defined the Scrollbar signal (above), these options select between a line mode

scrollbar and a bar mode scrollbar. Demos 1 and 3 use a line mode scrollbar; Demo 2

has a bar mode scrollbar. You can also invert the direction of the scrollbar by

checking the Invert direction box.

Blank Scroller Upon

This group of specify when the server will “blank” the scroller. As you can see from

the figure, a Standard Scroller can be blanked when the server protocol is started

and/or halted; and/or when the signal block is enabled and/or disabled. (The between

levels of successive query option is disabled because it is only relevant to the

successive query signals which are only available in a Custom Scroller.)

Other Signals

Non-optional signals implemented by the both standard and custom scrollers are not

listed in the Scroller Signal Block Definition windows. These include Enable and

Enabled; Done; and First, Prev, Next, and Last.

Discard “type-ahead”

This option is recommended (and is checked by default in a new definition).

Custom Scroller Options

Selecting ADDRBOOK and clicking the Modify… button opens the Custom Scroller

Signal Block Definition window.

25 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 26

Crestron e-control Database Manager SW-DBM

The Custom Scroller Signal Block Definition window, showing the defintiion of

the ADDRBOOK scroller from demo1.

This window allows the user to customize a scroller signal block to fit his needs. For

example, to set up a touchscreen scroller with 16 rows and 4 columns using list fields

and displaying 24 data fields, as described in Query 17, just enter the numbers here.

Check the signals QueryDescription and Scrollbar to include them in the signal

block definition.

Successive Query

Check this box to use the successive query technique used in Demo 2. You must also

indicate how many levels of GoLevel and GoLevelEcho signals are to be used in the

successive query. See “Successive Queries,” page 38, for complete information.

List Rows and List Columns Defined

Sets the number of rows (r) and columns (c) defined for the scroller signal block.

These are reflected in the number of List

and Pickr signals. That is, there are r x c

r,c

List signals and r Pick signals.

Local Feedback

Check this option to define the three error signals (ErrString, ErrNumber, and

ErrTrigger) in the signal block. These signals are routinely used by the server to

report errors to the control system. See the “Signal Reference” beginning on page 58

for more information. If these signals are not defined here, errors are reported instead

to the signal block that “owns” the scroller, if any. If that signal block also does not

define its error signals, errors are reported to the control system through the system

signal block. If that system signal block also does not have its error signals defined,

the errors are not reported to the control system at all, although they are still added to

the server’s error log.

26 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 27

Crestron e-control Database Manager SW-DBM

Special Modes

Check the Auto-Pick box to send a Pick1 signal automatically on each scroll action.

Data Fields

The Data Fields Defined textbox defines the number of Datad signals. The Data

Fields Filter textbox defines the initial value of the data filter bit pattern. See page

54 for a discussion of “Bit Patterns.’ The control system can change the data filter bit

pattern at run-time using the DataFilter signal. See the entry for the DataFilter

signal in the Signal Reference for more information.

Edit Signals

Checking the Edit Signals box defines the Writed signals. See the entry for the

Writed signal in the Signal Reference for more information.

Buffer

Checking the Buffer box enables the UpdateRec signal that copies changed scroller

records to the database. In the current version of the server, this signal is not

implemented; the Write signals currently update the database.

Server Windows and Menus

This section contains descriptions of the server’s two main windows, the Server

Monitor window and the Signal Analyzer window.

The Server Monitor Window

While the server protocol is running, the Server | Start w/Signal Analyzer

command from the Server Monitor window opens the Signal Analyzer window. (If

the server is already running, toggling Server | Signal Analyzer does the same

thing.)

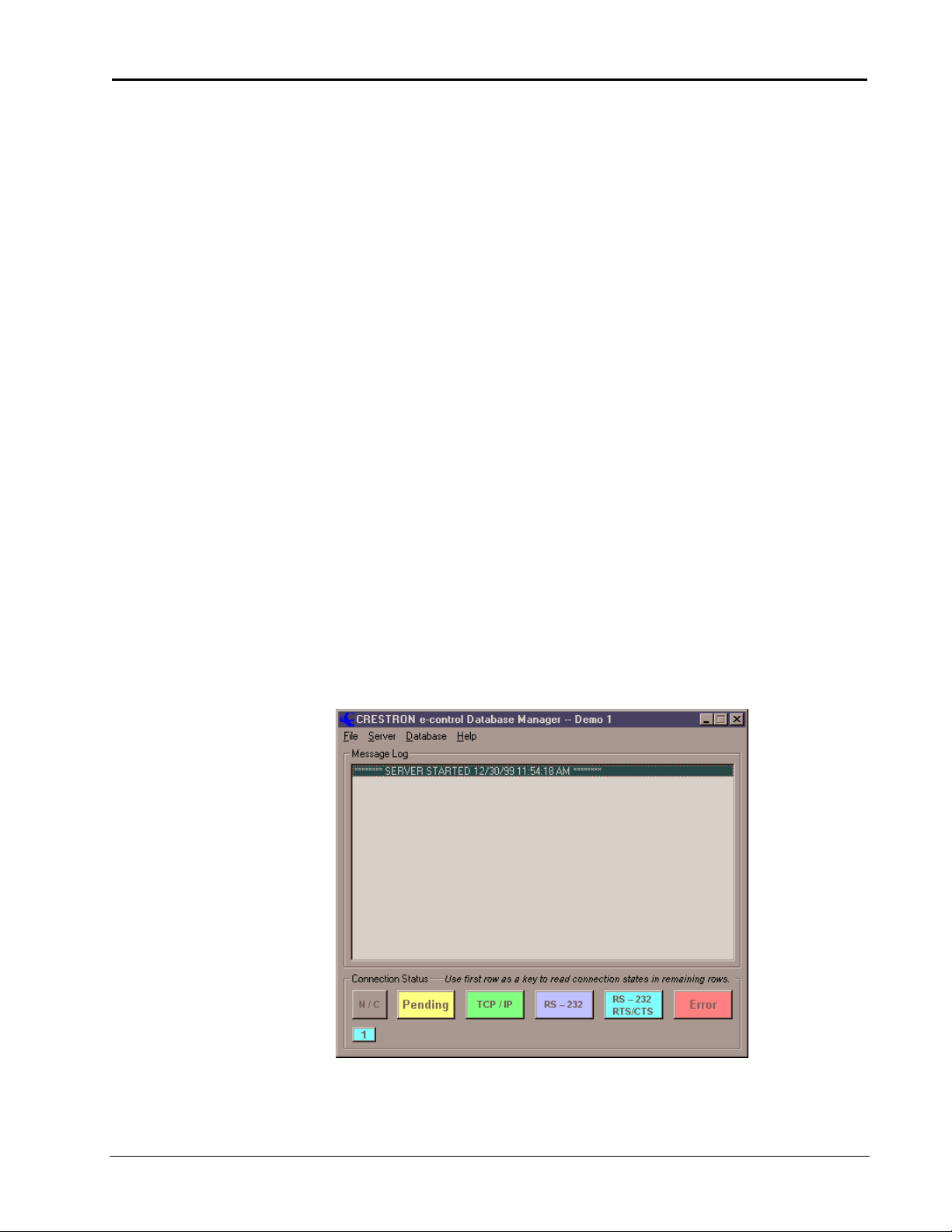

The Server Monitor window. The server protocol has been started with a single system connected via

RS-232. Note the name of the currently loaded configuration in the title bar.

27 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 28

Crestron e-control Database Manager SW-DBM

The Message Log Frame

When the server protocol is running, the Message Log frame shows status and error

messages; for example, it lists each time the protocol is started and halted.

The System Connection Status Frame

This frame contains a colorful legend above a series of small numbered rectangles,

representing each of the defined systems. The color of a control system’s rectangle

indicates its connection status, according to the legend. When the server protocol is

not running, all systems show a status of “Not Connected” (gray). In figure above,

the server protocol has been started. There is only one system defined and its status

is “[connected via] TCP/IP” (green) meaning that a successful TCP/IP connection

has been made to that system. The other possible states are “Waiting [for connection

or disconnection]” (yellow), “[connected via] RS-232” (blue), and “Fault” (red). If a

system cannot connect, it turns red and stays that way until the next connection

attempt. The protocol runs if at least one system connects successfully.

The File Menu

The following command is only available when the server protocol is halted:

• Configuration file…. This command can be used to instantly reconfigure the

server by indicating an alternate configuration settings file. Any configuration

changes made henceforth are saved to this new file. The name of this file is

stored in the Windows registry and becomes the default configuration. Use

this command to select the appropriate configuration file for each demo

before running it.

The following command is always available:

• Exit terminates the server application. If the server protocol is running, a

warning message appears.

The Server Menu

Before the server protocol is started, the following commands are available:

• Server | License… opens the e-control Software Server – Upgrade/Transfer

License window for licensing and activating the various server components.

• Server | Configure… opens the Configuration Options window (described

beginning on page 16).

To start the server protocol, use one of the following commands:

• Server | Start connects to the control systems and starts the server protocol. If

no successful connections are made, the protocol remains halted.

• Server | Start w/Signal Analyzer connects to the control systems, starts the

server protocol, and opens the Signal Analyzer window (see below).

• Server | Start without connecting opens the Signal Analyzer window and

starts the server protocol but without connecting to the control systems. This

is useful for testing server behavior simulating incoming signals and watching

the signals generated in response (which are not actually sent).

The above commands all become disabled (dimmed) when the server protocol starts,

whereupon the following signals, normally disabled, become enabled:

• Server | Stop halts the server protocol.

• Server | Signal Analyzer opens or closes the Signal Analyzer window. When

this item is checked, the window is opened. When it is unchecked, the window

is closed.

The remaining commands are always available:

28 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 29

Crestron e-control Database Manager SW-DBM

• Server | Log | Timestamps. Selecting this option puts a checkmark next to it

and henceforth all log items will contain a timestamp of the form hh:mm:ss

(24-hour clock) at the beginning of each line. Selecting the command again

removes the checkmark and timestamps will no longer be included in the log.

NOTES:

1. This option affects the server log and the signal log in the Signal Analyzer window as well.

2. This option is “sticky” — meaning that its most recently set state is saved in the Windows

Registry and is automatically applied to the option the next time the window is opened.

• Server | Log | Clear clears the message log.

The Database Menu

This menu contains a single command, Database | Queries Table, which opens the

Queries Table window. This window provides display and edit access to this

essential table in the database file named in Configuration Options window. See

“Editing the Table” on page 38 for more information.

The Signal Analyzer Window

While the server protocol is running, checking the Signal Analyzer command from

the Server menu opens this window.

The Signal Analyzer window, showing the all the active signal blocks defined in the demo configuration.

The ADDRBOOK signal block (from demo1) is selected. Therefore the ADDRBOOK signals are displayed

in the lists to the left and right. The Timestamps option is on; the Debug Info option off.

29 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 30

Crestron e-control Database Manager SW-DBM

Signal Simulator

The top part of the window is for simulating receipt of incoming signals and

transmission of outgoing signals.

Signal Blocks & Connections

This list contains all active signal blocks as well as all active connections that have

signals defined (and hence can behave as signal blocks too).

To simulate an incoming or outgoing signal, you must first select an item from this

list.

Signal lists

There are two lists which are displayed for all signal blocks (including system signal

blocks for systems with signals defined), an incoming list on the left labeled CS to

PC signals which contains all of the signals that go from the control system (CS) to

the server (PC); and an outgoing list on the right labeled PC to CS signals which

contains all the signals that go from the server to the control system.

The letters A for “analog”, S for “serial” (or “string”), or D for “decimal” preceding

each signal in the lists indicate the type of signal expected (incoming) or to be sent

(outgoing).

NOTE: A special feature of the server converts an analog signal to a string when that signal is

received with a signal number that expects a serial signal.

To simulate a signal, after selecting your signal block, select an item from one of the

signal lists. You are now ready to send the signal. To do so, give the

Simulate | Incoming or Simulate | Outgoing command (see below).

The value frames

Values for simulated signals are entered here. (See Incoming and Outgoing

commands, below.)

Signal Log

The bottom part of the window logs all signals going back and forth from all signal

blocks to and from all control systems.

Each signal logged consists of the following:

• An optional timestamp (see below); followed by

• an incoming signifier ( <- ) or an outgoing signifier ( -> ); followed by

• one of the letters A (“analog”), S (“serial” or “string”), or D (“decimal”);

followed by

• the name of the signal block the signal is a part of (based on its signal number

and the connection through which it has come or will go); followed by

• the name of the signal; followed by

• the signal number (relative to the start of the signal block) ; and, finally,

• the value of the signal.

There are two special signal values, “[Blank]” which indicates a null string and

“Pulse” which indicates a true/false sequence for outgoing digital signals. (Pulse is

never shown for incoming signals.)

NOTES:

1. The capacity of the log is limited to the 32,767 youngest (most recent) signals.

30 •• Server Configuration In Depth Installation & Reference Guide — DOC. 5823

Page 31

Crestron e-control Database Manager SW-DBM

2. The present release does not dump the log to a disk file.

3. Signals are only logged when the Signal Analyzer window is opened. However, in general,

do not keep the window opened unnecessarily as the logging routines can cause a noticeable

degradation of server responsiveness when the server is running on a slower PC.

The File Menu

The only currently implemented commands in this menu print the input and output

signal lists for the currently selected signal block (File | Print Signal

List | Selected), or for all active signal blocks (File | Print Signal List | All). This

printout can be used to create matching Intersystem Communication symbols in

SIMPL Windows. To this end, the lists contain signal labels identical to the labels

used in that symbol.

The Simulate Menu

This menu contains the following commands for simulating signals. Simulated

signals are added to the Signal Log on the bottom portion of the window, just like

real signals.

• Simulate | Incoming simulates receipt of the signal currently selected in the

incoming (“CS-to-PC”) signal list. Before issuing the command, set the value

to be “received” with the signal by entering data into one of the three value

frames. The frame to use is based on the signal selected. This function is also