Page 1

Crestron SIMPL Windows

Primer

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

All brand names, product names and trademarks are the property of their respective owners.

© 2003 Crestron Electronics, Inc.

Page 3

Crestron SIMPL Windows Software

Contents

CRESTRON SIMPL WINDOWS.................................................................................. 1

Overview................................................................................................................................... 1

About this Primer.......................................................................................................................1

Crestron Development Software ............................................................................................2

SIMPL Windows .......................................................................................................................2

Crestron VisionTools® Pro-e ....................................................................................................2

DEAL™ for Windows...............................................................................................................2

Media Manager™ System Builder™.........................................................................................3

D3 Pro™....................................................................................................................................3

Databases...................................................................................................................................3

Product Catalog CD...................................................................................................................3

Crestron Control Systems.......................................................................................................5

Why Program Control Systems?................................................................................................5

Elements of a Control System ...................................................................................................5

Main Processor ..........................................................................................................................5

Network Control Modules .........................................................................................................6

Plug-in Control Cards................................................................................................................6

User Interfaces...........................................................................................................................6

User devices...............................................................................................................................7

Control Methods ...................................................................................................................... 7

Relay closures............................................................................................................................7

Serial Communications..............................................................................................................8

IR (Infrared)...............................................................................................................................8

Custom Serial ..........................................................................................................................10

RS-232, RS-422, and RS-485..................................................................................................10

MIDI (Musical Instrument Digital Interface) ..........................................................................11

Analog Voltages ......................................................................................................................12

Custom Crestron Interfaces .....................................................................................................12

Cresnet.....................................................................................................................................12

SIMPL WINDOWS PROGRAMMING........................................................................ 15

Introduction to SIMPL..........................................................................................................15

Symbol Categories...................................................................................................................15

Device Symbols.......................................................................................................................15

Logic Symbols.........................................................................................................................16

Symbol Properties....................................................................................................................16

Inputs .......................................................................................................................................16

Outputs.....................................................................................................................................16

Parameters ...............................................................................................................................16

Signal Types ............................................................................................................................17

Digital Signals .........................................................................................................................18

Analog Signals.........................................................................................................................18

Primer – DOC. 6253

Contents • i

Page 4

Software Crestron SIMPL Windows

Serial Signals ...........................................................................................................................18

Special Signals ‘0’ and ‘1’.......................................................................................................19

Logic Waves and Logic Solutions ........................................................................................... 19

Programming with User Interfaces...................................................................................... 20

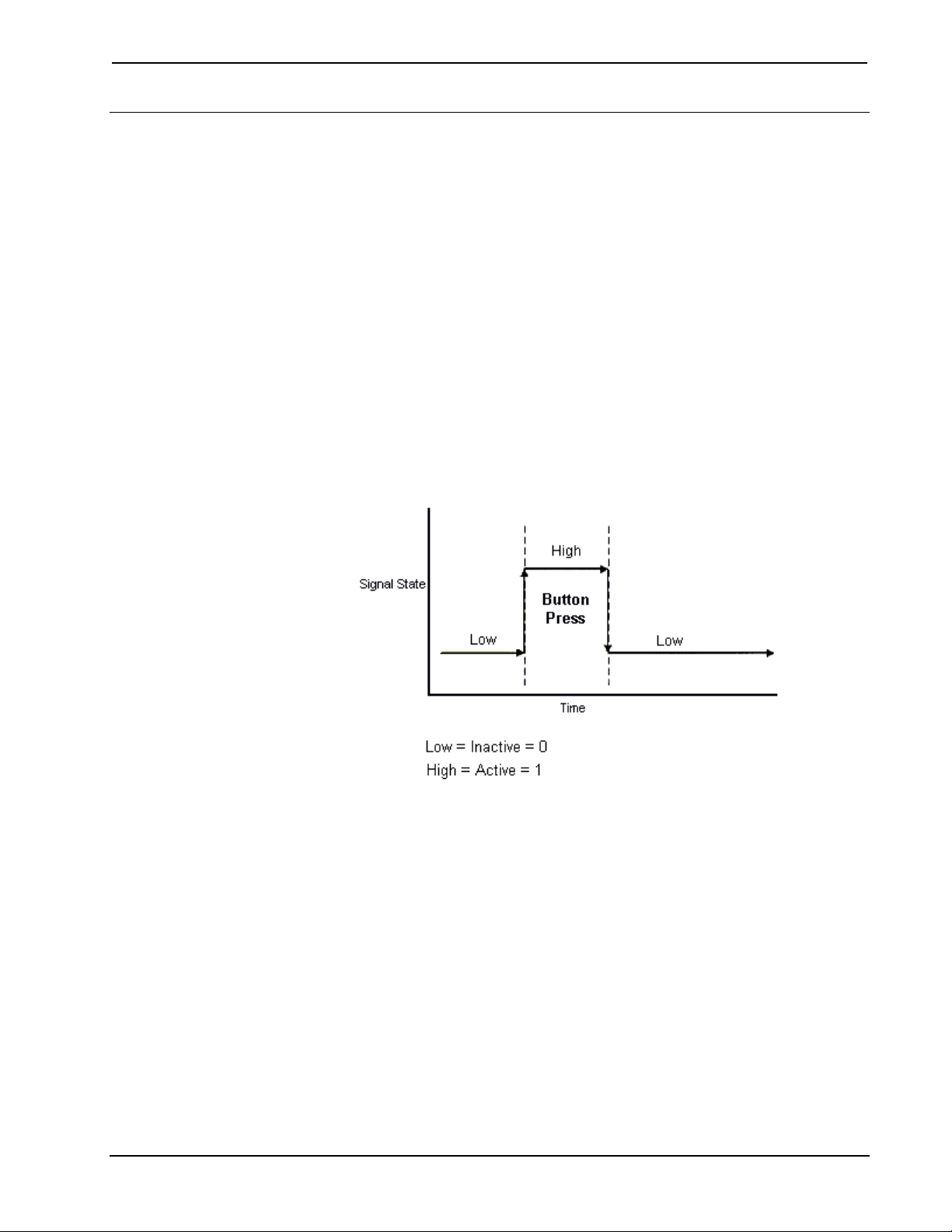

Button Presses..........................................................................................................................20

Button Feedback ......................................................................................................................21

Subpages (touchpanels only) ...................................................................................................22

Analog displays (touchpanels only).........................................................................................23

Indirect text (touchpanels only) ...............................................................................................23

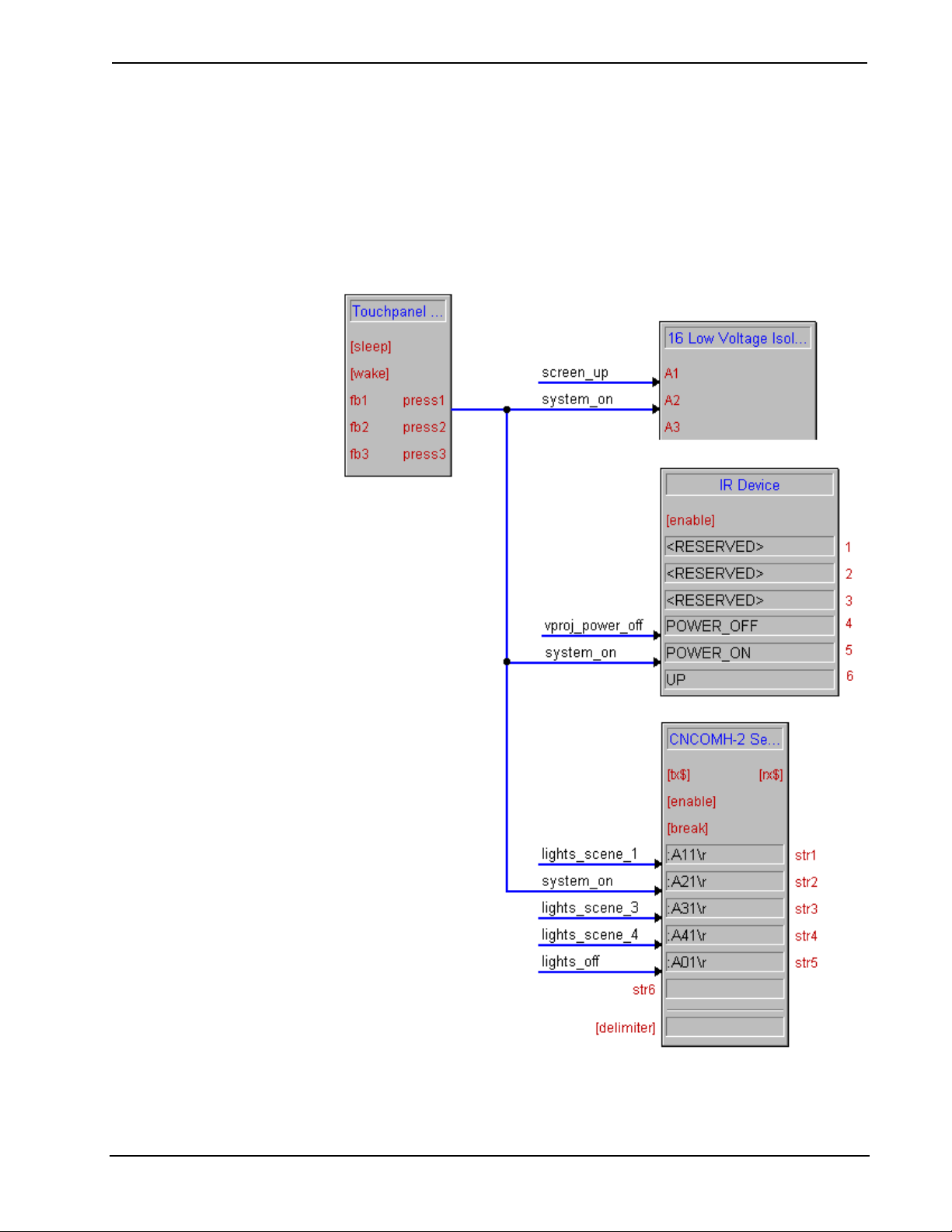

Building a Program with SIMPL Windows ........................................................................24

Programming Process ..............................................................................................................24

Basic Programming Rules .......................................................................................................24

Build a System......................................................................................................................... 24

Control Systems.......................................................................................................................26

Network Hardware...................................................................................................................27

Plug-in Control Cards..............................................................................................................28

Serial Devices .......................................................................................................................... 29

User Devices............................................................................................................................ 29

Network IDs ............................................................................................................................30

Configure Devices ...................................................................................................................30

Cresnet Devices .......................................................................................................................30

Ethernet Devices......................................................................................................................32

Serial Devices .......................................................................................................................... 33

Touchpanels............................................................................................................................. 33

Connecting Signals ..................................................................................................................34

Define Signals from User Interface .........................................................................................34

Using Logic Symbols ..............................................................................................................36

PROGRAMMING WITH LOGIC SYMBOLS ............................................................. 37

Introduction ...........................................................................................................................37

Types of Logic Symbols......................................................................................................... 37

Basic Logic..............................................................................................................................38

NOT Symbol............................................................................................................................38

NOT Symbol Example: Automatic Camera Control...............................................................39

OR Symbol ..............................................................................................................................39

OR Symbol Example: Volume Un-mute .................................................................................39

AND Symbol ...........................................................................................................................40

AND Symbol Example: discrete power on/off ........................................................................40

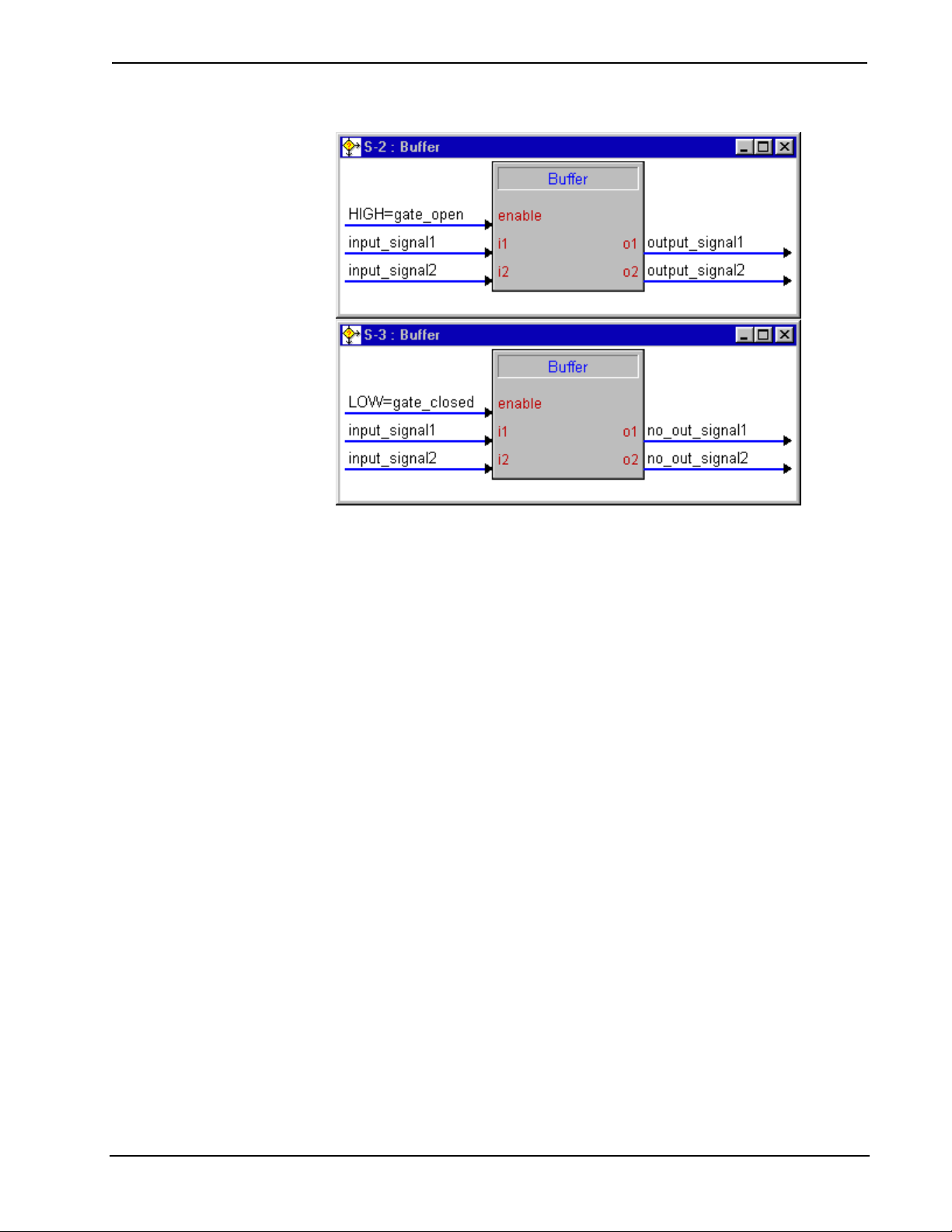

Buffer Symbol .........................................................................................................................41

Buffer Example: multi-device control .....................................................................................42

Buffer Example: triggering multiple events.............................................................................43

State Logic..............................................................................................................................46

Set/Reset Latch symbol ...........................................................................................................47

Set/Reset Latch Example: System Power Relay......................................................................47

Toggle Symbol.........................................................................................................................47

Toggle Example: Volume Mute...............................................................................................48

Toggle Example: Device Power On/Off..................................................................................48

Interlock Symbol .....................................................................................................................49

Interlock Example: Source Selection Feedback.......................................................................49

ii

• Contents Primer – DOC. 6253

Page 5

Crestron SIMPL Windows Software

Time-based Logic...................................................................................................................52

One Shot Family......................................................................................................................52

One Shot ..................................................................................................................................52

Multiple One Shot....................................................................................................................53

Retriggerable One Shot............................................................................................................53

Delay Symbol ..........................................................................................................................54

Oscillator Symbol ....................................................................................................................55

Analog Logic ..........................................................................................................................57

Analog Ramp Symbol..............................................................................................................57

Analog Initialize ......................................................................................................................58

Analog Preset Symbol .............................................................................................................60

Serial/Analog One-Shot...........................................................................................................61

Modules ...................................................................................................................................63

Communication Settings..........................................................................................................63

Compiling and Uploading Programs .......................................................................................65

Software License Agreement ................................................................................................67

Return and Warranty Policies..............................................................................................69

Merchandise Returns / Repair Service.....................................................................................69

CRESTRON Limited Warranty...............................................................................................69

Primer – DOC. 6253

Contents • iii

Page 6

Page 7

Crestron SIMPL Windows Software

Crestron SIMPL Windows

Overview

About this Primer

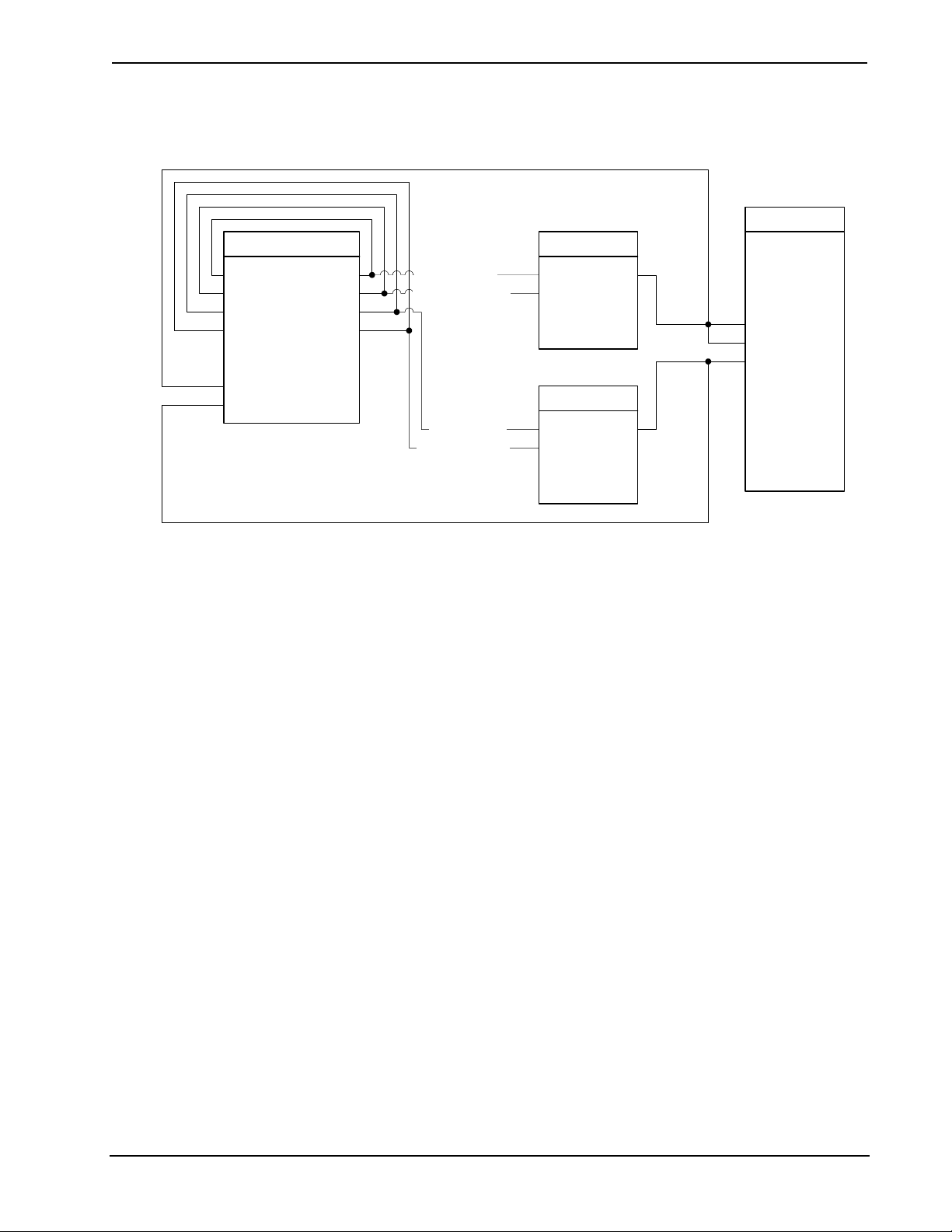

Simplified Control System

The intent of this primer is to introduce programmers to SIMPL Windows

programming techniques and how they apply to Crestron control systems. This

includes an understanding of how control systems use touchpanels and button panels

as user interfaces. Through these interfaces, a user might send a signal that is

processed by the control system (manipulated by logic symbols) and outputted to

eventually control a device.

The control process is more complex than this and has many more variables.

However, this is the basic concept of programming Crestron control systems. Users

of this information should have a basic understanding of the following:

Microsoft Windows

• Knowledge of basic Windows commands

• Familiarity with Windows features and functions

Audio/Visual

• Knowledge of different control formats (serial, IR, relays)

• Familiarity with A/V equipment

• Ability to read and understand control and wiring diagrams

SIMPL Windows provides a wide variety of symbols that are constantly being

expanded to support virtually every possible application. As you become proficient

at using SIMPL Windows it will become obvious that there are many ways to solve

the same control problem. This allows for programming creativity and independent

flexibility.

Primer – DOC. 6253 Crestron SIMPL Windows • 1

Page 8

Software Crestron SIMPL Windows

Crestron Development Software

SIMPL Windows

Crestron SIMPL Windows provides all the tools necessary to configure, program,

test and debug an integrated control system application. Combining the familiar

drag-and-drop functionality of Microsoft Windows with the programming power of

SIMPL (Symbol Intensive Master Programming Language), SIMPL Windows

provides the link between Crestron systems hardware, user interfaces, and the world

of equipment to be controlled.

The configuration aspect of SIMPL Windows allows you to select the control

system, user interfaces, network devices and controlled equipment required for the

installation. To these hardware components you can assign port addresses, Network

IDs and IP addresses, set communication parameters and specify which device is

connected to which card or network control module. You can also specify what

VisionTools™ Pro-e touchpanel projects are required for the system.

The programming aspect allows you to select the logic symbols the system will

require, assign signals to those symbols and connect the signals to other symbols or

devices as determined by the program logic. SIMPL Windows includes a wide

variety of symbols that are constantly being expanded to support virtually every

possible application. As you become proficient at using SIMPL Windows it will

become obvious that there are many ways to solve the same control problem. This

allows for programming creativity and independent flexibility.

Finally, the testing aspect allows you to test and debug your SIMPL Windows

program using powerful diagnostic tools including Test Manager, Network Analyzer,

and the Crestron Viewport. You can call these tools directly from SIMPL Windows

or launch the tools independently.

For even greater flexibility, the SIMPL Windows installation package includes

SIMPL+™, a development tool that allows advanced programmers to create and

compile custom control modules using a procedural language similar to C. You can

add SIMPL+ modules to your SIMPL Windows program or user module much like a

logic symbol, to extend functionality or solve a specific control problem.

SIMPL Windows is fully integrated with Crestron's suite of software tools, which

include the following:

Crestron VisionTools® Pro-e

VisionTools® Pro-e is Crestron's touchpanel page design software. Using

VisionTools Pro-e, programmers can create powerful touchscreen control interfaces

that include pop-up subpages for specific device transport controls, multi-mode

buttons and sliders with 3D effects, high-resolution graphics, dynamic text, video

windows, sound, and more. VisionTools Pro-e uses join numbers to identify button

presses, feedback, and other digital, analog and serial signals. These join numbers

correspond to inputs and outputs on the touchpanel symbol detail in SIMPL

Windows.

DEAL™ for Windows

Crestron's DEAL™ (Device Editor and Learner) for Windows software enables

programmers to learn manufacturer's IR signals. When used in conjunction with the

Crestron CNXLIR (IR Learner), DEAL allows you to create, modify and test IR

driver files, and to save the learned IR files in the User Database where you can add

them to your SIMPL Windows program.

2 • Crestron SIMPL Windows Primer – DOC. 6253

Page 9

Crestron SIMPL Windows Software

Media Manager™ System Builder™

The Media Manager™ System Builder™ offers automatic programming for such

residential and commercial applications as audio distribution, home theater, and

video conferencing. The System Builder provides a Wizard-like interface that takes

you through a series of programming screens. Simply follow the prompts to select

the control system, user interfaces, devices and functionality. The System Builder

then automatically programs, compiles, and uploads the system, including

VisionTools Pro-e touchpanel projects and control system logic.

D3 Pro™

Crestron D3 Pro™ software offers design, development, and documentation for a

complete residential lighting system, with additional support for auxiliary devices

such as security systems, motion detectors and shades. Like the System Builder, D3

Pro presents a Wizard-like interface. Programming is accomplished through a series

of simple but powerful System View screens. After the design is complete, D3 Pro

automatically creates, compiles, and uploads the control system program and

touchpanel projects.

These are just some of the software tools that Crestron has created to help you

accomplish your programming tasks more easily and efficiently. You can download

all Crestron software for free from the Software Updates area of the Crestron Web

site (requires registration).

Databases

The Crestron Database is a large collection of information that is accessed by

various Crestron software packages, including SIMPL Windows, D3 Pro, and the

System Builder. The bulk of the Database consists of IR driver files that control user

devices such as CD players, DVD players, conferencing equipment, and other thirdparty IR devices the end user interfaces with using the Crestron control system.

In addition to IR driver files, the Crestron Database contains hundreds of Crestron

logic modules that control third-party device functions. Modules are self-contained

logic programs that have been pre-coded, tested and debugged at Crestron. These

dedicated modules can be plugged into a program and used to generate all the proper

control codes for a device automatically.

The User Database is designed to store IR driver files that are not included in the

Crestron Database. Programmers usually generate IR files using the Crestron

CNXLIR (IR Learner) in conjunction with DEAL (Driver Editor and Learner) for

Windows software. Alternatively, you can obtain user IR files by downloading them

from the Crestron Design Center or Crestron FTP site.

In addition to IR driver files, the User Modules directory stores user-created logic

modules that are not included in the Crestron Database.

Product Catalog CD

Crestron provides a variety of ways for you to obtain information about Crestron

hardware. The most comprehensive resource is the Crestron Web site:

www.crestron.com. Here you can download the most up-to-date user manuals,

reference guides, and CAD drawings for all Crestron control systems, network

devices and touchpanels. You can also access the Crestron Design Center, which

provides extensive information about user modules that control equipment from I2P

partner manufacturers, including help files, sample logic programs, touchpanel

projects, cable diagrams, and more.

Primer – DOC. 6253 Crestron SIMPL Windows • 3

Page 10

Software Crestron SIMPL Windows

You can access the Crestron Web site directly from the SIMPL Windows Online

Support menu. Click Crestron Online for the Crestron home page, or click

Crestron Design Center to open the Dealer/Tech Resources page.

The Crestron Product Catalog and Technical Reference CD is another valuable

tool that you can use in conjunction with the Crestron Web site, or any time you're

not connected to the Internet. The CD is a comprehensive library of Crestron

brochures, catalogs, product specification sheets, CAD drawings and user manuals.

You can browse the CD independent of any Crestron program, or you can link the

CD directly to SIMPL Windows to display documentation for devices you select in

the Device Library.

To access user manuals from SIMPL Windows

1. Insert the Product Catalog CD into the CD-ROM drive (you can close the

selection screen if it opens automatically).

2. In the SIMPL Windows Device Library, select whichever Crestron control

system, network device, touchpanel or control card you want documentation

for and press F1.

3. The first time you try to access the Product Catalog CD from SIMPL

Windows you will be prompted to browse for the CD-ROM drive or folder

where the CD is located. Locate the drive or folder and click Open.

4. If documentation is available for the selected device, SIMPL Windows will

find the PDF file and open it in Adobe Reader. If no PDF file is available

for the device, then the SIMPL Windows help file will display

programming help for the device.

5. You can click Product Catalog CD on the SIMPL Windows Help menu

any time you want to open the CD selection screen for documents,

brochures, CAD drawings, or utilities.

6. If you do not have the CD inserted and you press F1 on a device in the

Device Library, SIMPL Windows will prompt you to insert the CD. You

can then either insert the CD or click Cancel to view the online help file.

4 • Crestron SIMPL Windows Primer – DOC. 6253

Page 11

Crestron SIMPL Windows Software

Crestron Control Systems

Why Program Control Systems?

The term program refers to the instructions loaded into the control processor that

cause it to operate in an intended way. For example, to control a DVD player, you

must write a program that tells the control system which port the unit is connected to,

what IR codes to send to it, and which buttons on a touchpanel trigger those

functions. A typical program may contain hundreds of similar instructions designed

to allow control of an entire rack full of audio/visual equipment. All programs are

written in the SIMPL programming language. Crestron has created the SIMPL

Windows development application expressly for writing in this language.

Elements of a Control System

Main Processor

The Crestron control system processor is the heart of a complete remote control

system. Its basic function is to integrate and communicate with equipment made by

other manufacturers. To do this the control system’s working memory (RAM) must

be programmed to use the specific instructions, or program, to communicate with the

devices being controlled.

In addition to working memory, control systems contain an operating system (OPS).

Similar to the operating systems that run personal computers, the OPS is a set of

instructions that enables the control system to understand the program that has been

loaded into it and to control equipment connected to the system by various

input/output devices (an infrared module, for example).

The need to upgrade the OPS will arise if programmers want to take advantage of

new programming capabilities, new Crestron hardware devices, or to correct a

problem found in a previous version. You can download control system updates from

the Crestron Web site. Operating system files on this site have file names such as

c2.v3080.cuz, with different extensions depending on the type of processor. Before

downloading, make sure the update is compatible with your control system by

verifying that the file name matches the OPS version number and the extension

corresponds to your control processor model.

2-Series processors use a CUZ file to load the operating system to the control

system. 2-Series processors provide 32 MB of DRAM, which is expandable to 4GB

for processors that include a Compact Flash slot. The size of the program, and

number of analog, digital, and serial signals that can be processed are limited only by

the amount of available RAM. In addition to RAM, the processor provides 256KB of

NVRAM (non-volatile RAM) that is used to store SIMPL+ variables and variables

expressly written to it by some “memory” symbols in SIMPL. These symbols

include Analog RAM, Digital RAM, and Analog Non-Volatile Ramp, and are

commonly used for lighting or volume presets. Non-volatile RAM retains data

written to it when power is turned off. The 256K of NVRAM may also be split to use

64K or 128K as an NVRAM disk.

X-Series processors have a base Monitor in addition to the operating system, as well

as separate TCP/IP stacks, all contained in a UPZ file. The separate stacks are for

systems that include the CNXENET or CNXENET+ card for Ethernet

communication. X-Series processors allow a total of 16373 user-defined digital

Primer – DOC. 6253 Crestron SIMPL Windows • 5

Page 12

Software Crestron SIMPL Windows

signals, and 2048 user-defined analog/serial signals. The processor also provides

256K of NVRAM that is divided in different ways depending on the type of Ethernet

card being used.

“Legacy” control processors such as the ST-CP and CN-Series processors allow a

total of 4085 user-defined digital signals and 512 analog/serial user-defined signals.

Processor Maximum number of signals

2-Series Depends on available RAM

X-Series 16373 digital

2048 analog/serial

ST-CP and CN-Series 4085 digital

512 analog/serial

Network Control Modules

Network control modules are devices connected to the Cresnet or Ethernet network

that extend the functionality of the control system and allow it to control third-party

equipment. Crestron provides an impressive variety of network control modules,

including audio receivers, mixers, distribution switchers, surround sound processors,

video processors, camera controllers and room solution boxes.

Any 2-Series processor is also capable of operating in “slave” mode, meaning that it

can be controlled by another 2-Series processor, in order to operate as a powerful

network control module.

Network control modules are located in the SIMPL Windows Device Library as

Cresnet Control Modules and Ethernet Control Modules. Lighting control

modules are located in the Lighting folder.

Plug-in Control Cards

Crestron plug-in control cards are circuit boards that can be easily installed in the

expansion slots of a processor and allow it to communicate with equipment. Plug-in

control cards include network interface cards that connect the 2-Series or X-Series

control system to the Ethernet network. Control cards are represented in the SIMPL

Windows Device Library as Plug-in Control Cards. Once installed and configured

the control cards allow the system to control virtually any number and variety of

devices.

Many control devices such as serial ports are available as either Plug-in Control

Cards or Network Control Modules.

Cards are usually less expensive since they don’t require housing or power

regulation. Of course, control cards are limited to the number of expansion slots in

the control processor.

User Interfaces

User interfaces are the controls that the user will use to request an action. Crestron

manufacturers a large variety of user interfaces, ranging from simple and

inexpensive handheld remotes and keypads to top-of-the-line touchpanels.

6 • Crestron SIMPL Windows Primer – DOC. 6253

Page 13

Crestron SIMPL Windows Software

Touchpanels

Crestron touchpanels are the most common user interface of any control system.

Touchpanels are available in Cresnet, Ethernet, and wireless versions with either

gray scale or color displays.

Programmers develop touchpanel screen layouts with VisionTools Pro-e software.

Buttons are assigned numbers that link them to the specific operation that it

represents in the SIMPL Windows program. These links are called join numbers

and will be describe in more detail later.

Wired Keypads

Wired keypads have a simple design and operate on the Cresnet network. Their

push-button operation offers classic styling. Many models offer a choice of button

configurations and panel finishes.

Wireless Remotes

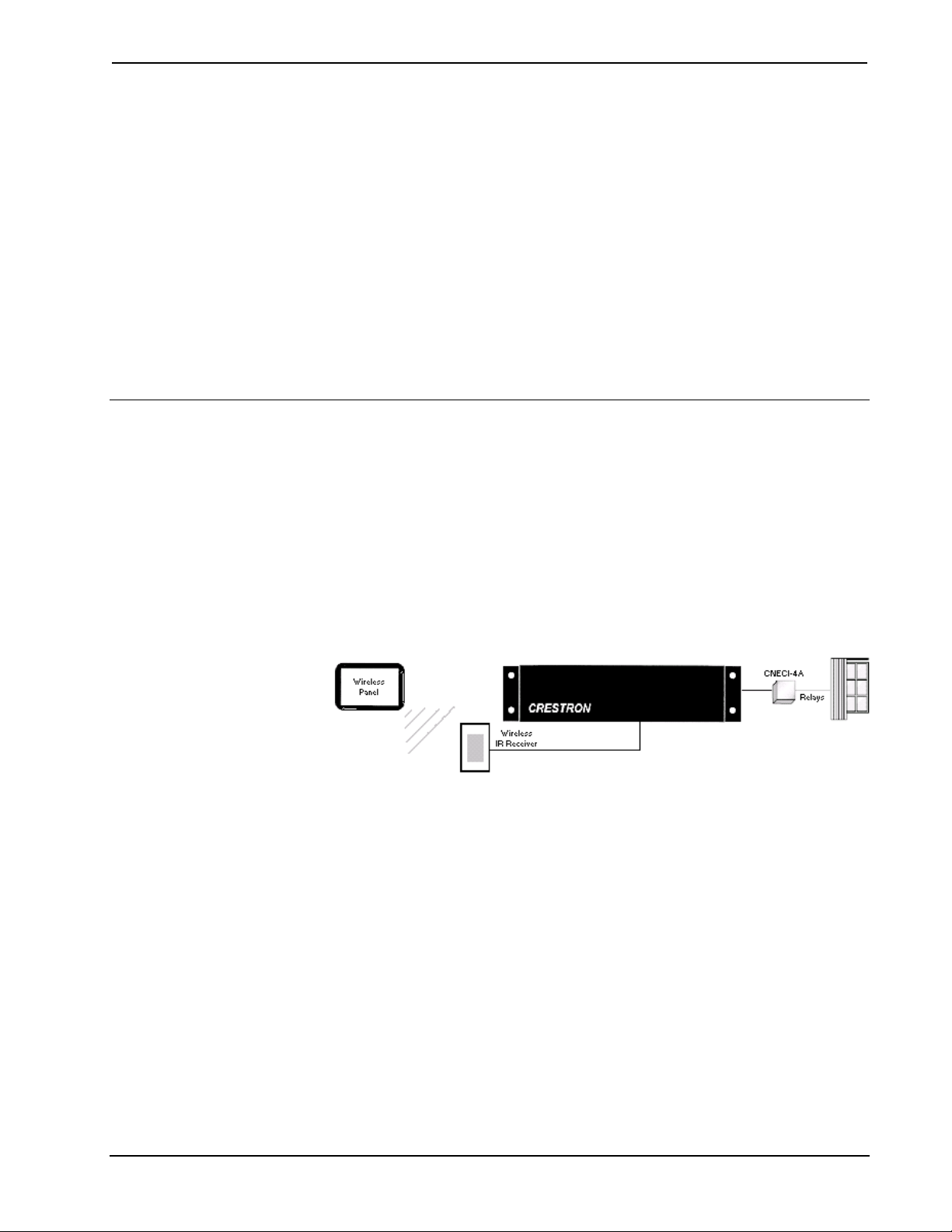

Crestron wireless touchpanels and remotes communicate with the control system

using Crestron gateway receivers (e.g. CNRFGWA, CNIRGWA, or CNRFGWX).

The gateway is connected to the control system via Cresnet. Wireless IR/RF

transmitters are one-way devices; they do not receive, but only transmit IR or RF

signals. Likewise, the Crestron CNIRGW is a one-way remote IR receiver and the

CNRFGWA is a one-way remote RF receiver.

Control Methods

User devices

User devices are the audio/visual equipment, such as CD players, TVs, and VCRs

that will be controlled by the Crestron control system. The User Devices folder

contains hundreds of driver files for these devices, organized by manufacturer or

device type.

When working with and programming Crestron control systems, it is important to

have a good understanding of how devices can be controlled. In general, any device

that has an electrical interface of some sort can be controlled by a Crestron control

system. The most common control methods are listed below:

• Relay closures (mechanical or solid-state)

• Serial communications

• Analog voltages

• Custom Crestron interfaces

Relay closures

Many devices employ internal electronics that allow functions to be triggered

through a simple electrical contact. In the world of control systems, this is

accomplished using relays. Devices such as screens and drapes, or third-party

lighting control systems tend to use this type of interface. In addition, some notdimmed lighting circuits can be switched on and off using relays. Crestron

manufactures relays of many different flavors: low-power relays for use with devices

that do not draw a lot of current or require high voltages, and high-power relays for

Primer – DOC. 6253 Crestron SIMPL Windows • 7

Page 14

Software Crestron SIMPL Windows

direct control of motors and lighting circuits. In addition, relays can either be

mechanical or solid-state. If you are unsure about what type of relay is needed for a

given application, you can call Crestron technical support for assistance.

Serial Communications

Many devices today can be controlled using various types of serial communication.

Typically serial-controlled devices use one of the following types of serial

communication: Infrared, RS-232, RS-422, RS-485, MIDI, and "custom serial". In

the next few paragraphs we will discuss the differences between these formats.

What does "serial" mean?

The term serial describes a communications format in which one piece of

information is transmitted and/or received after the next. As an analogy, think of a

telephone where you hear one word after word until a sentence is constructed. This is

different from parallel communications in which multiple pieces of information are

transmitted and received simultaneously.

Serial communication encompasses a wide variety of popular formats, many of

which are supported directly with Crestron control systems. The sections below

describe the most common formats in more detail.

IR (Infrared)

For many years infrared remote control has been very popular, and today it remains

among the most common forms of serial control. As the name implies, infrared

control consists of serial data transmitted via pulses of infrared light. In addition, IR

signals are usually modulated by a carrier signal. In most cases this carrier signal has

a frequency of approximately 40kHz, though some can go as high as 1MHz.

In the Crestron world there are two applications of IR control. Crestron wireless user

interfaces may use IR for communication with the control system. In this case the IR

is transmitted/received by Crestron equipment is in a proprietary format.

Crestron IR wireless interface

The other application of IR control is IR signals that the system generates to control

other manufacturer’s devices (e.g. to mimic Sony or Panasonic). The system can

generate the functions that were available on the device's remote control.

Since IR is a one-way communication, there is no feedback from the equipment

being controlled. That is, data is transmitted to the device to be controlled, but no

data is returned from the device to the control system. This means that when using

IR control, you have no true feedback from the device telling you that your

command was accepted, for example. This is one inherent disadvantage with this

type of control. Another disadvantage of IR is that it depends upon a line-of-sight

between the control system and the device to be controlled. To counter this problem,

Crestron can provide an IR probe, which provides a wired connection from the

8 • Crestron SIMPL Windows Primer – DOC. 6253

Page 15

Crestron SIMPL Windows Software

control system to the IR receiver on the controlled device. Care must be taken to

ensure that the IR emitter on the IR probe is properly located next to the receiver.

Remote IR Equipment

Manufacturers do not normally publish the exact nature of the data that is being sent

via their IR remote controls. Therefore in order to generate the proper signal out of

the Crestron IR card, the remote must be learned through the use of a special device

called an IR Learner. The device, when attached to a PC and used in conjunction

with Crestron’s IR learning software (DEAL for Windows), will generate a driver

file that can be inserted into your programs. Once the program is finished and loaded

into the control system, the control system’s IR card can convert the information in

the driver file into the proper electrical signal.

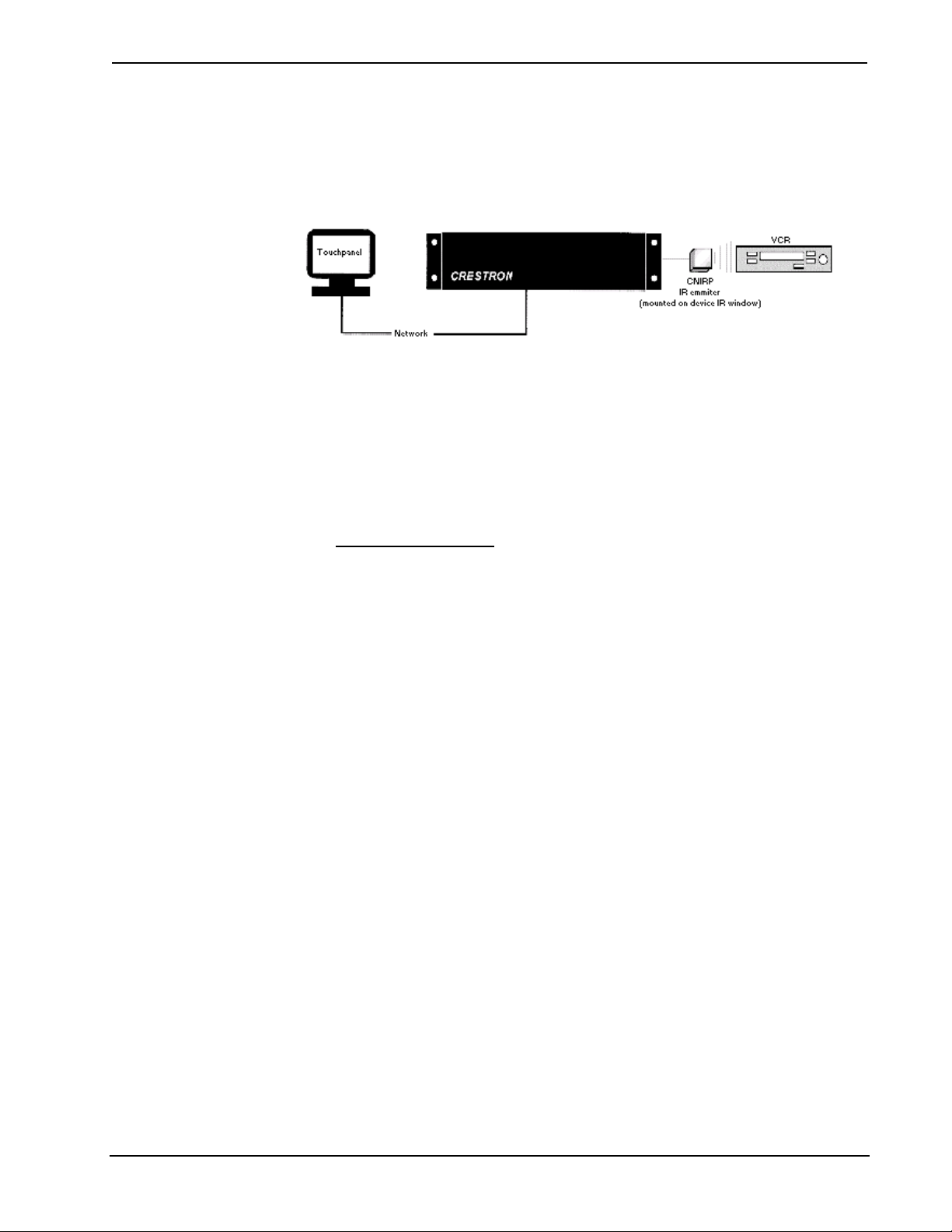

Crestron IR Equipment

IR Probes (CNXIRP and STIRP)

The IR probe (CNXIRP or STIRP) is a very small, wired IR emitter that Crestron

developed to be installed externally over a device’s IR window. The probe is wired

from the control system and emits IR signals directly into the device's IR window.

Since the IR Probe can be mounted externally on equipment, it eliminates the need to

open other manufacturer’s equipment in order to rewire or alter the IR window. In

addition, by installing the probe directly on the device being controlled, the

interference caused by direct sunlight and high efficiency fluorescent lighting can be

eliminated.

IR Sprayer

The IR sprayer in an IR emitter that can “spray” IR signals 90 degrees. It eliminates

the need for the IR probe and can be positioned in a central location to reach all

devices. It is designed to handle several IR codes so only one sprayer is needed for

many devices.

IR Device Modules/Control Cards

IR device modules, such as the C2IR-8 or the IR ports built into some control

systems, provide control of IR or some serial controlled devices. The C2IR-8 and the

built in IR ports require the IR probe (CNXIRP) when using IR communication.

See Serial IR for information on using IR ports for serial communication.

IR Learner (CNXLIR)

Crestron Electronics CNXLIR is used to "learn" the codes (pulses of infrared light)

that a device's remote sends to control a piece of equipment. By learning these codes

programmers can create custom IR device drivers. DEAL for Windows software

allows programmers to create, modify, and test driver files. Programmers can then

store the learned .IR files in the User Database for use in their SIMPL Windows

programs.

Primer – DOC. 6253 Crestron SIMPL Windows • 9

Page 16

Software Crestron SIMPL Windows

Crestron Database

As described earlier, the Crestron Database contains hundreds of pre-coded IR driver

files for programmers to utilize. This database covers most of the IR controlled

devices on the market today. In fact, the database supports all current control

formats, including relay control, analog voltages, and TCP/IP. Programmers can

search the database by manufacturer or device type.

Custom Serial

The term custom serial is used here to describe a communications protocol that is

similar to IR, but is carried out over a wire rather than light pulses, and there is no

carrier frequency. It is called custom because currently a number of manufacturers

employ this method, but there is no true standard. Sony Control-S and Marantz RC-5

are examples of custom serial formats in use today.

In terms of usage, this form of serial communications differs from IR only in that a

specially made wired cable must be used in place of an IR probe to connect from the

control system to the controlled device. Because the data format is normally identical

to a corresponding IR remote, serial drivers are created first by learning the remote to

generate an IR driver, then by passing the file through a special filter that removes

the carrier frequency. Just like with IR, custom serial signals are generated using an

IR card such as the C2IR-8.

Crestron Custom Serial Equipment

CNSP-109

The CNS-109 is an Electrahome/Vidikron Cable for use with C2IR-8 or (1) serial

output port.

CNSP-110

The CNSP-110 is a Sony VO 5000, 7000, 9000 serial Umatic cable for use with

C2IR-8 port.

CNSP-112

The CNSP-112 is a Sony Control-S cable for use with (1) C2IR-8 port.

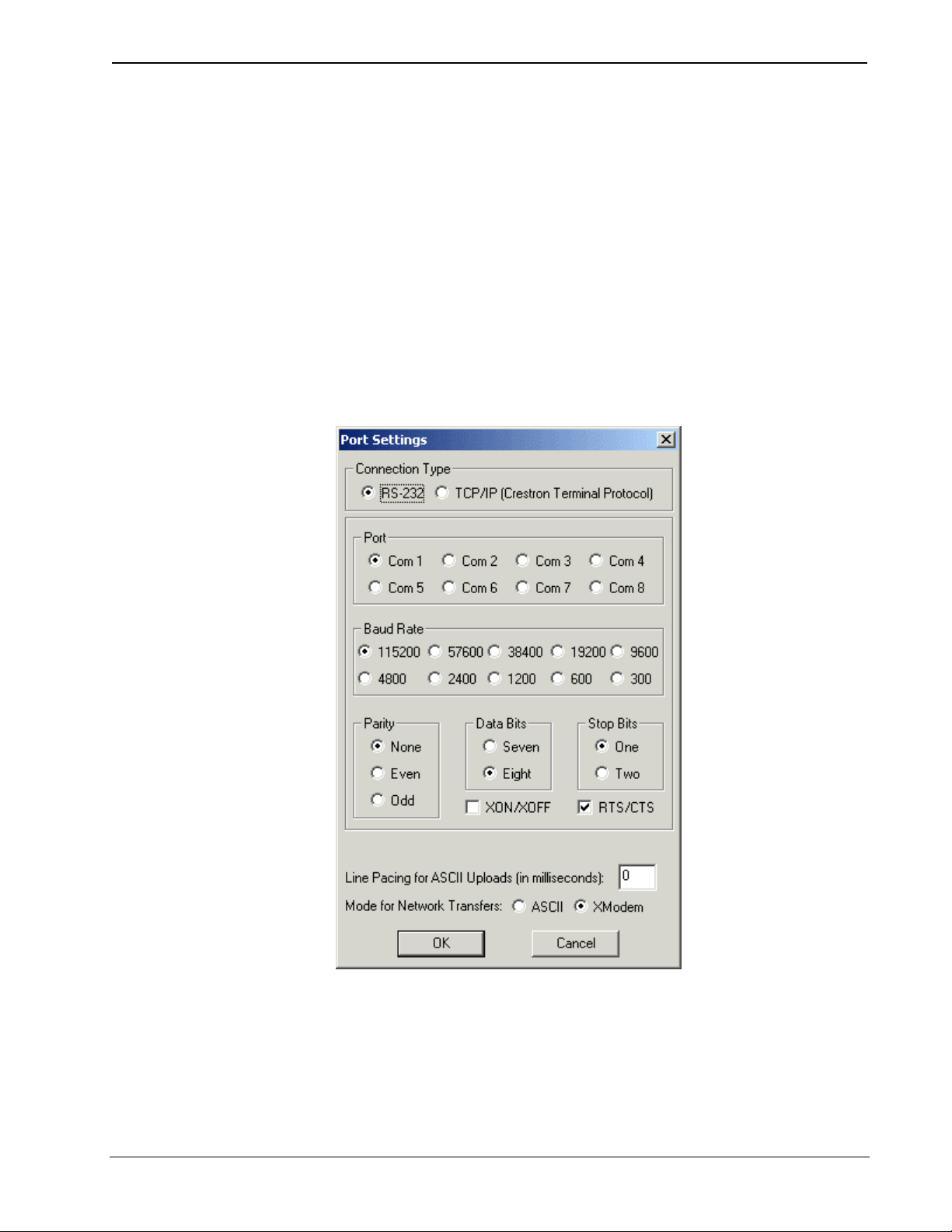

RS-232, RS-422, and RS-485

The terms RS-232, RS-422, and RS-485 all refer to physical standards for serial

communication developed by the Electronic Industries Association (EIA). The

standards specify the electrical interface between equipment. These standards have

been developed to allow various pieces of equipment to communicate with one

another without concern for special hardware; any device that conforms to one of the

standards above should be able to communicate with any other device conforming to

the same standard. Of the three formats, RS-232 is by far the most popular for use in

control systems. For the remainder of this section, the term RS-232 will be used to

describe any of the three protocols, except where noted.

Unlike the IR or custom serial formats, RS-232 control does not use ready-to-go

driver files. Instead, the data format, or protocol, that a controlled device is

expecting will be described in the unit's manual. This protocol includes the data that

the device expects to receive and transmit, the speed at which it communicates (baud

rate), the error checking (parity), the number of data bits and the number of stop bits.

In addition, a given device may require hardware (RTS/CTS) or software

(XON/XOFF) handshaking, which controls the flow of data between two devices.

All of these elements are adjusted in the control program to match the manufacturer's

specification.

10 • Crestron SIMPL Windows Primer – DOC. 6253

Page 17

Crestron SIMPL Windows Software

Because of the absence of a driver file, RS-232 control is generally considered more

difficult to program than IR or custom serial. This is because each time an RS-232

device is to be programmed, the programmer must look up the protocol in the

manual, and then write the necessary logic into his program to send this data. To

counter this, many devices have dedicated modules written for them. These modules

can be plugged into a program and used to generate all the proper control codes

automatically.

The differences between RS-232, RS-422, and RS-485 are physical in nature, and do

not affect the programmer, except that they must make sure that the Crestron product

being used to send the data supports the format, and has been configured properly.

RS-232 uses one wire to transmit data, and one wire to receive it. It is generally valid

for sending data up to 50 feet, but this distance can depend on many factors, such as

cable quality, baud rate, and the ambient electrical noise. The RS-422 format uses a

balanced pair of wires for transmission, and another pair for reception. The balanced

pair allows the data to be less susceptible to noise, and RS-422 signals can be sent up

to 2000 feet. The final standard, RS-485, is similar to RS-422 except that a single

pair of conductors is used for both transmitting and receiving data. This makes RS485 very attractive for network applications, where data is being shared between

more than 2 devices. A typical application might be an HVAC system that

communicates to various thermostats and to a control system over an RS-485 LAN.

The Crestron C2IR-8 plug-in control card can only transmit RS-232 one-way. The

C2COM-2 plug-in control card is capable of generating RS-232, RS-422 or RS-485

two-way signals. The ST-COM network device can generate RS-232, RS-422, or

RS-485 two-way communication data.

Crestron RS-232, RS-422, and RS-485 Equipment

C2IR-8

The C2-IR8 includes eight serial ports for one-way RS-232.

C2COM-2

The C2COM-2 is a Cresnet plug-in control card. It includes two bi-directional RS232/RS-422 (DB-9) ports with hardware handshaking.

CAUTION: The DB9 pin-outs on the C2COM-2 control card are not standard RS-

232. Connecting a straight-through serial cable may damage equipment. Refer to the

Crestron Cable database or contact Crestron for serial cable pin-out specifications.

ST-COM

The ST-COM network device can generate either RS-232, RS-422, or RS-485 data.

Limitations

RS-232 is limited to a wire length of 50ft (15 m) and a minimum of three conductors

(RXD, TXD, and Ground).

Each piece of equipment requires a specific (protocol) format for the data it is

expecting.

Programmer needs to be familiar with binary, hex, and/or ASCII in order to generate

the correct strings.

MIDI (Musical Instrument Digital Interface)

MIDI stands for Musical Instrument Digital Interface and is yet another serial

communications standard. As its name implies, MIDI is used most commonly for

allowing musical instruments to talk to one another. However, certain audio mixers,

Primer – DOC. 6253 Crestron SIMPL Windows • 11

Page 18

Software Crestron SIMPL Windows

which sometimes find their way into control system applications, use MIDI control.

From a programmer’s viewpoint, MIDI does not differ from RS-232, RS-422, or RS-

485. From a hardware standpoint, the CNX-MIDI card is required to generate the

proper control signals.

Crestron MIDI Equipment

CNX-MIDI

The CNX-MIDI interface card is a MIDI IN, OUT and THRU interface. It is used

with mixers and lighting equipment.

Analog Voltages

Certain devices, typically units such as camera pan-tilt heads, lighting control

systems, or voltage-controlled attenuators (VCAs) can be controlled with an analog

voltage. Programmable analog voltages can be generated using the CNXAO-8 card

or C2I-IO8. The latter card contains 8 Versiports capable of being programmed for

digital input/output or analog output.

Custom Crestron Interfaces

Certain devices have control interfaces that do not fall neatly into one control method

or category. In these instances Crestron has developed custom modules (either plugin control cards or network modules) to offer control. Examples of these include:

• Line-level audio attenuation (volume control)

• Pan/Tilt and Zoom/Focus control

• Slide projector control

• Keyboard/Mouse interface

• Lighting (dimmed and non-dimmed) and motor control

modules

For detailed information regarding the above, see the Crestron Catalog for exact

model names, and reference the User Guide for each module.

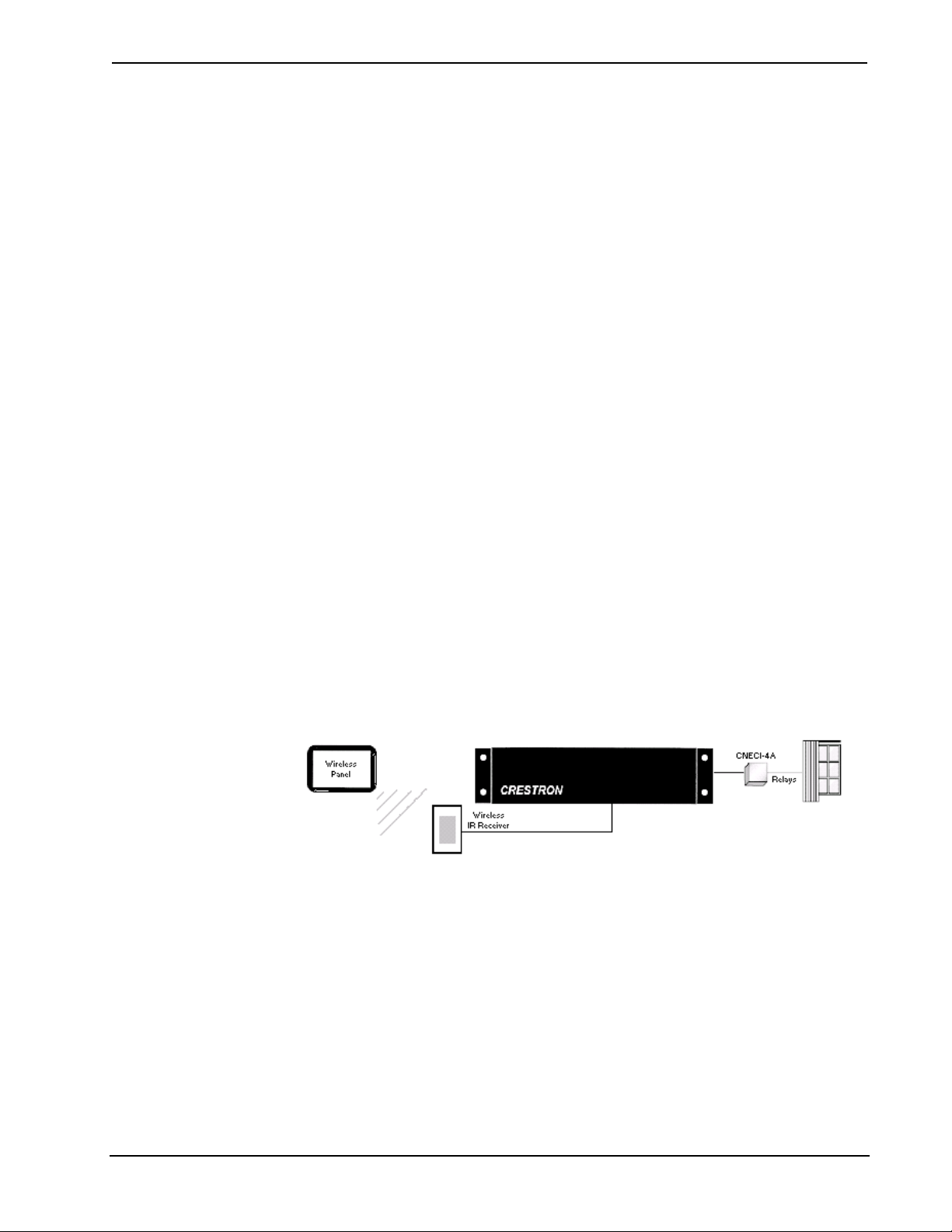

Cresnet

The Crestron network, or Cresnet, refers to the network topology that is used by

Crestron. The RS-485 bus is used to connect the control system to Crestron

‘network’ devices such as a CNECI-4A (electric control interface for AC powered

devices) or a CNSC-1A (slide projector interface). The RS-485 bus should be used to

locate devices remotely when the limitations of IR and RS 232 restrict the

installation plans. For example, IR must have line-of-sight to the device being

controlled. Serial communications (RS-232) is limited to 50ft. The Cresnet RS-485 is

a proprietary cable connection that can be connected to devices with up to 5,000 feet

of cable.

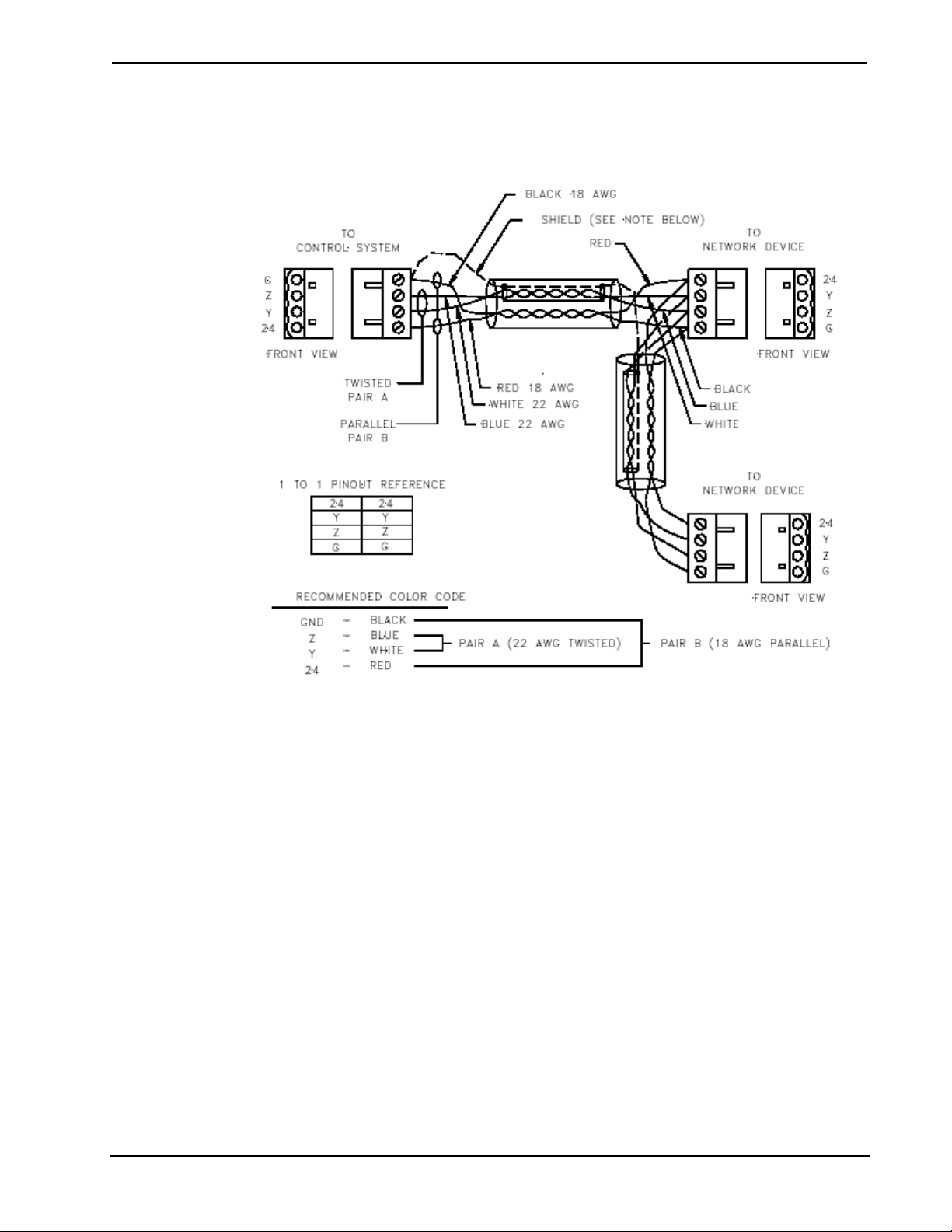

Cresnet cable consists of:

• Pair A #22 AWG, twisted pair with shield for data lines

• Pair B #18 AWG, twisted pair for power and ground

• PVC jacket

12 • Crestron SIMPL Windows Primer – DOC. 6253

Page 19

Crestron SIMPL Windows Software

Cresnet - Network Interconnect Specifications

CAUTION: POSSIBLE EQUIPMENT DAMAGE IF MISWIRED.

Do not power up system until all wiring is verified. Care should be taken to

ensure data (Y, Z) and power (24, G) connections are not crossed.

Ground shield at control system end only.

Model CNTBLOCK network terminal block is recommended for testing

purposes and convenience of wiring.

Primer – DOC. 6253 Crestron SIMPL Windows • 13

Page 20

Page 21

Crestron SIMPL Windows Software

SIMPL Windows Programming

Introduction to SIMPL

Crestron engineers are dedicated to the development of our products and the

interface with other manufacturer’s equipment. However, control systems need

individual programming in order to be customized for each installation. Crestron

control systems are programmed using SIMPL (Symbol Intensive Master

Programming Language).

SIMPL is an object oriented programming language designed for easy

implementation of your control system requirements. The objects that are used in

SIMPL are called symbols. Each symbol has a specific set of operations that it will

perform. The lines that connect symbols are called signals. The collection of SIMPL

symbols and their interconnection to one another is the program. Therefore, the

program is actually a picture created with objects (symbols) and lines (signals). This

type of picture is also referred to as a block diagram or flow diagram in other

applications. When planning an A/V installation, a block diagram indicating how all

of the system equipment is connected is essential to the installer. SIMPL allows the

programmer to develop a control program in a similar fashion. The collection of all

the symbols being used and the signals that connect them create a picture similar to a

block diagram. The development of a SIMPL program is intimately tied to the block

diagram of the A/V installation.

Symbol Categories

Writing a program in SIMPL is similar to wiring a circuit: you have to choose the

right components, and you have to wire them together properly. As just described, in

SIMPL the components are called symbols and the wires are called signals. Just like

in real-world electronics there are a multitude of symbols to choose from to

accomplish your goal, as you program more and more systems you will likely find a

subset of symbols that you use for most situations.

Symbols in SIMPL can be divided into two broad categories: device symbols and

logic symbols.

Device Symbols

Device symbols represent Crestron network control devices that can be included in a

program. They can be placed into or deleted from the program in the Configuration

Manager section of SIMPL Windows only. The Program Manager allows device

Primer – DOC. 6253 Crestron SIMPL Windows • 15

Page 22

Software Crestron SIMPL Windows

symbols to be connected, but not added or deleted. Device symbols are located in the

Device Library of the Configuration Manager.

Logic Symbols

While device symbols allow you to communicate with the outside world, logic

symbols allow you to make your program perform exactly the way you want. Logic

symbols can range from the very basic ones such as the AND, OR, or NOT symbols,

to those designed for very special applications. A more in-depth discussion of logic

symbols can be found in the Programming with Symbols section.

Symbol Properties

Although each symbol serves a special purpose, all symbols share some basic

properties. These are inputs, outputs, and parameters.

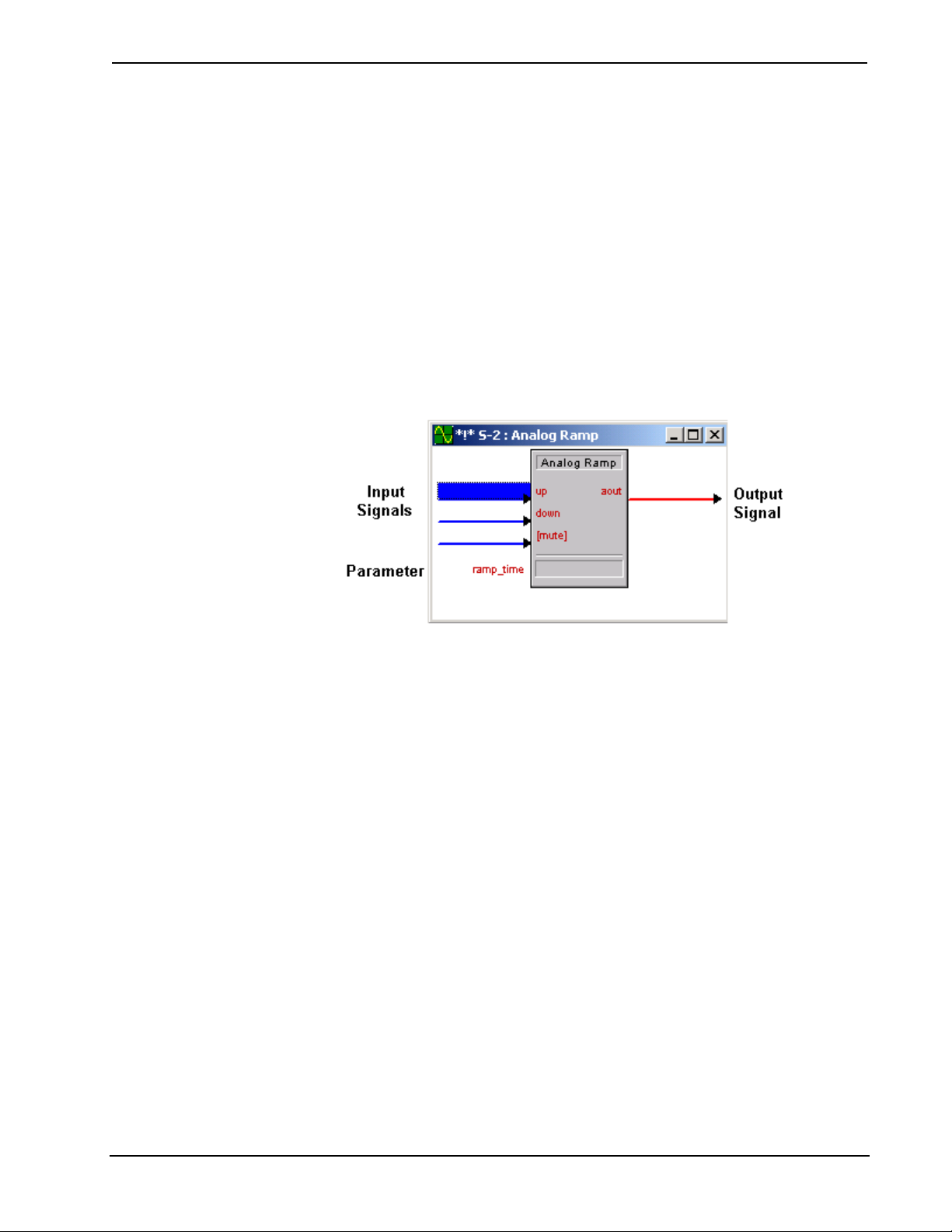

Example: Analog Ramp symbol

Inputs

Symbol inputs allow signals to be connected from other parts of the program.

Depending upon the symbol type, the current state of the input signal(s) may affect

one or more output signal(s). Some symbols have a fixed number of inputs, while

others can have a variable number of inputs, determined by the programmer based

upon need.

Outputs

Except for a few special cases, the ultimate purpose of a symbol is to modify the

states of its outputs. These outputs states will depend upon the symbol type, the

current or past states of the input signals, and the values of the parameters. Because

the symbol alone determines the states of its output signal(s), the symbol is

considered the driving source for the output signals. Depending on the nature of

signal, some outputs can have more than one driving source.

Similar to symbol inputs, the number of symbol outputs is fixed for some symbols,

or can be variable based on need for other symbols.

Parameters

Some symbols also have parameters, which are constant values that help determine

how the symbol behaves. For example, a symbol that delays an action for a specified

period of time would have a parameter determining how long the delay should be

for. The exact function of a parameter depends solely on the symbol type itself.

16 • Crestron SIMPL Windows Primer – DOC. 6253

Page 23

Crestron SIMPL Windows Software

For convenience, parameters may be expressed in a variety of formats (all of which

are directly related to one another). Although a parameter will default to one format

based upon the symbol type, you can alter the format by changing the format

specifier at the end of the value.

Listed below are the valid formats, where the character in parentheses represents the

format identifier.

• (d)ecimal

• (h)exadecimal

• (%) percentage of 65535

• (s)econds

• (t)icks – 1 tick = 1/100 seconds (2-Series); or 1/112.5 seconds (X-Series)

• (')character(') (single byte)

To set a parameter to a specific format, add the identifier after the value, i.e., 25%; if

the parameter is a single byte, place single quotes before and after the ASCII

character.

Parameters can also specify the time of day. Here the time of day is expressed in

military time followed by the “seconds” format specifier, as follows:

• HH.MM.SS.HSs

• MM.SS.HSs

• SS.HSs

• SSs

• .HSs

Where HH = hours; MM = minutes; SS = seconds; and HS = hundredths of a second.

For example, the parameter 20.03.05s signifies a time value of 20 minutes, 3

seconds, and 5 hundredths of a second. When using this notation you can leave out

the larger units if you are not using them, thus "3.00.00s" would mean 3 minutes, 0

seconds, and 0 hundredths of a second (it would NOT mean 3 hours).

Depending on the function of a symbol, a parameter can be signed or unsigned.

Signed values range from–32768 to +32767; unsigned values range from 0 to 65535.

Percentages can also be expressed as negatives, i.e., -25% = 25% of 65536, or

16384. (-16384 = 49152d). Thus a parameter of -25% is the same as 49152d. Refer

to the SIMPL Windows help file for further information on valid parameter values.

NOTE: Parameters are constants whose value must be known at compile time. The

value of the parameter cannot be changed while the program is running (e.g. a signal

cannot be assigned to a parameter). To change a parameter, the program must be

changed and recompiled.

Signal Types

The concept of the signal has already been broached. Signals are the elements used

in your program to interconnect the various device and logic symbols that comprise

your program. However the discussion of signals does not end there. For starters,

signals can be one of three types: digital, analog, or serial. For any given signal, the

signal type is determined by the driving source. If the symbol that drives the signal

Primer – DOC. 6253 Crestron SIMPL Windows • 17

Page 24

Software Crestron SIMPL Windows

has an analog output, then the signal connected there will by definition become an

analog signal. The three signal types are defined in more detail below:

Digital Signals

Digital signals are the most common in the SIMPL language, and a typical program

will be comprised of between 95% and 100% digital signals. This type of signal can

have only two states, often referred to as on/off. Other common descriptors are

high/low, active/inactive, or 1/0. This transition is called the rising edge, or positive

edge. Generally speaking, actions in SIMPL program are triggered by a digital signal

going from the low to the high state. Although most actions are edge-triggered,

others can be level-triggered (based upon current state, not just last transition). For

example, a Toggle symbol is edge-triggered; it drives its digital output high and low

with each rising edge of its input. In contrast, the Buffer symbol is level-triggered; its

‘enable’ digital input signal must remain high for signals to flow.

When looking through the symbol library reference, take note as to which symbols

are edge-triggered, and which are level-triggered. You can find this information by

selecting the symbol and pressing F1, which will open the context-sensitive help

window for the symbol.

As stated previously, the type of signal is determined by its driving source. In many

applications there are signals that have multiple driving sources. Such signals are

said to be jammed. As a general rule, digital signals should not be jammed; that is,

they should have only one driving source. But there are two important and common

exceptions: system inputs (such as button presses), and the outputs of Buffer

symbols. These exceptions can be very useful in applications where functionality

must be shared across several user interfaces. For example, a DVD player can be

controlled by a touchpanel as well as by a remote control transmitter.

In SIMPL Windows, digital signals are represented by a blue line.

Analog Signals

Analog signals are represented with 16-bit numbers, and thus can have values

between 0 and 65535 (2

can vary continuously in value, in the same manner as a parameter such as volume or

temperature. This property makes analog signals useful for controlling devices that

do not have discrete on/off settings, such as volume controllers, pan/tilt head

controllers, and lighting dimmers.

Unlike digital signals, analog signals by their very nature may have multiple driving

sources. Thus analog signals are said to be jammable. In practice, whenever more

than one symbol is driving the same analog signal, the symbol that lasts changes the

signal's value takes precedence. Typical applications for analog signals are volume,

lighting, and temperature levels, as well as advanced string manipulation.

In SIMPL Windows, analog signals are represented by a red line.

16

- 1). This means that unlike digital signals, analog signals

Serial Signals

Serial signals facilitate the transmission of serial data (i.e. strings of characters).

These signals can be generated by incoming data on a COM port or by a symbol that

has a serial output. Similar to analog signals, serial signals are jammable; thus

multiple symbols can be used to generate strings on a single signal. By default, serial

signals are transient, meaning that the data on a serial signal is only valid for the

logic wave in which it was created (logic waves are described below). Symbols such

as the Make String Permanent symbol allow serial strings to be retained in memory.

In SIMPL Windows, serial signals are represented by a black line.

18 • Crestron SIMPL Windows Primer – DOC. 6253

Page 25

Crestron SIMPL Windows Software

Example Signal Colors

Some signals are ambiguous, meaning that the signal type is determined by the

driving source. For example, the inputs and outputs of a Serial Buffer symbol can be

either serial or analog. The ambiguous signal is resolved when the signal is

connected to an analog or serial symbol. Ambiguous signals should be resolved

before the program is finalized; otherwise a compiler error will be generated.

In SIMPL Windows, ambiguous signals are represented by a green line. Once they

are resolved, the line color changes to blue (digital), red (analog) or black (serial).

Special Signals ‘0’ and ‘1’

The special signals ‘0’ and ‘1’ are used to force a value on a signal. ‘1’ is a digitalonly signal whose value is always logic high. A digital signal named ‘0’ will always

be logic low. A ‘0’ on an analog signal forces the signal to a constant value of zero.

On a serial signal, a ‘0’ will result in no string being transmitted.

Logic Waves and Logic Solutions

A logic wave is a processor unit of measurement defined as the elapsed time

between the moment a signal's state changes and the moment that all symbols

connected to that signal have been evaluated. This is analogous to the term

"propagation delay" used when describing digital hardware. Although logic waves

are not expressed in real-world time units (i.e., milliseconds) due to the fact that the

actual time is indeterminate at compile time, SIMPL guarantees that all symbols

have a propagation delay of exactly one logic wave.

Note that some symbols do not always conform to this rule. Examples are time-based

symbols such as Delay and One-Shot. While the propagation delay of the Delay

symbol is determined solely by its parameter values, a One-Shot will propagate in a

single logic wave when its trigger input goes high. However, the falling edge of the

input has no effect, and the symbol's output will go low only after the specified time

has expired.

One or more logic waves make up a logic solution.

A logic solution is defined as the time it takes, starting with an external impetus, for

the SIMPL logic processor to evaluate all symbols to the point at which all signals in

the program have reached a "steady state" that is, the time required for all signals to

settle to stable, unchanging states. The length of a logic solution can vary at runtime,

and can be expressed in logic waves, i.e., "when this button is pressed, the

subsequent logic solution should take 6 logic waves".

It is important to realize that time-based (scheduled) events do not occur during a

logic solution, except to serve as the impetus to initiate one. Thus using an Oscillator

symbol would not cause an endless logic solution. Instead, each time the output

signal of the Oscillator changes, it triggers a new logic solution that runs until all

affected signals arrive at their final states. On the other hand, endless logic solutions

can be created by connecting logic incorrectly (i.e., routing the output of a NOR

symbol back into its input). This situation should obviously be avoided.

Primer – DOC. 6253 Crestron SIMPL Windows • 19

Page 26

Software Crestron SIMPL Windows

Programming with User Interfaces

The heart of any well-designed control system is the user-interface. This is the link

between the end-user and the control system itself. Regardless of how cleverly

programmed, or technically savvy a given system is, if it lacks a quality userinterface it is unlikely that the system will be appreciated, or used to its full potential.

Crestron control systems offer an impressive array of user interface options, from the

top-of-the-line Isys TPS touchpanels, to cost-effective and simple wired button

panels. No matter what type of interface(s) you are using in your system, this section

will help explain how to use them in your program.

Button Presses

In a program button presses (whether from a touchpanel, wired or wireless button

panel, or other interface) are associated with signals. Since for a given device not all

buttons may be used, unused buttons are not given signal names. When a button is

pressed, the corresponding signal is asserted in the control system program. When

the button is released, that same signal is de-asserted. See the signal-state diagram

below for a graphical representation of this.

Simplified Button-Press

Note that in this case the button alone determines the state of the signal. That is,

when the button is pressed, the signal is high, and when the button is not pressed, the

signal is low. Because of this the button is the driving source for that signal. Since a

button can have only two states, high or low, the signal that it drives can only have

two states, thus this signal is a digital signal.

In most cases digital signals are limited to one driving source. That is, it is illegal to

have two different symbols driving the same digital signal. However, there are two

important exceptions to this rule. One concerns the Buffer symbol, which will be

described later. Button presses are another exception, in that a single signal may be

driven from multiple buttons. This can be very convenient, especially in cases where

you want to share functionality across several user interfaces. For example, the same

volume up and volume down controls may be accessible from a touchpanel as well

as from a wireless remote. Instead of having to create different signal names for each

case, and then using an OR symbol to combine the functionality, it is legal (and

desirable) to use the same signal names in both cases.

20 • Crestron SIMPL Windows Primer – DOC. 6253

Page 27

Crestron SIMPL Windows Software

Button Feedback

User-interfaces that support 2-way communication (any interface except for 1-way

wireless transmitters) also support button feedback. This term is used to describe the

button's active appearance. For button panels, feedback is usually indicated with a

LED located inside the button housing. For touchpanels, feedback can vary, and

often includes changing the frame and text color, along with a simulated 3D

appearance.

Visual Button Feedback

Feedback is vitally important to a good user interface design. For one thing, feedback

lets the user know that a button press has registered with the system. This is

especially important for touchpanels, where the user cannot tell from feel alone

whether they pressed in the right spot. Another purpose feedback serves is to provide

information to the user about the current state of the system (that the VCR is

currently in PLAY mode, for example). In this case, care should be taken to make

the feedback be as accurate as possible, as inaccurate or vague feedback will only

serve to confuse the user.

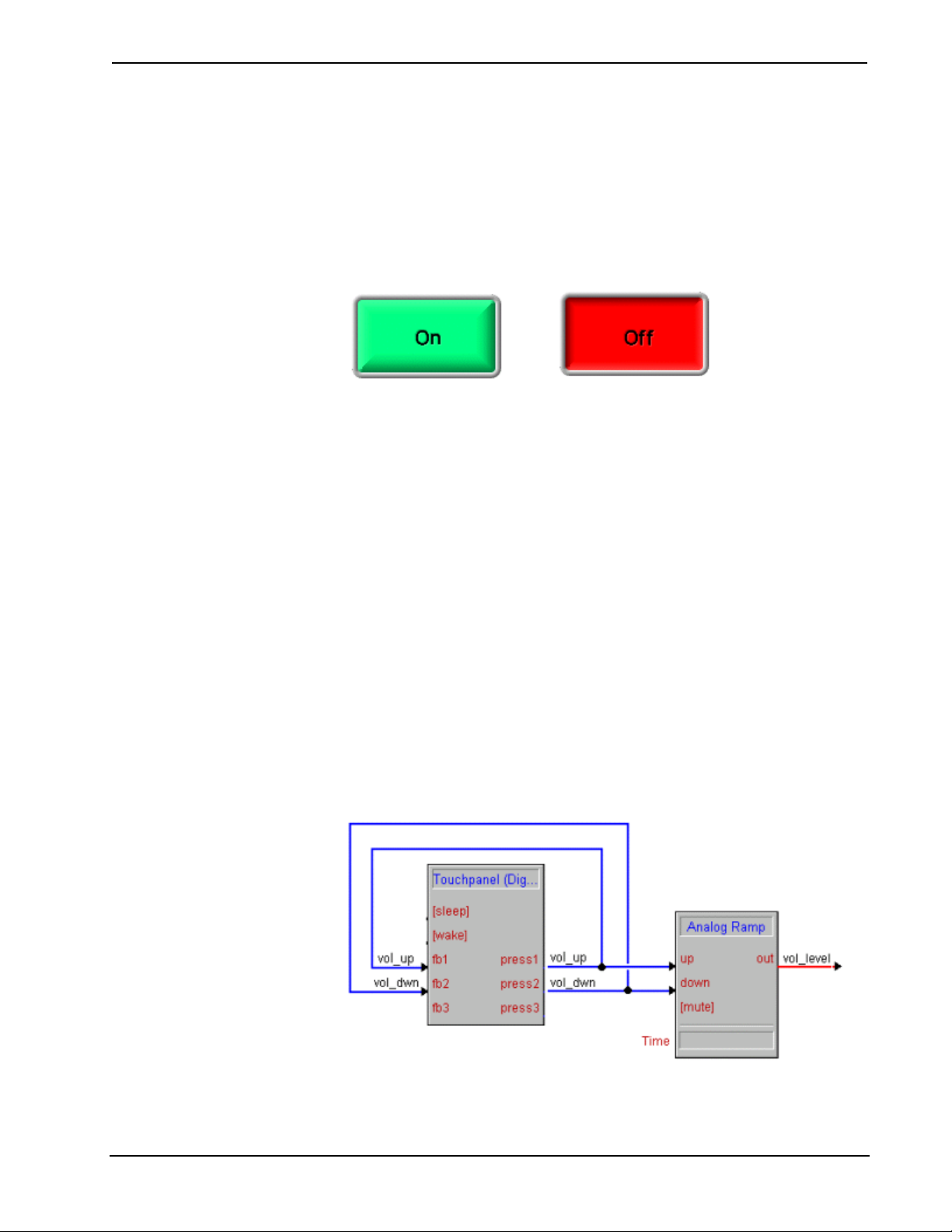

Volume Momentary Feedback

Whether a button is pressed or not is determined by the user (or the user's finger to

be exact!) but it is a signal that decides whether a button is shown in its feedback

state or not. Therefore, the signal is the driving force for the button feedback. Where

the signal comes from depends upon what type of feedback is needed. The most

basic type of feedback is called momentary feedback. Momentary feedback causes

the button to display in its feedback state only when the button itself is pressed. This

type of feedback makes sense for functions that occur only while the button is

pressed. For example, volume up and volume down buttons typically receive

momentary feedback because the volume level only changes (goes up or down)

while the corresponding button is pressed.

Momentary feedback can be achieved simply by connecting the button press signal

name to the feedback signal for the same button, as shown in the diagram below.

Primer – DOC. 6253 Crestron SIMPL Windows • 21

Page 28

Software Crestron SIMPL Windows

Certain buttons may call for more complex feedback. For example, a volume mute

button may alternately turn the mute on and off. To indicate this with feedback, the

button should display in the feedback state when the mute function is on, and turn off

when mute turns off. Clearly, momentary feedback will not do the trick here, so we

must use logic symbols to generate the desired behavior. This example shows how to

do this using the Toggle symbol.

Volume Mute – Toggle Feedback

An even more elaborate form of feedback is possible when there is 2-way

communications between the control system and a device being controlled. In this

case it is sometimes possible (and desirable) to show feedback based solely upon

information received from the device (NOTE: this information is also called

feedback. Don't confuse this with button feedback). For example, suppose you are

controlling a switcher, which allows you to choose one of 4 video sources. If the

switcher itself sent information back to the control system detailing which source

was currently selected, your program could use that information to highlight the

button representing the selected source. This would guarantee that the feedback was

always correct, even if a user performed the switch from the switcher itself, and not

via the control system.

Subpages (touchpanels only)

Subpages are powerful objects available for touchpanels only. Subpages are in many

ways similar to standard touchpanel pages, in that they may contain buttons, text,

graphics, etc. However, subpages ordinarily do not take up the entire display screen

area. Instead, a subpage often defines a small area with buttons serving a specific

function, such as VCR control buttons. A given subpage can then be designed to

22 • Crestron SIMPL Windows Primer – DOC. 6253

Page 29

Crestron SIMPL Windows Software

appear on top of a standard page at any time and then disappear when no longer

needed, similar to a dialog box in Windows or Macintosh computers.

In order to make the implementation of subpages as flexible as possible, they are

controlled (i.e. shown or hidden) via touchpanel feedback signals. That is, whenever

a subpage is needed, a subpage reference is created at the exact location where it is to

appear. This subpage reference is simply a link to the subpage object that was

created previously. Each subpage reference is then be assigned a join number, and

the feedback signal for that join number will determine whether or not the subpage

appears. As long as the signal is high, the subpage will appear, and will disappear as

soon as the signal goes low. The example below shows the logic necessary to control

a volume subpage from a single button, allowing the subpage to be toggled on or off

as necessary.

Analog displays (touchpanels only)

VisionTools Pro-e provides a number of objects for different types of analog

displays. For example, if you want to create a bargraph, you can go to the

VisionTools Pro-e toolbar, select the Gauge (bargraph) object and scale it to the size

you want. You would then assign an analog feedback join number to the gauge that

represents the analog channel that the gauge will display the value of.

VisionTools Pro-e provides several analog objects:

Serial Send to touchpanel text fields

1. Gauges (bargraphs)

2. Sliders (bargraphs that also can be moved via touch)

3. Digital gauges (display an analog signal in number format)

4. Percentages (display analog signals in %)

5. Time (display analog signals in time format: HH:MM:SS)

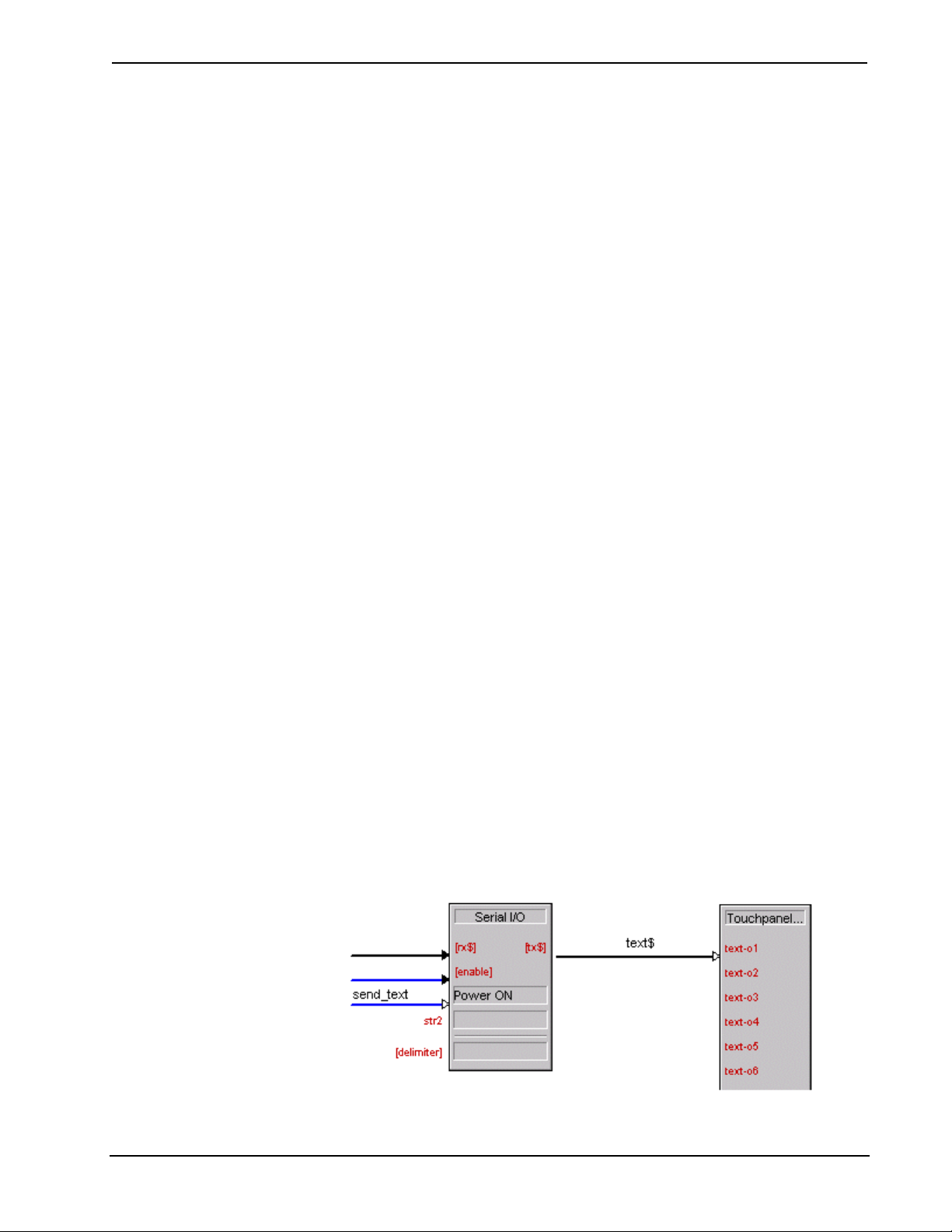

Indirect text (touchpanels only)

Indirect text is a feature where the particular text string that appears on a touchpanel

button can change, depending on the signal state. For example, when the user

touches a button it might read “Power ON”, and when touched again it might read

“Power OFF”.

In SIMPL Windows, touchpanel definitions have built-in serial feedback signals for

defined for indirect text fields. These text fields accept serial data signals directly.

Primer – DOC. 6253 Crestron SIMPL Windows • 23

Page 30

Software Crestron SIMPL Windows

Building a Program with SIMPL Windows

Programming Process

Identify the equipment that is going to be controlled.

Programmers should prepare documentation that lists all the equipment that is to be

controlled.

Determine how the equipment is going to be controlled.

Knowing how the various pieces of equipment are going to be controlled is very

important. This will let the programmer know what control devices (Network

Module, Control Card, or other) will be necessary to control the equipment.

For example: IR control devices require a C2-IR8 plug-in card.

Configure the system in SIMPL Windows

Configure the system by building it in the Configuration Manager. Locate the control

system in the Device Library. Drag and drop the control system into the System

Views window. Complete the system configuration by adding interfaces, network

modules, control cards, and other devices. All the necessary Crestron hardware

should be included in your configuration.

Program the system in SIMPL Windows

After the system is built by adding all the necessary Crestron hardware, begin

programming the system by working in the Programming Manager. Program each

button function from touchpanels and other user interfaces. Begin by naming the

output signals from the user interface. Select the symbol(s) needed for the program

in the Symbol Library. Drag and drop the symbols into the Program View window.

Assign signal names to symbol inputs and outputs in the Detail View window.

Basic Programming Rules

1. Symbols can be either device symbols or logic symbols.

2. Logic symbols perform an operation that manipulates signals.

3. Logic symbols only change states of output signals.

4. Signals connect symbols.

5. Digital signals should have only one driving source. Only one symbol in the

program should list the signal as an output.

NOTE: There are some exceptions to digital signals having only one driving source.

The exceptions are button presses and buffer outputs.

Build a System

The SIMPL Windows Configuration Manager allows you to do the following:

• Select the control system.

• Select additional Crestron hardware required for the installation. This can

include plug-in control cards, network control modules, touchpanels, and

wireless remotes.

24 • Crestron SIMPL Windows Primer – DOC. 6253

Page 31

Crestron SIMPL Windows Software

• Select user devices made by third-party manufacturers. These are usually

the devices being controlled and can include CD players, DVD players, TVs

and any other equipment the end user interfaces with using the control

system.

• Configure the devices by specifying which units are connected to which

control cards or network modules. Assign ports, network addresses and IP

information, specify communication settings and document the system with

connection/installation notes.

• Specify what VisionTools Pro-e projects are required for the system.

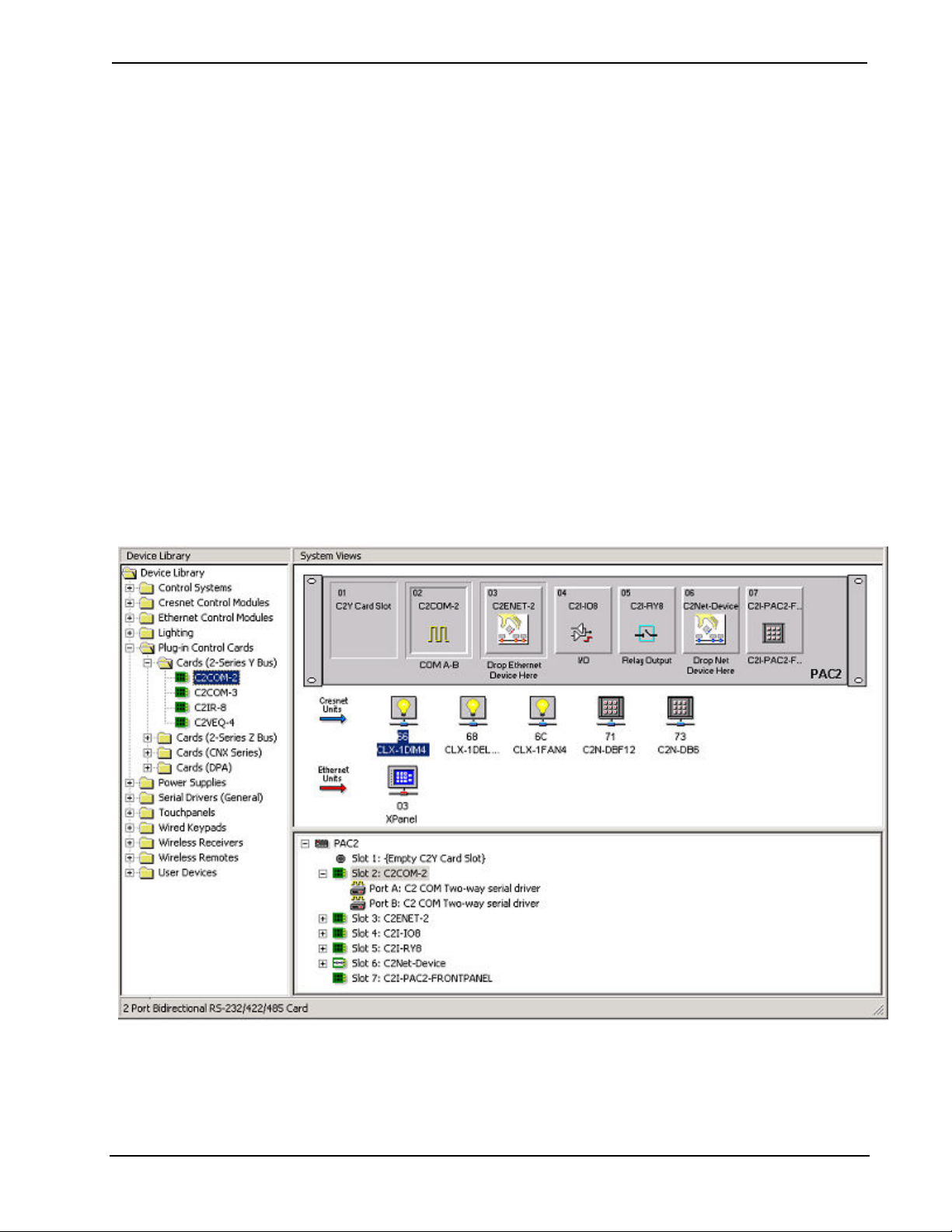

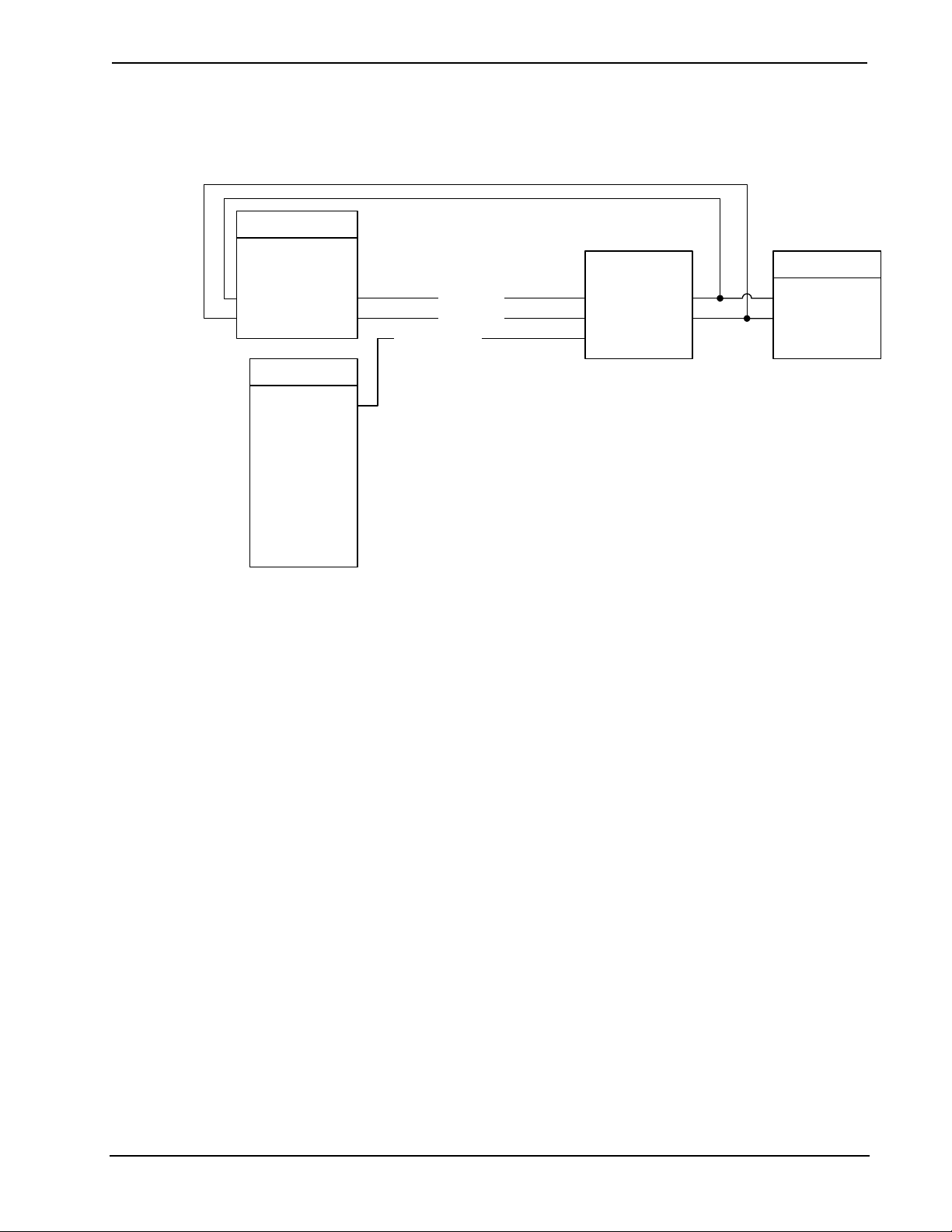

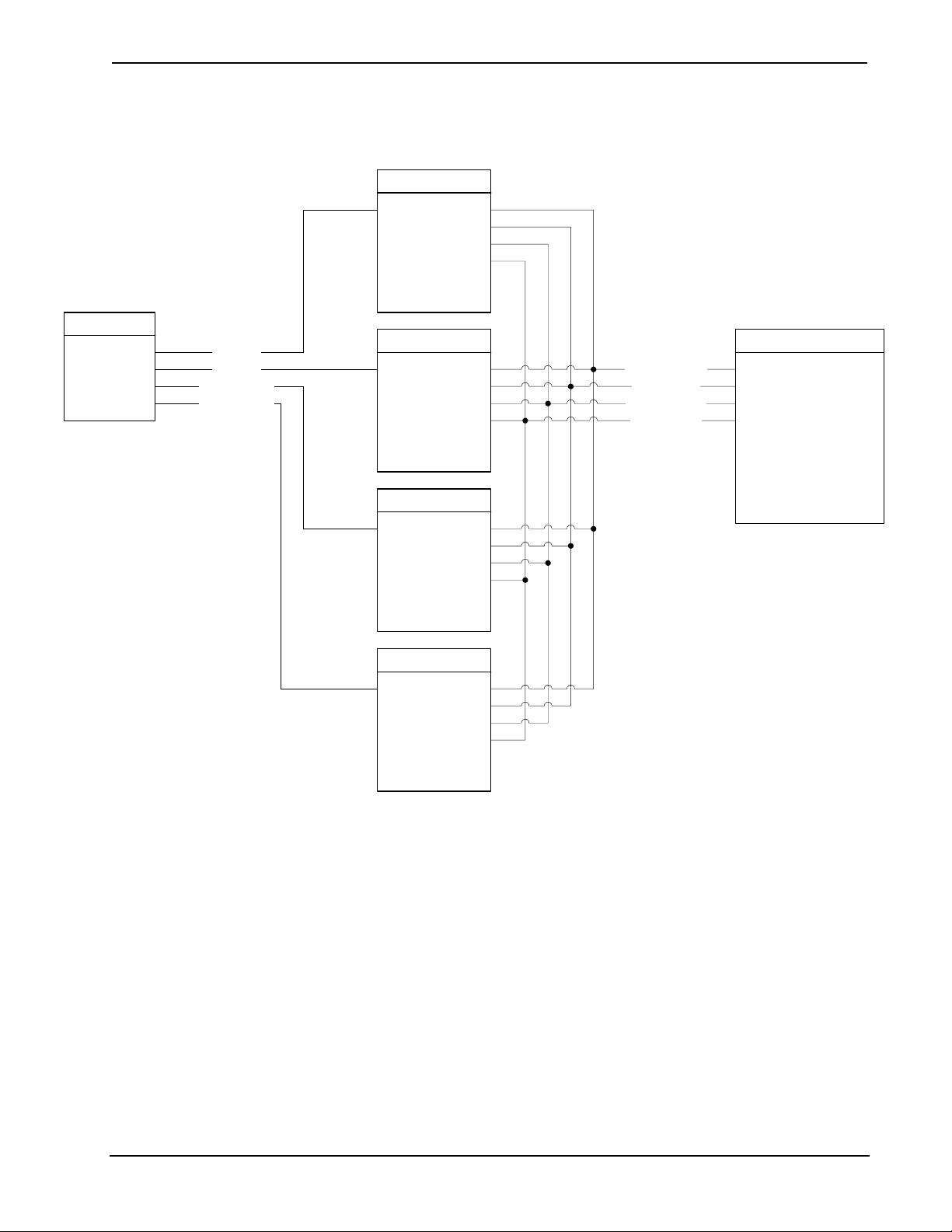

The Configuration Manager screen consists of three panes: a Device Library and

two System Views.

The Device Library is a tree with folders for all Crestron and third-party hardware,

including Crestron control systems, Cresnet and Ethernet control modules, plug-in

control cards, touchpanels, and user devices. You can view hardware by opening and

closing the folders in the tree. As you select devices the SIMPL Windows status bar

will display a description of the device.

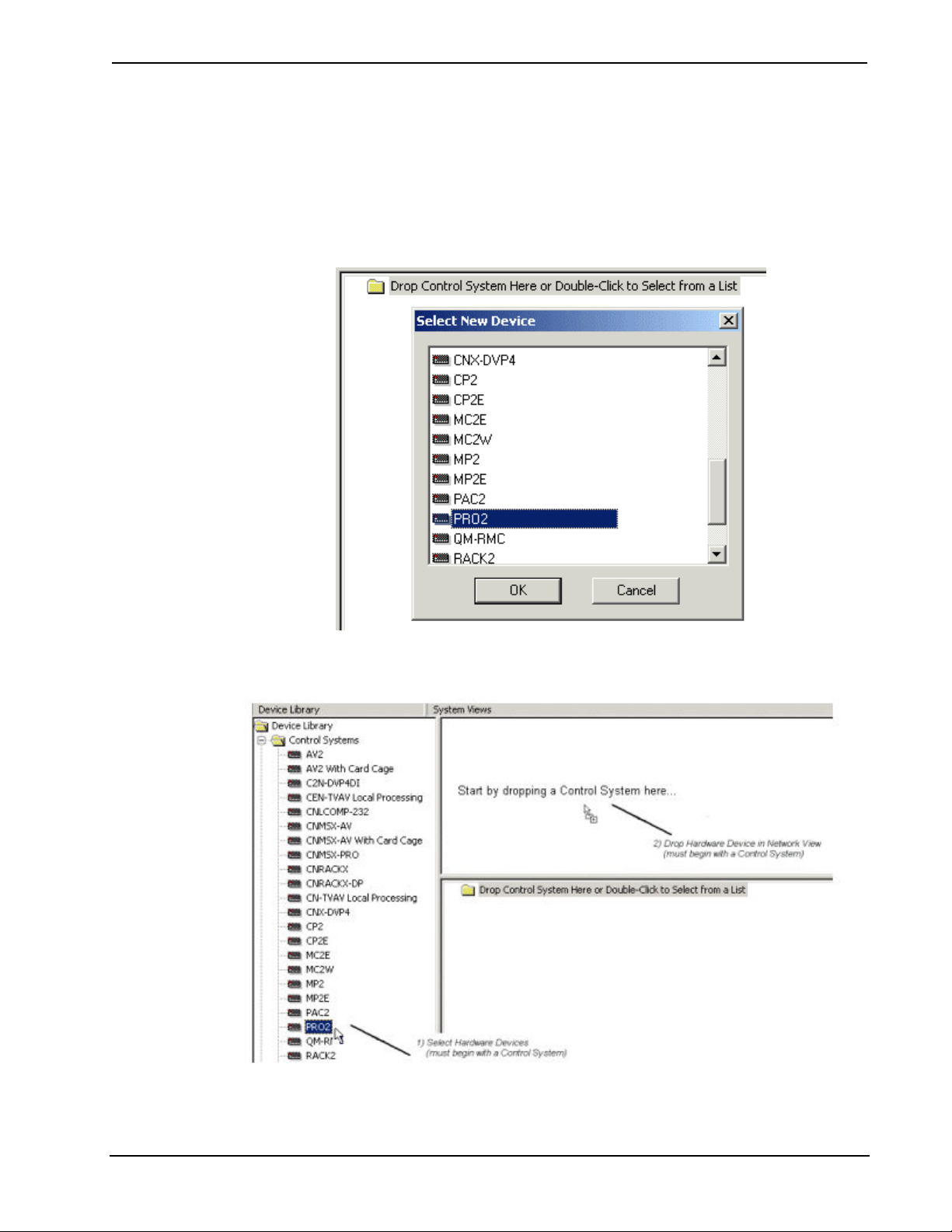

The top System View pane is a "picture view" of the control system and any Cresnet

or Ethernet devices you add to the program. The lower System View is a tree of the

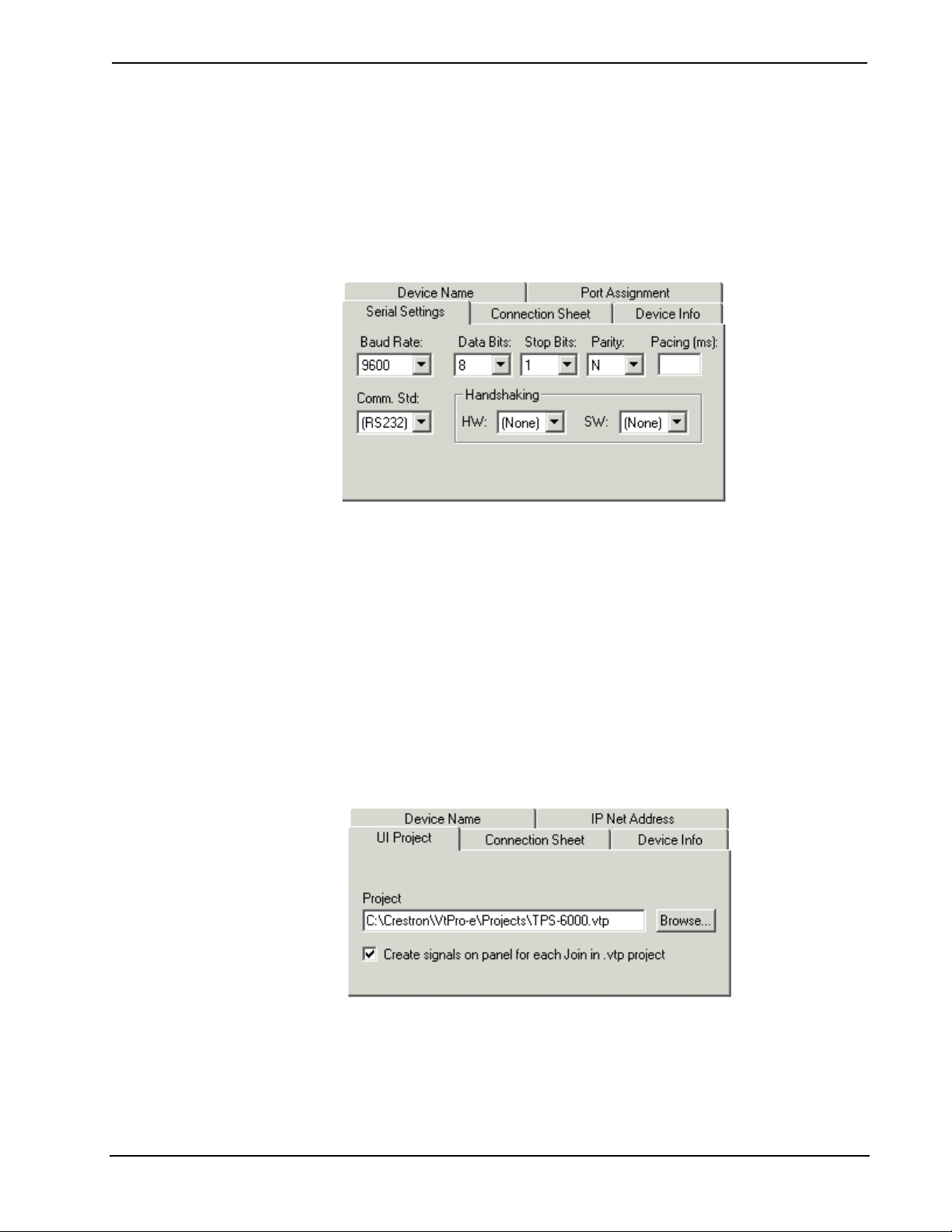

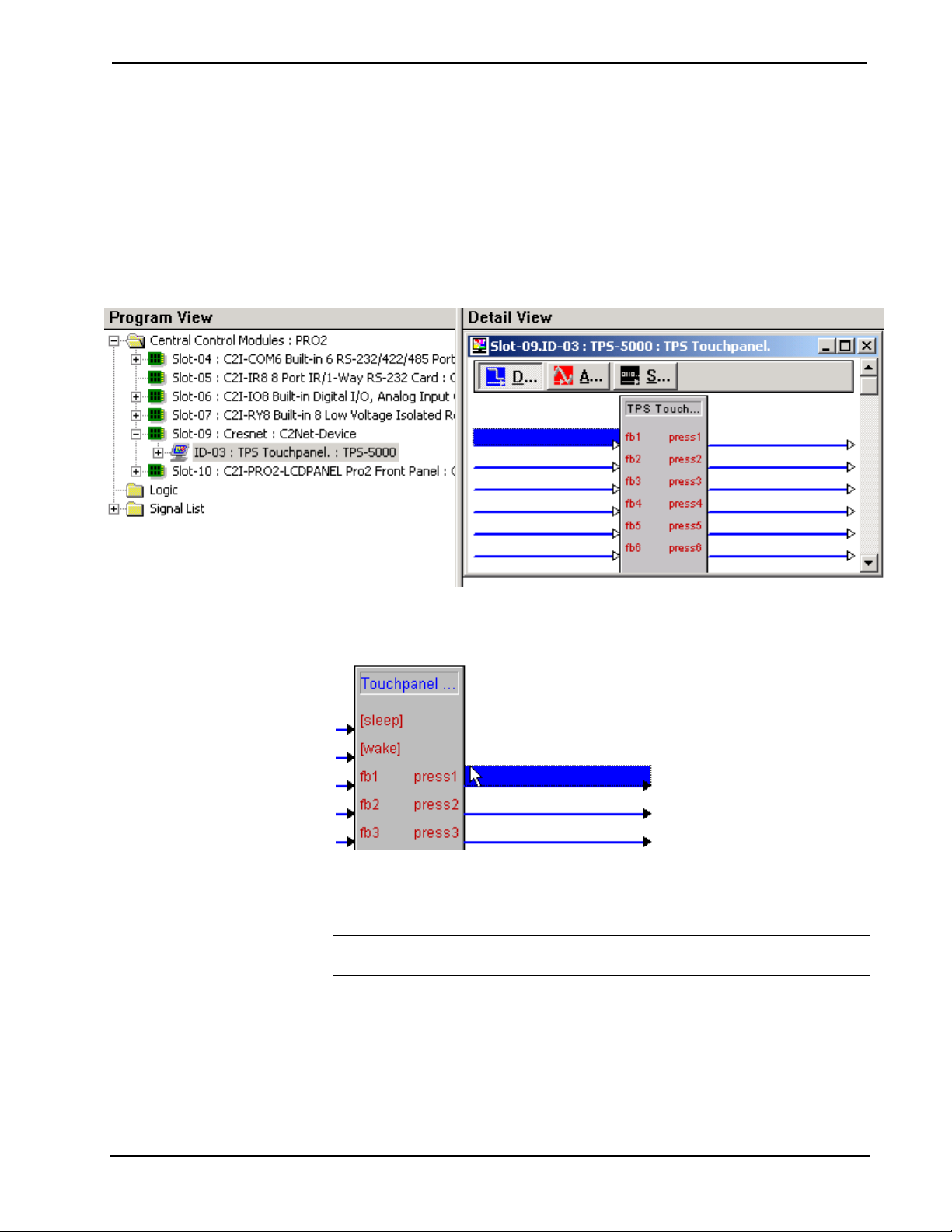

control system with numbered slots that you can open and close to view the network