Page 1

DIN-TSTAT-FCU

DIN-Rail Heating and Cooling Fan-Coil

Thermostat

Setup and Commissioning Guide

Crestron Electronics, Inc.

Page 2

Crestron product development software is licensed to Crestron dealers and Crestron Service Providers (CSPs) under a limited non-exclusive,

non-transferable Software Development Tools License Agreement. Crestron product operating system software is licensed to Crestron

dealers, CSPs, and end-users under a separate End-User License Agreement. Both of these Agreements can be found on the Crestron

website at www.crestron.com/legal/software_license_agreement.

The product warranty can be found at www.crestron.com/warranty.

The specific patents that cover Crestron products are listed at www.crestron.com/legal/patents.

Certain Crestron products contain open source software. For specific information, please visit www.crestron.com/opensource.

Crestron, the Crestron logo, and Cresnet are either trademarks or registered trademarks of Crestron Electronics, Inc. in the United States

and/or other countries. Modbus is either a trademark or registered trademark of SCHNEIDER ELECTRIC USA, INC., in the United States

and/or other countries. Windows is either a trademark or registered trademark of Microsoft Corporation in the United States and/or other

countries. Other trademarks, registered trademarks, and trade names may be used in this document to refer to either the entities claiming the

marks and names or their products. Crestron disclaims any proprietary interest in the marks and names of others. Crestron is not responsible

for errors in typography or photography.

This document was written by the Technical Publications department at Crestron.

©2017 Crestron Electronics, Inc.

Page 3

Contents

Introduction 1

Supported FCUs............................................................................................................ 1

Specifications ................................................................................................................ 1

Port Descriptions ........................................................................................................... 2

Safety Notes .................................................................................................................. 3

Device Parameters 4

Regulation Algorithms 6

FCU Wiring and Control 7

Initialization .................................................................................................................... 7

Water temperature ......................................................................................................... 7

Initial Operating Parameters ........................................................................................... 8

Modulated 0-10 Vac Valve ............................................................................................. 8

Modulated OP-CL 24 Vac Valve .................................................................................. 10

Spring-loaded 24 Vac Valve......................................................................................... 12

Modulated OP-CL 230 Vac Valve ................................................................................ 14

Spring-loaded 230 Vac Valve....................................................................................... 16

1-2 Stage Direct-expansion System ............................................................................ 18

Fan Speed Control ...................................................................................................... 20

Alarms 21

Temperature Probes 21

Cresnet® Communications 22

Port ............................................................................................................................. 22

Communication ........................................................................................................... 22

Joins ............................................................................................................................ 23

Light and Poll ............................................................................................................... 24

AUX Port 25

Port ............................................................................................................................. 25

Communication ........................................................................................................... 26

Registers ..................................................................................................................... 27

Parameters .................................................................................................................. 27

USB Port 27

Setup and Commissioning Guide – DOC. 8207A Contents • i

Page 4

Accessing USB Port .................................................................................................... 27

USB Driver Installation Procedure ................................................................................ 29

Install the DIN-TSTAT-FCU Configuration Tool 31

Using the DIN-TSTAT-FCU Configuration Tool 34

Menu Overview ............................................................................................................ 34

File Menu .............................................................................................................. 34

ComPort Menu ..................................................................................................... 35

Device Menu ......................................................................................................... 35

Configure the DIN-TSTAT-FCU .................................................................................... 40

Toolbar Bar ........................................................................................................... 40

Status Bar ............................................................................................................. 40

Main Screen .......................................................................................................... 40

Monitoring ............................................................................................................. 41

Variable Forcing .................................................................................................... 42

Troubleshooting 42

Error Code ................................................................................................................... 42

Troubleshooting ........................................................................................................... 43

ii • Contents Setup and Commissioning Guide – DOC. 8207A

Page 5

Electrical specifications

Binary outputs

Valve outputs

Binary inputs

Analog inputs

DIN-TSTAT-FCU: DIN-Rail Fan-Coil

Thermostat

Introduction

The Crestron® fan-coil controller DIN-TSTAT-FCU is a universal 2-pipe, 3-speed fan-coil unit

(FCU) controller designed for use in two-pipe applications. A wide range of I/O resources

and various FCU types are supported.

Supported FCUs

The DIN-TSTAT-FCU supports the following FCU types:

Type 1 - Modulated 0-10 Vac Valve

Type 2 - Modulated OP-CL 24 Vac Valve

Type 3 - Spring-loaded 24 Vac Valve

Type 4 - Modulated OP-CL 230 Vac Valve

Type 5 - Spring-loaded 230 Vac Valve

Type 6 - 1-2 Stage Direct-expansion System

Specifications

The specifications for the DIN-TSTAT-FCU are listed below.

DIN-TSTAT-FCU Specifications

SPECIFICATION DETAILS

Power supply

Main: 230 Vac ±10%, 50 Hz, 15 W max

Cresnet: 24 Vdc ±10%, 0.5 W max

3 relays 16 A for fan control*

2 relays 16 A for valve or compressor

control**

0–10 Vdc

Modulated OP-CL triac; 24 Vac, 6 W valves

4 potential free inputs

2x NTC temperature probe: 10 K, 12 K,

15 K, and 20 K supported

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 1

(continued on the following page)

Page 6

Communication channels

Primary port

Auxiliary port

USB mini

Operating temperature

Storage temperature

Operating humidity

Protection degree

Mounting

Dimensions

Weight

DIN-TSTAT-FCU Specifications (continued)

SPECIFICATION DETAILS

Cresnet

RS-485, Modbus® protocol master

Service port for programming

-10–55 °C

-40–85 °C

95% max RH noncondensing

IP20

DIN rail, for indoor use only

161.6 x 90 x 62.2 mm

600 g

* Only one fan speed relay can be active at the time.

** If one stage relay is active at one time, the maximum current is 16 A; if two stage relays are active at one time,

the sum of both currents must not exceed 20 A and the current through one relay must not be greater than 16 A.

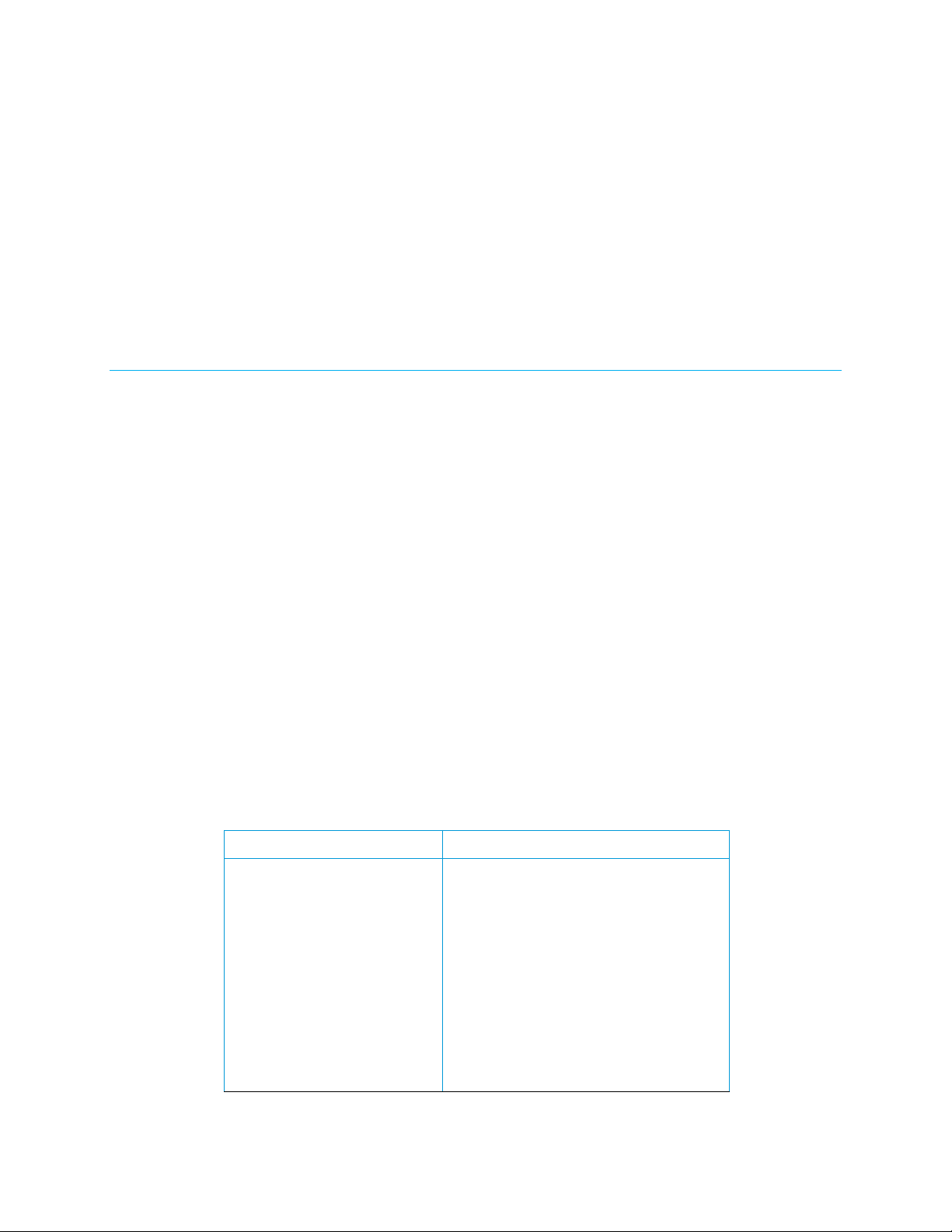

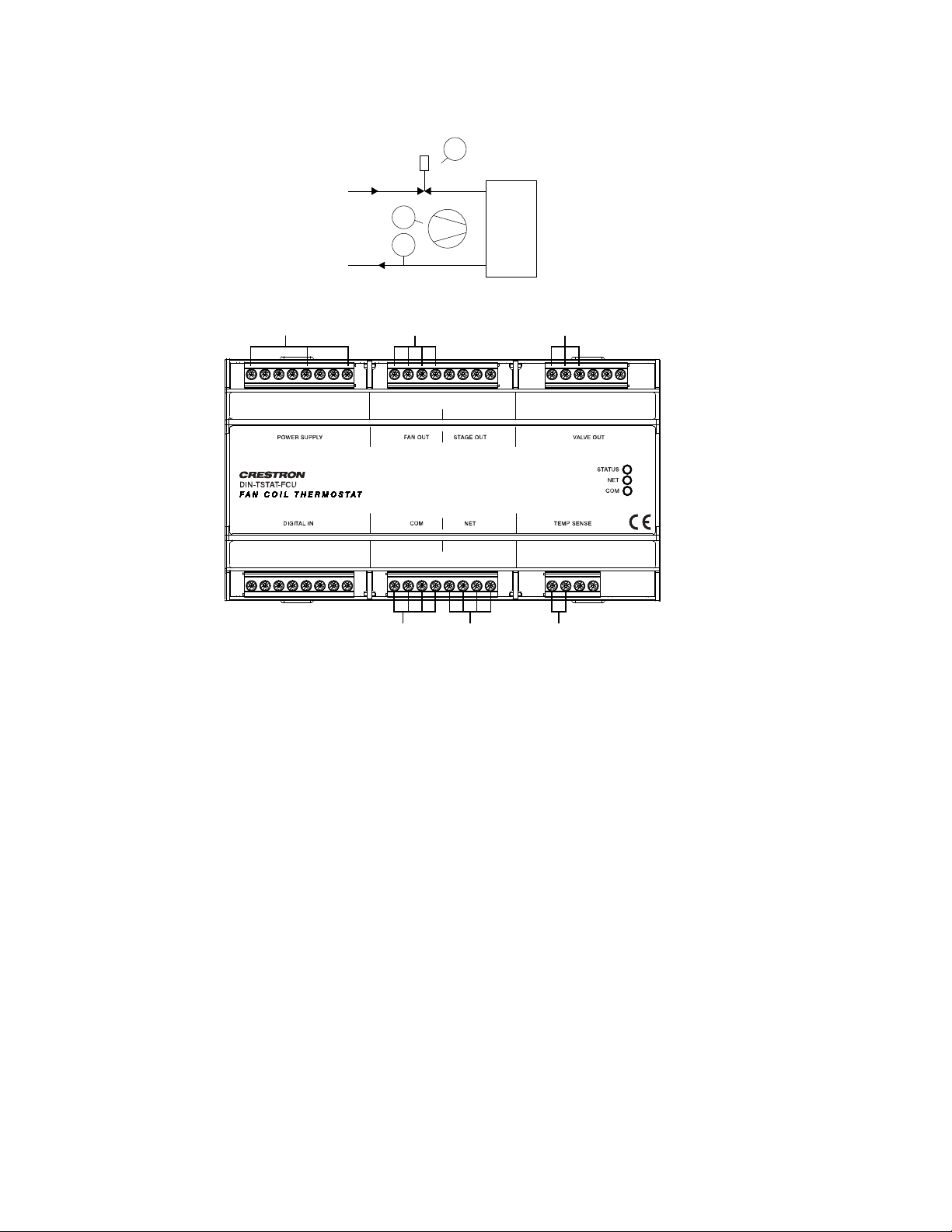

Port Descriptions

The illustration below depicts the port arrangements of the DIN-TSTAT-FCU. The following

table lists a description of the ports.

2 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 7

E

External protective earth

4 DI0

Digital input 1

NC

No connection

CDI

Digital inputs common terminal

N

Main power supply - Neutral

DI1

Digital input 2

N

Main power supply - Neutral

CDI

Digital inputs common terminal

N

Main power supply - Neutral

DI2

Digital input 3

L

Main power supply - Live

CDI

Digital inputs common terminal

L

Main power supply - Live

DI3

Digital input 4

L

Main power supply - Live

CDI

Digital inputs common terminal

L1

Common for fan supply

5 EP

AUX port power supply output

FL

Fan speed low

A AUX port + communication line

FM

Fan speed medium

B AUX port – communication line

FH

Fan speed high

G AUX port ground

NC

No connection

24

Cresnet power supply input

L2

Common for stage supply

Y Cresnet + communication line

ST1

Stage 1 relay output

Z Cresnet – communication line

ST2

Stage 2 relay output

G Cresnet ground

OP

Valve open triac output

6 TS1

NTC probe 1 input

24V

24Vac power supply output

G Ground

CL

Valve close triac output

TS2

NTC probe 2 input

0-10

Analog 0-10V output

N/A

N/A

G

Ground

N/A

N/A

DIN-TSTAT-FCU Port Descriptions

PORT NAME DESCRIPTION PORT NAME DESCRIPTION

1

2

3

24V 24Vac power supply output G Ground

Safety Notes

• Do not use the device outside the specified field of application, especially in aircraft

or in any other airborne means of transport.

• Properly trained personnel must install the device.

• Observe any and all legal regulations or regulations issued by authorities.

• The device may only be opened at the manufacturer’s site. It does not contain any

parts that can be replaced or repaired by the user.

• The device contains electrical and electronic components and is not allowed to be

disposed of as household refuse. All locally valid regulations and requirements must

be observed.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 3

Page 8

FCU type

1

1-6 Type 1: Modulated 0-10 Vac Valve

System

Regulation step

4

1-10

Regulation step (the width of the zone

regulated) in multiples of 0.5 °C

Valve minimum position

0

0-100

Minimum valve position when set point

is reached (1000 = 100%)

Fan speed OFF enable

1

0-1 If 0, fan will stay in speed 1 when the

is turned OFF

Fan speed change delay

1

1-10

[min]

Minimum time between two fan speed

changes

PI regulaton: Kp

20

1-500

PI regulator proportional parameter

PI regulaton: Ti

300100

0-600

PI regulator integration parameter

Temperature probe 1 type

NTC 20K

NTC 20K,

NTC 15K

Type of the temperature probe on

Temperature probe 2

enable

0

0-1 Enable usage of temperature probe on

analog input 2

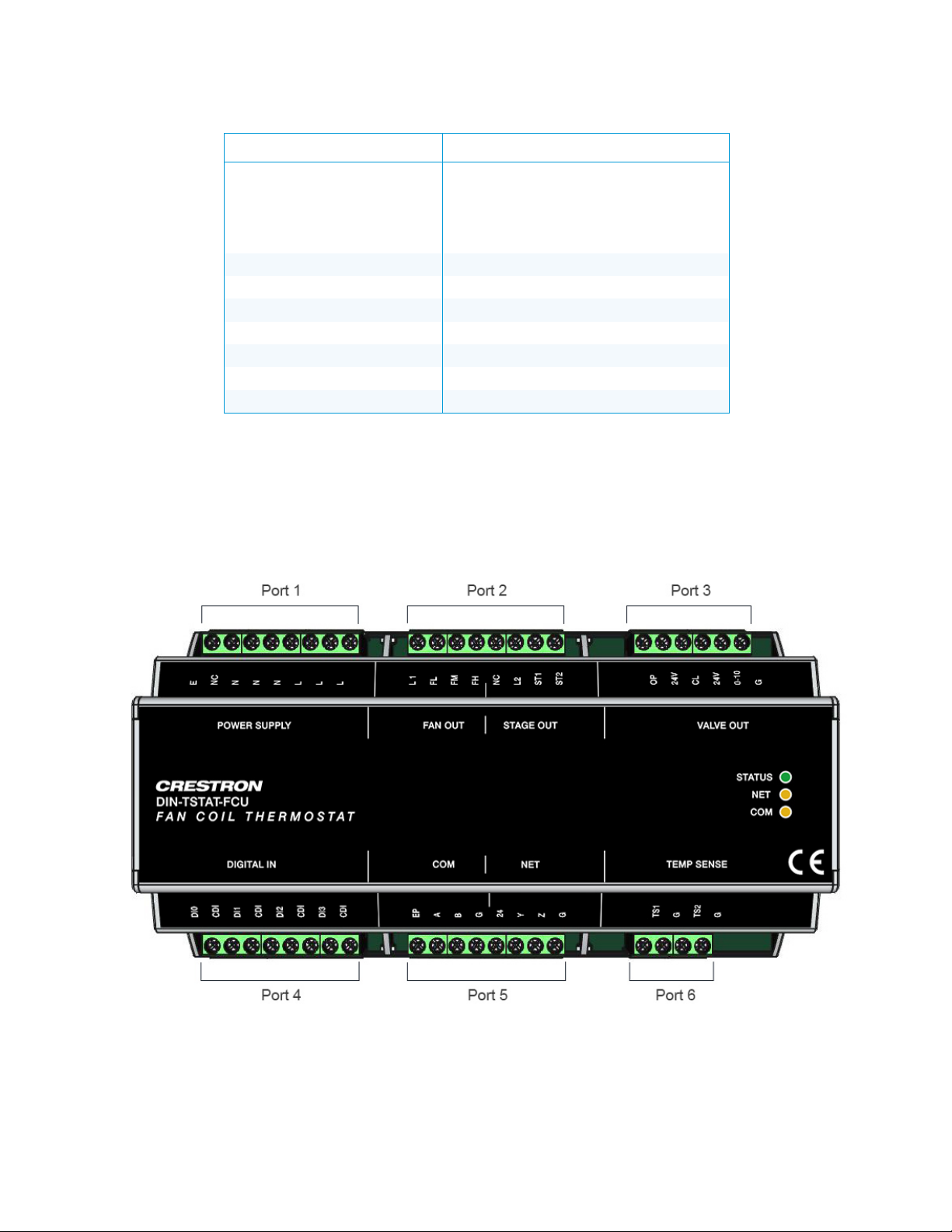

Device Parameters

Using the DIN-TSTAT-FCU Commissioning Tool, configure the DIN-TSTAT-FCU according

to the FCU type, valve parameters, and other requirements. Parameters are divided into

common and specific to each FCU type.

The common parameter to all FCUs that are subdivided by regulation, communication, and

alarm parameters. The first common parameter determines the FCU type.

Parameters specific to FCU type are presented in respective tables:

• Modulated 0-10 Vac Valve

• Modulated OP-CL 24 Vac valve

• Spring-loaded 24 Vac Valve

• Modulated OP-CL 230 Vac Valve

• Spring-loaded 230 Vac Valve

• 1-2 Stage Direct-expansion System

Common Parameters

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Regulation Parameters

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

NTC 10K,

NTC 12K,

Type 2: Modulated OP-CL 24 Vac

valve

Type 3: Spring-loaded 24 Vac Valve

Type 4: Modulated OP-CL 230 Vac

Valve

Type 5: Spring-loaded 230 Vac Valve

Type 6: 1-2 Stage Direct-expansion

around set point where the valve is

set point is reached; otherwise the fan

analog input 1 (1 - 20K NTC, 2 - 10K

NTC, 3 - 12K NTC, 4 - 15K NTC)

(Continued on the following page)

4 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

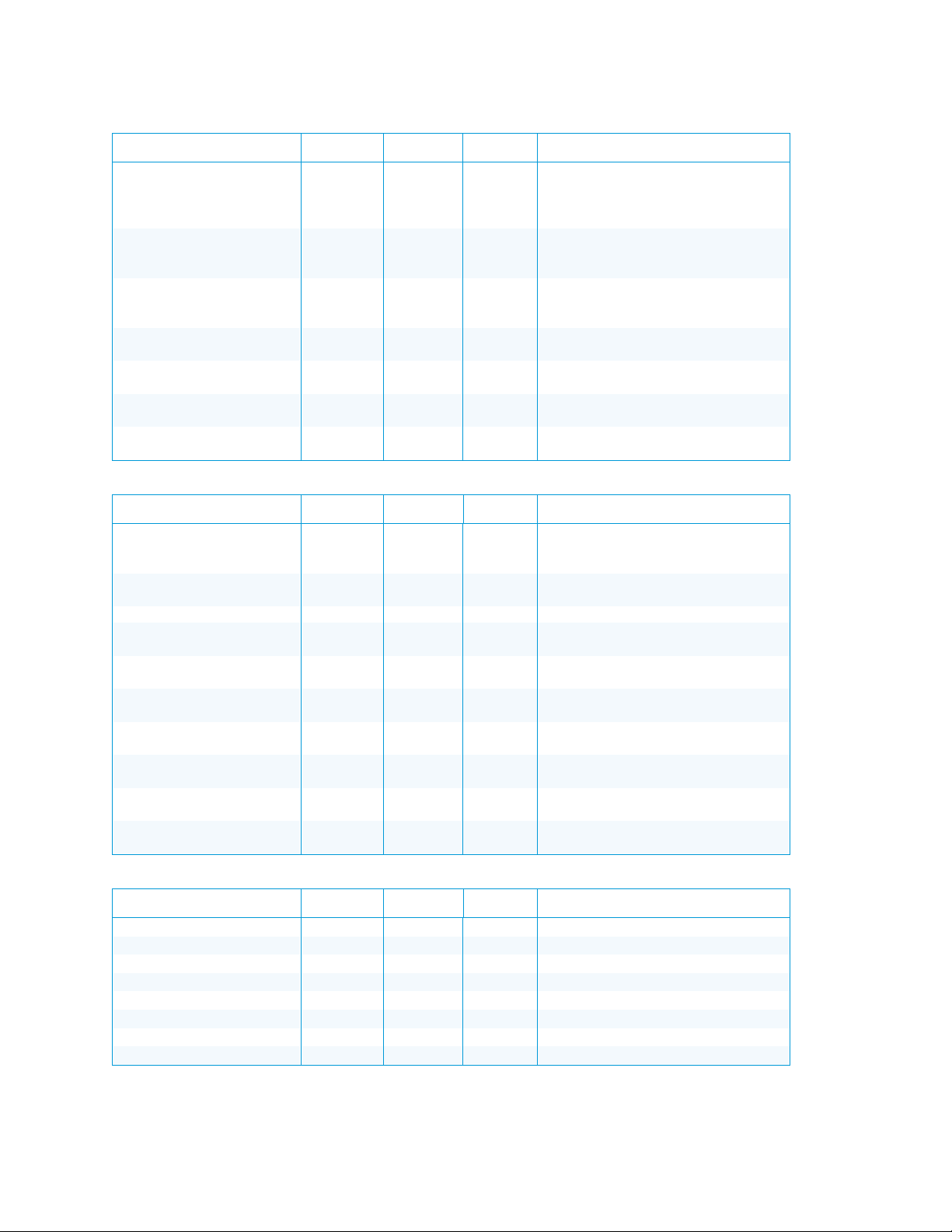

Page 9

Temperature probe 2 type

NTC 20K

NTC 20K,

NTC 15K

Type of the temperature probe on

cooling to work (fluid must be colder)

Minimum T diff for heating

10

0-20

°C

Minimum difference between ambient

cooling to work (fluid must be hotter)

Minimum set point for

heating

16

16-30

°C

Minimum set point value when heating

is active

Maximum set point for

heating

30

16-30

°C

Maximum set point value when heating

is active

Minimum set point for

cooling

16

16-30

°C

Minimum set point value when cooling

is active

Maximum set point for

cooling

30

16-30

°C

Maximum set point value when cooling

is active

Modbus baud

0

0–8 Modbus baud rate 0-0, 1-1200,

38400, 7-57600, 8-115200

Modbus parity

0

0–2 Modbus parity 0-no, 1-odd,

2-even

Modbus stop

2

1–2 Modbus number of stop bits

Modbus slave address

1

1–247

Modbus slave address of remote

display unit

Set point address

45001

0–65535

Address of temperature set point

register on remote display unit

Fan speed address

45002

0–65535

Address of fan speed register on

remote display unit

Mode address

45003

0–65535

Address of mode register on remote

display unit

Air temperature address

45011

0–65535

Address of register for ambient

temperature on remote display unit

Set point min address

45012

0–65535

Address of register for minimum set

point on remote display unit

Set point max address

45013

0–65535

Address of register for maximum set

point on remote display unit

Alarm 1 enable

0

Alarm 1 enable

Alarm 1 polarity

1

Alarm 1 active level

Alarm 1 delay

5

0–2000

[s]

Alarm 1 delay

Alarm 2 enable

0

0–1

Alarm 2 enable

Alarm 2 polarity

1

0–1

Alarm 2 active level

Alarm 2 delay

5

[s]

Alarm 2 delay

Alarm 3 enable

0

Alarm 3 enable

Alarm 3 polarity

1

0–1

Alarm 3 active level

Regulation Parameters (continued)

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

NTC 10K,

NTC 12K,

Minimum T diff for cooling 10 0-20 °C Minimum difference between ambient

analog input 2 (1 - 20K NTC, 2 - 10K

NTC, 3 - 12K NTC, 4 - 15K NTC)

temperature and fluid temperature for

temperature and fluid temperature for

Communication Parameters

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

2-2400, 3-4800, 4-9600, 5-19200, 6-

Alarms Parameters

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

(Continued on the following page)

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 5

0–1

0–1

0–2000

0–1

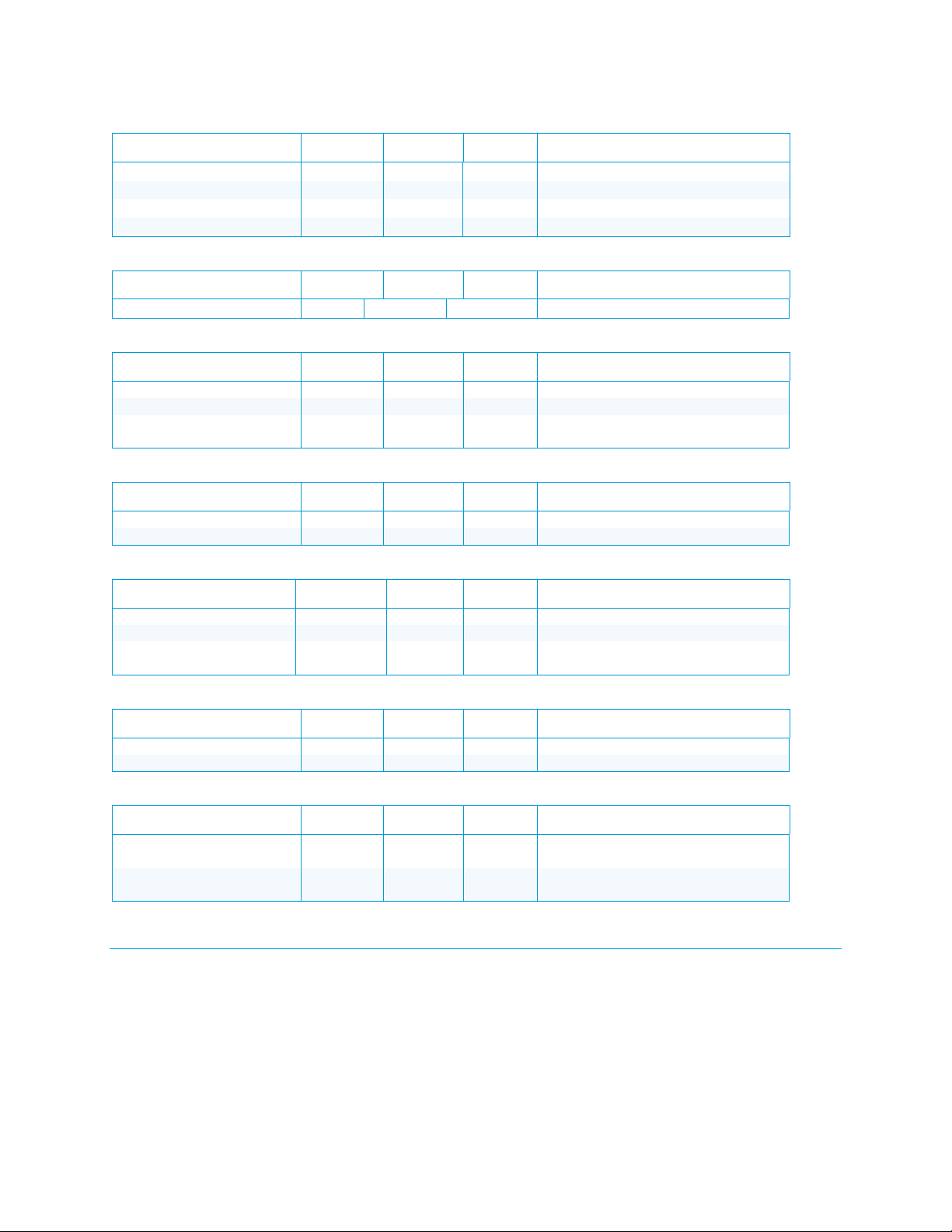

Page 10

Alarm 3 delay

5

0–2000

[s]

Alarm 3 delay

Alarm 4 enable

0

Alarm 4 enable

Alarm 4 polarity

1

0–1

Alarm 4 active level

Alarm 4 delay

5

0–2000

[s]

Alarm 4 delay

Valve opening time

120

20–300

[s]

Time required for valve to open

Valve opening time

120

60–300

[s]

Time required for valve to open

Valve closing time

120

60–300

[s]

Time required for valve to close

Reset valve error interval

8

4–24

[h]

Interval between two position error

annulations

Valve opening time

120

10–300

[s]

Time required for valve to open

Valve closing time

120

10–300

[s]

Time required for valve to close

Valve opening time

120

20–300

[s]

Time required for valve to open

Valve closing time

120

20–300

[s]

Time required for valve to close

Reset valve error interval

8

4–24

[h]

Interval between two position error

annulations

Valve opening time

120

10–300

[s]

Time required for valve to open

Valve closing time

120

10–300

[s]

Time required for valve to close

Stage 1 minimum ON time

300

60–1200

[s]

Minimum operating time for

compressor first stage

Stage 2 minimum ON time

300

60–1200

[s]

Minimum operating time for

compressor second stage

Alarms Parameters (continued)

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

0–1

Parameters for Type 1 - Modulated 0-10 Vac Valve

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Parameters for Type 2 - Modulated OP-CL 24 Vac Valve

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Parameters for Type 3 - Spring-loaded 24 Vac Valve

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Parameters for Type 4 - Modulated OP-CL 230 Vac Valve

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Parameters for Type 5 - Spring-loaded 230 Vac Valve

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Parameters for Type 6 - 1-2 Stage Direct-expansion System

SPECIFICATION DEFAULT RANGE UNITS COMMENTS

Regulation Algorithms

The DIN-TSTAT-FCU is a universal fan-coil controller designed for two-pipe HVAC systems.

The device controls the fan used for forcing air flow over the water coil and controls the

valve used to adjust the water flow rate through the coil. The fan speed of the fan-coil unit is

regulated with three speeds: low, medium, and high. The valve is regulated differently

depending on the fan-coil type used. The fan speed and valve position are set by the

regulation algorithm using the difference in the room temperature and the set point

6 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 11

temperature. The device supports cooling and heating modes, except when configured as

Type 6 where only cooling is supported.

On power up, the device has an initialization period where the system is stabilized before

temperature regulation can take place.

The DIN-TSTAT-FCU’s normal operation can be interrupted if it receives an alarm signal or if

the water temperature is inappropriate.

The device has various configurable parameters for adjusting the working state

corresponding to user application.

FCU Wiring and Control

For regulating different 2-pipe, 3-speed valve and fan-coil types the DIN-TSTAT-FCU has six

different software configuration types each for controlling different type of fan-coil unit. The

DIN-TSTAT-FCU configuration types are:

• Type 1 - Modulated 0-10 Vac Valve

• Type 2 - Modulated OP-CL 24 Vac Valve

• Type 3 - Spring-loaded 24 Vac Valve

• Type 4 - Modulated OP-CL 230 Vac Valve

• Type 5 - Spring-loaded 230 Vac Valve

• Type 6 - 1-2 Stage Direct-expansion System

Initialization

NOTE: Every configuration type has the same initialization procedure.

The device enters initialization period when it is turned on. During the initialization period the

fan is forced to off (fan outputs are inactive), and the valve output is forced to fully open in

order to run water through the heat exchanger and stabilize its temperature. The duration of

the initialization period depends on the type of device configuration, and it is 120% of the

Valve opening time parameter. In case of DX systems, the fan is also put to off state, and

stage relays are inactive for initialization time, which is calculated as 120% of the longer time

written in parameters Stage 1/2 minimum ON time. The means for valve control depends on

device configuration type.

Water temperature

A second NTC probe input can be wired to the TEMP SENSE – TS2 and G port for water

temperature measurement. The minimum temperature difference between ambient

temperature and water temperature for FCU to effectively perform its function is Minimal T

diff for cooling parameter in case of cooling and Minimal T diff for heating in case of heating.

When cooling is performed, the device checks that the water temperature is cooler than the

ambient temperature. When heating the device checks that the water temperature is hotter

than the ambient temperature. If water temperature is not adequate, the fan speed is set to

OFF and valve is fully open.

The water temperature measurement is enabled when the Temperature probe 2 enable

parameter is set.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 7

Page 12

∆T

∆T = × 0.5 °C

Y

=

1000

× 100%

Y (%)

T (˚C)

Sp-3∆T

Sp+3∆T

Sp-2∆T

Sp+2∆T

Sp-∆T Sp+∆TSpH

SpC

100

Ymin

0

Initial Operating Parameters

While operating, the device checks every 5 minutes for changes in operating parameters.

Operating parameters are the following:

• Temperature set point

• Selected fan speed

• Selected operating mode (off, cooling, heating)

If a change is detected, new parameters are stored in flash memory. On power up, these

parameters are read from flash memory and used as operating parameters.

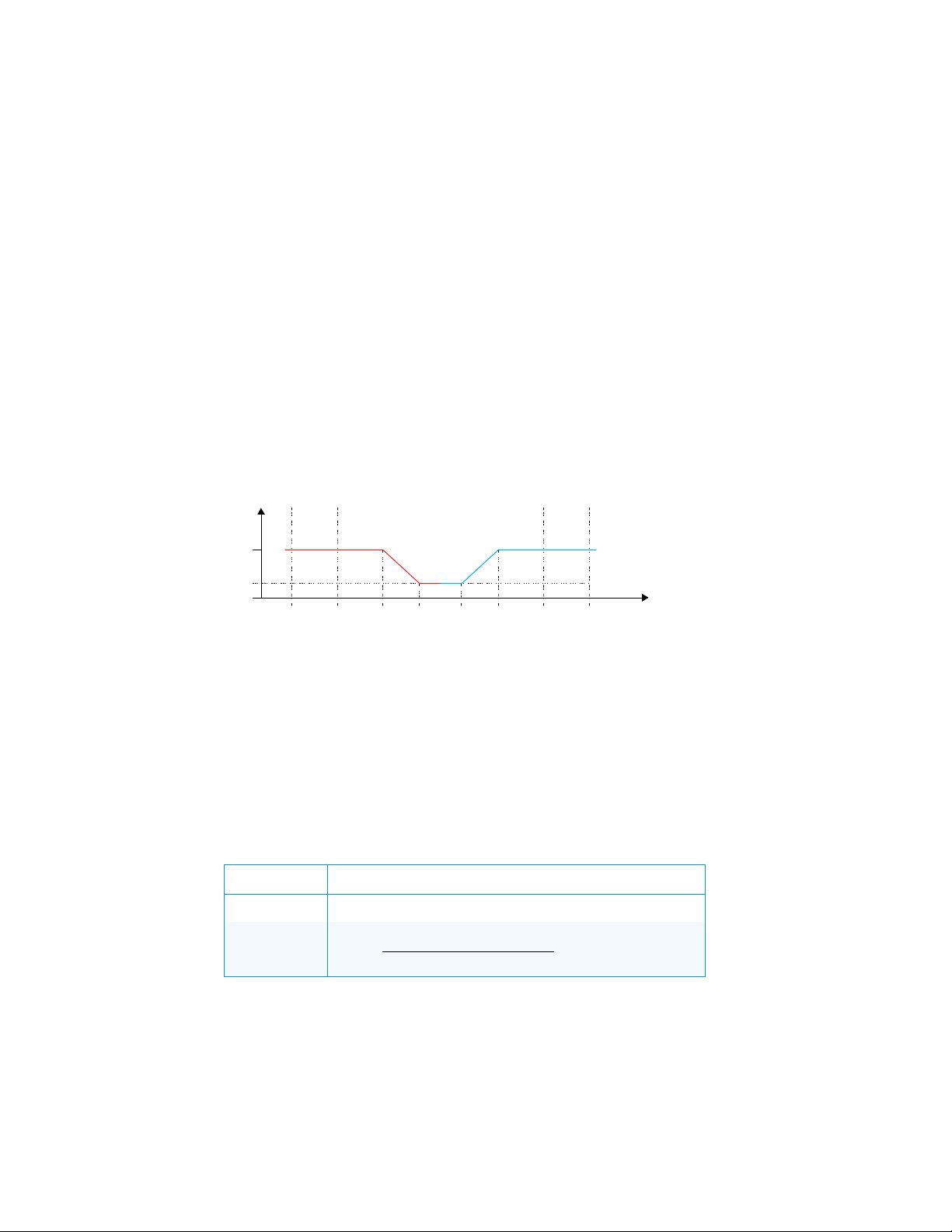

Modulated 0-10 Vac Valve

This device is designed for use with 2-pipe, 3-speed FCU with a 0-10 Vac modulated valve.

In this case, the valve performs regulation in the ∆T vicinity of set point. The valve opens and

closes according to the graph below. The valve is controlled using 0-10 Vac analog output.

For details on controlling the fan speed, refer to the “Fan Speed Control” section.

Valve Position according to Room Temperature

SpH – Set point for heating

SpC – Set point for cooling

Y – Valve position (0 close, 100 fully open)

Y

– Minimum position of valve when set point is reached

min

T – Room temperature

∆T – Step of temperature difference

The following table explains the connection between regulation parameters from the

diagram and user-settable parameters.

Regulation Parameters for Type 1 FCU

PARAMETER EXPLANATION

Y

min

min

8 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 13

NTC

1

Fan

1

CV

1

WS

WR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

VALVE OUT:

24 Vac power and 0-10 Vac

control to the valve

FAN OUT:

230 Vac max fan power

in and fan control out

STA

TUS

NET

COM

DIN

-

TS

TAT

-FCU

TEMP SENSE

DIGI

TAL IN

COM

VA

LVE OUT

POWER SUPP

LY

S

TAGE OUT

FAN OUT

NET

LLL

L 1FLFMFHNCL2ST1

ST2

OP

24V

CL

24V

0-10

G

E

NC

NNN

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EPABG24

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

Wiring Diagram

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 9

Page 14

∆T

∆T = × 0.5 °C

Y

=

1000

× 100%

= ×

1000 −

1000

= ×

1000 −

1000

Y (%)

T (˚C)

Sp-3∆T

Sp+3∆T

Sp-2∆T

Sp+2∆T

Sp-∆T

Sp+∆T

SpH

SpC

100

Ymin

0

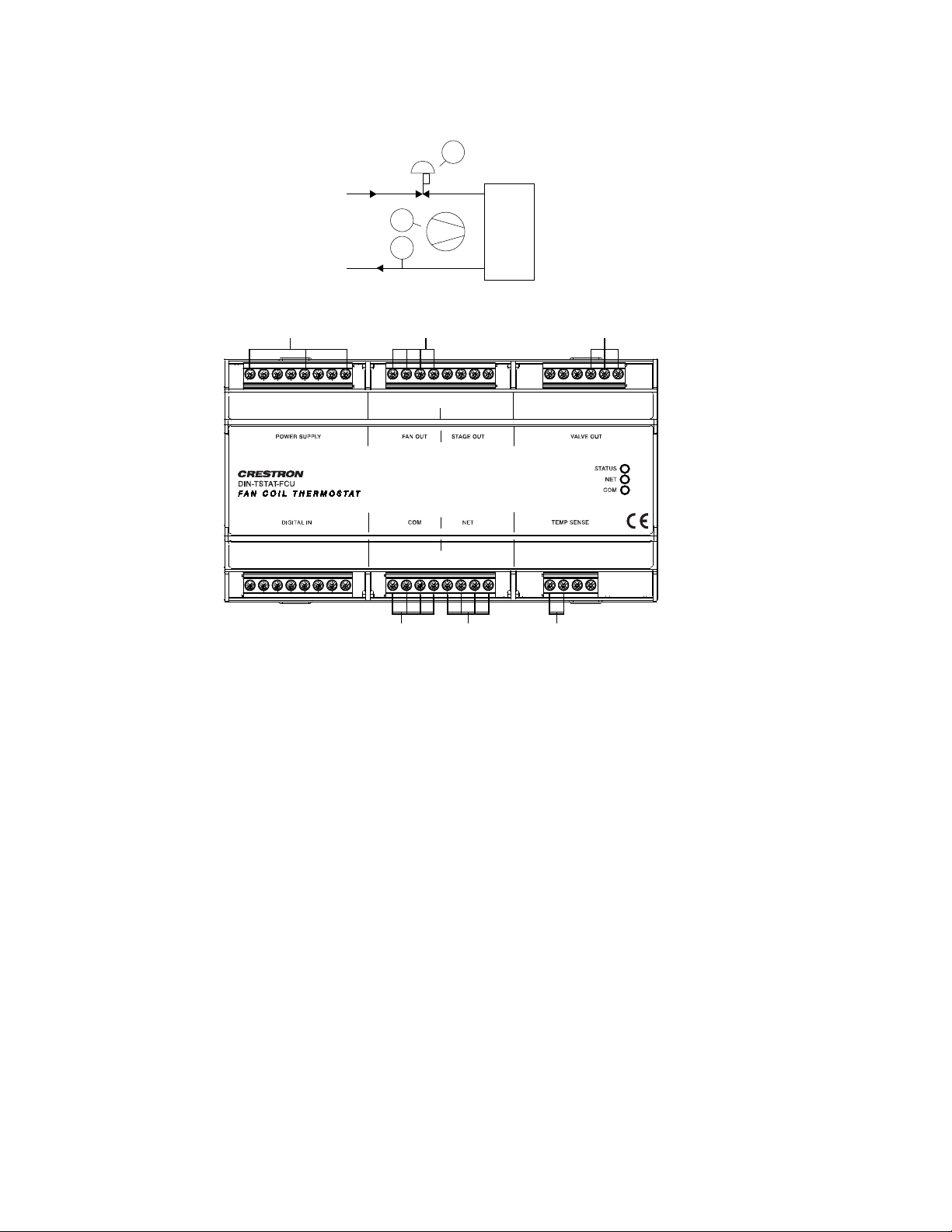

Modulated OP-CL 24 Vac Valve

This device is designed for use with a 2-pipe, 3-speed FCU with 24 Vac common open or

close valve.

In this case, the valve performs regulation in the ∆T vicinity of set point; the valve opens and

closes at the rate of its defined time, according to the graph below.

Periodically, the valve is forced to the fully open position to eliminate accumulated error. The

error correction period is defined by Reset valve error interval parameter.

For details on controlling the fan speed, refer to the “Fan Speed Control” section.

Valve Position according to Room Temperature

SpH – Set point for heating

SpC – Set point for cooling

Y – Valve position (0 close, 100 fully open)

Y

– Minimum position of valve when set point is reached

min

T – Room temperature

∆T – Step of temperature difference

t - Time for valve to reach open/close position

The following table explains the connection between regulation parameters from the

diagram and user-settable parameters.

Regulation Parameters for Type 2 FCU

PARAMETER EXPLANATION

Y

min

min

t when valve

is opening

t when valve

is closing

10 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 15

NTC

1

Fan

1

CV

1

S

WS

WR

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

VALVE OUT:

24 Vac out and solid state

switch control to valve

FAN OUT:

230 Vac max fan power

in and fan control out

STA

TUS

NET

COM

DIN-TS

TAT-FCU

TEMP SENSEDIGIT

AL IN COM

V

ALVE OUTPOWER SUPP

LY

STAGE OUT

FAN OUT

NET

L

L

L

L 1

FL

FM

FH

NC

L2

ST1

ST2

OP

24VCL24V

0-10

G

E

NC

N

N

N

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EP

ABG

24

Wiring Diagram

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 11

Page 16

∆T

∆T = × 0.5 °C

Y

=

1000

× 100%

T (˚C)

t (time)

Sp

∆T* Ymin

0

0

t (time)

100

valve %

T (˚C)

t (time)

Sp

∆T* Ymin

0

0

t (time)

100

valve %

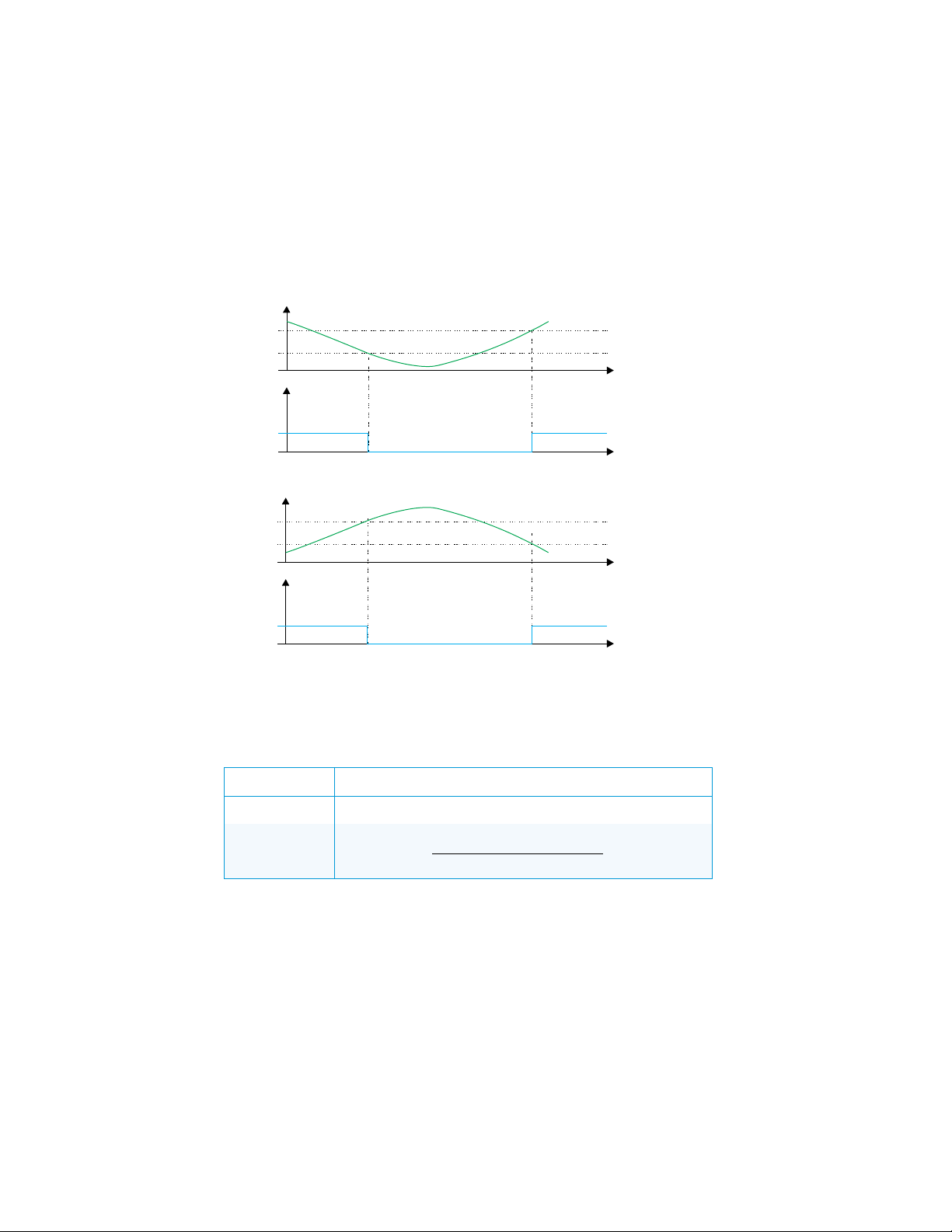

Spring-loaded 24 Vac Valve

This device is designed for use with a 2-pipe, 3-speed FCU with spring-loaded 24 Vac

valve.

In this case, the valve operates as an on and off valve. The valve value is calculated

according to room temperature, as shown in the graphs below. The valve is controlled using

one triac (Valve open).

For details on controlling the fan speed, refer to the “Fan Speed Control” section.

Valve Position according to Room Temperature - Cooling

Valve Position according to Room Temperature - Heating

12 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

∆T* Y

– temperature when valve open

min

The following table explains the connection between regulation parameters from the

diagram and user-settable parameters.

Regulation Parameters for Type 3 FCU

PARAMETER EXPLANATION

Y

min

min

Page 17

NTC

1

Fan

1

CV

1

WS

WR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

VALVE OUT:

24 Vac power out and solid

state switch control to the valve

FAN OUT:

230 Vac max fan power

in and fan control out

STATUS

NET

COM

DIN

-TSTA

T-FCU

TEMP SENSEDIGI

TAL IN COM

V

ALVE OUTPOWER SUPP

LY S

TAGE OUTF

AN OUT

NET

LLL

L 1FLFMFHNCL2ST1

ST2

OP

24V

CL

24V

0-10

G

ENCNNN

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EP

ABG

24

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

Wiring diagram

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 13

Page 18

∆T = × 0.5 °C

Y

=

1000

× 100%

= ×

1000 −

1000

= ×

1000 −

1000

Y (%)

T (˚C)

Sp-3∆T

Sp+3∆T

Sp-2∆T

Sp+2∆T

Sp-∆T

Sp+∆T

SpH

SpC

100

Ymin

0

Modulated OP-CL 230 Vac Valve

This device is designed for use with a 2-pipe, 3-speed FCU with 230 Vac common open or

close valve.

In this case, the valve performs regulation in the ∆T vicinity of set point; the valve opens and

closes at the rate of its defined time, according to the graph below.

Periodically, the valve is forced to the fully open position to eliminate accumulated error.

Error annulation period is defined by Reset valve error interval parameter.

For details on controlling the fan speed, refer to the “Fan Speed Control” section.

Valve Position according to Room Temperature

SpH – Set point for heating

SpC – Set point for cooling

Y – Valve position (0 close, 100 fully open)

Y

– Minimum position of valve when set point is reached

min

T – Room temperature

∆T – Step of temperature difference (∆T=N*0.5 °C, N is settable parameter)

t - Time for the valve to reach full open/close position

This table explains the connection between regulation parameters from the diagram and

user-settable parameters.

Regulation Parameters for Type 4 FCU

PARAMETER EXPLANATION

∆T

Ymin

t when valve

is opening

t when valve

is closing

min

14 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 19

NTC

1

Fan

1

CV

1

S

WS

WR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

STAGE OUT:

230 Vac max power for open

and close control to the valve

FAN OUT:

230 Vac max fan power

in and fan control out

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSEDIGITAL I N COM

VALVE OUTPOWER SUPPLY STAGE OUTFAN OUT

NET

LLL

L 1FLFMFHNCL2ST1

ST2

OP

24VCL24V

0-10

G

ENCNNN

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EPAB

G

24

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

Wiring Diagram

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 15

Page 20

∆T = × 0.5 °C

Y

=

1000

× 100%

T (˚C)

t (time)

Sp

∆T* Ymin

0

0

t (time)

100

valve %

T (˚C)

t (time)

Sp

∆T* Ymin

0

0

t (time)

100

valve %

Spring-loaded 230 Vac Valve

This device is designed for use with a 2-pipe, 3-speed FCU with spring-loaded 230 Vac

valve.

In this case, the valve operates as an on and off valve. The valve value is calculated

according to room temperature, as shown in the graphs below.

The valve is controlled using one relay (Valve open).

For details on controlling the fan speed, refer to the “Fan Speed Control” section.

Valve Position according to Room Temperature - Cooling

Valve Position according to Room Temperature - Heating

Sp – set point

∆T* Y

– temperature when valve is open

min

The following table explains the connection between regulation parameters from the

diagram and user-settable parameters.

Regulation Parameters for Type 5 FCU

PARAMETER EXPLANATION

∆T

Ymin

min

16 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 21

NTC

1

Fan

1

CV

1

WS

WR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

FAN OUT:

230 Vac max fan power

in and fan control out

STA

TUS

NET

COM

DIN-TS

TAT-FCU

TEMP SENSEDIGIT

AL IN COM

VA

LVE OUTPOWER SUPP

LY

S

TAGE OUTF

AN OUT

NET

L

L

L

L 1

FL

FM

FH

NC

L2

ST1

ST2

OP

24VCL24V

0-10

G

E

NC

N

N

N

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EPAB

G

24

STAGE OUT:

230 Vac max power for

open control to the valve

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

Wiring Diagram

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 17

Page 22

T (˚C)

t

∆T

∆T/2

Sp

S1

S2

0

0

t

valve %

1-2 Stage Direct-expansion System

This device is designed for use with a 3-speed, direct-expansion system with compressor

control - cooling only.

In this case, a compressor is controlled instead of a valve. The compressor state for stage

one and stage two is determined by the room temperature. The compressor is controlled

using two relays (Stg 1 – stage 1, Stg 2 – stage 2).

The diagram of working compressor according to room temperature is shown in the graph

below.

For details on controlling the fan speed, refer to the “Fan Speed Control” section.

Diagram of Working Compressor according to Room Temperature

Sp- set point

∆T – Step of temperature difference (∆T=N*0.5 °C, N is settable parameter)

S2 – Stage 2 ON

S1 – Stage 1 ON

18 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 23

NTC

1

Fan

1

AS

AR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

FAN OUT:

230 Vac max fan power

in and fan control out

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSEDIGITAL IN COM

VALVE OUTPOWER SUPP

L

Y S

TAGE OUT

F

AN OUT

NET

LLL

L 1FLFMFHNCL2ST1

ST2

OP

24V

CL

24V

0-10

G

ENCNNN

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EPABG24

STAGE OUT:

230 Vac max power for Stage 1 and

Stage 2 control to the compressor

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

Wiring Diagram

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 19

Page 24

High

Fan Speed

Medium

Low

T (˚C)

Sp-3∆T Sp+3∆TSp-2∆T

Sp+2∆TSp-∆T

Sp+∆TSpH SpC

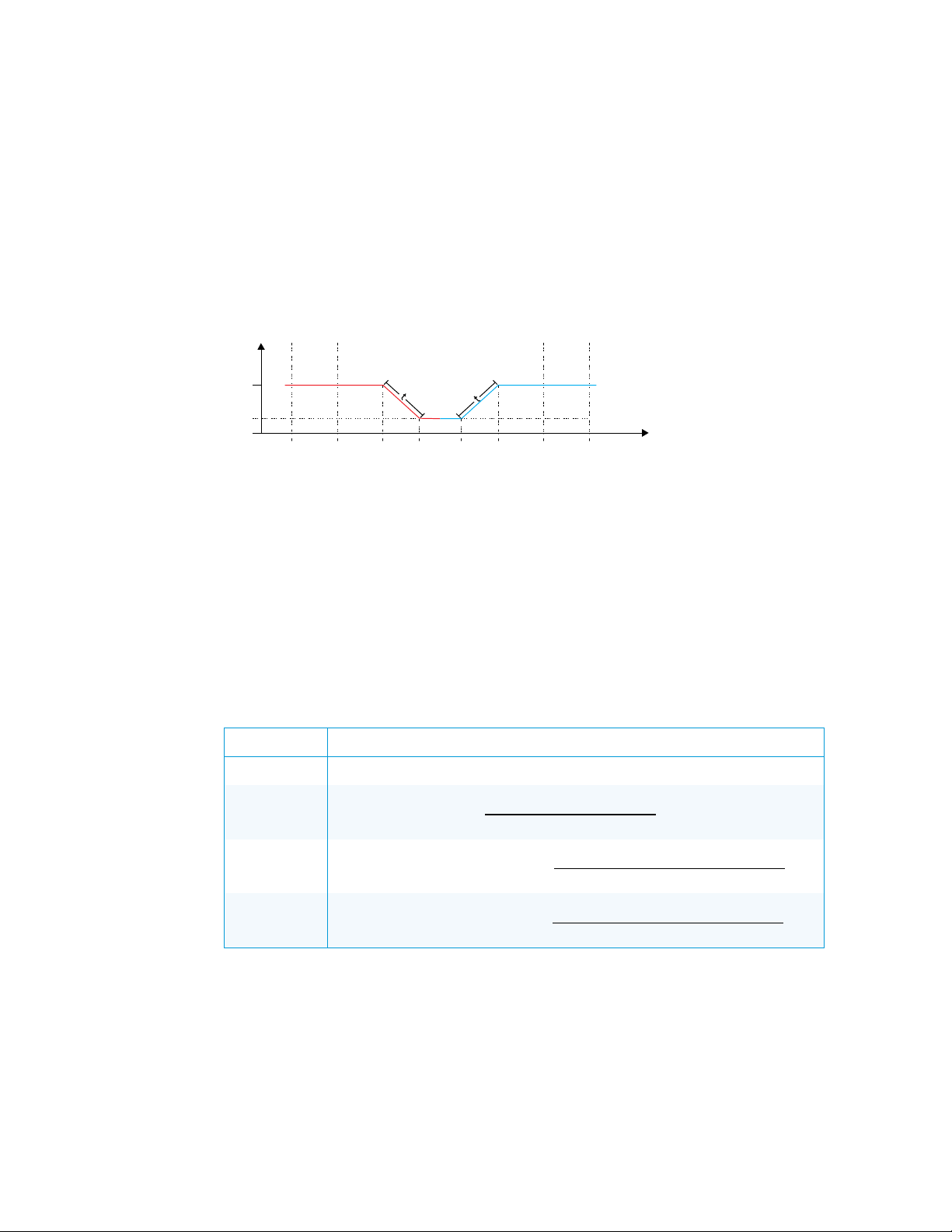

Fan Speed Control

This device is designed for all configuration, the fan shifts to low, medium, and high speed

based on room temperature. When room temperature reaches its set point, if parameter

Fan speed OFF enable is set to 1, the fan turns down; otherwise it remains in low.

If fan speed is forced, it constantly runs at the selected speed.

The diagram below shows the fan speed according to room temperature and operating

mode.

Fan Speed according to Room Temperature

SpH – Set point for heating

SpC – Set point for cooling

T – Room temperature

∆T – Step of temperature difference (∆T = × 0.5 °C)

20 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 25

DIGITAL IN:

From the window

switch, door switch, or

occupancy sensor

POWER SUPPLY:

Power input for line,

neutral, and earth

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSEDIGITAL IN CO M

VALVE OUTPOWER SUPPLY STAGE OUTFAN OUT

NET

LLL

L 1FLFMFHNCL2ST1

ST2

OP

24VCL24V

0-10

G

ENCNNN

CDI

DI3

CDI

TS1GTS2

G

DI0

CDI

DI1

CDI

DI2

YZG

EPABG24

COM:

To the

room

controller

NET:

To the

control

system

Alarms

The device has four digital inputs reserved for external alarm signals. Their usage is optional

and adjustable by device configuration parameters. Each of the four alarm inputs has three

adjustable parameters available:

• Alarm X enable – Determines if the alarm input is used

• Alarm X polarity – Alarm is active if the incoming input signal corresponds to the set

polarity

• Alarm 1 delay – Time interval from the alarm input signal activation to the activation

of the alarm state

Alarm inputs are used for accepting signals from window/door sensors, condensation

canister sensor, PIR sensors, etc.

If enabled and activated, the alarm blocks the device outputs for fan speed (fan speed will

be set to 0) and closes the valve by forcing valve outputs (different outputs depending on

device configuration type). If the delay time is set, alarm activation or deactivation is

postponed by alarm delay time.

The wiring diagram below shows an example where three alarm inputs are used.

Alarms Wiring Example

Temperature Probes

DIN-TSTAT-FCU device has two resistance measuring inputs for NTC probes. First input is

used for room temperature measurement. The second input can be used for water

temperature monitoring.

For the best results, use 20K NTC probes.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 21

Page 26

Supported NTC Probes

PROBE TYPE RANGE [OC] TEMPERATURE PROBE 1/2

NTC 20K 0 – 100 1

NTC 10K 0 – 100 2

NTC 12K 0 – 100 3

NTC 15K 0 – 100 4

Cresnet® Communications

The DIN-TSTAT-FCU primarily communicates using the NET port. The NET port has four

pins marked as 24, Y, Z, G, where 24 is 24 V input, Y and Z are + and – signal lines, and G

is ground.

Through the Cresnet network, a user can do the following:

• Change the temperature set point either by sending a new value or by sending raise

and lower commands

TYPE PARAMETER VALUE

• Set the desired fan speed mode (low, medium, high, or auto)

• Set the operating mode (cooling, heating, or off)

• Monitor the current temperature set point

• Monitor the currently active operating mode

• Monitor the currently active fan speed

• Monitor the status of binary inputs

• Monitor the measured temperatures

Commands issued using the Cresnet port are also reported back through the Modbus port.

The last received command is considered valid. The Cresnet network and local room

display unit are both informed about the last change.

Port

The device can operate using only power supplied from the Cresnet network, but in that

case, I/O resources are not operational and a main power supply error is reported. When

operating from network power supply, the device consumes 0.5 W.

Communication

The device is reported as a DIN-TSTAT-FCU on the Cresnet network. The serial number is

the same as serial number on the device label.

While Cresnet communication is active, the NET LED is ON.

22 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 27

Joins

The device input and output joins are listed in the tables below.

Input Joins

JOIN TYPE JOIN NAME JOIN NUMBER

Digital Raise_Setpoint 1

Digital Lower_Set point 2

Digital Mode_Heat 3

Digital Mode_Cool 4

Digital Mode_Off 6

Digital Fan_High 9

Digital Fan_Med 10

Digital Fan_Low 11

Digital Fan_Auto 12

Analog Setpoint 1

Output Joins

JOIN TYPE JOIN NAME JOIN NUMBER

Digital Mode_Heat_FB 3

Digital Mode_Cool_FB 4

Digital Mode_Off_FB 6

Digital Is_Cooling_FB 7

Digital Is_Heating_FB 8

Digital Fan_High_FB 9

(continued on the following page)

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 23

Page 28

Output Joins (continued)

JOIN TYPE JOIN NAME JOIN NUMBER

Digital Fan_Med_FB 10

Digital Fan_Low_FB 11

Digital Fan_Auto_FB 12

Digital Input_1_FB 13

Digital Input_2_FB 14

Digital Input_3_FB 15

Digital Input_4_FB 16

Analog Setpoint_FB 1

Analog Temperature_1_FB 2

Analog Temperature_2_FB 3

Analog MinHeatSetpoint_FB 4

Analog MaxHeatSetpoint_FB 5

Analog MinCoolSetpoint_FB 6

Analog MaxCoolSetpoint_FB 7

Analog FCU_Type 11

Light and Poll

Light and Poll (LP) is a mechanism that allows a device to identify itself through physical

input from a user. This helps identify devices in their physical location, as well as reduce the

chance of communicating with the wrong device. LP works in the following manner:

1. A Start Light and Poll (SLP) command is sent from the control system to

DIN-TSTAT-FCU.

2. The device blinks its NET LED to indicate that it is in Light and Poll mode.

3. Press the NET button to acknowledge the SLP command. This ends the Light and

Poll procedure by sending an End Light and Poll (ELP) command.

24 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 29

Press the Pushbutton to Acknowledge SLP

AUX Port

An auxiliary RS-485 port supports the Modbus RTU protocol. The device is master on

Modbus network. This port is used for connecting to a local room display unit. The local

room display unit enables user to do the following:

• Set the temperature set point

• Set the desired fan speed mode (low, medium, high, or auto)

• Set the operating mode (cooling, heating, or off)

• Monitor the current temperature set point

• Monitor the currently active operating mode

• Monitor the currently active fan speed

• Monitor the measured room temperature

Commands from the auxiliary port can be received concurrently with commands from the

NET port. The last received command is considered valid. The control system and local

room display unit are both informed about the last change.

Communication parameters are settable through user registers.

Port

The auxiliary port has four pins marked EP, A, B, G, where EP is external power supply, A

and B are + and – communication signals lines, and G is ground.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 25

Page 30

The DIN-TSTAT-FUC can supply power to other devices on the Modbus network. Supply

voltage is 20 Vdc and the maximum output current is 100 mA.

Communication

The device is preprogrammed to read and write particular values to and from local room

display.

Modbus reads:

• Temperature set point

• Desired fan speed mode

• Desired operating mode

Modbus writes:

• Active temperature set point

• Active fan speed mode

• Active operating mode

• Current room temperature

• Minimum set point value

• Maximum set point value

Write Multiple Registers command is used for register write and Read Holding Registers

command is used for register read. The registers are written on value change while read is

performed on best effort.

While communication is active, the COM LED blinks. If communication is error-free COM

LED blinks fast, and each error will introduce a delay of 1s between the LED flashes.

26 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 31

Registers

Registers that read and write from the local room display are shown below.

Modbus Read/Write Registers

USB Port

REGISTER

NAME

Set point Set point min – Set

Fan speed

command

Mode

command

Air

temperature

Set point min 0 – 1000 Write Temperature is in format oC x 10

Set point max 0 – 1000 Write Temperature is in format oC x 10

RANGE READ/WRITE NOTE

Read/Write Temperature is in format oC x 10

point max

1 – 4 Read/Write 1: Lo; 2: Med; 3: Hi; 4: Auto

0 – 2 Read/Write 0: OFF; 1: Cooling; 2: Heating

0 – 1000 Write Temperature is in format oC x 10

Parameters

For communication with the local room display unit to be established, correct parameters

must be written to communication registers. Refer to “Device Parameters” on page 4 for

details. After parameters are set, reboot the device for changes to take effect.

The USB port is used for device commissioning and software updates including operating

system and firmware updates. USB connector type on the DIN-TSTAT-FCU is Mini-B.

NOTE: It may be necessary to install a USB driver to be able to communicate with the

DIN-TSTAT-FCU over USB.

Accessing USB Port

USB port is located under the cover of the DIN-TSTAT-FCU. To open the cover, use a

2 mm wide flat screwdriver to gently pry the cover open using the four slots that are marked

below.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 27

Page 32

Releasing the Lid

Accessing the USB Port

28 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 33

USB Driver Installation Procedure

NOTE: USB driver installation procedure is necessary only if the USB driver is not installed

automatically after the USB cable is inserted.

Before the USB driver is installed, please install DIN-TSTAT-FCU Configuration Tool.

The USB driver installation procedure explained in this section is for Windows

system but is similar to other Windows versions.

To install the USB driver, follow these steps:

1. Connect the DIN-TSTAT-FCU to the PC using a USB cable.

®

7 operating

2. Open the

Device Manager

window.

3. Click the DIN-TSTAT-FCU with the missing driver.

4. Click on the

Update Driver

shortcut icon.

5. Click “Browse my computer for driver software.”

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 29

Page 34

6. Browse to the location that the DIN-TSTAT-FCU Configuration Tool is installed and

then click

Next. The default location is

C:\Program Files (x86)\Crestron\DIN-TSTAT-FCU Configuration Tool.

7. If the

Windows Security

anyway

.

window appears, click

Install this driver software

30 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 35

8. After installation is complete, a popup window indicating installation success

appears.

9. Check that the device has appeared in the

number associated with device.

Device Manager

list and note COM

Install the DIN-TSTAT-FCU Configuration Tool

To install the DIN-TSTAT Configuration Tool, do the following:

1. Double-click the DIN-TSTAT-FCU Configuration Tool.exe file to begin installation.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 31

Page 36

2. Enter the installation destination in the “Setup -Select Destination Location”

window. The default installation destination

“C:\Program Files (x86)\Crestron\DIN-TSTAT-FCU Configuration Tool”. Click

Next.

3. In the “Setup – Select Start Menu Folder,” set the installation options for creating a

shortcut for the configuration tool in the Start Menu folder. Click

Next.

32 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 37

4. In the “Setup – Select Additional Tasks” window, select or clear the Create a

desktop shortcut check box to create a shortcut to the DIN-TSTAT-FCU

Configuration tool on your desktop. Click

Next.

5. The DIN-TSTAT-FCU Configuration tool is installed. Upon completion, a summary

window is displayed gives the option to start the application. Select or clear the

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 33

Page 38

Launch DIN-TSTAT-FCU Configuration Tool check box to open the program after

exiting the installation process. Click

Finish to exit the installation process.

Using the DIN-TSTAT-FCU Configuration Tool

The DIN-TSTAT-FCU Configuration Tool sets the parameters for the DIN-TSTAT-FCU.

Menu Overview

The menu bar contains File, ComPort, Device, and Help menus that provide access to

various setup and operation features.

File Menu

The File menu contains New, Open, Save and Save As options.

New – creates new tables with the default parameters for Regulation and Alarms. It

populates default values for the the Valve/Compressor table based on the FCU type list.

Open – opens a previously saved value configuration from an xml file.

34 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 39

Save – saves the current values from the tables inside an xml file. If the current file is the

default-parameters.xml file, which cannot be overwritten, the program prompts a file

selection dialog so the user can select a new file to save in.

Save As – opens a file save dialog that lets the user choose a save location for the xml

table.

ComPort Menu

The ComPort menu contains a Settings option.

Settings Menu

Click the Scan Ports button to identify and list all used ports in the system. Select the port

that the DIN-TSTAT-FCU uses to communicate from the drop-down list.

Click OK to save the settings and exit the menu. Click Cancel to discard the settings and

exit.

Device Menu

The Device menu contains Firmware Update, OS Update, Device Info, Restore, and Restart

options.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 35

Page 40

Firmware Update

The “Firmware Update” window displays device firmware information and allows new

firmware to be loaded to the device.

To load firmware to the DIN-TSTAT-FCU, do the following:

OS Update

The “OS Update” window allows an updated OS to be loaded to the DIN-TSTAT-FCU. The

information about the current OS in the device is displayed in the “OS Info” section of the

window.

OS Update Window

1. Click the Select file button and select the firmware file to be loaded. The Firmware

information is displayed in the “File” section of the “Firmware Update” window.

2. Click the Update button to load the firmware onto the DIN-TSTAT-FCU.

To update the OS of the DIN-TSTAT-FCU, do the following:

1. Click the Select file button to select and load the updated OS.

36 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 41

2. In the pop-up dialog, click Yes to accept that the procedure cannot be terminated

after proceeding. The device is placed into OS Flash mode and all LEDs on the

DIN-TSTAT-FCU turn off.

CAUTION: The OS update procedure cannot be aborted after clicking Yes. The

remaining procedure must be completed and an OS must be flashed to the device.

3. Turn off power to the POWER SUPPLY and NET port.

4. Disconnect the USB cable from the DIN-TSTAT-FCU, and then reconnect the USB

cable.

NOTE: The USB cable must be removed and then reinserted into the

DIN-TSTAT-FCU before continuing.

5. Click Scan ports, and then select the port with which the DIN-TSTAT-FCU is

associated.

6. Click Next.

7. Click Update to start the OS update process.

8. When prompted, disconnect the USB cable from the DIN-TSTAT-FCU, and then

reconnect the USB cable. The LED lights when the USB cable is reconnected.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 37

Page 42

NOTE: The USB cable must be removed and then reinserted into the

DIN-TSTAT-FCU before continuing.

9. Restore power to the POWER SUPPLY and NET port.

Device Info

The “Device Info” window displays device information such as Device Info, Firmware Info,

and OS Info.

Restore

Device recovery is available only when an OS Update fails while a new OS is being written or

verified. It allows the DIN-TSTAT-FCU to recover to the last known working OS.

1. Turn off power to the POWER SUPPLY and NET ports.

2. Disconnect the USB cable from the DIN-TSTAT-FCU, and then reconnect the USB

cable.

NOTE: The USB cable must be removed and then reinserted into the

DIN-TSTAT-FCU before continuing.

3. Press Scan and then select the port with which the DIN-TSTAT-FCU is associated.

38 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 43

4. Click Next.

5. Click Recover.

6. When prompted, disconnect the USB cable from the DIN-TSTAT-FCU, and then

reconnect the USB cable. The LED lights when the USB cable is reconnected.

NOTE: The USB cable must be removed and then reinserted into the

DIN-TSTAT-FCU before continuing.

7. Restore power to the POWER SUPPLY and NET port.

8. Click Finish.

Restart

The “Restart” window allows the device to be restarted. When restarted, the

DIN-TSTAT-FCU is put into idle state, and then put into a normal operating state.

Help Menu

The Help menu contains About, DIN-TSTAT-FCU specifications, and Program Help options.

About - The “About” window displays the version number of the DIN-TSTAT-FCU

Configuration Tool and copyright information.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 39

Page 44

DIN-TSTAT-FCU specifications - The “DIN-TSTAT-FCU specifications” window displays a

PDF with the specifications of the device.

Program Help – The “Program Help” window displays the user manual for the program.

Configure the DIN-TSTAT-FCU

NOTE: When the DIN-TSTAT-FCU Configuration Tool is run for the first time, it searches for

available ports. If only one port is discovered, it connects to the DIN-TSTAT-FCU associated

with that port. Upon subsequent starts, it loads the port used during the last session.

NOTE: Configuration save is done automatically upon changing the working file or

changing the port, as well as upon closing the application.

Toolbar Bar

The toolbar contains Write, Read, and Set Default buttons.

Write – writes the values from the table to the DIN-TSTAT-FCU.

Read – reads the values from the DIN-TSTAT-FCU and populates them into the tables.

Set Default – sets the values in tables to the default values.

Status Bar

The toolbar contains Device, Parameters file, and Port information.

Device – displays the connected device.

Parameters file – displays the name of the active table that is being edited.

Port – displays the port of the connected DIN-TSTAT-FCU.

Main Screen

The main screen displays the FCU Type, TABLE Name and Expander, and Tables

information.

FCU Type List

The FCU type determines the content and the name of the Valve/Compressor parameters

table. When an FCU type is selected, the Valve/Compressor parameters table is populated

with default values. Existing values are erased.

40 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 45

Table Name and Expander

The Table Name and Expander displays the name of the table. Click the “+” or “-” button to

show or hide that table.

Tables

Every configuration file contains three tables: Regulation parameters, Alarm parameters,

and Valve/Compressor parameters. Each table contains the following parameters:

Name – user friendly name of the parameter.

Value – only editable field (shown also by the white column color) that represents the value

that parameter will have on the device.

Unit – shows what the parameter represents in the context of the device.

Range – shows the minimum and maximum values the value can have.

Description – shows a detailed description of what that parameter represents. This is also

available as a tooltip for that row.

Configuration Table Example

Monitoring

The monitoring feature allows dynamic monitoring of a set of values from the device.

Monitor – activates the monitoring process for the indicated set of values. Other functions

of the program are blocked.

Stop - Stops the monitoring process. All functionalities are enabled.

Monitoring table:

Name – the name of the variable.

Value – the read value from the device.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 41

Page 46

Unit – the unit of the displayed value.

Description – a short description of the variable.

Monitoring Table Example

The values that are displayed are stored in the monitoring.xml file, which is located in the

“files” folder where the DIN-TSTAT-FCU Commissioning Tool is installed.

Variable Forcing

For certain fields of the monitoring table, it is possible to force values. Enter the numeric or

binary value, and then click

to the previous state, click

Force to force the value. To stop forcing the value and return it

Deforce.

Troubleshooting

Error Code

Using Cresnet, the DIN-TSTAT-FCU can report certain errors. The errors are bit coded in

FCU_type join as presented in the table below.

Error Codes

BIT ERROR DESCRIPTION

15 Parameter error There is an error in parameters stored in flash.

14 Main power supply error The main power supply is off or voltage is below minimum

13 Water temperature error The water temperature is inadequate or the water

12 Probe 1 error The air temperature probe is not connected or is shorted.

11 Probe 2 error The second temperature probe is not connected or is

level.

temperature probe is not functioning. An error is reported

only if water temperature measuring is enabled.

shorted. An error is reported only if second temperature

probe is enabled.

42 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 47

Troubleshooting

The following provides corrective actions for possible trouble situations. If further assistance

is required, please contact a Crestron customer service representative.

DIN-TSTAT-FCU Troubleshooting

TROUBLE POSSIBLE CAUSE(S) ACTION

The LED indicators

are off on power up.

The Cresnet

communication is not

working.

The local room display

unit is off while the

device is turned on.

The communication

with the local room

display unit is not

functioning.

Power is not being

provided to the device.

The device was left in the

OS update mode.

The OS update procedure

was interrupted.

The Cresnet cable is

improperly wired.

There is an error in the

Cresnet network or

master device.

There is a wiring error. Check the room display unit wiring.

The Modbus

communication

parameters are bad.

The register addresses are

bad.

Check the ac and Cresnet wiring.

Use the DIN-TSTAT-FCU Configuration

Tool to perform an OS update

procedure.

Perform the restore procedure if the

Restore option is enabled in the

DIN-TSTAT-FCU Configuration Tool.

Ensure that the Cresnet connection is

properly made.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check the value

of Cresnet status variable (0-no

connection, 1-activity detected, 2connected).

Check the Cresnet wiring.

Check if either main or Cresnet power

supplies are present.

Turn off the device, reconnect the wiring,

and power up the device again.

Using a voltmeter, check if voltage

between the EP and G pins is 20 Vdc.

If the COM LED indicator blinks once per

second, then DIN-TSTAT-FCU is trying

to establish communication but no

response is received. Use the

DIN-TSTAT-FCU Configuration Tool in

Monitoring mode to check if Modbus is

detected.

Reconnect the communication cable.

Check the communication wiring.

Check if the DIN-TSTAT-FCU and Local

room display unit communication

parameters match.

If the COM LED indicator is Off, check

the communication parameters on the

DIN-TSTAT-FCU.

Use Monitoring mode to check the

Modbus parameters error variable.

(Continued on the following page)

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 43

Page 48

DIN-TSTAT-FCU Troubleshooting (continued)

TROUBLE POSSIBLE CAUSE(S) ACTION

The local room display

unit functions are not

working (e.g., fan

speed, mode change,

set point change,

etc.).

The fan is off when the

fan speed is set to 1,

2, or 3.

The fan is always

operating.

Fan does not change

speed.

Communication with the

local room display unit is

not functioning properly.

Commands from Cresnet

are overriding commands

received from AUX port.

The temperature probe

has an incorrect reading.

There is an error in the fan

speed wiring.

There is an error in the

main power supply wiring.

An alarm is active. Correct the issues that are causing the

The water temperature is

inappropriate.

The operating mode is set

to off.

The FCU initialization

function is in progress.

The Fan speed OFF

enable parameter is 0.

Temperature probe 1 is

reading the wrong

temperature.

The time from the last

speed change has not

expired yet.

The wrong operating

mode is active.

If communication is not functional, refer

to the “the communication with the local

room display unit is not functioning”

error.

Check traffic on Cresnet network.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check:

• Temperature probe error flags.

• Water temperature error flag.

• FCU initialization flag.

• Main power supply error flag.

• Alarm statuses.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, force fan speed

relay outputs

Check the fan speed wiring.

alarm.

Normal fan operation continues once the

water reaches the desired temperature.

Turn the DIN-TSTAT-FCU on.

Normal fan operation continues after the

initialization process is complete.

Using the DIN-TSTAT-FCU Configuration

Tool, read the Fan speed OFF enable

parameter value.

Using DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check the

measured Ambient temperature.

Using the DIN-TSTAT-FCU Configuration

Tool, read the fan speed change delay

parameter value, and wait for time equal

to the set value.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check the

Selected mode value.

(continued on the following page)

44 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 49

DIN-TSTAT-FCU Troubleshooting (continued)

TROUBLE POSSIBLE CAUSE(S) ACTION

A valve is off or is

inactive.

There are temperature

probe errors.

The valve output wiring is

incorrect.

An alarm is active. Using the DIN-TSTAT-FCU Configuration

Check the main power supply and the

valve wiring.

Check if the appropriate FCU type is

selected.

Tool in Monitoring mode, check:

• Temperature probe errors.

• The measured temperatures.

• The main power supply.

• The selected operating mode.

• The current alarm states.

• If Type 1 is selected, check the

analog voltage control output

value. Use the forcing option to

set the desired voltage on the

output regardless of current

regulation state.

• If Type 2 or 3 is selected, check

the OP-CL triac output

variables. Use the forcing

option to place outputs in the

desired state regardless of the

current regulation state.

• If Type 4, 5, or 6 is selected,

check Stage 1 or 2 relay output

variables. Use the forcing

option to place the outputs in

the desired state regardless of

the current regulation state.

(continued on the following page)

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 45

Page 50

DIN-TSTAT-FCU Troubleshooting (continued)

TROUBLE POSSIBLE CAUSE(S) ACTION

The valve remains in

the open position.

The alarms are

inactive when they

should be active.

An incorrect operating

mode is selected.

The FCU initialization has

not finished yet.

The water temperature is

inappropriate.

The freeze prevention

function is activated.

There is an error in the

valve output wiring.

There is an error in the

alarm wiring.

There is an error in the

alarm parameters.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check:

• Measured temperatures.

• Selected operating mode.

• Alarm states.

• If Type 1 is selected check

Analog voltage control output

value. Use forcing option to set

desired voltage on output

regardless of regulation state.

• If Type 2 or 3 is selected check

OP-CL triac output variables.

Use forcing option to place

outputs in desired state

regardless of regulation state.

• If Type 4, 5, or 6 is selected,

check Stage 1/2 relay output

variables. Use forcing option to

place outputs in desired state

regardless of regulation state.

If the mode is on and the measured

ambient temperature is lower than 5 °C,

the valve is fully open to prevent freezing.

Check the valve wiring.

Verify that the freeze prevention functions

are operating correctly.

Check the valve output wiring.

Check the alarm wiring.

Using the DIN-TSTAT-FCU Configuration

Tool, verify the alarm polarity and the

delay.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check the

binary input and alarm statuses. Use the

force option to place the input in the

desired state.

(Continued on the following page)

46 • DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat Setup and Commissioning Guide – DOC. 8207A

Page 51

DIN-TSTAT-FCU Troubleshooting (continued)

TROUBLE POSSIBLE CAUSE(S) ACTION

The alarms are

triggered too fast or

too slow.

The alarms are always

active.

There is an error in an

alarm parameter.

There is an error in the

alarm wiring.

There is an error in the

alarm parameters.

Using the DIN-TSTAT-FCU Configuration

Tool, check the selected alarm delay.

Check the alarm wiring.

Using the DIN-TSTAT-FCU Configuration

Tool, check the selected alarm polarity

and the delay.

Using the DIN-TSTAT-FCU Configuration

Tool in Monitoring mode, check the

binary input and the alarm statuses. Use

the force option to place the input in the

desired state.

Setup and Commissioning Guide – DOC. 8207A DIN-TSTAT-FCU: DIN-Rail Fan-Coil Thermostat • 47

Page 52

Crestron Electronics, Inc. Setup and Commissioning Guide – DOC. 8207A

15 Volvo Drive Rockleigh, NJ 07647 (2048992)

Tel: 888.CRESTRON 08.17

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Loading...

Loading...