Page 1

Crestron C2N/C2NI-CB Series

Cameo

™

Keypads

Operations & Installation Guide

Page 2

This document was prepared and written by the Technical Documentation department at:

Crestron Electronics, Inc.

15 Volvo Drive

Rockleigh, NJ 07647

1-888-CRESTRON

All brand names, product names and trademarks are the property of their respective owners.

©2007 Crestron Electronics, Inc.

Page 3

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Contents

Cameo™ Keypads: C2N/C2NI-CB Series 1

Introduction......................................................................................1

Features and Functions ..........................................................1

Specifications......................................................................... 3

Physical Description ..............................................................4

Industry Compliance..............................................................9

Setup...............................................................................................10

Network Wiring...................................................................10

Identity Code .......................................................................10

Assembly and Installation ...................................................10

Programming Software ..................................................................22

Earliest Version Software Requirements for the PC ...........22

Programming with Crestron SystemBuilder .......................23

Programming with D3 Pro...................................................23

Programming with SIMPL Windows..................................24

Example Program ................................................................ 27

Uploading and Upgrading..............................................................28

Establishing Communication...............................................28

Programs and Firmware.......................................................28

Program Checks...................................................................29

Problem Solving............................................................................. 30

Troubleshooting...................................................................30

Check Network Wiring........................................................ 31

Reference Documents..........................................................32

Further Inquiries ..................................................................32

Future Updates.....................................................................33

Appendix: Template for Flush Mount Hole ..................................34

Return and Warranty Policies ........................................................ 35

Merchandise Returns / Repair Service ................................35

CRESTRON Limited Warranty ..........................................35

Operations & Installation Guide - DOC. 6560 Contents • i

Page 4

Page 5

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Cameo™ Keypads: C2N/C2NI-CB

Series

Introduction

Features and Functions

• Stylish and versatile wall mount keypads (standard mount,

flush mount, or UK mount)

• Versatile combinations of up to six engravable buttons

• "Rocker" action supports up to three functions per button

• Installer-configurable with an assortment of three button sizes

and blank spacers

• Tapered buttons for enhanced tactile response

• Elegant white LED light pipe feedback

• Cresnet

®

communications

• Quick and easy installation—flush mount/standard electrical

box/UK box

• Standard mount model available in almond, black, or white

• Flush mount and UK mount models available in ten designer

colors

Crestron® Cameo introduces a totally different concept in keypad design,

featuring an incredibly small footprint and slim profile with an expanded

array of colors and versatile button configurations.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 1

Page 6

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Cameo Standard Mount

The Cameo standard mount model, C2N-CBD, is designed for

installation in a conventional electrical gang-box using a Decora

®

-style

faceplate (not included).

Cameo Flush Mount

Cameo's unique flush mount design affords a very discreet appearance

occupying just one-third the space of a conventional keypad. Employing

a smart spring clamp mounting system, the C2N-CBF Cameo flush

mount model installs easily in drywall without requiring a back box.

Cameo UK Mount

The version of the Cameo keypad designed for wall box applications

within the UK, C2NI-CBUK, may also be used anywhere a postconstruction flush-mount keypad is required.

Designer Colors

The flush mount and UK mount models are available in a palette of ten

designer colors that has been professionally formulated to harmonize

perfectly in a wide range of modern and traditional living spaces.

Customize Your Button Layout

Exquisitely simple yet extensively customizable, the Cameo keypad can

be configured easily by the installer to provide from one to six buttons.

Each keypad is actually furnished with an assortment of engravable

button caps and blank spacers in three different sizes to support a variety

of physical layouts. The button caps feature an ergonomically tapered

shape for excellent tactile response. The taper of each button can be

oriented upward or downward, enabling two vertically adjacent buttons

to emulate the feel of a single "rocker" switch.

Define Your Functionality

Through software, each button can be individually configured to operate

in one of three possible modes: single-press, left/right rocker, or

left/center/right rocker, supporting a total of up to 18 possible button

presses on a single keypad. Six pinhead-sized white LED light pipes

provide very versatile button feedback and bargraph capability. The

LED's may be oriented to the left or right of the buttons simply by

inverting the keypad. In their "off" state, the LED's may be set to glow

2 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 7

Crestron C2N/C2NI-CB Series Cameo™ Keypads

dimly for enhanced visibility in a darkened room. Adjustable button

backlighting is also provided.

Specifications

Specifications for the C2N/C2NI-CB Series keypads are listed in the

following table.

C2N/C2NI-CB Series Specifications

SPECIFICATION DETAILS

Power Requirements

Cresnet Power Usage 3 Watts (0.125 Amps @ 24 VDC)

Default Net ID

Minimum 2-Series Control

System Update File

1, 2, 3

25

Version 2.004.CUZ or later

C2N-CB Series Firmware C2N-CB.v2.10.upg or later

Environmental

Temperature

Humidity

32° to 113°F (0° to 45°C)

10% to 90% RH

(non-condensing)

Enclosure Injection-molded plastic, plus

model-specific mounting options

Dimensions:

Flush Mount Model

Standard Mount Model

Height: 3.20 in (8.13 cm)

Width: 1.73 in (4.38 cm)

Depth: 1.52 in (3.86 cm)

4

4

5

Height: 4.12 in (10.47 cm)

Width: 1.80 in (4.56 cm)

Depth: 1.52 in (3.86 cm)

5

UK Mount Model

Height: 3.38 in (8.58 cm)4

Width: 3.38 in (8.58 cm)

Depth: 1.52 in (3.86 cm)

4

5

Weight 2.6 oz (73 g) – Flush mount

3.1 oz (87 g) – Standard Mount

2.5 oz (70 g) – UK Mount

1. The latest versions can be obtained from the Crestron website. Refer to NOTE

after last footnote.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 3

Page 8

Cameo™ Keypads Crestron C2N/C2NI-CB Series

2. Crestron 2-Series control systems include the AV2 and PRO2. Consult the latest

Crestron Product Catalog for a complete list of 2-Series control systems.

3. Minimum Non 2-Series Control System Update Files:

CEN/CN/TVAV Version 5.12.63V.UPZ or later

CNMSX-AV/PRO Version 5.14.02X.UPZ or later

CNRACKX/-DP Version 5.14.02W.UPZ or later

ST-CP Version 4.02.4S.UPZ or later

CNX update files are required for either CNMSX-AV/PRO or CNRACKX/-DP.

Filenames for CNX update files have a UPZ extension, and ST-CP files are in one

EXE or zipped UPZ file. To avoid program problems, make sure you are using

the update file with the correct suffix letter (e.g., S, V, W, X).

4. Dimension includes faceplate.

5. The depth of the Keypad is listed without the Cresnet connector (approximately

0.45 in) and clearance for the wiring.

NOTE: Crestron software and any files on the website are for Authorized

Crestron dealers and Crestron Authorized Independent Programmers

(CAIP) only. New users may be required to register to obtain access to

certain areas of the site (including the FTP site).

Physical Description

This section provides information on the connections, controls and

indicators available on your C2N/C2NI-CB Series keypad.

C2N/C2NI-CB Series Keypad Physical Views

The illustration above shows three of many possible flush mount

configurations: two double-row switches with two single-row switches

(A); three double-row switches (B); and six single-row switches (C), all

with the LED indicators on the left. A UK configuration with three

4 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 9

Crestron C2N/C2NI-CB Series Cameo™ Keypads

double-row switches is also shown (D). The tapered button caps are

arranged here in a shingle style with the narrow part of the button cap at

the top. Each button cap can, however, be arranged in either orientation,

and the overall keypads can be installed with the LEDs on the right.

Spacers are flat and flush with the front of the bezel surface.

Button caps are laser-engravable using the Crestron Engraver software;

spacers are not. The engraving software provides up to three fields for

each button cap to allow for the left/right and center press functions,

permits multiple lines of text, and also allows you to specify the

orientation of each button cap. The Crestron Engraver software, Version

2.4 or later, is available from the Crestron website.

The following illustrations provide overall dimensions of the three

keypad styles.

Keypad Overall Dimensions – Flush Mount Configuration

(3.86 cm)

1.73 in

(4.38 cm)

1.52 in

3.20 in

(8.13 cm)

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 5

Page 10

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Keypad Overall Dimensions – Standard Mount Configuration

1.52 in

(3.86 cm)

1.80 in

(4.56 cm)

4.12 in

(10.47 cm)

6 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 11

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Keypad Overall Dimensions – UK Mount Configuration

1.14 in

(2.89 cm)

1.52 in

(3.86 cm)

0.30 in

(0.76 cm)

3.38 in

(8.58 cm)

3.38 in

(8.58 cm)

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 7

Page 12

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Rear Housing and Switch Assembly

1

Front

Rear

2

Bottom

Connectors, Controls & Indicators

# CONNECTORS*,

DESCRIPTION

CONTROLS &

INDICATORS

1 LED Light Pipes Six pinhead-sized white LED light

pipes provide button feedback

and bargraph capability

2 Four-position terminal block

connector for data and power.

Connects to Cresnet control

network.

Pin 1 (24) Power

Pin 2 (Y) Data

Pin 3 (Z) Data

Pin 4 (G) Ground

*Interface connector for the NET port is provided with the unit.

8 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 13

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Industry Compliance

As of the date of manufacture, the C2N/C2NI-CB Series keypads have

been tested and found to comply with specifications for CE marking and

standards per EMC and Radiocommunications Compliance Labelling.

NOTE: This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 9

Page 14

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Setup

Network Wiring

When wiring the network, consider the following:

• Use Crestron Certified Wire.

• Use Crestron power supplies for Crestron equipment.

• Provide sufficient power to the system.

CAUTION: Insufficient power can lead to unpredictable results

or damage to the equipment. Please use the Crestron Power

Calculator to help calculate how much power is needed for the

system (http://www.crestron.com/calculators

).

• For larger networks, use a Cresnet Hub/Repeater (CNXHUB) to

maintain signal quality.

For more details, refer to “Check Network Wiring” on page 31.

Identity Code

The Net ID of the C2N/C2NI-CB Series keypad has been factory set to 25.

The Net IDs of multiple C2N/C2NI-CB Series devices in the same system

must be unique. Net IDs are changed from a personal computer (PC) via the

Crestron Toolbox™ (refer to “Establishing Communication” on page 28).

When setting the Net ID, consider the following:

• The Net ID of each unit must match an ID code specified in the

SIMPL Windows program.

• Each network device must have a unique Net ID.

For more details, refer to the Crestron Toolbox help file.

Assembly and Installation

Assembly of the keypad consists of placing the button caps/spacers in

position based on how the unit is programmed, securing them together

with a plastic button support, putting the button cap/spacer assembly in

place on the rear housing and switch assembly, and attaching the bezel.

10 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 15

Crestron C2N/C2NI-CB Series Cameo™ Keypads

The button caps are tapered, and are often installed in a shingle-style

pattern (refer to the “C2N/C2NI-CB Series Keypad Physical Views”

illustration on page 4). Usual orientation of the keypad is with the LEDs

on the left. It can, however, be inverted with the LEDs on the right, but

the original relationship of the button numbers to the LEDs remains, i.e.,

with the unit inverted, row one is on the bottom – row six is on the top,

and programming of the switches would have to be done accordingly.

Installation consists of connecting the unit to the Cresnet system, and

then mounting it directly to the mounting surface or to a back box,

depending on the keypad configuration.

The following items are required for all installations:

• Cresnet network cable (not supplied)

• Cresnet 4-pin mating connector (supplied)

• No. 2 Phillips screwdriver (not supplied)

NOTE: Verify that you have sufficient Cresnet power to support your

net devices.

Flush Mounting Installation

The Cameo keypad for flush mounting installation is supplied partially

assembled along with several items as listed in the following table.

Supplied Parts/Assemblies – Flush Mounting

QTY ITEM DESCRIPTION

1 Rear housing and switch

assembly

1 Bezel Bezel assembly

1 4-pin female mini network

connector

2 Screws, Black, Phillips

pan head, 4-40 x 3/16”

Rear housing with switch circuitry

attached

Used to connect Cresnet network

cable to the keypad

Used to attach the bezel assembly to

the keypad rear housing and switch

assembly

6 Single row button cap Switch cover for a single row switch

3 Double row button cap Switch cover for two switches that

function as one

(Continued on following page)

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 11

Page 16

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Supplied Parts/Assemblies – Flush Mounting (Continued)

QTY ITEM DESCRIPTION

2 Triple row

button cap

2 Single row

spacer

1 Double row

spacer

1 Triple row

spacer

1 Plastic button

support

1 Spring clamp Used to secure the assembled keypad in the

1 Template Used to mark correct hole size in the wall

Switch cover for three switches that function as

one

Switch cover for single non-operational switch

Switch cover for two non-operational switches

Switch cover for three non-operational switches

Used to hold the button caps/spacers together

in position

wall

Assemble the keypad as described in the following steps. Refer to the

accompanying illustrations.

1. Place the button caps and/or spacers in position according to the

program plan. Attach the plastic button support to the button

caps/spacers, and put the assembled parts in place on the rear

housing and switch assembly. (Refer to the illustration for the

standard mounting installation procedures, step 1, on page 16.)

2. Carefully position the bezel assembly, LED edge first, down

and over the button caps/blanks and rotate slightly into position

on the rear housing and switch assembly.

3. Hold the bezel and rear housing together and install and tighten

the two supplied Phillips pan head, 4-40 x 3/16” cover screws

(black) into the rear housing and switch assembly, as shown in

the following illustration.

4. Press each button to be certain that you feel the press and

release to ensure that the button caps move freely.

12 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 17

Crestron C2N/C2NI-CB Series Cameo™ Keypads

LED

Holes

LED

Light

Pipes

Bezel

Button Caps

and Spacers

Plastic Button

Support

Rear Housing

and Switch

Assembly

Cover

Screw

5. Attach the spring clamp to the rear of the keypad, as shown in

the following figure, by loosening the screws sufficiently to

place the clamp over the screws and slide it down into position,

and then retighten the screws.

Loosen

Screws

Spring

Clamp

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 13

Page 18

Cameo™ Keypads Crestron C2N/C2NI-CB Series

6. Use the supplied template to prepare the hole in the wall. (Refer

to the Appendix on page 34 for an illustration of the template.)

NOTE: Be very careful when cutting the hole. There are no adjustments

for alignment with the spring clamp.

After the Cresnet network wiring has been installed and verified,

use the following procedure to install the keypad in the prepared

hole.

1. Turn Cresnet system power OFF.

2. Connect the Cresnet cable, using the supplied mating

connector, to the keypad’s Cresnet port.

3. Make sure the keypad is oriented properly and insert the keypad

in the hole. The natural action of the spring clamp holds the

keypad in position.

Slot

4. Turn Cresnet system power ON.

5. If the keypad needs to be removed from the wall, there is a slot

on one edge of the bezel (refer to the figure). Use a small flat

blade screwdriver to pry the keypad away from the wall, being

careful to avoid damage to the wall surface, and use your

fingers to remove the keypad.

14 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 19

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Standard Mounting Installation

The keypad for standard mounting installation is supplied partially

assembled along with several items as listed in the following table.

Supplied Parts/Assemblies – Standard Mounting

QTY ITEM DESCRIPTION

1 Rear housing and switch

assembly

1 Bezel assembly Bezel and metal plate assembly, with

1 4-pin female mini network

connector

2 Screws, Black, Phillips

pan head, 4-40 x 3/16”

6 Single row button cap Switch cover for a single row switch

3 Double row button cap Switch cover for two switches that

2 Triple row button cap Switch cover for three switches that

2 Single row spacer Switch cover for single non-

1 Double row spacer Switch cover for two non-operational

1 Triple row spacer Switch cover for three non-operational

Rear housing with switch circuitry

attached

ground wire

Used to connect Cresnet network

cable to the keypad

Used to attach the bezel assembly to

the keypad rear housing and switch

assembly

function as one

function as one

operational switch

switches

switches

1 Plastic button support Used to hold the button caps/spacers

together in position

2 Screws, Steel, Phillips,

pan head, 6-32 x 7/8”

Used to attach the assembled keypad

to a back box

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 15

Page 20

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Assemble the keypad as described in the following steps. Refer to the

accompanying illustrations.

1. Arrange the button caps

and/or spacers in position

according to the program

plan. Attach the plastic

button support to the button

caps/spacers, and put the

assembled parts in place on

the rear housing and switch

assembly.

2. Carefully position the bezel

assembly, LED edge first,

down and over the button caps/spacers and rotate slightly into

position on the rear housing and switch assembly.

LED

Holes

LED

Light

Pipes

Bracket

Bezel

Assembly

Ground

Button Caps

Wire

and Spacers

Plastic Button

Support

Rear Housing

and Switch

Assembly

Cover

Screw

3. Hold the bezel and rear housing together.

4. Install and tighten the two supplied Phillips pan head,

4-40 x 3/16” cover screws (black), as shown in the illustration.

5. Press each button to be certain that you feel the press and

release to ensure that the button caps move freely.

16 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 21

Crestron C2N/C2NI-CB Series Cameo™ Keypads

After the Cresnet network wiring has been installed and verified, use the

following procedure to install the keypad in a standard, single-gang

electrical box (not supplied).

1. Turn Cresnet system power OFF.

2. Connect the Cresnet cable to the keypad’s Cresnet port, using

the supplied mating connector.

CAUTION: Excess wire pinched between the keypad and electrical box

could short out. Make sure that all excess wire is completely inside the

electrical box and not between the box and the keypad.

3. Attach the ground wire to the ground screw of the electrical

box.

4. Make sure the keypad is oriented properly, place it in the

electrical box, and attach using the supplied 7/8 in. pan head

screws.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 17

Page 22

Cameo™ Keypads Crestron C2N/C2NI-CB Series

5. Attach the desired Decora style faceplate (not supplied).

6. Turn the Cresnet system power ON.

UK Mounting Installation

The keypad for UK mounting installation is supplied partially assembled

along with several items as listed in the following table.

Supplied Parts/Assemblies – UK Mounting

QTY ITEM DESCRIPTION

1 Rear housing and

switch assembly

1 Bezel Bezel assembly

1 Plastic wall plate Alternate mounting device and bezel

1 4-pin female mini

network connector

2 Screws, Black,

Phillips pan head,

4-40 x 3/16”

6 Single row button cap Switch cover for a single row switch

3 Double row button

cap

2 Triple row button cap Switch cover for three switches that

2 Single row spacer Switch cover for single non-operational

1 Double row spacer Switch cover for two non-operational

Rear housing with switch circuitry

attached

support

Used to connect Cresnet network cable

to the keypad

Used to attach the bezel assembly to the

keypad rear housing and switch

assembly

Switch cover for two switches that

function as one

function as one

switch

switches

1 Triple row spacer Switch cover for three non-operational

switches

2 Screws, Steel,

Phillips, pan head,

6-32 x 7/8”

Used only to attach assembled keypad to

back box

Assemble the keypad as described in the following steps. Refer to the

accompanying illustration.

1. Place the button caps and/or spacers in position according to the

program plan. Attach the plastic button support to the button

18 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 23

Crestron C2N/C2NI-CB Series Cameo™ Keypads

caps/spacers, and put the assembled parts in place on the Rear

Housing and Switch assembly. (Refer to the illustration for the

standard mounting installation procedures, step 1, on page 16.)

2. Carefully position the bezel assembly, LED edge first, down

and over the button caps/blanks and rotate slightly into position

on the rear housing and switch assembly.

3. Hold the bezel and rear housing together and install and tighten

the two supplied Phillips pan head, 4-40 x 3/16” cover screws

(black), as shown in the illustration.

LED

Holes

LED

Light

Pipes

Bezel

Button Caps

and Spacers

Plastic Button

Rear Housing

and Switch

Assembly

Cover

Screw

Suport

4. Press each button to be certain that you feel the press and

release to ensure that the button caps move freely.

The keypad can be mounted directly to an appropriate surface or it can be

mounted to a back box. In both cases, you can choose to have mounting

screws visible or hidden.

Mounting to the Surface

Use the supplied template to prepare the hole in the wall. (Refer to the

Appendix on page 34 for an illustration of the template.) After the

Cresnet network wiring has been installed and verified, use the following

procedure to install the keypad in the prepared hole.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 19

Page 24

Cameo™ Keypads Crestron C2N/C2NI-CB Series

1. Put the plastic wall plate in position over the prepared hole and

attach using two screws (not supplied) appropriate for the

mounting surface. (Refer to A in the figure on page 21.)

2. Turn Cresnet system power OFF, and connect the Cresnet cable

to the keypad’s Cresnet port, using the supplied mating

connector.

3. Insert the keypad into the hole and press the bezel against the

plastic wall plate until it snaps securely into position.

4. Turn the Cresnet system power ON.

If the keypad needs to be removed from the wall, there are two slots on

one edge of the bezel (visible on the bottom edge of view C in the figure

on page 21). Use a flat blade screwdriver to pry the bezel away from the

wall plate, being careful to avoid damage to the bezel.

Mounting to a UK Back Box

Prepare the hole in the wall appropriate for the back box. (Back boxes for

these keypads are typically square or rounded and have tabs with screw

holes for mounting the keypads on each side rather than top and bottom.)

After the Cresnet network wiring has been installed and verified, use the

following procedure to install the keypad in the back box.

1. Put the plastic wall plate in position over the back box and

attach using the supplied 7/8 in. pan head screws. (Refer to B in

the figure on page 21.)

2. Turn Cresnet system power OFF, and connect the Cresnet cable

to the keypad’s Cresnet port, using the supplied mating

connector.

3. Insert the keypad into the hole and press the bezel against the

plastic wall plate until it snaps securely into position.

4. Turn the Cresnet system power ON.

If the keypad needs to be removed from the wall, there are two slots on

one edge of the bezel (visible on the bottom edge of view C in the figure

on page 21). Use a flat blade screwdriver to pry the bezel away from the

wall plate, being careful to avoid damage to the bezel.

20 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 25

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Mounting Using Screws Through the Bezel

Refer to the figure on the next page and do the following.

1. Drill pilot holes through the bezel from the rear at each of the

drill center points. Then, from the front of the bezel, drill the

final holes and countersink as required. (Refer to C in the

following figure.)

2. Place the plastic wall plate over the keypad with the smooth

surface facing out, and snap the wall plate and bezel together.

3. Attach the keypad to the mounting surface or to the back box

using the appropriate screws.

4. Turn the Cresnet system power ON.

If the keypad needs to be removed from the wall, remove the screws

securing the keypad to the mounting surface/back box, and pull the

keypad free.

UK Mounting Options

A

Screws

(not supplied)

C2NI-CBUK

C

Bezel

(Rear View)

Plastic

Wall Plate

B

Screws

(supplied)

Back Box

(typical)

Plastic

Wall Plate

Drill

Centerpoint (2)

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 21

Page 26

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Programming Software

Have a question or comment about Crestron software?

Answers to frequently asked questions (FAQs) can be viewed in the

Online Help section of the Crestron website. To post a question or view

questions you have submitted to Crestron’s True Blue Support, log in at

http://support.crestron.com

account.

Earliest Version Software Requirements for the PC

. First-time users will need to establish a user

NOTE: Crestron recommends that you use the latest software to take

advantage of the most recently released features. The latest software is

available from the Crestron website.

Crestron has developed an assortment of Windows-based software tools

to develop a Cresnet system. The following are the minimum

recommended software versions for the PC:

Software

TASK REQUIRED SOFTWARE

VERSION

Program control

system to operate

C2N/C2NI-CB Series

keypads.

Upload program and

firmware.

SIMPL Windows version 2.05.22 or

later with SIMPL+ Cross Compiler

version 1.1. or later and Library

update 311 or later. Also requires

Crestron Database version 16.4 or

later.

Crestron Toolbox 1.01.11 or later.

(Continued on following page)

22 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 27

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Software (Continued)

TASK REQUIRED SOFTWARE

VERSION

Program with simple

wizards for systems

using a C2N/C2NI-CB

Series keypads.

Software for lighting

and environmental

controls (optional)

Create labels for front

panel buttons.

Crestron SystemBuilder™ version

1.0 or later (requires SIMPL

Windows, VT Pro-e, Crestron

Database and Crestron Engraver)

with SystemBuilder Templates

version 1.0 or later. Refer to software

release notes or Crestron website for

other required Crestron software

packages.

Crestron D3 Pro™ version 2.1.7 or

later (requires D3 Pro Templates

version 2.0.1 or later).

Crestron Engraver version 2.4 or

later.

Programming with Crestron SystemBuilder

Crestron SystemBuilder is the easiest method of programming but does

not offer as much flexibility as SIMPL Windows. For additional details,

download SystemBuilder from the Crestron website and examine the

extensive help file.

Programming with D3 Pro

Crestron’s D3 Pro lighting software provides all the tools necessary to

create a complete Crestron lighting system for residential applications.

The lighting system includes the control system logic program,

touchpanel projects and keypad programming, documentation and realtime lighting adjustment capabilities.

As with all Crestron software, D3 Pro provides extensive right-click and

drag-and-drop functionality in addition to convenient keyboard shortcuts

for frequently used functions and commands.

Programming is organized into six system Views of the lighting system,

each providing a moveable toolbox of devices such as interfaces, fixtures

and control modules. You can add a device to your system simply by

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 23

Page 28

Cameo™ Keypads Crestron C2N/C2NI-CB Series

selecting it from one of the toolboxes and dragging it to a room. The

available toolboxes differ depending on the View but all Views include a

"General" toolbox that allows you to add areas and rooms at any time.

Programming with SIMPL Windows

NOTE: While SIMPL Windows can be used to program the

C2N/C2NI-CB Series keypads, it is recommended to use SystemBuilder

for configuring a system.

SIMPL Windows is Crestron’s premier software for programming

Crestron control systems. It is organized into two separate but equally

important “Managers”.

Configuration

Manager

Configuration Manager is the view where programmers “build” a

Crestron control system by selecting hardware from the Device Library.

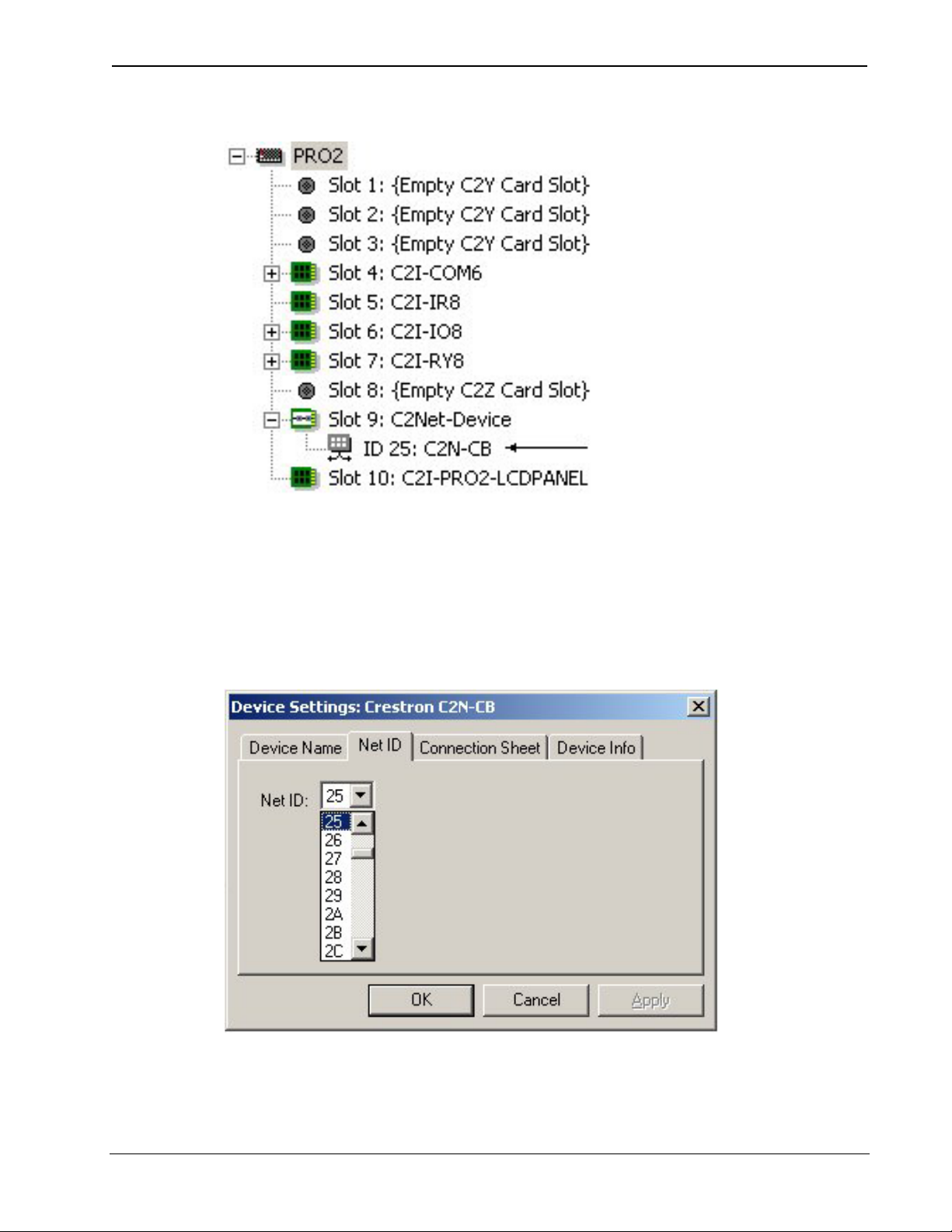

• To incorporate the C2N/C2NI-CB keypad into the system, drag the

C2N-CB icon, which includes all models, from the Wired Keypads

folder of the Device Library and drop it in the System Views.

Locating the C2N-CB in the Device Library

• The system tree of the control system displays the device in the

appropriate slot with a default Net ID as shown in the following

illustration.

24 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 29

Crestron C2N/C2NI-CB Series Cameo™ Keypads

C2Net Device, Slot 9

• Additional C2N/C2NI-CB Series devices are assigned different

Net ID numbers as they are added.

• If necessary, double click a device to open the “Device Settings”

window and change the Net ID, as shown in the following figure.

“C2N-CB Device Settings” Window

• The ID code(s) specified in the SIMPL Windows program must

match the Net ID of each unit.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 25

Page 30

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Program

Manager

Program Manager is the view where programmers “program” a Crestron

control system by assigning signals to symbols.

The symbol can be viewed by double-clicking on the icon or dragging it

into Detail View. Each signal in the symbol is described in the SIMPL

Windows help file (F1).

Standard Button Arrangement

The following illustration shows the standard arrangement of the buttons

and feedback LEDs on the keypad.

Cameo Keypad Button and Feedback LED Arrangement

Reverse Button Arrangement

In cases where it is desirable to mount the keypad with the feedback

LEDs on the right, programmers will have to take into account that

physically, button 6 is now at the top, button 1 is at the bottom, and that

the right and left switch positions are reversed. Bear in mind, however,

that when combining buttons in this orientation, the usual programming

constraints still apply. For example, if merging buttons 4, 5, and 6, even

though button 6 is now physically at the top of the keypad, button 4 still

controls the mode of the merged buttons.

NOTE: A Crestron module in Crestron Database version 17.1.0, the

C2N-Cameo Bargraph Feedback v1.0, makes it possible to use the

26 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 31

Crestron C2N/C2NI-CB Series Cameo™ Keypads

feedback LEDs like a bargraph, so that for a function like volume

control, as the switches are used to control the volume, the LEDs display

its approximate level.

Example Program

An example program for the C2N/C2NI-CB is available from the

Crestron website (http://www.crestron.com/exampleprograms

).

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 27

Page 32

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Uploading and Upgrading

Crestron recommends using the latest programming software and that

each device contains the latest firmware to take advantage of the most

recently released features. However, before attempting to upload or

upgrade it is necessary to establish communication. Once communication

has been established, files (for example, programs or firmware) can be

transferred to the control system (and/or device). Finally, program checks

can be performed (such as changing the device ID) to ensure proper

functioning.

Establishing Communication

Use Crestron Toolbox for communicating with the C2N/C2NI-CB; refer

to the Crestron Toolbox help file for details. There is a single method of

communication: indirect serial communication.

Indirect Serial Communication

PC RUNNING

CRESTRON TOOLBOX

SERIAL,

ETHERNET

OR USB

CONTROL SYSTEM

CRESNET

C2N/C2NI-CB

• C2N/C2NI-CB connects to control system via Cresnet.

• Establish communications between the PC and the control system

as described in the latest version of the 2-Series Control Systems

Reference Guide (Doc. 6256), which is available from the Crestron

website (http://www.crestron.com/manuals).

Programs and Firmware

Program, project or firmware files may be distributed from programmers

to installers or from Crestron to dealers. Firmware upgrades are available

from the Crestron website as new features are developed after product

releases. One has the option to upload programs via the programming

software or to upload and upgrade via the Crestron Toolbox. For details

on uploading and upgrading, refer to the SIMPL Windows help file or the

Crestron Toolbox help file.

SIMPL

Windows

If a SIMPL Windows program is provided, it can be uploaded to the

control system using SIMPL Windows or Crestron Toolbox.

28 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 33

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Firmware

Check the Crestron website to find the latest firmware. (New users may

be required to register to obtain access to certain areas of the site,

including the FTP site.)

• Upgrade C2N/C2NI-CB firmware via Crestron Toolbox.

• Establish indirect serial communications with the C2N/C2NI-CB

and display the “System Info” window.

• Select Functions | Firmware… to upgrade the C2N/C2NI-CB

firmware.

Program Checks

Display the network device tree (Tools | Network Device Tree) to show

all network devices connected to the control system. Right-click on the

C2N-CB to display actions that can be performed on the C2N/C2NI-CB.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 29

Page 34

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Problem Solving

Troubleshooting

The table below provides corrective action for possible trouble situations.

If further assistance is required, please contact a Crestron customer

service representative.

C2N/C2NI-CB Troubleshooting

TROUBLE POSSIBLE

CAUSE(S)

The keypad does

not function.

The keypad does

not function. All

six feedback

LEDs are on low.

The wrong power

supply is being

used.

The unit is not

receiving power, or

is receiving

insufficient power.

There is a loose

connection in the

network.

Improper Net ID

used.

CORRECTIVE

ACTION

Use a Crestron power

supply.

Verify that the cable

plugged into the NET

port is secure. Verify

that the power supply

is correct.

Verify that the cable

plugged into the NET

port is secure.

Verify that the Cameo

Net ID matches the

Net ID in the software

program.

Keypad does not

function, or does

not function as

expected.

However, it

reports on

Cresnet at the

proper Net ID.

30 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Not programmed

correctly

Use Test Manager to

check the behavior

when buttons are

pressed. Revise and

reload the program as

needed to correct the

behavior.

Page 35

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Check Network Wiring

Use the Right

Wire

Calculate

Power

In order to ensure optimum performance over the full range of your

installation topology, Crestron Certified Wire and only Crestron Certified

Wire may be used. Failure to do so may incur additional charges if

support is required to identify performance deficiencies because of using

improper wire.

CAUTION: Use only Crestron power supplies for Crestron equipment.

Failure to do so could cause equipment damage or void the Crestron

warranty.

CAUTION: Provide sufficient power to the system. Insufficient power

can lead to unpredictable results or damage to the equipment. Please use

the Crestron Power Calculator to help calculate how much power is

needed for the system (http://www.crestron.com/calculators).

When calculating the length of wire for a particular Cresnet run, the wire

gauge and the Cresnet power usage of each network unit to be connected

must be taken into consideration. Use Crestron Certified Wire only. If

Cresnet units are to be daisy-chained on the run, the Cresnet power usage

of each network unit to be daisy-chained must be added together to

determine the Cresnet power usage of the entire chain. If the unit is

home-run from a Crestron system power supply network port, the

Cresnet power usage of that unit is the Cresnet power usage of the entire

run. The wire gauge and the Cresnet power usage of the run should be

used in the following equation to calculate the cable length value on the

equation’s left side.

Cable Length Equation

L = Length of run (or chain) in feet

R = 6 Ohms (Crestron Certified Wire: 18 AWG (0.75 MM ))

or 1.6 Ohms (Cresnet HP: 12 AWG (4 MM ))

P = Cresnet power usage of entire run (or chain)

2

2

L <

Where:

40,000

R x P

Make sure the cable length value is less than the value calculated on the

right side of the equation. For example, a Cresnet run using 18 AWG

Crestron Certified Wire and drawing 20 watts should not have a length of

run more than 333 feet. If Cresnet HP is used for the same run, its length

could extend to 1250 feet.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 31

Page 36

Cameo™ Keypads Crestron C2N/C2NI-CB Series

NOTE: All Crestron certified Cresnet wiring must consist of two

twisted pairs. One twisted pair is the +24V conductor and the GND

conductor and the other twisted pair is the Y conductor and the Z

conductor.

Strip and Tin

Wire

Add Hubs

When daisy-chaining Cresnet units, strip the ends of the wires carefully

to avoid nicking the conductors. Twist together the ends of the wires that

share a pin on the network connector and tin the twisted connection.

Apply solder only to the ends of the twisted wires. Avoid tinning too far

up the wires or the end becomes brittle. Insert the tinned connection into

the Cresnet connector and tighten the retaining screw. Repeat the

procedure for the other three conductors.

For larger networks (i.e., greater than 28 network devices), it may

become necessary to add a Cresnet Hub/Repeater (CNXHUB) to

maintain signal quality throughout the network. Also, for networks with

lengthy cable runs it may be necessary to add a Hub/Repeater after only

20 devices.

Reference Documents

The latest version of all documents mentioned within the guide can be

obtained from the Crestron website (http://www.crestron.com/manuals

This link will provide a list of product manuals arranged in alphabetical

order by model number.

).

List of Related Reference Documents

DOCUMENT TITLE

2-Series Control Systems Reference Guide

Further Inquiries

If you cannot locate specific information or have questions after

reviewing this guide, please take advantage of Crestron's award winning

customer service team by calling the Crestron corporate headquarters at

1-888-CRESTRON [1-888-273-7876]. For assistance in your local time

zone, refer to the Crestron website (http://www.crestron.com/

listing of Crestron worldwide offices.

32 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

) for a

Page 37

Crestron C2N/C2NI-CB Series Cameo™ Keypads

You can also log onto the online help section of the Crestron website to

ask questions about Crestron products. First-time users will need to

establish a user account to fully benefit from all available features.

Future Updates

As Crestron improves functions, adds new features and extends the

capabilities of the C2N/C2NI-CB, additional information may be made

available as manual updates. These updates are solely electronic and

serve as intermediary supplements prior to the release of a complete

technical documentation revision.

Check the Crestron website periodically for manual update availability

and its relevance. Updates are identified as an “Addendum” in the

Download column.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 33

Page 38

Cameo™ Keypads Crestron C2N/C2NI-CB Series

Appendix: Template for Flush Mount Hole

The following figure (not to scale) illustrates the supplied template used

to prepare the hole in the wall or other mounting surface for the flush

mount Cameo keypad.

NOTE: Use only the original template, not a photocopy, to prepare the

hole. Photocopies usually alter the size of the image slightly, which

would make the hole the wrong size.

Be careful when cutting the hole, the spring clamp on the keypad does

not have provision for positioning adjustment. Also, ensure that there is a

sufficient clearance area behind the mounting surface as shown on the

template.

1.38 in

(3.50 cm)

(1 3/8 in)

2.38 in

(6.04 cm)

(2 3/8 in)

3.32 in

(8.42 cm)

(8 27/64 in)

5.38 in

(13.66 cm)

(5 3/8 in)

3.68 in

(9.34 cm)

(3 11/16 in)

2.68 in

(6.80 cm)

(2 11/16 in)

34 • Cameo™ Keypads: C2N/C2NI-CB Series Operations & Installation Guide - DOC. 6560

Page 39

Crestron C2N/C2NI-CB Series Cameo™ Keypads

Return and Warranty Policies

Merchandise Returns / Repair Service

1. No merchandise may be returned for credit, exchange or service without prior authorization

from CRESTRON. To obtain warranty service for CRESTRON products, contact an

authorized CRESTRON dealer. Only authorized CRESTRON dealers may contact the factory

and request an RMA (Return Merchandise Authorization) number. Enclose a note specifying

the nature of the problem, name and phone number of contact person, RMA number and

return address.

2. Products may be returned for credit, exchange or service with a CRESTRON Return

Merchandise Authorization (RMA) number. Authorized returns must be shipped freight

prepaid to CRESTRON, 6 Volvo Drive, Rockleigh, N.J. or its authorized subsidiaries, with

RMA number clearly marked on the outside of all cartons. Shipments arriving freight collect

or without an RMA number shall be subject to refusal. CRESTRON reserves the right in its

sole and absolute discretion to charge a 15% restocking fee plus shipping costs on any

products returned with an RMA.

3. Return freight charges following repair of items under warranty shall be paid by CRESTRON,

shipping by standard ground carrier. In the event repairs are found to be non-warranty, return

freight costs shall be paid by the purchaser.

CRESTRON Limited Warranty

CRESTRON ELECTRONICS, Inc. warrants its products to be free from manufacturing defects in materials

and workmanship under normal use for a period of three (3) years from the date of purchase from

CRESTRON, with the following exceptions: disk drives and any other moving or rotating mechanical

parts, pan/tilt heads and power supplies are covered for a period of one (1) year; touchscreen display and

overlay components are covered for 90 days; batteries and incandescent lamps are not covered.

This warranty extends to products purchased directly from CRESTRON or an authorized CRESTRON

dealer. Purchasers should inquire of the dealer regarding the nature and extent of the dealer's warranty, if

any.

CRESTRON shall not be liable to honor the terms of this warranty if the product has been used in any

application other than that for which it was intended or if it has been subjected to misuse, accidental

damage, modification or improper installation procedures. Furthermore, this warranty does not cover any

product that has had the serial number altered, defaced or removed.

This warranty shall be the sole and exclusive remedy to the original purchaser. In no event shall

CRESTRON be liable for incidental or consequential damages of any kind (property or economic damages

inclusive) arising from the sale or use of this equipment. CRESTRON is not liable for any claim made by a

third party or made by the purchaser for a third party.

CRESTRON shall, at its option, repair or replace any product found defective, without charge for parts or

labor. Repaired or replaced equipment and parts supplied under this warranty shall be covered only by the

unexpired portion of the warranty.

Except as expressly set forth in this warranty, CRESTRON makes no other warranties, expressed or

implied, nor authorizes any other party to offer any warranty, including any implied warranties of

merchantability or fitness for a particular purpose. Any implied warranties that may be imposed by law are

limited to the terms of this limited warranty. This warranty statement supersedes all previous warranties.

Trademark Information

All brand names, product names and trademarks are the sole property of their respective owners. Windows is a registered trademark

of Microsoft Corporation. Windows95/98/Me/XP and WindowsNT/2000 are trademarks of Microsoft Corporation.

Operations & Installation Guide - DOC. 6560 Cameo™ Keypads: C2N/C2NI-CB Series • 35

Page 40

Crestron Electronics, Inc. Operations & Installation Guide - DOC. 6560

15 Volvo Drive Rockleigh, NJ 07647 (2017268)

Tel: 888.CRESTRON 01.07

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Loading...

Loading...