Page 1

Introduction

CRESTRON GREEN LIGHT EXPRESS dimming panels come pre-configured with GLXX-2DIM8 dimming

modules already installed. The cabinets only require installation and wiring of feed and load circuits.

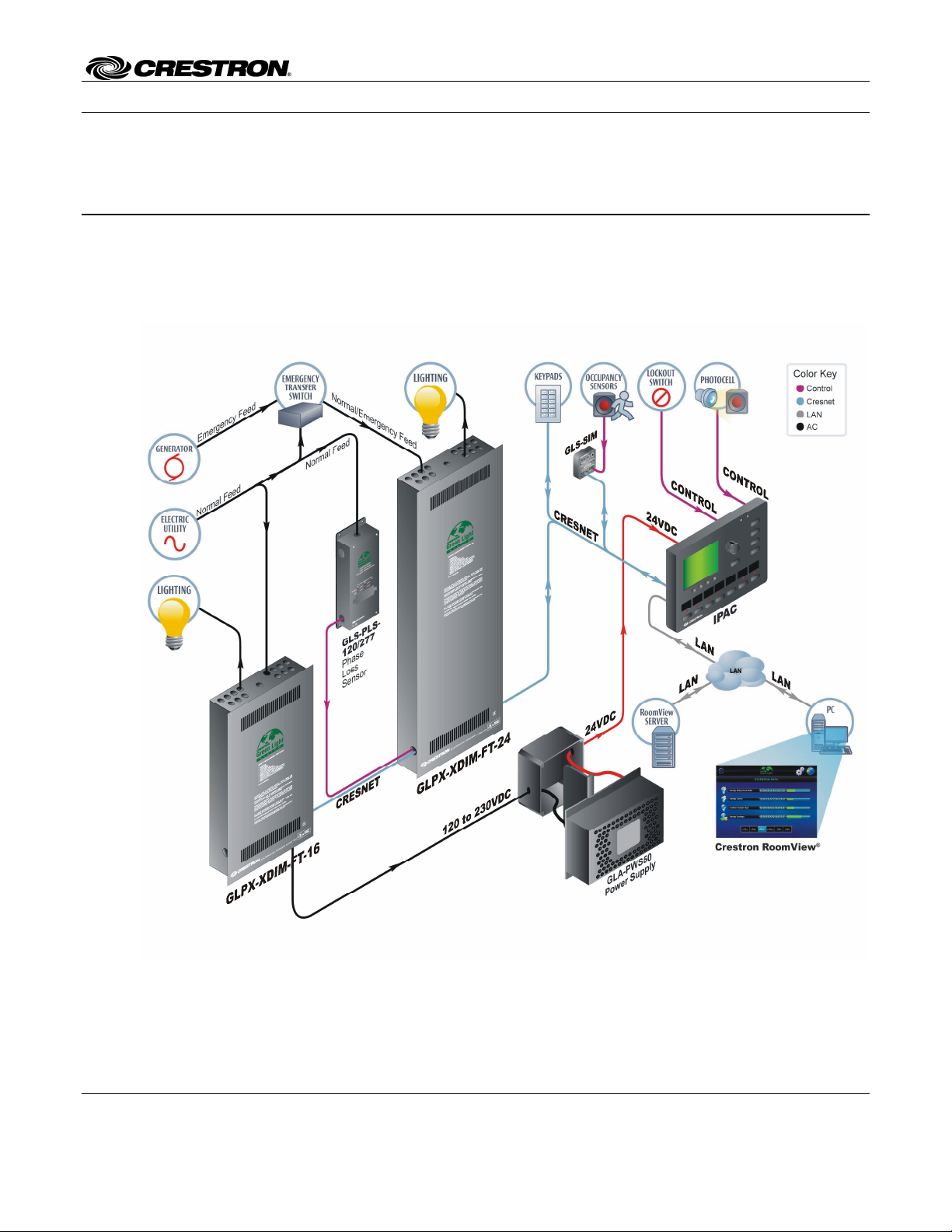

Application

The following diagram shows CRESTRON GREEN LIGHT EXPRESS dimming panels in a lighting application

that is controlled by an IPAC system.

CRESTRON GREEN LIGHT EXPRESS Dimming Panels in a Typical Lighting Application

GREEN LIGHT® EXPRESS Dimming Panel

C

R

E

S

N

E

T

C

R

E

S

N

E

T

O

V

E

R

R

I

D

E

C

O

N

T

R

O

L

C

R

E

S

N

E

T

Crestron Electronics, Inc. Installation Guide – DOC. 6889A

15 Volvo Drive Rockleigh, NJ 07647 (2025420)

Tel: 888.CRESTRON 05.10

Fax: 201.767.7576 Specifications subject to

www.crestron.com change without notice.

Page 2

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Regulatory Compliance

This product is Listed to applicable UL Standards and requirements by Underwriters Laboratories Inc.

As of the date of manufacture, the Green Light Express Dimming Panel has been tested and found to comply

with specifications for CE marking and standards per EMC and Radiocommunications Compliance Labelling.

Federal Communications Commission (FCC) Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following conditions:

(1) This device may not cause harmful interference and (2) this device must accept any interference received,

including interference tha t ma y cause undesired operation.

CAUTION: Changes or modifications not expressly approved by the manufacturer responsible for compliance

could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment genera tes, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particul ar installation. If

this equipment does cause harmful interference to radio or television reception, which can be dete rmined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

Consult the dealer or an experienced radio/TV technician for help

Industry Canada (IC) Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

2 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 3

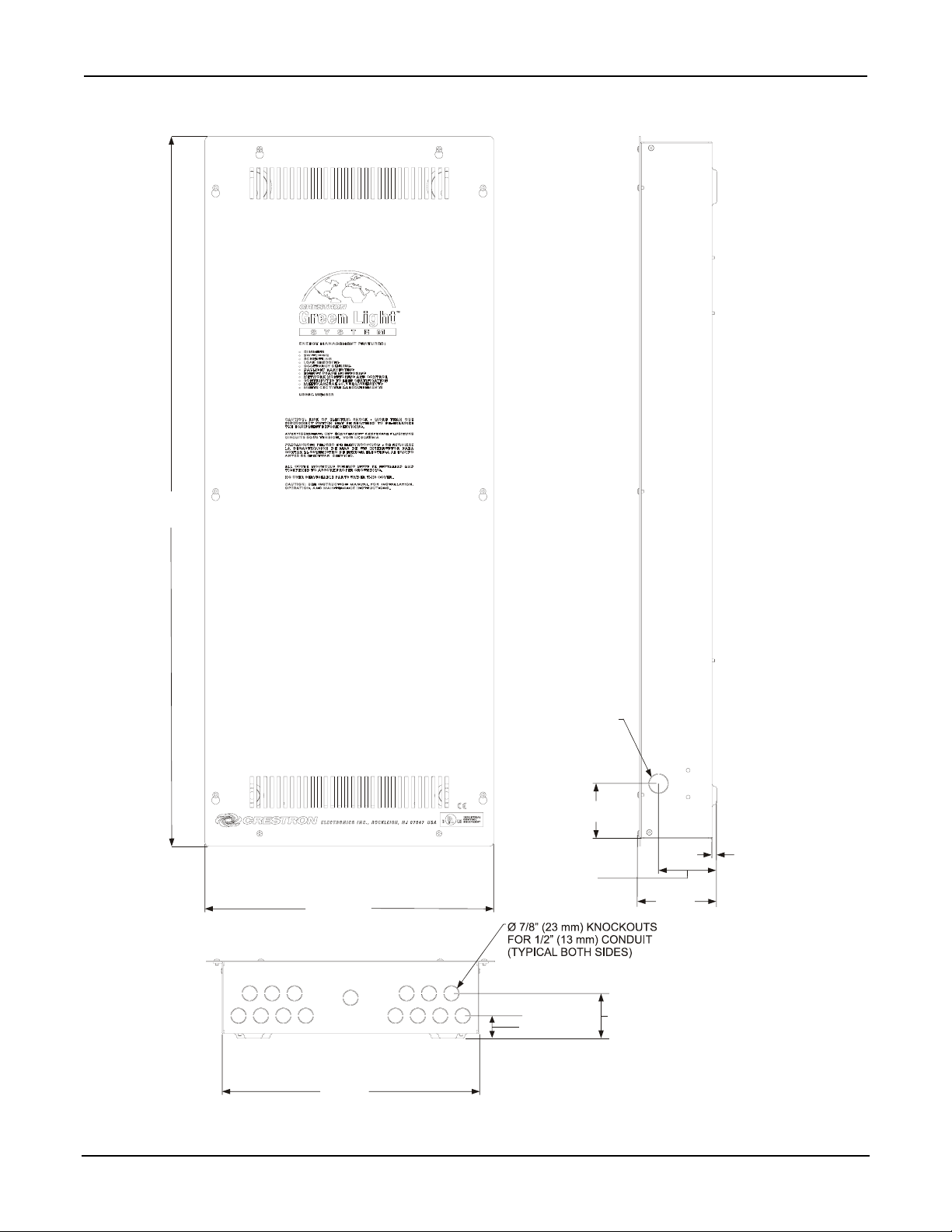

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Physical Description

This section shows the dimensions of the CRESTRON GREEN LIGHT EXPRESS dimming panels.

Dimensions of GLPX-XDIM-FT-8 Dimming Panels (Front, Side and Bottom View)

12 5/16"

(313 mm)

3 9/16"

(91 mm)

1 5/16"

(34 mm)

1/8"

14 1/8"

(359 mm)

2 15/16"

(75 mm)

4 3/8"

(111 mm)

(4 mm)

1 3/8"

(35 mm)

2 15/16"

(75 mm)

1 3/8"

(35 mm)

14 1/8"

(359 mm)

3 1/4"

(83 mm)

1 5/16"

(34 mm)

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 3

Page 4

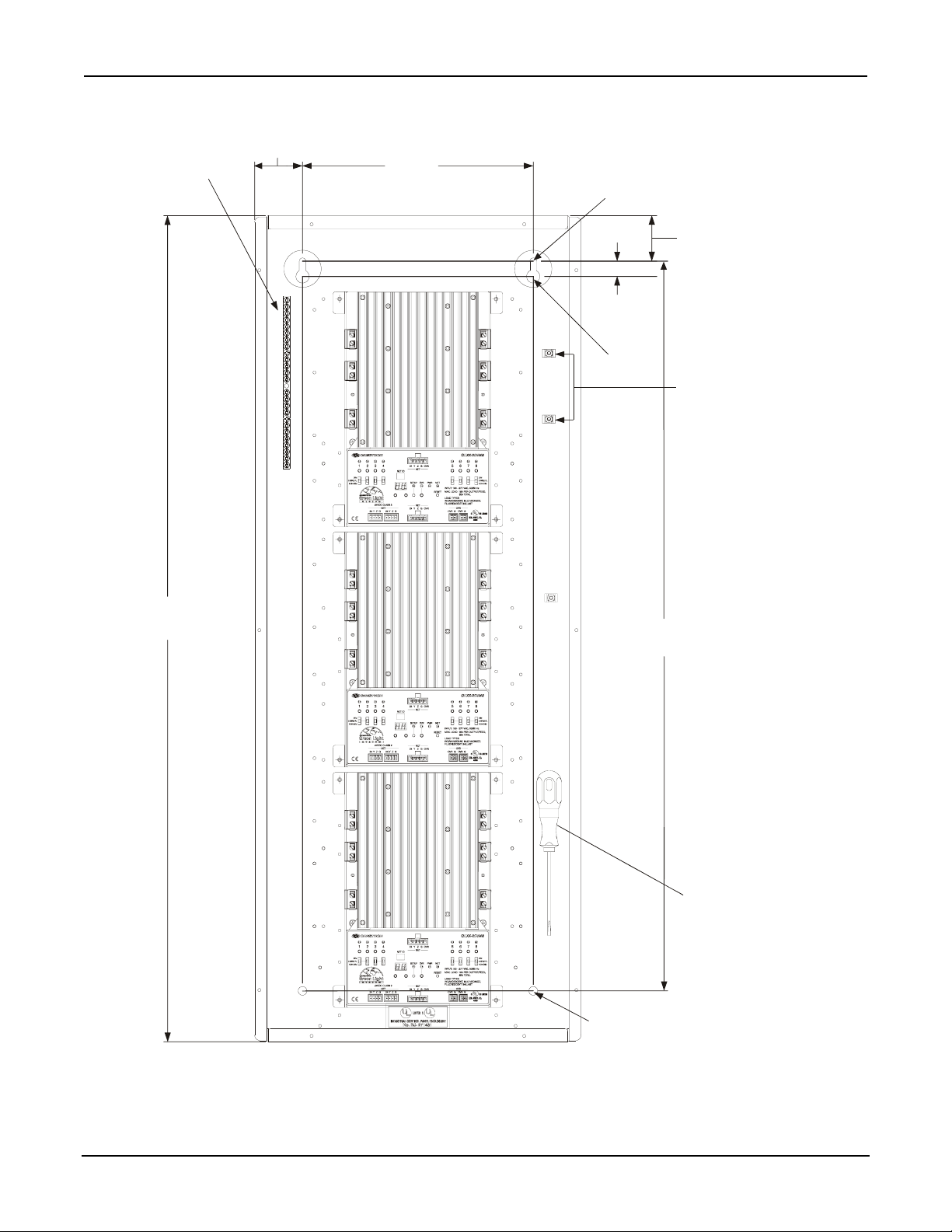

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

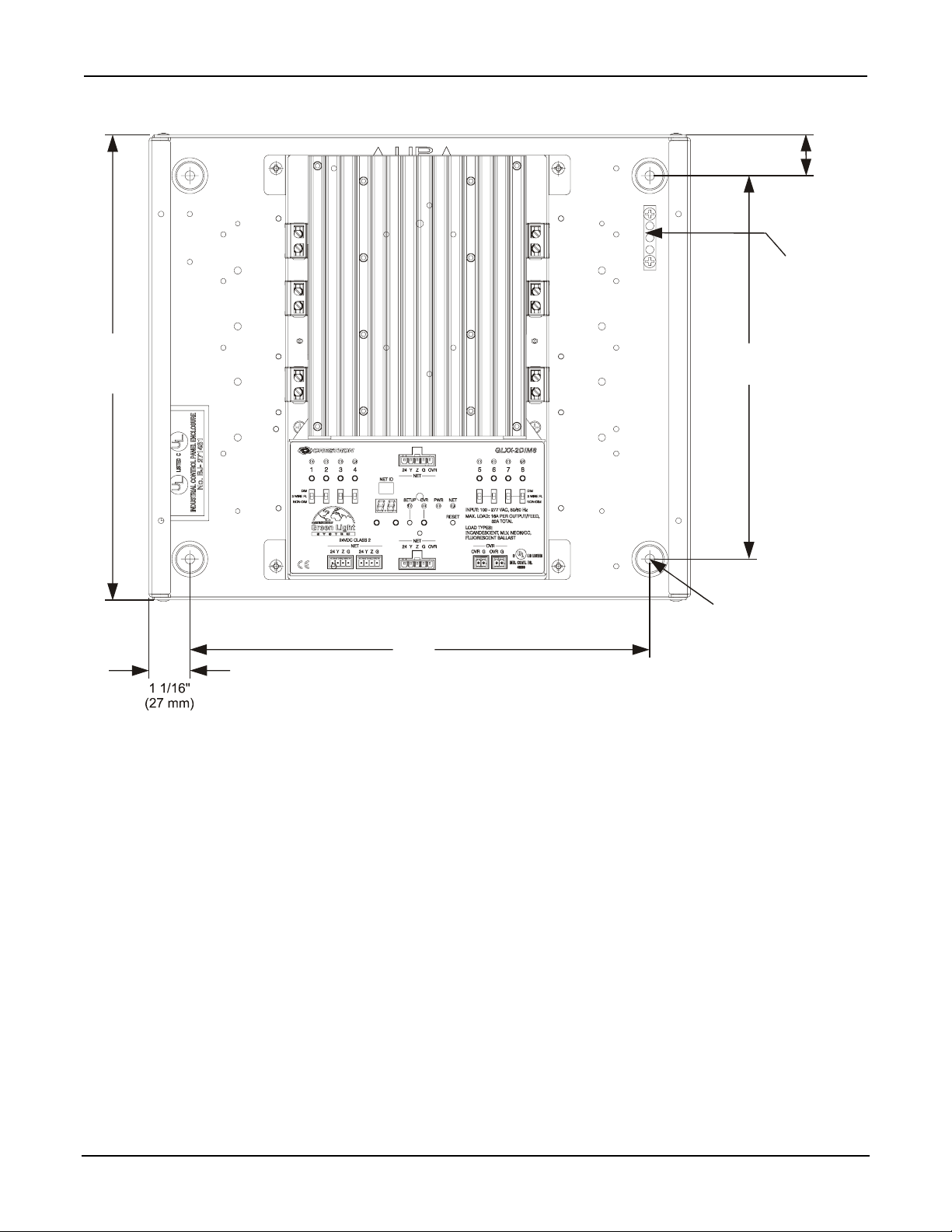

Dimensions of GLPX-XDIM-FT-8 Dimming Panels (Internal View)

1 1/16"

(27 mm)

GROUND

BUS

12 1/8"

(309 mm)

10 "

(254 mm)

(4X) Ø 1/4"

(Ø 7 mm)

MOUNTING HOLES

12 "

(305 mm)

4 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 5

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

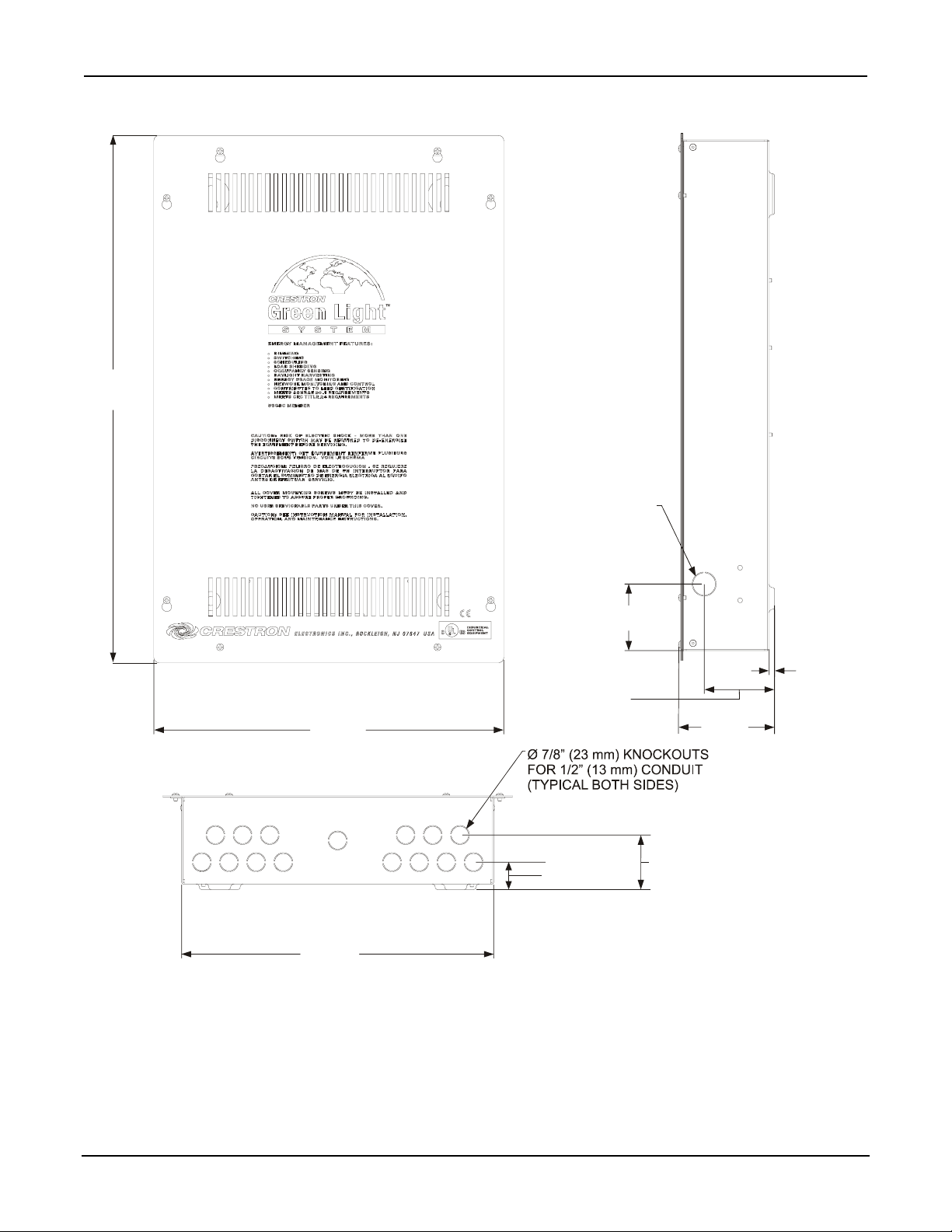

Dimensions of GLPX-XDIM-FT-16 Dimming Panels (Front, Side and Bottom View)

24 1/4"

(616 mm)

KNOCKOUT FOR 3/4”

(20 mm) CONDUIT

(TYPICAL BOTH

SIDES)

3 1/16”

(78 mm)

1/4” (7 mm)

3 1/4”

16 1/8”

(409 mm)

14 3/8"

(365 mm)

(83 mm)

4 7/16”

(113 mm)

2 1/2” (64 mm)

1 1/4” (32 mm)

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 5

Page 6

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

A

Dimensions of GLPX-XDIM-FT-16 Dimming Panels (Internal View)

2 1/4”

(58 mm)

10 7/8”

(276 mm)

(2X) Ø 5/16”

(Ø 8 mm)

MOUNTING HOLES

2 1/8” (55 mm)

(2x) 11/16”

(19 mm)

(2x) Ø 5/8”

(Ø 16 mm)

* TIE WRAP

HOLDERS (MAY

BE MOVED TO

OTHER HOLES

S REQUIRED)

23 1/2"

(597 mm)

18 15/16”

(481 mm)

SERVICE

SCREWDRIVER

(2X) Ø 7/16 ( 12 )

Ømm

MOUNTING HOLES

* Installed GLXX-2DIM8 modules come with additional tie wrap holders.

6 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 7

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Dimensions of GLPX-XDIM-FT-24 Dimming Panels (Front, Side and Bottom View)

39 5/8”

(1 m)

16 1/8”

(409 mm)

14 3/8"

(365 mm)

KNOCKOUT FOR 3/4”

(20 mm) CONDUIT

(TYPICAL BOTH

SIDES)

3 1/16”

(78 mm)

3 1/4”

(83 mm)

1 1/4” (32 mm)

1/4” (7 mm)

4 7/16”

(113 mm)

2 1/2” (64 mm)

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 7

Page 8

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

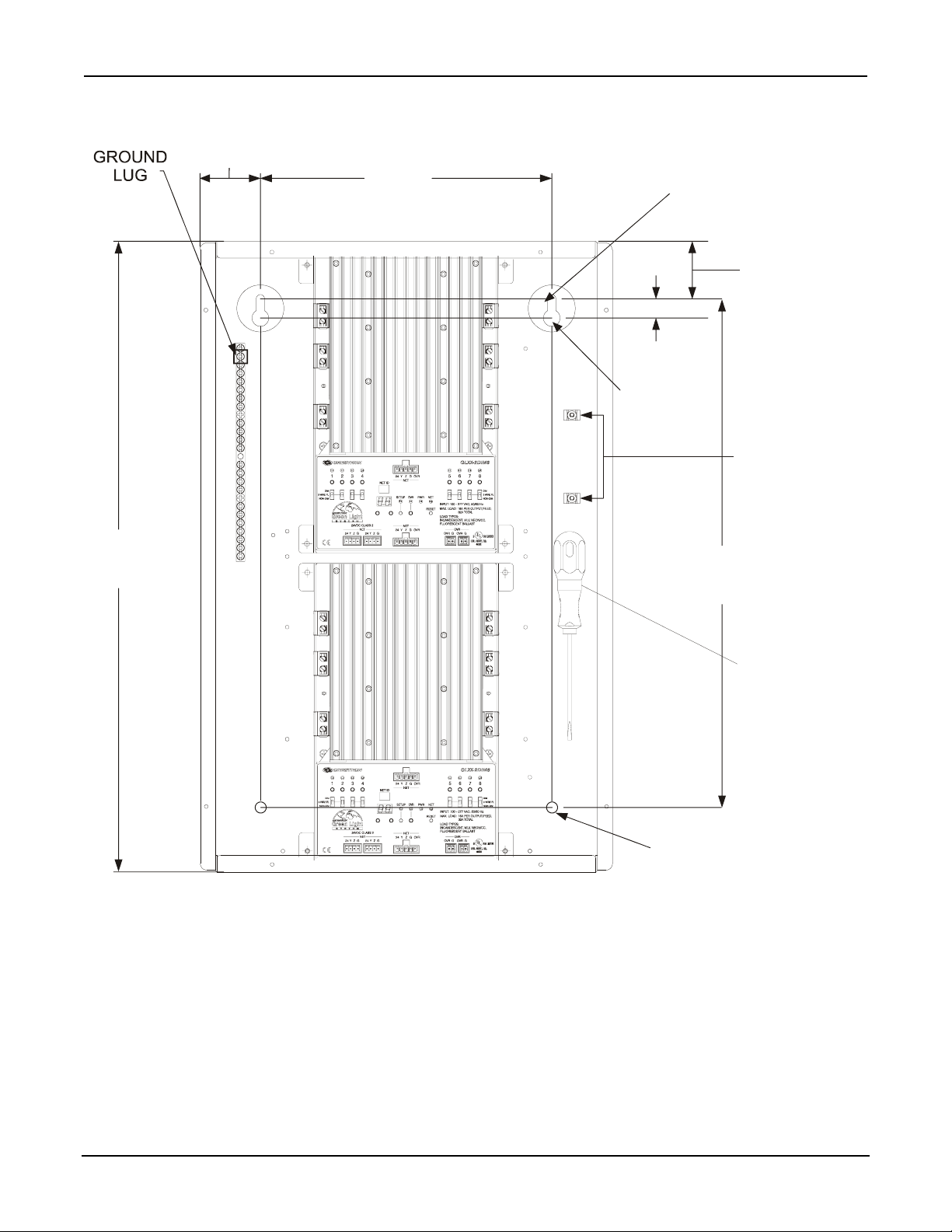

Dimensions of GLPX-XDIM-FT-24 Dimming Panels (Internal View)

2 1/4”

GROUND

LUG

(58 mm)

10 7/8”

(276 mm)

(2X) Ø 5/16”

(Ø 8 mm)

MOUNTING HOLES

2 1/8” (55 mm)

(2x) 11/16”

(19 mm)

38 7/8”

(998 mm)

(2x) Ø 5/8”

(Ø 16 mm)

34 3/8”

(873 mm)

* TIE WRAP

HOLDERS (MAY

BE MOVED TO

OTHER HOLES

AS REQUIRED)

SERVICE

SCREWDRIVER

(2X) Ø 7/16

(Ø 12 mm)

MOUNTING HOLES

* Installed GLXX-2DIM8 modules come with additional tie wrap holders.

8 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 9

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Installation

Observe the following when installing the panel:

• The panel must be mounted by a licensed electrician in accordance with all national and local codes. Refer

to the diagram below for specific requirements.

• The panel is designed for surface mounting on a wall.

• Panels are intended for indoor use only.

• The ambient temperature range should be 32°F to 104°F (0°C to 40°C). The relative humidity should range

from 10% to 90% (non-condensing). Allow adequate clearance in front of the cover for servicing.

Mounting Location

Wall

3 ft

(0.9 m)

Minimum

Required

Clearance

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 9

Page 10

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Wiring

NOTE: All wiring must be installed in accordance with all local and national electrical codes.

NOTE: Refer to the torque settings specified on pages 11 and 12.

CRESTRON GREEN LIGHT EXPRESS dimming panels are shipped with GLXX-2DIM8 dimming modules

installed. The following must be performed after mounting the panel:

• Connect incoming feed conductors to the input terminals and connect loads to output terminals (section A

of the following diagram)

• Connect control wiring (section B of the following diagram)

FEEDS

FROM

BREAKER

PANEL

TO

LOADS

FEEDS

FROM

BREAKER

PANEL

TO

LOADS

A

SERVICE

SCREWDRIVER

B

CLASS 2

WIRING ONLY

10 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 11

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Feed-Through and Load Wiring (Section A)

NOTE: Use copper conductors only – rated 75°C.

Wire Gauge and Torque Values

TERMINAL CONNECTOR MAX

WIRE RANGE

INPUTS 26-10 AWG 5.31 lb-in (0.6 Nm) to

7.08 lb-in (0.8 Nm) max

OUTPUTS 26-10 AWG 5.31 lb-in (0.6 Nm) to

7.08 lb-in (0.8 Nm) max

GROUND LUG 14-4 AWG 25-45 lb-in

(2.8-5.1 Nm)

Load Wiring for GLXX-2DIM8

}

DM1

DM2

TO LOADS

DM3

DM4

TORQUE STRIP

DM5

DM6

DM7

DM8

}

LENGTH

3/8”

(9 mm)

3/8”

(9 mm)

3/4"

(19 mm)

TO LOADS

TO BRANCH

BREAKER

TO NEUTRAL

NOTE: All GLXX-2DIM8 modules must be connected together via the NET ports.

L1

N1

N2

L2

TO BRANCH

BREAKER

TO NEUTRAL

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 11

Page 12

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Control Wiring (Section B)

The bottom of the cabinet contains Cresnet® connections for interfacing to the rest of the Crestron® control system.

It also provides overrides input which can be tied to devices such as the GLS-PLS-120/277 phase-loss sensor, or

other devices that provide a dry contact closure (manual switch, fire alarm relay, etc.).

To ensure optimum performance over the full range of your installation topology, use Crestron certified wire.

Failure to do so may incur additional charges if support is required to identify performance deficiencies because of

using improper wire.

NOTE: Interface connectors for NET (x4), and OVERRIDE (x3) ports are provided.

Wire Gauge and Torque Values

TERMINAL CONNECTOR MAX

WIRE RANGE

NET 26-12 AWG

OVERRIDE 26-12 AWG

Connector Wiring

TORQUE STRIP

LENGTH

4.43 lb-in

(0.5 Nm)

4.43 lb-in

(0.5 Nm)

MODULES:

TO GLXX-2DIM8

MODULES (PREWIRED)

1/4”

(6 mm)

1/4”

(6 mm)

OVERRIDE:

OTHER CABINET,

FROM ALARM, ETC.

(OPTIONAL); TO OTHER

RED

WHITE

TO CONTROL SYSTEM AND

OTHER CRESNET DEVICES

BLUE

BLACK

NET:

RED

BLUE

WHITE

BLACK

FROM GLS-PLS-120/277, FROM

CABINET(S) IF NECESSARY

NOTE: For instructions on network wiring, refer to “Appendix C: Network Wiring” on page 21.

12 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 13

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

NET Port Wiring

When wiring the supplied NET connectors for connection to a Crestron control system or other device on the

Cresnet network, use Crestron certified wire such as CRESNET-NP or CRESNET-P. For instructions on

network wiring, refer to “Appendix C: Network Wiring” on page 21.

When daisy-chaining connections between NET ports, strip the ends of the wires carefully to avoid nicking the

conductors. Twist together the ends of the wires that share a pin on the network connector, insert the connection

into the Cresnet connector, tighten the retaining screw. Repeat the procedure for the other three conductors.

OVERRIDE Port Wiring

When a connection is applied between the override terminals, the modules will enter Override mode. The

Crestron GLS-PLS-120/277 phase-loss sensor or any device that provides a dry contact closure can be

connected to the supplied OVERRIDE connector on the bottom of the cabinet.

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 13

Page 14

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Testing

Manual Load Control

Lighting loads can be manually controlled from the front panel. To dim or turn a load on or off, press the channel

button corresponding to the desired load. When a load is switched on, the status LED of the channel will illuminate

and the display on the GLXX-2DIM8 will indicate the current lighting level of the load.

GLXX-2DIM8 Channel Control (Channel 1 is shown)

STATUS LED (RED)

CHANNEL NUMBER

CHANNEL BUTTON

Manual Load Configuration

By default, all channels are set for dimmer operation. The 3-way slide switches provided on the GLXX-2DIM8

allows the user to manually configure each channel for either dimmer, 3-wire fluorescent or non-dimmer operation.

3-way Slide Switch

SLIDE SWITCH

{

When a channel pair is set to 3-wire fluorescent, the channel button corresponding to the first channel in the pair will

control dimming functionality. The button corresponding to the second channel in the pair will be disabled. The

status LED’s for both channels will operate in tandem.

14 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 15

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

2-Wire Dimmable or Non-Dimmable Operation

Connect wiring for 2-wire dimmable or non-dimmable operation as shown below. Set channel dip switches to DIM

or NON-DIM as required.

Wiring for 2-Wire Dimmable or Non-Dimmable Loads

LOAD

BRANCH

BREAKER

H

N

N1

L1

DM1

N1

L1

SET CHANNEL DIP SWITCH TO OR

NON-DIM

AS REQUIRED

DIM

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 15

Page 16

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

3-Wire Fluorescent Ballast Operation

Connect wiring for 3-wire fluorescent operation as shown below. The first channel in the pair will act as the

dimming control (1-100%). The second channel in the pair will provide full switched power according to the state of

the first channel. Set both channel dip switches in the pair to 3 WIRE FL.

Wiring for 3-Wire Fluorescent Loads

3-Wire

Fluorescent

Load

BRANCH

BREAKER

DH

SH

N

N1

L1

DM1

DM2

N1

L1

SET BOTH CHANNELS IN PAIR

TO

3-WIRE FL

16 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 17

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Override Mode

The Override mode overrides the control system program and sets all of the output states to the stored override

values. For instructions on saving override settings, refer to “Save Override Settings” below.

To enable Override mode, press and release the OVR button. The OVR LED flashes slowly.

NOTE: If the Override mode was enabled from an external device (i.e. a contact closure is present on the

OVERRIDE terminals), the OVR LED will flash quickly. Pressing the OVR button has no effect.

To disable Override mode, press the OVR button again. The OVR LED extinguishes and the outputs return to the

states set by the control system program.

NOTE: If override states have not been stored, the factory default override state is all loads on.

Save Override Settings

The state of each output can be saved as an override setting, which can be automatically recalled when the Override

mode is enabled.

NOTE: The control system program has a setting that can prevent locally saving the override state. If this setting is

enabled, the display shows “Er” when trying to save override states. For more information, refer to the SIMPL

Windows help file.

To save the states of all outputs as the override setting, press and hold the OVR button for three seconds until the

OVR LED blinks once.

System Operation and Commissioning

This cabinet has been designed as a component of a programmed Crestron system. System commissioning by an

authorized Crestron representative

Once the cabinet has been wired and the modules have been tested, contact Crestron at 1-888-CRESTRON

[1-888-273-7876] to schedule commissioning.

must be performed to ensure system operation.

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 17

Page 18

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Problem Solving

Troubleshooting

The following table provides corrective action for possible trouble situations. If further assistance is required, please

contact a Crestron customer service representative.

Troubleshooting

TROUBLE POSSIBLE CAUSE(S) CORRECTIVE ACTION

Module(s) does not

function.

Unit cannot be taken out

of Override mode

Device is not receiving

power from a Crestron

power source.

Device is not receiving

sufficient power via

Cresnet link.

System commissioning

not complete.

Short (contact closure)

exists between G and OVR

terminals on any of the

OVERRIDE terminals

present at bottom of the

cabinet.

Use the provided Crestron power source.

Verify connections.

Use the Crestron Power Calculator to help

calculate how much power is needed for

the system.

Arrange for system commissioning.

Determine the reason for the short.

Remove or remedy the short

(e.g. GLS-PLS-120/277 phase-loss sensor

may not have been installed properly, or

actual phase-loss has been detected).

Further Inquiries

If you cannot locate specific information or have questions after reviewing this guide, please take advantage of

Crestron's award winning customer service team by calling Crestron at 1-888-CRESTRON [1-888-273-7876].

You can also log onto the online help section of the Crestron website (

questions about Crestron products. First-time users will need to establish a user account to fully benefit from all

available features.

www.crestron.com/onlinehelp) to ask

18 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 19

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Appendix A: Setting Module Net IDs

The following procedure will normally be performed by an authorized Crestron rep resentative as part of the System

Commissioning phase. For system wiring and basic testing as described on pages 10 and 14, it is not necessary to

perform this step. Only perform this step if instructed by an authorized Crestron representative, or when replacing

modules on a system that have already been commissioned (in the latter case the Net ID should be set to match the

Net ID of the module being replaced).

The Net ID of each module in the cabinet can be changed from the front panel of each module. The Net IDs of each

module in the system must be unique.

To set the Net ID using the front panel:

1. Press the recessed SETUP button to enter the Setup mode. The SETUP LED illuminates.

2. As shown in the following diagram, press the left button under the NET ID display to change the left digit

of the Net ID or press the right button under the NET ID display to change the right digit of the Net ID

number.

Changing the Net ID

LABEL FOR

NET ID

RIGHT DIGITLEFT DIGIT

CHANGES

LEFT DIGIT

CHANGES

RIGHT DIGIT

SETUP

BUTTON & LED

3. When the desired Net ID is displayed, press the SETUP button to exit the Setup mode. The SETUP LED

extinguishes.

If the SETUP button is not pressed, the Setup mode will time out after one minute activity and the Net ID

will revert back to its original value.

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 19

Page 20

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Appendix B: Specifications

Specifications for the GLXX-2DIM8 modules are listed in the following table.

GLXX-2DIM8 Module Specifications

SPECIFICATION DETAILS

Input Voltage 100 – 277 VAC 50/60 Hz

Supported Load

Types

Maximum Load

Lighting 16 A per output (16A max total for group 1-4 and 16A max total for group 5-8)

Motor

Environmental

Temperature

Humidity 10% to 90% RH (non-condensing)

Heat Dissipation 154 BTU/HR

Cresnet Power

Usage

* Forward phase or leading edge compatible transformers only.

Incandescent, HID, magnetic low voltage (MLV), electronic low voltage* (ELV),

neon/cold cathode, and fluorescent ballasts, motor

1 hp @ 120V

2 hp @ 230V/277V

32º to 104º F (0º to 40º C)

5W

20 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 21

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Appendix C: Network Wiring

Check Network Wiring

Use the Right Wire

In order to ensure optimum performance over the full range of your installation topology, Crestron Certified Wire

and only Crestron Certified Wire may be used. Failure to do so may incur additional charges if support is required to

identify performance deficiencies because of using improper wire.

Calculate Power

CAUTION: Use only Crestron power supplies for Crestron equipment. Failure to do so could cause equipment

damage or void the Crestron warranty.

CAUTION: Provide sufficient power to the system. Insufficient power can lead to unpredictable results or damage

to the equipment. Please use the Crestron Power Calculator to help calculate how much power is needed for the

system (

When calculating the length of wire for a particular Cresnet run, the wire gauge and the Cresnet power usage of each

network unit to be connected must be taken into consideration. Use Crestron Certified Wire only. If Cresnet units

are to be daisy-chained on the run, the Cresnet power usage of each network unit to be daisy-chained must be added

together to determine the Cresnet power usage of the entire chain. If the unit is home-run from a Crestron system

power supply network port, the Cresnet power usage of that unit is the Cresnet power usage of the entire run. The

wire gauge and the Cresnet power usage of the run should be used in the following equation to calculate the cable

length value on the equation’s left side.

Cable Length Equation

www.crestron.com/calculators).

40,000

L <

R x P

Make sure the cable length value is less than the value calculated on the right side of the equation. For example, a

Cresnet run using 18 AWG Crestron Certified Wire and drawing 20 watts should not have a length of run more than

333 feet (101 meters). If Cresnet HP is used for the same run, its length could extend to 1250 feet (381 meters).

NOTE: All Crestron certified Cresnet wiring must consist of two twisted pairs. One twisted pair is the +24V

conductor and the GND conductor and the other twisted pair is the Y conductor and the Z conductor.

Where:

L = Length of run (or chain) in feet

R = 6 Ohms (Crestron Certified Wire: 18 AWG (0.75 MM ))

or 1.6 Ohms (Cresnet HP: 12 AWG (4 M M ))

P = Cresnet power usage of entire run (or chain)

2

2

Strip and Tin Wire

When daisy-chaining Cresnet units, strip the ends of the wires carefully to avoid nicking the conductors. Twist

together the ends of the wires that share a pin on the network connector and tin the twisted connection. Apply solder

only to the ends of the twisted wires. Avoid tinning too far u p the wires or the end becomes brittle. Insert the tinned

connection into the Cresnet connector and tighten the retaining screw. Repeat the procedure for the other three

conductors.

Add Hubs

Use of a Cresnet Hub/Repeater (CNXHUB) is advised whenever the number of Cresnet devices on a network

exceeds 20 or when the combined total length of Cresnet cable exceeds 3000 feet (914 meters).

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 21

Page 22

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Crestron Network Interconnect Diagram

Pair A

22 AWG Twisted

Blue = Z

Shield*

To Network Device

Front

View

Green

To Control System

G

Z

Y

24

Front

View

Green

White = Y

Pair B

18

AWG Parallel

Black = Ground

Red = 24 VDC

24

Y

Z

G

CAUTION: Possible Equipment Damage if Miswired

Do not power up system until all wiring is verified. Care should

be taken to ensure Data (Y & Z), and Power (24 & G)

connections are not crossed.

Ground Shield at the Control System end only.

Model CNTBLOCK network terminal expander and diagnostic

tool for the Cresnet system is recommended for testing purposes

and wiring convenience.

NOTE:

preferred method to daisy chain or expand the Cresnet network. If the blocks

are not available, use the method as shown.

Crestron recommends the use of C2N-HBLOCK or CNTBLOCK as the

To Network Device

24

Y

Z

G

Front

View

Green

22 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Page 23

CRESTRON GREEN LIGHT® EXPRESS Dimming Panel

Crestron Network to Mini Network Interconnect Diagram

Wire Nuts &

Jumper Wires

Pair A

22 AWG Twisted

Blue = Z

White = Y

To Control System

G

Black

Blue

Shield*

Z

Y

24

Front

View

Green

White

Red

Pair B

18 AWG Parallel

Black = Ground

Red = 24 VDC

CAUTION: Possible Equipment Damage if Miswired

Do not power up system until all wiring is verified. Care should

be taken to ensure Data (Y & Z), and Power (24 & G)

connections are not crossed.

Ground Shield at the Cont rol System end only.

Model CNTBLOCK network terminal expander and diagnostic

tool for the Cresnet system is recommended for testing purposes

and wiring convenien ce.

Jumper wires: Use #18 AWG. Use a wire nut that accomodates

all three wires.

NOTE: C

preferred method to daisy chain or expand the Cresnet network. If the blocks

are not available, use the method as shown.

restron recommends the use of C2N-HBLOCK or CNTBLOCK as the

To Mini Network Device

Black

To Network Device

Red

White

Blue

Black

24

Y

Z

G

Front

View

24

Y

Z

G

Front

View

Green

Installation Guide – DOC. 6889A GREEN LIGHT® EXPRESS Dimming Panel • 23

Page 24

Dimming Panel CRESTRON GREEN LIGHT® EXPRESS

Return and Warranty Policies

Merchandise Returns / Repair Service

1. No merchandise may be returned for credit, exchange or service without prior authorization from

CRESTRON. To obtain warranty service for CRESTRON products, contact an authorized

CRESTRON dealer. Only authorized CRESTRON dealers may contact the factory and request an

RMA (Return Merchandise Authorization) number. Enclose a note specifying the nature of the

problem, name and phone number of contact person, RMA number and return address.

2. Products may be returned for credit, exchange or service with a CRESTRON Return Merchandise

Authorization (RMA) number. Authorized returns must be shipped freight prepaid to

CRESTRON, 6 Volvo Drive, Rockleigh, N.J. or its authorized subsidiaries, with RMA number

clearly marked on the outside of all cartons. Shipments arriving freight collect or without an RMA

number shall be subject to refusal. CRESTRON reserves the right in its sole and absolute

discretion to charge a 15% restocking fee plus shipping costs on any products returned with an

RMA.

3. Return freight charges following repair of items under warranty shall be paid by CRESTRON,

shipping by standard ground carrier. In the event repairs are found to be non-warranty, return

freight costs shall be paid by the purchaser.

CRESTRON Limited Warranty

CRESTRON ELECTRONICS, Inc. warrants its products to be free from manufacturing defects in materials and

workmanship under normal use for a period of three (3) years from the date of purchase from CRESTRON,

with the following exceptions: disk drives and any other moving or rotating mechanical parts, pan/tilt heads and

power supplies are covered for a period of one (1) year; touchscreen display and overlay components are

covered for 90 days; batteries and incandescent lamps are not covered.

This warranty extends to products purchased directly from CRESTRON or an authorized CRESTRON dealer.

Purchasers should inquire of the dealer regarding the nature and extent of the dealer's warranty, if any.

CRESTRON shall not be liable to honor the terms of this warranty if the product has been used in any

application other than that for which it was intended or if it has been subjected to misuse, accidental damage,

modification or improper installation procedures. Furthermore, this warranty does not cover any product that

has had the serial number altered, defaced or removed.

This warranty shall be the sole and exclusive remedy to the original purchaser. In no event shall CRESTRON

be liable for incidental or consequential damages of any kind (property or economic damages inclusive) arising

from the sale or use of this equipment. CRESTRON is not liable for any claim made by a third party or made by

the purchaser for a third party.

CRESTRON shall, at its option, repair or replace any product found defective, without charge for parts or labor.

Repaired or replaced equipment and parts supplied under this warranty shall be covered only by the unexpired

portion of the warranty.

Except as expressly set forth in this warranty, CRESTRON makes no other warranties, expressed or implied,

nor authorizes any other party to offer any warranty, including any implied warranties of merchantability or

fitness for a particular purpose. Any implied warranties that may be imposed by law are limited to the terms of

this limited warranty. This warranty statement supersedes all previous warranties.

Trademark Information

All brand names, product names and trademarks are the sole property of their respective owners. Windows is a registered trademark of

Microsoft Corporation. Windows95/98/Me/XP/Vista/7 and WindowsNT/2000 are trademarks of Microsoft Corporation.

24 • GREEN LIGHT® EXPRESS Dimming Panel Installation Guide – DOC. 6889A

Loading...

Loading...