Page 1

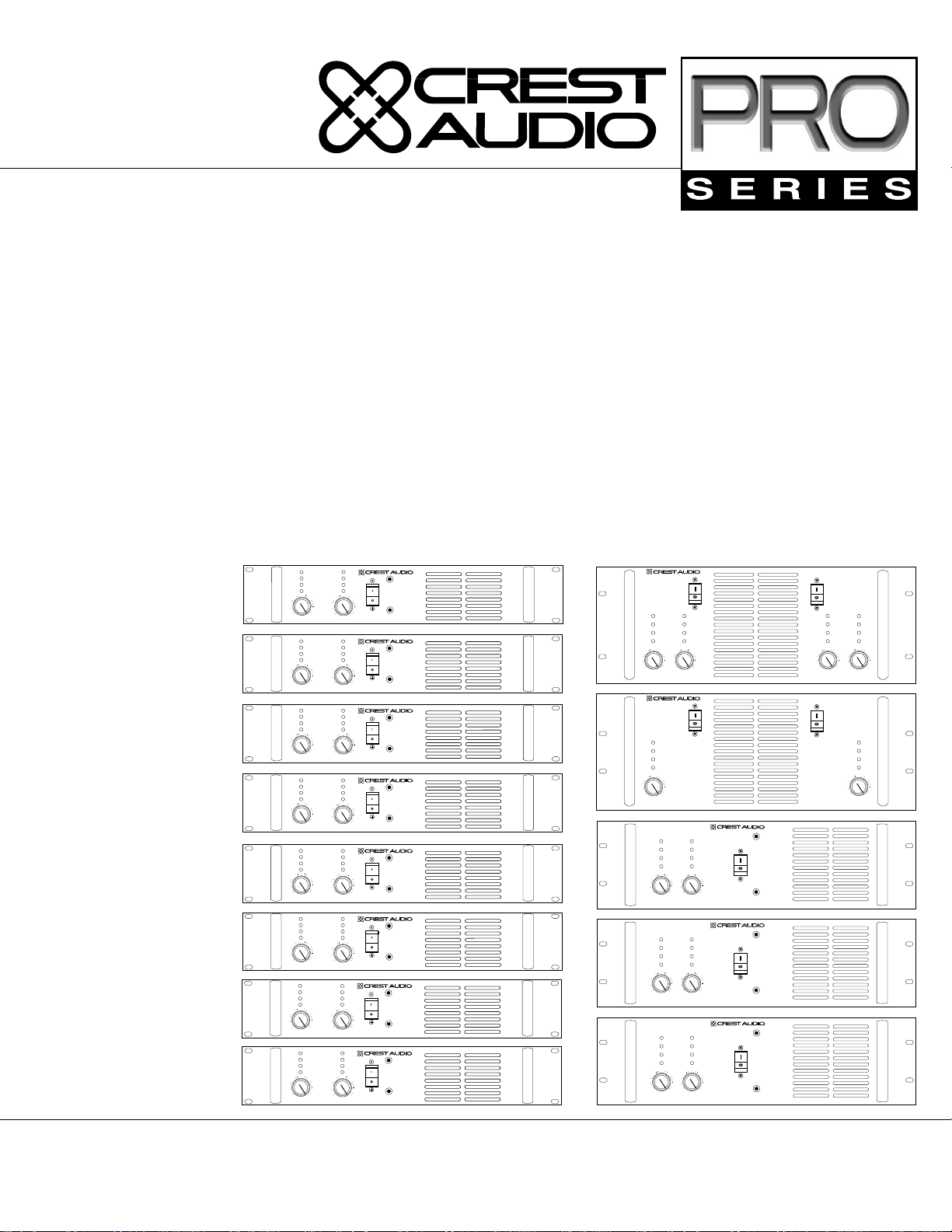

PROFESSIONAL

POWER AMPLIFIERS

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

LOWS

-6

Ch A

-6

Ch A

-6

Ch A

-6

Ch A

-6

Ch A

-6

Ch A

-6

Ch A

0dB

HIGHS

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-10

-3

-15

-1

-1

-30

0dB

-80

0dB

Ch B

7301 Professional Power Amplifier

7001 Professional Power Amplifier

6001 Professional Power Amplifier

4801 Professional Power Amplifier

4601 Professional Power Amplifier

3301 Professional Power Amplifier

MA7120 Professional Power Amplifier

MA5850 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-6

-6

-10

-10

-3

-15

-30

-80

-10

-15

-30

-80

-3

-15

-1

-1

-30

-80

0dB

0dB

Ch A

Ch B

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-1

0dB

Ch A

Clip/Limit

Signal

Temp/DC

Active

-6

-6

-10

-10

-15

-30

-80

-10

-15

-30

-80

-10

-15

-30

-80

-3

-3

-15

-1

-1

-30

-80

0dB

0dB

Ch B

Ch A

Clip/Limit

Signal

Temp/DC

Active

-6

-6

-10

-3

-3

-15

-1

-1

-30

-80

0dB

0dB

Ch B

Ch A

Clip/Limit

Signal

Temp/DC

Active

-6

-6

-10

-3

-3

-15

-1

-1

-30

-80

0dB

0dB

Ch B

Ch A

10004 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-10

-3

-15

-15

-1

-30

-30

-80

-80

0dB

Ch D

Ch C

10001 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-10

-15

-30

-80

Ch B

9001 Professional Power Amplifier

8001 Professional Power Amplifier

MA9130 Professional Power Amplifier

-6

-3

-1

0dB

-6

-3

-1

0dB

OWNER’S MANUAL

Including MA Series Amplifiers

Page 2

Important Precautions

This symbol is used to alert the operator to follow important operating procedures and precautions detailed in

documentation.

This symbol is used to warn operators that uninsulated “dangerous voltages” are present within the equipment enclosure that may pose a risk

of electric shock.

1. Save the carton and packing material

even if the equipment has arrived in

good condition. Should you ever need

to ship the unit, use only the original

factory packing.

2. Read all documentation before operating your equipment. Retain all docu-

mentation for future reference.

3. Follow all instructions printed on unit

chassis for proper operation.

4. Do not spill water or other liquids

into or on the unit, or operate the unit

while standing in liquid.

5. Make sure power outlets conform to

the power requirements listed on the

back of the unit.

6. Do not use the unit if the electrical

power cord is frayed or broken. The

power supply cords should be routed so

that they are not likely to be walked on

or pinched by items placed upon or

against them, paying particular attention to cords and plugs, convenience

receptacles, and the point where they

exit from the appliance.

7. Always operate the unit with the AC

ground wire connected to the electrical system ground. Precautions should

be taken so that the means of grounding

of a piece of equipment is not defeated.

8. Mains voltage must be correct and

the same as that printed on the rear

of the unit. Damage caused by connec-

tion to improper AC voltage is not covered by any warranty.

9. Have gain controls on amplifiers

turned down during power-up to prevent speaker damage if there are high

signal levels at the inputs.

10. Power down & disconnect units from

mains voltage before making connections.

11. Never hold a power switch in the

“ON” position if it won’t stay there

itself!

12. Do not use the unit near stoves, heat

registers, radiators, or other heat

producing devices.

13. Do not block fan intake or exhaust

ports. Do not operate equipment on a

surface or in an environment which may

impede the normal flow of air around

the unit, such as a bed, rug, weathersheet, carpet, or completely enclosed

rack. If the unit is used in an extremely

dusty or smoky environment, the unit

should be periodically “blown free” of

foreign matter.

14. Do not remove the cover. Removing

the cover will expose you to potentially

dangerous voltages. There are no user

serviceable parts inside.

15. Connecting amplifier outputs to

oscilloscopes or other test equipment

while the amplifier is in bridged mode

may damage both the amplifier and test

equipment!

16. Do not drive the inputs with a signal

level greater than that required to

drive equipment to full output.

17. Do not connect the inputs / outputs of

amplifiers or consoles to any other

voltage source, such as a battery, mains

source, or power supply, regardless of

whether the amplifier or console is

turned on or off.

18. Do not run the output of any amplifi-

er channel back into another channel’s input. Do not parallel- or seriesconnect an amplifier output with any

other amplifier output. Crest Audio is

not responsible for damage to loudspeakers for any reason.

19. Do not ground any + (“hot”) termi-

nal. Never connect a + (“hot”) output

to ground or to another + (“hot”) output!

20. Non-use periods. The power cord of

equipment should be unplugged from

the outlet when left unused for a long

period of time.

21. Service Information Equipment

should be serviced by qualified service

personnel when:

A. The power supply cord or the plug

has been damaged;

B. Objects have fallen, or liquid has

been spilled into the equipment;

C. The equipment has been exposed to

rain;

D. The equipment does not appear to

operate normally, or exhibits a

marked change in performance;

E. The equipment has been dropped, or

the enclosure damaged.

22. To obtain service, contact your nearest

Crest Audio Service Center ,Distributor,

Dealer, or Crest Audio at 201.909.8700

(USA).

All Professional Series power amplifier

models are UL LISTED, except for:

10001

10004

MA5850

MA7120

MA9130

Page 3

Power Amplifier Owner’s Manual

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Crest Audio Model 7301 Power Amplifier . . . . . . . . . . 3

Crest Audio Model 10004 Power Amplifier . . . . . . . . . 3

Models 3301, 4801, 6001 Features . . . . . . . . . . . . . . . . 4

Model 4601 Features . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model 7001 Features . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model 7301 Features . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model 8001 Features . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Model 9001 Features . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Model 10001 Features . . . . . . . . . . . . . . . . . . . . . . . . . 8

Model 10004 Features . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Crest Audio Octal Sockets . . . . . . . . . . . . . . . . . . . . . 10

®

NexSys

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bridging Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switches and Controls . . . . . . . . . . . . . . . . . . . . . . . . 12

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Speaker Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Amplifier Maintenance and User Responsibility . . . . . 15

Service/Warranty Information. . . . . . . . . . . . . . . . . . . 15

Professional Series Block Diagram . . . . . . . Appendix A

General Amplifier Specifications . . . . . . . . . Appendix B

Wire Gauge Charts. . . . . . . . . . . . . . . . . . . . Appendix C

Meyer-Compatible Power Amplifiers. . . . . . Appendix D

Crest Audio Pro Series Power Amplifiers Page 1

Page 4

Introduction

Congratulations...on your purchase of a Crest Audio Professional Series power amplifier. Designed for years of reliable, flawless operation under rigorous use. These power amplifiers offer the sonic superiority and unsurpassed reliability for which Crest Audio is

famous, while remaining surprisingly compact. Advanced technology and extensive protection circuitry allow operation with greater

efficiency into difficult loads and power conditions. All Professional Series amplifiers are fully compatible with Crest Audio’s Octal

Socket Accessories and the Ne xSys computer -controlled audio system. The IGM (Instantaneous Gain Modulation) circuit ensures trouble-free operation into loads as low as 2Ω. The clip limiting circuits protect drivers and ensure that sonic integrity is maintained, even

in extreme overload conditions. Crest Audio’s high-efficiency design uses tunnel-cooled heatsinks and variable speed DC fans. This

cooling topology maintains a lower overall operating temperature, resulting in longer output transistor life.

Model 9001, 10001, and 10004 power amplifiers use Crest Audio’s innovative “Power Density” circuitry.

Although the Crest Audio Professional Series amplifiers are quite simple to operate, and are housed in ultra-strong steel chassis,

improper use can be dangerous. Some of these models are very high-powered amplifiers that can put out high voltages and sizable currents at frequencies up to 30 kHz. Always use safe operating techniques with these amplifiers. FOR YOUR SAFETY, READ THE

IMPORTANT PRECAUTIONS SECTION ,AS WELL AS INPUT, OUTPUT, AND POWER CONNECTION SECTIONS.

Unpacking

Upon unpacking, inspect the amplifier. If you find any damage, notify your supplier immediately. Only the consignee may institute a

claim with the carrier for damage incurred during shipping. Be sure to save the carton and all packing materials. Should you ever need

to ship the unit back to Crest Audio, one of its offices, service centers, or the supplier, use only the original factory packing. If the shipping carton is unavailable, contact Crest to obtain a replacement.

Mounting

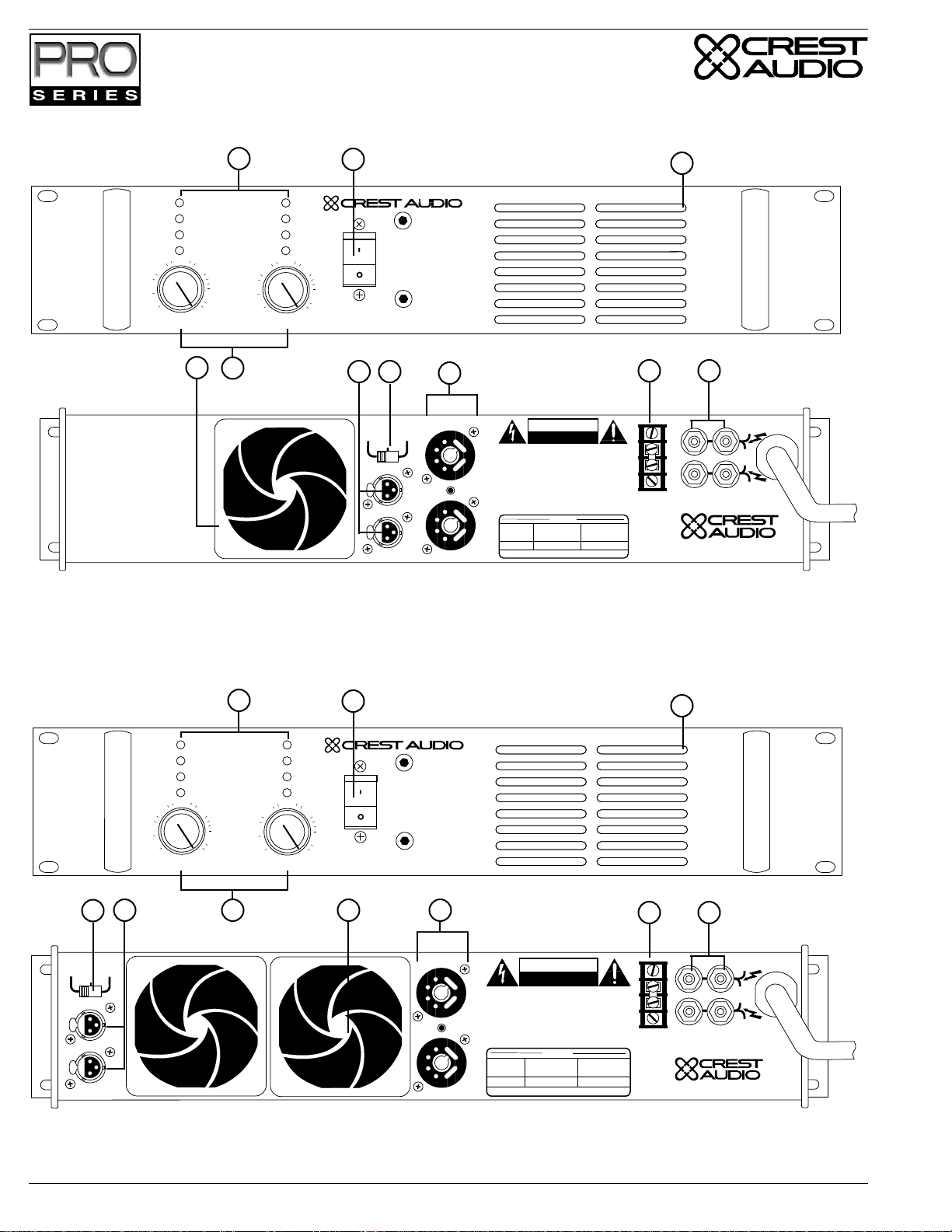

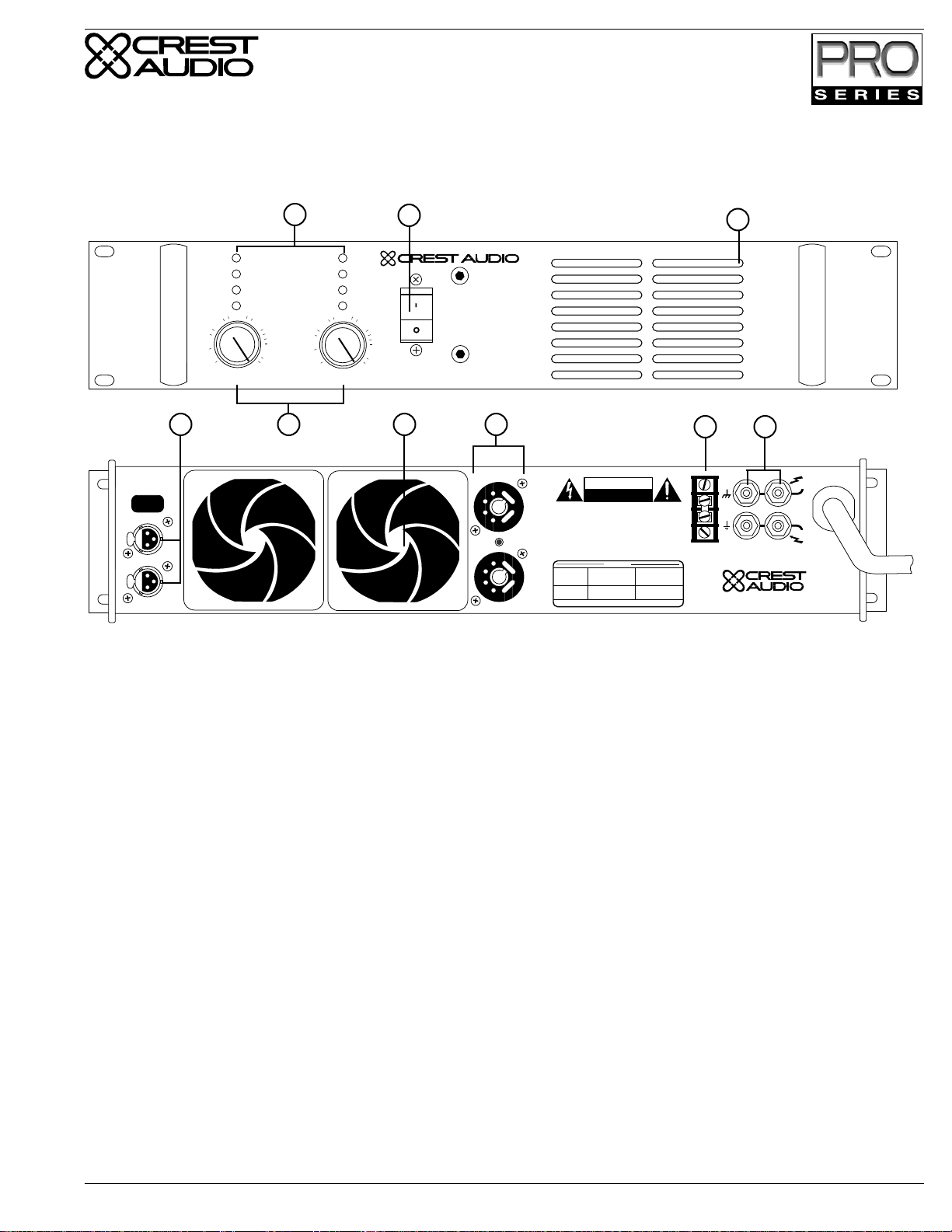

Professional Series power amplifiers will mount in standard 19-inch racks having sufficient depth. The 10004 & 10001 amplifiers are

four rack units high; the 9001 and 8001 models are three rack-spaces high, while the remainder are two rack-space units. All two and

three-rack space units (except for the 9001) are provided with four front panel mounting holes. The 9001, 10001, and 10004 have eight

front panel mounting holes. Crest Audio recommends using all mounting holes to secure the power amplifier in the rack; this will

ensure the safety of the equipment. Rear mounting ears are also provided on all amplifiers for additional support, which is essential in

non-permanent installations like mobile or touring sound systems, but recommended for permanent installations as well. Because of

the cables and connectors on the rear panel, a right-angle or offset screwdriver or hex key will make it easier to fasten the rear mounting ears to the rails.

Note: The 10001 and 10004 models, because of their size, require rack mounting screws stronger than standard rack screws. For customers in the USA, these are supplied with the unit. Customers in Europe and Asia should mount these models using heavy-duty metric bolts.

Page 2 Crest Audio Pro Series Power Amplifiers

Page 5

Cooling Requirements

The Professional Series amplifiers use a forced-air cooling system to maintain a low, even operating temperature. Air is drawn into the

amplifier by fan(s) on the rear panel, courses through the cooling fins of the back-to-back (tunnel-configured) channel heat sinks, and

then exhausts through the front panel slots.

If either heat sink gets too hot, its sensing circuit will open the output relay, disconnecting the load from that particular channel. If the

power transformer overheats, another sensing circuit opens the output relays on all channels until it cools to a safe temperature.

It is important to have an adequate air supply at the back of the amplifier and enough space around the front of the amplifier to allow

the cooling air to escape. If the amp is rack mounted, do not use doors or covers on the front of the rack; the exhaust air must flow

without resistance. If you are using racks with closed backs, use fans on the rear rack panel to pressurize the rack and ensure an ample

air supply; also make sure that there is one (1) standard rack space opening for every three mounted power amplifiers.

The Professional Series amplifiers are supplied with cooling fan air filters. The f ilters snap in place over the fan housing. Any filter will

decrease airflow somewhat, so use the filter only when the amplifier is used in a dusty environment without a filtered air supply. The

filter element must be cleaned or replaced periodically (see the section on Amplifier Maintenance for filter service procedures).

Operating Precautions

Make sure the mains voltage is correct and is the same as that printed on the rear of the amplifier. Damage caused by connecting the

amplifier to improper AC voltage is not covered by any warranty. See the Connecting Power section for more information on voltage

requirements.

Note: Always turn off and disconnect the amplifier from mains voltage before making audio connections. Also, as an extra precaution,

have the attenuators turned down during power-up.

Although the Professional Series amplifiers have AutoRamp circuitry, which raises the signal level gradually after the output relay closes, it is always a good idea to have the gain controls turned down during power-up to prevent speaker damage if there is a high signal

level at the inputs. Whether you buy or make them, use good-quality connections, input cables, and speaker cables, along with good

soldering technique, to ensure trouble-free operation. Most intermittent problems are caused by faulty cables.

Consult the W ire Gauge Charts to determine proper gauges for dif ferent load impedances and cable lengths. Remember that cable resistance robs amplifier power in two ways: power lost directly to resistance (I2R loss), and by lowering the total load impedance. Also

make sure the mode switch is correctly set for the desired application. See Sections on Stereo, Parallel, and Bridged Mono Operation

for more information.

The Crest Audio Model 7301 Power Amplifier

The Model 7301 is specifically designed for use in bi-amplified systems; because of its dissimilar channel design, the specifications

are reported in a separate fashion. The 7301 power specifications were obtained by driving the low frequency channel with a 100 Hz

signal and the high frequency channel with a 1 kHz signal.

The Crest Audio Model 10004 Power Amplifier

The Model 10004 power amplifier is unique in that it is a high-po wer, four-channel amplifier. Of fering the advantages of Crest Audio’s

Power Density engineering design philosophy, this amplifier provides 1400 watts at 2Ω from each of the four channels. All four channels have independent LED indicators, attenuation, and input /output connections. Power switching and NexSys interfaces are configured in pairs of two. Because a channel may have to drive more than one speaker line, each channel has two pairs of output binding

posts. The red binding posts are hot (+), while the black binding posts are at signal ground (-).

Crest Audio Pro Series Power Amplifiers Page 3

Page 6

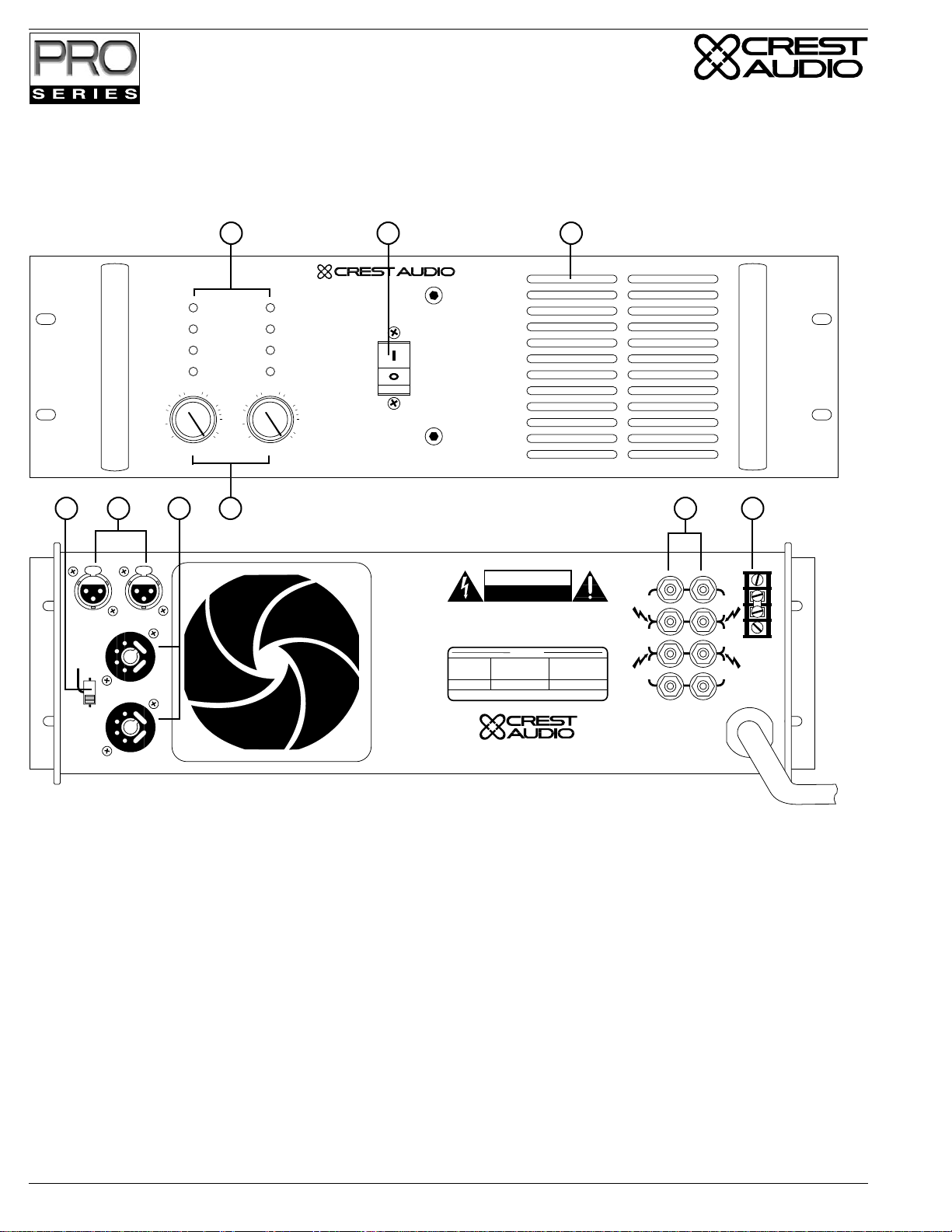

Models 3301, 4801, 6001 Features

1

Clip/Limit

2

3

3301 Professional Power Amplifier

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

Ch A

0dB

4

-1

5

-6

-10

-3

-15

-30

-80

Ch B

0dB

-1

6

STEREO

PIN 3+

IN A

IN B

PUSH

PUSH

BRIDGE

7

PARALLEL

8

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

A

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

B

L'HUMIDITÉ

USA ONLY

MAXIMUM

INPUT CURRENT

MODEL #

@ 120V, 60Hz

3301 11 AMPS

OUTPUT - CLASS 2 WIRING MAY BE USED

OUTPUT POWER

IN WATTS PER

CHANNEL, 4Ω

330W

9

SIGNAL

GROUND

LIFT

10

OUT A

+

BRIDGE

--

OUT B

Designed & manufactured in the USA by:

Crest Audio Inc.

100 Eisenhower Dr.

Paramus, New Jersey 07652 USA

1-Channel A & B Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switch.3-Heated Air Exhaust Grill.

4-Fan Intake Grill & Filter 5-Channel A & B Gain Attenuators.6-Channel A & B XLR Input Connectors. 7-Mode Select Switch.

8-Crest Audio Octal Accessory Sockets.9-Signal Ground Lift Barrier Strip. 10-Five-Way Output Binding Post Connectors.

STEREO

PIN 3+

IN A

IN B

PUSH

PUSH

BRIDGE

4

PARALLEL

Model 4601 & 7001 Features

1

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

Ch A

-1

0dB

-6

-10

-15

-30

-80

0dB

Ch B

6

2

3

4601 Professional Power Amplifier

-3

-1

85 7

CAUTION

RISK OF ELECTRIC SHOCK

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

A

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

B

DO NOT OPEN

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

L'HUMIDITÉ

USA ONLY

MAXIMUM

INPUT CURRENT

MODEL #

@ 120V, 60Hz

4601 18 AMPS

OUTPUT - CLASS 2 WIRING MAY BE USED

OUTPUT POWER

IN WATTS PER

CHANNEL, 4Ω

425W

9

SIGNAL

GROUND

LIFT

Designed & manufactured in the USA by:

10

OUT A

+

BRIDGE

--

OUT B

Crest Audio Inc.

100 Eisenhower Dr.

Paramus, New Jersey 07652 USA

3-Heated Air Exhaust Grill. 4-Mode Select Switch. 5-Channel A & B XLR Input Connectors. 6-Channel A & B Gain Attenuators.

1-Channel A & B Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switch.

7-Fan Intake Grills & Filters.8-Crest Audio Octal Accessory Sockets

9-Signal Ground Lift Barrier Strip. 10-Five-Way Output Binding Post Connectors.

Page 4 Crest Audio Pro Series Power Amplifiers

Page 7

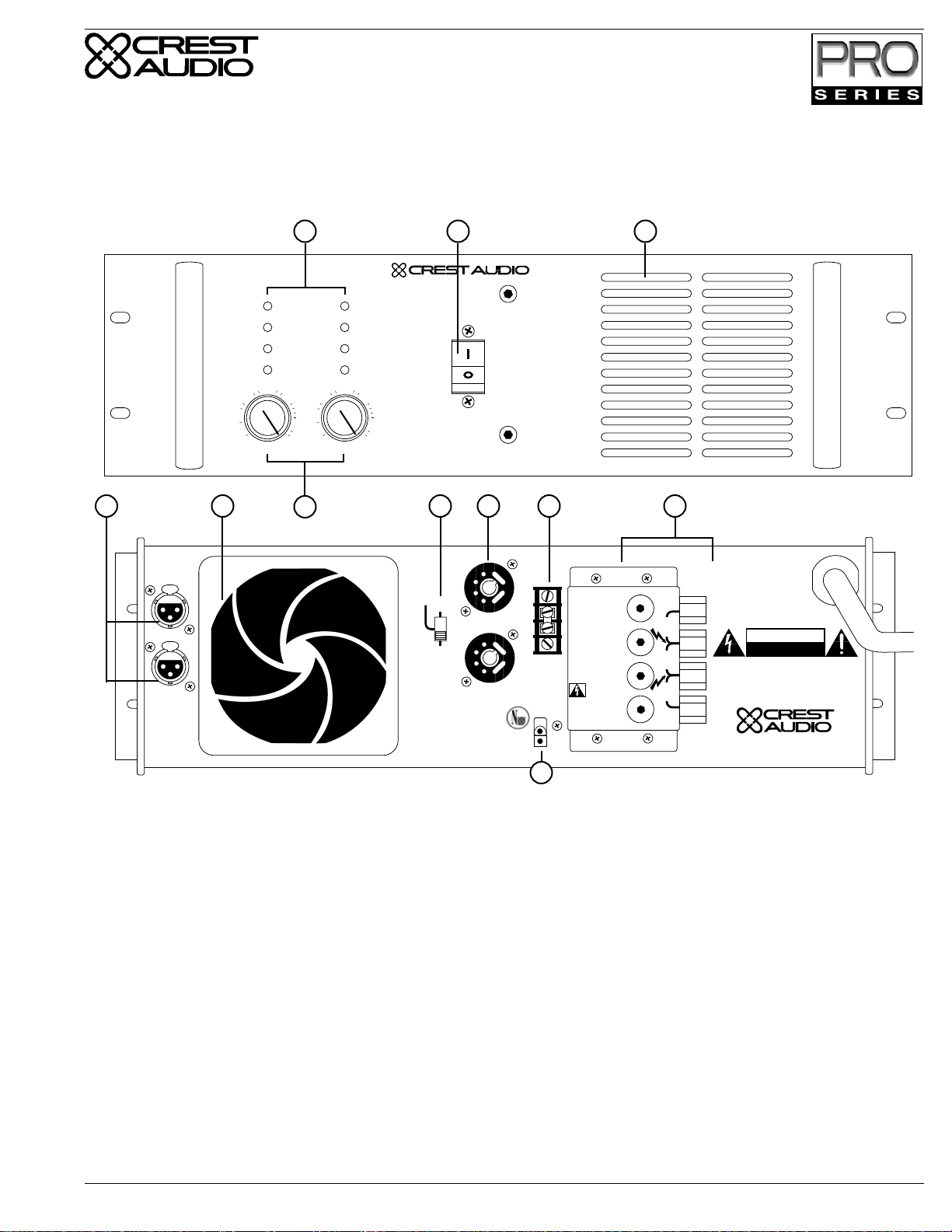

Model 7301 Features

1

2

3

LOWS

HIGHS

Clip/Limit

7301 Professional Power Amplifier

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

LOWS

-1

0dB

5

IN

PUSH

3+

PIN

IN

PUSH

-15

-30

-10

-80

-6

HIGHS

0dB

-3

-1

74 6

CAUTION

LOWS

HIGHS

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

MODEL #

L'HUMIDITÉ

USA ONLY

MAXIMUM

@ 120V, 60Hz

OUTPUT POWER

IN WATTS PER

CHANNEL, 2Ω

CH. A 990W

{

CH. B 220W

INPUT CURRENT

7301 21 AMPS

OUTPUT - CLASS 2 WIRING MAY BE USED

8 9

SIGNAL

GROUND

LIFT

Designed & manufactured in the USA by:

Paramus, New Jersey 07652 USA

Crest Audio Inc.

100 Eisenhower Dr.

OUT LOWS

OUT HIGHS

1-Lows and Highs Channel Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switch.

3-Heated Air Exhaust Grill. 4-Lows and Highs Channel XLR Input Connectors. 5-Lows and Highs Channel Attenuators.

6-Fan Intake Grills & Filters.7-Crest Audio Octal Accessory Sockets.

8-Five-Way Output Binding Post Connectors.9-Signal Ground Lift Barrier Strip.

Crest Audio Pro Series Power Amplifiers Page 5

Page 8

Model 8001 Features

PIN 3+

PARALLEL

BRIDGE

STEREO

1

2 3

8001 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

IN B

A

B

IN A

PUSHPUSH

Ch A

-1

0dB

-6

-10

-3

-15

-30

-80

Ch B

-1

0dB

7 8 95 64

CAUTION

RISK OF ELECTRIC SHOCK

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

MODEL #

DO NOT OPEN

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

L'HUMIDITÉ

USA ONLY

MAXIMUM

INPUT CURRENT

@ 120V, 60Hz

8001 30 AMPS

OUTPUT - CLASS 1 WIRING MAY BE USED

Designed & manufactured in the USA by:

100 Eisenhower Dr.

Paramus, New Jersey 07652 USA

Crest Audio Inc.

OUTPUT POWER

IN WATTS PER

CHANNEL, 2Ω

1400W

--

OUT A

+

+

BRIDGE

--

+

OUT B

--

--

OUT A

+

+

BRIDGE

--

+

OUT B

--

SIGNAL

GROUND

LIFT

1-Front Panel Channel Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switch.

3-Heated Air Exhaust Grill. 4-Mode Select Switch. 5-XLR Input Connectors. 6-Crest Audio Octal Socket Accessory Connectors.

7-Channel A & B Attenuators. 8-Five-Way Output Binding Post Connectors. 9-Signal Ground Lift Barr ier Strip.

Page 6 Crest Audio Pro Series Power Amplifiers

Page 9

Model 9001 Features

PIN 3+

PUSH

PUSH

1

2 3

9001 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

IN A

IN B

Ch A

-1

0dB

-6

-10

-3

-15

-30

-80

6

Ch B

0dB

-1

8 9 104 75

A

PARALLEL

BRIDGE

STEREO

B

SIGNAL

GROUND

LIFT

MODEL 9001

MAXIMUM OUTPUT

POWER PER CHANNEL

8Ω 1200 WATTS

4Ω 2200 WATTS

DO NOT OPERATE

WITHOUT THIS

PROTECTIVE COVER

OUT A

-BRIDGE

+

OUT B

-+

+

--

RISK OF ELECTRIC SHOCK

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

Designed & manufactured in the USA by:

CAUTION

DO NOT OPEN

L'HUMIDITÉ

NEXSYS

OUTPUT

SAMPLE

Crest Audio Inc.

100 Eisenhower Dr.

Paramus, New Jersey 07652 USA

11

1-Front Panel Channel Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switch.

3-Heated Air Exhaust Grill. 4-XLR Input Connectors. 5-Air Intake/Fan Filter.6-Channel Attenuators.

7-Mode Select Switch 8-Crest Audio Octal Socket Accessory Connectors.

9-Signal Ground Lift Barrier Strip. 10-Single-Screw Solderless Output Connectors.11-NexSys Output Sample Connector

Crest Audio Pro Series Power Amplifiers Page 7

Page 10

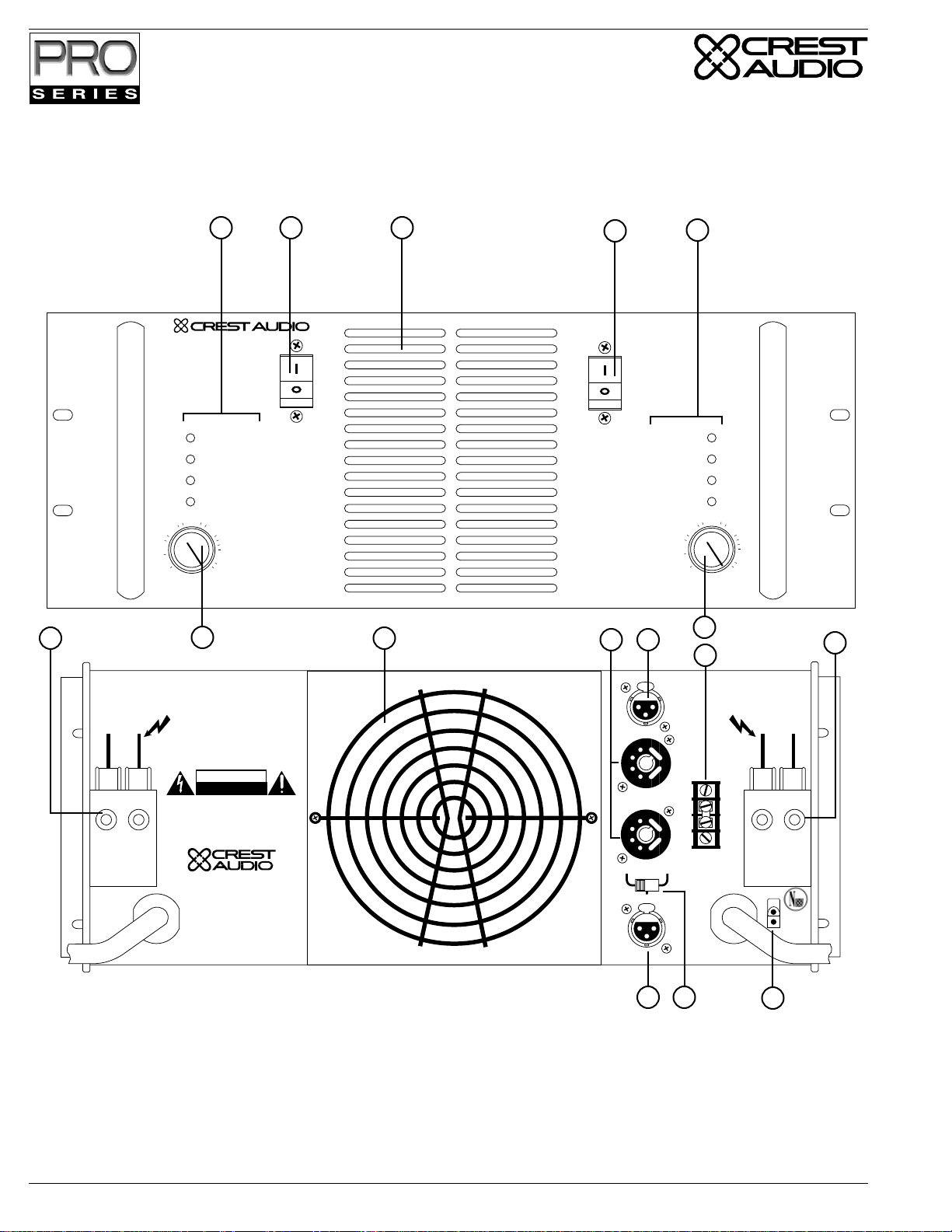

Model 10001 Features

1

32

2

1

10001 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

4

Ch A

-1

0dB

5

6

7

Clip/Limit

Temp/DC

8

Signal

Active

-10

-15

-30

-6

-3

-1

-80

0dB

Ch B

5

4

9

PUSH

IN A

BRIDGE

PUSH

8

STEREO

IN B

PIN 3+

10

SIGNAL

GROUND

LIFT

AC MAINS-INPUT

CH. A

OUT A

+

11

-

NEXSYS

OUTPUT

SAMPLE

-

OUT B

+

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

Designed & manufactured in the USA by:

Crest Audio Inc.

100 Eisenhower Dr.

Paramus, New Jersey 07652 USA

AC MAINS-INPUT

CH. B

L'HUMIDITÉ

PARALLEL

1-Front Panel Channel Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switch.

3-Heated Air Exhaust Grill. 4-Single-Screw Solderless Output Connectors. 5-Channel Attenuators. 6-Air Intake/Fan Filter.

7-Crest Audio Octal Socket Accessory Connectors.8-XLR Input Connectors. 9-Signal Ground Lift Barrier Strip.

10-Mode Select Switch 11-NexSys Output Sample Connector

Page 8 Crest Audio Pro Series Power Amplifiers

Page 11

Model 10004 Features

1

32

2

1

10004 Professional Power Amplifier

Clip/Limit

Signal

Temp/DC

Active

-6

-10

-3

-15

-30

-80

4

Ch A

-1

0dB

5

-6

-10

-3

-15

-30

-80

6

Ch B

7

-1

0dB

8

-10

-15

-30

Clip/Limit

Signal

Temp/DC

Active

-6

-3

-1

-80

0dB

Ch C

7

6

-6

-10

-3

-15

-30

-80

Ch D

-1

0dB

5

4

9

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS : RISQUE DE CHOC ÉLECTRIQUE—NE PAS OUVRIR

WARNING TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

ATTENTION! POUR ÉVITER LE RISQUE D'INCENDIE OU DE CHOC

ÉLECTRIQUE, NE PLACEZ PAS CET APPAREIL SOUS LA PLUIE OU Á

L'HUMIDITÉ

--

OUT C

+

+

BRIDGE

--

+

OUT D

--

NEXSYS

OUTPUT

SAMPLE

AC MAINS-INPUT

CH. C & D

10

IN C

PIN 3+

C

D

IN D

PARALLEL

PUSH

BRIDGE

PUSH

7

STEREO

PUSH

PIN 3+

A

B

STEREO

PARALLEL

BRIDGE

PUSH

11

7

IN A

IN B

SIGNAL

GROUND

11

LIFT

AC MAINS-INPUT

Designed & manufactured in the USA by:

Crest Audio Inc.

100 Eisenhower Dr.

Paramus, New Jersey 07652 USA

--

OUT A

+

+

BRIDGE

--

+

OUT B

--

NEXSYS

OUTPUT

SAMPLE

CH. A & B

10

1-Front Panel Channel Clip/Limit, Signal, Temp/DC, and Active LEDs.2-Combination Circuit Breaker/Power Switches.

3-Heated Air Exhaust Grill. 4-Five-Way Output Binding Post Connectors. 5-Channel Attenuators. 6-Crest Audio Octal Socket

Accessory Connectors. 7-XLR input connectors. 8-Air Intake/Fan Filter.9-Signal Ground Lift Barrier Strip.

10-NexSys Output Sample Connector. 11-Mode Select Switch

Crest Audio Pro Series Power Amplifiers Page 9

Page 12

Connecting Inputs

Input connections are made via the 3-pin XLR connectors (pin 3+) on the rear panel of the amplifier. The

inputs are actively balanced. Pinout and polarity of connection cables should be configured as shown at the

right. The input overload point is high enough to accept the maximum output level of virtually any signal

source. All models have two input connections; the exception being Model 10004, which has four.

Connecting Outputs

On the models 9001 and 10001, speaker cables must be connected to the single screw solderless lug connectors on the back of the amplifiers. For all other models, speaker cables can be connected with banana plugs,

spade lugs, or bare wire to the 5-way binding posts. On the Models 8001 and 10004, two pairs of 5-way binding posts are provided for each channel, so that paralleling of speakers is possible. Consult the Wire Gauge

Chart to find a suitable wire gauge to minimize losses of power and damping factor in the cables.

Note: See the section on model 7301 for pertinent output connection information.

Never connect a “hot” (red) output to ground or to another “hot” (red) output! Always

turn off the amplifier before making connections.

Octal Accessory Sockets

Professional Series amplifiers have two octal accessory sockets on the back panel that provide convenient insertion points for accessories in the signal path between the mode switch and the preamps.

Some of the available Octal Socket Accessories include the Crest Audio XO-2 24 dB/Octave

Crossover, LX-2.2 24 dB/Octave Crossover with Limiter, LM-1 Limiter, LM-2.2 Dual Limiter, PA-1

Precision Attenuator, CDEQ-2 Constant Directivity Horn Compensation Filter, or the TX-1 Input

Isolation Transformer. To use the accessory sockets, first remove the factory-installed jumpers. The

list below indicates the socket pinouts:

Pin Channel A Channel B

1 Ch. A(-) Inverting Signal Return Ch. B (-) Inverting Signal Return

2 Ground* Same as Ch. A*

3 Reserved Reserved

4 +24VDC @ 25mA -Vcc High Voltage (Unregulated)

5 +24VDC (Regulated) +24VDC (Regulated)

6 Ch. A (+) Non-inverting Signal Return Ch. B (+) Non-inverting Signal Return

7 Ch. A (+) Non-inverting Signal Send§ Ch. B (+) Non-inverting Signal Send

8 Ch. A (-) Inverting Signal Send Ch. B (-) Inverting Signal Send

3

4

Ground ( )

Positive (+)

Negative (--)

XLR Pinouts

2

5

Octal Pinouts

1

6

3

2

1

8

7

* From input ground; reference ground for DC voltages at octal pins 4 - 5.

§ From Ch. A (+) non-inverting input.

For normal operation (not using the accessory sockets), jump Pin 1 to Pin 8 and Pin 6 to Pin 7 on both sockets (indicated by the dotted lines in Figure 7; the jumpers are set this way at the factory). To invert the input polarity, that is, to make XLR Pin 2 (+ ) and Pin

3 ( - ), remove the existing jumpers and jump Pin 1 to Pin 7 and Pin 6 to Pin 8. If the jumpers are misplaced, use solid wire; 4mm

(metric) or No. 10 (AWG) will suffice. If the wire is too small, it will not fit snugly in the socket holes and may fall out; if it is too

large, it may distort the socket contacts.

NexSys

Professional Series amplifiers are compatible with NexSys, Crest Audio’s dynamic hardware/software package that allows for sound

system control and management from a Windows-based PC. The octal socket is used to connect between the amplifier and the NexSys

supervisor via the NS-CCM-2 Control Module.

Page 10 Crest Audio Pro Series Power Amplifiers

2

Page 13

Connecting Power

Professional Series power amplifier power requirements are rated at:

a) “idle”

b) 1/8th power (“typical” music conditions)

c) 1/3rd power (“continuous” music conditions)

d.) maximum rated power.

The maximum power current draw rating is limited only by the front panel circuit breaker. Consult the specifications in the

Appendices section for figures on the current that each amplifier will demand. Make sure the mains voltage is correct and is the same

as that printed on the rear of the amplifier. Damage caused by connecting the amplifier to improper AC voltage is not covered by any

warranty. Unless otherwise specified when ordered, Crest amplifiers shipped to customers are configured as follows:

North America - 120VAC / 60Hz

Europe - 230VAC / 50Hz

Asia - 220VAC / 50Hz

Australasia - 240VAC / 50Hz

South America - 120VAC / 60Hz or 220VAC / 50Hz

Japan - 100VAC / 50Hz

NOTE: Always turn off and disconnect the amplifier from mains voltage before making audio connections. Also, as an extra precaution, have the attenuators turned down during power-up.

Never try to hold the power

switch in the “ON” position if it

won’t stay there itself! Always

turn off the amplifier before

changing operating modes!

Operation Modes

Stereo Operation

For stereo (dual channel) operation, turn the amplifier of f and set the mode select switch to the stereo position. In this mode, both channels operate independently of each other, with their input attenuators controlling their respective levels. Thus, a signal at Channel A’s

input produces an amplified signal at Channel A’s output, while a signal at Channel B’s input produces an amplified signal at Channel

B’s output. F or models 9001 and 10004, the recommended minimum nominal load impedance for stereo or parallel operation is 2Ω per

channel. For model 10001, the minimum is 1 ohm per channel. Note: The Model 7301 has no mode select switch; it always operates

as a dual-channel amplifier. Model 10004 has two mode select switches, one for channels A/B, and one for channels C/D.

Parallel Operation

For parallel (dual-channel/single input) operation, turn the amplifier off and set the mode switch in the parallel position; both amplifier channels are then driven by the signal at Channel A’s input. No jumper wires are needed. Output connections are the same as in the

stereo mode. In the parallel mode, only Channel A’s input is active; Channel B’s is out-of-circuit. Both input attenuators remain active,

allowing you to set different levels for each channel. Power and other general performance specifications are the same as in the stereo

mode. Note: Model 7301 has no mode select switch; it always operates as a dual-channel amplifier.

Bridged Mono Operation

Both amplifier channels can be bridged together to make a very po werful single-channel monaural amplifier. Use extreme caution when

operating in the bridged mode; potentially lethal voltage may be present at the output terminals. To bridge the amplifier, set the rear

panel mode select switch to the bridge position. Apply the signal to Channel A’s input and connect the speakers across the hot outputs

(the “+” binding posts of Channels A and B).

Unlike the stereo and parallel modes, in which one side of each output is at ground, in the bridged mode both sides are hot. Channel

A’s side is in phase with the input. For proper operation, both input attenuators must be in the same position. This keeps the load balanced between the channel outputs. As in the parallel mode, only Channel A’s input is active. Note: The Model 7301 cannot operate in

bridged mono mode; it always operates as a dual-channel amplifier. See the separate section on this model.

Bridged Mono Operation - Model 10004

The Model 10004 power amplifier is configured so that one or both pairs of channels can be bridged to mono. Using the rear panel

mode select switches, follow the same procedures as outlined above to bridge channels A&B together and/or C&D together.

Crest Audio Pro Series Power Amplifiers Page 11

Page 14

Bridging Precautions

Use extreme caution when operating the amplifier in the bridged mode; as potentially lethal voltage may be present at the output terminals. Never ground either side of the speaker cable when the amplifier is in the bridged mode; both sides are hot. If an output patch

panel is used, all connections must be isolated from each other and from the panel. The recommended minimum nominal load impedance in the bridged mode is 4Ω (equiv alent to dri ving both channels at 2Ω). Dri ving bridged loads of less than 4Ωwill activate the IGM

circuitry resulting in a loss of power, and may also cause a thermal overload.

Connecting amplifier outputs to oscilloscopes or other test equipment while the

amplifier is in bridged mode may damage both the amplifier and test equipment!

Switches & Controls

AC Power Switch/Circuit Breaker

The Professional Series amplifiers have a combination AC switch/circuit breaker on the front panel. If the switch shuts off during normal use, push it back to the ON position once. If it will not stay on, the amplifier needs servicing. The 10001 has two AC switch/circuit breakers (one for each channel); the 10004 has two, one for each twin-channel amp.

Input Attenuators

Whenever possible, set the attenuators fully clockwise to maintain optimum system headroom. The input attenuator controls (one for

channel A, one for channel B) located at the front panel adjust gain for their respective amplifier channels in all modes. See the specifications at the end of this manual for standard voltage gain and input sensitivity information.

When operating a Professional Series amplifier in the bridged mode, both attenuators must be in the same position so the speaker load

will be equally shared between the channels. See the section on Bridged Mono Operation for more information and precautions.

Note: on the Model 7301, channel attenuators are labeled "LOWS" and "HIGHS", corresponding to the low and high frequency monitor output channels.

Mode Select Switch

The rear panel Mode Select Switch determines whether the amplifier is in the stereo, parallel, or bridged mono mode. Do not operate

the Mode Select Switch with the amplifier powered on. See the sections on Stereo and Bridged Mono Mode for more information.

Note: On the 10004 model, there are two Mode Select Switches on the rear panel. The Model 7301 power amplifier does not have a

Mode Select Switch. For more information, see the Model 7301 section.

Signal Ground Lift Jumper

In a properly designed system (for safety and to minimize noise), the amplifier should receive its ground from the AC line cord.

Whenever possible, the signal source equipment should share the same AC ground as the amplif ier(s). In some cases,however ,this may

result in a ground loop. If this happens, remove the ground lift jumper (supplied) on the rear barrier strip. This jumper electrically connects the signal ground (Pin 2) to the chassis/AC ground (Pin 1). If the jumper is removed, the signal ground is lifted and completely

isolated from the chassis/AC ground. Do not remove the jumper if the amplifier and the signal source equipment are not on the same

AC ground.

Note: On the Model 10004 power amplifier, there are two (2) signal ground lift jumpers.

Page 12 Crest Audio Pro Series Power Amplifiers

Page 15

Indicators

Professional Series amplifiers feature four front panel LED indicators per channel: Clip/Limit, Signal, Temp/DC, and Active. These

LED indicators inform the user of each channel’s operating status and warn of possible abnormal conditions.

Clip/Limit LED

A channel’s Clip/Limit LED will light dimly at the onset of clipping and increase in brilliance as clipping becomes more severe, staying on until the clipping ceases. If the LED’s are flashing quickly and intermittently, the channel is just at the clip threshold, while a

steady, bright glow means the amp is clip limiting, or reducing gain to prevent severely clipped waveforms reaching the loudspeakers.

See the Clip Limiting section for more information.

Signal LED

This LED lights when its channel produces an output signal of about 4 volts RMS or more (0.1 volt or more at the input, with 0 dB

attenuation and standard X40 voltage gain). It is useful in determining whether a signal is reaching and being amplified by the amplifier.

Temp/DC LED

The Temp/DC LED lights to indicate that the channel’s output relay is open, disconnecting the speaker(s) for any of the following reasons:

1. The unit was just powered up and is in the turn-on delay mode.

2. The amplifier senses a DC voltage at its output.

3. The channel has overheated.

Active LED

The Active LED indicates that its channel’s output relay is closed and the channel is operational. It lights under normal operation and

remains on even when the channel is in clip limiting or IGM gain reduction. These are protection features which leave the output relay

closed. If the Active LED goes off, there is no signal at the module output point.

Protection Features

Professional Series amplifiers incorporate several circuits to protect both themselves and loudspeakers under virtually any situation.

Crest Audio has attempted to make the amplifiers as foolproof as possible by making them immune to short and open circuits, mismatched loads, DC voltage, and overheating. If a channel goes into the clip limiting or IGM gain reduction mode, the speaker load

remains connected, but clipping percentage or output power are instantly reduced. When a problem occurs that causes a channel to go

into a protection mode, the Temp/DC LED for that channel will glow. DC voltage on the output, excessive subsonic frequencies, or

thermal overload will cause the channel’s output relay to disconnect the speaker load until the problem is corrected or the amplifier

cools down.

Clip Limiting

Any time a channel is driven into hard, continuous clipping, the clip limiter circuit will automatically reduce the channel gain to a level

just slightly into clipping, guarding the speakers against the damaging high power continuous square waves that may be produced.

Situations that may activate the clip limiter include uncontrolled feedback, oscillations, or an improper equipment setting or malfunction upstream from the amplifier. Normal program transients will not trigger the clip limiter; only steady, excessive clipping will. The

Clip/Limit LED will glow brightly and continuously when limiting occurs.

IGM Impedance Sensing

Professional Series amplifiers feature innovative circuitry that allows safe operation into any load. When an amplifier sees a load that

overstresses the output stage, the Instantaneous Gain Modulation (IGM) circuit adjusts the channel gain to a safe level. This method of

output stage protection is far superior to conventional,brute force type limiting found on other amplifiers. Like the clip limiter,the IGM

circuit is sonically transparent in normal use and unobtrusive when activated.

Crest Audio Pro Series Power Amplifiers Page 13

Page 16

Thermal Protection

The internal fan(s) will keep the amplifier operating well within its intended temperature range under all normal conditions. If a channel’s heat sink temperature reaches 75°C, (85°C for Models 7001 and 8001) which may indicate an obstructed air supply, clogged air

filter, etc., that channel will independently protect itself by disconnecting its load and shutting down until it has cooled to 72°C ( 82°C

for Models 7001 and 8001). During this time, the channel’s DC/Temp LED will light. If the power transformer gets too hot, its thermal sensing circuit will disconnect both channel outputs. Normal operation will resume automatically once the transformer cools to a

safe level. During this time, the Active LED will extinguish, the Temp/DC and Clip/Limit LED’s will stay lit, and the cooling fan will

stay running.

Short Circuit

If an output is shorted, the IGM and thermal circuits will automatically protect the amplifier. The IGM circuit senses the short circuit

as an extremely stressful load condition and attenuates the signal, protecting the channel’s output transistors from overcurrent stress. If

the short circuit remains, the channel will eventually thermally protect itself by disconnecting the load.

DC V oltage Protection

If an amplifier channel detects DC voltage at its output terminals, its output relay will immediately open to prevent loudspeaker damage. The channel’s Temp/DC LED will light.

Subsonic Frequencies

The Professional Series amplifiers have built-in 12 dB per octave high-pass filtering, cornered at 8 Hz, to provide subsonic frequency

protection for each channel. In addition, a channel’s output relay will open if excessive subsonic energy appears at the output.

Turn-On/Turn-Off Protection

At power-up, the amplifier stays in the protect mode, with outputs disconnected, for about 3 seconds while the power supplies charge

and stabilize. While the output relays are open, the Temp/DC LED’s light. When power is remo ved, the speaker loads immediately disconnect so that no thumps or pops are heard.

AutoRamp Signal Control

Whenever a Professional Series amplifier powers up or comes out of a protect mode, the AutoRamp circuit activates. While the speakers are disconnected, the AutoRamp circuit fully attenuates the signal. After the output relay closes, the signal slowly and gradually

raises up to its set level. The AutoRamp Signal Control circuit has some important advantages over the conventional instant-on circuits:

1. If a signal is present during power-up (or when coming out of protect), the speakers are spared a sudden, potentially damaging burst

of audio power.

2. Because the gain is reduced until after the output relay closes, no arcing occurs at the contacts, thereby extending their useful life.

Speaker Protection

Page 14 Crest Audio Pro Series Power Amplifiers

Page 17

All loudspeakers have electrical, thermal, and physical limits which must be observed to prevent damage or failure. Too much power,

low frequencies applied to high frequency drivers, severely clipped waveforms, and DC voltage can all be fatal to cone and compression drivers. The Crest Audio Professional Series amplifiers automatically protect speakers from DC voltages and subsonic signals. For

more information, see the section on Protection Features. Mid- and high-frequency speakers, especially compression drivers, are highly susceptible to damage from overpowering, clipped waveforms, or frequencies below their rated passband. Be extremely careful that

the low and mid bands of an electronic crossover are connected to the correct amplifiers and drivers and not accidentally connected to

those for a higher frequency band. The amplifier’s clipping point is its maximum peak output power, and some of the higher power

Crest Audio Professional Series amplif iers can deli v er more po wer than man y speakers can safely handle. Be sure the peak power capability of the amplifier is not excessive for your speaker system.

To ensure that the speakers never recei ve excessive power and that the amplifier never clips,use a properly adjusted external limiter (or

a compressor with a ratio of 10:1 or higher) to control power output; in systems with active electronic crossovers, use one for each frequency band. The clip limiter will automatically limit the duration of squared-off, continuous waveforms applied to the speakers. The

amplifier will, however, allow normal musical transient bursts to pass. Of course, when the amplifier does clip, it is right at its maximum output power. Some speaker systems are packaged with processors that have power limiting circuits and should not require additional external limiting. Fuses may also be used to limit power to speaker drivers, although as current-limiting rather than voltage-limiting devices, they are an imperfect solution, and as the weakest links, they only limit once before needing replacement. Some poor

quality fuses have a significant series resistance that could de grade the amplif ier’s damping of the speaker’s motion and may even deteriorate the system’s sound quality. If you elect to use fuses, check with the speaker manufacturer to determine the proper current rating and time lag required.

Do not drive any low-frequency speaker enclosure with frequencies lower than its own tuned frequency; the reduced acoustical damping could cause a ported speaker to bottom out even at moderate power. Consult the speaker system specifications to determine its frequency limits.

Use common sense…

it’s the most important facet of any speaker protection scheme.

Amplifier Maintenance and User Responsibility

If you use the air filter supplied with your Professional Series amplifier, the filter element must be cleaned or replaced periodically to

maintain adequate airflow. How often you must do this depends on the environment in which you operate the amplifier. A very dusty

environment will necessitate a shorter service interval than a less dirty one. To clean the element, unsnap the filter element/guard assembly from the fan housing, and remove the filter element. On two-piece guards,pry the two sides apart to remove the element. Wash and

rinse the element using soap and water, then squeeze it dry and reinstall. Instead of cleaning, you may also cut a replacement element

from a sheet of air conditioner foam filter material, using the old element as a pattern. Never operate an amplifier with a clogged filter; it will quickly overheat. Replacement filter elements and element/guard assemblies can also be ordered from Crest Audio. A

Professional Series amplifier requires no other routine maintenance and should never need any internal adjustment during its lifetime.

Your Professional Series amplifier is very powerful and can be potentially dangerous to loudspeakers and humans alike. It is your

responsibility to read the Important Precautions section and to make sure that the amplifier is installed, wired, and operated properly

as instructed in this manual. Many loudspeakers can be easily damaged or destroyed by overpowering, especially with the high power

available from a bridged amplifier. Read the Speaker Protection section and always be aware of the speaker’s continuous and peak

power capabilities.

Service / Warranty Information

In the unlikely event that your amplifier develops a problem, it must be returned to an authorized distributor, service center or shipped

directly to our factory. To obtain service, contact your nearest Crest Audio Service Center, Distributor, Dealer, or any of the worldwide

Crest Audio offices. For contact information, reach Crest Audio Inc. Customer Service directly at: TEL 201.909.8700 (USA) FAX

201.909.8744 (USA). For technical inquiries only, the Crest Audio Technical Services department can be faxed at 201.587.0550 (USA).

Because of the complexity of the design and the risk of electrical shock, all repairs should be attempted only by qualified technical per-

sonnel. If the unit needs to be shipped back to the factory, it must be sent in its original carton. If improperly packed, your amplifier

may be damaged.

For those with Internet access, please visit the Crest Audio website at: http://www.crestaudio.com

Crest Audio Pro Series Power Amplifiers Page 15

Page 18

non-inverting

inverting

Appendix A - Professional Series Block Diagram

The block diagram shown is accurate for all the Professional Series amplifiers.

(The Model 10004 amplifier has four channels arranged in two pairs.)

accessory

Octal

socket

Channel A

Attenuator

Output stage

ground

non-inverting

inverting

ground

B

Mode switch

P

S

Preamp

Channel B

Attenuator

Preamp

Amp front end

Amp front end

Output relay

Output stage

Output relay

Appendix A Crest Audio Pro Series Power Amplifiers

Page 19

Appendix B - General Amplifier Specifications (Model 3301)

1kHz, <0.025% THD+N 20Hz-20kHz, <0.1% THD+N

8Ω Stereo Power

4Ω Stereo Power

2ΩStereo Power

8Ω Bridged Mono Power

4Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserves the right

to make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available in

downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

240W 220W

380W 330W

425W 400W

725W 660W

830W 800W

49V

69V

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.025%

<0.1%

400:1

>60 dB

0.908V RMS

X40

>20kΩ

> -100 dB

> -60dB

Class

AB

Female XLR (pin 3+), Octal Socket

5-way output binding posts

29,200 µF

(USA)

120V, 60Hz

1.0A

6.25A

9.0A

11.0A

2235 BTU/hr

2821 BTU/hr

Rear to front tunnel heatsink, variable speed DC fan

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: mode switch, signal ground lift jumper.

Clip/Limit, Signal, Temp/DC, Active

16 ga. single piece steel chassis, .187" (5mm) alum. front panel

3.5"x19"x15" (16" to rear ears)

89mm x 483mm x 381mm (406mm to rear ears)

47.0 lbs (21.34 kg.), 42.0 lbs (19.07 kg.)

5 years, parts and labor†

Crest Audio Pro Series Power Amplifiers Appendix B

Page 20

Appendix B - General Amplifier Specifications (Model 4601)

1kHz, <0.012% THD+N 20Hz-20kHz, <0.05% THD+N

8Ω Stereo Power

4Ω Stereo Power

8Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserv es the right

to make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available in

downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

350W 300W

485W 425W

925W 825W

59V

83.4V

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.012%

<0.1%

400:1

>60 dB

1.03V RMS

X40

>20kΩ

> -100 dB

> -60dB

Class

AB

Female XLR (pin 3+), Octal Socket

5-way output binding posts

40,800 µF

(USA)

120V, 60Hz

1.1A

7.3A

11.1A

18.0A

2576 BTU/hr

3443 BTU/hr

Rear to front tunnel heatsink, 2 variable speed DC fans

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: mode switch, signal ground lift jumper.

Clip/Limit, Signal, Temp/DC, Active

16 ga. single piece steel chassis, .187" (5mm) alum. front panel

3.5"x19"x15" (16" to rear ears)

89mm x 483mm x 381mm (406mm to rear ears)

48.0 lbs (21.79 kg.), 43.0 lbs (19.52 kg.)

5 years, parts and labor†

Appendix B Crest Audio Pro Series Power Amplifiers

Page 21

Appendix B - General Amplifier Specifications (Model 4801)

1kHz, <0.025% THD+N 20Hz-20kHz, <0.05% THD+N

8Ω Stereo Power

4Ω Stereo Power

8Ω Bridged Mono Power

2ΩStereo Power

4Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

(120V)

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserves the right

to make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available in

downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

400W 300W

575W 480W

1150W 960W

700W 600W

1300W 1200W

60V

85V

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.025%

<0.1%

400:1

>60 dB

1.1V RMS

X40

>20kΩ

> -100 dB

> -60dB

Class

H

Female XLR (pin 3+), Octal Socket

5-way output binding posts

80,000 µF

120V, 60Hz

1.1A

5.6A

11.46

18.0A

1803 BTU/hr

3385 BTU/hr

Rear to front tunnel heatsink, variable speed DC fan

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: mode switch, signal ground lift jumper.

Clip/Limit, Signal, Temp/DC, Active

16 ga. single piece steel chassis, .187" (5mm) alum. front panel

3.5"x19"x15" (16" to rear ears)

89mm x 483mm x 381mm (406mm to rear ears)

54.0 lbs (24.52 kg.), 49.0 lbs (22.25 kg.)

5 years, parts and labor†

Crest Audio Pro Series Power Amplifiers Appendix B

Page 22

Appendix B - General Amplifier Specifications (Model 6001)

1kHz, <0.025% THD+N 20Hz-20kHz, <0.05% THD+N

8Ω Stereo Power

4Ω Stereo Power

2ΩStereo Power

8Ω Bridged Mono Power

4Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserves the

right to make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available

in downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

430W 400W

700W 600W

800W 720W

1320W 1200W

1500W 1440W

70V

99V

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.025%

<0.1%

400:1

>60 dB

1.2V RMS

X40

>20kΩ

> -100 dB

> -60dB

Class

H

Female XLR (pin 3+), Octal Socket

5-way output binding posts

120,000 µF

(USA)

120V, 60Hz

1.1A

5.96A

13.26A

21A

1844 BTU/hr

3838 BTU/hr

Rear to front tunnel heatsink, variable speed DC fan

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: mode switch, signal ground lift jumper.

Clip/Limit, Signal, Temp/DC, Active

16 ga. single piece steel chassis, .187" (5mm) alum. front panel

3.5"x19"x15" (16" to rear ears)

89mm x 483mm x 381mm (406mm to rear ears)

56.0 lbs. (25.42 kg.), 51.0 lbs. (23.10 kg.)

5 years, parts and labor†

Appendix B Crest Audio Pro Series Power Amplifiers

Page 23

Appendix B - General Amplifier Specifications (Model 7001)

1kHz, <0.02% THD+N 20Hz-20kHz, <0.05% THD+N

8Ω Stereo Power

4Ω Stereo Power

8Ω Bridged Mono Power

2ΩStereo Power

4Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced/unbalanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power f igures are watts per channel, both channels driven. Crest Audio reserves the right

to make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available in

downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

560W 550W

810W 715W

1650W 1510W

850W 850W

1700W 1600W

83V

117V

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.02%

<0.1%

400:1

>60 dB

1.4V RMS

X40

>20kΩ/10kΩ

> -100 dB

> -60dB

Class

H

Female XLR (pin 3+), Octal Socket

5-way output binding posts

80,000 µF

(USA)

120V, 60Hz

1.4A

7.8A

15.5A

21.0A

2503 BTU/hr

4505 BTU/hr

Rear to front tunnel heatsink, 2 variable speed DC fans

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: mode switch, signal ground lift jumper.

Clip/Limit, Signal, Temp/DC, Active

16 ga. single piece steel chassis, .187" (5mm) alum. front panel

3.5"x19"x15" (16" to rear ears)

89mm x 483mm x 381mm (406mm to rear ears)

57 lbs. (25.88 kg.), 52 lbs. (23.60 kg.)

5 years, parts and labor†

Crest Audio Pro Series Power Amplifiers Appendix B

Page 24

Appendix B - General Amplifier Specifications (Model 7301)

Lows @ 100Hz, <0.1% THD+N Highs @ 1kHz, <0.05% THD+N

Both Channels @ 4Ω

Lows @ 2Ω, Highs @ 4Ω

Lows @ 4Ω, Highs @ 8Ω

Lows @ 8Ω, Highs @ 16Ω

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (8Ω)

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserv es the right

to make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available in

downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

940W 240W

990W 220W

940W 125W

670W 95W

83V(Low Ch.) 49V(High Ch.)

117V(Low Ch.) 69V(High Ch.)

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.02% @ 800W (Low Ch.); 200W ( High Ch.)

400:1

>60 dB

1.53V RMS (Low ) .79V RMS (High )

X40

>20kΩ

> -100 dB

> -60dB

Class

H (Low Channel); AB (High Channel)

Female XLR (pin 3+), Octal Socket

5-way output binding posts

80,000 µF

(USA)

120V, 60Hz

1.2A

7.0A

12.25A

21.0A

2300 BTU/hr

3700 BTU/hr

Rear to front tunnel heatsink, 2 variable speed DC fans

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: signal ground lift jumper.

Clip/Limit, Signal, Temp/DC, Active

16 ga. steel chassis, 0.187" (5mm) aluminum front panel

3.5"x19"x15" (16" to rear ears)

89mm x 483mm x 381mm (406mm to rear ears)

57 lbs. (25.88 kg.), 52 lbs. (23.60 kg.)

5 years, parts and labor†

Appendix B Crest Audio Pro Series Power Amplifiers

Page 25

Appendix B - General Amplifier Specifications (Model 8001)

1kHz, <0.025% THD+N 20Hz-20kHz, <0.1% THD+N

8Ω Stereo Power

4Ω Stereo Power

8Ω Bridged Mono Power

2ΩStereo Power

4Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserves the right to

make improvements in manufacturing or design which may affect specifications. Crest Audio specification literature is available in downloadable PDF file format; visit our website at http://www.crestaudio.com. ©1997 Crest Audio Inc. 12/15/97

750W 720W

1225W 1200W

2450W 2250W

1400W 1400W

2800W 2800W

91V

129V

20 Hz-20 kHz, -3dB @ 53kHz

20 Hz-20 kHz, +0/-0.2dB

Clip Limit, IGM, AutoRamp, High Temp, short-circuit,

DC voltage, turn-on/off transient, sub/ultrasonic input.

<0.025%

<0.1%

400:1

>60 dB

1.75V RMS

X40

>20kΩ

> -100 dB

> -60dB

Class

H

Female XLR (pin 3+), Octal Socket

2 pair 5-way output binding posts

70,000 µF

(USA)

120V, 60Hz

1.6A

10.8A

21.8A

37.5A

3380 BTU/hr

6140 BTU/hr

Rear to front tunnel heatsink, 105 CFM AC fan, 2-speed optional.

Front panel: 2 attenuators, circuit breaker/power switch;

Rear panel: mode switch, signal ground lift jumper.

Clip/Limit, Signal, Temp/DC,Active

14 ga. steel chassis, 0.25" (6mm) aluminum front panel

5.25"x19"x15" (16" to rear ears)

133mm x 483mm x 381mm (406mm to rear ears)

85 lbs. (38.6 kg.), 80 lbs. (36.0 kg.)

5 years, parts and labor†

Crest Audio Pro Series Power Amplifiers Appendix B

Page 26

Appendix B - General Amplifier Specifications (Model 9001)

1kHz, <0.02% THD+N 20Hz-20kHz, <0.1% THD+N

8Ω Stereo Power

4Ω Stereo Power

8Ω Bridged Mono Power

2ΩStereo Power

4Ω Bridged Mono Power

Max RMS Output Voltage

(each channel)

Peak Output Voltage (each channel)

Frequency Response (+0 / -0.3dB, 1W/8Ω)

Power Bandwidth (rated power at 4Ω, 1% THD+N)

Protection Circuitry

THD+N

(rated power at 4Ω, 1kHz)

SMPTE IMD (rated power at 8Ω, 60Hz & 7kHz)

Damping Factor (10-400Hz at 8Ω)

Input CMRR (1kHz)

Input Sensitivity (rated power at 4Ω )

Voltage Gain

Input Impedance

(balanced)

Hum and Noise (“A” weighted, full power, 4Ω)

Crosstalk (“A” weighted, full power, 4Ω)

Input Connectors

(per channel)

Output Connectors (per channel)

Filter Storage

Standard Power Supply

Idle Current Draw (120V)

1/8 Power Curr. Draw (typical music, 120V/4Ω)

1/3 Power Curr. Draw (continuous music, 120V/4Ω)

Max Curr. Draw (circuit breaker rating, 120V/4Ω)

Thermal Emissions (1/8 Power, 4Ω)

Thermal Emissions (1/3 Power, 4Ω)

Cooling

Controls

LED Indicators

(per channel)

Construction

Dimensions

(Height x Width x Depth)

Gross Weight, Net Weight

Warranty

† USA, Canada, U.K., and many other countries. Power figures are watts per channel, both channels driven. Crest Audio reserves the