Crest Audio CKS-100, CKS-1600 Mk2, CKS-1200 Mk2, CKS-200, CKS-800 Owners manual

...

POWER PROCESSING

AMPLIFIERS

Protect

ACL

On

Off

Remote

Active

Protect

On

Off

Remote

Active

Protect

On

Off

Remote

Active

ACL

Ch B

Ch A

Signal

Signal

ACL

ACL

Ch B

Ch A

Signal

Signal

ACL

ACL

Ch B

Ch A

Signal

Signal

CKS 800

Professional Power Amplifier

CKV 80 0

Professional Power Amplifier

CKX 500

Professional Power Amplifier

OWNER’S MANUAL

Important Precautions

This symbol is used to alert the operator to follow important operating

procedures and precautions detailed

in documentation.

This symbol is used to warn operators that uninsulated “dangerous voltages” are present within the equipment enclosure that may pose a risk

of electric shock.

1. Save the carton and packing material

even if the equipment has arrived in

good condition. Should you ever need

to ship the unit, use only the original

factory packing.

2. Read all documentation before operating your equipment. Retain all doc-

umentation for future reference.

3. Follow all instructions printed on unit

chassis for proper operation.

4. Do not spill water or other liquids

into or on the unit, or operate the unit

while standing in liquid.

5. Make sure power outlets conform to

the power requirements listed on the

back of the unit.

6. Do not use the unit if the electrical

power cord is frayed or broken. The

power supply cords should be routed so

that they are not likely to be walked on

or pinched by items placed upon or

against them, paying particular attention to cords and plugs, convenience

receptacles, and the point where they

exit from the appliance.

7. Always operate the unit with the AC

ground wire connected to the electrical system ground. Precautions should

be taken so that the means of grounding of a piece of equipment is not

defeated.

8. Mains voltage must be correct and

the same as that printed on the rear

of the unit. Damage caused by connec-

tion to improper AC voltage is not covered by any warranty.

9. Have gain controls on amplifiers

turned down during power-up to prevent speaker damage if there are high

signal levels at the inputs.

10. Power down & disconnect units from

mains voltage before making connections.

11. Never hold a power switch in the

“ON” position if it won’t stay there

itself!

12. Do not use the unit near stoves, heat

registers, radiators, or other heat

producing devices.

13. Do not block fan intake or exhaust

ports. Do not operate equipment on a

surface or in an environment which

may impede the normal flow of air

around the unit, such as a bed, rug,

weathersheet, carpet, or completely

enclosed rack. If the unit is used in an

extremely dusty or smoky environment, the unit should be periodically

“blown free” of foreign matter.

14. Do not remove the cover. Removing

the cover will expose you to potentially

dangerous voltages. There are no user

serviceable parts inside.

15. Connecting amplifier outputs to

oscilloscopes or other test equipment

while the amplifier is in bridged mode

may damage both the amplifier and test

equipment!

16. Do not drive the inputs with a signal

level greater than that required to

drive equipment to full output.

17. Do not connect the inputs / outputs

of amplifiers or consoles to any other

voltage source, such as a battery,

mains source, or power supply, regardless of whether the amplifier or console

is turned on or off.

18. Do not run the output of any amplifi-

er channel back into another channel’s input. Do not parallel- or

series-connect an amplifier output

with any other amplifier output.

Crest Audio is not responsible for damage to loudspeakers for any reason.

19. Do not ground any + (“hot”) termi-

nal. Never connect a + (“hot”) output

to ground or to another + (“hot”)

output!

20. Non-use periods. The power cord of

equipment should be unplugged from

the outlet when left unused for a long

period of time.

21. Service Information Equipment

should be serviced by qualified service

personnel when:

A. The power supply cord or the plug

has been damaged;

B. Objects have fallen, or liquid has

been spilled into the equipment;

C. The equipment has been exposed to

rain;

D. The equipment does not appear to

operate normally, or exhibits a

marked change in performance;

E. The equipment has been dropped,

or the enclosure damaged.

22. To obtain service, contact your near-

est Crest Audio Service Center,

Distributor, Dealer, or Crest Audio at

201.909.8700 (USA).

Power Amplifier Owner’s Manual

Table of Contents.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Quick Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation and Mounting . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Side Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input Bay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Input Module Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Network Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power/Output Bay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Module Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Signal Ground Lift Jumper . . . . . . . . . . . . . . . . . . . . . . . 8

®

TourClass

Protection Features . . . . . . . . . . . . . . . . . . . . 9

Sequential Turn-On/Off. . . . . . . . . . . . . . . . . . . . . . . . . 10

Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CKS Series Specifications. . . . . . . . . . . . . . . Appendix A

CKV Series Specifications. . . . . . . . . . . . . . . Appendix B

CKX Series Specifications. . . . . . . . . . . . . . . Appendix C

Wire Gauge Charts. . . . . . . . . . . . . . . . . . . . . Appendix D

Distributed/Constant Voltage Systems. . . . . . Appendix E

Crest Audio CK Power Processing Amplifiers Page 1

Introduction.

Congratulations on your purchase of a Crest Audio CK family of

Power Processing amplifiers. Please read this manual carefully (especially the the “Important Precautions” section located inside the front

cover) as it contains information vital to the safe operation of the

amplifier. Also, please fill out and return the enclosed product registration card.

The CK Power Processing amplifiers represent new levels of value

and flexibility never before offered to the contracting market. CKS

Series models are specially designed to drive low impedance speaker

loads - down to two ohms with “-2” models,. CKV Series models feature a unique proprietary front end circuit to provide directly coupled

70.7 volt outputs, eliminating the need for step-up transformers. CKX

Series models feature transformer-isolated outputs for 100V operation (50V optional). Together, these amplifiers cover almost every

conceivable installed or distributed sound power requirement.

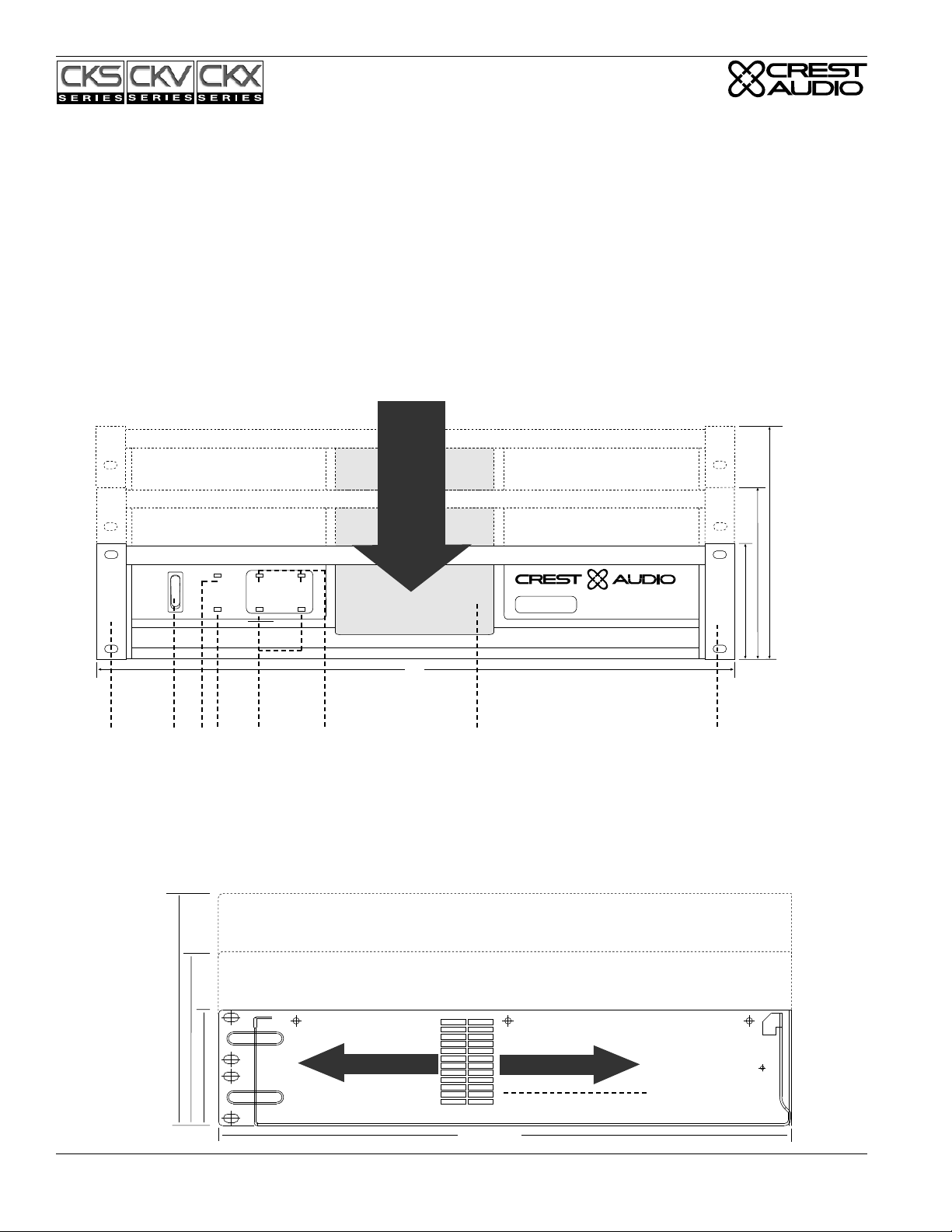

Front View

Cooling

Air

Intake

On

Off

Remote

Protect

Active

Signal

ACL

ACL

Signal

By combining legendary Crest performance with three unique plug-in

module bays located on the rear panel, these amplifiers can become

very sophisticated audio processors. The CK family is everything that

you expect from Crest Audio. They are ruggedly built from high quality components, intelligently laid out, and possess comprehensive protection features.

After-sale support is considered paramount at Crest Audio. For any

assistance in the set-up or operation of this product please call Crest

Audio’s Customer Service department or your local Crest Audio representative. Should you have any problems at all, or suggestions that

may help us improve our products or service, please contact us. We

encourage your participation in Crest’s future. (See back cover for

contact info).

Crest Audio may also be contacted on the World Wide Web at:

http://www.crestaudio.com.

4U-6.94" / 176mm

CKS1200-2

CKS1600-2

CKV1600

CKV2400

3U-5.13" / 130mm

CKS800

CKX150

CKS800-2

CKX300

CKV800

CKX500

CKX800

2U - 3.44" / 87mm

CKS100 CKV100

CKS200 CKV200

CKS400 CKV400

CKS 400

Professional Power Amplifier

1

Side View

4U-6.94" / 176mm

CKS1200-2

CKS1600-2

CKV1600

CKV2400

3U-5.13" / 130mm

CKS800

CKS800-2

CKV800

2U - 3.44" / 87mm

CKS100 CKV100

CKS200 CKV200

CKS400 CKV400

19"

234 5 6 7

CKX150

CKX300

CKX500

CKX800

Heated Air Exhaust

1

Heated Air Exhaust

8

17.125"/435mm

Page 2 Crest Audio CK Power Processing Amplifiers

Unpacking.

Upon unpacking, inspect the amplifier. If you find any damage, notify your supplier immediately. Only the consignee may institute a

claim with the carrier for damage incurred during shipping. Be sure

to save the carton and all packing materials. Should you ever need to

ship the unit back to Crest Audio, one of its offices, service centers,

or the supplier, use only the original factory packing. If the shipping

carton is unavailable, contact Crest to obtain a replacement.

Amplifier Quick Set-Up.

Crest Audio CK Power Processing amplifiers are configured to a

standard set-up at the factory. They are functional and ready to use

‘out of the box’. All controls and input/output connections are clearly labeled. Units are shipped standard with modules as follows:

Input Bay: CC-IPB Module.

Network Bay: CC-BLK (Blank) Module.

Power/Output Bay: CC-STL Module.

To set the amplifier up for basic usage:

1. Rack mount the amplifier in the location where it is to be used,

remembering to allow for adequate access and cooling space. For

more information, see the sections on Installation, Mounting, and

Cooling Requirements.

2. Make input connections to the input barrier strips on the Input

Module. Be sure to make the correct connections for stereo, parallel, or bridged mono configuration. See the sections on Mode

Configuration and Input Module Connections and Controls for

more information.

3. Connect speakers to the output barrier strips on the Power/Output

Module. Be sure to make the correct output connections for

stereo, parallel or bridged mono configuration. See the section on

Power/Output Module Connections for more information.

4. Make power connections, allowing for proper current draw. See

the section on Connecting Power/Circuit Size Requirements for

more information.

5. Turn the front panel three-position AC switch to 'on', and bring

up the rear panel gain attenuators to the desired levels.

Front Panel.

1. Rack Mounting Ears.

Two to four mounting holes are provided on each front mounting

ear.

2. Three-position AC Power Switch.

A three-position switch is on the front panel. With the switch pushed

towards the upper position the amplifier is On. The middle position

is Off and the lower position is marked Remote. When switched to

Remote, the amplifier must be activated by the sequential turn

on/turn off (STO) circuit. (CK amplifiers are shipped with the CCSTL Power/Output module standard, which permits STO. If NexSys

compatible modules are used, STO can also be performed under

NexSys computer control.) When a voltage of +8 to +18V DC is

applied to the rear-mounted STO terminal and the “In” terminal is

connected to the “Com” terminal, the amplifier will turn on. When

no voltage is present or the In-Com connection is opened, the amplifier will switch off. Other CK Power Processing amplifiers can be

“daisy-chained” together and will turn on at 200ms intervals. See the

section on Sequential Turn-On/Turn-Off for more information about

STO.

3. Protect LED.

If the amplifier is in Protect mode, the output relay will open, and

this LED will light.

4. Active LED.

The Active LED indicates the amplifier is turned on.

5. Signal LED.

Each channel has a Signal LED, which comes on gradually, first

dim, and then brighter as the signal level increases.

6. ACL LED.

Each channel has an ACL (Active Clip Limiting) LED. This LED

comes on at the clipping point, and indicates that ACL is engaged.

See the section on TourClass Protection for more information.

7. Fan Grill & Filter.

A high-efficiency DC fan (with continuously variable speed) mounted behind the fan filter & fan intake grill draws cooling air into the

amplifier. Do not block this intake! The fan operates only when the

amplifier heatsinks require cooling. Fan filters are easy to remove

and must regularly be cleaned to ensure optimum performance.

Installation and Mounting.

CK Power Processing amplifiers are 2, 3 & 4-rack space units of 17

1/8" (437mm) depth that mount in a standard 19-inch rack. On all

amplifiers except 4-rack space units, four front panel mounting holes

are provided. (4-rack space units have eight front panel mounting

holes). Rear mounting ears are also provided on all amplifiers for

additional support, which is essential in non-permanent installations

like mobile or touring sound systems, but recommended for permanent installations as well.(Distance from the back of the front rack

ear to the center of the rear mounting ear holes is 16 5/8" / 422mm )

Because of the cables and connectors on the rear panel, a right-angle

or offset screwdriver or hex key will make it easier to fasten the rear

mounting ears to the rails. Dimension drawings are included on page

4.

Crest Audio CK Power Processing Amplifiers Page 3

Side Panels.

8. Exhaust Ports.

Heated air exits through the exhaust ports, located on the sides of the

amplifier chassis. Do not block these ports when rack-mounting the

amplifier. See Side View.

Rear Panel.

Module Bays & Modules.

The rear panel of CK Power Processing amplifiers provides three

bays (Input, Network and Output/Power) configured to accept interchangeable plug-in modules. Your amplifier may have been factoryconfigured with some of the optional modules. In this case, info on

the relevant modules will be enclosed in the amplifier box, or in a

separate binder. If all required information is not included, please

call Crest Audio’s Customer Service department or your local Crest

Audio representative.

About CC Modules and NC Modules.

CC modules fit into the Power/Output or Input module bays in the

rear panel of CK Power Processing amplifiers. These "basic" analog

modules are non-programmable and non-NexSys

the STO function can be controlled (through hardwiring).

NC Modules can be controlled, programmed and/or monitored. They

fit into the rear panel of the amplifiers. NC Input Modules can be

controlled and/or programmed over the NexSys network or via the

N-Coder (Hand-Held) or N-Coder/PC software. (NexSys is Crest

Audio’s hardware and software package that offers network connection of Crest Audio amplifiers and associated devices.). NC Input

and NC Output/Power Modules are NexSys-compatible. Using

NexSys with the appropriate NC Network Module, NC Input and

Output/Power Modules can be controlled, programmed and/or monitored remotely. NexSys also offers a number of diagnostic facilities.

On the NC Input Modules, the individual channel attenuators offer

manual level adjustment and removable knobs for additional security. Except for the STO feature, NC Modules are “tamper-proof” in

that there are no user-accessible setup controls.

9. Circuit Breaker.

A re-settable, protective AC circuit breaker is located at the upper

left of the amplifier rear panel. Two and three rack space amplifiers

have a push-type breaker fitted, while four rack space units have a

throw-switch style breaker. If the breaker has tripped, push it back in

(or, in the case of four rack space units, flip the breaker up) to return

the amplifier to operating condition. If the breaker trips repeatedly,

the amplifier needs servicing.

10. IEC Power Connector with removable Power Cord or

Captive Power Cord.

On two rack space amplifiers, a standard IEC power connector is

located at the lower left corner of the amplifier rear panel. An AC

mains cord having an appropriate AC plug for the intended operating

voltage is included. Three and four rack space units have a captive

power cord.

11. Power/Output Bay.

All Power/Output modules (CC-STL module is shipped standard)

provide a ground lift jumper, barrier strip output connectors, and

connections for sequential turn-on /off (STO) activation.

®

compatible; only

A barrier strip is provided for connection of loudspeakers with bare

wire or spade lug connectors. A signal ground lift jumper permits the

audio ground to be lifted from the chassis ground. For more informa-

tion see the sections on Signal Ground Lift Jumper, Module

Removal, and Sequential Turn-On/Turn-Off.

12. Network Bay.

The CC-BLK (blank panel) comes standard with all amplifiers. See

the section on Replacing or Installing a Network Module for more

information.

13. Input Bay.

CK Power Processing amplifiers come standard with a CC-IPB Input

module. Barrier strip input connectors and individual channel rotary

attenuators are provided. All Input modules have an internal voltage

gain/input sensitivity jumper that is factory-set for X40 gain. See the

sections on Input module Connections and Removing or Replacing

an Input module for more information.

Operation.

Connecting Power/Circuit Size Requirements.

CK Power Processing amplifier power requirements are rated at

“idle”, 1/8th power (“typical” music conditions), 1/3rd power, and

maximum rated power. The maximum power current draw rating is

limited by the amplifier's circuit breaker. Consult the specifications

at the end of this manual for the current that each amplifier will

demand. AC mains voltage must be the same as that indicated on the

rear of the amplifier. Damage caused by connecting the amplifier to

improper AC voltage is not covered by any warranty. Note: Always

turn off and disconnect the amplifier from the mains voltage before

making audio connections. If possible, as an extra precaution, have

the attenuators turned down during power-up.

Cooling Requirements.

CK Power Processing amplifiers use a forced-air cooling system to

maintain a low, even operating temperature. Drawn by a continuously-variable-speed fan mounted behind the front panel, air enters

through the front grill and courses through the cooling fins of the

heat sink, (which dissipates power transistor heat), before exiting

through the side panel ports. The fan will remain inactive until operating temperature rises above 45° C. Make sure that there is enough

space around the front of the amplifier to allow air to enter, and

around the sides to allow the heated air to exit. (See page 4 for intake

and exhaust locations. Note: If the amplifier is rack-mounted, do not

use doors or covers on the front or rear without pressurizing the

rack. Whatever type of rack you are using, make sure that heated air

can escape freely, and that there is no resistance to the intake of cool

air through the front grill. Intake and exhaust air must flow without

resistance. Ensure that fan filters are regularly cleaned and periodically replaced. (No tools are required for filter removal).

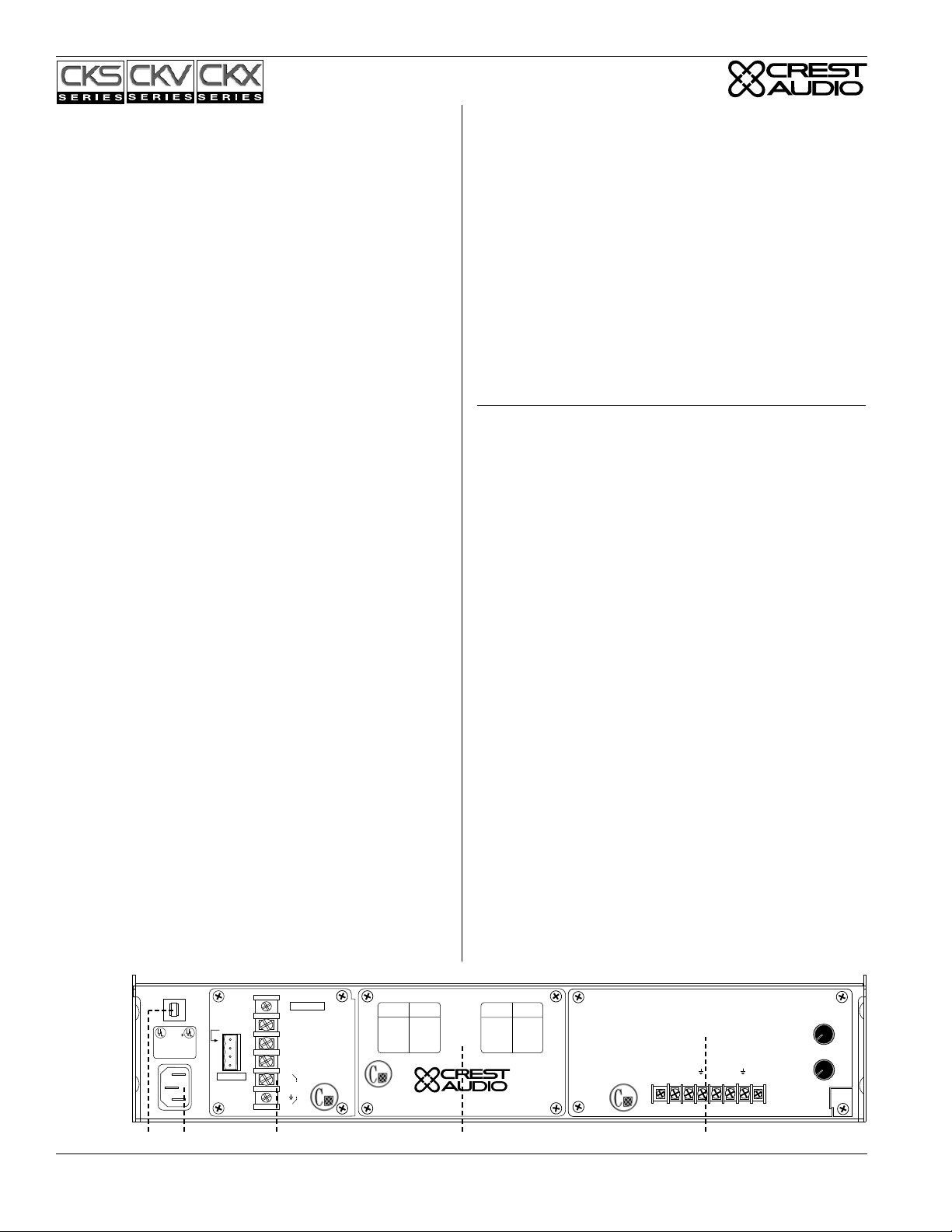

Rear

View

LISTED 8B42

COMMERCIAL

POWER

AMPLIFIER

120V~60 Hz 15A

In

Out

Com

+8 to +18VDC

20 mA

NEC

CLASS 2 ONLY

Model

CC-STL

CLASS 2 WIRING

MAY BE USED

Output

–

A

+

+

B

–

Signal

Ground

Lift

Jumper

Model

Output Power

Name

@70.7V

CKV 100

50W

CKV 200

100W

CKV 400

200W

CKV 800

400W

CKV 1600

800W

CKV 2400

1200W

Designed & manufactured in the USA by:

Paramus, New Jersey 07652 USA

Crest Audio Inc.

100 Eisenhower Dr.

Model

Name

CKS 100

CKS 200

CKS 400

CKS 800

CKS 800-2

CKS 1200-2

CKS 1600-2

Output Power

@8Ω/Ch.

50W

100W

200W

400W

400W

600W

800W

Model

CC-BLK

5

Level

4

6

A

3

7

2

8

1

9

0

10

5

Level

4

6

B

Model

CC-IPB

3

7

2

8

1

9

0

10

Input A

Input B

–

–

+

+

11 12 13109

Page 4 Crest Audio CK Power Processing Amplifiers

Loading...

Loading...