Page 1

CREST CRE57000

TM

ON BOARD RADIO CONTROL SYSTEM

INSTALLATION

AND OPERATION MANUAL

This manual describes proper installation and

operation of the following products:

CRE57001 REVOLUTION TRAIN ENGINEER 2.4 Ghz TRANSMITTER

CRE57002 REVOLUTION TRAIN ENGINEER 2.4 Ghz RECEIVER

Page 2

INTRODUCTION

Congratulations on your purchase of the Crest Revolution Train Engineer wireless

control system. This product has been manufactured to the highest standards using

only quality components and, with proper care, will provide you with reliable

service. The Revolution TE operates on the 2.4Ghz frequency band for ultimate

stability and interference free operation.

The Revolution TE lets you walk around your model railroad layout and remotely

control your locomotive speed, direction, lights, sounds, and smoke from up to 400

feet away. The Revolution TE was developed to provide the model train enthusiast

with complete integrated control of their dream layout, without the need for

complicated layout wiring or complex control panels.

The Revolution TE receiver is designed to operate between 12 to 24 volts applied

either to the track or from on board batteries. The Receiver is designed for “plug

and play” installation in any Aristo-Craft Locomotive with a DCC/RCC board. The

receiver can also be installed in any large scale locomotive with the use of a supplied

Adaptor Plug. General instructions for custom installations are included in this

manual.

OPERATION OVERVIEW

Before you start working with the Revolution TE there are a few concepts that you

need to understand.

The transmitter and the receivers in your locomotives are designed to communicate

and exchange information about the way you want your trains to operate. In order to

establish a link between them you need to set up some basic parameters that dene

the locomotive for the Transmitter such as the locomotive’s name and road number.

Once these parameters are set, the link between the transmitter and receiver is

nalized by a process called “Linking”. Once linked, the transmitter and receiver are

set to communicate and run your train. As you get comfortable with the Revolution

TE, you can start ne tuning the optional settings for each locomotive. These options

include setting the top speed that you want a locomotive to achieve, the rate at

which you want it to accelerate, how long you want it to delay when the direction is

changed, headlight operation and many more.

The second concept has to do with the Cab Assignment. Once you link a locomotive

receiver to a transmitter you must set the Cab Number that the locomotive will run

under. Cab Numbers range from CAB-0 through CAB49. This allows you to easily

move between as many as 50 Single Unit locomotives and Multiple Unit Consists

while operating your model railroad. CAB-0, CAB-1 and CAB-2 might be used to

operate three different locomotives while CAB-3 can be used to operate those same

three locomotives in a consist. Changing between Single Unit (SU) operation and

Multiple Unit (MU) operation is as simple as selecting a Cab Number.

Once you have an opportunity to experience the process used to operate trains with

the Revolution TE you will nd that Aristo-Craft has found an elegant, easy to

understand solution, to what can be a complex problem.

2

Page 3

CONTENTS

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Revolution TE Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Revolution TE Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BASIC OPERATIONS SECTION

Basic Receiver Installation (For Plug-N-Play Locomotives) . . . . . . . . . . . . 7

Link Switch Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Powering your Locomotives. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Transmitter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Basic Transmitter Programming. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LCD Screen - Basic Reference guide . . . . . . . . . . . . . . . . . . . . . 12

Programming a Locomotive . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting The Cab Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating Your Locomotive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Basic Troubleshooting Direction . . . . . . . . . . . . . . . . . . . . . . . 17

Basic Troubleshooting Headlights . . . . . . . . . . . . . . . . . . . . . . 17

ADVANCED OPERATIONS SECTION

Advanced Installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Auxiliary Control Harness . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CRE57073 Smoke Control Board Installation . . . . . . . . . . . . . . . . 19

Advanced Programming And Functions . . . . . . . . . . . . . . . . . . . 20

Transmitter Operating Screen. . . . . . . . . . . . . . . . . . . . . . . . . 20

Menu Functions and Navigation . . . . . . . . . . . . . . . . . . . . . . . 23

1.ASSIGN FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.USAGE OF CABS . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.ADD MU/SU CAB. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operating Multiple Locomotives In Consists (MUing). . . . . . . . . . . . 27

4. COPY LOCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5. SYSTEM CONFIGURE . . . . . . . . . . . . . . . . . . . . . . . 28

6. RADIO CONFIGURE. . . . . . . . . . . . . . . . . . . . . . . . . 29

7. MY MEMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8. RESET MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . 30

QUICK MENU LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

AUX FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

STEP SPEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

A->Z NAME SEARCH . . . . . . . . . . . . . . . . . . . . . . . . . 31

ABOUT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Custom Receiver Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adaptor Plug Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Headlight Connections (Incandescent) . . . . . . . . . . . . . . . . . . . . 34

Headlight Connections (LED lamps) . . . . . . . . . . . . . . . . . . . . . 35

APPENDIX A - Text Entry Help . . . . . . . . . . . . . . . . . . . . . . . . . 36

APPENDIX B - Installation Records . . . . . . . . . . . . . . . . . . . . . . . 37

3

Page 4

REVOLUTION TRAIN ENGINEER FEATURES

SYSTEM FEATURES:

Spread spectrum radio transmission provides immunity from other radio sources•

Range exceeds 400 feet outdoors and 300 feet indoors.•

Continuous bidirectional 2.4Ghz communication between transmitter and •

receiver for smooth operation and operator feedback.

The active locomotive is shown on a graphical, backlit, LCD display The receiver automatically shuts down if overload or overheating occurs -

The error that causes a locomotive shut down is displayed on LCD display Locomotives are identified by name and road number•

Up to 6 locomotives can be linked together (MUed) into a consist•

Up to 10 MU consists can be setup and controlled by one transmitter•

Locomotives can be added or removed from an MU consist without relinking•

TRANSMITTER FEATURES:

Large LCD graphic screen, backlit for night operation•

One handed operation•

Intuitive, simple data input is entered using cell phone style texting techniques•

Memory For Up To 50 Unique Locomotives On Each Transmitter•

Multiple transmitters can operate without interference with one another•

Simultaneous Single Unit ‘SU’ and Multiple Unit ‘MU’ operation•

All Stop Key to provide an emergency stop for all trains on a transmitter•

RECEIVER FEATURES:

Plug and play installation in most Aristo-Craft locomotives•

On-board battery or track power •

Six auxiliary outputs on the receiver to control sound, smoke and lights•

5 Amps continuous power with peak loads up to 8 amps•

Polarity protection•

Overload protection•

INDIVIDUALIZED LOCOMOTIVE PROGRAMMABLE SETTINGS:

Programmable momentum control and forward & reverse delay•

Adjustable start speed •

Adjustable top speed•

Direction control headlights•

Direction control motor setting for MUing locomotives back-to-back.•

Function key assignment for • six auxiliary outputs

Copy locomotive settings for fast replication of similar locomotives•

ADDITIONAL EQUIPMENT AVAILABLE SEPARATELY:

CRE57001 Revolution TE Transmitter•

CRE57002 Revolution TE Receiver•

CRE57073 Smoke Control Board•

CRE57076 Capacitor Board•

CRE57080 TX Battery NI-Cd Battery & Charger•

CRE57072 Transmitter Battery Charger (without batteries)•

4

Page 5

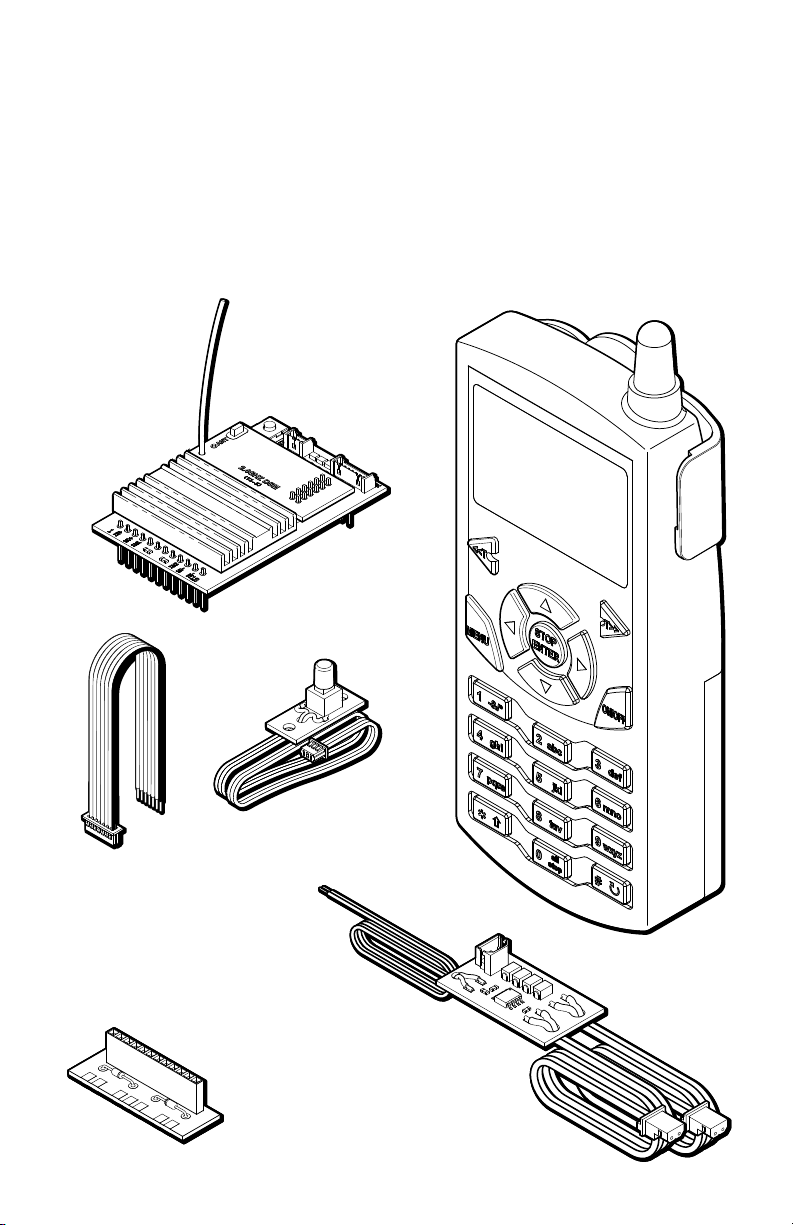

CRE57000 SYSTEM COMPONENTS

REMOTE LINK

SWITCH

CRE57002

RECEIVER

AUXILARY CONTROL

HARNESS

ADAPTER PLUG

(for custom Installations)

CRE57001 TRANSMITTER

CRE57073

SMOKE CONTROL

BOARD

The CRE57000 Crest Revolution TE Wireless Control System consists of the following

components:

CRE57001 Transmitter•

CRE57002 Receiver which includes a Remote Link Switch, an Auxiliary •

Control Harness and an Adaptor Plug

CRE57073 Smoke Control Board.•

5

Page 6

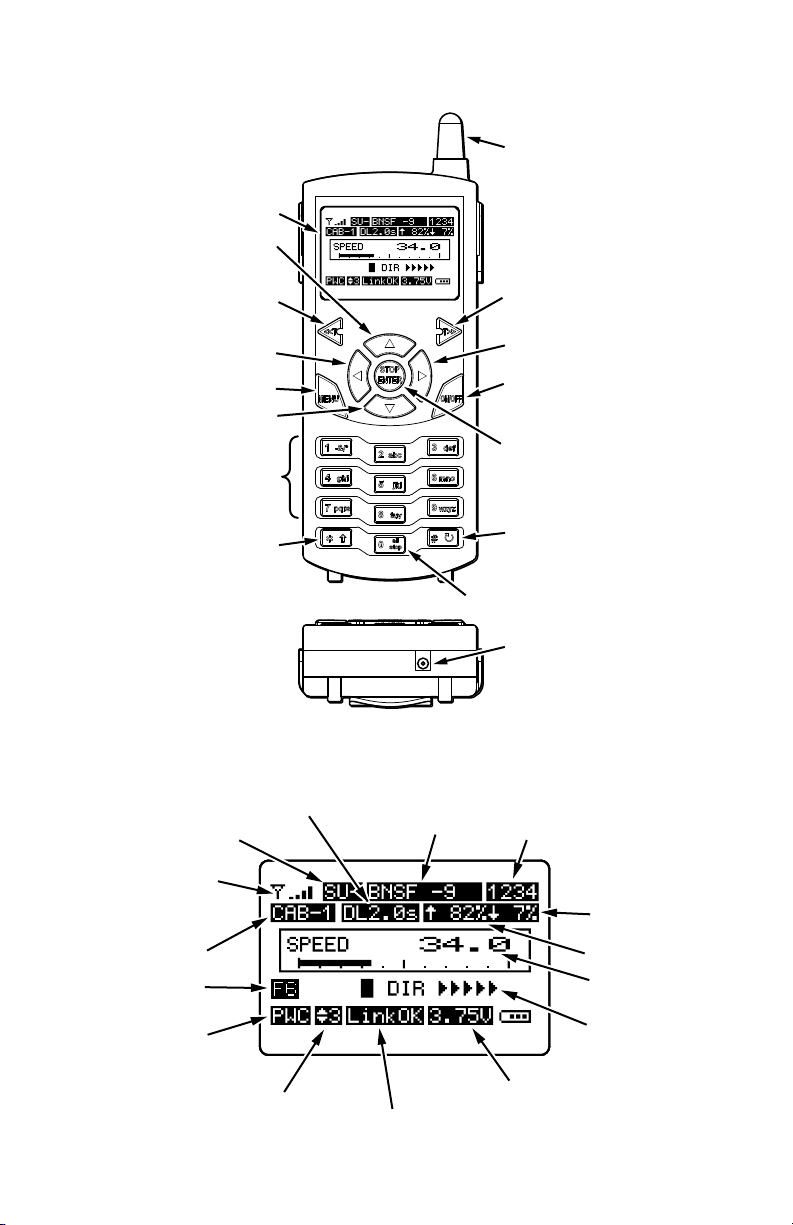

CAB NUMBER

SELECT DOWN

SPEED - FAST

ANTENNA

LCD SCREEN

SPEED - SLOW

NUMBER

LETTER

KEYS

VIEW MU

ENGINES

ALL STOP

CHARGING

JACK

# KEY

DELETE

QUICK MENU

MENU

DIRECTION

(REVERSE)

DIRECTION

(FORWARD)

ON / OFF

STOP / ENTER

CAB NUMBER

SELECT UP

RECEIVER

SIGNAL STRENGTH

ACTIVE CAB

PWC/LINEAR

POWER

SPEED STEP

SU/MU

LOCO

NAME

LOCO ROAD

NUMBER

DELAY SETTING

START SPEED

TOP SPEED

CURRENT SPEED

LOCO DIRECTION

TRANSMITTER

BATTERY VOLTAGE

RECEIVER LINK

AUX FUNCTION

FEEDBACK

REVOLUTION TE TRANSMITTER

LCD SCREEN

6

Page 7

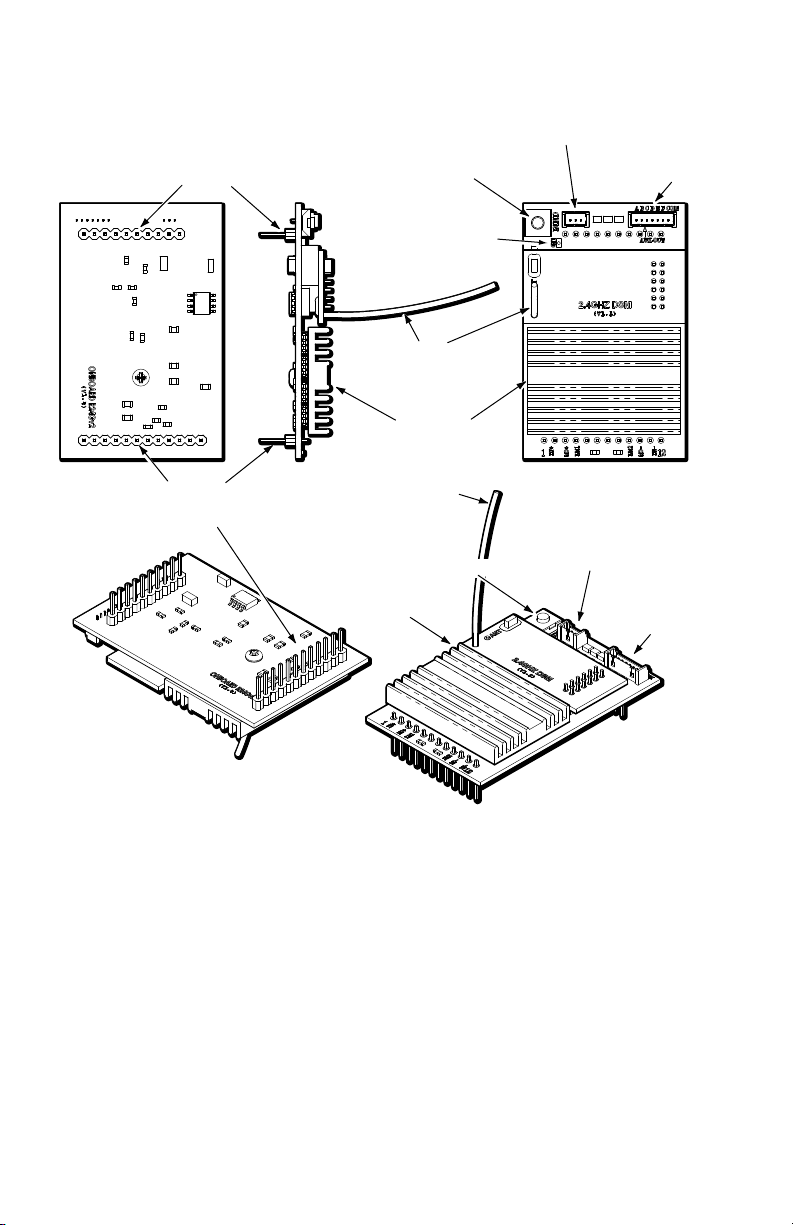

LINK SWITCH

ANTENNA

LINK SWITCH

HEAT SINK

AUXILARY

CONNECTOR

10 PIN SUPPORT

HEADER

12 PIN DCC/RCC

CONTROL HEADER

REMOTE LINK SWITCH

CONNECTOR

REMOTE LINK SWITCH

CONNECTOR

LINK LED

ANTENNA

LINK SWITCH

AUXILARY

CONNECTOR

HEAT SINK

REVOLUTION TE RECEIVER

BASIC RECEIVER INSTALLATION FOR PLUG-AND-PLAY DCC/RCC

EQUIPPED LOCOMOTIVES

You will need the following items for installation:

CRE57002 Revolution TE 2.4 Ghz Receiver•

REMOTE Link Switch •

Phillips head screwdriver•

A drill and drill bits to install the remote Link Switch (if desired)•

NOTE: If the locomotive does not have a DCC/RCC compatible main circuit

board, see the custom installation instructions beginning on page 31 of this

manual.

7

Page 8

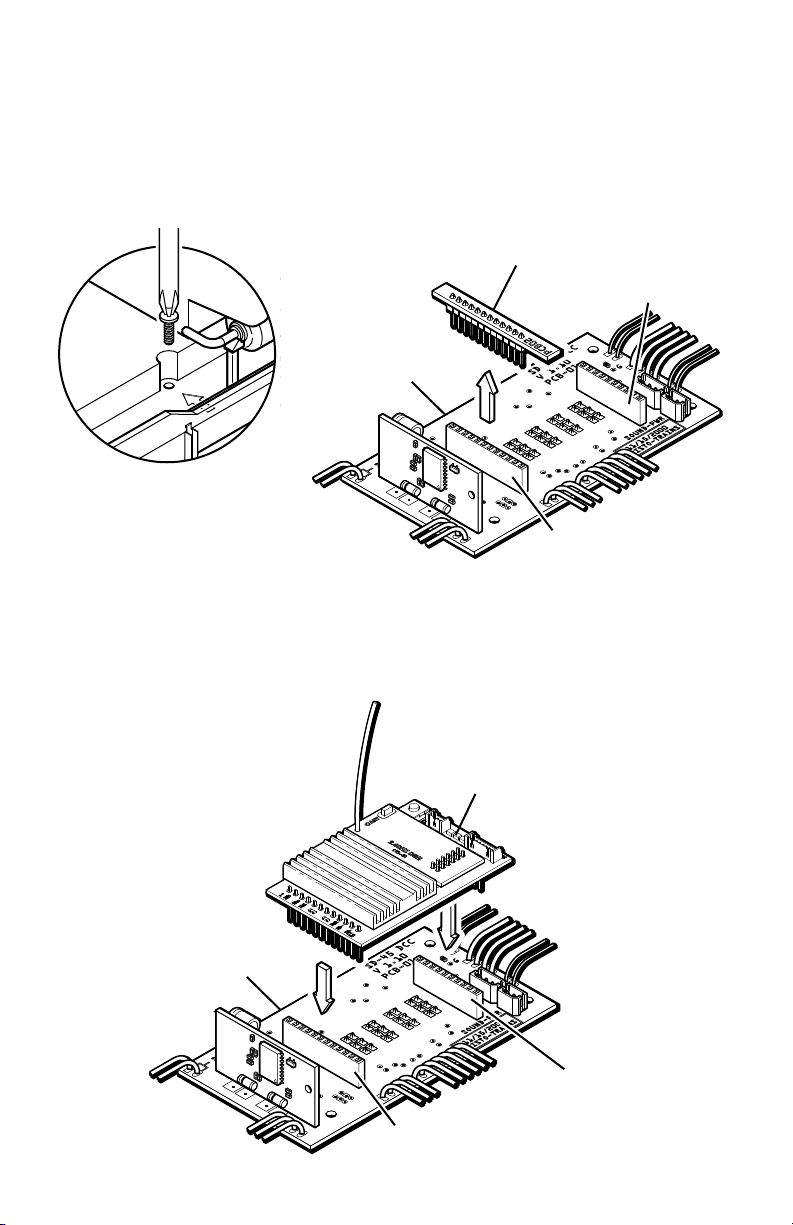

1) Remove the locomotive shell. Refer to the manual included with your locomotive

Engine Main

Circuit Board

Jumper Plug

12 Pin DCC Socket

10 Pin Accessory

Socket

ENGINE MAIN

CIRCUIT BOARD

12 PIN DCC/RCC SOCKET

10 PIN SUPPORT

SOCKET

TE REVOLUTION

RECEIVER

to determine where the DCC/RCC socket is located. Turn the locomotive (or

tender) over, and remove all screws that hold the shell to the frame. Depending

on the model of the locomotive, the number of screws will vary.

2) Remove the jumper plug on the DCC/RCC socket and set it aside. You can

restore the locomotive to its pre-installation state by reinstalling the jumper plug.

3) Install the receiver in the 12 pin DCC/RCC socket and the 10 pin support socket

as shown making sure to match the 12 pin header to the 12 pin socket and the 10

pin header to the 10 pin socket.

8

Page 9

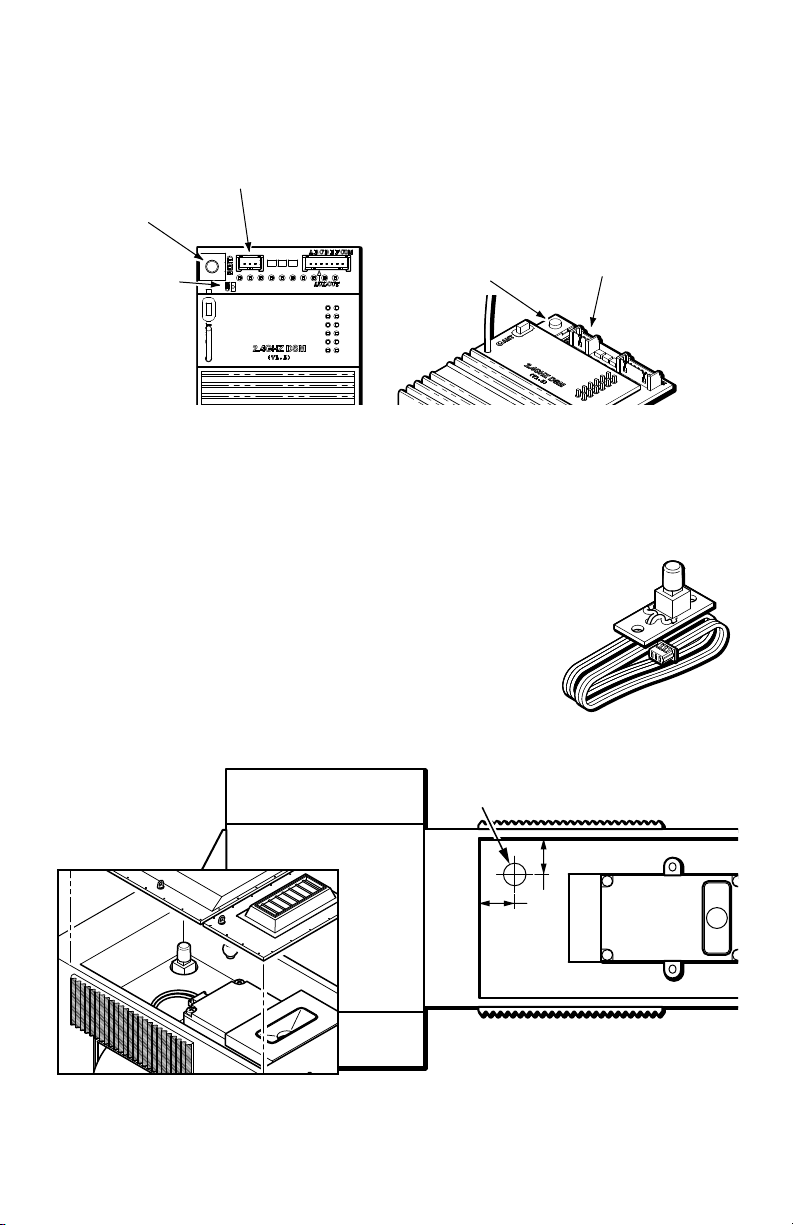

4) Install the Remote Link Switch

1/2"

9/32" DIA.5/16" DIA.

LINK SWITCH

LINK SWITCH

REMOTE LINK SWITCH

CONNECTOR

REMOTE LINK SWITCH

CONNECTOR

LINK LED

LINK SWITCH

REMOTE LINK SWITCH

NOTE: There is a Link Switch on the receiver. If the Link Switch on the receiver

is accessible from outside the locomotive you may wish to skip this step

Locate a place to install the supplied Remote Link Switch where it will be

accessible from the outside of the locomotive, yet obscured from view. Under

a removable hatch or through the bottom of the locomotive or tender are

convenient locations, in most cases. The Remote Link Switch must not be

mounted on a metal or conductive surface since this may cause a short circuit.

A typical installation in the Aristo-Craft SD45 is

shown below.

Drill a 5/16”(8MM) diameter hole in the selected

location. Install the Remote Link Switch through the hole

from inside and secure it with hot melt glue or silicone

adhesive.

5) Attach the remote link switch connector on the Remote Link Switch to the three

pin header on the receiver as shown on the following page.

9

Page 10

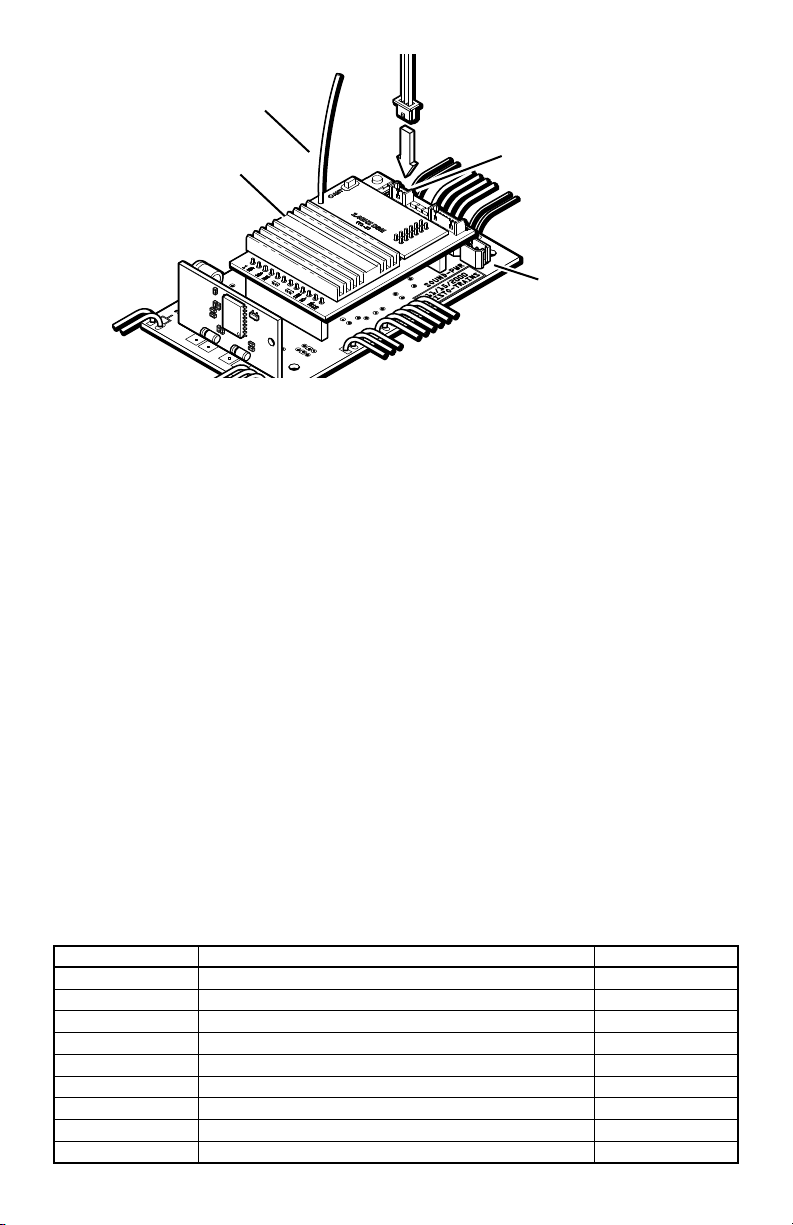

Engine Main

Circuit Board

Receiver

Remote Link

Switch Connector

Link Switch

Header

Antenna

(Fully Extended)

6) Reinstall the locomotive shell. Use care when reassembling the locomotive. Be

careful that you do not pinch any wires between the shell and internal parts of the

locomotive.

THIS COMPLETES BASIC INSTALLATION OF THE RECEIVER. After the

Transmitter set-up is complete, you will have full remote control of your locomotive

speed, direction and lights. If you wish to add advanced options such as remote

operation of smoke and sound please refer to the advanced section later in this

manual.

POWERING YOUR LOCOMOTIVES

TRACK POWER. The Revolution TE receiver will work on voltages ranging from

12 to 24 volts DC. When running from track power, connect DC power directly to

the track and set your controller power to the highest setting, but not more than 24

volts. You can also connect a DC power supply of up to 24 volts, without any speed

controller, directly to the track. Set the track/battery switch on your locomotive to

‘Track’.

BATTERY POWER. The Revolution TE receiver can also be powered from Li-Ion

(Lithium Ion), Ni-MH (Nickel Metal Hydride), Ni-Cd (Nickel Cadmium) or Gel Cell

batteries. The maximum voltage must not exceed 24 volts. Multiple batteries can

be wired in series or parallel to increase voltage or run time. When operating from

batteries, set the track/battery switch on your locomotive to ‘Battery’. The following

batteries and cables are available from Aristo-Craft dealers.

PART NUMBER DESCRIPTION CHARGER

CRE55610 Li-Ion, 2 AMP - 21.5 Volts CRE55620

CRE55650 Ni-MH 2.8 AMP - 12 Volts CRE55660

CRE55653 Ni-MH 2.8 AMP - 19.2 Volts CRE55661

CRE57080 Ni-Cd 1.5 AMP - 12 Volts CRE55660

CRE55493 Gel Cell 3.2 AMP - 3 X 6V CRE55494

CRE55601 Auto Cutoff For Gell Cell Battery

CRE55602 Wire Harness For Battery Set

CRE55611 Y Plug In Parallel

CRE55613 Y Plug in Series

10

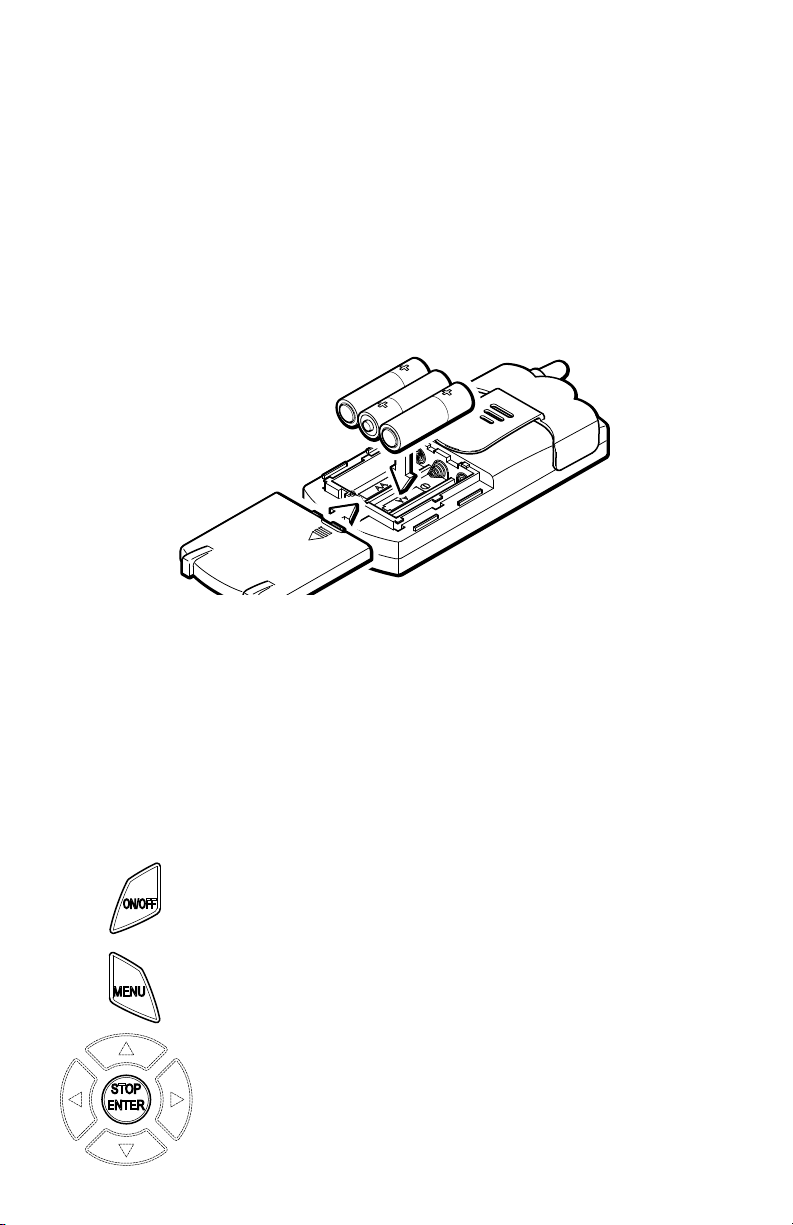

Page 11

TRANSMITTER SETUP

ON/OFF

MENU

STOP

ENTER

1) REMOVE THE BATTERY COMPARTMENT COVER on the back of the

transmitter case.

2) INSERT THREE “AA” BATTERIES The Revolution Transmitter will operate

on your choice of three “AA” Alkaline, Ni-MH (Nickel Metal Hydride) or Ni-Cd

(Nickel Cadmium) batteries of 1.2 to 1.5 volts each. All three batteries must be

identical, do not mix battery types. Insert the batteries making sure that they face

in the directions indicated in the battery compartment.

Crest Battery Charger CRE57072, is available for charging Ni-Cd batteries

through the charging port in the bottom of the transmitter.

3) REPLACE THE BATTERY COMPARTMENT COVER

BASIC TRANSMITTER PROGRAMMING PROCEDURE

The following section describes the basic programming necessary to begin running

your trains with the Revolution TE system. Since the Revolution TE is an advanced

and full featured system, you may wish to operate your trains at the basic level

described here until you feel ready to take advantage of all of the features that the

Revolution has available. The Revolution TE’s advanced functions are described in

the advanced section of this manual.

Please take the time to familiarize yourself with the transmitter design, key and

button layout as well as the transmitter’s LCD screen on the following pages.

ON/OFF - Press and hold the ON/OFF to turn the Transmitter

on. Press and hold the ON/OFF to turn the Transmitter off.

MENU - Press MENU to select the Transmitter’s setup menus.

While accessing menus, pressing MENU will move you back

one level.

STOP/ENTER - When operating a locomotive the STOP/

ENTER key will STOP the active locomotive and set its

speed to zero. When accessing menu’s, the STOP/ENTER

key will operate as an ENTER key to conrm a selection.

11

Page 12

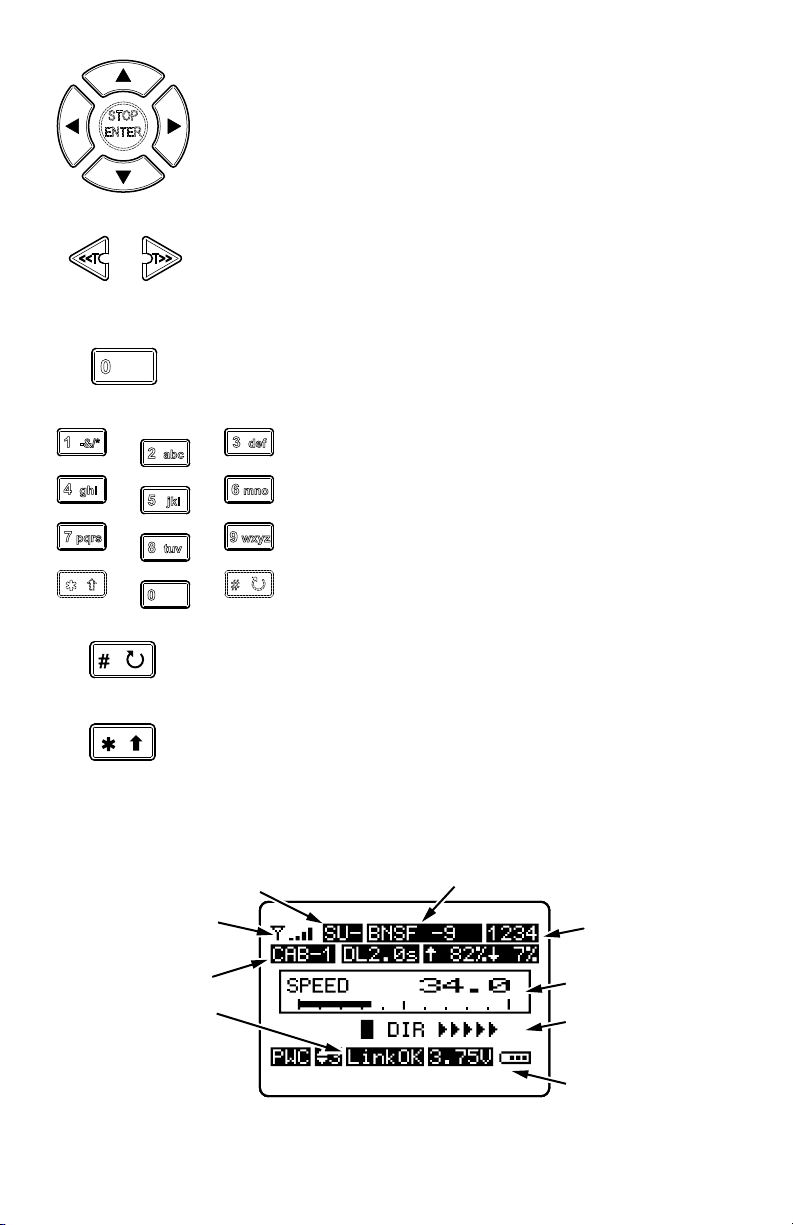

ARROW Keys - When operating a locomotive the up and

<<T

T>>

0

all

stop

3 def

7 pqrs

8 tuv

9 wxyz

0

1 -&/*

4 ghi

5 jkl

6 mno

2 abc

all

stop

RECEIVER

SIGNAL STRENGTH

ACTIVE CAB

SU/MU

LOCO NAME

LOCO ROAD

NUMBER

LOCO DIRECTION

(FORWARD SHOWN)

TRANSMITTER

BATTERY VOLTAGE*

RECEIVER LINK

CURRENT SPEED

*NOTE: THE TRANSMITTER WILL SHUT OFF WHEN THE BATTERY VOLTAGE DROPS TO 3.4 VOLTS.

down arrows (p and q) increase or decrease speed and the left

and right arrows (t and u) select direction. When accessing

menu items the up and down arrows (p and q) scroll between

items and the left and right arrows (t and u) change that item’s

value.

<<T and T>> - Used to select the active locomotive Cab. Press

the <<T key to scroll down and the T>> to scroll up the list. The

locomotive names and road numbers will be displayed on the

main operation screen.

ALL STOP - PRESS AND HOLD the “0 all stop” key and

this immediately stops all locomotives on the same transmitter

and sets their speed to zero. This key is also used to reset a

locomotive after an overload or overheat error occurs.

NUMBER / LETTER KEYS - Use when entering

numeric or textual information the use of these keys

is identical to those on a cell phone. When operating

a locomotive, keys 1 through 6 are used to operate six

auxiliary functions. For example, pressing key “1”

might activate the horn sound. Programming these

keys is covered in the advanced programming section

of this manual.

# (POUND) - When the Operating screen is being

displayed pressing the # key accesses the Quick Menu. During

text entry, this is the ‘space’ key

* (STAR) - When operating an MU consist, pressing this key

selects the locomotive in the consist whose auxiliary functions,

such as smoke or sound, that you want to control.

LCD SCREEN - Basic Reference guide

12

Page 13

PROGRAMMING A LOCOMOTIVE

OPERATION NOTE: Use the p and q keys to highlight a menu option and

then press STOP/ENTER to select the item.

The transmitter and the receivers in your locomotives are designed to communicate

and exchange information about the way you want your trains to operate. In order to

establish a link between them you need to set up some basic parameters that dene

the locomotive for the transmitter and for you, such as the locomotive’s name and

road number. Once these parameters are set, the link between the transmitter and

receiver is nalized by a process called “Linking”. Once linked, the transmitter and

receiver are set to communicate. Finally you must assign a Cab Number to your

locomotive and then you are ready run your train with the Revolution TE.

As you get comfortable with the Revolution TE, you can start ne tuning the optional

settings for each locomotive, as described, in the advanced section of this manual.

1) Turn on the transmitter by pressing On/

Off. The main “Operating” screen will be

displayed.

2) Press MENU to access the MAIN SET

UP menu.

MAIN SET UP

1.ASSIGN FUNCTION ¤

3) Press the STOP/ENTER key (or the ‘1’

key) to select:

1.ASSIGN FUNCTION

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

4) a.LINK ADDR - The link address for the locomotive must be chosen.

This number is different for each locomotive and is a number from “00” to “49”.

The default entry, when you access the Assign Functions menu, is ‘49’. Use

link address [00] for the rst locomotive.

Note that you can quickly move to link

address [00] by pressing the STOP/

ENTER key. To select another address,

use the t and u keys until the address

you want is displayed. This is also the

method used to access previously dened

locomotives for editing.

13

1.ASSIGN FUNCTIONS

a.LINK ADDR [49] ¤

b.RxType [OnBoard]

c.NAME [L49 ]

d.ROAD No. [RdNo]

e.MOMENTUM [ 10%]

Page 14

5) c.NAME - Use the p and q keys

move to NAME. Use the keypad to

type letters or numbers to name the

locomotive. Names may be up to 9

characters long. There is a guide to

entering names in Appendix “A” on

page 35 of this manual.

1.ASSIGN FUNCTION

a.LINK ADDR [00]

b.RxType [OnBoard]

c.NAME [GN SD45 ] ¤

d.ROAD No. [RdNo]

e.MOMENTUM [ 10%]

6) d.ROAD NO. - Use the p and

q keys move to ROAD No. Enter a

1.ASSIGN FUNCTION

road number of up to four characters

using the number keypad.

7) Place the locomotive on the track.

a.LINK ADDR [00]

b.RxType [OnBoard]

c.NAME [GN SD45 ]

d.ROAD No. [400 ] ¤

e.MOMENTUM [ 10%]

8) Apply power. If running on batteries

make sure the locomotive’s battery is

12 to 24 volts and is fully charged. If using track power, apply 12 to 24 volts to

the track.

9) m.LINKING - Use the p and

q keys move to LINKING. Press

and hold the Link Switch on the

locomotive. Release the Link Switch

when the locomotive’s lights begin

ashing.

NOTE: There is an LED on the

1.ASSIGN FUNCTION

i.HD LIGHT [ ON]

j.TOP SPEED [100%]

k.START SPEED[ 0%]

l.AUX FUNC. SETUP

m.LINKING £

Revolution TE Receiver that also

ashes during this linking process. See

the illustration of the receiver, on page

7, to locate the LED.

While the lights (and LED) are ashing

press the STOP/ENTER key on the

transmitter.

In a moment the screen will show that

1.ASSIGN FUNCTION

i.HD LIGHT [ ON]

j.TOP SPEED [100%]

k.START SPEED[ 0%]

l.AUX FUNC. SETUP

m.LINKING PASSED! £

the programming of the unit has been

successful and the ashing will stop.

11) Press the MENU key once to return to the Main Menu.

BASIC LOCOMOTIVE PROGRAMMING IS NOW COMPLETE.

14

Page 15

Setting the CAB number

Each locomotive must be assigned to a cab number. This provides a simple way

to choose locomotives from the main

operating screen.

MAIN SET UP

1) Press MENU to display the main set up

menu.

3) Press the 3 key to select:

3.ADD MU/SU

4) Use the p and q keys to select a CAB

number. CAB-0 is the rst available

active locomotive in the list so you

want to start here.

5) Use the p and q keys to select

SU [49] L49

1.ASSIGN FUNCTION ¤

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

MAIN SET UP

1.ASSIGN FUNCTION

2.USAGE OF CAB

3.ADD MU/SU ¤

4.COPY LOCO

5.SYSTEM CONFIGURE

3.ADD MU/SU CAB

CAB NO: CAB-0 ¤

MU MODE: OFF

SU [49] L49

6) Use the t and u keys to scroll thru

the locomotive listings until you nd

the locomotive (by Link Address) that

you programmed previously. As shown

in the example to the right for a GN

3.ADD MU/SU CAB

CAB NO: CAB-0

MU MODE: OFF

SU [00] GN SD45 ¤

SD45.

7) Press the MENU key to return to the

Main Menu

The transmitter and receiver are now linked an ready to operate your

locomotive. When you feel ready to move into advanced features and programming

please turn to the advanced setup section in this manual.

15

Page 16

OPERATING YOUR LOCOMOTIVE

1) Use <<T and T>> keys to select the cab number that you assigned to the

locomotive that you want to operate. The locomotive’s name & road number will

be displayed on the top line along with SU-, indicating that this is operating as a

single unit locomotive.

2) Use the up and down arrow keys (p and q) to increase and decrease the

locomotive’s speed.

3) Use the Right Arrow key ( u) to go forward and the Left Arrow key (t) to run

backwards.

While it is preferred that you stop you trains gradually by using the down arrow

(q) key you can stop the selected locomotive quickly by pressing STOP/ENTER.

You can now add additional locomotives following these same procedures but

using a different Link Address for each new locomotive.

Controlling two locomotives (trains) independently, at the same time

1) Make sure that both locomotives have been identied in the transmitter, that

linking has been successful and that the locomotives have each been assigned a

Cab Number.

2) Place each locomotive on the track, separated by some distance .

3) Use the <<T and T>> keys until the display shows cab number, name and road

number for the locomotive that is in front.

4) Use the UP Arrow (p) key to start it running slowly in a forward direction.

5) Select the other locomotive with the <<T and T>> keys. Use the p and q keys

to get it running.

Note that the displayed speed for both locomotives may not be the same when they

are actually running at the same speed as it can vary from locomotive to locomotive.

You can continue to operate each locomotive independently by switching from one

CAB to the other using the <<T and T>> keys and then make changes in speed or

operate accessories.

That is all there is to get up and running. With practice you will become a master

at controlling your trains. When you are ready to take the next step please read the

advanced section of this manual to learn how to make the most of the Revolution TE.

16

Page 17

BASIC OPERATING TROUBLESHOOTING

“The engine runs backwards when the transmitter is set to forward”

1) Press MENU to display the MAIN SET

UP menu.

2) Press the STOP/ENTER key to select:

1.ASSIGN FUNCTION

3) Use the p and q keys to scroll down

the list of functions to:

g.MOTOR

4) Use the t and u keys to toggle motor direction between NORmal and

REVerse.

5) Press MENU to exit to the main menu screen.

6) Press MENU again to exit to the operating screen.

The locomotive will now respond to direction in the opposite way that it did initially

and should now match the transmitter indication.

1.ASSIGN FUNCTIONS

c.NAME [L49 ]

d.ROAD No. [RdNo]

e.MOMENTUM [ 10%]

f.DELAY [3.0s]

g.MOTOR [NOR] ¤

“My engine’s headlight does not match the direction of the locomotive”

1) Press MENU to display the main set up

menu.

2) Press the STOP/ENTER key to select:

1.ASSIGN FUNCTION

3) Use the p and q keys to scroll down

the list of functions to:

h.HD DIR

4) Use the t and u keys to toggle the headlight direction between NORmal and

REVerse.

5) Press MENU to exit to the main menu screen.

6) Press MENU again to exit to the operating screen.

The headlight will now match the direction of travel of your locomotive.

17

1.ASSIGN FUNCTIONS

d.ROAD No. [RdNo]

e.MOMENTUM [ 10%]

f.DELAY [3.0s]

g.MOTOR [REV]

h.HD DIR [NOR] ¤

Page 18

ADVANCED OPERATIONS, INSTALLATIONS AND PROGRAMMING

Engine Main

Circuit Board

Receiver

Auxiliary Control

Harness

Remote Link

Switch Harness

Black Wire

1 - Blue

2 - Green

3 - Yellow

4 - Orange

5 - Red

6 - Brown

7 - Black

Wire Color I.D.

AUXILIARY CONTROL HARNESS

An Auxiliary Control Harness is supplied with the

Revolution TE Receiver. The Auxiliary Control

Harness plugs into a seven pin auxiliary wiring

connector at one end of the receiver circuit board.

The wires, which correspond to keys 1 thru 6 on the

transmitter, are connected to control functions of your

choice.

NOTE: The functions listed in the table below

represent how we envisioned the system to operate.

This does not mean to say that this is the only way that

you can use each of the six functions. More important is

that you assign a purpose to each auxiliary function and

stay consistent from one locomotive to the next so that

you know which key does what on each of your locomotives.

The six switch positions will need to be connected to the accessory you wish to

control with the Transmitter. Please refer to the manufacturer’s instructions for

connecting sound triggers when using third party sound systems.

The six functions of the Auxiliary Control Harness are independently programmable

and intended to operate as follows:

AUXILIARY CONTROL HARNESS

Wire #/Color Tx Key Typical Use Setting

1 Blue 1 Horn/Whistle sound Momentary

2 Green 2 Bell sound Latching

3 Yellow 3 Brake sound Momentary

Orange 4 Other sound Momentary

4

5 Red 5 Running/Cab/Ditch Lights Latching

Brown 6 Smoke

6

(use with CRE57073 Smoke Control Board) Latching

7 Black N/A Common (ground) for all functions

18

Page 19

CRE57073 SMOKE CONTROL BOARD

Plugs go to

Smoke Unit(s)

Connect to Auxiliary

Control Harness

Plug in Power

for Smoke Unit(s)

Solder

Heat Shrink Tubing

Auxiliary Harness

Brown Wire

Black Wire

In order to control a smoke generator which has a relatively high power draw, a

Smoke Control Board (Available separately CRE57073) has been designed to work

with the Revolution TE Receiver. This Smoke Control Board has been designed to

be used with the Auxiliary Control Harness to remotely operate smoke generators by

acting as an electronic switch or relay. The Smoke Control Board has the ability to

operate two smoke generators simultaneously.

1) If you use heat shrink tubing to insulate solder joints, place a short piece on the

black wire and another on the brown wire of the Auxiliary Control Harness.

Solder the black wire from the Smoke Control Board to the black wire in the

Auxiliary Control Harness. Solder the white wire from the Smoke Control Board

to the brown wire on the Auxiliary Control Harness. Carefully heat the heat

shrink tubing (or use electrical tape) to insulate the solder joints.

2) Unplug the wire harness that is plugged into the smoke generator in your

locomotive and plug this connector into the socket on the Smoke Control Board.

If your locomotive has dual smoke generators, like the Aristo-Craft E8, unplug

both smoke units and plug only one of these connectors into the Smoke Control

Board.

3) Plug one of the connectors from the Smoke Control Board (either one will work)

into the smoke generator, where the original connector was plugged in. If you

have a second smoke generator in your locomotive, plug the other connector from

the Smoke Control Board into the second smoke unit.

4) Use double sided foam tape to securely mount the Smoke Control Board to the

interior of the locomotive using care that the circuit board does not come in

contact with any metal inside of the locomotive.

5) Set the smoke switch (in the locomotive) to on. This switch should remain on.

6) Refer to the Advanced Programming section of this manual to program F6 to

‘LATCH’ under AUX FUNC. SETUP in the locomotive ASSIGN FUNCTIONS

menu.

The onboard Revolution receiver now has control of the locomotive smoke

generator. When you want to operate the smoke generator in your locomotive, add

smoke uid to the smoke generator and when operating the locomotive, simply press

key ‘6’ to turn the smoke on and press key ‘6’ again to turn the smoke off.

19

Page 20

ADVANCED PROGRAMMING AND FUNCTION INFORMATION

RECEIVER

SIGNAL STRENGTH

ACTIVE CAB

PWC/LINEAR

POWER

SPEED STEP

SU/MU

LOCO

NAME

LOCO ROAD

NUMBER

DELAY SETTING

START SPEED

TOP SPEED

CURRENT SPEED

LOCO DIRECTION

TRANSMITTER

BATTERY VOLTAGE

RECEIVER LINK

AUX FUNCTION

FEEDBACK

The following section is a comprehensive list of functions, displays and descriptions

of the options available under each menu item. Accessing and setting these functions

uses exactly the same techniques described in the basic programming section of this

manual.

The Transmitter Operating screen

OPERATING SCREEN - First Line

Receiver Signal Strength - The antenna symbol and signal bars, in the upper left

corner of the screen shows the strength of the radio signal between the transmitter

and the locomotive’s receiver. This is reference information only and has no user

setable function.

SU/MU - SU- indicates that the locomotive under control is a single independent

unit. MU2 or MU3 indicates that a Multiple Unit conguration of 2 or more

locomotives is being operated. This is also reference information and it indicates

the selected CAB type.

Loco Name - The active locomotive’s name is programmed by the operator when

programming locomotives

Loco Road Number - The active locomotive’s road number is programmed by the

operator when programming locomotives

OPERATING SCREEN - Second Line

Cab # - The cab number is associated with the locomotive that is being controlled.

This number is programmed by the operator under item 3 of the main menu

ADD MU/SU CAB which is used to assign either single locomotive or multiple

locomotives to a CAB Number for operating purposes. This is what makes MUed

locomotives work as a unit.

20

Page 21

Delay Setting - Is the number of seconds that the train will stay stopped when its

direction is changed. DL2.0s in this example means that the locomotive will

pause for 2.0 seconds before it reverses direction. This setting is available for

programing by the operator when a locomotive is being dened under Item 1,

ASSIGN FUNCTIONS

Top Speed - The locomotive’s maximum speed is expressed as a percentage of the

maximum possible speed. This setting is available for programing by the operator

when a locomotive is being dened under Item 1, ASSIGN FUNCTIONS. TOP

SPEED is useful when the operator would like to limit the maximum speed of a

locomotive to a scale speed for realistic operation. This item can also be useful if

you wish to limit the speed at which children an operate a locomotive.

Start Speed - The locomotive’s start speed is expressed as a percentage of the

amount of power required for the locomotive to begin to move. This setting is

available for programing by the operator when a locomotive is being dened

under Item 1, ASSIGN FUNCTIONS. START SPEED is used to reduce the

dead zone between speed setting 0 and the speed setting at which the locomotive

begins to move.

OPERATING SCREEN - Current Speed Box

Current Speed - shows the locomotive’s current speed as a percentage of the

maximum possible speed. At the bottom of this box the speed of the locomotive

is shown graphically in the form of a bar.

OPERATING SCREEN - Loco Direction Line

Loco Direction - shows the direction of travel for the active locomotive. Arrows

pointing to the right indicate forward while arrows pointing to the left indicate

reverse

Aux Function Feedback - Flashes when an Auxiliary Function key is pressed.

OPERATING SCREEN - Bottom Line

PWC/Linear Power - The rst item on the bottom line shows that the system is

using PWC (Pulse Width Coding) speed control.

Speed Step - This shows the sensitivity level for speed of reaction after pressing

the t and u keys. This is an operator dened setting under the QUICK MENU

LIST. For switching you might want a lower sensitivity and for big trains a faster

key reaction. This setting is applied to all locomotives being controlled by the

transmitter.

LinkOK or NOLink - tells whether the transmitter and receiver of the active

locomotive are communicating. This same area on the display will show error

messages such as OVERLOAD or OVERHEAT. This is reference information

only and has no user setable function.

Normally the transmitter’s main control display shows LinkOK on the bottom

line of the screen. This indicates that there is a good radio link between the

transmitter and the receiver in the locomotive. If that link is lost due to an

21

Page 22

exhausted battery, excessive distance, a short circuit or open circuit on the track, a

derailment or no power on the track the message will change to NOLink.

When the amperage drawn by a locomotive exceeds 8 amps, the capacity of the

onboard receiver, which can continuously supply 5 amps, the receiver will shut

down and the transmitter will display OVERLOAD on the LCD.

The receiver will send an OVERHEAT signal to the transmitter if the receiver’s

temperature exceeds 175 degrees Fahrenheit. If the receiver overheats wait for 5

to minutes for the receiver to cool before continuing to operate it.

After you correct an overload or overheat condition press the zero key [0] on the

transmitter keypad to reset the error message.

Transmitter Battery Voltage - Shows the voltage level of the transmitter’s batteries.

Fresh alkaline batteries should show about 4.5 volts for example. The last item is

a graphic of the transmitter’s battery level. These are for operator reference only

and have no user setable function.

NOTE: The Transmitter will shut off when the battery voltage drops to 3.4 Volts

NOTES:_____________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

22

Page 23

MENU FUNCTIONS AND NAVIGATION

In this section each menu item is shown along with comments about its use.

The MAIN SET UP menu is accessed by pressing MENU from the main control

screen. To navigate this menu use the p and q keys to select the item that you wish

to edit and press ENTER to access the item submenu.

1.ASSIGN FUNCTION - This Menu

is used to dene individual locomotives.

To navigate this menu use the p and q

keys to select the function that you wish

to change. To change a setting that has a

pre-dened range, use the t and u keys.

Under NAME and ROAD NO. Use the

number and letter keys to add text and

MAIN SET UP

1.ASSIGN FUNCTION¤

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

numbers. When programming is complete,

press Menu to return to the Main Menu.

After a new locomotive is dened in this Menu, you must then assign the new

locomotive a Cab Number in Menu 3.ADD MU/SU CAB, before you can control

your newly dened locomotive.

FUNCTION SETTINGS

a.LINK ADDR - The link address for the

locomotive must be chosen. This number

is different for each locomotive and is a

number from “00” to “49”. Use the t and

u keys to select a Link Address. 00 is the

rst available address in the list and should

be used for the rst locomotive. Note that

you can quickly move to address 00 by

pressing the STOP/ENTER key.

b.RxType - This menu item tells the

transmitter which type of receiver is being

dened. OnBoard is the receiver type used

in locomotives while BASE RX is the

1.ASSIGN FUNCTIONS

a.LINK ADDR [49]

b.RxType [OnBoard]

c.NAME [L49 ]

d.ROAD No. [RdNo]

e.MOMENTUM [ 10%]

f.DELAY [0.0s]

g.MOTOR [NOR]

h.HD DIR [NOR]

i.HD LIGHT [ ON]

j.TOP SPEED [100%]

k.START SPEED[ 0%]

l.AUX FUNC. SETUP

m.LINKING

receiver type used for stationary functions

such as remote switch control. Use the t

and u keys to select the Receiver Type that you are dening. Once linked, the

receiver type cannot be changed without relinking.

c.NAME - This is where you give your locomotive an easy to identify name.

Use the keypad to type letters or numbers to “Name” the locomotive. Names may

be up to 9 characters long. Something like BNSF GP40 or UP -9 or some similar

description is good. There is a guide to entering text in Appendix “A” (page35).

d.ROAD NO. - Enter the road number of the locomotive being dened. One to

four characters is allowed. This lets you distinguish between two locomotives that

were both named BNSF GP40 for example.

23

Page 24

e.MOMENTUM - If momentum is set to 0 (zero) your locomotive will accelerate

rapidly if you press and hold the UP ARROW key. Its speed will instantly

become what it is set to. As the momentum setting is increased the time that it

takes the locomotive to catch up with the speed setting you set increases. This

means that you can set the speed to 60% by holding the UP ARROW key for a

few seconds but the locomotive may take several more seconds to actually make

it to that speed. Use the t and u keys to select the amount of Momentum that

you want to apply to the locomotive you are dening.

Momentum And Step Speed (described later) both effect how quickly a

locomotive will reach its top speed.

f.DELAY - When the direction of the locomotive is reversed this setting

determines how long, in seconds, that the locomotive will be completely stopped

before it starts up again in the other direction. The range is 0 to 5 seconds in

1/10th second increments. Use the t and u keys to select the amount of delay, in

seconds, that you want your locomotive to wait before reversing direction.

g.MOTOR - This item sets the default direction of travel when the transmitter

says the locomotive is going forward. This can be set to NOR (normal) or REV

(reverse). If set to NOR the locomotive will go forward when the transmitter

shows that it is going forward. If set to REV the locomotive will go backwards

when the transmitter shows that it is going forward. This is used primarily when

you are operating multiple locomotives (MUing) and you want them to run backto-back. Use the t and u keys to select the Motor default direction.

h.HD DIR - This can be set to NOR (normal) or REV (reverse). If set to NOR

the headlight on the locomotive will come on when the locomotive is going

forward. If set to REV the headlight will come on when the locomotive is going

backwards. This is useful if your headlights do not match the direction of travel

of the locomotive. Use the t and u keys to change the headlight direction.

i.HD LIGHT - This can be set to ON or OFF. If set to ON the headlight will

operate normally. If set to OFF the headlight will not function. This function is

used when adding locomotives into a Multiple Unit consist. Typically only the

lead locomotive has it’s headlight on when operating and all trailing units have

their headlights off. Use the t and u keys to set the headlight to On of Off.

j.TOP SPEED - Sets the locomotives top speed as a percentage of its possible

top speed. This comes in handy if you have visitors who are operating your trains

and have been known to run them at too high a speed. If you set this to 70% that

is all the faster the locomotive will go, 70% of its possible top speed. Use the t

and u keys to set the locomotives Top Speed.

k.START SPEED - Sets the speed at which acceleration of the locomotive

begins. If you have a large locomotive or one that is pulling a long, heavy train

you can set the start speed so that the power level will jump to the set percentage

as soon as you begin accelerating. For example, if you have a locomotive that

doesn’t start moving till the throttle setting is at 25% you can set the start speed to

that number and not have to wait for the speed to get to that level before the train

moves. As soon as you press the UP ARROW key the speed will jump to 25%

24

Page 25

and increase from there as the UP ARROW key is held. Use the t and u keys to

set the Start Speed of the locomotive.

l.AUX FUNC. SETUP - This menu item is used to set each of the function

keys to operate either as momentary or

latching. MOMENTARY means that the

function being controlled is on while the

Function key is pressed and turns off when

the key is released. LATCHING means

that the function being controlled is turned

on when the Function key is pressed and

remains on till the same Function key is

pressed again.

AUX FUNC. SETUP

AUX MODE: BASIC

F1: MOMENTARY

F2: MOMENTARY

F3: MOMENTARY

F4: MOMENTARY

F5: MOMENTARY

F6: MOMENTARY

AUX MODE: BASIC vs. EXTEND

- Select either BASIC or EXTEND. In

BASIC mode, you will be able to control function keys F1 thru F6. If your

receiver supports more than six auxiliary functions then EXTEND mode is

chosen so that you can control up to 16 auxiliary functions, F1 thru F16.

Use the t and u keys to set each Aux Function to either momentary or latching.

m.LINKING - This nal menu item is used to establish a Link between the

transmitter and the receiver that you just dened.

1) Press and hold the Link Switch on the receiver or locomotive until the LED

on the receiver, or lights on the locomotive, begin to ash.

2) While the LED/lights are ashing press the ENTER key on the transmitter.

In a moment the screen will show that the programming of the unit has been

successful and the ashing will stop. Once linked, the function settings are saved for

this locomotive. Press MENU to return to the Main Menu.

2.USAGE OF CABS

The Revolution transmitter can store up to as

many as 50 locomotives. Since it is unlikely

that each of us would have this number of

locomotives active at one time you can use this

menu item to limit the number of locomotives

that show up when you press the <<T and T>>

keys while viewing the control screen.

1) From the Main Menu screen use p and q

to select 2.USAGE OF CABS and press

ENTER

2) Use the t and u keys to increase or

decrease this range from CAB-0 thru

CAB49.

Press MENU to save this set-up and return to

the Main Menu.

25

MAIN SET UP

1.ASSIGN FUNCTION

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

2.USAGE OF CABS

CONTROL CAB

CAB-0 TO CAB-5

¤

Page 26

3.ADD MU/SU CAB

This Menu is used each time a new locomotive

is added to the transmitter. Its purpose is to

assign a Cab Number a locomotive so that it

can be quickly identied and selected from the

main operation screen. This is where you assign

a locomotive it’s Single Unit (SU) Cab Number

MAIN SET UP

1.ASSIGN FUNCTION

2.USAGE OF CAB

3.ADD MU/SU ¤

4.COPY LOCO

5.SYSTEM CONFIGURE

and where you set up consists of up to six

locomotives and assign them Multiple Unit (MU) Cab Numbers.

Single Unit (SU) Cab assignments

1) Use the t and u keys to choose a Cab

Number to assign to a locomotive. This range

is set by 2.USAGE OF CABS.

2) Make sure that MU MODE: is set to OFF for

SU mode.

3.ADD MU/SU CAB

CAB NO: CAB-0

MU MODE: OFF

SU [49] L49

3) Use the t and u keys to select your

locomotive, under SU by the Link Address assigned in 1.ASSIGN FUNCTIONS.

4) Press MENU to save this set-up and return to the Main Menu. Press MENU again

to return to the operating screen.

Multiple Unit (MU) Cab assignments

1) From the Main Menu screen use p and q

to select 3.ADD MU/SU CAB and press

ENTER

2) Use the t and u keys to choose a Cab

Number to assign to the Multiple Unit (MU)

consist. This range is set by 2.USAGE OF

CABS.

3) Use the t and u keys to change MU MODE

to ON. The menu changes to allow you to

3.ADD MU/SU CAB

CAB NO: CAB-0

MU MODE: ON

MU1 [00]

MU2 NOT SELECTED

MU3 NOT SELECTED

MU4 NOT SELECTED

MU5 NOT SELECTED

MU6 NOT SELECTED

enter a list of locomotives that are to be

MUed.

4) Select the rst (lead) locomotive as MU1 by using t and u keys to select the

Link Address assigned to it. Use the q key to move to the next locomotive.

5) Select the second locomotive in the consist as MU2 by using t and u keys to

select the Link Address assigned to it. Use the q key again to move to the next

locomotive.

6) Continue the MU assignments until all of the locomotives (up to a maximum of 6)

that you want to MU in a single consist, are listed.

7) Press MENU to save this set-up and return to the Main Menu. Press MENU again

to return to the operating screen.

26

Page 27

Operating multiple locomotives in consists (MUing)

Once the set-up is complete, operating MUed locomotives is quite simple.

THE MU SET UP:

For this example let’s say that you set up two locomotives are called LOCO1 and

LOCO2 and that their Cab Addresses are set to CAB-0 and CAB-1 respectively

(LOCO1 is CAB-0 and LOCO2 is CAB-1).

Since the two locomotives can operate independently as CAB-0 and CAB-1 you set

up CAB-2 for them to operate together in an MU consist.

In order to make sure that both locomotives are going to work in harmony, place both

locomotives on the track a few feet apart. On the operating screen, select the MU on

CAB-2 with the <<T and T>> keys.

Speed up the locomotives and conrm that both are going in the same direction.

If you want one locomotive to run backwards you can make that change under

1.ASSIGN LOCOMOTIVE, a.MOTOR [REV].

THE OPERATION SCENARIO:

You want to make up an MU consist in order to haul the daily freight west.

First, you operate LOCO1 in SU mode (CAB-0) and spot it at the assigned location

in the yard. Stop LOCO1 by bringing the speed down to 0%.

Next, Select CAB-1 (LOCO2) on the transmitter, and operate LOCO2 in SU mode

to meet LOCO1. You then couple LOCO2 to LOCO1 automatically and stop it,

bringing LOCO2’s speed to 0%.

You then select CAB-2 (MU LOCO1 & LOCO2) and now you operate the MU as

a single unit. You pick up your assigned train in the yard and off you go to your

assigned destination.

You now arrive at your destination and you bring your train to a full stop. You

uncouple the lead locomotive (LOCO1), select CAB-0 and go off to the next

assignment. Meanwhile LOCO2 is on yard duty to classify the cars it just delivered.

You change to CAB-1 and work the yard with LOCO2 until all of the cars have been

sorted.

NOTES:

For more than 2 locomotives in a consist just add additional locomotives to CAB-2

under 3.ADD MU/SU CAB. Up to six locomotives may be MUed together into a

single consist.

You can use the number key labeled “*” (star) to select from the locomotive names

in a consist so that you can access their accessory functions independently. For

example, if you have a smoke unit in both LOCO1 and LOCO2 and each is attached

to Auxiliary output #6 you could turn on the smoke in LOCO1 when the display

shows LOCO1 at the top. To access the smoke unit on LOCO2 you would press the

“*” (star) key and LOCO2 would be displayed. Now button 6 will activate LOCO2’s

smoke unit.

27

Page 28

4.COPY LOCO

Once you set up a locomotive with a set of

options you can copy that locomotive’s settings

to use for another locomotive without having to

re-enter all of the settings. For example, if you

have set up an SD45 locomotive on link address

00 and want to copy the settings to link address

01 because you have another SD45 to set up:

MAIN SET UP

1.ASSIGN FUNCTION

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO ¤

5.SYSTEM CONFIGURE

1) From the Main Menu select 4.COPY LOCO

and press ENTER

2) On the FROM: line use the t and u keys to

select Loco 00 (or any dened locomotive in

your transmitter)

4.COPY LOCO

FROM: [00] L00

TO: [01] L01

COPY: [00]->[01]

3) On the TO: line use the t and u keys to

select Link Address 01 (or any other Link

Address of your choice)

4) Scroll down to COPY: Conrm that the FROM and TO entries are correct and

press ENTER to conrm the copy.

Press MENU to return to the Main Menu.

CAUTION: Copying a locomotive to a Link Address that has previously been

dened will overwrite all existing settings for that Link address.

5.SYSTEM CONFIGURE

This Menu gives you the ability to customize

your transmitter to suit your preferences.

1) From the Main Menu screen select

5.SYSTEM CONFIGURE and press ENTER

2) Highlight POWER OFF and use the t and

u keys to change the time, from 1 to 30

MAIN SET UP

1.ASSIGN FUNCTION

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

minutes, that you want the transmitter to

stay on after the last key was used. This will

help conserve transmitter battery power.

3) Scroll down to BRIGHTNESS and use the

t and u keys to change the brightness of

the LCD Screen backlight from 0 to 100%.

4) Scroll down to CONTRAST and use the t

5.SYSTEM CONFIGURE

a.POWER OFF [ 5min]

b.BRIGHTNESS [ 50%]

c.CONTRAST [50%]

d.KEY SOUND [ON ]

and u keys to change the Contrast of the

LCD Screen from 0 to 100%.

5) Scroll down to KEY SOUND and use the t and u keys to turn the key (chirp)

sound ON or OFF.

Press MENU to return to the Main Menu.

28

Page 29

6.RADIO CONFIGURE

This menu has two settings available, RFCHANNEL and GROUP ID.

RF-CHANNEL - All Revolution transmitters are

factory set to channel 16. In most cases this can

be left as is but if you suspect that interference

from a local source is effecting the range of

MAIN SET UP

2.USAGE OF CAB

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

6.RADIO CONFIGURE¤

YOUR system, you can choose a new channel

to help eliminate the interference. Note that

you must relink any locomotives that you have

if you change the RF Channel number.

GROUP ID - If you have more than 50

6.RADIO CONFIGURE

a.RF-CHANNEL[CH:16]

b.GROUP ID. [8455]

locomotives that you want to control or you

have multiple areas that you want to control

with separate transmitters, you can select a

different Group ID for each transmitter and they

will operate independently of one-another. It

is also important that visitors who might bring their own Train Engineer Revolution

and locomotives have a different group ID. Group ID numbers are set randomly

at the factory so duplication should not be a problem and you may never have to

change this setting. Note that you must relink any locomotives that you have if you

change the Group ID number.

1) From the Main Menu screen select 6.RADIO CONFIGURE and press ENTER

2) When RF-CHANNEL is highlighted, use the t and u keys to change to the new

RF-CHANNEL. Available Channels are channel 16 thru channel 26

3) Highlight GROUP ID and use the t and u keys to SELECT a new GROUP ID

Number. The range for Group ID numbers is 0000 thru 9999

Press MENU to return to the Main Menu.

7.MY MEMO

This menu item is provided to allow you

to personalize your transmitter so that the

owner can be identied if it gets mixed up

or left behind at a running session with other

Revolution TE owners. Each eld can contain up

to 20 letters and/or numbers.

1) From the Main Menu screen select 7.MY

MEMO and press ENTER

2) Fill in your name and contact information.

Press MENU to return to the Main Menu.

29

MAIN SET UP

3.ADD MU/SU

4.COPY LOCO

5.SYSTEM CONFIGURE

6.RADIO CONFIGURE

7.MY MEMO ¤

7.MY MEMO

NAME:

___________________

INFO:

___________________

Page 30

8. RESET MEMORY

This last item on the Main Menu is used to

8.RESET MEMORY

revert the transmitter back to the original

factory software settings.

ARE YOU SURE

RESET ALL MEMORY?

You have two choices, Yes or No.

Yes No

WARNING: THERE IS NO “UNDO”, if you

choose YES and then press STOP/ENTER,

ALL user entered settings on the transmitter are

erased.

QUICK MENU LIST

To access the QUICK MENU LIST, press the pound (#) key.

AUX FUNCTIONS

This menu item, under the Quick

Menu List, shows each Auxiliary

Function and whether it is set to

Latch or Momentary for the currently active

locomotive. It also shows the current setting

for each function. This is an easy way to see,

QUICK MENU LIST

AUX FUNCTIONS

STEP SPEED [ 3]

A->Z NAME SEARCH

ABOUT SYSTEM

for example, if your smoke unit is on or off.

You can also change the setting of each function

(ON to OFF or OFF to ON) by highlighting the

line and pressing ENTER

You cannot change the way that a key functions in this menu (momentary/latching),

you must use the ASSIGN FUNCTIONS menu to make this change.

STEP SPEED

Under this menu item, in the Quick Menu List,

you can set the Step Speed. Step Speed is the

setting that determines how fast locomotives

accelerate (and decelerate) based on the

number of increments required to go from 0

to full speed. The range is from 1 to 5. When

QUICK MENU LIST

AUX FUNCTIONS

STEP SPEED [ 3]

A->Z NAME SEARCH

ABOUT SYSTEM

set to 1 the rate at which the speed increases,

when you hold the p key will be the slowest.

A higher number will increase the rate of

acceleration. For precise control of a locomotive, for switching operations, set the

Step Speed to 1 or 2. To have your locomotives accelerate quickly, set it to 4 or 5.

When Step Speed is set to ‘1’ each time you press the p or q Keys the speed

changes by 0.1 %. When set to ‘2’, the speed changes in increments of 0.5 %. A

30

Page 31

setting of ‘3’ changes the speed by 1.0% each time the p or q Keys are pressed. A

setting of ‘4’ will increase speed by 2.5% and a setting of 5 jumps up or down by 5%

each time the p or q Keys are pressed.

Step Speed

Setting

Number of steps to

go from 0 to 100%

Speed increment on

each key press

1 1000 1/10% Very delicate operations

2 200 1/2%

3 100 1% Normal operations

4 40 2.5%

5 20 5% Rapid speed changes

A->Z NAME SEARCH

This menu item is reference information

only and shows an alphabetized list of

all locomotives with road names and link

addresses. This is a fast way to nd the

locomotive you want to operate. Use the p and

q Keys to scroll through the list

ABOUT SYSTEM

This nal item briey displays the system

frequency and software version number when

you press STOP/ENTER.

A->Z NAME SEARCH

2-8-2 7631 [04]

BNSF -9 1119 [02]

BNSF -9 1072 [05]

GN SD45 400 [06]

L07 RdNo [07]

ABOUT SYSTEM

FRQ: 2.4GHz/US

Ver 1.14

Hold STOP/ENTER key to keep showing

information

Use

CUSTOM RECEIVER INSTALLATION

For custom installations, you will need the following items:

Phillips head screwdriver•

12 to 24 volt DC power source connected to the track or onboard batteries.•

A drill and drill bits to install the remote Link Switch (if desired)•

A soldering iron and solder •

Wire cutter and wire stripper•

Heat shrink tubing or electrical tape•

Electronic components for headlights•

Many locomotives do not come equipped to accept the Revolution TE in a plug and

play installation. In this case, the wiring of the locomotive will require modication

31

Page 32

to accept the receiver. To facilitate custom installations, a Adaptor Plug is provided.

TR+ RIGHT SIDE TRACK PICK-UP

TRK- LEFT SIDE TRACK PICK-UP

HD1 REAR HEADLIGHT NEGATIVE

HD2 FRONT HEADLIGHT NEGATIVE

HD COM FRONT HEADLIGHT POSITIVE

MOT+ MOTOR POSITIVE POWER

MOT- MOTOR NEGATIVE POWER

TOP

BOTTOM

The Adaptor Plug has a 12 position socket. Wire the Adaptor Plug to your locomotive

with the connections as shown below.

1) POWERING THE Revolution TE. The Revolution TE is designed to work

from either track power or on board battery power of at least 12 volts DC to a

maximum of 24 volts DC. The receiver is self-protected for polarity and input

current. However, if you use a battery, you should install a 3-amp fuse directly

from the battery before any other wiring is connected. The fuse will protect your

wiring and the battery from damage in case of an accidental short circuit.

2) ISOLATE THE MOTOR(S). The motor(s) MUST be isolated from ALL other

wiring before the Revolution TE can be installed in a locomotive. This is critically

important. Failure to isolate the motors will cause the receiver to malfunction or

possibly fail. After you have located and disconnected the motor wires from the

locomotive, use an ohmmeter to check the resistance between the motor wires and

any other wires that you can nd in the locomotive. If any connection is indicated

at all, locate the connection and isolate the motor wires.

3) ADAPTOR PLUG CONNECTIONS. All wiring connections should be soldered

and insulated with heat shrink tubing or electrical tape.

I.D. USE TRADITIONAL WIRE COLOR

TR+ RIGHT SIDE TRACK PICK-UP Black (BLK)

MOT+ MOTOR POSITIVE POWER Gray (GRY)

HD1 REAR HEADLIGHT NEGATIVE Yellow (YEL)

HD COM FRONT HEADLIGHT POSITIVE Blue (BLU)

HD2 FRONT HEADLIGHT NEGATIVE White (WHT)

MOT- MOTOR NEGATIVE POWER Orange (ORG)

TRK- LEFT SIDE TRACK PICK-UP Red (RED)

Connect the motor wires: Solder the motor’s Right Side terminal to the Adaptor

Plug at MOT+. Solder the motor’s Left Side terminal to MOT-.

Connect the power wires: For track power installations, solder the Right Side

power pick-ups to TR+. Solder the Left Side power pick-ups to TRK-. For

Battery Power installations, Battery installations should include a 3-amp fuse in

32

Page 33

line with the positive power connection to prevent damage to both the Revolution

Receiver

12 Pin Header

TE and the battery pack. Solder the Negative side of the battery pack to TRK-.

Solder the Positive side of the battery pack to TR+.

Connecting the Headlights: The headlights will most likely require rewiring. All

of the wiring to the headlights MUST be isolated from all other wiring. See the

following wiring diagrams to connect the headlights in your locomotive.

HD2 is soldered to the Front headlight and is the negative power lead for the front

headlight. HD1 is soldered to the rear headlight and is the negative power lead for

the rear headlight. HD COM is soldered to both the Front and Rear Headlights

and is the positive power lead for both front and rear headlights.

Remaining connections: You can now connect any remaining lights and smoke unit,

that you want to control manually, to the power source (track pickups or battery)

and control switches. If you want to control these functions remotely please see

the Auxiliary Wiring Harness instructions (page 18) and Smoke Control Board

instructions (page 19) for guidance.

4) SECURING THE Revolution TE. The Revolution TE should be located so that it

is secure and insulated from any metal inside the locomotive. The Revolution TE

can be attached to the shell or interior oor of the locomotive with double stick

foam tape. Or the circuit board on the wire harness can be glued to the shell or

interior oor, using silicone adhesive or hot melt glue.

5) FINISHING THE INSTALLATION. Refer to Step 4 (beginning on page 9)

in the Receiver Installation instructions of this Manual to continue the receiver

installation.

6) PROGRAMMING THE LOCOMOTIVE. Refer to Page 13 to program your

locomotive in the Revolution TE Transmitter.

Note: The Revolution TE Receiver antenna may be extended when installed in

a locomotive which has an all metal body. Generally, the exposed portion of the

antenna (outside of the metal body) should be equal in length to the antenna supplied

on the receiver and located as high as possible on the locomotive. You may have

to make adjustments to your antenna for best reception. DO NOT MODIFY THE

ANTENNA WHEN INSTALLING THE TE RECEIVER IN PLASTIC BODY

LOCOMOTIVES.

33

Page 34

Front

Headlight

Front

Headlights

Rear

Headlight

Rear

Headlights

Adaptor Plug

Adaptor Plug

HD1

HD COM

HD2

Solder

Heat Shrink

Tubing

Heat Shrink

Tubing

Heat Shrink

Tubing

WIRING DIAGRAM FOR INCANDESCENT HEADLIGHTS

Wiring For Dual Headlights

100 Ohm Resistors

(Brown/Black/Brown)

100 Ohm Resistors

(Brown/Black/Brown)

HD1

HD COM

HD2

34

Page 35

1K Ohm Resistors

(Brown/Black/Red)

Front LED

Headlight

Rear LED

Headlight

Rear LED

Headlights

Short Lead (-)Short Lead (-)

Long Lead (+)

WIRING DIAGRAM FOR LED HEADLIGHTS

Typical Wiring For Dual

Front and Rear LED Headlights

Single Headlight

Negative (-)

Short Lead

Positive (+)

Long Lead

1K Ohm Resistors

(Brown/Black/Red)

Front LED

Headlights

Heat Shrink

Tubing

Heat Shrink

Tubing

Heat Shrink

Tubing

Adaptor Plug

HD1

HD COM

HD2

Adaptor Plug

HD1

HD COM

HD2

35

Page 36

Appendix “A” – Text entry with the transmitter’s keypad

Each number on the transmitter’s keypad is accompanied by three or four letters

or characters. This arrangement allows us to quickly and easily enter numeric and

textual information into the controller.

The method of entry is identical to that used on most cell phones. If you can enter

names and phone numbers into your cell phone’s address book you can use text entry

on the transmitter.

When you want to enter text, a locomotive’s name, for example, you can press a

number key once to enter a number or you can press that key two or more times to

cycle through the other available characters. Once the character you want appears on

the screen pause for a bit over a second and the cursor will automatically move to the

right for the next character. You can back up to make corrections with the left arrow

key. You can move to the right with right arrow key.

Here is a list of each key and the number of times you must press it to get each

character.

Key Pad 1st press 2nd press 3rd press 4th press

1 -&/* - & / #

2 abc A B C

3 def D E F

4 ghi G H I

5 jkl J K L

6 mno M N O

7 pqrs P Q R S

8 tuv T U V

9 wxyz W X Y Z

* no character

0 all stop

# space

NOTES:_____________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

36

Page 37

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

37

Page 38

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

38

Page 39

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

LOCOMOTIVE:_________________________ DATE:_________________

a.LINK ADDR j.TOP SPEED

b.RxType k.START SPEED

c.NAME l.AUX FUNC SU

d.ROAD No. F1

e.MOMENTUM F2

f.DELAY F3

g.MOTOR F4

h.HD DIR F5

i.HD LIGHT F6

39

Page 40

TM

A

R

I

S

T

O

CRAFT

T

R

A

I

N

S

TM

40

Loading...

Loading...