Page 1

erogatori

regulators

detendeur

atemregler

regulador

пользователя

呼吸调节器

Manuale d’uso

Direction for use

Manuel d’instructions

Bedienungsanleitung

Manual de istrucciones

Pуководство

潜水呼吸调节器使用手册

made in Italy

Page 2

44

Introduction . . . . . . . . . . . . . . . . . . . . . . . . .page 45

Main Components . . . . . . . . . . . . . . . . . .page 45

1) FIRST STAGES . . . . . . . . . . . . . . . . . . . . . .page 47

1.1 T10 - T10 S.C.-T10 SC Cromo . . . . . . . . . . .page 48

1.2 MC9 - MC9 S.C. . . . . . . . . . . . . . . . . . . . . . . .page 52

1.3 MC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 54

1.4 AC2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 56

1.5 Performance . . . . . . . . . . . . . . . . . . . . . . . . . .page 57

2) SECOND STAGES . . . . . . . . . . . . . . . . . . .page 61

2.1 Galaxy Adjustable/Master / Master Cromo / Galaxy /

Octopus MG Balanced . . . . . . . . . . . . . . . . .page 62

2.2 Master / Master Cromo / Galaxy,

Octopus MG Balanced

disassembly and maintenance . . . . . . . . . .page 65

2.3 XS Compact Pro / XS Compact / Octopus . .page 66

2.4 XS Compact Pro / XS Compact

Disassembly and maintenance . . . . . . . . . . .page 69

2.5 XS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 70

2.6 Performance . . . . . . . . . . . . . . . . . . . . . . . . . .page 73

3) USE AND MAINTENANCE . . . . . . . . . . .page 77

3.1 Use of the regulator and risk assessment .page 78

3.2 Checks before use . . . . . . . . . . . . . . . . . . . . .page 78

3.3 Mounting the regulator to the tank . . . . . . .page 79

3.4 Use of the regulator in cold water . . . . . . . . page 80

3.5 Care and maintenance

of the equipment . . . . . . . . . . . . . . . . . . . . . .page 80

3.5.1 Caring for the equipment . . . . . . . . . . . . . . . .page 80

3.5.2 Equipment maintenance . . . . . . . . . . . . . . . .page 81

3.6 Use with Nitrox mixtures . . . . . . . . . . . . . . . .page 81

3.7 Maintenance/recording of procedures

(Service Record) . . . . . . . . . . . . . . . . . . . . . .page 83

3.8 Cressi-sub Certified Combinations . . . . . . .page 84

4) TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 303

TABLE OF CONTENTS

Page 3

ENGLISH

Introduction

Congratulations! Continual research and evolution carried out at

our technical centres, together with Cressi-sub’ s usual reliability,

have led to the product you just purchased, which will allow you

to dive comfortably and safely for a long time.

All Cressi-sub regulator are certified to 146 ft (50 m), and some

for use in cold water with temperatures below 10° C, having

passed the stringent operations testing at 4° (+0-2) set forth

under the standard EN 250:2014 (and all previous editions) in

compliance with new EU regulation 2016/425 (ex 89/686/CEE).

This regulation establishes the conditions for bringing to market

and the essential minimum safety requirements for Personal Protective Equipment (PPE). It will officially take effect April 21, 2018,

abrogating the previous Directive 89/686/EEC, upon the conclusion of a transitional period granted to manufacturers of PPE.

Main Components

Regulators’ main task is reducing the pressure of the compressed air contained in the tank to the same level as the environment’ s, supplying breathable air when required by the diver.

They are composed of a “first stage”, working as main pressure

reducer and a “second stage” (kept in the diver’ s mouth), which

adjusts the pressure precisely to the same value as the environment’ s. The regulator is part – together with tank, valves and

sling – of a complete underwater breathing system, known as

“SCUBA” (Self Container Underwater Breathing Apparatus).

This handbook describes all models of Cressi-sub range, all realized in high quality materials to guarantee pleasant dives and

high performance, together with the easiest ways of use andmaintenance. The instructions and directions found in this manual

are based on the most up-to-date information about the equipment available before printing.

Cressi Sub reserves the right to make changes at any time.

NOTE: The instructions and directions found in this manual are

based on the most up-to-date information about the equipment available before printing. Cressi Sub reserves the right to

make changes at any time.

NOTE: This handbook does not replace a diving training course! All Cressi-sub devices must be used by divers who have

attended regular courses held by certified trainers.

Using underwater devices without a licence or the necessary

technical training may be dangerous for the diver’ s safety and

life itself.

Besides, in order to guarantee the maximum safety, the devices must be serviced only by the producer or an authorizedcentre.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: info@cressi.com).

WARNING: CRESSI-SUB DECLINE ANY RESPONSIBILITY FOR ANY SERVICING CARRIED OUT BY

UNAUTHORIZED PERSONNEL.

WARNING: SCUBA devices complying with EN

250:2014 standard must not be used by more

than a diver at the same time.

WARNING: in case the components of a SCUBA

are set and used by more than a diver at the same

time, their performance in cold water might not

satisfy the requisites prescribed by EN 250:2014

standard.

WARNING: if the components of the SCUBA

equipment are configured and used simultaneously

by multiple divers, the equipment may not be used

at depths of greater than 30 meters, or at water

temperatures below 10 °C (if specified).

45

Page 4

Direction for use regulators

FIRST STAGES

1.1 - T10 - T10 S.C. - T10 SC Cromo

1.2 - MC9 - MC9 S.C.

1.3 - MC5

1.4 - AC2

Page 5

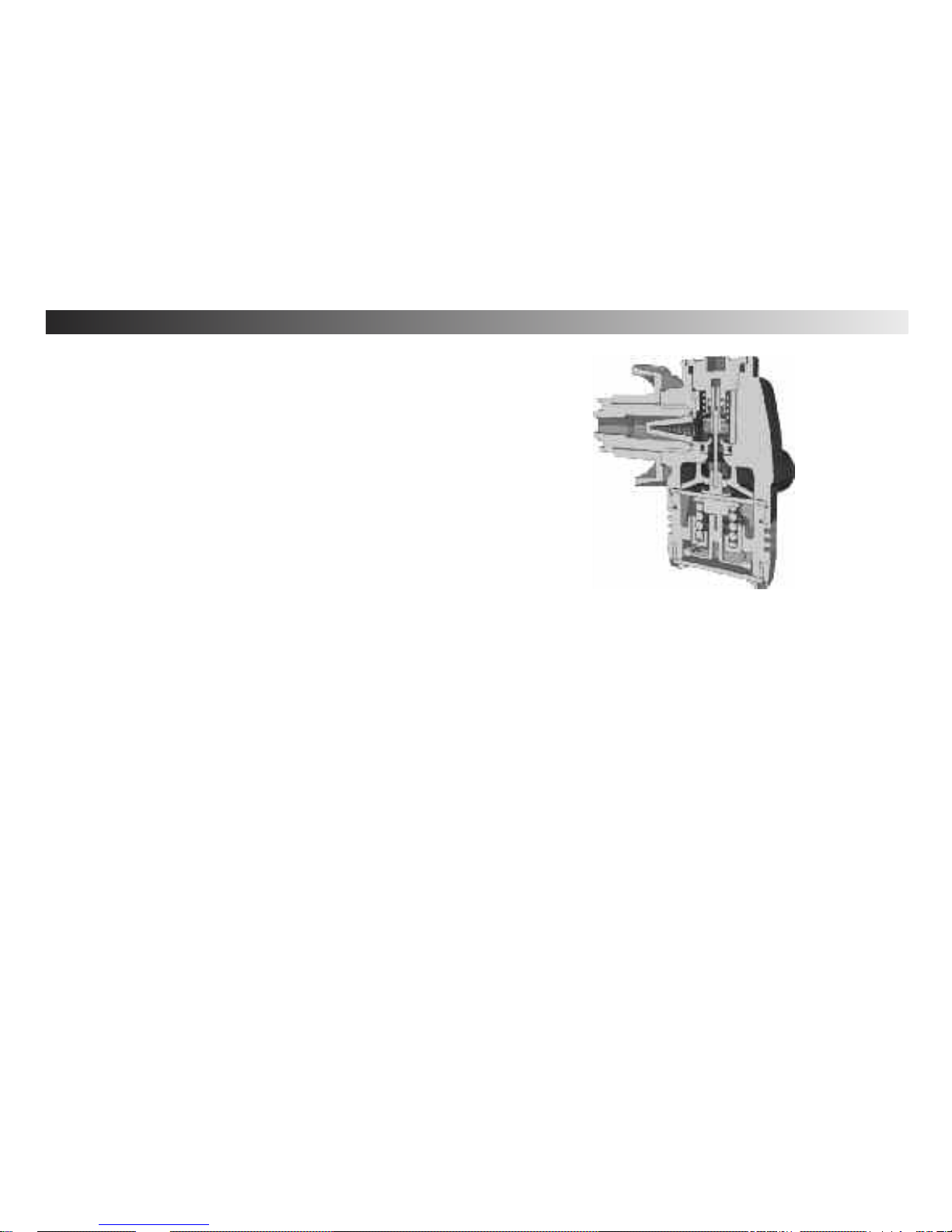

1.1. - T10 - T10 S.C.-T10 SC Cromo

The T10 balanced diaphragm first stage features a lightweight

structure of compact design, protected by the special and innovative PVD (Physical Vapor Deposition) treatment, which creates

a highly resistant surface coating with extraordinary chemicalphysical characteristics and a high technical, very pleasing appearance. Unlike the T10 version, the Cromo version has a

protective surface coating of electroless chrome plating.

The ergonomics of the T10 balanced diaphragm first stage presents the functioning mechanism arranged perpendicular to the

air entry axis that thereby forms a “T” profile designed to guarantee perfect arrangement of the HP and LP hoses, avoiding interference with the equipment connected to the first stage; reduced

size (particularly used in the SC version particularly suited to cold

water), as well as additional inspection capacity and access to the

HP valve mechanism to simplify maintenance and disassembling

of the regulator.

It provides outstanding respiratory performance, constant in any

use condition, thanks to the compensated diaphragm mechanism that enables maximum respiratory comfort to be obtained

during any dive phase, from the surface to maximum depths.

In fact, the regulator provides the same intermediate pressure independent of the pressure contained in the tanks and maintains

performance at any depth.

Contrary to most regulators currently on the market, offering optimum performance when the tank is full at maximum working

pressure, the T10 first stage was designed to offer optimum performance when the tank is close to empty.

This “hyper balancing” feature was possible using a system that

adapts intermediate pressure taking into account the air density

as the depth increases and the progressive increase in pressure

drop as the tank empties.

Thanks to this feature, the T10 first stage assists the diver in the

dive, guaranteeing the highest working performance which increases further during the notoriously critical surfacing phase of

surfacing.

The compensated diaphragm mechanism phase, with a "T" air

entry, or rather the HP valve arranged perpendicular to the air

entry axis further guarantees considerable passage of air quantity

with a pressure drop, between the inhalation and exhalation

phase, which is reduced considerably.

These characteristics are the result of innovative technical solutions in the design and make the 1st stage among the smallest

and lightest regulators on the market and one of the top performing in its category.

In this first stage (Fig. 1), the flexible diaphragm protects and seals

the mechanism inside the system and transmits pressure variations in the water to the high pressure valve.

fig. 1

48

FIRST STAGES

Page 6

ENGLISH

The HP poppet valve, which is extremely resilient and easily replaced during periodic maintenance, is manufactured in the latest

generation thermoplastic elastomers. This valve boasts the exclusive feature of sliding inside a special lined cylinder, also manufactured in self-lubricating thermoplastic material. The inner surface of

this cylinder, which is completely free of oxidation phenomena,

drastically reduces friction and makes the valve stroke extremely

fluid and precise, guaranteeing optimum respiratory comfort. The

HP poppet valve can also work perfectly guided on a pneumatic

seal compartment, guaranteed to last long thanks to the special

design of the piston sleeve that hinges the valve, without even

making it rotate on its own axis. By doing so, the 1st stage performance can be kept constant and unchanged over time.

The HP valve closure nozzle, manufactured in stainless steel 316, is

interchangeable to facilitate periodic maintenance of the 1st stage.

Air entry in the first stage is protected by a sintered conical filter in

compact, sintered and nickel-plated phosphor bronze microspheres, to enable better air filtering thanks to the broader filtering

surface guaranteed by the shape which also guarantees the passage of an elevated air flow, typical of this regulator and withholds

any impurities from tank and valve.

The intermediate pressure regulation system of the T10 balanced

diaphragm 1st stage follows the tradition of all Cressi-sub first

stages, allowing convenient and fast regulation of intermediate

pressure without having to disassemble parts of the regulator.

WARNING: intermediate pressure regulation should only be

carried out by authorised Cressi-sub centres and the calibration

values CANNOT and MUST NOT be changed by the user, to

avoid prejudicing the good working order of the regulator. We

cannot be held in any way liable for any intervention carried out

by staff unauthorised by Cressi-sub.

The Cressi-Sub authorised centres can be indicated

by retailers or, alternatively by Cressi Sub s.p.a.

(email: info@cressi.com).

The balanced diaphragm first stage features a lightweight structure

of compact design, made from seagoing brass, protected on the

surface by means of a PVD (Physical Vapor Deposition) treatment

(version T10SC) or coated with chromed copper (version T10 S.C.

Cromo); the interior components are made of stainless steel,

chromed brass and new generation thermoplastic resins.

It avails of 4 low pressure (LP) 3/8” ports, adequately angled for

optimal distribution of the hoses that avoid interference with the

attached equipment, and 2 high pressure (HP) 7/16” ports with a

micrometric perforation for air release, ensuring maximum safety

also in the event of accidental breakage of the high pressure

hose, avoiding the risk of rapid tank emptying.

WARNING: on the HP ports of the first stage, an underwater

gauge and/or an underwater computer must be connected to

also incorporate the gauge function. Since the tanks are not

equipped with a reserve device, it is absolutely indispensable to

use a gauge that indicates progressive air consumption when

diving and which clearly highlights the reserve pressure has been

reached, which should be considered as unusable air for the

purpose of the dive itself, but only as an emergency air reserve.

Diving without a gauge is dangerous because there is no way of

controlling consumption and you can suddenly find yourself without air during a dive, putting your life in serious danger.

Connection of the first stage to the tank valve can take place

using an international connection, using a new yoke with an extremely modern design or a threaded coupling DIN 300 bar, both

according to EN ISO 12209 as referenced in the standard EN

250:2014.

As with all regulators in the Cressi-sub range, the T10 first stage

offers the possibility of making certain manufacturing components of the regulator compatible, allowing interchanging parts

with other diaphragm first stages in the current range.

49

FIRST STAGES

Page 7

Use of the T10 balanced diaphragm first stage is advised, compared to the piston models, for diving in waters full of suspended

particles or dissolved mineral salts, or for use in cold water (with

temperatures under 10°C), because all parts of the regulator

mechanism are insulated for contact with water.

For diving in extreme conditions we recommend using combinations with the T10SC or the T10 Cromo SC versions equipped with

the Seal Chamber (S.C.)

WARNING: to deal with diving in cold water (temperature

<10°C or < 50°F) Cressi-sub recommends use of a tank

equipped with a pillar valve with two independent ports outlet,

where two complete regulators can be connected.

WARNING: adequate technical preparation is necessary to

deal with diving in cold water (temperature <10°C or < 50°F ).

Cressi-sub recommends you carry out this type of diving after

taking a specific course given by qualified instructors. It is important not to wet the regulator before use and then expose it

to air (which can be well under zero degrees). Do not use the

purge button, particularly with the regulator level with Venturi

effect in the “dive” position. If possible, keep the regulator in

warm surroundings when not in use.

The Seal Chamber is used to make the T10 balanced diaphragm

first stage completely waterproof, avoiding water entry not only

inside, but also in contact with the diaphragm and the calibration

spring on the 1st stage, thereby creating an air chamber upstream of the regulator and its components, working like a proper

thermal barrier. All problems are therefore avoided relating to

contact with water full of suspended particles, sand, dissolved

mineral salts and with cold water which, especially at temperatures below 10°C could form the foundation for possible freezing

of the regulator.

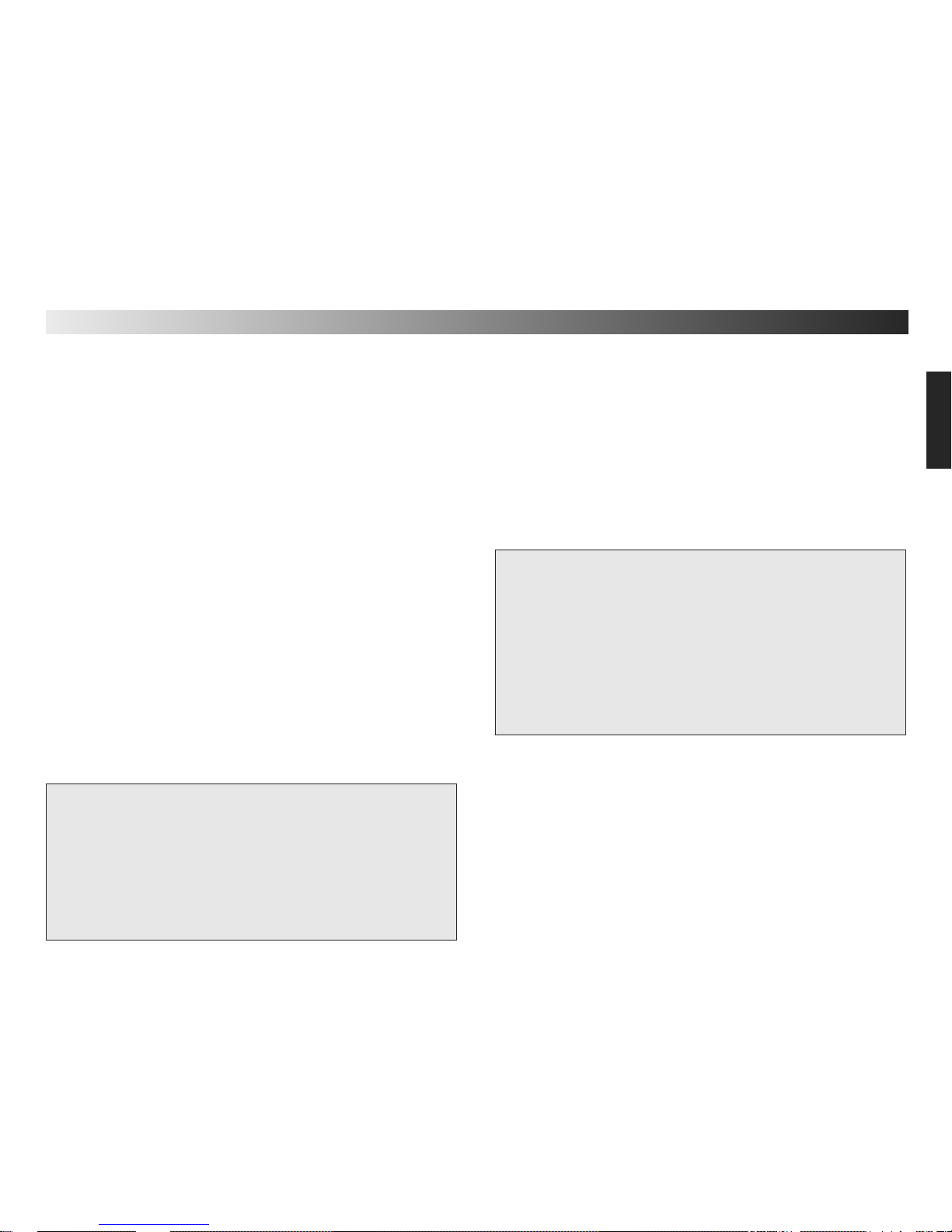

The Seal Chamber (fig.2) consists of a special metal insert with a

particular “radiator” shape designed to increase thermal ex-

change between the ambient temperature and the temperature

inside the regulator, preventing its possible freezing effect, and a

metal cap containing a silicone membrane inside. This, on warning of the ambient pressure variations, inverts and thereby transmits oscillations to the ambient pressure transducer beneath

which, coming in contact with the main diaphragm, acts as a

transmission element which transfers all information on the extreme pressure variations to the diaphragm. The main diaphragm

which, in turn, protects and seals the mechanism inside the system, then transmits the pressure variations of the water to the

high pressure valve.

NOTE: before assembling the Seal Chamber S.C. the

balanced diaphragm first stage must be calibrated. To ensure

the regulator works properly, strictly comply with the calibration

values outlined in the regulator performance table. Regulator

calibration is not restricted by the ambient pressure variations

transmission disk.

fig. 2

50

FIRST STAGES

Page 8

ENGLISH

WARNING: intermediate pressure adjustment should only

be carried out by authorised Cressi-sub centres and the calibration values CANNOT and MUST NOT be changed by the

user, to avoid prejudicing the good working order of the regulator. We cannot be held in any way liable for any intervention

carried out by staff unauthorised by Cressi-sub.

The Cressi-Sub authorised centres can be indicated

by retailers or, alternatively by Cressi Sub s.p.a.

(email: info@cressi.com).

The T10 first stage can therefore be used in cold water (with

water temperature below 10 °C/50 °F), since it complies with Directive 89/686/EEC dated 21/12/1989, checked and certified by

Test Authority No. 0474 RINA located in Genoa, tested in compliance with standard EN 250:2014 that establishes the requirements for Personal Protective Equipment (PPE) category III. It

therefore bears the CE marking followed by identification of the

certification authority (0474) that checks its manufacture pursuant to module B+C2 of EU Regulation 2016/425. The standard

also dictates the essential health and safety requirements for Category III PPE and governs the conditions for bringing it to market.

The considerable technical solutions, combined with the high

quality of the materials used, ensure that this first stage regulator

is fully reliable and capable of providing the highest performance

extended over time.

Additional important information relating to our equipment can be

found on the website www.cressi.com

51

FIRST STAGES

Page 9

1.2 - MC9 - MC9 S.C.

The MC9 - MC9 S.C. balanced diaphragm first stage features a

lightweight structure of compact design, enclosed in an “aesthetic-protective” shell made from a special elastomer, specially

conceived to protect the regulator from impact.

It guarantees high breathing performance in every condition,

thanks to its balanced diaphragm mechanism, allowing the

maximum breathing comfort in every diving phase, starting from

the surface up to the maximum depth. The regulator, in fact,

supplies the same intermediate pressure independently from

the tank pressure, and keeps its performance independently

from the depth.

Unlike the most regulators on the market, offering their best

performance when the tank is loaded at its maximum working

pressure, MC9 first stage was designed to give its best performance when the tank is about to empty. This ”hyper-balanc-

ing” feature is possible thanks to a system of regulation of the

intermediate pressure, which takes into account both the

air density as the depth increases and the progressive pressure

decrease due to the tank running down.

Thanks to this feature, MC9 first stage assists the diver during

the whole dive, guaranteeing the highest performance, which

improves during the most critical phase of surfacing.

Moreover, the balanced diaphragm mechanism, delivering air

“online”, allows remarkable amounts of air to pass, by a very small

pressure decrease between inhalation and exhalation phases.

These features are the results of several innovating technical

solutions taken by designing MC9 1st stage, making it one of the

best performing small and light regulators on the market.

In this first stage (fig. 3), the elastic diaphragm protects and seals

the system’ s inner mechanism, transmitting the changes of

water pressure to the high pressure valve.

The latter is made of special thermoplastic state-of-the art elastomers, is highly resistant and easily replaceable. It boasts the

exclusive innovation of sliding inside a special self-lubricating

cylinder in a special thermoplastic material. The cylinder’ s inner

surface is completely free of oxidation, reduces any friction dramatically and makes the valve slide in an extremely easy and

precise way, guaranteeing the highest breathing comfort.

The HP seat is made of 316 stainless steel and is interchangeable, in order to make the maintenance of the 1st stage easier.

The passage of air through the first stage is protected by a special cup-shaped conical sintered filter, retaining any impurity from

tank and valves.

The regulation system of intermediate pressure in MC9 balanced

diaphragm first stage is the same as all other Cressi-sub first

stages, which allows an easy and quick adjustment of intermediate pressure without having to disassemble any component of

the regulator.

fig. 3

52

FIRST STAGES

Page 10

ENGLISH

WARNING: intermediate pressure must be set only at au-

thorized Cressi-sub centres; the setting values must NOT and

can NOT be modified by the user, in order not to affect the

good working of the regulator. Cressi-sub decline any responsibility

for any intervention carried out by unauthorized personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: info@cressi.com).

Balanced diaphragm first stage features a light compact structure

in chromium-plated brass with inner components in stainless steel,

chromium-plated brass and state-of-the-art thermoplastic resins.

It is supplied with four low pressure (LP) 3/8” ports - specially

angled to allow the best hose positioning, avoiding any encumbrance among different devices - and two high pressure (HP)

7/16” ports with a micrometric air exit hole, guaranteeing maximum safety even in the case of damage to the high pressure

hose, since it greatly reduces air loss from the thank.

WARNING: an underwater pressure gauge or a computer

with such function must be connected with the HP ports of

the first stage.

Since the tanks are not supplied with a reserve device, a pressure gauge must always be used, reporting the progressive

air consumption by diving and the reaching of reserve pressure, which has to be considered as not to be used by diving

but only as emergency air supply.

Diving without any gauge is dangerous, since the diver can

not control his own air reserve, which might suddenly run out,

at his own high risk.

The first stage can be connected to the tank valve with an international, by means of an extremely modern designed bracket, or

with a threaded connection DIN 300 (EN ISO 12209) bar, bothcomplying with EN 250:2014 standard.

Like all Cressi-sub regulators, whose components are often interchangeable one with the other, MC9 is compatible with other

diaphragm first stages of the present range.

MC9 balanced diaphragm first stage, like other Cressi-sub diaphragm first stages as well, is to be recommended rather than other

piston models, by diving in suspension or mineral salts rich water,

or in cold water at temperature lower than 10 °C/50 °F. All innercomponents of the regulators are in fact perfectly watertight.

For diving in extreme conditions we recommend using combinations with the MC9SC version, equipped as standard with the Seal

Chamber (S.C.).

WARNING: In case of dives in cold water (temperature less

than 10°C/50° F), Cressi-sub recommend to use a tank supplied with a valve featuring two separate outlet ports, with

which two complete regulators are to be connected.

WARNING: diving in cold water at temperature lower than

10°C/50 °F requires a special technical training. Cressi-sub

recommend such diving only after attending a special training

course by certified trainers. The regulator must absolutely not

get wet and exposed to freezing air before use. Do not press

the discharge button, particularly when the Venturi effect

adjustment lever is on “dive”. If possible, keep the regulator in

a warm place before use.

The Seal Chamber’ s task is to make MC9 balanced diaphragm

first stage perfectly watertight, preventing water from seeping

inside or on the diaphragm and the main spring: it works as an air

chamber above the regulator and its components, like a real

thermal barrier. It avoids any problem caused by contact with

suspension, sand, mineral salts rich water and with cold water,

which might eventually cause the regulator to freeze, especially

at temperature lower than 10° C/50° F.

fig. 4

53

FIRST STAGES

Page 11

The Seal Chamber is composed of a metal cap containing a silicon seal. The seal responds to any environmental pressure

change bending towards the inside and transmitting it to the

underlying plate; the latter transmits such information to the main

diaphragm. The main diaphragm protects and seals the device’

s inner mechanism, transmitting pressure changes to the high

pressure valve.

NOTE: before assembling the Seal Chamber S.C. the

balanced diaphragm first stage must be set. In order to get

the regulator to work perfectly, the setting values must be

strictly those reported in the regulator’s performance table.

The setting is independent from the plate transmitting environmental pressure changes.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres, while the setting values can

NOT and must NOT be modified by the user, in order not to

affect the regulator’ s performance. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself (email:

info@cressi.com).

The MC9 S.C. first stage can therefore be used in cold water (with

water temperature below 10 °C/50 °F), since it complies with Directive 89/686/EEC dated 21/12/1989, checked and certified by

Test Authority No. 0474 RINA located in Genoa, tested in compliance with standard EN 250:2014 that establishes the requirements

for Personal Protective Equipment (PPE) category III. It therefore

bears the CE marking followed by identification of the certification

authority (0474) that checks its manufacture pursuant to module

B+C2 of EU Regulation 2016/425. The standard also dictates the

essential health and safety requirements for Category III PPE and

governs the conditions for bringing it to market.

Its remarkable technical features, together with its high quality

materials, make this first stage a highly reliable regulator, guaranteeing best performances for a long time.

Visit our web-site www.cressi.com, where you can find further information relating to your safety.

1.3 – MC5

MC5 balanced diaphragm 1st stage features an extremely light

and compact structure enclosed in an “esthetical-protective”

shell of a special elastomer, designed to protect the regulator

from collision.

It guarantees high breathing performance in every condition,

thanks to its balanced diaphragm mechanism, allowing the

maximum breathing comfort in every diving phase, starting from

the surface up to the maximum depth. The regulator, in fact,

supplies the same intermediate pressure independently from

the tank pressure, and keeps its performance independently

from the depth.

The balanced diaphragm mechanism, delivering air “on line”,

allows remarkable amounts of air to pass, by a very small pressure decrease between inhalation and expiration phases.

These features are the results of innovating technical solutions

taken by designing MC5 1st stage, making it one of the best

performing small and light regulators on the market.

fig. 5

54

FIRST STAGES

Page 12

55

ENGLISH

In this first stage (fig. 5), the elastic diaphragm protects and seals

the system’ s inner mechanism, transmitting the changes of

water pressure to the high pressure valve.

The latter is made of special thermoplastic state-of-the art elastomers, is highly resistant and easily replaceable. It boasts theexclusive innovation of sliding inside a special self-lubricating cylinder in

a special thermoplastic material. The cylinder’ s inner surface is completely free of oxidation, reduces any friction dramatically and makes

the valve slide in an extremely easy and precise way, guaranteeing

the highest breathing comfort.

The passage of air through the first stage is protected by a special

cup-shaped conical sintered filter, retaining any impurity from tank

and valves.

The regulation system of intermediate pressure in MC5 balanced diaphragm first stage is the same as all other Cressi-sub first

stages, allowing an easy and quick adjustment of intermediate pressure without having to disassemble any component of the regulator.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres, while the setting values can

NOT and must NOT be modified by the user, in order not to

affect the regulator’ s performance. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: info@cressi.com).

Balanced diaphragm first stage features a light compact structure in chromium-plated brass with inner components in stainless steel,

chromium-plated brass and state-of-the-art thermoplastic resins.

It is supplied with three low pressure (LP) 3/8” ports - specially

angled to allow the best hose positioning, avoiding any encumbrance among different devices - and a high pressure (HP)7/16”

port with a micrometric air exit hole, guaranteeing maximum safety even in the case of damage to the high pressurehose, since it prevents the tanks from emptying.

WARNING: an underwater pressure gauge or a compu-

ter with such function must be connected with the HP port of

the first stage.

Since the tanks are not supplied with a reserve device, a pressure gauge must always be used, reporting the progressiveair

consumption by diving and the reaching of reserve pressure,

which has to be considered as not to be used by diving but only

as emergency air supply.

Diving without any gauge is dangerous, since the diver can

not control his own air reserve, which might suddenly run out,

at his own high risk.

The first stage can be connected to the tank valve with an international, by means of an extremely modern designed bracket,

orwith a threaded connection DIN 300 bar (4350 psi) (EN ISO

12209), both complying with EN 250:2014 standard.

Like all Cressi-sub regulators, whose several components are

interchangeable one with the other, MC5 is compatible with

other diaphragm first stages of the present range.

MC5 balanced diaphragm first stage, like other Cressi-sub

diaphragm first stages, having all inner components watertight,

is to be recommended, rather than other piston models, by

diving in suspension or mineral salts rich water.

MC5 conforms to EU Regulation 2016/425, having been tested

and certified by Notified Body number 0474, RINA, with registered

office in Genoa, with testing conducted pursuant to standard EN

250:2014 which specifies the requirements for class III Personal

Protective Equipment (PPE), and therefore it bears the CE mark

followed by the ID data of the notified body (0474) pursuant to

form B+C2 of EU regulation 2016/425.

Its remarkable technical features, together with its high quality

materials, make this first stage a highly reliable regulator, guaranteeing best performances for a long time.

Visit our web-site www.cressi.com, where you can find further information relating to your equipment.

FIRST STAGES

Page 13

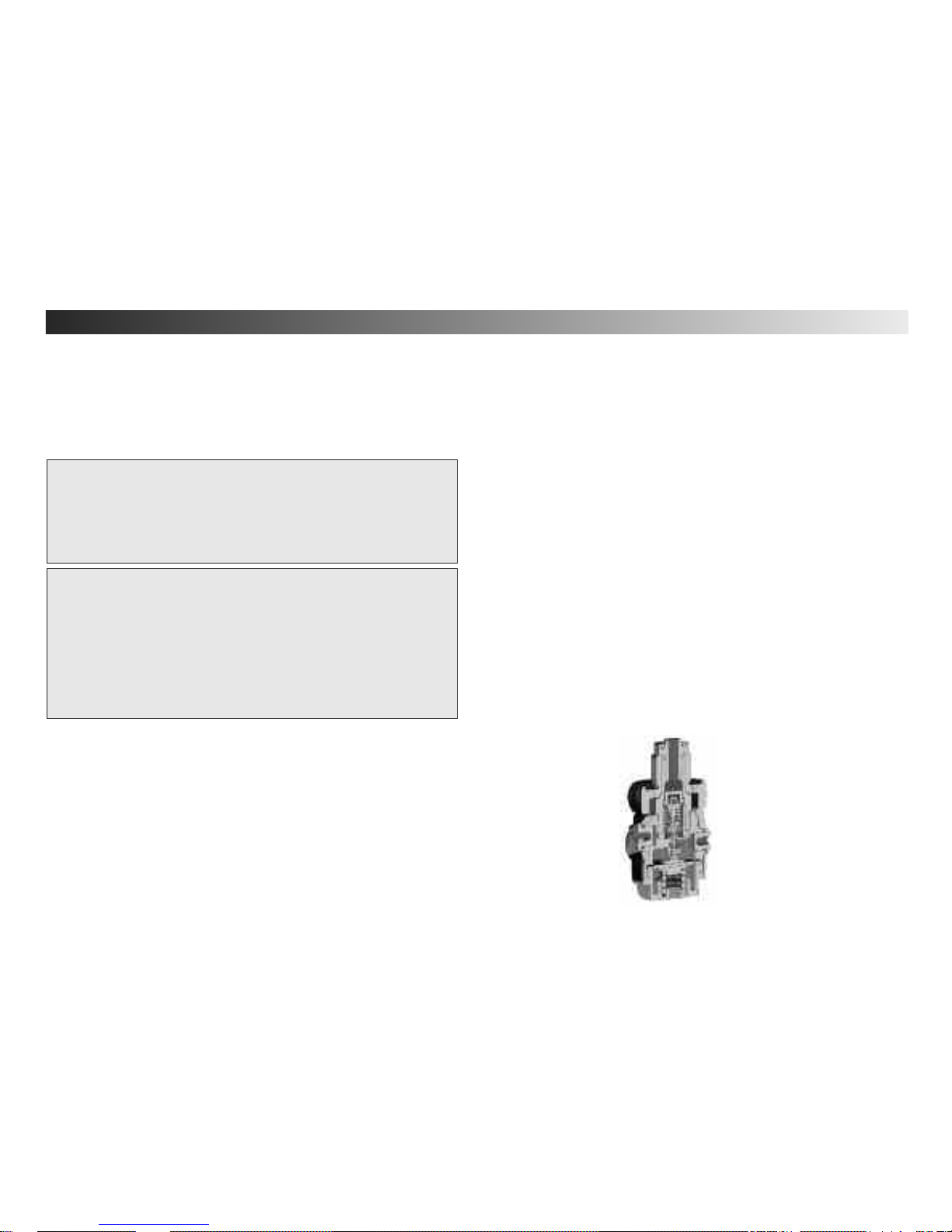

1.4 - AC2

AC2 regulator has the task to reduce the tanks’ pressure. It isconnected

to the second stage by means of a hose supplying the diver with

breathable air at environmental pressure. The first stage’ s main task is

therefore to reduce the tanks’ air to an intermediate pressure, about

10 bar (145 psi) higher than the environmental.

Small dimensions, light weight, extremely simple structure, special sturdiness and easy maintenance: here are the main features of this in-line

first stage, offering as high performances as a balanced piston model’s.

Its compact and attractive design features four low pressure

3/8” ports in pairs, with preset angles to allow easy connection with

any accessory equipment. The setting is easily performed thanks to

the special revolving ring system, allowing a quick, precise and continuous adjustment, without having to disassemble the regulator.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres; the setting values must NOT

and can NOT be modified by the user, in order not to affect

the good working of the regulator. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: info@cressi.com).

Inside, a conical filter provides a filtering action 200% higher than

a standard flat filter.

Airflow capacity is remarkable, due to new larger air ports, offering unequalled performance in this class of regulators.

Both international yoke and DIN (at 200 or 300 bar) (2900÷4350

psi) connection are fully interchangeable and are replaced with

each other very quickly (only at authorized Cressi-sub centres).

Its satin finish guarantees the regulator’ s best surface performance, while contributing to its outstanding strength and reliability. The first stage is manufactured with the finest materials and

Cressi-sub experience.

The first stage can be connected with the tank’ s valve either

with an international through an extremely modern designed

bracket, or with a threaded connection DIN (EN ISO 12209), both

complying with EN 250:2014 standard. Should the tank sused

have a working pressure higher than 200 bar (2900 psi), a DIN

connection is recommended.

Besides its technical innovations, this first stage differs from previous models as to its new esthetical look, enriched with careful

particulars in its finishing as well. It is a top quality high technology

regulator, showing a pleasant as well as aggressive look, united

with outstanding sturdiness and easy mechanics, which allows

an easy and simple maintenance.

The AC2 first stage conforms to EU Regulation 2016/425, having

been tested and certified by Notified Body number 0474, RINA, with

registered offices in Genoa, with testing conducted pursuant to standard EN 250:2014 which specifies the requirements for class III Personal Protective Equipment (PPE), and therefore it bears the CE

mark followed by the ID data of the notified body (0474) pursuant to

form B+C2 of EU regulation 2016/425.

Its remarkable technical solutions, together with high quality

materials, make this first stage a highly reliable regulator, offering

top quality performance for a long time.

Visit our web-site www.cressi.com, where you can find further

information relating to your equipment.

fig. 6

56

FIRST STAGES

Page 14

Direction for use regulators

1.5 - Performance First Stages

Page 15

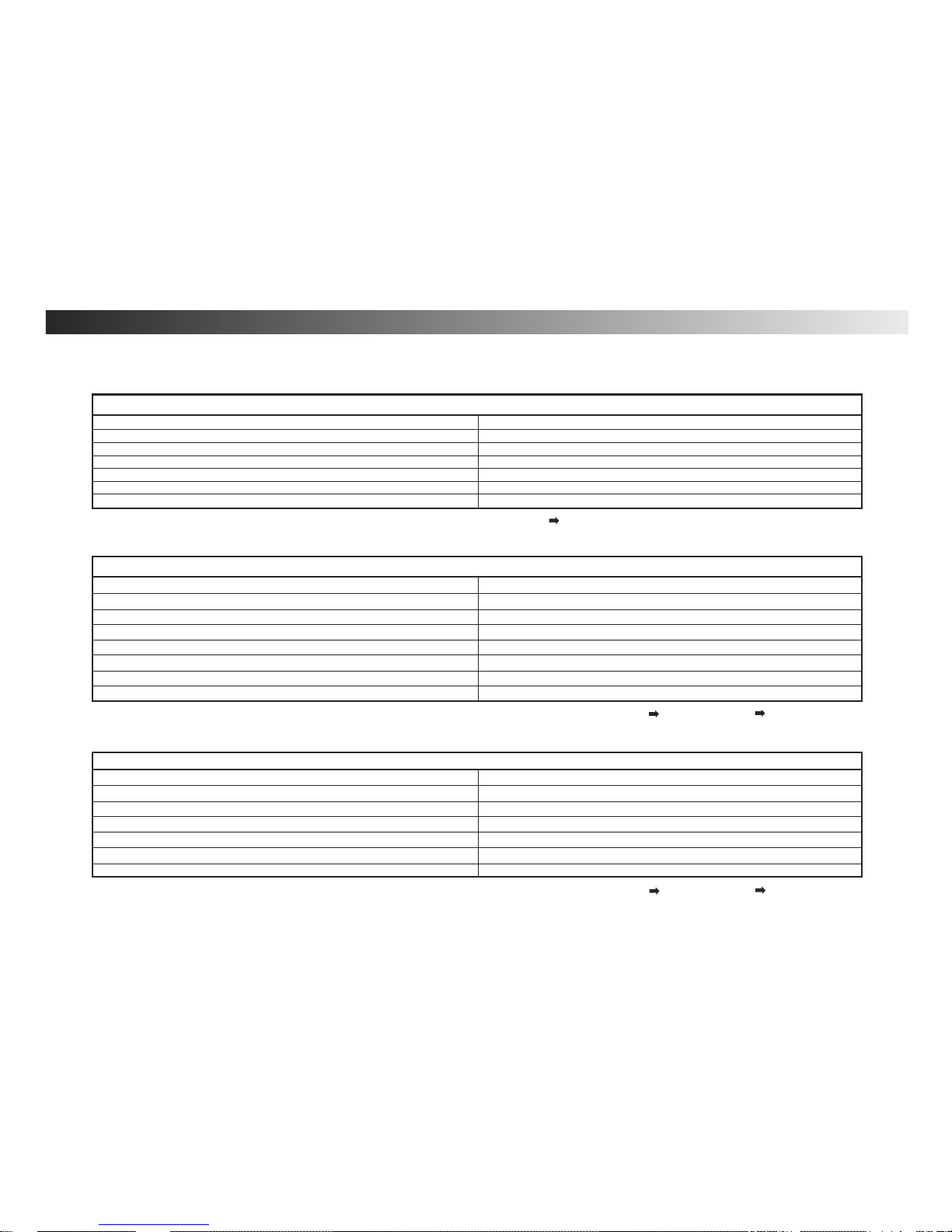

1.5 - Performance

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (200 bar feeding)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

Weight without hose MC9

Weight without hose MC9 SC

0÷232 bar - (0÷3365 psi)

0÷300 bar - (0÷4350 psi)

10 bar - (145 psi)

4500 l/min (*)

2

4

590 gr (INT) - 450 gr (DIN)

650 gr (INT) - 510 gr (DIN)

MC9 / MC9 S.C.

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (200 bar feeding)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

Weight without hose MC5

0÷232 bar - (0÷3365 psi)

0÷300 bar - (0÷4350 psi)

10 bar - (145 psi)

3000 l/min (*)

1

3

450 gr (INT) - 350 gr (DIN)

MC5

(*) Values measured at LP port with second stage connected and tank pressure at 200 150 bar (2900 2175 psi)

(*) Values measured at LP port with second stage connected and tank pressure at 200 150 bar (2900 2175 psi)

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (with 200 bar supply)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

Weight without hose T10 SC

0÷232 bar

0÷300 bar

10 bar

4500 l/min (*)

2

4

720 gr (INT) - 602 gr (DIN)

T10 / T10 S.C. / T10 S.C. Cromo

(*) Values measured on LP port with second stage connected and 200 150 bar pressure in the tanks.

58

Page 16

ENGLISH

1.5 - Performance

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (200 bar feeding)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

0÷232 bar - (0÷3365 psi)

0÷300 bar - (0÷4350 psi)

10 bar - (145 psi)

2100 l/min (*)

1

4

AC2

(*) Values measured at LP port with second stage connected and tank pressure at 200 150 bar (2900 2175 psi)

59

Page 17

Direction for use regulators

SECOND STAGES

2.1 - Galaxy Adjustable /Master / Master Cromo / Galaxy /

Octopus MG Balanced

2.2 - Master / Master Cromo / Galaxy / Octopus MG Balanced

disassembly and maintenance

2.3 - XS Compact Pro / XS Compact

2.4 - XS Compact Pro / XS Compact, disassembly and servicing

2.5 - XS2

Page 18

2.1. - Master / Master Cromo / Galaxy /

Octopus MG Balanced

Cressi sub's line of balanced second stages is represented by

revolutionary pneumatic balanced regulators. They are elliptical in

shape and are more lightweight (in fact, the adjustable Master

version weighs just 207 gr - the lightest in its category!). Their futuristic designs boast many innovative patented features and are

available in three different versions: Galaxy Adjustable (Fig. 7),

Master (Fig. 8) (adjustable) and Galaxy (Fig. 9) (non-adjustable).

Both versions provide air on-demand, i.e. only when the diver inhales through the mouthpiece, generating slight negative pressure

inside the regulator - it needs to be as light as possible so as not to

cause undue respiratory exertion. The special adjustable elliptical

diaphragm reacts to the negative pressure; it is designed to increase its usable surface accordingly, in order to keep the breathing effort to the absolute minimum. This regulator’s level of

performance is guaranteed to be similar - if not superior - to any

other regulator of a bigger in size.

The diaphragm gets sucked back inside the casing and brings the

central disc - made of state-of-the-art friction-proof thermoplastic

- into contact with the new lever designed with revolutionary geometrics in order to enhance performance and drastically reduce

friction.

The lever is subsequently lowered and in doing so, opens the valve.

Cressi-Sub’s range of second-stage balanced regulators are

equipped with a pneumatically balanced piston with a hole of minimal diameter going through it lengthwise.

The air from the first-stage comes through this hole and enters a

small chamber (called the “balance chamber”) positioned at the

edge of the piston.

The air contained in this chamber exercises a level of pressure

which varies according to the depth of the water and pushes the

closing piston towards the valve nozzle. This way, a certain balance

62

SECON D STAGES

fig. 11

fig. 8

fig. 7

fig. 9

fig. 10

Page 19

ENGLISH

is reached between the pressure that arises when the valve opens

and closes so that a low-load carrying spring can be used so that

no effort whatsoever is involved in opening the valve.

The pressure of the air flowing through the nozzle generates a reaction on the part of the pad, which subsequently opens. The pad

is perforated as well and placed at the edge of the shaft, where

the pressure is contrasted by the combined force of the spring and

the air penetrating the balance chamber.

The end result of this in practical terms is a breathing effort reduced

to near inexistent levels, and an outstanding level of performance

even in very deep waters.

The adjustable Galaxy/Master second-stage regulator makes it

possible to modify the inhalation effort thanks to the external metal

knob, thus directly affecting inhalation resistance. In practice,

screwing the external knob clockwise increases inhalation resistance whereas screwing it anticlockwise decreases inhalation resistance. This regulation system includes two seals designed to

protect the water infiltration mechanism. When adequately lubricated during manufacturing/maintenance phase, these seals protect the mechanism thread from the formation of oxide which

could stiffen or even block the rotation of the regulation knob.

This way, the knob remains consistently effortless and the subsequent adjustment of the inhalation effort can be achieved with precision and ease as the regulating mechanism thread remains

waterproof.

The Galaxy second-stage regulator (fig.9) doesn’t allow you to adjust the inhalation effort since it isn’t equipped with the regulation

mechanism. It does however include all the other features of the

adjustable Master version.

The adjustable nozzle is positioned inside the valve compartment

so that when the mechanism is opening, the air that comes out of

it is directed towards the mouthpiece thanks to the extremely precise and detailed design of the inner walls and casing of the regulator.

In order to ensure the negative pressure isn’t too violent for the

body - which could potentially suck the diaphragm back in and

make the regulator to free-flow - there’s a diaphragm balance hole

inside the valve unit.

Once the airflow delivered through the injector and directed towards the mouthpiece becomes consistent, it generates negative

pressure inside the regulator casing due to the increase in airflow

speed. This phenomenon of negative pressure called the “Venturi

effect”, keeps the diaphragm flat, which in turn significantly reduces

the inhalation effort of the diver.

The Venturi effect immediately ceases as soon as the diver stops

breathing; the diaphragm then reverts back to its normal position

and the lever, actioned by the spring, lifts up and makes the piston

touch the nozzle, which interrupts the passage of air.

In order to enhance the Venturi effect, both stages of Cressi-Sub

regulators are equipped with an air flow deflector which can be positioned two ways, as indicated by the etched scale on the casing:

In the first position, the flow-limitation device place in the mouthpiece’s inlet duct, is actioned and the Venturi effect is stopped and

any free-flowing is prevented. In the “+” position however, the Venturi effect is unrestrained and the air flow provided by the regulator

to the maximum level subsequently increases.

WARNING: always remember to keep the flow deflector

lever in pre-dive position (-) when the regulator is not in use; if

not, any accidental impact or pressure on the manual switch

when the regulator isn’t positioned inside the mouth, or if it is

63

SECON D STAGES

DIVE PRE-DIVE

fig. 12

Page 20

suddenly removed or the self-breathing apparatus falls into the

water, can generate even violent high air-consumption freeflowing. The dive position (+) must exclusively be used underwater and only when the regulator is positioned inside the

mouth.

When the diver is breathing, he generates an increase in the pressure inside the regulator casing which opens the oblique elliptical

release valve whose larger diameter makes it possible for the air

to exit outwards. The exhaust port delivers the air to the sides of

the head and prevents the valve being opened because of potential water turbulence, or from being flooded whenever the inner

case is not being pressurized.

Another special feature to be found in Cressi-Sub’s second-stage

regulators comes into play when the regulator is used in cold waters (water temperature of <10°C or 50°F), a feature engineered

with great precision and detailed attention and made possible

thanks to the special design of the regulator’s valve unit.

Indeed the valve unit’s internal flap takes advantage of the temperature increase generated by the diver when he/she exhales,

specifically around the nozzle area of the valve, where the risk of

freezing is the highest. This patented system greatly enhances the

regulator’s freeze-resistance.

WARNING: for diving in cold waters (temperature <10°C)

Cressi-Sub recommends the use of a tank with a pillar valve

with two independent outputs, to which two complete regulators can be connected.

WARNING: adequate technical preparation is required be-

fore undertaking cold water diving (temperature <10°C).

Cressi-Sub recommends undertaking this type of diving only

after having taken a specific training course with qualified instructors. The use of diving equipment in cold water without a

certification or adequate technical preparation is potentially

dangerous for the diver's health and wellbeing.

It is important not to wet the regulator before use (it would then be

exposed to an air temperature of potentially well under zero degrees).

Do not use the purge button, particularly when the adjustable Venturi effect knob is in the “dive” position. If possible, keep the regulator in a warm environment before use.

The Cressi-Sub balanced second-stage regulators are connected

to one of the 3/8” ports of the first-stage via a new medium-pressure, high-capacity flexible hose in thermoplastic, a material which

has excellent mechanical qualities, very high elastic flexibility and

remains anti-kink in any situation due to its internal structure. This

high-performance material, combined with the regulators’ special

aesthetically pleasing look and scratch-resistant features make

them unique on the current market. Production batches per tube

and fittings are labelled according to standard EN 250:2014.

All Cressi-Sub second-stage regulators are downstream, i.e.

equipped with an automatic valve opening in the event of firststage calibration loss or a sudden increase in intermediate pressure.

This means that any excess upstream pressure on the secondstage will never lead to the regulator getting blocked but indeed to

spontaneous free-flowing.

The casing of Cressi-Sub second-stage balanced regulators is

made of new engineered fabrics with impressive mechanical qualities and characteristics, noise-absorption being one of them.

The new cap (only in the adjustable version) is aesthetically pleasing and designed with special etched Titanium, a material of unsurpassable lightness and corrosion resistance.

The aforementioned cap is computer-designed and the various

water passages in the frontal parts of the casing have been thoroughly studied in order to enhance and improve the already impressively high level of performance of Cressi-Sub second-stage

regulators.

Cressi-Sub second-stage regulators meet the requirements set

by standard EU 250:2014 in compliance with regulation UE

64

SECON D STAGES

Page 21

ENGLISH

2016/425 which sets out the conditions for bringing to market and

the minimal essential safety requirements of PPE. Consequently,

they bear the CE mark followed by the certifying agency identification number 0474, identifying RINA, the registered testing

agency that monitors its manufacture pursuant to Form B+C2 of

the EU 2016/425 regulation, as well as the critical health and safety

requirements for category III PPE. It also regulates the conditions

for bringing such equipment to market.

2.2. - Galaxy Adjustable / Master / Master Cromo /

Galaxy, Octopus MG Balanced

disassembly and maintenance

In designing the Master regulator, quick and easy dismantling and

maintenance were taken into account, as they are indispensable

features for a regulator that is always perfectly serviced, calibrated and efficient.

WARNING: the dismantling, maintenance and calibration of

the 2nd stage regulators should only be carried out by authorized Cressi-Sub centres and the calibration values CANNOT

and MUST NOT be changed by the user, to avoid prejudicing

the safe operating of the regulator. We cannot be held in any

way liable for any intervention carried out by technicians that

have not been authorised by Cressi-Sub.

You can open and dismantle the second-stage regulator by

using the Allen key provided, in order to dismantle the first stage

HP and LP plugs, directly accessing its internal mechanics. This

extraordinary feature, which is patented and found nowhere

else on the market, makes it very easy to open and clean the

casing, as well as check the smooth-functioning of each and

every component.

Indeed, the cap and central chamber of the exhaust are mechanically connected thanks to the innovative patented “cam-lock”

system that enables an ultra-fast “hinged” opening and closing of

the case, which simultaneously blocks the cap and the diaphragm with extreme efficiency and precision.

Opening and closing your regulator has never been as safe and

easy!

In keeping with our objective of quick and easy control maintenance and tuning operations, the mechanics of Cressi-Sub second-stage regulators have been designed so as to be instantly

removable, without risking altering the level of calibration. Dismantling and replacing worn components whenever maintenance interventions are required can be carried out with the whole

mechanics system having been removed from the casing, making it much easier to complete operations.

Logon to our website: www.cressi.com for further important information about our products and equipment.

65

SECON D STAGES

Page 22

2.3 - XS Compact Pro / XS Compact / Octopus

The line of XS Compact second stages features revolutionary

“downstream” regulators that are lightweight (just 135 gr - the

lightest in the Cressi-sub line), with incredibly sleek design.

With a design that puts the accent on quality raw materials, they

offer a number of innovative features, protected by various

patents, and are produced in two distinct versions: XS Compact

PRO and XS Compact together with their respective Octopuses.

The XS Compact PRO model together with its relative Octopus

called Octopus Compact PRO may only be used in combination

with the first stage MC9 S.C., since it has been specifically designed for use in cold waters (T<10°C), thanks to the revolutionary

technology intrinsic in the material of the 2nd stage casing made

from a new heat conductive techno polymer. This material, thanks

to its high thermal conductivity, guarantees advanced heat exchange between ambient temperature and the internal temperature in the regulator, preventing icing phenomena in the second

stage, which is generally due to the formation of micro-crystals of

ice (the result of the natural humidity inside the second stage), following an abrupt drop in the temperature of the air arriving from

the first stage which, as it expands during inhalation inside the second stage, in cold water can drop to a few degrees below zero.

WARNING: In the case of dives in cold water (temperatures

lower than 10°C/50° F), Cressi-sub recommend using a tank

supplied with a valve featuring two separate outlet ports, with

which two complete regulators can be connected.

WARNING: diving in cold water at temperatures lower than

10°C/50 °F requires special technical training. Cressi-sub recommends this sort of diving only after having attended a special

training course by certified trainers. The use of underwater

equipment without a licence or adequate training may be dangerous for the diver’s health safety and can even be deadly.

The regulator must absolutely not get wet or be exposed to

freezing air before use. Do not press the discharge button, particularly when the Venturi effect adjustment lever is on “dive”. If

possible, keep the regulator in a warm place before use.

The XS Compact model and its relative Octopus called octopus

Compact may be sold in combination with various first stage

products of the Cressi sub range, which have the same components and functional characteristics but differ in their combinations thanks to the variously coloured caps. All types of XS

Compact second stage are designed for use in warm water

(>10°C/50°F) and guarantee the easiest use to both the beginner

and the most experienced diver, offering a complete range of

regulators for any type of use.

The case of the XS Compact second stage is made of a new

elastic techno-polymer that offers excellent mechanical qualities

and that is extremely carefully finished, including 3D photo-incision anti-scratch treatment to protect it from shocks and abrasions to make it exceptionally durable.

66

SECON D STAGES

fig.13 – XS Compact PRO fig.14 – XS Compact

Page 23

ENGLISH

When the diver exhales, he causes the pressure inside the case

The cap of the XS Compact second stage features a larger manual airflow button, with a functional return that is better than previous regulators in the Cressi-sub line. It also has a special

asymmetrical design in the way the holes are distributed that calibrates the flow of water in order to better optimize the regulator

performance.

Second stages in the XS Compact line have been designed to

deliver air on demand, that is, only when the diver inhales through

the mouthpiece, creating a light depression inside the regulator.

This light depression, which is slight enough not to cause breathing effort, works in combination with the external pressure to

press against the XS Compact diaphragm, which is properly calibrated to ensure the best useful working surface. In this way the

breathing effort is kept at the lowest level while the performance

is guaranteed to be the same as that of much larger regulators.

The circular diaphragm, one of the smallest currently on the market, is sucked toward the inside of the case when the diver inhales, pushing the central Teflon coated plate into contact with a

lever featuring a revolutionary new patented geometry and variable shape, designed to optimize and drastically reduce friction

due to contact between the lever and the diaphragm, by focusing

them in a single point on the plate. Friction between lever and

plate, as happens in other regulators, is therefore avoided, along

with the consequent reduction of the regulator’s performance.

As it descends, the lever opens the air supply valve, which is also

been completely redesigned for maximum manufacturing simplicity compared to previous models.

The air exiting the nozzle on the adjustable valve when the mechanism is open is channelled into the injector, which carries it directly to the mouthpiece. Here, the air is accelerated by the

Venturi effect, causing a vacuum inside the case. In order to prevent the depression from being too violent and sucking in the diaphragm, which would lead to free flow, the ends of injector and

case are designed to optimize and direct a light counter-flow of

air towards the diaphragm.

When the air flow inside the injector towards the mouthpiece increases, it is accelerated, as discussed above, by the Venturi effect.

The subsequent depression inside the regulator case keeps the

diaphragm lowered, and virtually eliminates second stage inhalation effort.

The Venturi effect immediately stops as soon as the diver stops

breathing. The diaphragm returns to its normal position, the lever

comes up again pushed by its spring, and the nozzle is closed by

the piston.

In order to enhance the Venturi effect, XS Compact is equipped

with a new ergonomic flow deviator in two modes, which are

clearly shown on the regulator:

fig. 16

67

SECON D STAGES

fig.15 – XS Compact Octopus

Page 24

pre-dive and dive (Fig. 16). In the first mode, a flow limiting device

placed in the mouthpiece inlet starts operating, and inhibits the

Venturi effect, preventing free flow. With the latter on, the Venturi

effect is able to work at its best, increasing the air flow released

by the regulator to the maximum level.

WARNING: Always remember to set the flow deflector’s

lever in PRE-DIVE (-) mode when not using the regulator; otherwise, an accidental collision, the regulator falling into water,

pressing the manual regulation button without having the

mouthpiece in one’s mouth, or suddenly taking the regulator

out of the mouth might trigger a strong free flow, causing high

air consumption.

When the diver exhales, he causes the pressure inside the case

to increase and open the discharge valve. This valve, with a completely new design and specially calibrated dimensions, is conical

in shape to guarantee a perfect seal for the regulator under all

conditions and all positions during use. In addition, the second

stage case exhaling section has been designed so as to offer the

best performance in combination with the exhaling baffle.

The latter, which can be taken out of the case by means of a special sliding hook, directs all exhaled air away from the diver’s face,

thanks to a partition placed on its centre which presses the discharge valve in its middle section ensuring that it opens in an extremely controlled way. This way, the regulator's exhaling

performance is optimized while also protecting the valve from turbulence in the water that might otherwise open it when the inside

of the case is not pressurized, leading to flooding.

The second stage is connected to one of the 3/8” LP ports on

the first stage by means of an extremely light and flexible

medium-pressure hose, made of a state-of-the-art thermoplastic

material that is extremely durable, lightweight, and with excellent

flow capacity.

68

SECON D STAGES

fig. 18

fig. 19

fig. 17

PRE-DIVE

DIVE

Page 25

ENGLISH

All Cressi-sub XS Compact second stages are downstream, that

is, the valve automatically opens in case of calibration loss in the

first stage or of a sudden intermediate pressure increase.

This means that any condition of over pressure upstream the

second stage leads to automatic free flow, never causing the regulator to get stuck.

The range of Cressi-sub XS Compact regulators is compliant with

the requirements of directive EU 2016/425, having been tested

and certified for use exclusively with:

• warm water (>10°C) relative to model XS Compact/Octopus XS

Compact (A>10°C);

• cold water (<4°C) relative to model XS Compact PRO /Octopus

Xs Compact Pro (A),

Consequently, they bear the CE mark followed by the certifying

agency identification number 0474, identifying RINA, the registered testing agency that monitors its manufacture pursuant to

Form B+C2 of the EU 2016/425 regulation, as well as the critical

health and safety requirements for category III PPE. It also regulates the conditions for bringing such equipment to market.

2.4 - XS Compact Pro / XS Compact disassembly and

servicing

When designing the XS Compact regulator, particular attention

was paid to the disassembly and servicing phases, which can always be carried out in utmost safety thanks to its innovative features that make all servicing phases easier, as maintenance is

crucial to always have a perfectly serviced, calibrated, and highperforming device.

WARNING: intermediate pressure must be set only at au-

thorized Cressi-sub centres, while the setting values can NOT

and must NOT be modified by the user, in order not to affect the

regulator’ s performance. Cressi-sub decline any responsibility

for any intervention carried out by unauthorized personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: info@cressi.com).

NOTE: we recommend to have the regulator completely serviced yearly or even oftener in case of intensive use; only original

Cressi-sub spare parts are to be used.

The unique bayonet mount lock system of the cap allows the

case to be easily opened and closed, and at the same time it

locks cap and seal in all safety and precision; there is no mechanic

coupling thread as in most other regulators on the market, that

may cause problems affecting their performances. Moreover, a

specially sized mechanic insert guarantees the regulator to be

safely and precisely locked.

Opening and locking a common circular seal case regulator has

never been so easy as well as so safe. Every operation of checking, servicing and setting of the second stage is made easier and

faster.

To reach this goal, we designed a revolutionary patented cap on

the device side, which avoids using a threaded coupling. The

valve as well can be serviced and set in an extremely easy way

guaranteeing the second stage utmost performance and perfect

tightness.

fig. 20

69

SECON D STAGES

Page 26

WARNING: the second stage can be opened, disassem-

bled and set only and exclusively at authorized Cressi-sub

centres; the setting values CANNOT and MUST NOT be varied

by the user, so as not to affect the device performances. We

decline any responsibility for any operation carried out by

unauthorized personnel.

NOTE: we recommend to have the regulator completely serviced yearly or even oftener in case of intensive use; only original

Cressi-sub spare parts are to be used.

Visit our site www.cressi.com: you will find more information about

our equipment.

2.5 – XS2

Second stage supplies air “on demand”, that is only when the

diver inhales from the mouthpiece, causing a slight vacuum inside the regulator, which must be very slight in order not to make

breathing difficult. Such vacuum acts on the diaphragm, which is

sucked in towards the inside, causing the central plate to touch

the lever. The latter opens the air supply valve.

The valve of XS2 is composed of a renovated modular poppet

in plastic and chromium-plated brass, which is interchangeable

with previous models of XS range: on one side, it is connected to

the lever, on the other side, it houses a newly designed thicker

rubber pad, closing the new adjustable nozzle, through which

the air flows at a pressure by 10 bar (145 psi) higher than the

environmental.

The air contained in the nozzle pushes the pad, which is contrasted by the poppet’ s spring.

Therefore, the renovated poppet “floats” between the push of inflowing air and the spring which, having a slightly higher

strength, clos es the nozzle perfectly.

The adjustable nozzle is placed inside the valve seat. The outflow

air, when the mechanism is open, is directed through the injector and directly into the mouthpiece.

70

SECON D STAGES

fig. 21

fig. 22

fig. 23 - Octopus XS

Page 27

ENGLISH

When the air flow inside the injector towards the mouthpiece

increases, it generates a vacuum inside the regulator’ s case,

due to its acceleration. This vacuum, called Venturi effect flattens

the diaphragm, remarkably reducing the diver’ s breathing effort.

The Venturi effect immediately stops as soon as the diver stops

breathing. The diaphragm returns to its normal position, the lever

comes up again pushed by its spring, and the nozzle is closed by

the piston.

To optimize the Venturi effect, XS2 CE is supplied with a flow

deflector with two operating modes, clearly shown by the scale

on the regulator housing:

pre-dive “-“ and dive “+” (picture 23). In first mode, a flow limiting

device placed in the mouthpiece inlet starts operating and inhibits

the Venturi effect, preventing free flow. In “+” mode, the Venturi

effect works at its best, increasing the air flow supplied to the regulator to the maximum level.

WARNING: Always remember to set the flow deflector’ s

lever in pre-dive (-) mode when not using the regulator;

otherwise, an accidental collision, the regulator falling into

water, pressing the manual regulation button without having

the mouthpiece in one’ s mouth, or suddenly taking the regulator out of the mouth might operate a strong free flow, causing high air consumption.

The dive (+) mode can only be used while diving and only

when the regulator is inside the mouth.

When the diver exhales, the pressure inside the regulator’ s case

increases, opening the exhaust valve. This has been fully redesigned and shows a larger diameter as well as a specially angled

conical shape, allowing air to flow outside. The exhaust tee

directs the air towards the head’ s sides and protects the valve

from water turbulences which might lift it, when the inside is

depressurized, and flood it.

The 2nd stage is connected to one of the first stage’ s 3/8”

ports by means of a flexible medium pressure and high capacity

hose.

All Cressi-sub second stages are downstream, that is the valve

automatically opens in case of calibration loss of first stage or of

a sudden intermediate pressure increase.

This means that any condition of over pressure upstream the

second stage leads to automatic free flow, never causing the

regulator to get stuck.

XS2 features a case in new techno-polymers with excellent

mechanic qualities and an attractive aggressive look. The maintenance is outstandingly easy and affordable, still easier on this

model thanks to a side tap, with its own O-Ring, for the valve

precise setting.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres, while the setting values can

NOT and must NOT be modified by the user, in order not to

affect the regulator’ s performance. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

fig. 24

71

SECON D STAGES

Page 28

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: info@cressi.com).

Inner components are in chromium-plated brass, stainless steel

and acetyl resins; springs are in stainless steel, diaphragms in silicone, O-rings in NBR and the mouthpiece in comfortable

hypoallergenic silicone.

Cressi-Sub second-stage regulators meet the requirements set

by standard EU 250:2014 in compliance with regulation UE

2016/425 which sets out the conditions for bringing to market

and the minimal essential safety requirements of PPE. Consequently, they bear the CE mark followed by the certifying agency

identification number 0474, identifying RINA, the registered testing agency that monitors its manufacture pursuant to Form B+C2

of the EU 2016/425 regulation, as well as the critical health and

safety requirements for category III PPE. It also regulates the conditions for bringing such equipment to market.

72

SECON D STAGES

Page 29

Direction for use regulators

2.6 - Performance Second Stages

Page 30

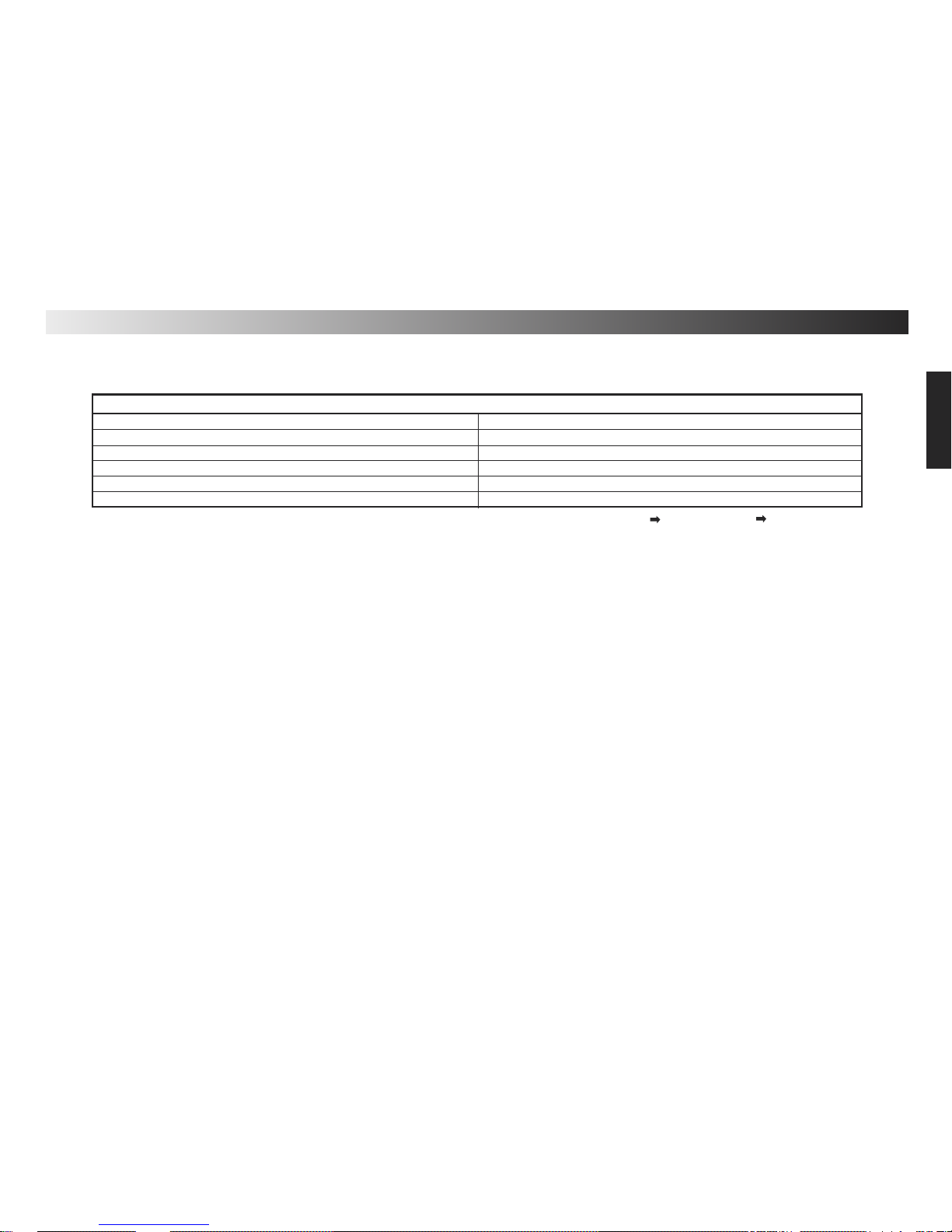

2.6 - Performance

Working pressure

Calibration pressure (with 200 bar supply)

Average inhalation effort (*)

Average exhalation effort (*)

Average work of breathing (*)

Air Supply

Weight without hose

0÷232 bar (INT); 0÷300 bar (DIN)

9,5 bar (T10 S.C. - T10 S.C. Cromo)

3 mbar

7 mbar

0,6 J/l

2500 l/min.

207 gr

Galaxy Adjustable / Master

(*) Values measured in compliance with standard EN 250:2014.

Working pressure

Calibration pressure (with 200 bar supply)

Average inhalation effort (*)

Average exhalation effort (*)

Average work of breathing (*)

Air Supply

Weight without hose

0÷232 bar (INT); 0÷300 bar (DIN)

9,5 bar (T10 S.C.)

3 mbar

7 mbar

0,6 J/l

2500 l/min.

182 gr

Galaxy

(*) Values measured in compliance with standard EN 250:2014.

74

Page 31

ENGLISH

Working pressure

Calibration pressure (200 bar feeding)

Average inhalation effort (*)

Average exhalation effort (*)

Average breathing effort (*)

Air supply

Weight without hose

0÷232 bar (INT); 0÷300 bar (DIN)

9,5 bar (MC9 - MC5 - AC2)

6 mbar

10 mbar

1,1 J/l

1600 l/min.

135 gr

XS Compact Pro / XS Compact / Octopus

(*) Values measured in compliance with EN 250:2014 standard.

2.6 - Performance

Working pressure

Calibration pressure (200 bar feeding)

Average inhalation effort (*)

Average exhalation effort (*)

Average breathing effort (*)

Air supply

Weight without hose

INT: 0÷232 bar (INT); 0÷300 bar (DIN)

9,5 bar (AC2)

10 mbar

13 mbar

1,4 J/l

1050 l/min.

200 gr

XS2

(*) Values measured in compliance with EN 250:2014 standard.

75

Page 32

Direction for use regulators

3 - Use and Maintenance

Page 33

3.1 – Use of the regulator and risk assessment

The regulator should be used only by divers who have attended

and completed successfully a special technical training course,

obtaining an underwater licence.

Nonetheless, before any use all environmental conditions should

be assessed, as well as the diver’ s psychophysical state: if just

one aspect is risky, diving must be avoided.

Among possibly risky environmental conditions, are the sea

state, the presence of currents, particularly low water temperature, reduced visibility.

Among psycho-physical conditions, please consider imperfect

health, emotional or physical stress, ack of training, tiredness,

bad digestion.

Do not forget that after a long time without diving, you are particularly at risk, since you might have lost part or all of the skills

learnt at the training course.

Cressi-sub regulators’ top quality materials and anti-corrosion

treatments allow their use in full safety.

Please remember that the depth of equipment certification is

164ft (50m), in compliance with the EN 250:2014 standard, which

purpose is to ensure a minimum level of safe operation of the apparatus down to a maximum depth of 164ft (50m), but recreational diving should not be deeper than 146ft (40m), without any

type of underwater work.

3.2 – Checks before use

Before using your Cressi-sub regulator, we recommend to carry

out some easy though very important and unavoidable checks,

in order to avoid any kind of problem.

Check, for example, if the hoses are perfectly connected with

the first stage: in case they can be manually disconnected, you

should screw them down with a key, before loading the regulator. Moreover, check the hoses do not look worn in any way and

are not cut or damaged at all.

In the same way, check the first and second stages for any

damage: check, for example, the second stage’ s mouthpiece

for cuts or scratches and connect it perfectly with the first stage

by means of a lock band.

Before opening the tank’ s valve, check the underwater pressure gauge reports zero pressure.

The tanks’ pressure must be checked by means of the special

underwater gauge or of a computer with such function: after

opening the tank’ s valve, the gauge must show the tank’ s correct working pressure.

WARNING: the regulator must be checked out of the water,

by depressing the manual supply button repeatedly, in order to

check the regular air supply; then, wear your mouth-piece and

make some deep inhalations and exhalations, in order to check

its perfect working (not for use in cold water < 10°C/< 50°F).

The same must be done on the water surface, before plunging, wearing your mouthpiece and turning you head so that

the regulator is completely under water: inhale and exhale

deeply, in order to check its perfect working, in both phases

of air supply and discharge.

This test must be done also with the reserve regulator, be it an independent regulator or an octopus (two

second stages connected with an only first stage).

Should you have also an “octopus” (two second stages connected with an only first stage) you must test the reserve

second stage as well.

A last acoustic test might discover and/or point out possible losses from connections and hoses or a free air flow from the

second stage: these are all anomalous situations requiring

immediate servicing or replacement of damaged components.

Should these anomalies be revealed, DO NOT dive and get to

anauthorized Cressi-sub centre to ask for all necessary servicing,

before using your equipment again.

78

Page 34

ENGLISH

WARNING: After assembling and checking it, the regulator

must be laid down horizontally, in order to prevent any

accidental fall from causing damage to its components or

injury to people.

3.3 – Mountig the regulator to the tank

Before assembling, check the tank has been filled with exclusively

compressed air working pressure, using a suitable compressor,

which supplies breathable air in compliance with EN 12021 standards.

We remind that only test certified tanks can be filled within the

lapse of time reported by the certificate itself.

WARNING: check the perfect state of the valves waterti-ght

O-rings. They must not show any cut, scratch or other damage;

they must be replaced anyway at regular intervals of time, even

if being in perfect state, since they are subdued to the tanks air

high pressure and to atmospheric agents as well. We recommend to use only original Cressi-sub spare parts.

For yoke connected first stages, use following procedure:

slightly unload the tank, opening its valve a little, in order to free

its end from any residual water. After unscrewing the yoke’ s lock

knob, take the protection tap out of it seat and place the first stage

on the air exit valve, checking the second stage is positioned correctly.

Now, screw the yoke’ s knob to lock the first stage on the

valve.

You do not need to tighten the knob too much.

Open the tank valve, turning it anticlockwise, keeping pressed

the manual supply button of the second stage for a while (this is

to be avoided in cold water).

WARNING: diving in cold water at temperature lower than

10°C/50 °F requires a special technical training. Cressi-sub

recommend such diving only after attending a special training

course by certified trainers. Using underwater equipment in

cold water without adequate training may be dangerous for

the diver’ s health and life.

The regulator must absolutely not get wet and exposed to

freezing air before use. Do not press the discharge button, particularly when the Venturi effect adjustment lever is on “dive”. If

possible, keep the regulator in a warm place before use.

We highly recommend, as a rule, to open the tank valve slowly,

so that the regulator gets filled gradually. If the regulator gets

pressurized too suddenly, in fact, it creates an adiabatic compression of the breathable gas inside the 1st stage, that might cause

the equipment to work imperfectly.

As soon as you hear air flowing out of the second stage, stop

pressing the manual supply button and open the valve fully. It is

advisable to turn the valve clockwise for a quarter, in order to