Page 1

5925 Heisley Road • Mentor, OH 44060-1833

75

0-

D

D

D

INSTALLATION, OPERATION and MAINTENANCE

MANUAL for Cres Cor

RADIANT OVENS

Ovens

Rev. 0 (5/13) Page 1 of 11

FL-2374

750-CH-SS-D

CH-SS-

750-CH-AL-D

750-CH-AL-

Cabinet model number:

Cabinet serial number:

Authorized Service Agency:

Ph: Fax:

Keep this manual for future reference.

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

500-CH-SS-D

500-CH-SS-

500-CH-AL-D

Page 2

Ovens

Rev. 0 (5/13) Page 2 of 11

FL-2374

5925 Heisley Road • Mentor, OH 44060-1833

TABLE OF CONTENTS

SUBJECT PAGE

INSTALLATION INSTRUCTIONS ......................................................................................3, 4

OPERATING INSTRUCTIONS ............................................................................................5

Illustration, Control Panel ............................................................................................ 6

MAINTENANCE INSTRUCTIONS

How to Clean the Unit ..................................................................................................7

Trouble Shooting Guide ...............................................................................................8

Replacement Parts ........................................................................................................9

Illustration; Ovens ........................................................................................................10

Wiring Diagram ............................................................................................................11

SERVICE POLICY and AGENCY LIST .........................................................................FL-1400

WARNING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK)

NO USER-SERVICEABLE PARTS INSIDE

REPAIR SHOULD BE DONE BY AUTHORIZED SERVICE

PERSONNEL ONLY

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 3

Ovens

Rev. 0 (5/13) Page 3 of 11

FL-2374

5925 Heisley Road • Mentor, OH 44060-1833

INSTALLATION INSTRUCTIONS

VENTING YOUR OVEN:

1. The purpose of ventilating hoods is to direct and

capture smoke, grease-laden vapors, heat, odors, or

fumes.

2. Low temperature equipment (maximum

temperature 250°F/121°C) does not produce heat,

odors, fumes, grease-laden vapors or smoke and is

not required to be vented.

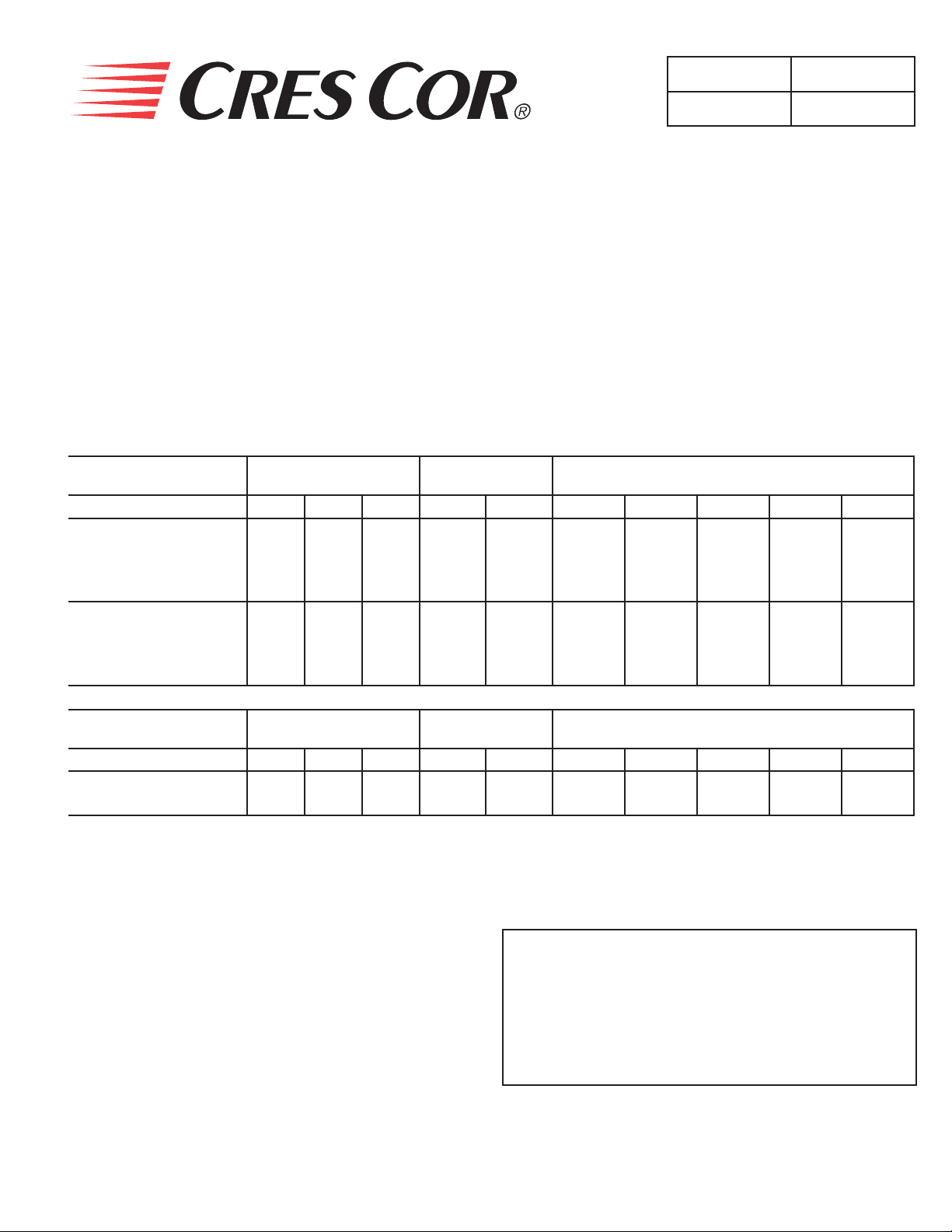

SPECIFICATIONS: All units are rated 3000 watts/2650 watts at 208 Volts/240 Volts

CMP MODEL NOS.

SINGLE OVENS Volts Ph Hz. Amps Volts Amps Ph Wire Volts NEMA

ELECTRICAL SPECS

(AC SERVICE)

ELEC. LOAD POWER SUPPLY REQUIREMENT

3. Most jurisdictions consider our low-temperature

ovens (maximum temperature is 350°F/177°C) as

low-heat appliances not requiring vent hoods.

4. Installation must conform with local codes. The

authority having jurisdiction of enforcement of

the codes will have the responsibility for making

interpretations of the rules.

500CHSSD

500CHALD

750CHSSD

750CHALD

500CHSSD3

500CHALD3

750CHSSD3

750ALD3

208

240

208

240

1

1

3

3

60

60

60

60

14

11

8

7

208

240

208

240

20

20

20

20

1

1

3

3

2

2

3

3

208

240

208

240

6-20P

6-20P

L15-20P

L15-20P

SPECIFICATIONS: All units are rated 2000 watts.

CMP MODEL NOS.

SINGLE OVENS Volts Ph Hz. Amps Volts Amps Ph Wire Volts NEMA

500CHSSD120

750CHSSD120

Model number “AL” is aluminum outer body with stainless steel doors and interior.

All models designed for AC Service. Model number may include a variety of informational suffi x letters.

NOTE: OVENS NEED TO BE INSTALLED BY A

QUALIFIED PERSON.

ELECTRICAL SPECS

(AC SERVICE)

120 1 60 16.6 120 20 1 2 120 5-20P

ELEC. LOAD POWER SUPPLY REQUIREMENT

For models rated at 2/08/240 Volts:

Check the voltage selector switch which is under an access

cover on the back of the oven near the power cord.

Flip the switch “UP” for 208 Volts

Flip the switch “DOWN” for 240 Volts

MAKE SURE THE SWITCH POSITION MATCHES

YOUR POWER SOURCE.

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 4

Ovens

FL-2374

Rev. 0 (5/13) Page 4 of 11

5925 Heisley Road • Mentor, OH 44060-1833

INSTALLATION INSTRUCTIONS (continued)

INSTALLATION INSTRUCTIONS (continued)

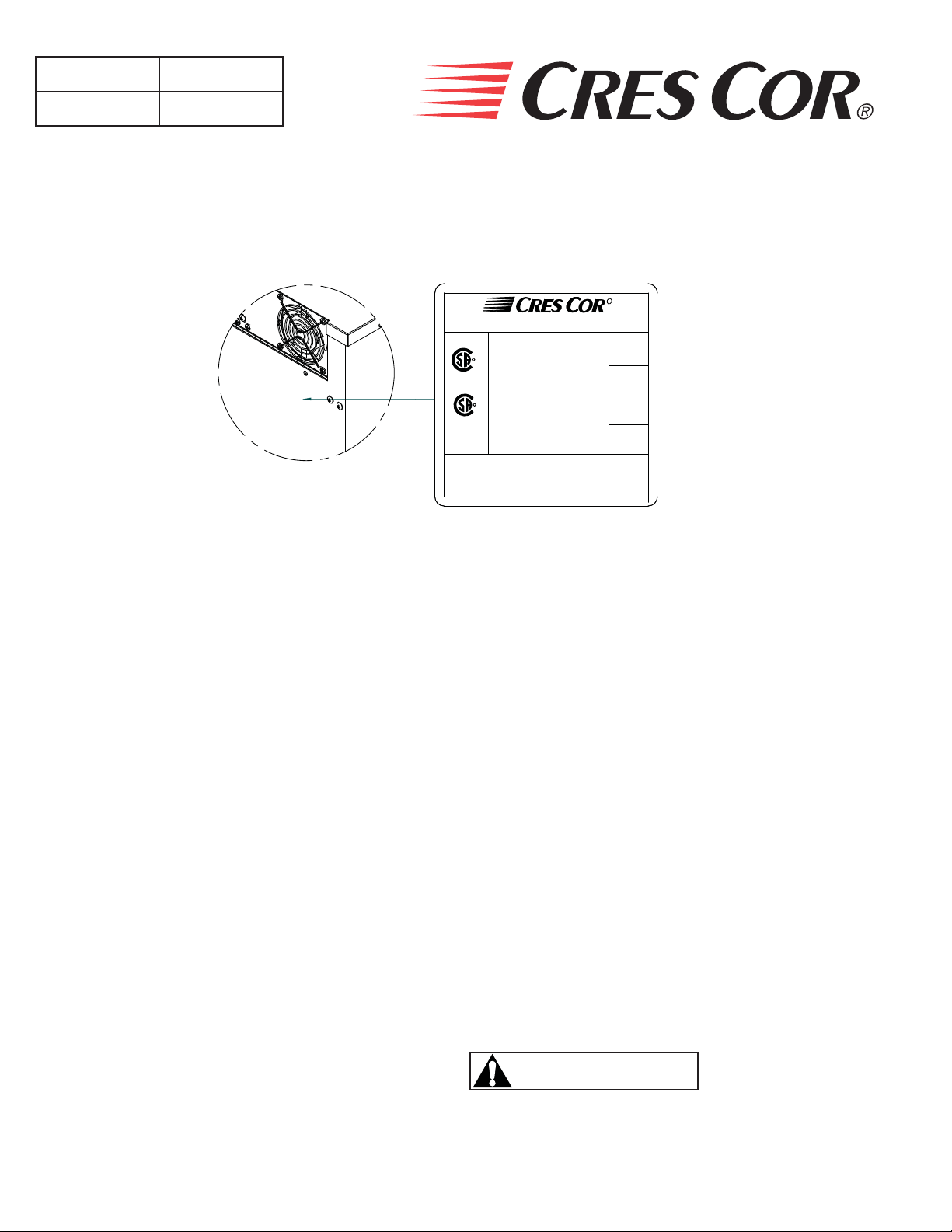

IDENTIFYING YOUR CABINET:

Look for this label on the back of your cabinet. This information is needed when calling for questions or service.

R

5925 HEISLEY RD. MENTOR, OHIO 44060

MOD.

MOD.

1000CH

FAA-K5645C-001

FAA-K5645C-001

SER.

SER.

R

SAMPLE

29

AMPS

AMPS

VOLTS

VOLTS

208/240

3000

WATTS

WATTS

COMMERCIAL COOKING APPLIANCE

MADE IN USA

CSA certified to UL 197 Rev. 9

Hz.

Hz.

60

60

PH.

PH.

1

1

UPPER RIGHT CABINET CORNER

R

C

US

HOW TO INSTALL CABINETS:

1. Remove all packing material from the inside and all

vinyl from the outside of oven.

2. Place the oven in a well ventilated area on level fl oor.

Clearance requirements: 3” (76mm) at the back, 2”

(51mm) at the top, 1” (25mm) at both sides.

3. Install the pan slide racks on the sidewalls, if necessary.

4. Slide drip pan(s) onto the bottom of the compartment(s).

5. Remove (3) screws at the bottom front of the oven,

under the door (See Figure).

6. Screw the drip tray bracket to the oven in those holes

and place the drip tray onto the bracket.

All models are rated at 208/240 Volts.

HOW TO REVERSE THE DOOR OPENINGS, IF

NEEDED:

1. Unscrew and remove the latch from the door and

magnetic strike from the cabinet.

2. Unscrew the hinges from the cabinet body and remove

door.

3. Remove the screws plugging the mating hinge, latch

and strike holes on the opposite sides of the cabinet

body and door.

4. Re-mount the hinges to the opposite side of the cabinet

and door.

5. Remount the latch and strike to the opposite side

FOR FIRST-TIME OPERATION ONLY:

A new oven needs to “burn off” factory oils and glue before

it’s fi rst use. Do NOT load food into oven until this has

been done!

1. Push switch to “ON”; the light will come on.

NOTE: The letters “LOTPR” (low temperature) will show

on the control panel until it reaches 140°F (60°C).

2. Press the “COOK” button.

3. Push down and turn the control knob to show 200°F.

Push the knob again to set the temperature. Run the unit

for one (1) hour.

4. Turn the unit off and let cool.

5. Wipe the inside clean with detergent and hot water.

DOOR VENT ADJUSTMENT:

Open the door(s) and move the vent tabs on the

inner door(s) as needed to release humidity.

WARNING

Air is VERY HOT when door is opened.

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 5

5925 Heisley Road • Mentor, OH 44060-1833

OPERATING INSTRUCTIONS

Ovens

Rev. 0 (5/13) Page 5 of 11

FL-2374

HOW TO USE THE COOK-N-HOLD CONTROL:

*Push the lighted switch on the control panel; the light will

come on and the cabinet will start heating.

*The display will read “LOTPR” (low temperature) below

140°F. (60°C.).

NOTE: Wait one (1) hour after start up before loading the

food for best results.

The display will read “PREHT” until the cabinet reaches

the set temperature, then it will show “READY”.

Cooking:

1. Press the COOK button.

2. Turn the control knob to the desired cooking

temperature between 200°F (93°C) and 350°F (176°C).

3. Push the knob to set the temperature.

4. The control automatically goes to the HOLD mode.

(Continue to step 1 below).

Holding:

(Press the HOLD button only if you are just holding food),

1. Turn the control knob to the desired holding temperature

between 140°F (60°C) and 220°F (104°C).

2. Push the knob to set the temperature.

3. The control automatically goes to the TIME mode.

Setting the time or Food Probe:

1. If NOT using the Food Probe:

a) Turn the control knob to the desired hours/minutes.

b) Push the knob to set the time.

2. Using the Food Probe:

Plug in the food probe BEFORE you enter the TIME

mode. Otherwise, you have to press the PROBE button

to set the probe temperature.

a) Turn the knob to the desired temperature.

b) The timer will stop when the probe reaches the set

temperature.

3. Press the START button. The display will read

“PREHT” until the cabinet reaches the set temperature,

then it will show “READY”.

4. Press the START again to use this recipe (see Recipes”).

Note: Press the knob for 4 seconds to cancel the recipe.

The DISPLAY button shows (cycles through) all the values

when in each mode:

• “PREHEAT” OR “READY”: momentarily shows the

actual cabinet temperature.

• “COOK” (Timed): shows Home screen, set point,

count down time, actual cabinet temperature.

• “COOK” (Probe): shows Home screen, set point, count

up time, actual cabinet temperature.

• “HOLD”: shows Home screen, set point, count up

time, actual cabinet temperature.

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 6

Ovens

Rev. 0 (5/13) Page 6 of 11

FL-2374

5925 Heisley Road • Mentor, OH 44060-1833

RECIPES:

The control can hold up to 18 saved recipes.

To save a recipe:

1. Press and hold both the TIME button and the knob for

5 seconds. The screen will be fl ashing. This is the setup

menu.

2. Turn the knob through the menu until you get to “Edit”.

3. Press the knob and turn to the recipe you want to edit.

There are 18 blank recipes to customize and save.

4. Press the knob and enter the cook, hold and time values.

5. After the entering the fi nal value, “Edit” will show

again.

6. Press the knob to edit more recipes or turn to “End” to

exit the menu.

To use one of the recipes:

1. Push one of the three RECIPE group buttons for the

recipe number you want.

2. Turn the knob to the recipe you want and press the knob

to select.

3. Press the START button to preheat.

4. After it shows “READY”, press the START button

again to begin the recipe.

Note: The display button will cycle through all the values

as before, but will include the recipe number, if

using a saved recipe.

Quick Recipe Note:

You can set “Quick Recipes” for recipes that you use often.

This way, when you press a recipe group button and press

start, that recipe will start cooking without searching

for the recipe number. Recipe numbers can be set up as

“quick recipes” as follows:

1. Press and hold both the TIME button and the knob for 5

seconds to get into the menu.

2. Turn the knob to “RBTN” and press the knob. The word

“PUSH” will fl ash.

3. Press one of the recipe group buttons to assign a recipe.

Note: Recipe numbers 1-6 can be set up as Group button 1.

Recipe numbers 7-12 can be set up as Group button 2.

Recipe numbers 13-18 can be set up as Group button 3.

4. Turn the knob to the recipe number you want to assign

to that button and press the knob.

Repeat the process to assign recipes to the other two recipe

group buttons; or,

turn the knob to “END” the submenu; turn to “END” the

menu.

Additional Menu Settings:

Press and hold both the TIME button and the knob for 5

seconds to get into the menu.

Here you can set the recipes, quick recipes, temperature

units (°C or °F) and the datalog

settings (USB connection required):

”RECE” allows you to enable or disable the data record

feature.

“RECF” allows you set how often (in minutes) a

datapoint will be recorded.

“RECD” allows you to set how long (in days) you would

like the data to be stored in memory.

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 7

5925 Heisley Road • Mentor, OH 44060-1833

HOW TO CLEAN THE UNIT:

WARNING

Ovens

Rev. 0 (5/13) Page 7 of 11

FL-2374

BEFORE cleaning the cabinet:

1. Unplug cord from wall. Allow cabinet to cool.

2. Do NOT hose cabinet with water.

3. Do NOT get water on controls.

4. Do NOT use abrasives or harsh chemicals.

Wipe up spills as soon as possible.

Clean regularly to avoid heavy dirt build-up.

MODELS: 500-CH-SS-D & 750-CH-SS-D

SOIL CLEANER METHOD

Soap or mild detergent* and

water.

Mild abrasive made for

Stainless Steel.

Chemical oven cleaner made

for Stainless Steel.

STAINLESS

STEEL

CABINET

Inside and

Outside

Routine Cleaning

Stubborn Spots, Stains

Burnt on Foods or Grease

Hard Water Spots & Scale Vinegar

Cleaning Hints:

1. Use the mildest cleaning procedure that will do the job.

2. Always rub in the direction of polish lines to avoid

scratching the surface.

3. Use only a soft cloth, sponge, fi brous brushes, plastic or

stainless steel pads for cleaning and scouring.

4. Rinse thoroughly with fresh water after every cleaning

operation.

5. Always wipe dry to avoid water marks.

1. Sponge on with cloth

2. Rinse

1. Apply with damp sponge or cloth.

2. Rub lightly.

Follow oven cleaner manufacturer’s

directions.

1. Swab or wipe with cloth.

2. Rinse and dry.

MODELS: 500-CH-AL-D & 750-CH-AL-D (Aluminum cabinet outside only with stainless steel doors and pan slides)

SOIL CLEANER METHOD

1. Use soft, damp cloth.

2. Rinse with hot water.

3. Wipe dry.

1. Rinse after steam cleaning.

2. Wipe dry.

1. Wipe with soft, damp cloth.

2. Rinse with hot water.

3. Wipe dry.

Follow oven cleaner manufacturer’s

directions

Apply with soft, clean cloth.

ALUMINUM

CABINET

Outer body

ONLY

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Mild detergent* and hot water,

or mild abrasive cleaner.

Dirt

Steam (no strong alkaline

additive).

Detergent* and hot water.

Fingerprints, Grease, Oil

Water Spots Mild abrasive cleaner. Wipe with damp cloth.

Chemical oven cleaner made

for aluminum.

Mild abrasive cleaner.

Oily or waxy cleaner.

*Mild detergents include soaps and non-abrasive cleaners.

Page 8

Ovens

FL-2374

Rev. 0 (5/13) Page 8 of 11

MAINTENANCE INSTRUCTIONS

IF UNIT GETS TOO HOT OR WON’T SHUT OFF, DISCONNECT

WARNING

1. Cord is unplugged from wall outlet.

POWER AT BRANCH PANEL. DO NOT UNPLUG CORD!

If hot unit is NOT working, fi rst check the following causes:

5925 Heisley Road • Mentor, OH 44060-1833

TROUBLE-SHOOTING GUIDE

3. Switch(es) are turned off.

2. Circuit breaker/fuse to wall outlet is blown.

4. Thermostat(s) are turned off, or are set too low.

IF THE OVEN TURNS ON:

PROBLEM POSSIBLE CAUSE SOLUTION

Oven does not heat, or doesn’t heat

properly

Heater will not shut off

Vent fans do not shut off

Vent fans do not operate (See Note)

Control will not switch from “COOK” to

“HOLD” (timed mode)

Control will not switch from “COOK” to

“HOLD” (probe mode)

Control will not switch to “COOK” (probe

mode)

1. Sensor

2. Heater relay

3. Loose connection

4. Oven control

5. High Limit

1. Control defective

2. Heater relay

1. Vent fan switch defective

2. Control compartment is still hot.

1. Vent fan switch defective

2. Vent fan defective

1. Oven is in “PROBE” mode.

2. Oven control defective

1. Oven is in the “TIMED” mode

2. Probe not plugged in

3. Probe defective

4. Oven control defective

1. Oven in “TIMED” mode

2. Probe temperature setting lower

than probe temperature

3. Probe not plugged in

4. Oven control defective

1. Replace

2. Replace

3. Replace

4. Replace

5. Replace

1. Replace

2. Replace

1. Replace

2. Wait until it cools

Check “Heater will not shut off”

1. Replace

2. Replace

1. Cancel recipe and switch to “TIMED” mode

2. Replace

1. Cancel recipe and switch to “PROBE” mode

2. Plug in probe

3. Replace

4. Replace

1. Switch to “PROBE” mode

2. Set probe temperature to desired temperature

3. Plug in probe

4. Replace

ERROR CODES:

CODE DISPLAYED CAUSE SOLUTION

no p No meat probe Plug in probe

Err0 Temp probe bad Replace

NOTE: Vent fans will not operate until the control compartment requires ventilation to limit temperatures. Replacement

of electrical components must be done by a qualifi ed electrician.

Refer to our Service Agency list, FL-1400 (found in the back of this manual), of authorized service centers.

Instructions for replacing parts are included in replacement parts list.

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 9

5925 Heisley Road • Mentor, OH 44060-1833

REPLACEMENT PARTS

Include all information on nameplate when ordering parts

8 9

4

3

2

Ovens

FL-2374

Rev. 0 (5/13) Page 9 of 11

INSULATION

7

24

23

20

13

11

12

14

12

18

1

29

19

25

22

21

10

17

16

26

5

6

HEATER

WIRE COVER

SIDE

PANEL

15

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 10

5925 Heisley Road • Mentor, OH 44060-1833

REPLACEMENT PARTS

Include all information on nameplate when ordering parts

Ovens

Rev. 0 (5/13) Page 10 of 11

FL-2374

ITEM DESCRIPTION CMP Part No.

1. Switch (On/Off) 0808-125

2. Digital Control 0848-092-08-K

3. Switch, Fan 0848-034

4. Relay 0857-136

5. Terminal Block (Input) 0852-109

6. T erminal Block 0852-091

7. Switch, toggle 0808-020

8. Vent Fan (240V) 0769-174

Vent Fan (120V) 0769-165

9. Fan Guard 0769-167

10. Heater Kit 240V, 1325W 0811-296-K

Heater Kit 120V, 1000W 0811-295-K

11. Door Latch Kit 1006-122-01-K

12. Latch Strike Kit 1006-122-02-K

13. Door Assembly (750 Series) 1221-576-K

Door Assembly (500 Series) 1221-570-K

14. Door Gasket (750 Series) 0861-269

Door Gasket (500 Series) 0861-270

15. Door Hinge 0519-109

ITEM DESCRIPTION CMP Part No.

16. Casters, Rigid 0569-288

17. Casters w/Brake 0569-287-B

18. Pan Slides (750 Series) 0692-203

Pan Slides (500 Series) 0692-202

19. Drip Pan (750 Series) 1017-117

Drip Pan (500 Series) 117-109

20. Hi-Limit 0848-033

21. Drip Tray (750 Series) 1017-118

Drip Tray (500) Series 1017-107

22. Wire Shelf (750 Series) 1170-217

Wire Shelf (500 Series) 1170-030-SS

23. Power Cord (3000W, 1Ph) 0810-173-01-K

Power Cord (3000W, 3Ph) 0810-164-02

Power Cord (2000W, 1Ph) 0810-065-1

24. Strain Relief 0818-050

25. Clear Drip Pan 1017-058

26. Transformer 0769-197

27. Strainer 1052-094

Probe-Food 6” 0848-112

Probe Connector 0848-106-02

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Page 11

Ovens

FL-2374

Rev. 0 (5/13) Page 11 of 11

1000-CH-SS-SPLIT-D and 1000-CH-SS-SPLITD120

5925 Heisley Road • Mentor, OH 44060-1833

WIRING DIAGRAM FOR

L

N

N

L

AIR

PROBE

t°t°

MEAT

PROBE

AIR

LOOKING AT REAR

RENAU CONTROL

8

7

6

5

4

3

2

1

K3 K1 K2

16

15

14

13

12

11

10

9

POWER

SWITCH

(rear view)

AIR HEATER

SOLID STATE RELAY

A2(-) A1(+)

L1 T1

HIGH LIMIT

89

1PG*GCVGT%QPHKI

blue

brown

BLOCK

TERMINAL

*GCVGTU

9CVV

6QIING

5YKVEJ

8

brown

blue

BLOCK

TERMINAL

HIGH TEMP

FAN

VENT

closes @130F

blue

brown

BLOCK

TERMINAL

FAN

VENT

BLUE

RED

208/240

BROWN

PURPLE

12

VAC

WHITE

YELLOW

VAC

BLACK

TRIAD

GRAY

ORANGE

YELLOW

BROWN

GRAY

VAC

208/240

VAC

12

BLUE

WHITE

BLACK

HAMMOND

RED

GROUND*

POWER CORD

Call Toll-free: 877-CRES COR (273-7267) • Fax: 800-822-0393 • www.crescor.com

Loading...

Loading...