Cres Cor 309 Installation Manual

DELHI INDUSTRIES INC.

DESCRIPTION

UNPACKING

GENERAL SAFETY INSTRUCTIONS

INSTALLATION

300 SERIES - ROOF EXHAUSTERS

OPERATION INSTRUCTIONS AND PARTS MANUAL

MODELS: 307, 309, 310, 312, 315, 318

instruction

Always disconnect power source before working on or near a motor or its connected load. Lock the power

Read installation and operation instructions carefully before attempting to install, operate or service DELHI 300 SERIES

BLOWERS. Failure to comply with instructions could result in personal injury and/or property damage. Retain

for future reference.

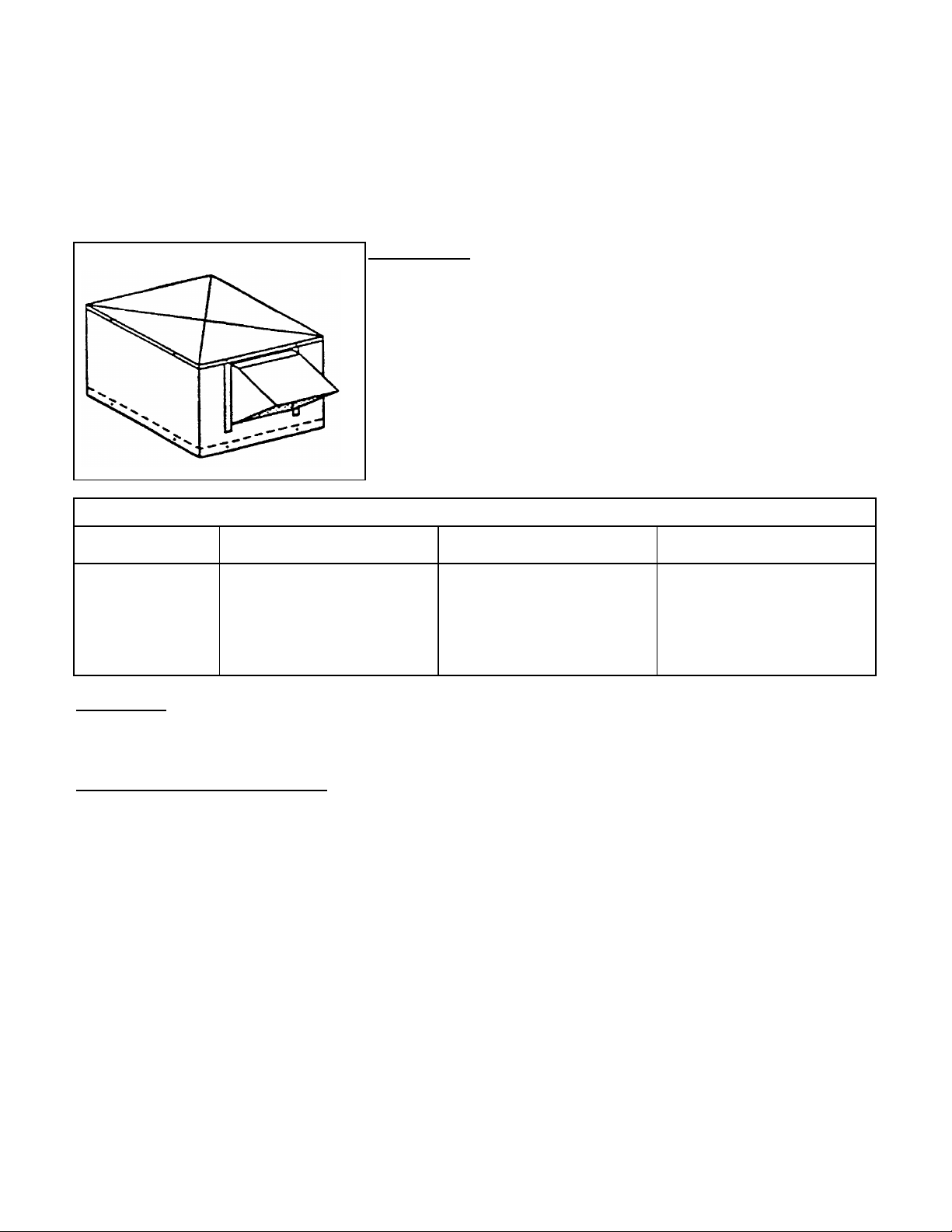

Figure 1: DELHI 300 SERIES

DELHI 300 Series Blowers are designed as a quiet and efficient outdoor roof

exhauster for high-rise apartments, schools, and commercial industrial

applications. These forward curved, double inlet blowers are enclosed in a

sturdy insulated steel cabinet c/w a recessed bottom for mounting to an

existing curb, with discharge in any of four positions. These blowers are belt

drive and may be installed with or without back draft dampers.

Motor, drive installations and servicing may be completed through a

removable top cover.

Prelubricated ball bearings, motor bracket, back draft dampers and

hardware, motor adjustment hardware and a dynamically balanced wheel are

standard equipment. Operating temperature range is -65 to 250 deg. F.

Maximum HP Ratings and Shaft Details

Model No. Max. H.P. Shaft Dia. Shaft End

307

309

310

312

315

318

3/4

3/4

1-1/2

2

3

3/4

3/4

3/4

3/4

1

1

keyway

keyway

keyway

keyway

keyway

keyway5

Once the packaging has been removed inspect the unit carefully. Check for loose, missing, or damaged parts. Rotate

the wheel by hand to ensure the wheel spins freely. Tighten all set screws.

1

disconnect in the open position and tag to prevent unauthorized application of power.

2

Follow all local and national electrical and safety codes.

3

Blower must be electrically grounded. This can be accomplished by using a separate ground wire connected

to the bare metal of blower frame, or other suitable means.

4

Ensure that the power source conforms to the requirements of your equipment.

5

Do not put hands near or allow loose and hanging clothing to be near belts, pulleys, or blower wheel while the

unit is running.

NOTE: Check the interior of the blower housing. It should be clean and free of debris.

1

Rotate the blower wheel by hand. It should not rub against the housing inlet. If rubbing occurs, loosen the set

screws on the wheel hub and shift the wheel to obtain clearance. Retighten all set screws.

DELHI INDUSTRIES INC., 523 JAMES ST., DELHI, ONTARIO, CANADA N4B 2Z3 PH:(519)582-2440 FX:(519)582-0581

OIPM-300-B

AUGUST 1998

DELHI INDUSTRIES INC.

The

first

damper

tobeinstalled

should

overlap

the

WARNING:

EXCESSIVE

BELT

TENSION

IS

THE

MOST

FREQUENT

CAUSE

OF

BEARING

WEAR

AND

RESULTING

WARNING:

A

GROUND

WIRE

MUST

BE

CONNECTED

FROM

THE

MOTOR

HOUSING

TOASUITABLE

ELECTRICAL

Establish

the

direction

of

exhauster

discharge.

Carefully

lift

the

unit

and

position

over

the

existing

curb.

Confirm

the

unit

is

within the bracket.

Adjust

belt

tension

by

turning

the

motor

adjustment

hook

bolt.

Ideal

belt

tension

is

the

lowest

tension

at

which

the

belt

will

not

2

properly seated and secure into position by fastening through the 5/16" holes located in the unit's skirt.

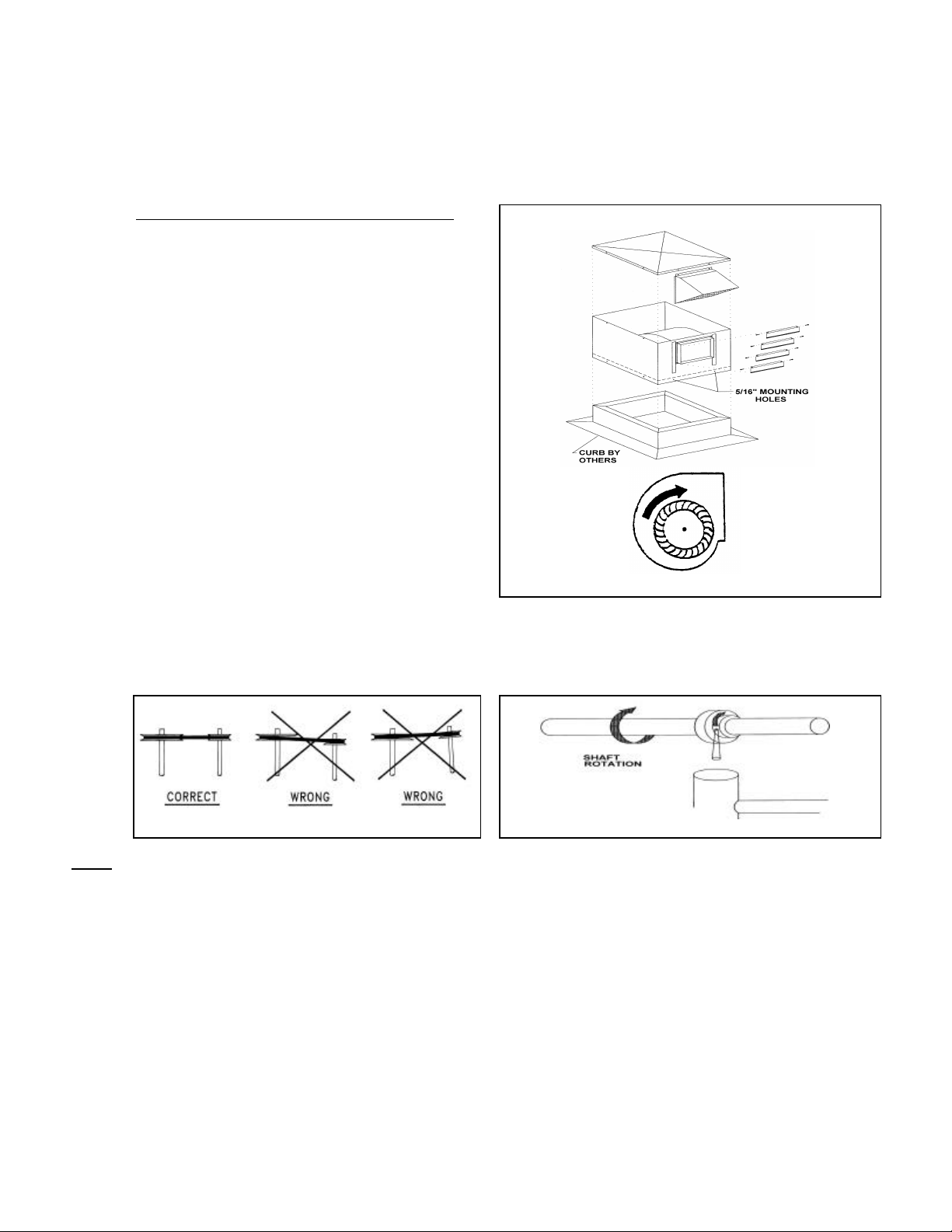

OPTIONAL: INSTALLING BACK DRAFT DAMPERS: Figure 2: Installation Method

3

discharge baffle with subsequent dampers overlapping the

previous damper, until the top of the discharge is reached.

Use the #8 x 1-1/4" screws provided to secure the damper

into position with the brake facing inward. Insert the

screws through the plastic snap bushing located on either

side of the blower discharge into the shutter recess.

Maintain that each damper installed rotates freely within

the snap bushing. (See Figure 2)

4

Insert the exhaust cowl (air direction downward) into the

channels provided on either side of the exhaust port.

5

Mount the blower sheave on the blower shaft and tighten

its set screw securely on the key of the shaft. (See Table

1 for Drive Data)

6

Mount the motor sheave on the motor shaft. Leave some

clearance between the pulley and the motor end bell.

Tighten the set screws on the key of the motor shaft.

7

Slide the square head bolts into the channel provided in

the motor bracket. Place the motor into position, finger

tighten the nuts to temporarily secure the motor. Attach

the motor adjustment (belt tension) assembly.

WHEEL ROTATION

8

With the motor adjusting bolt in its minimum position install the V belt within the sheave grooves. Slide the motor within the

motor bracket to ensure proper pulley alignment (see Figure 3). A straight edge across the face of the driven pulley should be

parallel to the belt once proper alignment has been achieved. Tighten the nuts on the motor base to anchor the motor position

Figure 3: Pulley Alignment Figure 4: Bearing Replacement

NOTE: Pulley alignment may change when adjusting variable pitch pulleys.

9

slip during start up. A rule of thumb suggests that 3/4" of deflection mid span under medium finger pressure (2-3 lbs.) for every

foot of span is approximately proper belt tension. Lock the motor adjustment (belt tension) assembly once proper belt tension

has been achieved.

NOISE

10

Before connecting the motor to the electrical supply, check the electrical characteristics and wiring instructions as indicated on

the motor nameplate to ensure proper voltage and phase. Make your electrical connections.

GROUND

OIPM-300-B AUGUST 1998

Loading...

Loading...