Page 1

INSTALLATION AND OPERATING

MANUAL

P25 Series UHF

CONTINUOUS DUTY

POWER AMPLIFIER

Crescend Technologies

140 E. State Parkway

Schaumburg, IL 60173

Tel: 847-908-5400

Fax: 847-908-5408

sales@crescendtech.com

www.crescendtech.com

040003A010 Rev B

Page 2

User Manual

040003A010 Rev B Page 2 of 25

Page 3

User Manual

040003A010 Rev B Page 3 of 25

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

This manual contains installation and operating information for the Crescend High Power Amplifier.

The manual is organized into multiple sections as follows:

1 GENERAL DESCRIPTION .................................................................................................................... 3

1.1 INTRODUCTION .................................................................................................................. 3

1.2 PRODUCT DESCRIPTION ................................................................................................... 3

2 INSTALLATION ..................................................................................................................................... 5

2.1 INSTALLATION INSTRUCTIONS ......................................................................................... 5

2.2 INITIAL STARTUP ................................................................................................................ 6

3 OPERATING INFORMATION ............................................................................................................... 7

3.1 INTRODUCTION .................................................................................................................. 7

3.2 STATUS INDICATORS AND MONITOR CONNECTOR ...................................................... 7

3.3 DETAILED STATUS INDICATOR AND MONITOR CONNECTOR INFORMATION ............ 9

3.4 DIGITAL COMMUNICATION INTERFACE (RS232) ...........................................................13

3.5 POWER SET CONTROL .....................................................................................................17

4 TROUBLESHOOTING ..........................................................................................................................18

4.1 INTRODUCTION .................................................................................................................18

4.2 TROUBLESHOOTING .........................................................................................................18

4.3 RETURN FOR SERVICE PROCEDURES...........................................................................20

4.3.1 OBTAINING RMA ........................................................................................................20

4.3.2 REPACKAGING FOR SHIPMENT ..............................................................................20

5 MAINTENANCE ...................................................................................................................................21

5.1 INTRODUCTION .................................................................................................................21

5.2 PERIODIC MAINTENANCE .................................................................................................21

5.3 CLEANING AIR INLETS/OUTLETS .....................................................................................21

6 RF ENERGY EXPOSURE ....................................................................................................................22

6.1 RF ENERGY EXPOSURE AWARENESS, CONTROL INFORMATION, AND OPERATIONAL

INSTRUCTIONS FOR COMPLIANCE WITH FCC RF EXPOSURE LIMITS ........................................22

6.2 FEDERAL COMMUNICATION COMMISSION REGULATIONS .........................................22

6.3 RF EXPOSURE COMPLIANCE, CONTROL GUIDELINES AND OPERATING

INSTRUCTIONS ...................................................................................................................................22

1.2 PRODUCT DESCRIPTION

The Crescend Technologies High Power UHF RF power amplifier is designed for paging and other

applications that use a single carrier constant envelope waveform. The amplifier is designed to be

powered from either an external +48 VDC source or an optional internal AC power supply. Model

Page 4

User Manual

040003A010 Rev B Page 4 of 25

GA amplifiers cover the 406.1-420 MHz band without retuning. Model HA amplifiers cover the

450-454MHz, 456-462.5375MHz, 462.7375-467.5375MHz, 467.7375-470 -470MHz band without

retuning. Amplifier specifications are shown in Table 1-1. There are seven input ranges available

as shown in Table 1-2. Closed loop power control is used to maintain a constant output power

under varying voltage, signal input level, frequency and output load conditions. Several design

features work to protect the amplifier under adverse conditions.

The amplifier is designed to fit into 5.25 inches (3RU) of vertical 19-inch rack space. The front

panel includes LED indicators for monitoring status and alarm conditions. This information is also

accessible via a monitor connector on the rear of the amplifier. The fan assembly draws ambient

air in from the front and blows the air across the heat sink fins out the back of the amplifier.

NOTE: The manufacturer’s rated output power of this equipment (see Table 1-1) is specified

for single carrier operation using constant-envelope modulation. This equipment is

NOT designed for multiple-carrier operation, nor is it intended to be used with nonconstant envelope modulation waveforms.

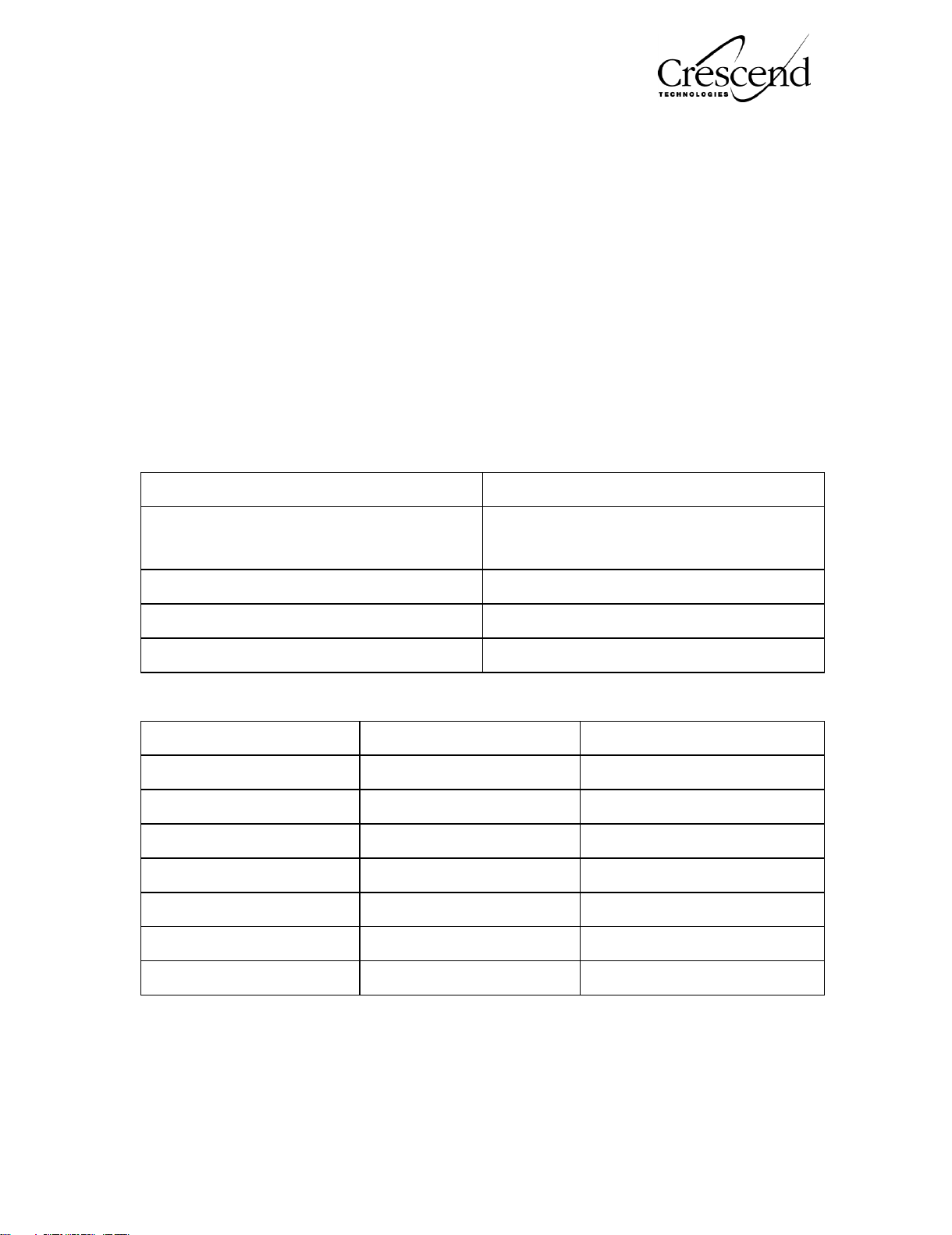

Table 1-1 Amplifier Specifications

Specification

Value

Instantaneous Bandwidth

406.1-420 MHz (GA models), 450-454MHz, 456-

462.5375MHz, 462.7375-467.5375MHz, 467.7375-470 470MHz (HA models)

Output Power Range

25 W - 250 W

Input Impedance

50 Ohms

Output Impedance

50 Ohms

Table 1-2 Amplifier Input Power Ranges

Input Power Designator Code

Input Power Range

Nominal Gain (250W Output)

R2GA, R2HA

0.2 - 0.5 W

28.5 dB

R5GA, R5HA

0.5 - 1 W

25.0 dB

1GA. 1HA

1 - 2 W

22.0 dB

2GA, 2HA

2- 5 W

18.5 dB

5GA, 5HA

5 - 10 W

15.0 dB

10GA, 10HA

10 - 20 W

12.0 dB

20GA, 20HA

30 - 40 W

8.5 dB

Page 5

User Manual

040003A010 Rev B Page 5 of 25

2 INSTALLATION

2.1 INSTALLATION INSTRUCTIONS

The amplifier is designed for installation in a rack that permits access to the rear of the unit for

connection of RF and monitor/control cables, and DC power cables or AC line cord if the unit

incorporates the internal AC power supply option. The amplifier must have a minimum of 3 inches

of open space in front and to the rear of the chassis to allow adequate air flow and ventilation. If

installed in a closed or multi-unit rack, the operating ambient temperature within the rack

environment may be greater than the room ambient. The equipment installation must be

compatible with the +60°C maximum temperature rating of the amplifier. Caution should be

exercised when rack mounting the amplifier to avoid creation of a hazardous condition due to

uneven mechanical loading. Avoid “top-heavy” or cantilever installations which may cause the

equipment rack to become unbalanced. Consideration should be given to the connection of the

equipment to the AC or DC supply circuit and the effect that overloading of the circuits might have

on overcurrent protection and supply wiring. Consideration of the appropriate current rating (10A

for 110-125VAC operation, 20A for +48VDC operation) should be used in addressing this concern.

Caution should be exercised with supply connections which are not direct connections to the

branch circuit (e.g. use of power outlet strips). Reliable grounding of rack-mounted equipment

should always be maintained.

To install the amplifier, proceed as follows:

1. Mount the amplifier in equipment rack and secure in place.

2. Connect a properly sized 50 Ohm cable and load (antenna) to the RF OUT connector on

rear of amplifier.

3. Connect the transceiver/exciter output to RF IN connector on rear of amplifier.

4. If monitoring of PA is desired, connect alarm cable to MONITOR connector on rear of

amplifier module. See section 3 for more details about monitor pins.

5. Connect a ground cable to the rear panel stud of the amplifier. A UL Listed ground bonding

conductor assembly is recommended, such as Harger p/n UBC61411/4KIT5,

UBC61811/4KIT5, or UBC63211/4KIT5. These ground cable interfaces consist of Harger

p/n 6-6R1 ring tongue lugs crimped to various lengths of Harger p/n 6XLPE133G/YS #6

AWG ground cable.

6. If the unit is the 48 VDC version, measure the DC output voltage of the external power

supply. DC voltage should be +48 +/- 0.5VDC. Turn off the DC voltage.

NOTE:

Make sure power supply DC is well filtered and well behaved with minimal voltage

overshoot.

Keep DC cables as short as possible (recommend no greater than 2 feet) to

minimize inductive voltage transients.

Size DC cables properly to handle the load current to minimize voltage drop during

times of transmission when current draw is highest.

WARNING:

Turn off external primary DC power before connecting DC power cables.

Connect positive primary power wire (+48VDC) to terminal marked +48VDC and

Page 6

User Manual

040003A010 Rev B Page 6 of 25

negative primary power wire to GND terminal next to it on rear of amplifier.

7. Check your work before applying DC voltage to the system. Make certain all connections

are tight and the DC wires are going to the correct terminals.

8. If the unit has the optional internal AC power supply: Connect an unpowered AC cord to

AC plug on rear of amplifier.

9. Refer to Section 2.2 for initial start-up procedures.

2.2 INITIAL STARTUP

To perform the initial start-up, proceed as follows:

1. Check to ensure that all input and output cables are properly connected and tightened.

NOTE: Use high quality coaxial cable and connectors. Properly install all connectors for

reliability.

CAUTION: Before applying power, make sure that the input and output of the amplifier are

properly terminated in 50 ohms. Do not operate the amplifier without a load attached.

Refer to Table 1-2 for input power requirements. Excessive input power will damage

the amplifier.

NOTE: The output coaxial cable between the amplifier and antenna must be 50 Ohm cable

and adequately sized to handle the rated power level with additional stresses from

high VSWR taken into account. The shield of the 50 Ohm coaxial cable must be

connected to ground at the entrance of the building in which the equipment is installed.

This should be done in accordance with applicable national electrical installation

codes. In the U.S., this is required by Section 820.93 of the National Electrical Code,

ANSI/NFPA 70.

2. Apply 48 VDC from your power supply or AC mains power (depending on whether amplifier

has the optional internal AC power supply) to the amplifier with the supplied line cord. After

a short delay, the fans will power on. Check that all fans are running.

3. Visually check the indicators on the front of the amplifier and verify the following:

a. The PWR ON indicator (green) is on.

b. All other LED indicators (red and yellow) are off.

4. Set the external exciter power level so that it is within the specified input power range and

apply the RF signal to the amplifier input port. The amplifier will deliver nominally 250W

at the output connector. The green exciter drive status LED will illuminate when the RF

drive is detected. This LED is meant to give the user a general indication that the exciter

is active and is delivering output power when troubleshooting an alarm condition.

However, it does not indicate that the minimum input power level has necessarily been

reached.

5. Remove the RF input signal. The output power will drop to zero. Only the Power On

indicator will be illuminated. The amplifier is ready to use.

Page 7

User Manual

040003A010 Rev B Page 7 of 25

3 OPERATING INFORMATION

3.1 INTRODUCTION

This section contains general amplifier operating information

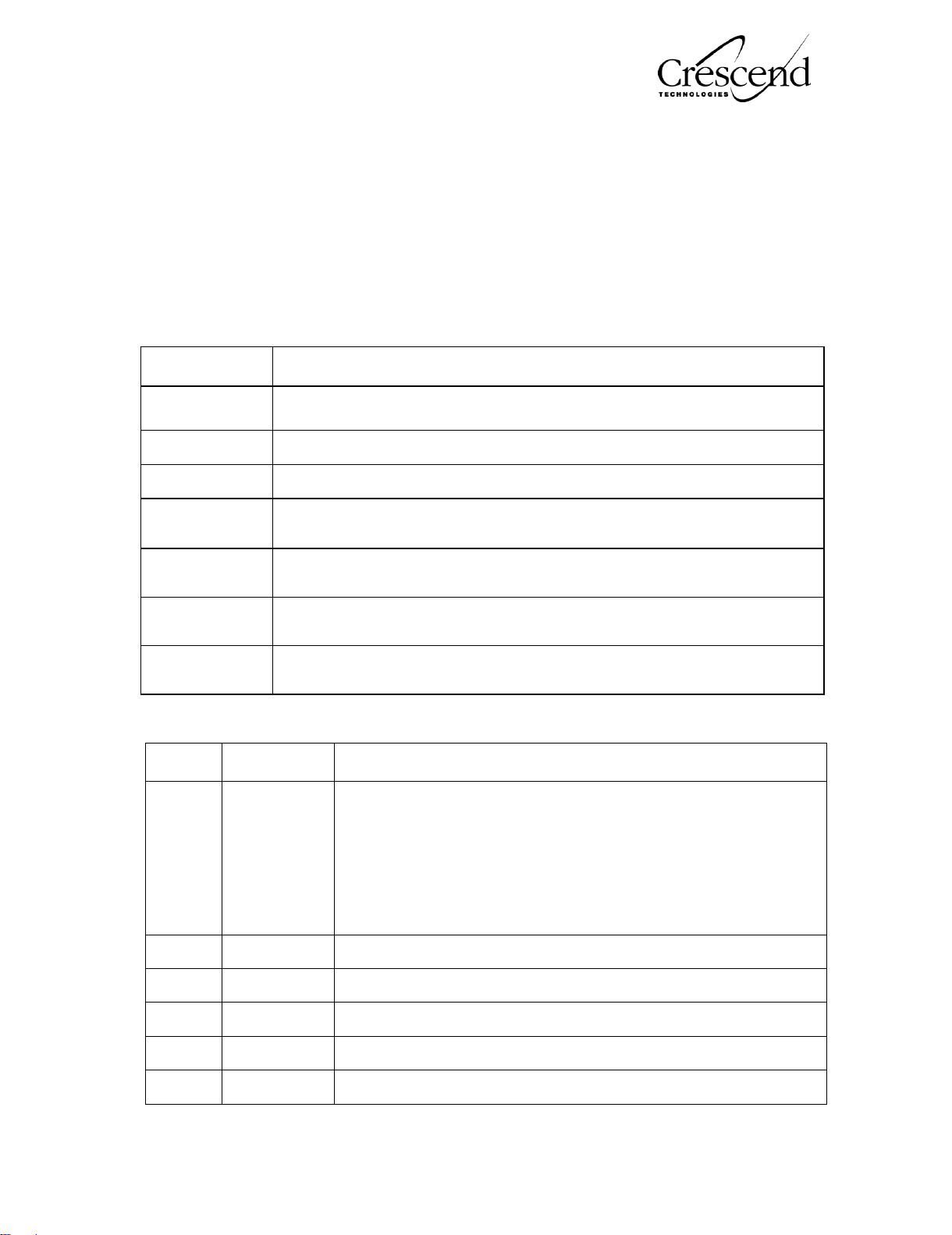

3.2 STATUS INDICATORS AND MONITOR CONNECTOR

The amplifier status indicators and alarms are described in Table 3-1 and Table 3-2.

Table 3-1 High Power UHF Amplifier Status LED Indicators

STATUS LED

FUNCTION

PWR ON

Green LED. Illumination indicates unit is powered on

EXCITER DRIVE

Green LED. Illumination indicates RF input power has been applied

CHECK FAN

Red LED. Illumination indicates low fan speed or a locked rotor

HIGH TEMP

Red LED. Activates when the amplifier exceeds a safe operating temperature. Unit shuts down

until safe operating temperature returns

HIGH VSWR

Red LED. Activates when load VSWR > 3:1. Amplifier shuts down. Alarm active until RF input

removed and reapplied

HIGH INPUT

Yellow LED. Illumination indicates RF input power exceeds safe level (~125%) of rated input

power. Alarm active until RF input removed

LOW OUTPUT

Yellow LED. Can activate if power drops due to low gain or minimum specified input level is not

applied

Table 3-2 Monitor Connector Description

PIN NO

NAME

DESCRIPTION

1

POWER CTL

Output Power Level Control.

POWER CTL signal is pulled up internally to 10V and pulled down by POWER SET

potentiometer located on front panel. To ensure the full adjustment range of output

power from 250W to 25W with POWER CTL signal, make sure POWER SET is

turned fully clock wise (refer to section 3.5 for details).

Both POWER CTL analog input and POWER SET potentiometer can be disabled by

digital communication interface if either “PS=***\r” or “PM=***\r” command is sent to

the amplifier (refer to Table 3-7 in section 0 for details).

2

REV PWR

Reverse Power Voltage

3

GND

Ground Return

4

HI TEMP

Alarm - High Temperature Amplifier Shutdown

5

RXD

RS232 Interface Received Data

6

GND

Ground Return

Page 8

User Manual

040003A010 Rev B Page 8 of 25

PIN NO

NAME

DESCRIPTION

7

HI INPUT

Alarm - RF Input Power Above Maximum Rating

8

CHECK FAN

Alarm - Low fan speed or locked rotor detected

9

PA FAULT

Alarm - Low Output Power, RF Input Power Above Maximum Rating, High

Temperature Amplifier Shutdown, High VSWR or No Power Supply Voltage

10

FWD PWR

Forward Power Voltage

11

HI VSWR

Alarm - High VSWR

12

RF DRIVE

Minimum RF Input Drive Indicator

13

TXD

RS232 Interface Transmitted Data

14

GND

NOT FOR EXTERNAL CONNECTION - DO NOT USE

15

LOW PWR

Alarm - Low Output Power

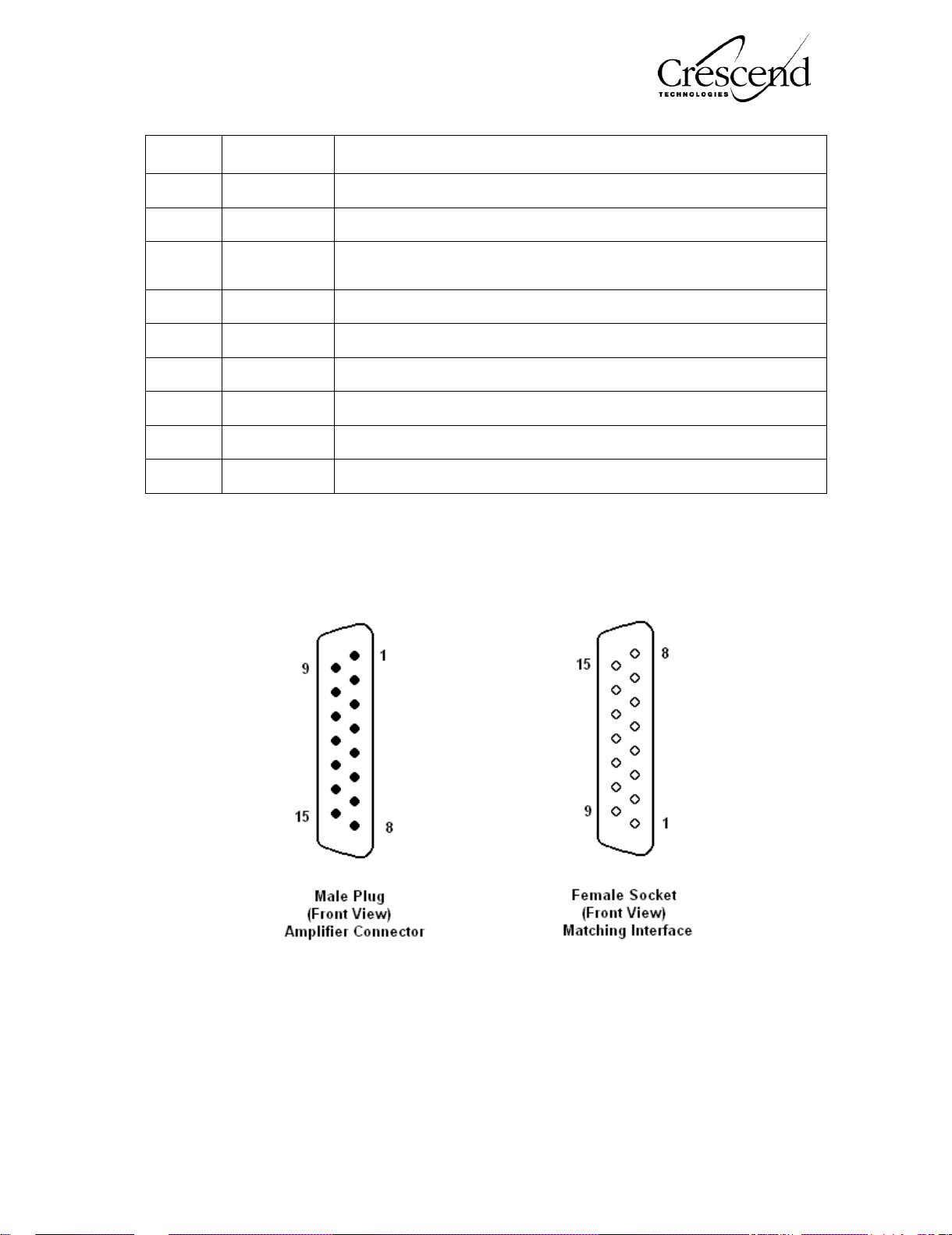

Figure 3-1 DSUB-15 Connector Pin Numbers

Page 9

User Manual

040003A010 Rev A Page 9 of 25

3.3 DETAILED STATUS INDICATOR AND MONITOR CONNECTOR INFORMATION

The detailed amplifier status indicators, alarm truth table and monitor connector information is

described in detail in Table 3-3 through Table 3-5.

Table 3-3 Amplifier Status Indicators

LED NAME

FUNCTION

INDICATION

CONDITION

RECOVERY

PWR ON

DC Power Up

Indicator

Green Light

Power is turned on

Power source is active

Off

Power is turned off

EXCITER

DRIVE

RF Input Power

Indicator

Green Light

RF input power is at or above

threshold. If no other alarms present,

the amplifier is placed into transmit

mode

Set RF input power above threshold

Off

RF power at input is below the

activation threshold. Amplifier is in

standby mode

CHECK FAN

Alarm - Fan

Failure or

Service

Required

Red Light

Alarm - Low fan speed or locked

rotor detected. May require cleaning

or replacement

To reset the alarm, it is necessary to

perform fan maintenance procedure

Off

Normal operation

HI TEMP

Alarm - High

Temperature

Amplifier

Shutdown

Red Light

Alarm – Temperature has exceeded

maximum operation threshold. The

amplifier output is shutdown

To reset the alarm, it is necessary for

the amplifier to cool down to below

the maximum safe operation

threshold

Off

Normal operation

HI VSWR

Alarm - High

VSWR at

Amplifier Output

Red Light

Alarm > 3:1VSWR at the amplifier

output was detected. The amplifier

output is shutdown

To reset the alarm, it is necessary to

remove the high VSWR from the

amplifier output and reapply RF input

power (The alarm will remain

illuminated after RF input power is

removed)

Off

Normal operation

HI INPUT

Alarm - RF Input

Power Above

Maximum Rating

Yellow Light

Alarm - RF power at input exceeds

maximum threshold level

To reset the alarm, it is necessary to

reduce RF drive signal level and

reapply RF input power (The alarm

will remain illuminated after RF input

power is removed)

Off

Normal operation

LOW OUTPUT

Alarm - Low

Output Power

Yellow Light

Alarm – the analog control loop is

open. Amplifier is no longer able to

adjust the output power

Alarm is turned off only when the

analog control loop is closed. Check

if input signal level is within normal

limits. If RF input is within range, and

all other conditions are normal, this

indicates a potential PA failure

Off

Normal operation

Page 10

User Manual

040003A010 Rev A Page 10 of 25

Table 3-4 Alarm Truth Table

Alarm

LED Color

Amplifier

Shutdown

PA Fault

Recovery

CHECK FAN

Red

No

High

Clean fans, replace if defective

HI TEMP

Red

Yes

High

Reduce PA temperature below 65°C

HI VSWR

Red

Yes

High

Input Re-Key

HI INPUT

Yellow

No

High

Input Re-Key

LOW OUTPUT

Yellow

No

High

Set input drive above minimum threshold

Table 3-5 Monitor Connector Description

PIN NO

NAME

SIGNAL

TYPE

DESCRIPTION

SIGNAL

STATES

CONDITION

APPROPRIATE

LOAD

1.

POWER

CTL

Analog

Input

Output Power

Level Control

(refer to section

0 and 3.5 for

limitations)

Open

Maximum output power

Signal is pulled

up internally to

10V. Pull down

signal with

appropriate

circuitry.

0-10V

Adjusts output power setting

2.

REV PWR

Analog

Output

Reverse Power

Voltage

0-10V

Uncalibrated analog voltage that is

proportional to the reflected power

detected at the amplifier output

> 100 kOhm,

< 100pF

3.

GND Ground return

4.

HI TEMP

Digital

Output

Alarm - High

Temperature

Amplifier

Shutdown

<0.8V

Alarm – Temperature has exceeded

maximum operation threshold. The

amplifier output is shutdown. To reset the

alarm, it is necessary for the amplifier to

cool to a temperature below the maximum

safe operation threshold

> 100 kOhm,

< 100pF

>3.3V

Normal operation

5.

RXD

Digital

Input

Received data

RS232

voltages

RS232 communication interface

6.

GND Ground return

Page 11

User Manual

040003A010 Rev A Page 11 of 25

PIN NO

NAME

SIGNAL

TYPE

DESCRIPTION

SIGNAL

STATES

CONDITION

APPROPRIATE

LOAD

7

HI INPUT

Dig

Alarm – High

Input Power

Detected at

Amplifier Input

<0.8V

Alarm – RF input power exceeds

maximum power threshold level. To reset

the alarm, it is necessary to reduce RF

drive signal level and reapply RF input

power (The alarm will remain illuminated

after RF input power is removed)

>3.3V

Normal Operation

8.

CHECK

FAN

Dig

Digital Output

<0.8V

Alarm – Low fan speed or locked rotor

detected. May require fan maintenance or

replacement if defective.

> 100 kOhm,

< 100pF

>3.3V

Normal operation

9.

PA FAULT

Digital

Output

Open Collector

(External Pull-

Up Resistor

Required)

Open

Fault - CHECK FAN, HI TEMP, HI VSWR,

HI INPUT, LOW OUPUT, No Supply

Power

10.

FWD PWR

Analog

Output

Forward Power

Voltage

0-10V

Uncalibrated analog voltage that is

proportional to the forward power detected

at the amplifier output

> 100 kOhm,

< 100pF

11.

HI VSWR

Digital

Output

Alarm - High

VSWR Detected

at Amplifier

Output

<0.8V

Alarm – > 3:1 VSWR at the amplifier

output was detected. Amplifier output is

shutdown. To reset the alarm, it is

necessary to remove the high VSWR from

the amplifier output and reapply RF input

power (the alarm LED will remain

illuminated after RF input power is

removed)

> 100 kOhm,

< 100pF

>3.3V

Normal operation

12.

EXCITER

DRIVE

Digital

Output

Minimum RF

Input Power

Indicator

<0.8V

Minimum RF power on input is present.

With no alarms amplifier is set into

transmit mode

> 100 kOhm,

< 100pF

>3.3V

RF power at input is below an activation

threshold. Amplifier is in standby mode

13.

TXD

Digital

Output

Transmitted

data

RS232

voltages

RS232 communication interface

14.

GND

Ground return (Caution: Not for external

connection, do not use)

14.

Page 12

User Manual

040003A010 Rev A Page 12 of 25

PIN NO

NAME

SIGNAL

TYPE

DESCRIPTION

SIGNAL

STATES

CONDITION

APPROPRIATE

LOAD

15.

LOW PWR

Digital

Output

Alarm - Low

Output Power

<0.8V

Alarm – the analog control loop is open

and unable to adjust the output power

level. Alarm is turned off only when the

analog control loop is closed. Check if

drive level is within normal limits. If RF

input is within range, and all other

conditions are normal, this may indicate a

potential PA failure.

> 100 kOhm,

< 100pF

>3.3V

Normal operation

Page 13

User Manual

040003A010 Rev A Page 13 of 25

3.4 DIGITAL COMMUNICATION INTERFACE (RS232)

The amplifier is supplied with a RS232 digital communication interface that provides status and

alarm information. The communications interface settings are described in detail in Table 3-6.

Table 3-6 Digital Communication Interface Settings

Voltage Level

RS232 voltage levels

Transmission Bit Rates

38.4 Kbps

No of Data Bits

8

Stop Bits

1

Parity

No parity

Flow Control

No flow control

The digital communication interface uses readable ASCII characters. Characters are sent by the

amplifier only in response to commands. Commands and responses are terminated by a carriage

return (“\r”).

If characters are sent to the amplifier before the carriage return (“\r”) and do not match a legal

command, the amplifier ignores the characters and sends no response. The amplifier will respond

to lower case version of commands (e.g. “sn?\r” or “Rt?\r”).

Digital communication commands are described in detail in Table 3-7

Table 3-7 Digital Communication Interface Commands

COMMAND

RETURNED ANSWER

NOTES

“CN?\r”

“CN=*********\r”

Example:

“CN=151238614\r”

Return Crescend serial number.

“SV?\r”

“SV=****\r”

Example:

“SV=0001\r”

Return software version.

“PN?\r”

“PN=**********************\r"

Example:

“PN=P25-20GA3-PS1-C8-

001\r”

Return part number.

“RN?\r”

"RN=****\r"

Example:

“RN=O\r”

Return revision number.

Page 14

User Manual

040003A010 Rev A Page 14 of 25

COMMAND

RETURNED ANSWER

NOTES

“RT?\r”

“RT=***C”

Examples:

“RT=095C”, “RT=-09C”

Return active stage temperature.

“RV?\r”

“RV=**.***V\r”

Example:

RV=47.985V

Return DC supply voltage.

“RC?\r”

“RC=**.***A\r”

Example:

“RC=09.233A\r”

Return DC supply current. Current does

not include fan current.

“EX=1\r”

“EX=1\r”

Enable the external control of output

power level. With the external control

enabled, the power level can be controlled

through POWER SET potentiometer and

POWER CTL analog input. The command

changes registers in the nonvolatile

memory. The external control of output

power level will remain enabled after the

amplifier is powered down. The external

control of output power level is set by

default at the factory.

"PS=***W\r"

Example:

“PS=250W\r”

"PS=***W\r"

Example:

“PS=250W\r”

Set power level. The value range is from

050 to 250 with step 010. The controller

will round any numbers that do not meet

this criterion. The command does not

change registers in the nonvolatile

memory. If the external control of output

power level is enabled prior the command

is send, it will remain enabled after power

down.

"PM=***W\r"

Example:

“PM=250W\r”

"PM=***W\r"

Example:

“PM=250W\r”

Set power level and save into the

nonvolatile memory. The value range is

from 050 to 250 with step 010. The

controller will round any numbers that do

not meet this criterion. The digital control

of output power level will remain enabled

after amplifier power down.

"PS?\r"

"PS=***W\r"

Example:

“PS=250W\r”

“PS=EX\r”

Return power level that is set in the

volatile memory. If the external control of

output power level is enabled, the

amplifier returns “EX” value.

Page 15

User Manual

040003A010 Rev A Page 15 of 25

COMMAND

RETURNED ANSWER

NOTES

"PM?\r"

"PM=***W\r"

Example:

“PM=250W\r”

“PM=EX\r”

Return power level that is saved in

nonvolatile memory. If the external control

of output power level is enabled, the

amplifier returns “EX” value.

"CF?\r"

“CF=1\r”

Return CHECK FAN alarm status.

(0 - alarm; 1 - normal operation)

"F1?\r"

“F1=*****RPM\r”

Example:

“F1=03450-454MHz, 456-

462.5375MHz, 462.7375-

467.5375MHz, 467.7375470 RPM\r”

Return fan 1 speed.

"F2?\r"

“F2=*****RPM\r”

Example:

“F2=03500RPM\r”

Return fan 2 speed.

"FT?\r"

“FT=*****RPM\r”

Example:

“FT=03500RPM\r”

Return CHECK FAN alarm speed

threshold.

“PF?\r”

“PF=*\r”

Example:

“PF=1\r”

Return PA FAULT alarm sate.

(0 - alarm; 1 - normal operation)

“LO?\r”

“LO=*\r”

Example:

“LO=1\r”

Return LOW OUTPUT alarm state.

(0 - alarm; 1 - normal operation)

“HT?\r”

“HT=*\r”

Example:

“HT=1\r”

Return HI TEMP alarm state.

(0 - alarm; 1 - normal operation)

“HI?\r”

“HI=*\r”

Example:

“HI=1\r”

Return HI INPUT alarm state.

(0 - alarm; 1 - normal operation)

Page 16

User Manual

040003A010 Rev A Page 16 of 25

COMMAND

RETURNED ANSWER

NOTES

“HR?\r”

“HR=*\r”

Example:

“HR=1\r”

Return HI VSWR alarm state.

(0 - alarm; 1 - normal operation)

“ED?\r”

“ED=*\r”

Example:

“ED=0\r”

Return EXCITER DRIVE condition state.

(0 - RF input signal present; 1 - no RF

signal at PA input)

* - represents a single char

Page 17

User Manual

040003A010 Rev A Page 17 of 25

3.5 POWER SET CONTROL

The amplifier is equipped with a single turn POWER SET potentiometer located on the front panel.

The potentiometer allows the user to adjust the amplifier output power from 250W down to 25W.

Turning the potentiometer fully clockwise sets the amplifier to the maximum output power level.

POWER SET potentiometer pulls down the POWER CTL signal located in the Monitor connector

(section 3.2 and 3.3). To ensure the full output power adjustment range from 250W to 25W with

POWER SET potentiometer, make sure that POWER CTL analog output is either left open or

connected to a 10V source.

Both POWER SET and POWER CTL can be disabled by the digital communication interface if

either “PS=***W\r” or PM=***W\r” command is sent to the amplifier (refer to Table 3-7 section 0 for

details).

Page 18

User Manual

040003A010 Rev A Page 18 of 25

4 TROUBLESHOOTING

4.1 INTRODUCTION

This section contains a list of potential problems and suggested actions to be taken. If the

suggested corrective action does not eliminate the problem, please contact the Crescend factory

for further instructions.

NOTE: Do not break the seals on equipment under warranty or the warranty will be null and

void. Do not return equipment for warranty or repair service until obtaining RMA and

proper shipping instructions from the factory.

4.2 TROUBLESHOOTING

Refer to Table 4-1 for troubleshooting suggestions.

Table 4-1 Troubleshooting Guide

PWR ON

EXCITER DRIVE

/ RF DRIVE

OUTPUT POWER

STATUS

PA FAULT

CHECK FAN

HI TEMP

HI VSWR HI INPUT

LOW OUTPUT

OTHER

SYMPTOMS

POSSIBLE

CAUSE

SUGGESTED

ACTIONS

ON

ON

Full

power

Low

Amplifier is in

transmit mode.

No action is required.

ON

OFF

No

power

Low

Amplifier remains

in standby mode.

Apply RF input signal

to amplifier.

Input power is

below activation

threshold.

Verify exciter signal

level.

ON

High

ON

Low fan speed due

to dirt.

Clean dirt from fans

and vents

Low fan speed due

to aging.

Obtain RMA to have

amplifier checked at

factory.

Fan rotor locked.

Obtain RMA to have

amplifier checked at

factory.

ON

ON

Low or

no

power

High

ON

Input power is

above activation

threshold but lower

than minimum

specified value.

Verify exciter signal

level.

Input signal

frequency is out of

amplifier operation

band.

Verify exciter signal

frequency.

Page 19

User Manual

040003A010 Rev A Page 19 of 25

PWR ON

EXCITER DRIVE

/ RF DRIVE

OUTPUT POWER

STATUS

PA FAULT

CHECK FAN

HI TEMP

HI VSWR HI INPUT

LOW OUTPUT

OTHER

SYMPTOMS

POSSIBLE

CAUSE

SUGGESTED

ACTIONS

Amplifier failure.

Verify exciter signal

frequency and level.

Obtain RMA to have

amplifier checked at

factory.

ON

ON

Full

power

High ON

High power input

signal level has

been detected.

Turn off input drive.

Verify exciter signal

level.

OFF

OFF

No

power

High

Fuse failure

Disconnect AC cord.

Check fuse and

replace if necessary.

No AC power is

applied to amplifier.

Verify AC power

source.

Power Supply

failure

Obtain RMA to have

amplifier checked at

factory.

OFF

OFF

No

power

High Fans

operate

Amplifier failure

Obtain RMA to have

amplifier checked at

factory.

ON

ON No

power

High ON

Ambient

temperature is

above 60C.

Turn off input drive.

Allow amplifier to cool

down.

Verify cabinet

ventilation and room

air temperature.

Air circulation is

blocked.

Turn off input drive.

Allow amplifier to cool.

Disconnect AC cord.

Clean up air vents.

Remove any obstacles

from air inlet and

outlet.

Page 20

User Manual

040003A010 Rev A Page 20 of 25

PWR ON

EXCITER DRIVE

/ RF DRIVE

OUTPUT POWER

STATUS

PA FAULT

CHECK FAN

HI TEMP

HI VSWR HI INPUT

LOW OUTPUT

OTHER

SYMPTOMS

POSSIBLE

CAUSE

SUGGESTED

ACTIONS

ON

ON

No

power

High ON One or

more

inactive

fans

Fan failure

Turn off input drive.

Allow amplifier to cool.

Disconnect AC cord.

Try removing any

obstacles from fan

blades if present.

Obtain RMA to have

amplifier checked at

factory.

ON

ON

No

power

High

ON

Output load VSWR

is above 3:1.

Turn off input drive.

Check output

connections and

cables for integrity and

tightness.

Check antenna,

combiner, etc. for

proper return loss.

ON

OFF

No

power

Low

ON

Output load VSWR

higher than 3:1 was

detected before RF

input signal was

removed.

ON

ON

Low

power

Low

Low signal is

applied to POWER

CTL pin.

Remove any voltage or

short attached to

POWER CTL pin.

POWER SET

potentiometer is

turned counter

clockwise.

Turn POWER SET

potentiometer fully

clockwise.

4.3 RETURN FOR SERVICE PROCEDURES

When returning products for service to Crescend, please follow the procedures below.

4.3.1 OBTAINING RMA

A Return Material Authorization (RMA) number must be obtained prior to returning equipment to

the factory for service. Please contact our Customer Service Department at 800-872-6233 to obtain

this number. Failure to obtain this RMA number may result in considerable delays in receiving repair

service.

4.3.2 REPACKAGING FOR SHIPMENT

To ensure safe shipment of the amplifier, it is recommended to use the packaging designed for the

amplifier. The original packaging material is reusable. If it is not available, contact Crescend

Customer Service Department for packing materials and information.

Page 21

User Manual

040003A010 Rev A Page 21 of 25

5 MAINTENANCE

5.1 INTRODUCTION

This section contains periodic maintenance requirements for reliable amplifier operation.

5.2 PERIODIC MAINTENANCE

Periodic maintenance requirements are listed in Table 5-1. Table 5-1 also lists the intervals at which

the tasks should be performed.

Table 5-1 Periodic Maintenance

TASK

INTERVAL

ACTION

Clean Air Vents/Check

Fan

30 Days

Inspect and clean per paragraph 5-3.

Verify fans are working properly.

Inspect Cables and

Connectors and General

Site Conditions

6 Months

Inspect signal and power cables for frayed

insulation and proper attachment. Check

RF connectors to make sure that they are

tight. Inspect the lightning protection

system and ground at the site.

5.3 CLEANING AIR INLETS/OUTLETS

The air inlets and outlets should be checked every 30 days and cleaned if necessary. If the

equipment is operated in a severe dust environment, it should be checked and cleaned more often.

If dust and dirt are allowed to accumulate, the cooling efficiency will be diminished. Using either

compressed air or a brush with soft bristles, loosen and remove accumulated dust and dirt from the

air inlet panels.

Check that the fans are running smoothly. A slow running or noisy fan may indicate an imminent

fan failure. Heat is one of the biggest factors in reducing the reliability of the amplifier. Ensure the

fan has access to cool and clean airflow within the rack.

Page 22

User Manual

040003A010 Rev A Page 22 of 25

6 RF ENERGY EXPOSURE

6.1 RF ENERGY EXPOSURE AWARENESS, CONTROL INFORMATION, AND

OPERATIONAL INSTRUCTIONS FOR COMPLIANCE WITH FCC RF EXPOSURE

LIMITS

NOTE: This power amplifier product is intended for use in environments in which personnel

have full knowledge of their exposure and can exercise control over their exposure to

meet FCC limits. This power amplifier is NOT authorized for use by the general

population, consumer, or for use under conditions where unintended or accidental

exposure may occur.

This power amplifier product generates electromagnetic energy in the radio frequency (RF)

spectrum to provide communications between users over a distance. RF energy is one specific

form of electromagnetic energy. Other forms include, but are not limited to, sunlight and x-rays. RF

energy, however, should not be confused with these other forms of electromagnetic energy, which

when used improperly, can cause biological damage. Very high levels of x-rays, for example, can

damage tissues and genetic material.

Experts in science, engineering, medicine, health, and industry work with organizations to develop

standards for safe exposure to RF energy. These standards provide recommended acceptable

levels for personnel who may be exposed to RF energy. The RF exposure levels described therein

include substantial margins of protection.

When properly installed and used, Crescend power amplifier products meet all governmentestablished RF exposure levels. In addition, Crescend recommends specific operating instructions

for users of its power amplifier products. These instructions are important because they inform

users about RF energy exposure and provide simple procedures on how to control it.

Please refer to the following Web sites for more information on the nature of RF energy exposure

and how to control your exposure to assure compliance with established RF exposure limits.

http://www.fcc.gov/oet/rfsafety/rf-faqs.html

http://www.osha.gov/SLTC/radiofrequencyradiation/index.html

6.2 FEDERAL COMMUNICATION COMMISSION REGULATIONS

The FCC rules require manufacturers to comply with the FCC RF energy exposure limits for

communication devices before they can be marketed in the U.S. The FCC further requires users to

be fully aware of and able to control their exposure to meet RF energy exposure limits. This

document includes operating instructions and information required to control your RF exposure and

to satisfy compliance requirements.

6.3 RF EXPOSURE COMPLIANCE, CONTROL GUIDELINES AND OPERATING

INSTRUCTIONS

To control exposure to yourself and others and to ensure compliance with the RF exposure limits,

always adhere to the following guidelines.

1. Crescend power amplifier products are intended for use in fixed communication locations

(e.g. base station sites). The antenna installation must comply with the following

requirements to ensure optimum performance and compliance with the RF energy

exposure limits required by the FCC.

Page 23

User Manual

040003A010 Rev A Page 23 of 25

a. The antenna should be mounted outside the site building on a roof, tower, or other

support structure such that its location is inaccessible to personnel within the

Minimum Permissible Exposure radius (see below).

b. The licensee must undertake the responsibility to manage the site in accordance

with the applicable regulatory requirements. This may include, but is not limited

to, providing advisory notices to all personnel who may be exposed to RF energy

in the vicinity of the antenna, restricting access to areas adjacent to the antenna,

or ceasing use of the power amplifier when RF energy exposure safety cannot be

guaranteed.

2. When the power amplifier is operating, a front panel LED will be illuminated. The power

amplifier will be generating measurable RF energy exposure when transmitting.

3. The maximum permissible exposure (MPE) radius is unique to each base site installation

and is based on several factors such as the transmitter power output level, antenna gain,

feed line loss, etc. It is the responsibility of the licensee to determine the MPE for the base

site installation.

a. For frequencies of operation between 300 and 1500MHz, the maximum exposure

limit is f/1500 mw/cm2, where f = frequency in MHz

b. An example calculation of the MPE radius for a 250 Watt 406.1 MHz transmitter

installation having a 5 dBi gain antenna and 1dB of feedline loss is provided below:

14.1feet

12

inches

feet

169.2inches

2.54

R

inches

compliancefor required (cm) distance 429.7R

S4π

Gn)(Po

R

(numeric)gain 2.512Gn

10Gn

CL-G1G

losscoax dB 1.0 CL

1.1310 CFR 47 See dBi 5G1

cm

mW

0.27067

1500

f

S dBiin gain 2.15 dBd G1

dBdin gain antenna 2.85 dBd

MHz 406 f mWatts 250000 Po

10

G

2

•

•

Page 24

User Manual

040003A010 Rev A Page 24 of 25

4. In instances where the effective antenna gain (antenna gain – feedline loss) differs from

the example above, the MPE radius must be calculated by the licensee. Table 4-1 presents

the results of calculations of the MPE radius for a 250 Watt 406.1 MHz transmitter having

various effective antenna gain values.

Table 6-1 Calculations of the MPE Radius for a 250 Watt 406.1 MHz Transmitter

WARNING: Failure to observe the minimum safe distance radius may result in exposure to RF

radiated energy in excess of the FCC Maximum Permissible Exposure (MPE) limit.

The licensee is responsible for the safe operation of the base site and must ensure

that the Maximum Permissible Exposure limits are observed at all times.

Effective Antenna Gain

(dBi)

Minimum Safe Distance

(meters)

Minimum Safe Distance

(feet)

3.0

3.83

12.6

4.0

4.30

14.1

5.0

4.82

15.8

6.0

5.41

17.7

7.0

6.07

19.9

8.0

6.81

22.3

9.0

7.64

25.1

10.0

8.57

28.1

Loading...

Loading...