Page 1

User Guide

English

399Z1R557B

Dolev

800V+/800V

www.creo.com

2

/800V

3

Page 2

Page 3

Dolev 800V+/800V

User Guide

2

/800V

3

Page 4

Page 5

Copyright

Trademarks

Copyright © 2003 Creo Inc. All rights reserved.

No copying, distribution, publication, modification, or incorporation of this document, in whole or part, is

permitted without the express written permission of Creo. In the event of any permitted copying, distribution,

publication, modification, or incorporation of this document, no changes in or deletion of author attribution,

trademark legend, or copyright notice shall be made.

No part of this document may be reproduced, stored in a retrieval system, published, used for commercial

exploitation, or transmitted, in any form by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the express written permission of Creo Inc.

This document is also distributed in Adobe Systems Incorporated's PDF (Portable Document Format). You may

reproduce the document from the PDF file for internal use. Copies produced from the PDF file must be

reproduced in whole.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Creo wordmark, Creo logo, and the names of the Creo products and services referred to in this document are

trademarks of Creo Inc.

Adobe, Acrobat, and the Acrobat logo are registered trademarks of Adobe Systems Incorporated, and are

registered in the U.S. Patents and Trademark Office and may be registered in other jurisdictions.

Apple, AppleTalk, AppleShare, EtherTalk, LocalTalk, Macintosh, and LaserWriter are trademarks of Apple

Computer, Inc.

Microsoft, Windows, Windows 2000, and Windows NT are trademarks or registered trademarks of Microsoft

Corp.

Xerox is a registered trademark of Xerox Corp.

Other brand or product names are the trademarks or registered trademarks of their respective owners.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Compliance

The Creo equipment referred to in this document complies with the requirements in Part 15 of FCC Rules for a

Class A computing device. Operation of the Creo equipment in a residential area may cause unacceptable

interference to radio and TV reception, requiring the operator to take whatever steps are necessary to correct the

interference.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limitation of Liability

The product, software or services are being provided on an "as is" and "as available" basis. Except as may be stated

specifically in your contract, Creo Inc. expressly disclaims all warranties of any kind, whether express or implied,

including, but not limited to, any implied warranties of merchantability, fitness for a particular purpose and noninfringement.

You understand and agree that Creo Inc. shall not be liable for any direct, indirect, incidental, special,

consequential or exemplary damages, including but not limited to, damages for loss of profits, goodwill, use, data

or other intangible losses (even if Creo has been advised of the possibility of such damages), resulting from: (i)

the use or the inability to use the product or software; (ii) the cost of procurement of substitute goods and

services resulting from any products, goods, data, software, information or services purchased; (iii) unauthorized

access to or alteration of your products, software or data; (iv) statements or conduct of any third party; (v) any

other matter relating to the product, software, or services.

Page 6

Patents

The text and drawings herein are for illustration and reference only. The specifications on which they are based

are subject to change. Creo Inc. may, at any time and without notice, make changes to this document. Creo Inc.,

for itself and on behalf of its subsidiaries, assumes no liability for technical or editorial errors or omissions made

herein, and shall not be liable for incidental, consequential, indirect, or special damages, including, without

limitation, loss of use, loss or alteration of data, delays, or lost profits or savings arising from the use of this

document.

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This product is covered by one or more of the following U.S. patents:

RE37,376

4,558,302

4,743,091

4,992,864

5,049,901

5,079,721

5,103,407

5,111,308

5,113,249

5,122,871

5,124,547

5,132,723

5,150,225

5,153,769

5,155,782

5,157,516

5,208,818

5,208,888

5,247,174

5,249,067

5,283,140

5,291,273

5,323,248

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creo Inc.

3700 Gilmore Way

Burnaby, B.C., Canada

V5G 4M1

Tel: 1-604-451-2700

Fax: 1-604-437-9891

http://www.creo.com

399Z1R557B

Revised September 2003

5,325,217

5,339,176

5,343,059

5,355,446

5,359,451

5,359,458

5,367,360

5,384,648

5,384,899

5,412,491

5,412,737

5,420,702

5,420,722

5,459,505

5,473,733

5,481,379

5,488,906

5,497,252

5,508,828

5,509,561

5,517,359

5,519,852

5,526,143

5,532,728

5,561,691

5,568,595

5,576,754

5,579,115

5,592,309

5,594,556

5,600,448

5,608,822

5,615,282

5,625,766

5,636,330

5,649,220

5,650,076

5,652,804

5,680,129

5,691,823

5,691,828

5,696,393

5,699,174

5,699,740

5,708,736

5,713,287

5,742,743

5,764,374

5,764,381

5,771,794

5,785,309

5,813,346

5,818,498

5,854,883

5,861,904

5,861,992

5,875,288

5,894,342

5,900,981

5,934,196

5,942,137

5,946,426

5,947,028

5,958,647

5,966,504

5,969,872

5,973,801

5,986,819

5,995,475

5,996,499

5,998,067

6,003,442

6,014,471

6,016,752

6,031,932

6,043,865

6,060,208

6,063,528

6,063,546

6,072,518

6,090,529

6,096,461

6,098,544

6,107,011

6,112,663

6,115,056

6,121,996

6,130,702

6,134,393

6,136,509

6,137,580

6,147,789

6,158,345

6,159,659

6,164,637

6,180,325

6,181,362

6,181,439

6,186,068

6,189,452

6,191,882

6,204,874

6,208,369

6,214,276

6,217,965

6,260,482

6,266,080

6,266,134

6,267,054

6,268,948

6,283,589

6,295,076

6,299,572

6,318,266

6,352,816

6,353,216

6,366,339

6,371,026

6,377,739

6,387,597

6,396,422

6,396,618

6,407,849

6,414,755

6,422,801

6,435,091

6,441,914

6,450,092

6,456,396

6,476,931

6,477,955

6,509,903

Page 7

Contents

Using This Manual vii

Who Should Use This Manual ................................................................................................................. viii

1 Safety Precautions 1

Installation Safety Precautions................................................................................................................... 2

General Safety Precautions ....................................................................................................................... 2

Disconnection from the Mains Supply ................................................................................................ 2

Lithium Battery .................................................................................................................................. 2

Maintenance ..................................................................................................................................... 3

Safety Interlocks ................................................................................................................................ 3

Laser Safety Precautions ........................................................................................................................... 4

Warning Labels......................................................................................................................................... 6

2 Introduction to Dolev 800V+/800V2/800V

Introduction to the Imagesetter .............................................................................................................. 14

Imagesetter Front View........................................................................................................................... 15

Imagesetter Rear View............................................................................................................................ 18

Startup ................................................................................................................................................... 20

Shutdown .............................................................................................................................................. 20

Reset Button........................................................................................................................................... 21

Control Panel ......................................................................................................................................... 21

LCD Screen...................................................................................................................................... 22

Soft Buttons and Soft Functions....................................................................................................... 24

Main Screen Soft Functions.............................................................................................................. 25

Specifications ......................................................................................................................................... 28

3

13

3 Media Management 35

Overview ................................................................................................................................................ 36

The Supply Cassettes .............................................................................................................................. 38

Using Two Large Cassettes .............................................................................................................. 38

Unloading the Supply Cassette ........................................................................................................ 39

Mounting Media onto the Supply Cassette ...................................................................................... 40

Loading the Supply Cassette into the Imagesetter ............................................................................ 43

Set Loading (Automatic Media Loading) ................................................................................................. 45

Performing Set Loading via the Control Panel .................................................................................. 45

Cassette Sign In ............................................................................................................................... 46

The Output Cassette............................................................................................................................... 48

Unloading the Output Cassette........................................................................................................ 48

Developing Film with Off-line Processor ........................................................................................... 49

Developing Film (In-line Processor) ................................................................................................... 50

Page 8

vi Dolev 800V+/800V2/800V3 User Guide

The Punch System .................................................................................................................................. 50

Punch System Design and Operation ...............................................................................................51

Punch Calibration ............................................................................................................................ 52

Defining Punch Parameters.............................................................................................................. 53

Removing Stuck Film from the Imagesetter............................................................................................. 56

4 Res-Intensity Calibration 57

Dolev 800V+/800V2/800V3 Calibration Workflow.................................................................................. 58

Film Specifications .................................................................................................................................. 59

Imaging .......................................................................................................................................... 59

Chemistry........................................................................................................................................ 60

Film Handling .................................................................................................................................. 60

Dimensions...................................................................................................................................... 61

Preparing Exposure Strips ....................................................................................................................... 61

Exposing the Strips ................................................................................................................................. 64

Measuring the Density on the Exposed Strips.......................................................................................... 64

Recording New Laser Intensity Values ..................................................................................................... 64

5 Data Configuration Setting 67

Data Connectivity................................................................................................................................... 68

Using TSP Data Cable Link (Data Connectivity)................................................................................. 69

Accessing the Output Device Configuration............................................................................................ 70

The Output Device Handling Window.............................................................................................. 70

Configuring the Dolev 800V+/800V

2

/800V3 Imagesetters....................................................................... 74

Index 79

Page 9

Using This Manual

Who Should Use This Manual ...........................................................viii

Page 10

viii Using This Manual

Who Should Use This Manual

This guide describes the options available with the Dolev® 800V3/800V4

imagesetter. The Dolev 800V+/800V

2

/800V3 imagesetter is a high-speed

large-format internal drum output device. The large exposure format is

convenient for tradeshops and printers. In addition, the Dolev 800V+/

2

800V

/800V3 imagesetter supports the preparation of plate-ready

separation films using the Creo Imposition feature.

Chapter 1, Safety Precautions warns against laser, mechanical and

electrical hazards.

Chapter 2, Introduction to Dolev 800V+/800V2/800V

3

, introduces the

imagesetter, and explains the start up and shut down procedures.

These are followed by the Control Panel description, and the imagesetter

specifications.

Chapter 3, Media Management, explains how to unload the supply

cassette, load film into it, and load it back into the imagesetter.

The following sections explain the media setup functions, how the media

is exposed, ejected into the output cassette and developed, and the last

section explains how to remove stuck media.

Chapter 4, Res-Intensity Calibration, explains how to guarantee high

quality exposures using a unique laser intensity for each plotting

resolution.

Chapter 5, Data Configuration Setting, explains how to configure the

imagesetter with the Brisque.

For further technical information refer to the Dolev 800V+/800V2/800V

Installation Guide, 399Z1R556B.

For further information on error messages refer to the Dolev 800V+/800V

3

800V

Troubleshooting Guide, 653-00095B.

3

2

/

Page 11

Safety Precautions

Read this chapter carefully before installing, operating, or

maintaining the Dolev 800V+/800V

Installation Safety Precautions .............................................................2

General Safety Precautions..................................................................2

Laser Safety Precautions......................................................................4

Warning Labels ...................................................................................6

2

/800V3 imagesetter.

Page 12

2 Chapter 1 – Safety Precautions

Installation Safety Precautions

WARNING: Installation must be done by authorized service personnel only.

WARNING: To avoid the risk of fire, no connections to the supply are to be made

before the service engineer sets the line voltage selector!

General Safety Precautions

Disconnection from the Mains Supply

Dolev 800V+/800V2/800V3 is equipped with a Master circuit breaker,

located at the lower rear part of the imagesetter, and an

located near the Control Panel at the front part of the imagesetter.

On/Off switch,

Lithium Battery

To achieve complete disconnection from the mains supply, the

circuit breaker

WARNING: Switching off only the On/Off switch leaves several circuits of the

imagesetter energized.

must be disconnected (switched to 0 position).

Master

The Dolev 800V+/800V2/800V3 contains a Lithium battery in the CPU

board.

The battery should be replaced by qualified service personnel. The battery

must not to be replaced by the user.

DANGER: Danger of explosion if battery is incorrectly replaced.

Page 13

General Safety Precautions 3

Maintenance

The Dolev 800V+/800V2/800V3 imagesetter is installed and serviced

exclusively by specialized technicians trained in the proper procedures for

working with and adjusting the laser beam power and its optical path.

You are allowed to perform only one (1) maintenance procedure, that is, to

remove film (supply media) stuck on the inside of the imagesetter drum

area. For details, please refer to Chapter 3, Media Management, Removing

Stuck Film from the Imagesetter.

Safety Interlocks

Upon opening a side door or taking out the loading assembly:

• Interlock switches are designed to disconnect power from the motors

and deacivate the laser.

• It may take up to 30 seconds for the spinner motor to halt after a door

is opened. Wait 30 seconds from the time the door is opened before

you dismantle the internal side protective barrier.

• You are forbidden, under any circumstances, to open covers that need a

screwdriver or any other tool to do so.

• Refrain from tampering with the electrical wiring inside the

imagesetter.

WARNING: Some wiring, located inside the electrical boxes, will remain

energized if the Master circuit breaker is not switched off.

• You are forbidden, under any circumstances, to defeat any of the

interlock switches.

While the Imagesetter is switched on and the interlocks are defeated:

• There is power present in the electrical, optical and mechanical

assemblies and inside the imagesetter.

DANGER: Electrical, laser and mechanical hazards exist!

Page 14

4 Chapter 1 – Safety Precautions

Laser Safety Precautions

WARNING: Even brief exposure of the eyes to the laser beam or its reflections

may cause permanent loss or permanent degradation of eyesight.

DANGER: Use of controls and/or adjustments, or performance of

procedures other than those specified in this manual may result in

hazardous radiation exposure.

Upon opening a side door or taking out the loading assembly:

• Interlock switches are designed to disconnect power from the motors

and deactivate the laser.

• You are forbidden, under any circumstances, to defeat any of the

interlock switches.

• You are forbidden, under any circumstances, to open covers that need a

screwdriver or any other tool to do so.

• Refrain from tampering with the electrical wiring inside the

imagesetter.

While the Imagesetter is switched on and the interlocks are defeated:

• There is power present in the electrical, optical and mechanical

assemblies and inside the imagesetter.

DANGER: Electrical, laser and mechanical hazards exist!

Page 15

Laser Safety Precautions 5

For Dolev 800V+/800V2/800V3 (see Figure 1 on page 9 and Figure 2 on

page 10):

• Up to 5 milliwatt of laser power at a wavelength of approx. 650 nm

may be present in the Output optical connector of the Static optics

assembly, Dynamic optics assembly, Optical fibers, Optical fibers

connectors, and on the inside of the imagesetter drum.

• Up to 10 milliwatt of laser power at the same wavelength may be

present inside the Static optics assembly.

WARNING: This laser radiation is hazardous to the eye and skin! Avoid exposure

to the beam and its reflections.

Page 16

6 Chapter 1 – Safety Precautions

Warning Labels

The following pages show the labels and their locations. Please notify Creo

service personnel if any of them are missing or damaged.

DANGER

LASER LIGHT WHEN OPEN AND INTERLOCK DEFEATED.

AVOID EXPOSURE TO BEAM.

K2G954

CAUTION:

HANDS OFF UNTIL

SPINNER MOTOR HAS RESTED!

WAIT 30 SECONDS AFTER

OPENING DOOR.

K2G955

DANGER

LASER LIGHT WHEN OPEN

AVOID EXPOSURE TO BEAM.

K2G956

LASER LIGHT WHEN OPEN

AVOID EXPOSURE TO BEAM.

DANGER

Page 17

Warning Labels 7

CLASS 1

LASER PRODUCT

EN60825, 21CFR 1040

K2G957

DANGER

LASER LIGHT WHEN

OPEN AND INTERLOCK

DEFEATED.

AVOID EXPOSURE

TO BEAM.

K2G958

SEE INSTALLATION

INSTRUCTIONS BEFORE

CONNECTING TO THE SUPPLY

K1F658

LASER LIGHT WHEN OPEN.

DANGER

K8F711

AVOID EXPOSURE TO BEAM

Page 18

8 Chapter 1 – Safety Precautions

DANGER

LASER LIGHT CONDUCTED

THROUGH OPTICAL FIBERS.

AVOID EXPOSURE TO BEAM.

K8F712

374A30170A

Electrical hazard!

Choc electrique!

Elektroschockgefahr!

374A7B951 (374A30170)

374A2G961

Page 19

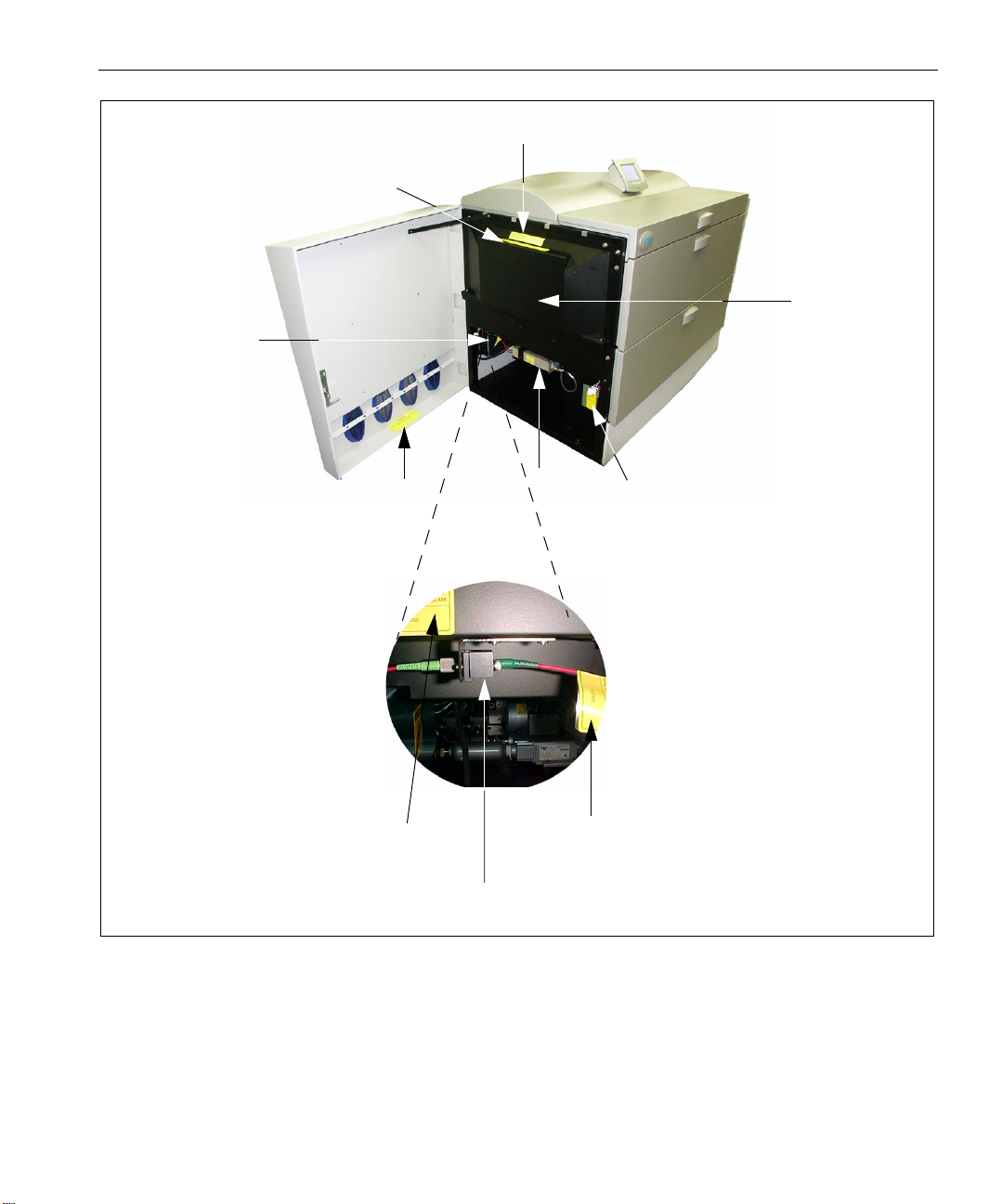

Warning Labels 9

K2G955

K8F711

Internal Side

K2G956

(attached on

the fiber of static optic,

near optical connector)

Protective Barrier

K2G954

K2G956

Fiber connector locker

290F7B8685

K2G956

K2G956

K2G958

Figure 1: Dolev 800V3 - left side door open

Page 20

10 Chapter 1 – Safety Precautions

K2G955

K8F711

K2G958

374A7B951

(374A30170)

K2G954

Figure 2: Right side door open

K8F711

(same on left side)

Figure 3: Right side, internal protective barrier removed

Page 21

Warning Labels 11

Figure 4: Rear view

K1F658

K2G957

Page 22

Page 23

Introduction to

2

Dolev 800V+/800V

/

3

800V

Introduction to the Imagesetter.........................................................14

Imagesetter Front View .....................................................................15

Imagesetter Rear View ......................................................................18

Startup .............................................................................................20

Shutdown.........................................................................................20

Reset Button .....................................................................................21

Control Panel....................................................................................21

Specifications....................................................................................28

Page 24

14 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Introduction to the Imagesetter

3

The imagesetter uses laser optics to output onto film or polyester plates.

Dolev 800V+/800V

2

/800V3 does not require computer experience to

operate. During normal use, once exposure starts, there is no need for

operator intervention since all functions are performed automatically.

The Dolev 800V+/800V

2

/800V3 handles high-volume film output of color

and black-and-white pages of text and graphics, and processes this data to

produce high-quality film output.

Media can be exposed in single or multiple runs continuously, without

operator intervention.

Procedures for film exposure are controlled by the Dolev 800V+/800V

3

micro controller.

800V

2

/

A punch option allows you to define customized registration marks. This

function is especially important when preparing film for impositioning.

The film is automatically cut, exposed and unloaded into a removable

output cassette. At the completion of a work session, the cassette is taken to

a film processor for development. An optional internal conveyor and inline

processor can be used for continuous film development.

The Dolev 800V+/800V

2

/800V3 changes the way images for plateimposition are prepared. Instead of using time consuming step-and-repeat

machines, Dolev 800V+/800V

2

/800V3 prepares plate-ready separation

films to copy directly to plate. Files are transferred from the workstation to

the imagesetter and exposed to the film. The film is then transferred to the

plate department.

Page 25

Imagesetter Front View 15

Imagesetter Front View

[4]

[2]

[5]

[3]

[1]

[6]

[7]

Figure 5: Dolev 800V+/800V2/800V3 Front View

[1] - Left service door

This door allows access to the Drum area. You may open this door to clear

media stuck in the drum area. Service engineers access the electronics and

optomechanics via the service doors.

[2] - Supply cassette compartment door

The small and medium supply cassettes are loaded via this door.

[3] - Large cassette door

The large supply cassette is loaded via this outer door.

Note: Another inner door is located behind this outer door.

Page 26

16 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

[4] - Control Panel

Film loading and most basic operations are performed via the Control

Panel. In addition, the

top of the Control Panel. The

Reset switch. The imagesetter is turned

Reset switch [a] is recessed behind the bezel at the

On/Off switch [b] is also located next to the

on/off using this switch.

3

[a]

Figure 6: Reset and On/Off Switches

[b]

[5] - Right service door

This door allows access to the Drum area. You may open this door to clear

media stuck in the drum area. Service engineers access the electronics and

optomechanics via the service doors.

[6] - Output cassette door

The output cassette is located behind this door. Exposure media can be

output either to the output cassette or to an in-line processor.

[7] - Adjustment legs

Four (4) adjustment legs are used to level the imagesetter. Before moving

the unit, unlock the legs.

Wheels

Four (4) wheels allow easy positioning of the imagesetter. Once the

machine is in place, the adjustment legs are locked into position and the

wheels are ineffective.

Page 27

Imagesetter Front View 17

Large supply cassette (#1)

This is a 34 inch wide cassette suitable for film widths from 10 to 34 inch in

one inch step intervals.

[B]

[A]

Figure 7: Dolev 800V+/800V2/800V3 Small and Medium Cassettes

[A] - Small supply cassette

This is a 12 inch wide cassette for film widths 10, 11 and 12 inch.

[B] - Medium supply cassette

This is a 20 inch wide cassette suitable for film widths from 10 to 20 inch in

one inch step intervals.

Page 28

18 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Imagesetter Rear View

[1]

3

[2]

[6]

[4]

[5]

Figure 8: Dolev 800V+/800V2/800V3 Rear View

[9]

[1]

[3]

[7]

[1] - Upper service panel

The panel is not removed.

[2] - In-line processor panel (not shown)

Remove the panel if you connect to the in-line processor.

[8]

[3] - Lower service panel

Use the panel to access the power distribution unit, and the vacuum

system.

[4] - Fan

The fan does not require maintenance. It does require that the imagesetter

be kept at least 70 cm. from the wall.

Page 29

Imagesetter Rear View 19

[5] - Punch system (optional) pressure inlet

[6] - Connection to in-line processor

The in-line processor is an option for the Dolev 800V+/800V2/800V3.

[7] - Power inlet

The power cord is connected here.

[8] - Master circuit breaker

If a power surge or some other electrical problem has shorted power to the

imagesetter, check the breaker.

[9] - Vacuum pump outlet

Outlet for vacuum pump.

Turbo Screening connection

The Turbo Screening board is connected via a host cable 30 meters long:

For Dolev 800V+/800V2 - between the E-Box (SOMC) and the TSP inside

the Brisque.

For Dolev 800V

Brisque.

For further information about Turbo Screening see the TSP Board Installation

Guide.

3

- between the E-box (MB-SOMC) and TSP 100 inside the

Page 30

20 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Startup

To start up the imagesetter:

1. Make sure that the Master circuit breaker ([9] in the Imagesetter rear

view above) is

Figure 9: Master circuit breaker

Press the On/Off switch on the Control Panel.

2.

UP.

3

Shutdown

Under normal conditions, leave the Dolev 800V+/800V2/800V3 working at

all times (you do

not need to turn off the power overnight).

If you intend to leave the imagesetter idle for 48 hours, turn off the

imagesetter:

¾ Press the On/Off switch to turn off the imagesetter.

Note: During normal operation, do not shut down the power using the Master

circuit breaker. In case a power surge or some other electrical problem has

shorted power to the imagesetter, the circuit breaker may shut down the

machine (that is, it will be in the DOWN position); to turn on the power, pull the

circuit breaker upwards.

Page 31

Reset Button 21

Reset Button

The Reset button is located on the right side of the Control Panel.

¾ In case of a software error (that is, when the Control Panel or the

imagesetter is

to resume work.

Note: Depressing the Reset button does not help in case of stuck media or

media out.

not responding to commands), depress the Reset button

Control Panel

The Dolev 800V+/800V2/800V3 sends the imagesetter options, status and

error messages to the Control Panel.

The Control Panel is located on the middle of the upper part of the

imagesetter.

[4]

[3]

[1]

[2]

Page 32

22 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

The Control Panel contains the following:

[1] - LCD screen

[2] - 4 soft buttons

[3] - On/Off Switch

[4] - Reset Button

3

LCD Screen

For details on the

On/Off Switch and Reset Button, refer to the Startup,

Shutdown and Reset section on the previous page.

The LCD screen displays a variety of text (such as, messages) and graphical

representations (such as, icons, and imagesetter views) that inform you of

the current status of the imagesetter and of the cassettes.

In addition, it displays menus and windows through which you may

perform both basic and advanced operations related to the machine and to

the exposure media.

The LCD screen standby is shown below:

[1]

[2]

[4]

[3]

Page 33

Control Panel 23

The display on the LCD screen consists of the following areas:

[1] - Imagesetter Micro Version

[2] - Current Process (or Progress Indicator)

[3] - Status of Loading Cassette

[4] - Soft Functions

Current Process/Progress Indicator

This area (on the top left part of the screen) displays the name of the

process that is currently running, or the current state of the imagesetter.

The startup process includes 12 stages, some of which are indicated by

StartUp # (# specifying a number), while others are indicated by the name

of the task, for example,

STANDBY - appears when the imagesetter is ready to expose, i.e. film is

already loaded, and both the Loading and Unloading drawers are closed.

NOT READY - appears when the imagesetter is not ready to expose (for

example, film is not loaded or one of the drawers/doors is open).

Attach.

HostOnLine - appears when communication between the Host and the

imagesetter has been established (for example, at the beginning of the

expose process or after selecting Get Params from Plotter).

Progress Indicator

When the imagesetter is exposing, a Progress indicator is displayed in the

Current Process area.

The pie chart fills from 0% to 100% when the exposing is completed.

Imagesetter Micro Version

This area (on the top of the screen) displays the number and the date of the

imagesetter Micro software version that is currently installed on the

Imagesetter PC.

Page 34

24 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Status of Loading Cassette

This area (on the left side of the screen) displays three (3) bars that

represent the Loading cassettes.

Soft Buttons and Soft Functions

Four (4) soft Buttons are located below the LCD screen of the Control

Panel. Press the requested soft button to activate the function that is

indicated on the LCD screen directly above it.

3

Four (4) soft

Functions are indicated on the bottom part of the LCD screen.

Each soft function indicates the action that is activated when you press the

corresponding soft button below it.

Note: The functionality of a specific soft button is variable and depends on the

soft function that is currently indicated on the LCD screen.

¾ To return to the previous function, press the SHIFT + ESC soft buttons.

Page 35

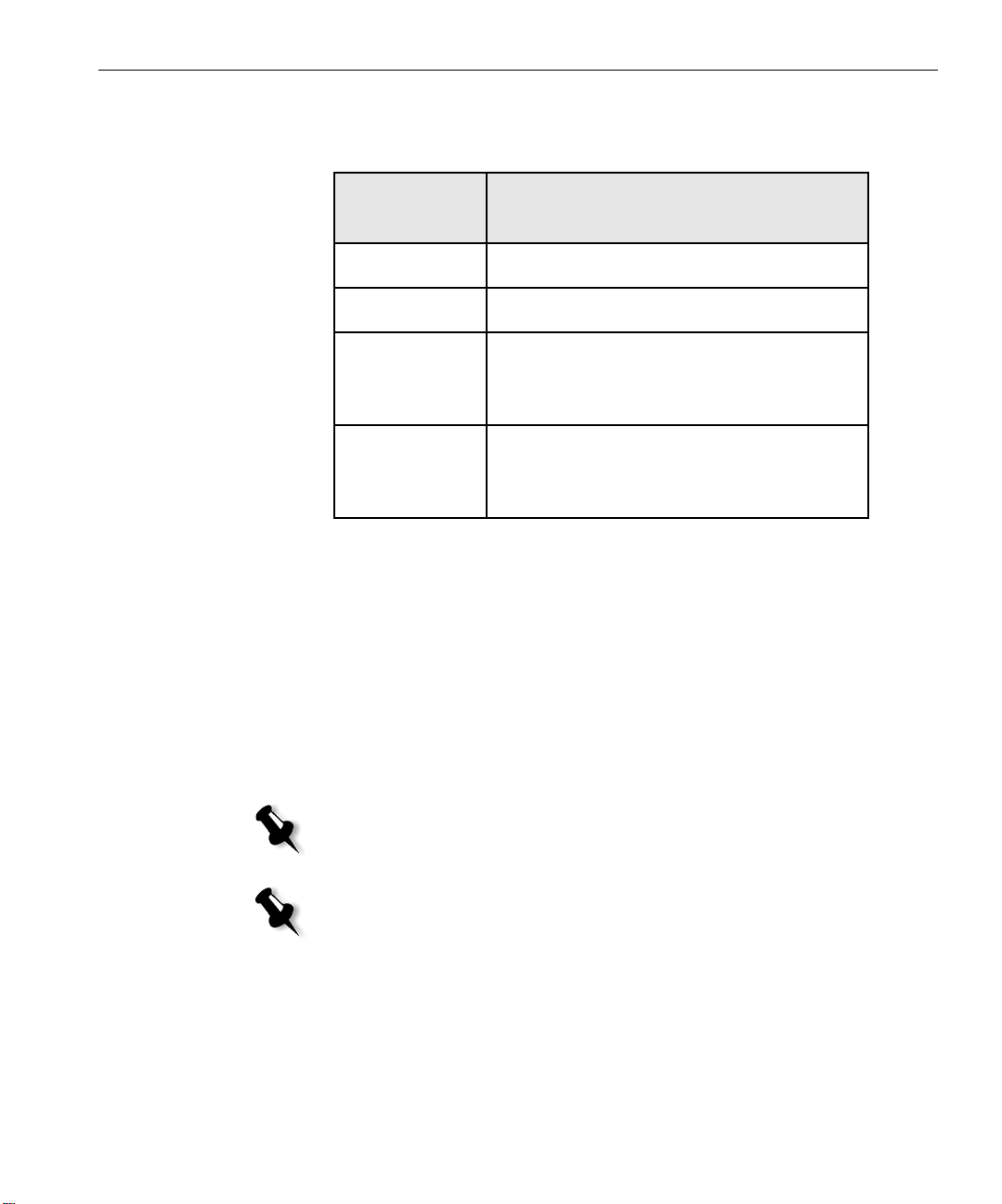

Control Panel 25

Main Screen Soft Functions

In STANDBY state the soft buttons function as follows:

Press the soft

button

Abort

Status

Params

To...

Stop the current process

View system messages.

View the parameters of the last/current

exposure that the Host sent to the

Imagesetter.

Util

Perform various functions related to the

exposure media, and to get information on

the media.

Utilities

Set Loading

Use this option to automatically cut the section of the media that was

exposed to light, and dispose of it in the unloading cassette/inline

processor.

¾ Move the Cassette field to LRG, MED, or SML (the default), according

to the size of cassette currently used.

Note: If the machine does not work properly at 0 parameter, the engineer must

change it. To do this, go to: Tools > Operation > Setup > Factory Table >

Conveyor Delay Time.

Note: If you are using 2 large cassettes, toggle the field to LWR (lower) or UPR

(upper).

Update Cst Mode

Use this option to indicate whether you wish to use one or two large

cassettes.

Page 36

26 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

After you select Update CasMode from the menu, the Update CasMode

form appears.

¾ Toggle the Large Csts Mode field to 1 cst (the default) for 1 large

cassette (together with one small cassette and one medium cassette), or

2 cst for 2 large cassettes.

to

Media Info

Use this option to set the parameters of the selected cassette. After you

select the Cassette from the menu, the

Media Info table appears:

3

Parameter Range Default Do the following...

Current Length

0 - 61 61 The default (61 m) specifies that the loaded film is a full

roll. If you did not load a full roll of film, enter the

current length (in meters). This is the only field that

updates during exposure.

Material

Media

Thickness

Media Width

Res/Int Table #

Film, Plate,

Paper

Film Toggle this field to Film (the default), Plate, or Paper,

according to the media you loaded.

4 - 7 4 Toggle this field to 4 mil (the default) or to 7 mil,

according to the media you loaded.

254 - 838 304 Enter the width of the media you loaded.

- 1 Toggle this field to 1 (the default) to automatically select

a Res/Intensity table to suit the vendor (if such is

indicated in the Vendor field).

If the loaded film is not of the same type as the one

previously loaded, toggle this field to the appropriate

Res/Intensity table number.

Page 37

Control Panel 27

Parameter Range Default Do the following...

Full Length

Vendor

0 - 63 61 Enter the length of a full roll of film.

Note: If you loaded a full roll of film, this value is identical to

that of Current Length.

- None Toggle this field to None (the default) in order to use the

table specified in the Res/Int Table field.

Toggle this field to the name of the vendor of the loaded

media to use the Res/Int table that is specified in the

Res/Int Table # field. Note: If the Res/Int Table specifies

0, the system automatically selects a Res/Int table to suit

the specified vendor.

Mechanical Startup

This function will activate the mechanical start up procedure.

Use the function after opening one of the doors or if you want to set back

the machine to standby.

Active Task Operation

This function will show the parameters during the active task.

Slave Board Statuses

This function will show the status of the boards.

Messages

This function will show the messages from the machine.

Tools Operation

The tools operation are tools for service engineer.

Page 38

28 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Specifications

Tab le 1: Te c h n o l o g y

3

Structure

Dolev 800V+ Dolev 800V

Large-format,

Internal Drum

Large-format, Internal

Drum

2

Dolev 800V

Large-format,

Internal Drum

3

Light Source

Spot Size

Repeatability

Spinner

Raw Imaging Speed

@100 lpmm/ 2540 dpi

@ 80 lpmm/ 2032 dpi

@ 50 lpmm/ 1270 dpi

Laser Diode 650 nm

wavelength

Light Power 5

milliwatts

variable, 10-25

microns

±5µm οver the full

format of

successively imaged

films, disregarding

any distortion caused

by temperature,

humidity and film

material.

Air bearing up to

24,000 rpm

37.27 cm2/second

(346 in

89.3 cm

(831 in

2

/min)

2

/second

2

/min)

Laser Diode 650 nm

wavelength

Light Power 5

milliwatts

variable, 10-25

microns

±5µm over the full

format of successively

imaged films,

disregarding any

distortion caused by

temperature,

humidity and film

material.

Air bearing up to

45,000 rpm

2

/min)

2

/min)

2

/second (564

2

/second (882

60.7 cm

in

94.9 cm

in

Laser Diode 650 nm

wavelength

Light Power 5

milliwatts

variable, 10-25

microns

±5µm over the full

format of

successively imaged

films, disregarding

any distortion

caused by

temperature,

humidity and film

material.

Air bearing up to

45,000 rpm

4995 / 774

6283 / 974

10053 / 1558

Throughput

@100 lpmm/ 2540 dpi

@ 80 lpmm/ 2032 dpi

(full formats per

hour)

10 full formats/hr

(80 A4 pages/hr)

12 full formats/hr

(96 A4 pages/hr)

(full formats per

hour)

16.2 full formats/hr

(130 A4 pages/hr)

21.4 full formats/hr

(171 A4 pages/hr)

(full formats per

hour)

23 full formats/hr

27 full formats/hr

Page 39

Specifications 29

Tab le 1: Te c h n o l o g y

3

@ 50 lpmm/ 1270 dpi

Dolev 800V+ Dolev 800V

17 full formats/hr

(136 A4 pages/hr)

28.6 full formats/hr

(229 A4 pages/hr)

2

Dolev 800V

36 full formats/hr

Brisque

Table 2: Image Features

Maximum Net Image

Area

Page Formats

Capability

Press Formats

Capability

Resolution

TSP / VLSI TSP TSP 100

Dolev 800V+ Dolev 800V

838 x 1117 mm (33 x

44 in)

Up to 8*A4, 4*A3,

2*A2, 8*B4, 4*B3,

2*B2, 1*B1

Heidelberg GTO,

SM52, SM74, SM102

MAN Roland 100,

200. 600

Komori 26, 28, 44

50-200 pixels/mm,

1270-5080 dpi;

continuously

variable.

Optional lower and

higher resolutions

838 x 1117 mm (33 x

44 in)

Up to 8*A4, 4*A3,

2*A2, 8*B4, 4*B3,

2*B2, 1*B1

Heidelberg GTO,

SM52, SM74, SM102

MAN Roland 100,

200. 600

Komori 26, 28, 44

50-200 lpm, 12705080 dpi;

continuously

variable.

Up to 400 lpm

(10,000 dpi) for

security printing

models (UHR)

2

Dolev 800V

838 x 1117 mm (33 x

44 in)

Up to 8*A4, 4*A3,

2*A2, 8*B4, 4*B3,

2*B2, 1*B1

Heidelberg GTO,

SM52, SM74, SM102

MAN Roland 100,

200. 600

Komori 26, 28, 44

50-200 lpm, 12705080 dpi;

continuously

variable.

Up to 400 lpm

(10,000 dpi) for

security printing

models (UHR)

3

Screen Technology

Creo Turbo Screening

including

conventional dot

shapes: round,

square, diamond,

gravure. Creo

composite,

GeometricDOT and

FM.

Creo Turbo Screening

including

conventional dot

shapes: round,

square, diamond,

gravure. Creo

composite,

GeometricDOT and

FM.

Creo Turbo Screening

including

conventional dot

shapes: round,

square, diamond,

gravure. Creo

composite,

GeometricDOT and

FM.

Page 40

30 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Table 2: Image Features

3

Screen Ruling

Dolev 800V+ Dolev 800V

(frequency) 20-246

lpcm / 50-625 lpi

(frequency) 20-246

lpcm / 50-625 lpi

2

Dolev 800V

(frequency) 20-246

lpcm / 50-625 lpi

3

Screen Angles

User-selectable from

a variety of preset

angles.

Table 3: Media and Related Features

Dolev 800V+ Dolev 800V

Types of Media

Roll, medium to high

contrast, red sensitive,

film or polyester

plates

Media Width

254-863 mm in steps

of 25.4 mm 10–34 in.

in steps of 1 in

Media Length (inside

Drum)

Min. 420 mm (15 in);

Max. 1200 mm

(47 in)

Thickness and

Capacity

60 m/200 ft at

0.1 mm/4 mil

30 m/100 ft at

0.2mm/8 mil

User-selectable from

a variety of preset

angles.

2

Roll, medium to high

contrast, red sensitive,

film or polyester

plates

254-863 mm in steps

of 25.4 mm 10–34 in.

in steps of 1 in

Min. 450 mm (16 in);

Max. 1200 mm

(47 in)

60 m/200 ft at

0.1 mm/4 mil

30 m/100 ft at

0.2mm/8 mil

User-selectable from

a variety of preset

angles.

Dolev 800V

3

Roll, medium to

high contrast, red

sensitive, film or

polyester plates

254-863 mm in steps

of 25.4 mm 10–34 in.

in steps of 1 in

Min. 450 mm (16

in); Max. 1200 mm

(47 in)

60 m/200 ft at

0.1 mm/4 mil

30 m/100 ft at

0.2mm/8 mil

Page 41

Specifications 31

Table 3: Media and Related Features

3

Load/ Unload System

Dolev 800V+ Dolev 800V

Fully automatic from

three selectable

loading cassettes.

Vacuum film holddown. Dual unload

options: unload

cassette or inline

processor.

Fully automatic from

three selectable

loading cassettes.

Vacuum film holddown. Dual unload

options: unload

cassette or inline

processor.

2

Dolev 800V

Fully automatic from

three selectable

loading cassettes.

Vacuum film holddown. Dual unload

options: unload

cassette or inline

processor.

Loading Cassette

Unloading Cassette

Inline Processor

Punch System

Three different size

cassettes for rolls,

including daylight

film. Sizes up to:

304, 508, 863 mm

(12, 20, 34 in)

or

Two optional large

(863 mm/

34 in) cassettes

instead of three

cassettes.

One, accumulating

cut sheet type, 12

sheets capacity for

0.1 mm/4-mil film.

Optional (refer to

recommended list)

Customized head

punch up to

10 holes.

Optional, Bacher and

Stasser standard.

Three different size

cassettes for rolls,

including daylight

film. Sizes up to:

304, 508, 863 mm

(12, 20, 34 in)

or

Two optional large

(863 mm/

34 in) cassettes

instead of three

cassettes.

One, accumulating

cut sheet type, 12

sheets capacity for

0.1 mm/4-mil film.

Optional(refer to

recommended list)

Customized head

punch up to

10 holes.

Optional, Bacher and

Stasser standard.

Three different size

cassettes for rolls,

including daylight

film. Sizes up to:

304, 508, 863 mm

(12, 20, 34 in)

or

Two op ti o n a l l a r g e

(863 mm/

34 in) cassettes

instead of three

cassettes.

One, accumulating

cut sheet type, 12

sheets capacity for

0.1 mm/4-mil film.

Optional(refer to

recommended list)

Customized head

punch up to

10 holes.

Optional, Bacher

and Stasser standard.

Page 42

32 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Table 4: Environment

Dolev 800V+ Dolev 800V

2

Dolev 800V

3

3

Electrical

Requirements

Operating

Environment

Temperature:

Relative

Humidity:

Audible Noise:

Heat

Dissipatoin:

Area

Requirements

200/220/240 VAC, ±

10%

Europe: Single Phase,

50/60 Hz ± 2 Hz

USA/Japan: 2 Phase

50/60 Hz ± 2 Hz

Power

Less than 3 KVA

23°C ± 3°C

73.4°F ± 5.4°F

55% ± 5% RH

<55dbA

2500 BTU/hr

200/220/240 VAC, ±

10%

Europe: Single Phase,

50/60 Hz ± 2 Hz

USA/Japan: 2 Phase 50/

60 Hz ± 2 Hz

Power

Less than 3 KVA

23°C ± 3°C

73.4°F ± 5.4°F

55% ± 5% RH

<55dbA

2500 BTU/hr

200/220/240 VAC, ±

10%

Europe: Single Phase,

50/60 Hz ± 2 Hz

USA/Japan: 2 Phase 50/

60 Hz± 2 Hz

Power

Less than 3 KVA

23°C ± 3°C

73.4°F ± 5.4°F

55% ± 5% RH

<55dbA

2500 BTU/hr

6.7 square meters 6.7 square meters 6.7 square meters

Table 5: Physical Dimensions

Dolev 800V+ Dolev 800V

Dimensions

Height: 1230 mm

(48 in)

Width: 1650 mm

(65 in)

Depth: 1000 mm

(39 in)

Weight

550 kg (1210 lb) 550 kg (1210 lb) 550 kg (1210 lb)

2

Height: 1230 mm

(48 in)

Width: 1650 mm (65 in)

Depth: 1000 mm (39 in)

Dolev 800V

3

Height: 1230 mm

(48 in)

Width: 1650 mm

(65 in)

Depth: 1000 mm

(39 in)

Page 43

Specifications 33

Tab le 6: R I P

Dolev 800V+ Dolev 800V

2

Dolev 800V

3

Brisque

Processor: Power PC

604

Ty pe : Software

Operating System:

AIX

Architecture: CPSI

with composite

workflow and

Turbo Screening

CPU Speed: 332 MHz

and up

Interpreter: Postscript

Levels 2

and 3

DataFormats: PDF,

Postscript, EPS,

DCS1, DCS2, TIFF/

IT-PI, CopyDot

(scanned film),

(N)LW, CT, ICF

(Imposition Control

File), Brisque Page.

Communication

Formats:

Built-in Helios

EtherShare, NFS,

TCP/IP.

Processor: Power PC

604

Ty pe : Software

Operating System:

AIX

Architecture: CPSI

with composite

workflow and

Turbo Screening

CPU Speed: 332 MHz

and up

Interpreter: Postscript

Levels 2

and 3

DataFormats: PDF,

Postscript, EPS, DCS1,

DCS2, TIFF/IT-PI,

CopyDot (scanned

film), (N)LW, CT, ICF

(Imposition Control

File), Brisque Page.

Communication

Formats:

Built-in Helios

EtherShare, NFS, TCP/

IP.

Dual Processor: Power

PC 604

Ty pe : Software

Operating System:

AIX

Architecture: CPSI

with composite

workflow and

Turbo Screening

CPU Speed: 332 MHz

and up

Interpreter: Postscript

Levels 2

and 3

DataFormats: PDF,

Postscript, EPS,

DCS1, DCS2, TIFF/

IT-PI, CopyDot

(scanned film),

(N)LW, CT, ICF

(Imposition Control

File), Brisque Page.

Communication

Formats:

Built-in Helios

EtherShare, NFS,

TCP/IP.

Page 44

34 Chapter 2 – Introduction to Dolev 800V+/800V2/800V

Tab le 6: R I P

3

PS/M

Dolev 800V+ Dolev 800V

Macintosh platform:

Power Macintosh 604,

604e with Apple OS 6

or 7.5.3 or higher

Macintosh platform:

Power Macintosh 604,

604e with Apple OS 6

or 7.5.3 or higher

2

Dolev 800V

Macintosh platform:

Power Macintosh 604,

604e with Apple OS

7.5.3 or higher

3

Prinergy

RIP: Software type,

Adobe CPSI with

composite workflow

and Turbo Screening

Data Formats: PDF,

Postscript, EPS,

DCS1, DCS2, TIFF/

IT-PI, CopyDot

(scanned film), LW

CT, ICF (Imposition

Control File).

Communication

Formats

:

Appletalk, TCP/IP.

RIP: Software type,

Adobe CPSI with

composite workflow

and Turbo Screening

Data Formats: PDF,

Postscript, EPS, DCS1,

DCS2, TIFF/IT-PI,

CopyDot (scanned

film), LW CT, ICF

(Imposition Control

File).

Communication

Formats

:

Appletalk, TCP/IP.

CS Xpose with

DataFormats: PDF,

Postscript, EPS, DCS1,

DCS2, TIFF/IT-PI,

CopyDot (scanned

film), LW CT, ICF

(Imposition Control

File).

RIP: Software type,

Adobe CPSI with

composite workflow

and Turbo Screening

Data Formats: PDF,

Postscript, EPS,

DCS1, DCS2, TIFF/

IT-PI, CopyDot

(scanned film), LW

CT, ICF (Imposition

Control File).

Communication

Formats

:

Appletalk, TCP/IP.

CS Xpose with

DataFormats: PDF,

Postscript, EPS,

DCS1, DCS2, TIFF/

IT-PI, CopyDot

(scanned film), LW

CT, ICF (Imposition

Control File).

or Direct connectivity

through 1-bit tiff

Table 7: Specification Performance

Class 1 Laser Product according to IEC Standard 825-1

or Direct connectivity

through 1-bit tiff

Page 45

Media Management

The Dolev 800V+/800V2/800V3 imagesetter accepts film or

polyester plates. The media is loaded onto a supply cassette and

inserted into the imagesetter. You can select one of three supply

cassettes: a small (12in), medium (20in) or large (33in) cassette.

Overview ..........................................................................................36

The Supply Cassettes ........................................................................38

Set Loading (Automatic Media Loading)............................................45

The Output Cassette .........................................................................48

The Punch System.............................................................................50

Removing Stuck Film from the Imagesetter........................................56

Page 46

36 Chapter 3 – Media Management

t

Overview

The Dolev 800V+/800V2/800V3 imagesetter accepts film or polyester

plates. The media is loaded onto a supply cassette and inserted into the

imagesetter. You can select one of three supply cassettes: a

medium (20 inch) or large (34 inch) cassette.

small (12 inch),

heigh

Imagesetter

Media width

Figure 10: Dolev 800V+/800V2/800V3 Film

You access the media setup functions by moving through a tree-like series

of menus on the host computer screen. All the functions can also be

accessed through the imagesetter Control Panel.

2

The Dolev 800V+/800V

/800V3 has an automatic media setup

mechanism. Once the supply cassette is inserted, performing the Set

Loading procedure (via the Control Panel or the workstation) starts film

loading.

The media is pulled between a set of rollers onto the exposure drum. The

media is cut, and a vacuum system ensures that the media is held down on

the inner drum surface.

Page 47

Overview 37

Film on

Film cutter

F

c

Film roller

F

t

During setup, the imagesetter cuts and ejects the first piece of media. This

is done since a small piece of media was exposed to light when the cassette

was carried from the darkroom.

The next step is to expose the media. You choose the file, the file resolution,

and layout (these topics are covered in the user guide of the relevant host

workstation).

The media is exposed and ejected. The ejected media is sent to the output

cassette, or to an optional inline processor.

The following figure shows the media path in the imagesetter.

arms

ilm guide

o conveyor

ilm

onveyor

exposure

drum

Small (12")

supply cassette

Film loading

mechanism

Large (33")

supply cassette

Film guides

to output

cassette

Output

cassette

Figure 11: Dolev 800V+/800V2/800V3 media path (left-side view)

Note: Since the medium cassette is located to the right of the small cassette, it

is not seen in the figure.

Page 48

38 Chapter 3 – Media Management

The Supply Cassettes

The three (3) Dolev 800V+/800V2/800V3 supply cassettes are used with

medium to high contrast red sensitive light or line film, paper, or polyester

plates.

The steps you follow when loading new exposure media:

• Unloading the supply cassette and taking it to the darkroom.

• Mounting media onto the supply cassette.

• Loading the supply cassette into the imagesetter.

• Performing Set Loading and Cassette Sign In.

Using Two Large Cassettes

The option to use two Large cassettes enables higher efficiency.

To use 2 large cassettes, do the following:

• Remove the small and medium cassettes as well as the separator plate

in between them.

• Load film into another large cassette.

• Place new large cassette where the small and medium cassette were.

• Change the mode in the machine to Two Large Cassettes.

• From the workstation, configure the Dolev again.

Page 49

The Supply Cassettes 39

Unloading the Supply Cassette

1. To unload either the small (12 inch) or medium (20 inch) cassette,

open the Supply cassette compartment door

locking bar

[2].

[1]

[2]

[1], and push back the

[3]

Figure 12: Unloading the Small or Medium Supply Cassette

Remove the cassette [3] and take it to the darkroom.

2.

Page 50

40 Chapter 3 – Media Management

3. To unload the large (34 inch) cassette [1], open the Large cassette door

[2] (located on the front on the imagesetter) and then open the

additional

inner door [3].

Figure 13: Unloading the Large Cassette

Remove the cassette and take it to the darkroom.

4.

Mounting Media onto the Supply Cassette

1. Check that the film you intend to load on the cassette is in the

darkroom before you lock the door and turn

CAUTION: Dolev 800V+/800V2/800V3 requires a bright cyan light source for

film development. Do not use red or yellow illumination!

2. Close and lock the door to the darkroom.

3. Tu r n on the bright cyan light.

4. Two latches secure the cassette lid. To open the supply cassette, push

the latches horizontally toward the center of the cassette, and pull up

the lid until it is in a resting position.

off the lights.

Page 51

The Supply Cassettes 41

1

Supply cassette

o

e

Removable

F

s

C

f

pening latch

Inch film lead

Film: Emulsion

side down

Smart electronic

NVM

Cassett

handle

Figure 14: Opening the Supply Cassette

Grasp the outer surface of both flanges and lift the film spool out of

5.

the supply cassette.

Two flanges are attached to the spool, namely the

removable flange.

ilm: Emulsion

ide down

radle prongs

or spool

fixed flange and the

mounting

Spool

Exposure

media

Fixed

flange

Figure 15: Lifting the Film Spool out of the Supply Cassette

Lid

Cassette

latch

Cassette

handle

Page 52

42 Chapter 3 – Media Management

6. Twist the inner rim of the removable flange and, using the supplied

tool, remove it from the spool.

7. Place the new roll of film on the table.

Note the film position: rolled away from the cassette, emulsion down.

Note: If the cassette contains a film roll, remove it from the spool. Place any

unexposed film in a film case or container, and mark it.

1. Open supply

cassette lid

2. Remove mounting

flange from spool

3. Place film roll

emulsion side

down

Figure 16: Removing the Film Spool

Grasp the spool by the fixed flange, and insert the spool through the

8.

film roll (film emulsion down).

9. Place the removable flange onto the spool, and twist it to tighten it on

the spool.

10. Lower the spool into the cassette, so that its ends fit between the

prongs of the cradle. Allow approximately 1 inch of film to stick out,

over the edge of the cassette.

Note: If too much film sticks out, cut the excessive part (do not push it back).

11. Check that the film is straight (that is, parallel to the cassette lid), and

shut the cassette lid.

12. Lead film cutter (supplied) can be used to trim the film to the

required length.

Page 53

The Supply Cassettes 43

Loading the Supply Cassette into the Imagesetter

Note: Before leaving the darkroom and loading the cassette, double-check that

you have protected any unexposed film.

To load a small or medium cassette:

1. Open the Supply cassette compartment door [1], and push back the

locking bar

2. Load the cassette [3,4] so that the film extends from the bottom of the

cassette toward the rear of the imagesetter (that is, away from you).

3. Fold down the cassette handles [5]. Pull the locking bar forward.

[2].

[1]

[2]

[3]

Figure 17: Loading the Small or Medium Cassette

Close the Supply cassette compartment door.

4.

[5]

[4]

Page 54

44 Chapter 3 – Media Management

To load the large cassette:

1. Open the Large cassette door [1] (located on the front on the

imagesetter) and then open the additional inner door

2. Place the cassette on the inner door and slide the cassette [3] into

[2].

place.

[3]

[4]

[2]

[1]

Figure 18: Loading the Large Cassette

Fold down the cassette handles [4] and close the inner cassette door.

3.

4. Close the Large cassette door. The Media Info window appears on the

Control Board.

At this stage you need to perform the Set Loading and Cassette Sign In

procedures described below.

Page 55

Set Loading (Automatic Media Loading) 45

Set Loading (Automatic Media Loading)

The Set Loading procedure assists you during the loading process. During

loading, the section of media exposed to light must be cut.

automatically loads a minimum length of media onto the drum, cuts the

exposed media, and ejects it into the output cassette.

You must then unload and discard the length of film that was exposed to

light. Do this before you begin your first exposure.

Set Loading may be performed via the Control Panel (as explained on the

following page), or via the host workstation.

Performing Set Loading via the Control Panel

1. At STANDBY, press the <Util> soft button.

Utilities menu appears; the pointer cursor points to

The

Set Loading.

2. Press the Done soft button.

Set Loading

3. Press the Next-Value soft button to toggle the SML in the Parameter

area to

Note: To cancel the selection, press the Esc operator button.

4. Press the Done soft button to confirm the selection of the desired

MED or LRG as desired.

supply cassette.

5. When loading is completed successfully, the following appears on the

Control Panel:

PASS

6.

Press the ESC soft button to return to the Utilities menu, or the ERROR

soft button to see a list of errors (if such exist).

Page 56

46 Chapter 3 – Media Management

After performing Set Loading (via the Control Panel or the host

workstation), proceed as follows:

1. Open the Output cassette door, and slide out the output cassette.

2. Open the output cassette, remove the exposed film, and dispose of the

film.

3. Put the output cassette back in the imagesetter. You are now ready to

expose film on the imagesetter.

For a detailed explanation, see The Output Cassette on page 48.

Cassette Sign In

Whenever you load a new supply cassette into the imagesetter, you must

Sign In the cassette.

Cassette Sign In records the type of media, manufacturer, batch number,

and the length of media on the cassette.

The information is used to automatically select the correct exposure values

for your specific media type. It is very important that you provide as much

information as possible about the cassette media. Once you record this

information, it is stored on the cassette and used during media exposure.

Cassette Sign In may be performed via the Control Panel (as explained

below), or via the host workstation.

Page 57

Set Loading (Automatic Media Loading) 47

Performing Cassette Sign In via the Control Panel

1. At STANDBY, press the Util soft button; the Utility menu appears.

2. Select the cassette you are registering in the Media Info menu:

Medium, Small, Lower or Upper (Lower and Upper refer to the large

cassette):

a. Update the required parameters: cassette size, media type, media

thickness

b. Select the media type: film or polyester plate.

c. Select the media thickness: 4 mil or 7 mil.

Note: The media catalog number contains the code for the media thickness.

Note: If you use the incorrect media thickness, it will cause misregistration.

d. Register the initial length of the media on the cassette.

If the cassette contains less than a full roll of film, modify the

length in the

e. Select the vendor (manufacturer).

3. Press the Done soft button.

, etc.

Parameter area.

Note: If the machine does not work properly at 0 parameter, the engineer must

change it. To do this, go to: Tools > Operation > Setup > Factory Table >

Conveyor Delay Time.

Page 58

48 Chapter 3 – Media Management

The Output Cassette

The output cassette is track mounted on the imagesetter door. If the

cassette is installed, the film is ejected into the cassette.

Note: The imagesetter may output film to an output cassette, or through an

internal conveyor directly to a processor. The following explanations describe the

output cassette only.

Unloading the Output Cassette

¾ Press the handle [1] on the imagesetter Output cassette door [2], and

open the door.

Tip: Grasp the cassette [3] by its handle, and pull the cassette towards you to

remove it.

Figure 19: Unloading the Output Cassette

[3]

[1]

[2]

Page 59

The Output Cassette 49

Developing Film with Off-line Processor

CAUTION: Do not open the output cassette until you are in the developing

area and the door is LOCKED.

1. Carry the output cassette to a darkroom which is equipped with a

bright cyan light.

2. Close the developing room door and lock it. Turn on the cyan light.

3. To open the output cassette, press the three (3) fasteners on the front

of the cassette and open the cassette lid upwards.

4. Remove the exposed films one at a time, and feed each piece of film

into the processor.

Note: You may find one narrow strip of film in the cassette (less than 4

inches wide). This is the piece of film that was exposed to light when a new

supply cassette was loaded onto the imagesetter. Dispose of this waste film.

5. Depending on your processor, you receive a signal from the processor

when you are allowed to feed each subsequent film. When you have

fed the last film into the processor and received the signal that the feed

is complete, you may unlock the door.

Note: Be sure to check the bottom and sides of the cassette carefully for any

film that may have slid into the base of the cassette.

6. Load the output cassette back into the imagesetter, and close the

output cassette door.

Page 60

50 Chapter 3 – Media Management

Developing Film (In-line Processor)

1. Align the imagesetter to the in-line processor with lips located on the

back of the imagesetter.

2. Connect the communication cable between the processor and the

imagesetter.

3. Change the selector position to in-line mode.

4. Send a setloading from each cassette: Small, Medium and Large.

5. Ve r i f y normal feed via the in-line processor.

The Punch System

Creo offers a leading edge, customer-defined punch system for the

2

Dolev 800V+/800V

/800V3.

The punch system is used by printers to eliminate the need for mounting

film to carrier sheets, manual registration and punching.

A maximum of 10 punch assemblies can be installed in the imagesetter

width direction, on the right flange of the Dolev 800V+/800V

2

/800V3

drum.

To assist Creo and the customer in the punch system definition, Punched

Film Layout form has been prepared. The customer and the Creo engineer

should complete all requested values on this form.

Note: Since numerous configurations are available and some restrictions exist

(such as, minimum hole distances, hole size, and hole placement relative to the

exposed area), Creo assists in the punch system definition. This ensures that all

details regarding the customer's punch system are transmitted to the local Creo

experts.

Based on the information which is gathered, Creo prepares a confirmation

drawing for customer approval. This drawing is subsequently used by the

Creo engineer when installing the punch system.

Note: Although filling the form is not a pre-requisite for ordering a punch

system, the system can not be installed without the customer-approved

confirmation drawing supplied by Creo.

Page 61

The Punch System 51

Punch System Design and Operation

The moving part of the punch assembly is the unit. It can be either in the

OUT position or in the IN (punching) position.

The moveable cutting blade of the punch is the

either in the

OUT position or in the IN position.

rod. Like the unit, it can be

Both rod and unit are activated by air cylinders. There are two doubleaction air cylinders (not spring-activated) per punch assembly. The punch

system therefore requires a continuous, external air pressure supply for

operation.

An additional operation of every punch assembly is the ejection of used

film slugs from the system. Three blasts of compressed air are used to

achieve this

.

The film slugs are collected into a large black hose, located near the

unloading cassette. You should empty this hose 2 to 4 times per month.

Note: This operation is performed following the film punch, and before moving

the punch rod to its OUT position.

The following describes a typical punching sequence:

Sequence leads to Result

Unit

IN◊

--> brings unit to punching

position

One (1) sec. delay◊

--> allows pressure stabilization

Rod IN◊

One (1) sec. delay ◊

Three (3) blasts of air◊

One (1) sec. delay◊

Rod OUT

One (1) sec. delay◊

Unit OUT◊

--> executes film punch

--> allows pressure stabilization

--> ejects used film slug

--> releases pressure completely

--> returns to OUT position

--> allows pressure stabilization

--> returns unit to OUT position

Page 62

52 Chapter 3 – Media Management

Punch Calibration

The calibration of the punch system should be done only after the

exposable area is calibrated.

1. After installing the punch system, expose a full format with punch

requested, without alignment to punch (AutoArrange or Single with

alignment "none" ).

2. Check that the file is still exposed entirely after the punch system is

installed. If not, repeat exposable area calibration.

3. Check that the central punch hole is exactly at the position across the

center of the file. If not, calibrate the punch central hole.

4. Only after the central hole of the punch system is calibrated to the full

format center, continue with the rest of the punch-system's

calibration. After calibration is complete, check again exposure of a

full format file and the location of its center in relation to the punch

system.

5. Start the punch pivot calibration by setting the punch pivot to 820 H

(Center Height), 558 W (Center Width) [NVM screen, Cri, Service

Tables, Punch Settings]. Drag a full format file on an expose template,

request bottom-center alignment to the punch with a -10,0 mm offset

from pivot [job ticket launcher, expose dialog, punch subdialog].

a. If the Brisque announces that the file exceeds the exposable area

on the left or right side, add/subtract to the punch W pivot setting

(in the plotter) according to the message.

b. Initiate the plotter configuration dialog, press the "punch" button

in the dialog and check that the punch pivot is identical to the

pivot value entered in the plotter.

c. If the Brisque announces that the file exceeds the exposable area

on the top or bottom side, change the alignment of the file now

requesting bottom-center alignment, with a -10± (exceeding

value), 0 mm offset from punch pivot.

d. Repeat the exposure of the file.

e. Check again that the punch central hole is exactly at the requested

offset from the file's bottom center. If not, adjust the punch pivot

setting accordingly. Repeat exposure after initiating the plotter

configuration dialog and check offset again.

Page 63

The Punch System 53

Defining Punch Parameters

Use the Punch option to designate a punch system and define the punch

alignment parameters.

To define the punch parameters:

1. Click the Punch check box. The Params button next to it is enabled.

2. Click Params. The Punch dialog box appears. The options that appear

in the window vary, depending on the connected output device, and

on the selected punch system.

Page 64

54 Chapter 3 – Media Management

Item Description

Exposable

Area

Pivot Position

Punch System

Alignment

Offset from

punch

Displays the maximum image size supported by the

imagesetter. The exposable area is defined according

to the cassette’s exposable area.

Exposable Area =

cassette’s size - offset values of output device. Varies

between Dolev 4press and Dolev 800. You cannot edit

these boxes.

Displays the existing punch configuration. They

indicate the position of the punch hole that is defined

as the pivot (normally the round hole). You cannot

edit these boxes.

(If the selected

Punch System is External, this option

is unavailable.)

Enables you to select a punch system from a list of

available systems.

Designates the point on the image to be the reference

point (for example, the top-left) when you position

the image relative to the punch.

If you select

None, or External, you will not be able to

define an offset.

Defines exactly where the reference point (top-left,

bottom-right, and so on) is positioned relative to the

punch. Default is 0,0.

If the defined Alignment is None or External, the

Offset boxes are disabled.

Minimum Film

Feed

Note: Each punch system has one origin (pivot), or

reference point, from where the measurements of the

alignment are made. The plus and minus signs in the R-icon

indicate a positive or negative offset and the direction. A