Page 1

ContactDetails

Pleasenotethatsomeofthecontactdetailson

thisPDFdocumentmaynotbecurrent.

Pleaseusethefollowingdetailsifyouneedto

contactus:

Telephone:08448793588

Email:customer.services@gdcgroup.co.uk

TheHelpCentresectionofthiswebsitealsofeaturesawiderange

ofinformationwhichmaybeofusetoyouandisavailable24

hoursaday.Itincludes:

• Operatingandinstallationinstructionsdownloads

• Requestarepair

• Wheretobuyourproducts

• Literaturedownloads

•

Heatingrequirementcalculator

www.credaheating.co.uk/help‐centre

A division of GDC Group Ltd

Millbrook House Grange Drive Hedge End Southampton SO30 2DF

www.credaheating.co.uk

Registered No: 1313016 England

VAT GB 287 1315 50004

EEE Producer Registration Number –

WEE/GE0057TS

Paper from sustainable sources

Page 2

Installation and Operating Instructions

Models Covered:

CSQ15

CSQ30

CSQ45 08/51150/0 Issue 0

IMPORTANT

These instructions should be read and carefully retained by the user. ∗

The installation of these appliances must always be carried out by a competent ∗

electrician and be in accordance with the current wiring regulations and relevant

Building Regulations.

The radiated heat from the heater is considerable and must be taken into account

∗

when locating the heater. Ensure that the heater is not used in close proximity to

the skin or eyes.

Always isolate the heater from the supply before undertaking any maintenance

∗

work on the appliance.

The CSQ range of heaters are designed for internal use only. They are not rated as

∗

ame-proof and must not be used when ammable dusts, gases, or vapours, etc.

are likely to be present in the atmosphere. If in doubt, advice should be sought

from the Health and Safety Executive inspectors or local re ofcers.

Quartz lamps are extremely fragile and must be handled with extreme care at all

∗

times. Avoid touching the surface of the quartz sleeve with bare ngers. If the

sleeve is accidentally touched remove the nger print with a soft cloth moistened

with methylated spirits.

This heater must not be located immediately above or below a xed socket outlet

∗

or connection box.

WARNING – THIS APPLIANCE MUST BE EARTHED.

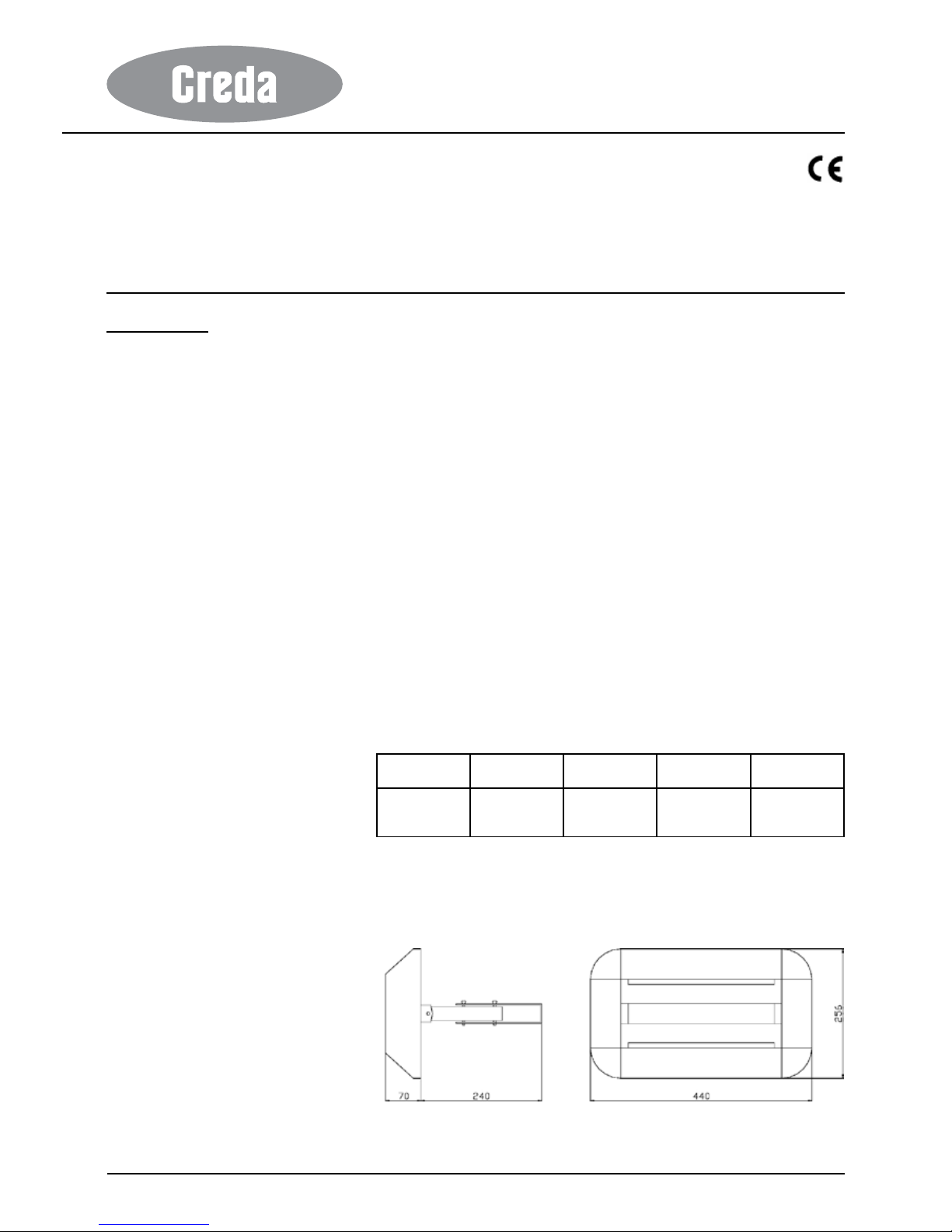

SPECIFICATIONS

The Creda CSQ range is available in 1,2 and 3 lamp models with outputs of 1.5kW,

3.0kW and 4.5kW respectively. The 4.5KW model is supplied as a dual voltage unit and is

suitable for use on 230V ~ 1PN and 400V ~ 3PN supplies.

General Data:

Model No. No. of Lamps Rating

(kW)

Voltage

(V)

Weight

(kg)

CSQ15

CSQ30

CSQ45

1

2

3

1.5

3.0

4.5

230V ~ 1PN

230V ~ 1PN

230V ~ 1PN

3.7

4.3

5.8

Material and Finished

Body Casing – Low carbon steel, powder coated.

Reectors – 1080 (SIA) 99.8% Alum. Electrochemically brightened specular nish.

DIMENSIONS

CSQ15

All dimensions in mm

Page 3

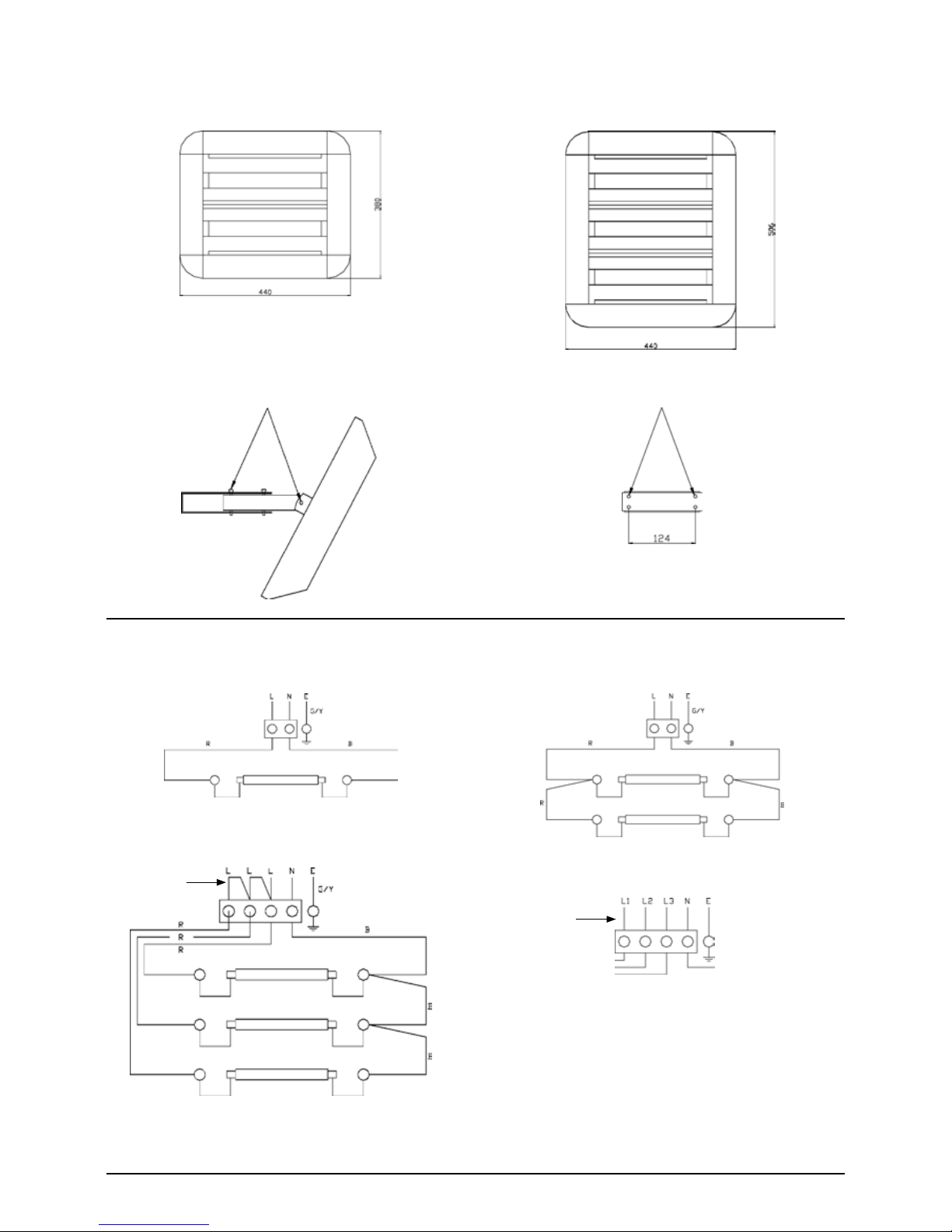

CSQ30

All dimensions in mm

CSQ45

UNIVERSAL BRACKET MOUNTING

ANGLE ADJUSTMENTS

4 FIXING HOLES

WIRING DIAGRAMS

CSQ15

CSQ30

CSQ45

(a) External connections for 230V ~ 1PN (b) External connections for 400V ~ 3PN

G/Y = GREEN/YELLOW

R = RED

B = BLACK

LINKS MUST

BE FITTED

HEATER WIRING

AS OPPOSITE

CABLE ALL MODELS 2.5MM

2

SILICONE INSULATED

LINKS MUST

BE REMOVED

Page 4

1. Location

The siting of the heater(s) should be such as to allow an even and uninterrupted

distribution of radiation to the area(s) to be heated. Heaters are most effective when the

beam angle is inclined down at an angle of 30º to 45º to the vertical.

2. Mounting IMPORTANT

When deciding upon the best location, consideration must be given to the following

requirements.

(a) Avoid structures liable to vibration, e.g. crane gantries, which could otherwise

adversely affect lamp life.

(b) The lamps are designed to operate within 5º of the horizontal plane. It is very

important to ensure that the heater is mounted horizontally, otherwise the

operating life of the lamp could be impaired.

(c) Allow a minimum of 0.5 metre clearance between the top of the heater and the

ceiling. (Dimension ‘C’ on the appliance rating label.) Allow a minimum of 1.5

metre clearance between the edge of heater and the adjacent wall facing that

edge. (Dimension ’B’ on the appliance rating label.)

(d) Ensure appliance is mounted the correct way up so that it can be tilted down but

not up.

Mounting height: Allow the following mounting height between the base of the heater and

the oor. (Dimension ‘A’ on the appliance rating label.)

Model No. Rating

(kW)

Min. Height

(m)

Recommended Height

(m)

CSQ15

CSQ30

CSQ45

1.5

3.0

4.5

2.1

2.5

3.0

2.5

2.5-3.5

3.5

Note: If more than one heater is to be installed, ensure that the lamps of adjacent

heaters are more than 3.5 metres apart.

Mounting Brackets

Heaters are supplied with a universal bracket which may be xed through the mounting

holes to any suitable structure. The bracket allows the heater to be inclined to the required

angle from the vertical and permits the heater to be swivelled laterally. It is recommended

that when inclined from the vertical and swivelled care is taken to ensure that the lamps

are still horizontal. WARNING – THESE HEATERS ARE DESIGNED TO BE WALL

MOUNTED ONLY – THEY MUST NOT BE CEILING MOUNTED. THEY MUST NOT BE

MOUNTED IN A ROOM CONTAINING A BATH OR SHOWER.

ENSURE THE HEATER IS MOUNTED A MINIMUM DISTANCE OF 3.5M FROM

ADJACENT CURTAINS AND SOFT FURNISHINGS.

3. Electrical Supplies

Wiring to the heater must be installed in compliance with the requirement of the wiring

regulations and any local or insurance regulations.

All heaters are suitable for use on 230V ~ 1PN single phase supplies. The 4.5kW model

is supplied as a dual voltage unit and is also suitable for use on 400V ~ 3PN three phase

supplies.

Heaters must be protected by fuses to the following rates:

Model No Input Rating

(kW)

Current Rating

(A)

Fuse Rating

(A)

230V ~ 1PN 400V ~ 3PN 230V ~ 1PN 400V ~ 3PN

CSQ15

CSQ30

CSQ45

1.5

3.0

4.5

6.25

12.5

18.75

-

-

6.25/Ph

10

13

20

-

-

10/Ph

Wiring between the heater and the spur outlet or isolation switch must be in a heat

resisting cable (e.g. butyl rubber or high temperature PVC insulated). Sufcient slack

cable must be left to allow for angular adjustment of the heater body.

An all-pole isolating switch with a minimum separation of 3mm in each pole must be tted

adjacent to the heater to facilitate local isolation.

If miniature circuit breakers are to be used, to avoid ‘nuisance tripping’ due to the high in

rush at switch on, a type 3 or ‘C’ rated MCB with a tripping coefcient of 7-10 times rated

current should be used. Any other switching device should be Tungsten lamp load rated.

4.5kW heaters must be connected in accordance with the instructions. When connecting

to 400V three phase supplies the links must be removed from the terminal block (see

wiring diagrams section B). When using the heater on 230V ~ 1PN supplies the “Danger

400V” notice should be removed from the terminal cover.

∗ Always ensure that the cable grip is tightened. ∗

Page 5

4. Coverage for Spot Heating

Applications

The area heated by a Quartz Halogen Heater depends on the height and the angle at

which the heater is mounted.

For 30° Heater Mounting Angle:

Area Covered = (Height)² x 2.66

Average Width of Beam = Height x 2.0

Throw of Beam = Height x 1.33

For 45° Heater Mounting Angle:

Area Covered = (Height)² x 5.72

Average Width of Beam = Height x 2.2

Throw of Beam = Height x 2.6

*Note:

Area covered, width and throw of beam are

measured at oor level.

The table below indicated throw and spread

measured 1 metre above oor level which may

be a more appropriate measurement for some

applications.

The following tables show the recommended mounting heights for three typical average

intensity requirements:

Average

Radiant

Intensity

on Heated

Area

(W/m²)

CSQ15 CSQ30 QXD45

Height

(m)

Throw

(m)

Spread

(m)

Height

(m)

Throw

(m)

Spread

(m)

Height

(m)

Throw

(m)

Spread

(m)

Angled 30° from vertical

150 2.9 2.5 3.8 3.7 3.6 5.4 4.4 4.4 6.7

200 2.7 2.2 3.3 3.4 3.1 4.7 3.9 3.8 5.8

250 2.5 2.0 3.0 3.1 2.8 4.2 3.6 3.4 5.2

Angled 45° from vertical

150 2.3 3.4 2.9 2.9 4.9 4.2 3.3 5.6 5.0

200 2.1* 2.9 2.4 2.6* 4.1 3.5 3.0* 5.2 4.4

Note

Intensity is average intensity in W/m² based on Wattage of heater and area covered 1.

and measured on a horizontal plane 1m above the oor level.

Heater mounting heights are in metres and are above oor level. Those marked ‘*’ are 2.

minimum mounting heights for the particular heater model.

Throw and spread gures are in metres.3.

Page 6

5. COMMISSIONING

Checks on the electrical installation should include earth continuity and insulation tests 1.

and must be undertaken by a competent person.

Ensure that all the electrical connections at the lamps and the terminal rails have been 2.

made correctly, that they are tight and that there is no loose or frayed wire.

Replace and secure the terminal cover and replace and secure the front panel.3.

Check that the mounting bracket is securely xed in the vertical position such that the 4.

lamps remain in a horizontal plane at all angles of heater displacement.

Roughly align the heater(s) and tighten the adjusters.5.

Switch on the heater(s) and check that the lamp(s) are all operating. If time or 6.

temperature controls are tted check these for correct and safe operation by reference

to the supplier’s instructions.

Make any adjustments that are necessary to give an even spread of heat over the 7.

required area. This may be done simply by perception of the heating effect or by using

the distribution of visible light either at night or by darkening the room.

Hand over

Hand over these instructions and make sure the user is familiar with all aspects of

operation and safety including the need for regular cleaning and an annual inspection.

In the event of the premises being unoccupied then leave heater(s) switched off and

isolated from the electrical supply. Leave instructions adjacent to the electricity meter.

6. MAINTENANCE

Since the Creda Quartz Heater contains no moving parts little maintenance is required

beyond cleaning the lamp replacement. It is however, essential that the heater is not

operated with accumulation of dust or dirt on the lamp(s) or reector(s) as this can cause

a build up of heat and eventual damage. For this reason the heater must be inspected

regularly depending upon conditions and at least at yearly intervals.

Before undertaking any maintenance work on the heater due attention must be paid to the

following:

Always disconnect the heater from the electricity supply before attempting to work on 1.

or near it.

Always ensure a safe means of access using an access tower or properly supported 2.

ladder.

Some types of quartz lamps run with an internal pressure in excess of atmospheric 3.

pressure and while construction is very strong there is a slight risk of shattering. If it is

necessary to examine a bare lamp whilst in operation then a protective screen must

be used.

Allow adequate time for the lamps and body casing to cool before attempting to work 4.

on the heater.

7. LAMP REPLACEMENT

WARNING. BEFORE UNDERTAKING THIS TASK ENSURE THE HEATER IS

DISCONNECTED FROM THE ELECTRICITY SUPPLY.

Detach heater from its mounting position.1.

Unscrew the front panel by loosening the corner xing screws, and then lift front panel 2.

clear.

Disconnect the wires to the old lamp by removing the lock nuts retaining the terminal 3.

ends adjacent to the lamp clips. Do not slacken the screws as this could disturb the

internal wiring.

Remove the lamp by gently releasing the ends from the spring clips. Keep the lamp 4.

secure and do not twist the ends or apply undue force.

Before removing the new lamp(s) from its protective packing it is important to be 5.

aware that quartz lamps are fragile and must be handled with care at all times. Avoid

touching the surface of the quartz sleeve with bare ngers. If the sleeve is accidentally

touched remove the nger print with a soft cloth moistened with methylated spirit.

Hold the lamp rmly but gently at each end and offer up to the spring mounting clips. 6.

The wire leads should face towards the front of the heater. Push the lamp fully into the

clips taking care to keep it square. Do not twist the ends or apply undue force. If either

end of the lamp will not easily engage in the spring clips remove the lamp and gently

ease the spring.

The wire from each end of the lamp must be connected to the threaded connector ON 7.

THE SAME CLIP AS THE LAMP END. With the outside not loosened, insert the spade

between the two outside nuts and tighten rmly.

When the lamp has been tted check that the electrical connections have been 8.

correctly made. Re-t the front panel, checking that wires are not trapped.

Page 7

INSPECTION AND CLEANING

Check that all the lamps are functioning. If any thermostatic or time controls are tted 1.

ensure that the supply is ‘on’ before checking lamps. Any failed lamps should be

replaced (see lamp replacement). Remove any accumulated dirt and check wiring and

connections.

Clean the lamp(s) and reector(s) using a mild detergent solution and soft cloth. 2.

Do not use any abrasive or caustic cleaners. Dry with a soft cloth. Avoid touching

either, the quartz lamp sleeve or the aluminium reector with bare ngers. If they

are accidentally touched remove any nger prints using a soft cloth moistened with

methylated spirit.

Check that the lamp(s) are properly located in the spring retaining clips and that they 3.

have not been disturbed by cleaning. The lamps should be pushed fully back into the

clips for applying light pressure on the end caps only.

SAFETY IN OPERATION

The heater is operated by simply switching on the electrical supply, or, if used in

conjunction with a control system, then the supplier’s instructions must be observed.

ALWAYS disconnect the heater from the supply before attempting to work on or near it.

NEVER operate the heater with a high accumulation of dust or dirt on the lamp(s) or

reector or with a damaged or corroded reector.

This appliance is not intended for use by children or other persons without assistance

or supervision if their physical, sensory or mental capabilities prevent them from using it

safely. Children should be supervised to ensure they do not play with the appliance

NEVER use the heater outside or in contact with water.

NEVER use the heater where ammable dusts, gases or vapours, etc. are likely to be

present in the atmosphere.

NEVER operate the heater in close proximity to the skin or eyes.

NEVER allow materials which could be damaged or ignited by the radiated heat to be

placed in close proximity to the heater.

NEVER cover the heater – even when it is switched off.

ALWAYS refer to these instructions before attempting to dismantle the heater.

AFTER SALES SERVICE

Your product is guaranteed for one year from the date of purchase. Within this

period, we undertake to repair or exchange this product free of charge (excluding

element & subject to availability) provided it has been installed and operated

in accordance with these instructions. Your rights under this guarantee are

additional to your statutory rights, which in turn are not affected by this guarantee.

Should you require after sales service you should contact our customer services help

desk on 0845 6042399. It would assist us if you can quote the model number, series,

date of purchase, and nature of the fault at the time of your call. The customer services

help desk will also be able to advise you should you need to purchase any spares.

Please do not return a faulty product to us in the rst instance as this may result in loss or

damage and delay in providing you with a satisfactory service. Please retain your receipt

as proof of purchase.

c] GDC Group Ltd,

All rights reserved. Material contained in this publication may not be reproduced in whole or in part, without prior permission in writing of Dimplex.

A division of GDC Group Ltd,

TEL: 0845 604 2399

FA X: 01489 773064

WEBSITE: www.credaheating.co.uk

Republic of Ireland Tel. 01 8424833

CREDA HEAT ING

MILLBROOK HOUSE

GRANGE DRIVE

HEDGE END

SOUTHAMPTON

SO30 2DF

Loading...

Loading...