CreatBot DX User Manual

CreatBot 3D Printer

User manual

English V7.0

Henan Suwei Ele ctroni cs Technology Co., Ltd.

- 1 -

CONTENTS

Notice ················································3

Machine Diagram

Front and Back·························4

Hotend / Feeder ·····················5

Hardware Installation

Unpacking·································6

Install Build Platform ············· 7

Install Feeder ····························· 8

Printer Operation

LCD Screen································9

Keypad / Knob························9

LCD Menu Tree ·····················10

Leveling Platform ················ 11

Paving Crepe Paper ············· 11

Load Filament························12

Unload Filament···················13

Software Operation

CreatWare Setup·················· 14

Quick Print UI ······················· 15

Print Your First Model ········ 15

Full Setting UI ······················· 16

Mouse Operation ················ 17

Model Rotate/Scale············18

Model Mirror··························19

View Mode ······························ 19

Right Click on Model ············ 20

Toolpath Structure················20

Basic Setting ··························· 21

Advanced Setting·················22

Expert Setting ························ 23

Skirt/Brim/Raft ······················ 24

Plugins ····································· 24

Start/End GCode ·················· 25

Dual Head Printing ·············· 25

Align Dual Head Horizon ··· 26

Align Dual Head Vertical····27

Add Multi Type Printer······· 27

Frequently Asked Questions

Routine Maintenance·········28

Print PLA and ABS ··············· 28

Paving Kapton······················29

Change Fuse ·························· 30

Adjust Z Limit ························ 30

Hardware Troubleshoot·····31

Printing Troubleshoot ········ 32

Specifications ······························ 33

Icon conventions

Tip icon to remind users to have a good method or technique.

Note icon, to remind the user must be given adequate attention.

Prohibition icons, prevents users from unauthorized operation.

26 Jun 2015

- 2 -

Notice

Read First

Thank you for choosing CreatBot 3D printer!

This manual contains important information about the installation, use,

maintenance and common problems of CreatBot 3D printer. Please read this

manual carefully before using 3D printer. All losses caused by the breach of the

notes and the operation process of the operation process will be borne by the user.

Please use the filament provide by CreatBot, or high quality filament of third

manufacturers. Due to the use of third party inferior material caused by the failure

of the printer, the loss will be borne by the user.

Software running environment, 2G or above processors, at least 1G memory,

compatible with Windows, MAC, or Linux, please use memory as much as possible.

I wish you a fun with CreatBot!

Danger Warning

The nozzle's temperature will reach 300 degrees, don't touch.

The platform's temperature will reach 120 degrees, don't touch.

Please make sure that the printer connected to the ground.

Do not attempt to open the case, be careful of electric shock.

Working Environment

The 3D printer can work in the indoor environment of 5 ℃ to 30 ℃.

Long-term not use of the printer, be sure to dust, moisture.

Long-term not use of the filament, please be sealed to prevent deterioration.

- 3 -

Machine Diagram

Front and Back

12. Power socket

13. Spool holder

14. Filament

15. Z stop limit

16. Filament inlet

17. X stop limit

18. Filament feeder 1

19. Compression nut

20. Filament feeder 2

1. Power switch

2. SD-card slot

11

3. Keypad

4. LCD display

5. Leveling nut

6. Leveling spring

10

9

8

7

6

5

4

3

2

1

7. Build platform

8. Baffle holes

9. X stepper motor

10. Printer head

11. Filament guide pipe

1920

18

17

16

15

14

13

- 4 -

12

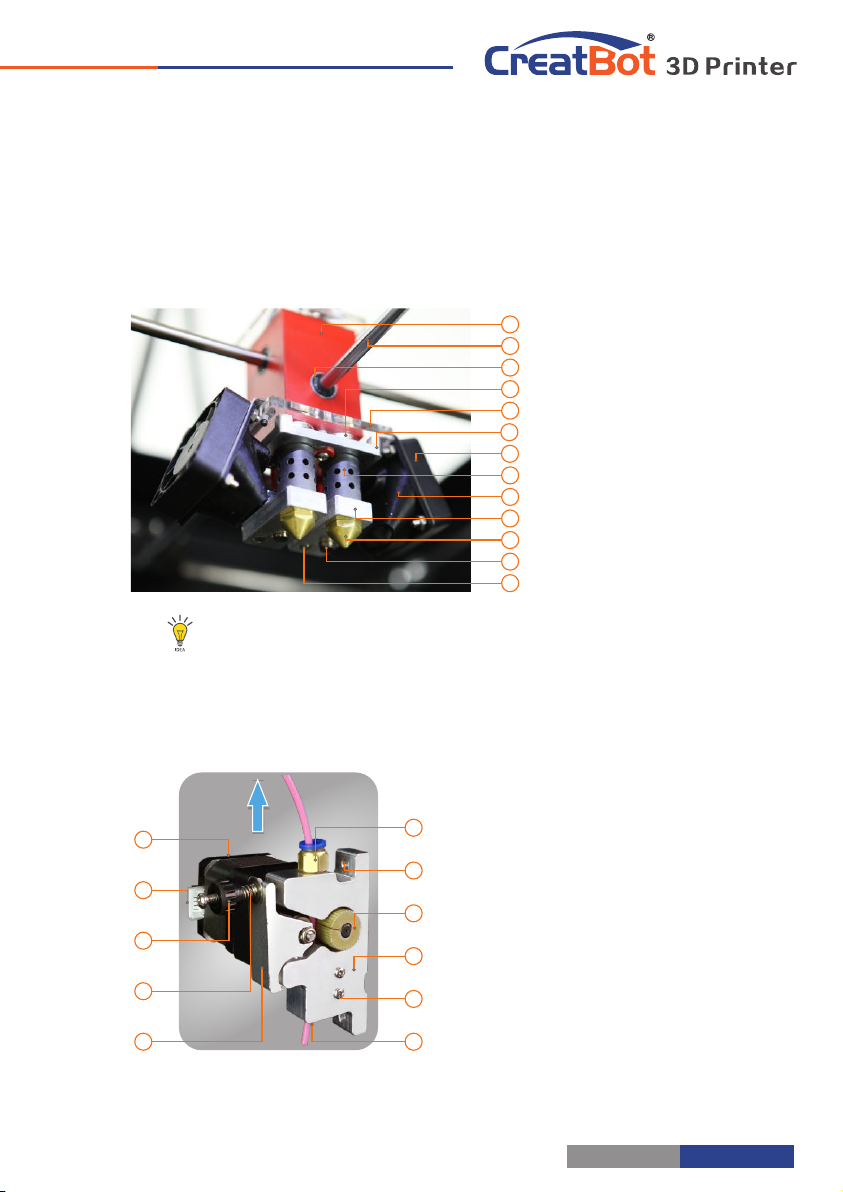

Machine Diagram

Printer Head

Hea d w il l b e up d at e a t an y t im e .

1. Thermostat tube

2. Heating tube

13

3. Nozzle

12

11

4. Heating block

10

5. Fan duct

9

6. Insulation tube

8

7. Cooling fan

7

8. Head Al. frame

6

9. Adapter plate

5

4

10. Head adjust

3

11. Linear bearing

2

12. Linear axis

1

13. Head main block

Filament Feeder

1. Pressure arm

5

4

3

2

1

11

10

9

8

7

6

- 5 -

2. Pressure spring

3. Pressure nut

4. Wire socket

5. Geared motor

6. Filament inlet

7. Filament sensor

8. Feeder body

9. Feeding wheel

10. Fixed hole

11. Pipe joint

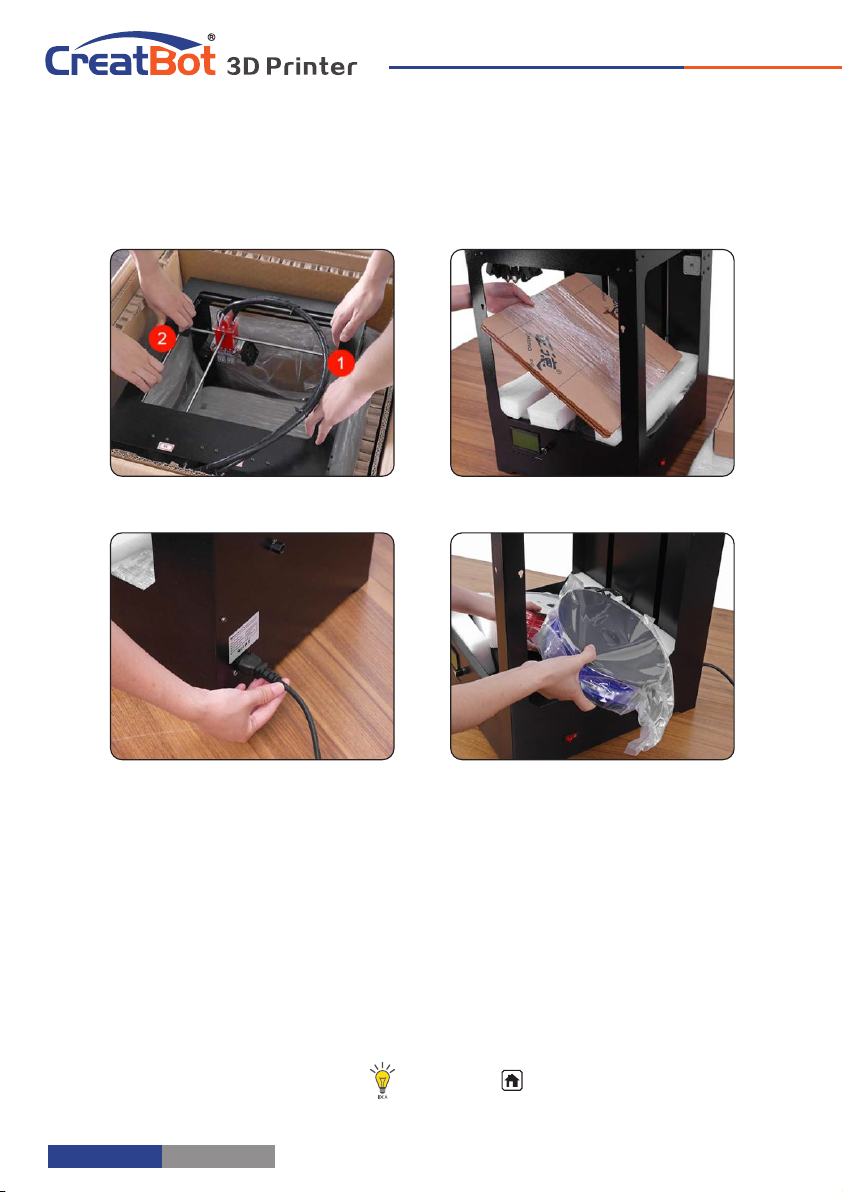

Hardware Installation

Unpacking Install Build Platform

Unpacking

Turn on printer

1. Ensure the packing is not broken.

2. Need two people at the same time.

3. Lift it out by grasping the frame, not the belt or rails.

4. Takeout the accessories, will see the bracket and the filament.

5. Turn on the printer, enter "Move axis" menu, select "Auto home", the bracket

will rise, now you can takeout filament.

Takeout accessories

Takeout filament

same as "Auto home".Tips: Press

- 6 -

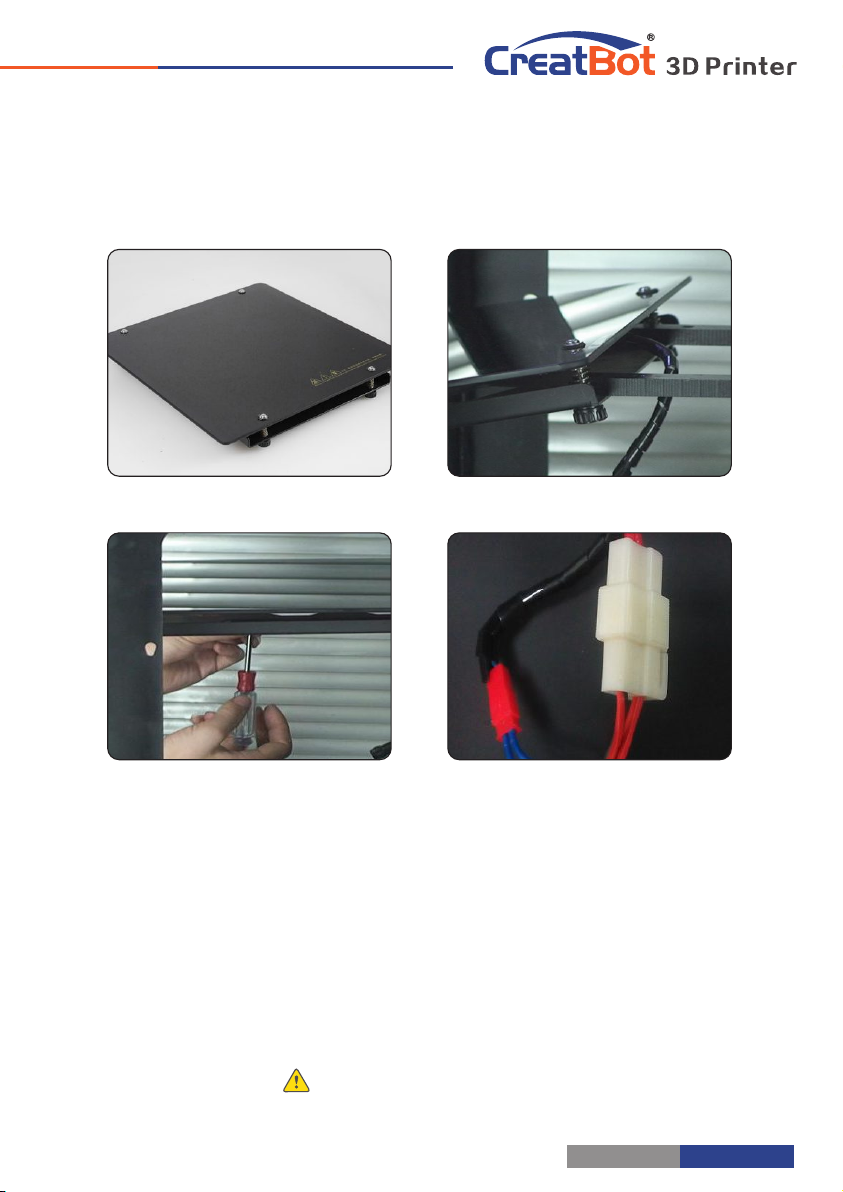

Hardware Installation

Takeout platform

Tighten the screws

1. Enter "Move axis" menu, move the platform a little down.

2. Fix the M5 screw to the hole of bracket, do not tighten.

3. Insert platform to the bracket, the bracket is between plate and tray.

4. Aim the tray fix hole to the M5 nut, then tighten the screws.

5. Connect the power plug and temperature sensor plug.

Notice: Ensure the plug is well contacted.

Insertplatform

Connect the cables

- 7 -

Hardware Installation

KEY

FUNCTION

KEY

FUNCTION

Up

Move Z up

Down

Move Z down

OK

Browse SD card

Status/Home

Pause/Resume

Preheat nozzle/bed, and switch between them

Install Feeder LCD Display

Fixed feeder

Plugin cable

1. Take out the feeder, pay attention to the order between left and right feeder.

2. Mount the feeder fixing hole on the back the chassis.

3. Tighten the screw nut firmly with a wrench.

4. Tighten the joint nut firmly on the feeder.

5. Plug in the motor cable to the socket.

6. Install spool's holders.

7. Install rack sleeve, you can download it from our website.

Connect joint

Install spool's holders

Notice: Feeder must same order to the nozzle.

- 8 -

Printer Operation

KEY

FUNCTION

KEY

FUNCTION

Up

Move Z up

Down

Move Z down

OK

Browse SD card

Status/Home

Pause/Resume

Preheat nozzle/bed, and switch between them

13 11 10

12

-

Z

OK

+

Z

986421 3 5 7

1. Current temp. 1

2. Target temp. 1

3. Current temp. 2

4. Target temp. 2

5. Current temp. 3

6. Target temp. 3

7. Cur. hotbed temp.

8. Tar. hotbed temp.

9. Fan speed

10. Cur. Z position

11. Remaining time

12. SD card icon

13. printing speed

Keypad

-

Z

+

Z

OK

Notice : Up/ Dow n can c hange glo bal p rint spee d.

PUSH

Knob

1. Push knob to confirm, rotate to move up down.

2. Ratate knob can change global print speed.

- 9 -

Printer Operation

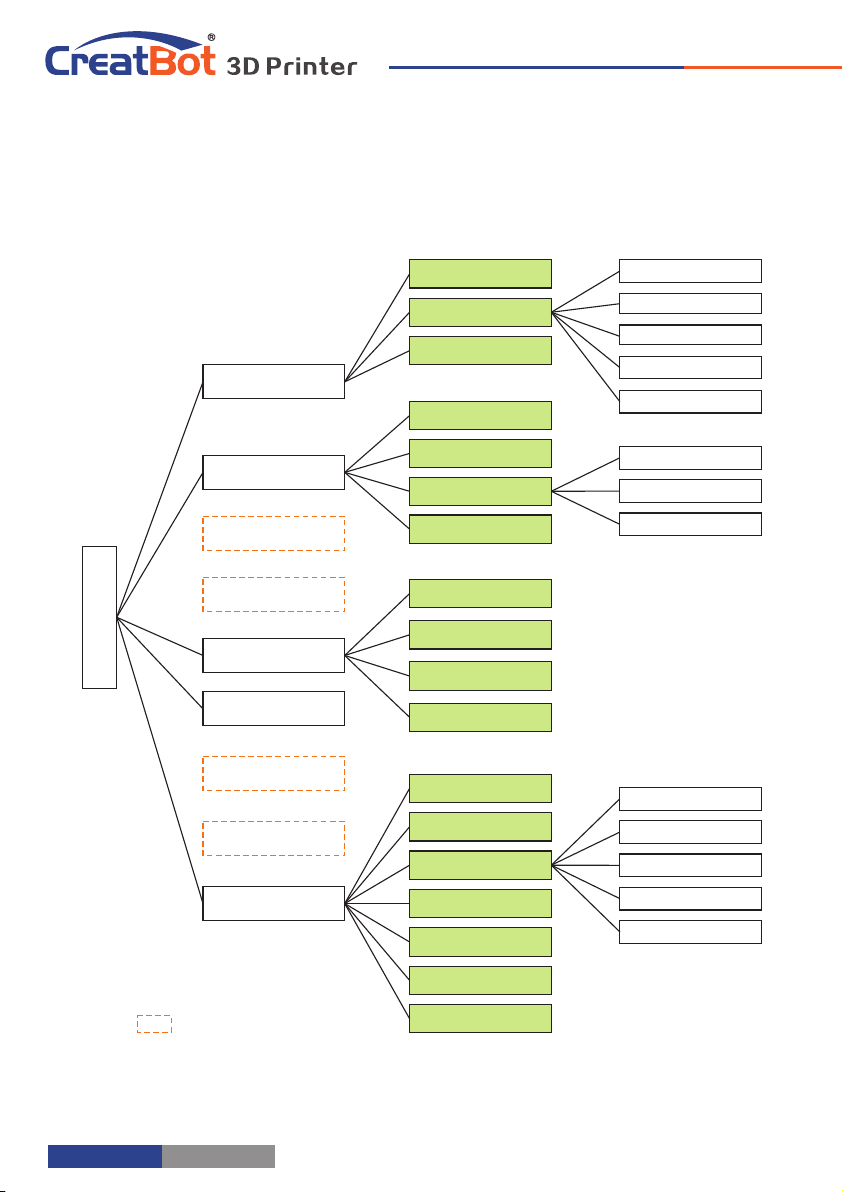

LCD Menu Leveling Platform

Preheat PLA

Preheat ABS

Cooldown

Preheat

Auto home

Move axis

Tune

Statu s

Change filam.

Filament

SD card

Pause print

Cancel print

Setting

10 mm

1 mm

0.1 mm

Extruder 1

Extruder 2

Unload 1

Unload 2

Temperature

Leveling bed

Motion

Save setting

Factory setting

Preheat nozzle 1

Preheat nozzle 2

Preheat nozzle 3

Preheat hotbed

Preheat All

X axis

Y axis

Z axis

Xsteps/mm

Ysteps/mm

Zsteps/mm

Esteps/mm

Reg. Number

Display while printing

Firmware Ver.

Time used

- 10 -

Printer Operation

2

1

3

4

1. Enter setting menu->leveling bed, waiting for the platform back to home.

2. Adjust first leveling nut, make nozzle close to the platform.

3. Press Up/Down button or rotating knob, adjust other three leveling nut.

4. To adjust repeatedly, eventually distance (0.2mm) to insert a name card is

advisable.

5. All the leveling nut should uniform, nozzle can't too close to the platform.

6. All will be subject to the actual effect of print, please make more little adjust at

the beginning of printing.

Paving Masking Paper

Platform need paste masking paper or

Kapton to achieve best viscosity, and the

model will be firmly fixed on the platform.

Kapton is double-sided tape, please tear

film on both sides.

- 11 -

Loading...

Loading...