Page 1

INSTALLATION and USE MANUAL

NOTICE D’INSTALLATION

MANUAL DE INSTALACIÓN

Turbofast

Page 2

Page 3

3

ENGLISH

Dear Client,

Thank you for purchasing our convection oven.

We feel certain that the oven you have purchased will meet your expectations, and will be a trustworthy assistant in your

work for a long time to come, providing performance of the highest levels.

You will also receive efficient and timely after-sales technical and operational service.

Your oven is quick and easy to install. Nonetheless, please CAREFULLY read this instruction manual, and keep

it for future use.

We hope you enjoy your work!

The manufacturer reserves the right to end convection ovenion of any model and/or to make modifications without being

required to carry out those modifications on previously supplied convection ovens.

The manufacturer shall not be liable for any errors in transcription or printing.

The manufacturer shall also not be held liable if the ovens are used improperly or in a manner which is different from the

instructions set forth in this manual.

Page 4

4

INDEX

TECHNICAL DATA

Data plate ...................................................................................................................................................................................4

Power supply terminal board ..............................................................................................................................................4

After sales service ....................................................................................................................................................................4

SPEEDY oven technical data ...............................................................................................................................................5

Part reserved for installer ...........................................................................................................................................................6

Safety standards .....................................................................................................................................................................6

Environmental standards ......................................................................................................................................................6

Transport and unpacking .....................................................................................................................................................6

Installation instructions ..........................................................................................................................................................7

Electrical connections ............................................................................................................................................................8

Automatic safety and control devices of the oven ......................................................................................................9

Replacing spare parts ...........................................................................................................................................................9

Part reserved for user ..............................................................................................................................................................11

General safety standards ...................................................................................................................................................11

Use of the oven .................................................................................................................................................................... 12

Routine maintenance .........................................................................................................................................................13

What to do in case of a breakdown or long periods of disuse ...........................................................................15

EXPLODED ....................................................................................................................................................................................44

ELECTRICAL DIAGRAM .............................................................................................................................................................46

DATA PLATE

The data plate containing the oven characteristics is glued to the back.

POWER SUPPLY TERMINAL BOARD

The power supply terminal block is inside the

right side of the oven. A small data plate positioned near the terminal block states the types

of connections which are possible.

AFTER SALES SERVICE

Te c h n i c a l Se r v i c e

Perfect operation over time of our convection

ovens is ensured by a wide-ranging technical

service network. Specialized technicians are

ready to intervene in a timely manner to ensure

the work of food services professionals continues uninterrupted.

Wa r r a n T y

All our convection ovens undergo careful operating tests before they go on the market, as

shown by the test certificate that is enclosed

with each one of them and by the one-year

guarantee.

Page 5

5

ENGLISH

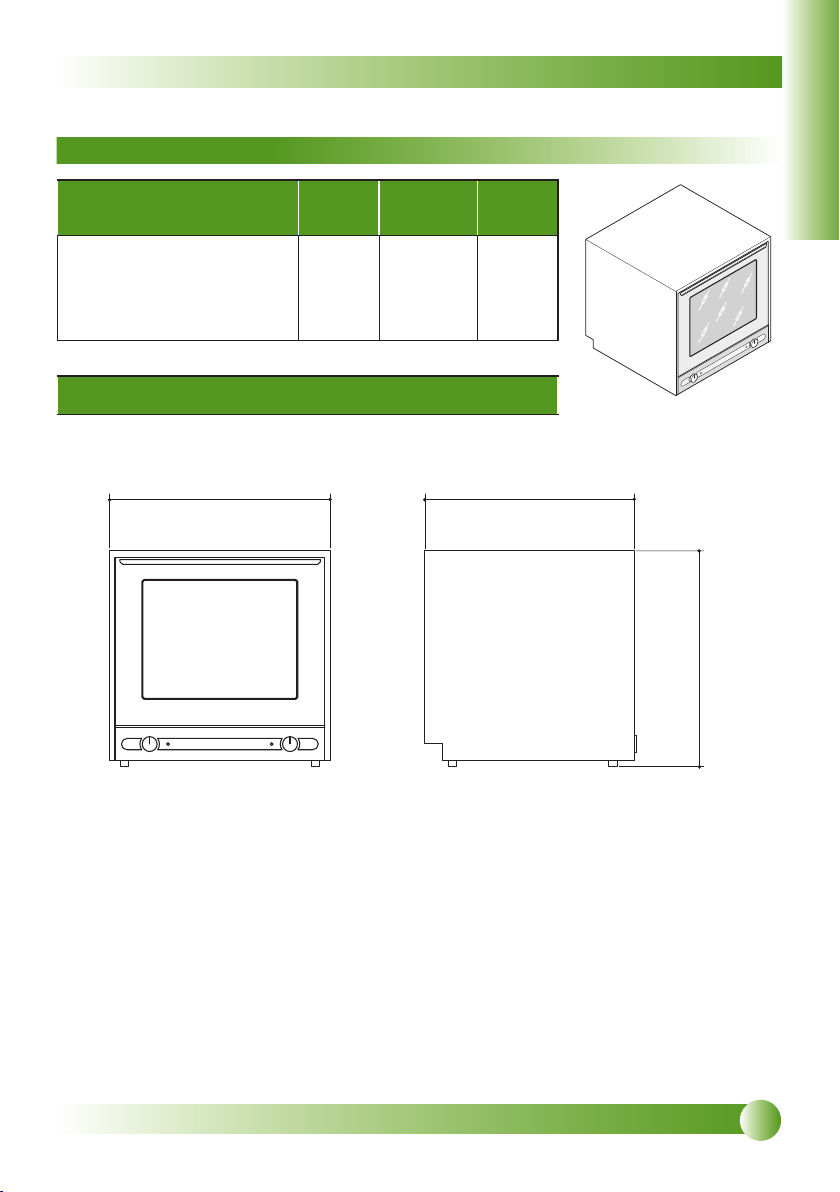

TURBOFASTTF 1/2 OVEN TECHNICAL DATA

v

v

v

Dimensions

WxDxL

External dimensions:

27”x21 3/4”x25 1/4”

Internal dimensions:

21 1/2”x14 1/2”x16 1/8”

Rack dimensions:

1/2 size

For further electrical details, refer to the electrical diagram at the end of

the manual.

No. of

pans

or racks

Power supply

4 1Phase 15

Amp 240V

Plug NEMA

6-20P stan-

Power

Kw 3.2

60Hz

dard

Page 6

6

PART RESERVED FOR INSTALLER

SAFETY STANDARDS

• The installer must read this booklet

carefully before installing the convection oven.

• Installation and subsequent maintenance,

cleaning, inspection and repairs must be

carried out with the electrical power supply

disconnected.

• Installation of the ovens must be in comply with current standards in the country of use. Otherwise the manufacturer

shall not honor the warranty in the event of

direct or indirect damage.

• Installation, adjustment and assistance are to be carried out by qualified

personnel in compliance with current

accident prevention legislation in the

country of use. The installer must

also check for any fire prevention

regulations.

• The manufacturer shall not be held liable

for any damage arising from improper use

of the convection oven, unauthorized modifications and anything not covered by this

manual.

ENVIRONMENTAL STANDARDS

All materials used for packaging are compatible

with environmental protection standards. They

may be stored without any hazard, or disposed

of in accordance with current laws in the country

of use.

Do not leave the plastic coverings

within reach of children or animals as

they are potentially hazardous.

The plastic components which can be disposed

of and recycled are marked as follows:

POLYETHYLENE: packaging outer film, instructions bag, etc.

POLYPROPYLENE: clips, etc.

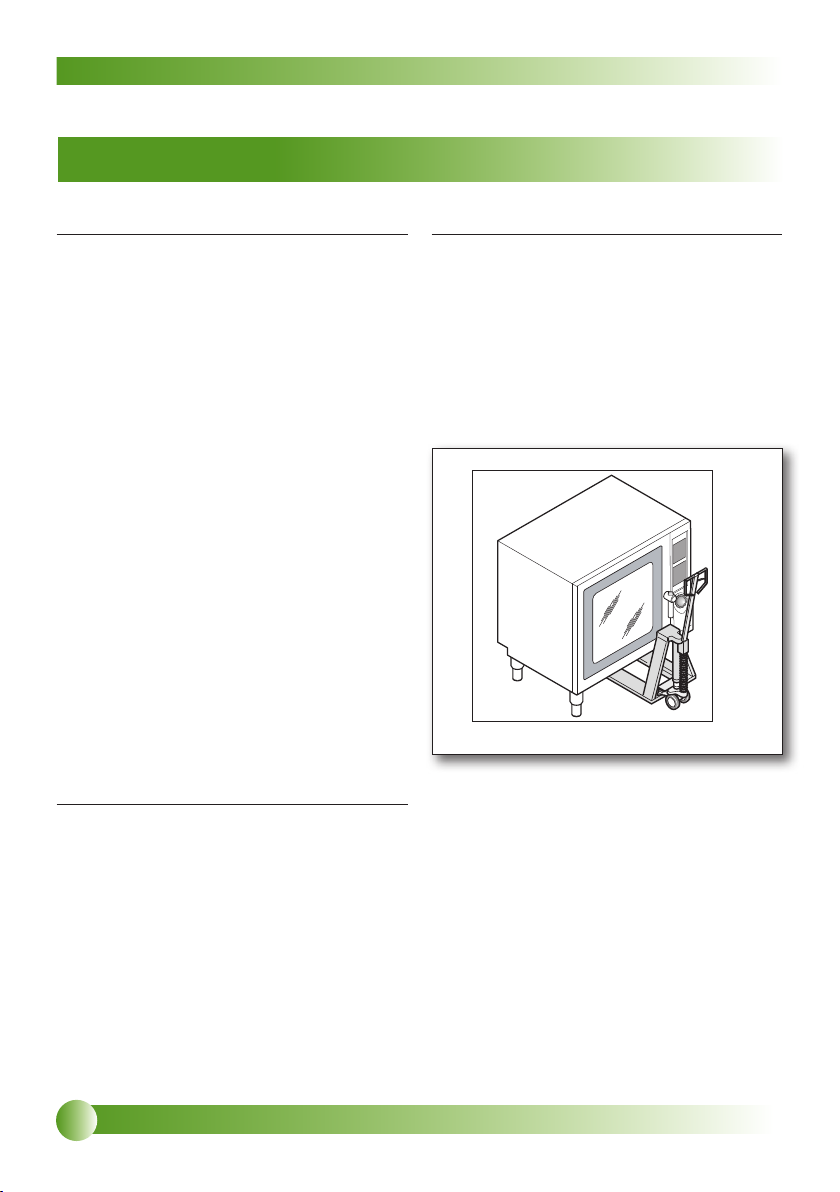

TRANSPORT AND UNPACKING

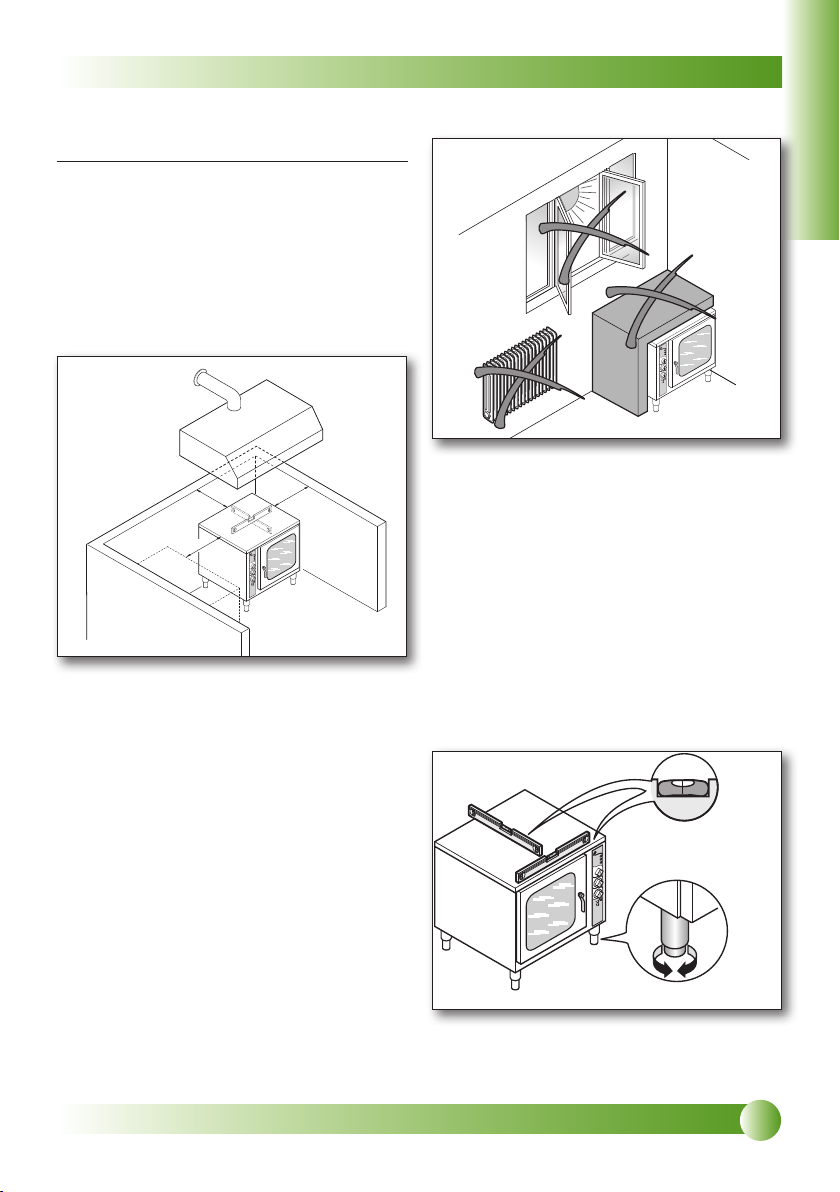

Any movement of the oven must be carried out

by suitable means such as a forklift or pallet

loader. These must be at least half as large as

the convection oven (see fig.1).

If it is necessary to store the oven temporarily,

keep it in a covered, ventilated place at a temperature from 14°F to 122°F, with humidity no

higher than 95%.

Fig.1

Use protective gloves and remove the packaging. Lift the oven with a forklift, remove the

base and place it in its intended location.

After removing the packaging, immediately check the condition of the oven.

If in doubt, do not use the oven.

Contact an authorized retailer.

Page 7

7

ENGLISH

INSTALLATION INSTRUCTIONS

19”

19”

19”

Po S iT i o n i n g a n d S e T -u P f o r u S e

1) Place the machine in its place of intended

use in compliance with the following instructions:

- Check that there is enough space (minimum 19”) from any walls or obstacles

which may prevent proper air flow (fig.2).

Fig.2

-

Check that maintenance can be performed

with a certain freedom of movement.

- Avoid placing the oven in places with poor

air circulation, in places exposed to sunlight,

where there are high temperatures, near

heat sources or in windy locations (fig.3).

- Ambient air temperature must not exceed

89°F. Above that temperature, proper operation of the oven cannot be ensured.

Fig.3

-

Always install the oven under a properly operating aspiration hood for the extraction of

vapors.

2) Remove the film which covers some parts

of the oven before starting to use it.

3) Clean all substances, including glue residue.

Do not use abrasive substances.

4) Position the machine so that it is perfectly

level and set the height by means of the

leveling feet (fig. 4).

Fig.4

Page 8

8

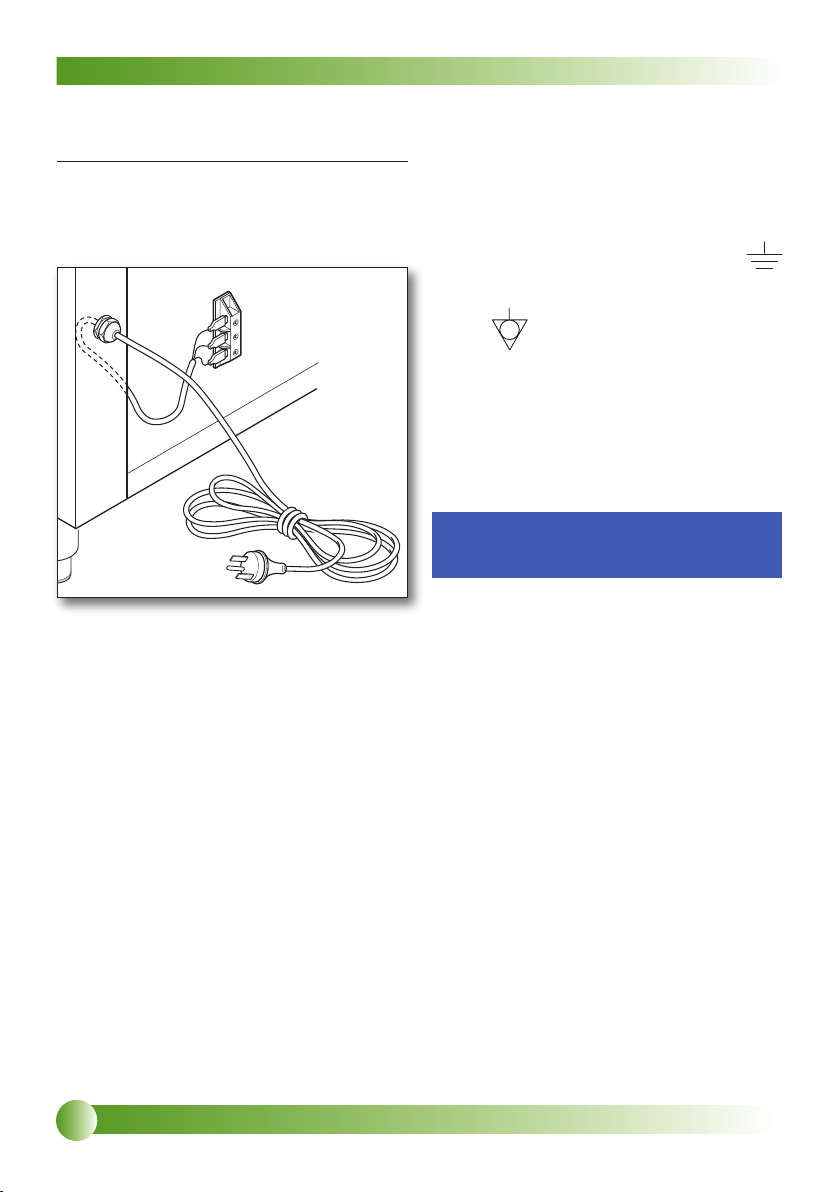

ELECTRICAL CONNECTIONS

The oven is setup for operation at the voltage

set forth on the technical data plate.

All ovens are provided with a power cord.

Fig.5

The flexible cable for connection to the electrical mains must not have characteristics which

are less than those of a type with rubber insulation mod. H07RN F and it must have a section which corresponds with that set forth in

the section “Technical Data” of the oven. The

cable must also be anchored to the frame with

the cable clamp, the screw of which can be

reached through a hole in the frame. It must

in any case be positioned in such a way that at

no point does it reach a temperature which is

122°F greater than the ambient temperature.

It must be type SJTO plug 20A 250V P section

3xAWG12.

The connection to the electrical line must be

made by placing an automatic switch of sufficient capacity (see “Technical data” of the

oven) and with an opening distance between

contacts of at least 3 mm.

Also, during operation of the oven, the power

supply must not vary from the nominal voltage

value by ±10%.

The oven MUST be earthed by means of the

terminal which carries the earth symbol

on the connection board.

It must also be inserted in an equipotential

system (the efficiency of which must be

checked in accordance with current standards)

using the terminal with the equipotential symbol (fig. 6). It is located near the electrical cable

entry on the panel of the oven bottom.

The manufacturer will not be held liable if

this accident prevention standard is not

adhered to.

Page 9

9

ENGLISH

AUTOMATIC SAFETY AND CON-

1

2

B

A

TROL DEVICES OF THE OVEN

Pr o T e c T i o n o f T h e a u x i l i a r y e l e c T r i c a l c i r c u i T

It is checked by the fuses positioned on a terminal block at the line entry.

Pr o T e c T i o n o f T h e c h a m b e r f a n

A remote switch stops the fan motor in the

event of a malfunction or overload. It is located

behind the oven and must be reset manually.

When it cuts in, it stops the motor and shuts

off the heating elements.

ov e n c h a m b e r S a f e T y T h e r m o S T a T

The safety thermostat disconnects the heating

elements if the temperature in the oven chamber is too high (644°F).

It must be reset manually. If it activates, technical service must be notified.

All components are protected by the following

type of fuse: CLASS CC,G 600V 20A.

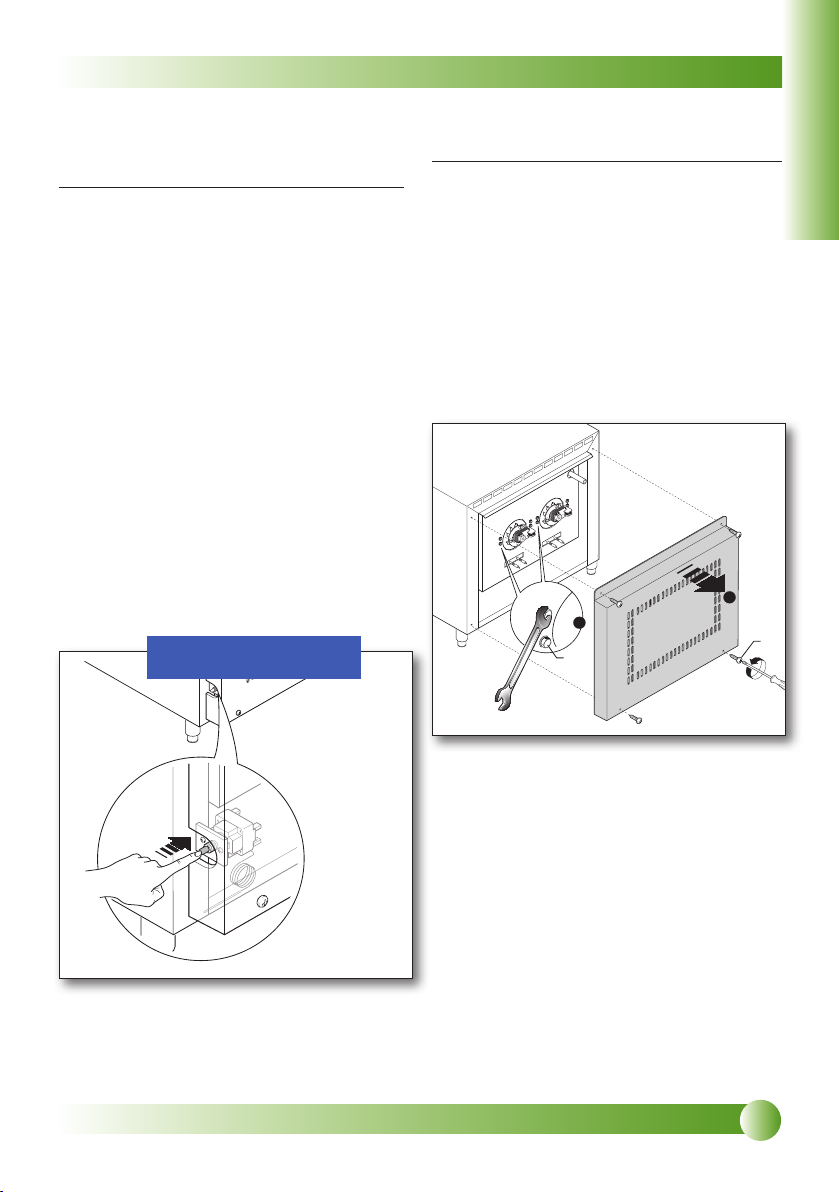

REPLACEMENT OF SPARE PARTS

Replacement of spare parts must be performed exclusively by qualified and AUTHORIZED personnel.

Turn the main switch OFF and unplug

the convection oven before carrying out any

spare parts replacement.

r e P l a c e m e n T o f m o T o r S : it is necessary to re-

move the back by removing the 4 fastening

screws “A” and the 4 screws “B” that support

them (fig.8).

Fig.8

Fig.7

Page 10

10

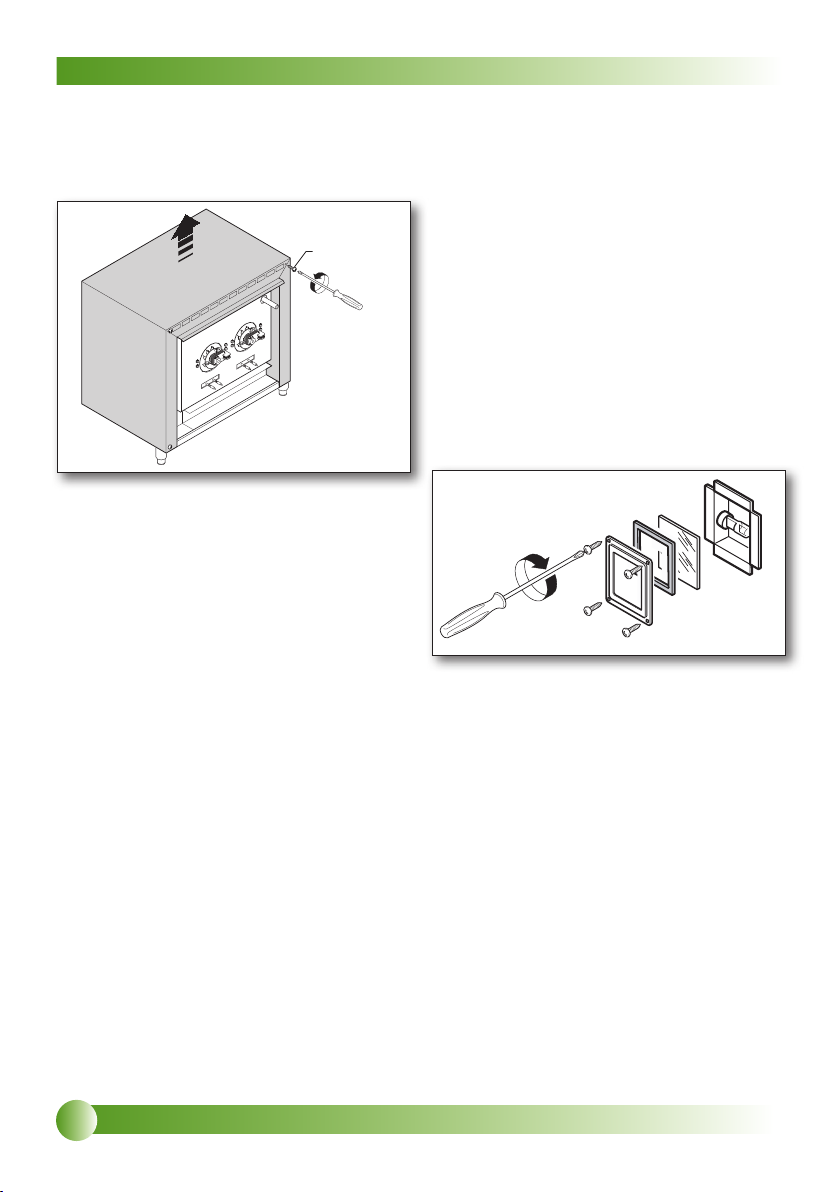

ou T e r c o v e r i n g : remove the 4 rear fastening

C

screws “C” (fig.9).

Fig.9

bu l b , h e a T i n g e l e m e n T a n d m o T o r f a n : it is

necessary to access the inside of the oven, first

removing pans, racks and related supports, and

then the conveyor.

30W m o T o r : remove the fan by following the

procedure outlined above, disconnect the motor

from the electrical system, loosen the 4 screws

and replace the motor. Before re-installing the

fan, check that there is no friction between the

motor shaft and the ring nut located inside the

oven. If there is, loosen the fixing screws of the

ring nut and re-tighten them after eliminating

the friction and having centred the ring nut on

the motor shaft.

he a T i n g e l e m e n T S : Disconnect the heating ele-

ment connections outside the oven chamber.

Loosen the heating elements from inside the

oven chamber and replace them.

el e c T r o -m e c h a n i c a l c o n T r o l S : All the electric

components are visible. To replace them it is

necessary to disconnect the attachments, remove the knobs, unscrew the fastening screws

or nuts and replace them. Attention: For the

adjustable thermostat, safety thermostat and

thermometer, unscrew the guard and the supports and remove the bulbs. Once they have

been replaced use high-temperature resistant

silicone to seal the holes. After replacement, reseal the holes for the passage of the capillaries

with high temperature silicone.

ch a m b e r f a c e g a S k e T : It is simply pressed in.

Pull to remove it. NB: Before removing it, note

its position carefully so as to place the new one

in the same position.

re P l a c e m e n T o f c h a m b e r l i g h T a n d g l a S S

g a S k e T : Check and replace the glass gasket and

any lights in the oven chamber (fig.10).

Fig.10

Page 11

11

ENGLISH

PART RESERVED FOR THE USER

GENERAL SAFETY STANDARDS

• This manual is

part of the documentation provided

with the oven and

contains all re-

quired information

for proper use and

maintenance of the convection oven.

• Carefully read the user’s instructions

contained in this manual before turning the oven on. Special attention must

be given to the standards concerning the

automatic safety and control devices.

• The user must carefully read the instructions in it and keep it where it is accessible

to all authorized users;

• The ovens is of a professional type and

must be used only by qualified personnel, which is the cooking of foods in

food service facilities.

•

Always turn off the main electrical switch after

using the oven, especially during maintenance

and repair or in the event of long periods of

disuse.

• It is advisable to have the oven checked on

a yearly basis by an authorized technical

service center.

• The owner of the oven must periodically

train their staff on the use of the machines

and provide them with safety instructions.

• During cooking, the external parts of the

oven (e.g. door glass) may get hot. Becareful when touching them.

ge n e r a l i n S T r u c T i o n S f o r u S e

• The oven may be used to bake creams,

cookies, cakes, sauces and pizza, for au

gratin cooking and for defrosting frozen food

convection ovens.

• Avoid adding salt to foods in the cooking

chamber.

•

Try to distribute foods evenly in the pans,

avoiding accumulations.

Fig.11

• Between one level and the next there must

be a space of at least 1 1/2”. Hot air must

be able to circulate both above and below

the food in order for it.

• Do not use pans with sides that are higher

than necessary. The sides create a barrier to

air circulation.

• When using the oven for the rst time, it

is advisable to run it empty at maximum

temperature for about an hour.

This will eliminate any unpleasant odors

from protective lubricants used in the factory.

• Leave room between dishes on the same

level.

• Preheat the oven. It is always better to place

the food in a pre-heated oven.

• During cooking, racks and pans reach very

high temperatures. Use caution to prevent

burns.

Page 12

12

0

5

10

15

20

25

30

40

50

60

70

8090

100

110

120

)

/

²&

USE OF THE OVEN

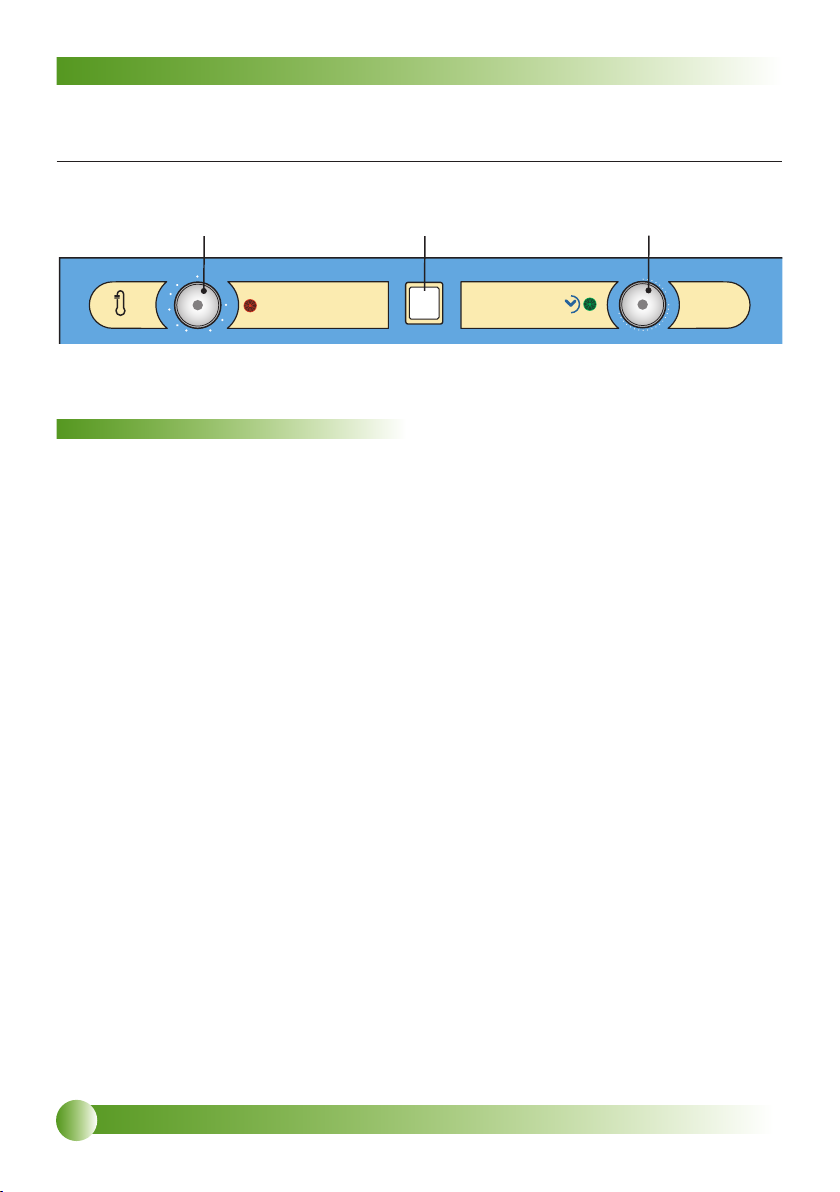

ke y T o c o n T r o l P a n e l S y m b o l S

1) TIME SETTING KNOB

Sets cooking time from 0 - 120 minutes or to

continuous operation.

2) TEMPERATURE SETTING KNOB

Sets chamber temperature from 50 to 520°F

3) ON/OFF MAIN SWITCH

ST a r T -u P a n d u S e

To start the oven, press the main switch (3)

ON/OFF.

Set the cooking time by turning the time setting knob (1) .

Then use knob (2) to set the desired cooking temperature. If knob (2) is left in position

‘0’, only the light and fan will operate, and the

oven chamber will not heat up.

SW i T c h i n g o f f

Cooking ends automatically when the cooking

time set on knob (1) has expired

Nonetheless, turn all knobs to “O” and turn off

the main switch (3) ON/OFF.

Page 13

13

ENGLISH

ROUTINE MAINTENANCE

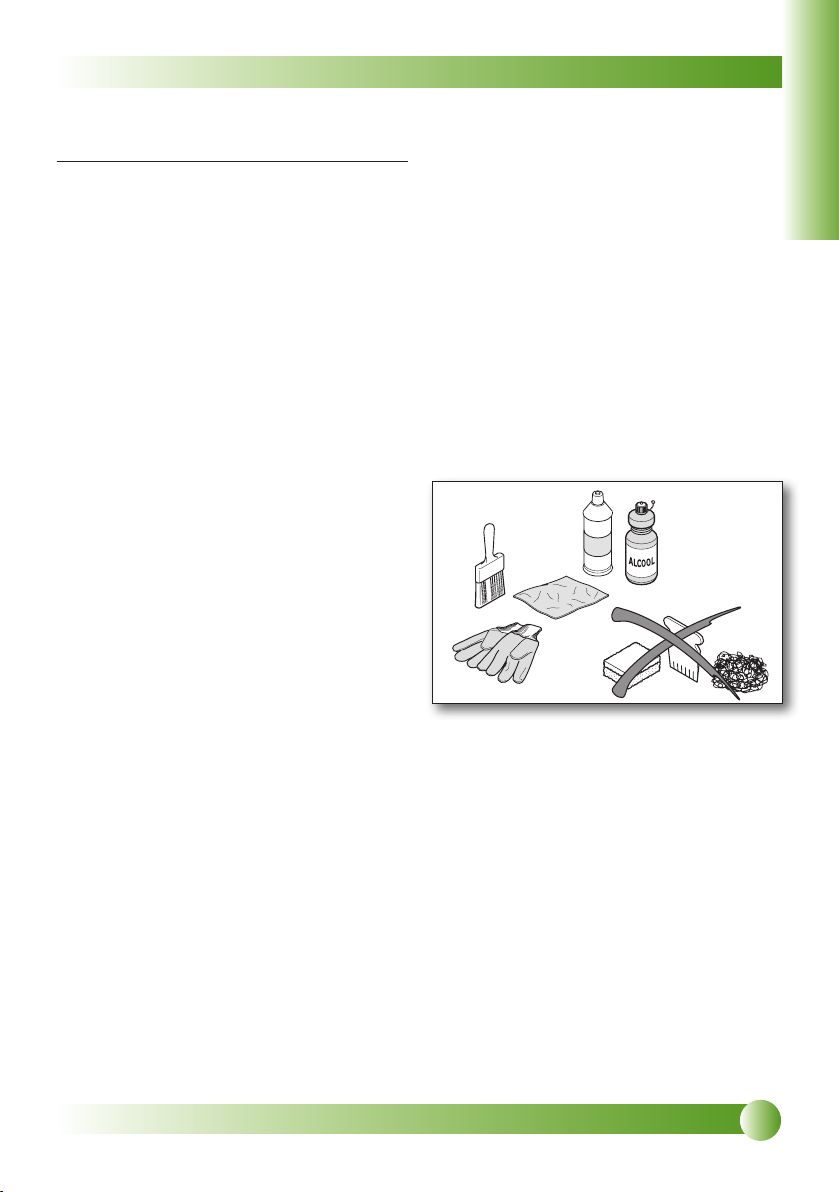

Before performing maintenance, unplug

the oven.

During cleaning, use protective gloves, mask

and garments as required by standards.

At the end of each workday clean the inside of the oven with appropriate convection

ovens following the suggestions of your supplier. Do not use corrosive or acidic convection

ovens, or convection ovens which are not suitable for this type of cleaning.

To make cleaning easier, remove the lateral diffusers by lifting them slightly so they are free of

the holding pegs.

Clean the stainless steel parts daily with lukewarm soapy water, and rinse thoroughly. Then

dry.

Absolutely do not clean the stainless steel with

steel wool or common steel brushes, since they

may leave ferrous particles which may oxidize,

thus causing rust spots.

Stainless steel wool can be used in the direction of the satin finish.

If the oven is not used for long periods, use a

cotton ball to lay a coat of petroleum jelly on all

surfaces; also regularly ventilate the rooms.

ov e n c h a m b e r c l e a n i n g

•

Remove any food and/or fat residues from

the oven chamber after each cooking cycle.

• The combination of fat, heat and forced circulation dirties the oven. Only by cleaning

the oven daily is it possible to avoid difficult

cleaning operations.

• To clean the oven, use a suitable de-greasing convection oven (non-foaming) as suggested by your detergent retailer. A spray

is preferable to reach behind the protection shield. Do not use abrasive or corrosive substances, scrapers or steel wool (fig.

12).

Fig.12

Adhere to safety instructions included with

cleaning convection ovens for the protection

of skin and eyes. When cleaning, proceed as

follows:

a) Heat the oven chamber to approx.158-

176°F and clean it using the de-greasing

detergent in the recommended quantities.

b) Close the oven and heat it.

c) Let the cleansing convection oven act for

20-30 minutes and then turn the oven off.

d) Slowly open the oven with care to avoid

eye and skin damage.

Page 14

14

e) Remove the racks or pans from the oven, re-

2

1

A

A

move the rack supports attached to the side

and shield, remove the shield by loosening

the fastening screws. Wash separately (they

can also be placed in the dishwasher).

f) Clean and rinse the oven and fan with water.

g)

Re-install the shield and the rack supports.

h)

Dry the oven by turning the CONVECTION

cycle on.

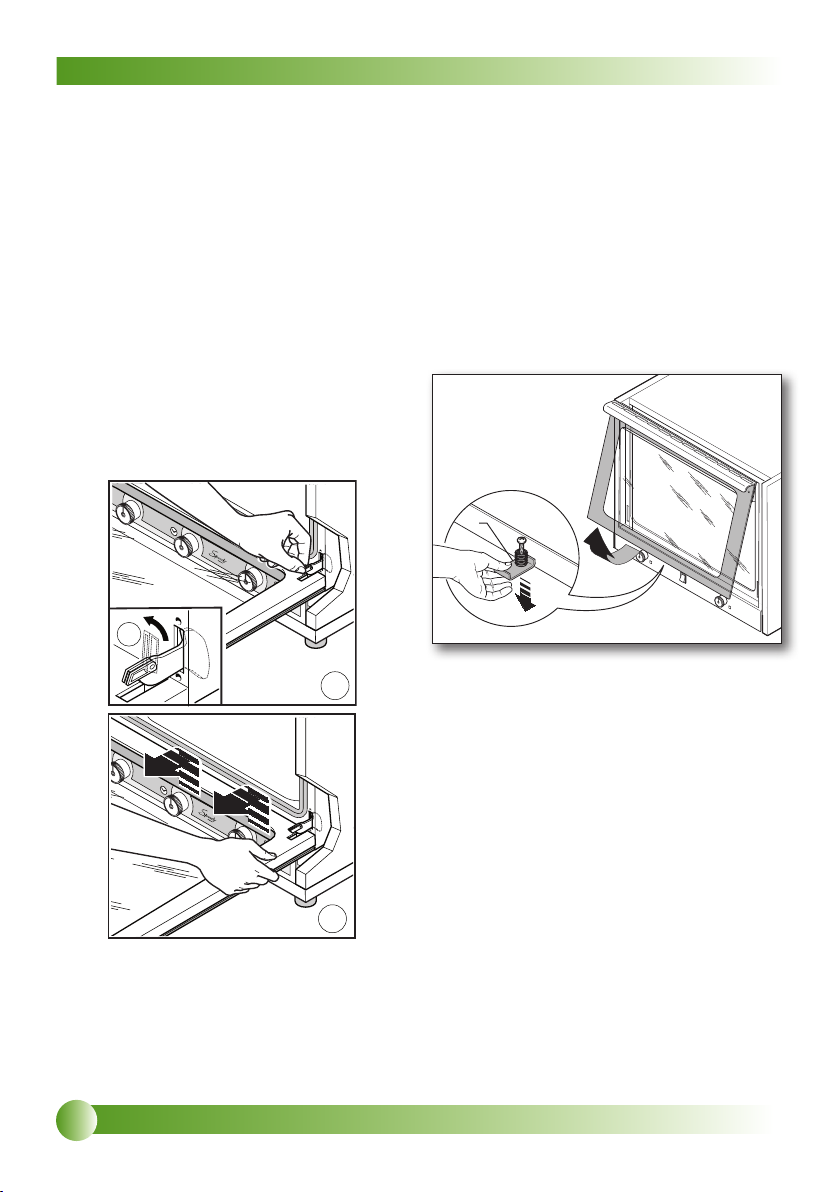

To make cleaning the oven chamber easier, it

is possible to remove the door completely in a

few simple steps as shown in figure 13. Follow

the sequence in reverse order to re-install the

door.

cl e a n i n g d o o r g l a S S

To reach the inside glass of the oven door, use

the lower latch “A”, open outer glass “B” raising it from the bottom upwards. This will make

it possible to get inside the glass for normal

cleaning. Upon completion, close the external

glass by pushing it slowly downwards until the

click is heard of insertion in component

“A”.

Fig.14

cl e a n i n g T h e f a n

Periodically check the condition of the fan.

Make sure that there is not too much grease

on the blades since it may slow motor rotation

(which in turn may lead to overheating) and

uneven heat distribution (resulting in uneven

cooking).

Fig.13

Page 15

15

ENGLISH

WHAT TO DO IN CASE OF A BREAKDOWN OR LONG PERIODS OF INACTIVITY

a malfunction).

• Clean the oven inside and out.

• Switch off the main electrical switch.

• Set all control panel knobs to zero.

• Inform technical assistance (only in case of

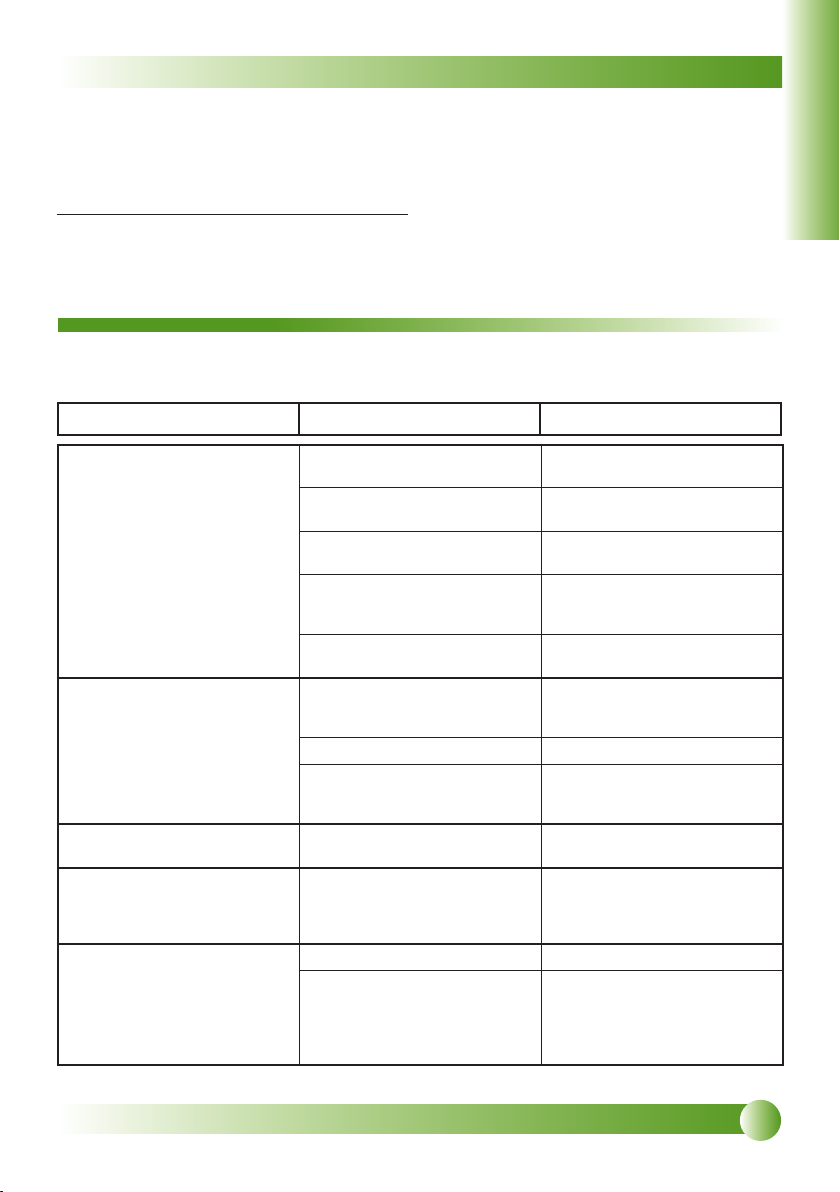

TroubleShooTing guide

Pr o b l e m Pr o b a b l e c a u S e re m e d y

Unit unplugged

Fuses

Oven does not turn on

Oven does not warm up

Lights not lit Switch/lights

Motors do not work Motor contactor/Motor

Oven suddenly stops

Cables/terminal block

Switch

Safety thermostat

Resistor contactor

Heating element burn out Replace the heating element

Thermostat

Safety thermostat Push the red button on the thermostat

Short circuit

Check the plug connection and reconnect if necessary

Check the fuses and replace them if

necessary

Check the cables connection for loose

wire and reconnect if necessary

Check the switch and the voltage at

the inlet and outlet. Replace switch if

necessary

Check the safety thermostat and push

the red button

Check the voltage at the inlet and

outlet of the contactor and replace if

necessary

Check the temperature with a manual

thermometer and if necessary replace

the thermostat

Check the switch and the lights and

replace if necessary

Check the voltage at the inlet and outlet of the contactor. Check the motor

and replace the contactor or the motor

if necessary

Check the fuses and replace them if

necessary, if the failure persists check

all parts with an appropriate tester in

order to find which is the part to replace

Page 16

16

Page 17

17

FRANÇAIS

Cher client,

Nous vous remercions pour avoir choisi l’un de nos produits.

Nous sommes certains que l’appareil que vous venez d’acheter saura répondre à vos attentes et qu’il représentera

longtemps pour vous un outil fiable grâce à des prestations de très haut niveau.

sur un service après-vente efficace et rapide.

Bien que l’installation et l’utilisation de votre appareil soient simples et immédiates, nous vous prions de lire

très ATTENTIVEMENT ce livret d’instructions et de le conserver soigneusement pour pouvoir le consulter par

la suite.

Nous vous souhaitons un Bon travail!

Vous pourrez notamment compter

Le Fabricant se réserve le droit d’interrompre la production de ses modèles et/ou d’introduire des modifications sans que

ceci ne l’oblige à effectuer lesdites modifications sur les produits déjà livrés.

Le Fabricant ne répond pas des éventuelles erreurs de transcription ou d’impression

Le Fabricant décline toute responsabilité au cas où les appareils seraient utilisés de façon incorrecte ou différente de celle

qui est prescrite dans ce manuel.

Page 18

18

SOMMAIRE

CARACTÉRISTIQUES TECHNIQUES

Plaquette signalétique ........................................................................................................................................................18

Bornier de connexion ......................................................................................................................................................... 18

Assistance après vente ....................................................................................................................................................... 18

Caractéristiques techniques four Speedy .................................................................................................................... 19

Partie réservée à l’installateur .................................................................................................................................................20

Normes de sécurité .............................................................................................................................................................20

Normes pour la sauvegarde de l’environnement .................................................................................................... 20

Transport et déballage ......................................................................................................................................................20

Modalités d’installation .......................................................................................................................................................21

Branchements électriques ................................................................................................................................................22

Dispositifs automatiques de contrôle et de sécurité ...............................................................................................23

Remplacement des pièces détachées .........................................................................................................................23

Partie réservée à l’utilisateur ...................................................................................................................................................25

Normes générales de sécurité .......................................................................................................................................25

Utilisation du four .................................................................................................................................................................26

Entretien ordinaire ................................................................................................................................................................27

Que faire en cas de panne ou d’arrêt prolongé ....................................................................................................... 29

VUE ÉCLATÉE ............................................................................................................................................................................... 44

SCHÉMA ÉLECTRIQUE ..............................................................................................................................................................46

PLAQUETTE SIGNALÉTIQUE

La plaquette signalétique est collée sur le devant de l’appareil, sous le bac d’égouttement,

ou sur le côté droit.

BORNIER DE CONNEXION

Le bornier de connexion se trouve à l’intérieur

du côté droit de l’appareil ; une plaquette située

près du bornier indique le type de connexion

possible.

ASSISTANCE APRÈS VENTE

aS S i S T a n c e oP é r a T i o n n e l l e

La Société, avec la collaboration de chefs professionnels externes, peut fournir à tous ceux

qui ont choisi la qualité de l’un de nos fours,

des conseils sur l’emploi correct des appareils,

avec possibilité d’intervention sur place.

Notamment, des séminaires sur les techniques

de cuisson sont habituellement organisés et tenus par des chefs sélectionnés, qui se tiennent

également à la disposition de la clientèle pour

résoudre tout problème de cuisine.

aS S i S T a n c e Te c h n i q u e

Le bon fonctionnement de tous nos produits

est garanti par un réseau continu d’assistance

technique composé par des techniciens spécialisés prêts à intervenir rapidement, pour garantir la continuité du travail des opérateurs de

la restauration.

ga r a n T i e

Tous nos produits sont soumis à des tests de

fonctionnement rigoureux avant d’être introduits sur le marché, comme l’atteste le certicat

d’essai qui accompagne chaque produit garanti

un an.

Page 19

19

FRANÇAIS

CARACTÉRISTIQUES TECHNIQUES FOUR SPEEDY

v

v

v

Dimensions

L x Px H

Dimensions externes :

68,5 x 55 x 64cm - 27” x 25 1/2” x 22

1/4”

Dimensions internes :

54x36x37cm-21 1/2” x 14 1/2” x 16 1/8”

Dimensions grilles :

52,7 x 36,8cm - 1/2 size

Pour plus de détails électriques, voir le schéma électrique à la fin de ce

livret

N° de plats

à four

ou de

grilles

Alimentation

4 1Phase 15

Puissance

KW 3,2

Amp 240V

60Hz

Fiche NEMA

6-20P

standard

Page 20

20

PARTIE RÉSERVÉE A L’INSTALLATEUR

NORMES DE SÉCURITÉ

• L’installateur doit lire attentivement ce

livret avant de procéder à l’installation

de l’appareil.

• L’installation ainsi que les opérations d’entretien,

de maintenance, d’inspection et de réparations

doivent être effectuées après avoir coupé l’alimentation électrique.

• Les opérations d’installation des appareils doi-

vent être conformes aux normes en vigueur

dans le Pays où l’appareil est installé. Dans

le cas contraire, les éventuels dommages subis

directement ou indirectement ne seront pas

couverts par la garantie.

• L’installation, le réglage, l’assistance doivent être effectués par des techniciens

qualifiés en respectant les directives sur

la prévention des accidents, en vigueur

dans le Pays où l’appareil est installé

; par ailleurs, l’installateur est tenu de

vérifier l’existence de normes contre l’incendie.

• Le fabricant décline toute responsabilité en cas

de dommages causés par : une utilisation incorrecte, une manutention effectuée avec des

moyens inadéquats, des modications non

autorisées et quoi qu’il en soit, par tout ce qui

n’est pas contemplé dans le présent livret d’ins-

tructions.

la portée des enfants et des animaux car elles sont potentiellement dangereuses.

Les composants en matière plastique pouvant être

recyclés sont marqués de la façon suivante :

POLYÉTYLÈNE : pellicule externe emballage, sachet

instructions, etc.

POLYPROPYLÈNE : feuillards, etc.

TRANSPORT ET DÉBALLAGE

Ne déplacer l’appareil qu’avec un moyen approprié,

comme un chariot élévateur ou un transpalette muni

de fourches dépassant de la moitié la dimension du

produit (voir fig.1).

Au cas où l’appareil devrait être entreposé de façon

provisoire, le conserver dans un endroit couvert et

aéré, à une température comprise entre -10° C et

50° C et un taux d’humidité pouvant aller jusqu’à

95%.

NORMES POUR LA SAUVEGARDE DE

L’ENVIRONNEMENT

Tous les matériaux utilisés pour l’emballage sont

conformes aux normes sur la sauvegarde de l’envi-

ronnement. Ils peuvent être conservés sans danger

ou éliminés en respectant les lois en vigueur dans le

Pays où l’appareil est installé.

Ne pas laisser les enveloppes en plastique à

Fig.1

Enfiler des gants de protection, enlever l’emballage,

soulever l’appareil avec un chariot élévateur, retirer la

base et la positionner sur le lieu de destination.

Page 21

21

FRANÇAIS

Après avoir enlevé l’emballage, contrôler im-

50mm

50mm

50mm

médiatement l’état de l’appareil.

En cas de doute, ne pas utiliser pas l’appareil

et contacter un revendeur agréé.

NORMES POUR L’INSTALLATION

em P l a c e m e n T e T P r é P a r a T i o n

1) Placer la machine à l’endroit prévu en suivant les

modalités d’installation suivantes :

- Vérier que la distance du mur ou d’éventuels

obstacles est suffisante (50 cm minimum) pour

permettre une bonne circulation de l’air (fig.2).

Fig.3

- Toujours installer l’appareil sous une hotte aspi-

rante dont le bon fonctionnement aura été vérié.

2) Enlever la pellicule qui recouvre certaines parties

de l’appareil avant de le mettre en marche.

3) Nettoyer soigneusement l’appareil en veillant

à éliminer les résidus de colle, sans utiliser de

substances abrasives.

4) Après quoi effectuer la mise à niveau et régler la

hauteur de l’appareil au moyen des pieds d’ap-

pui prévus à cet effet (g.4).

Fig.2

- Vérier que les opérations d’entretien et de

maintenance puissent être effectuées avec une

certaine liberté de mouvement.

- Éviter d’installer l’appareil dans des endroits peu

aérés, exposés aux rayons du soleil, présentant

des températures élevées, à proximité de source de chaleur ou dans des endroits exposés au

vent (fig.3).

- La température de l’air ambiant ne doit pas dépasser 89° F ; au-delà de cette température, le

bon fonctionnement de la machine ne pourra

être garanti.

Fig.4

Page 22

22

BRANCHEMENTS ÉLECTRIQUES

L’appareil est conçu pour fonctionner avec la tension

indiquée sur la plaquette signalétique.

Tous les appareils sont munis de cordon d’alimentation.

Il est nécessaire de monter une prise homologuée,

adéquate à la charge indiquée sur la plaquette signalétique ; pour accéder au bornier, enlever le panneau du coté droit de l’appareil en dévissant les vis

de fixation (fig.5).

Le raccordement au réseau électrique doit être réalisé en interposant un interrupteur automatique de

portée adéquate (voir “Caractéristiques techniques”

de l’appareil) présentant un écart d’ouverture entre

les contacts d’au moins 3 mm.

En outre, pendant le fonctionnement de l’appareil,

la tension d’alimentation ne doit pas s’écarter de

±10% de la valeur de tension nominale.

L’appareil DOIT être relié à la terre au moyen de la

borne qui porte le symbole de terre située

sur le bornier.

L’appareil doit notamment être relié à un disposi-

tif équipotentiel (dont l’efcacité devra être

contrôlée tel que prévu par les normes en vigueur)

en utilisant la borne reportant le symbole relatif

(g.6). Celle-ci se trouve près de l’entrée du câble

électrique sur le panneau situé au fond du four.

Le fabriquant décline toute responsabilité au

cas où la norme portant sur la prévention des

accidents ne serait pas respectée.

Fig.5

Les caractéristiques du câble exible devant être

branché au réseau électrique ne doivent pas être inférieures à celles du type de câble avec isolation en

PVC mod. H07RN F et doit avoir une section corres-

pondant à la section indiquée au paragraphe “Caractéristiques techniques” de la notice de l’ appareil. Le

câble doit également être xé au châssis au moyen

de l’attache prévue à cet effet dont la vis est accessible à travers un trou percé sur le châssis et doit quoi

qu’il en soit, être placé de sorte qu’aucun point ne

puisse atteindre une température supérieure à 122°

F par rapport à la température ambiante ; le câble

doit être du type SJTO che 20A 250V P section 3

x AWG12.

Page 23

23

FRANÇAIS

CONTRÔLES ET TEST

, .

Avant la mise en marche, contrôler que :

- La soupape de limitation et le réseau peuvent

supporter la charge de l’appareil (voir plaquette

signalétique et caractéristiques techniques).

- Le réseau électrique est équipé d’une prise de

terre efficace conforme aux normes et aux dispositions en vigueur.

- La prise ou l’interrupteur omnipolaire utilisés

pour le branchement sont facilement accessi-

bles une fois que l’appareil installé.

- Vérier le branchement électrique

- Vérier la consommation électrique.

- Effectuer un cycle de cuisson complet.

Fig.6

DISPOSITIFS AUTOMATIQUES DE

CONTRÔLE ET DE SÉCURITÉ

Pr o T e c T i o n d u c i r c u i T é l e c T r i q u e a u x il i a i r e

Ce circuit est contrôlé par des fusibles situés sur le

bornier à l’arrivée de la ligne.

Pr o T e c T i o n d u m o T o v e n T i l a T e u r d e l’e n c e i n T e .

Un télérupteur éteint le moteur en cas de mauvais

fonctionnement ou de surcharge. Il est placé derrière le four et doit être réarmé manuellement. Sa

fonction est d’ éteindre le moteur ainsi que les élé-

ments de chauffage.

Th e r m o S T a T d e S é c u r i T é e n c e i n T e d u f o u r .

Le thermostat de sécurité éteint les résistances en

cas de température trop élevée dans l’enceinte du

four. Il doit être réarmé manuellement. Pour accéder au thermostat de sécurité, démonter le panneau

postérieur du four. En cas d’intervention, prévenir

l’assistance technique.

Tous les composants sont protégés par des fusibles

de type : CLASSE CC,G 600V 20A.

Fig.7

REMPLACEMENT DES PIÈCES DÉTACHÉES

Le remplacement des pièces détachées doit

être effectué uniquement par des techniciens

qualifiés et agréés.

Avant de remplacer des pièces détachées, comme

indiqué ci-dessus, éteindre l’interrupteur géné-

ral et fermer les robinets d’eau (posés par votre

installateur).

r e m P l a c e m e n T d e S m o T e u r S : Enlever le panneau

postérieur en dévissant les 4 vis de xation “A” et les

4 vis “B” (fig.8).

Page 24

24

1

2

B

A

Fig.8

C

en v e l o p p e e x t e r n e : retirer les 4 vis de fixation pos-

térieures “C” (g.9).

et le collier en bronze situé à l’intérieur du four. Le

cas échéant, desserrer les vis de xation du collier

puis les revisser après avoir résolu le problème de

frottement et avoir bien centré le collier sur l’arbre

moteur.

ré S i S T a n c e S : débrancher les attaches des résistan-

ces de l’extérieur de l’enceinte du four puis celles de

l’intérieur et les remplacer.

co m m a n d e S é l e c T r o m é c a n i q u e S : tous les compo-

sants électriques sont visibles. Pour les remplacer,

ôter les attaches, enlever les boutons de commande,

retirer les vis ou les écrous de xation et remplacer

les éléments. Attention : pour les thermostats réglables, le thermostat de sécurité et le thermomètre,

retirer les ampoules de la chambre de cuisson après

avoir dévissé leur protection et leurs supports. Après

avoir remplacé les pièces, boucher les trous de passage des ls avec du silicone spécial pour hautes

températures.

Jo i n T f a ç a d e e n c e i n T e : il est inséré simplement par

pression ; il suft de le tirer en le dégageant de son

logement ; bien observer la façon dont il est monté

pour pouvoir insérer le joint neuf correctement et

dans la même position.

re m P l a c e m e n T J o i n T v i T r e e T a m P o u l e S e n c e i n T e :

contrôler et si nécessaire remplacer le joint de la vitre

et/ou les ampoules à l’intérieur de l’enceinte du four

(fig.10).

Fig.9

ve n T i l a T e u r d u m o T e u r , d e S r é S i S T a n c e S e T d e S

b u l b e S : il faut accéder également à l’intérieur du

four, après avoir retiré les plats à four, les grilles, leurs

supports et le convoyeur.

mo T e u r 30W : extraire le ventilateur comme in-

diqué ci-dessus, débrancher le moteur du réseau

électrique, dévisser les 4 vis de xation et remplacer

la pièce. Avant de remonter le ventilateur, vérier

qu’il n’y ait pas de frottement entre l’arbre moteur

Fig.10

Page 25

25

FRANÇAIS

PARTIE RÉSERVÉE A L’UTILISATEUR

NORMES GÉNÉRALES DE SÉCURITÉ

• Le présent manuel fait partie des

documents qui accompagnent l’appareil. Il fournit tous les

renseignements nécessaires pour une utilisation et un entretien

corrects du produit.

• Avant d’utiliser le four, LIRE ATTENTIVEMENT LE MODE D’EMPLOI en prêtant

une attention particulière aux normes

concernant les dispositifs de contrôle auto-

matiques et les dispositifs de sécurité.

• L’utilisateur est tenu de lire attentivement

l’ensemble des indications reportées dans

ce livret qui devra être soigneusement

conservé dans un endroit accessible à tous

les utilisateurs autorisés ;

• Ces appareils sont de type professionnel et

ne doivent être utilisés que par du person-

nel qualifié et seulement pour l’usage

pour lequel ils ont été conçus, c’est-à-

dire pour la cuisson des aliments en cuisines

industrielles.

•

Éteignez toujours l’interrupteur électrique prin-

cipal à la fin de l’utilisation du four, surtout pen-

dant les opérations d’entretien et de réparation

ou en cas d’arrêt prolongé de l’appareil.

• Il est recommandé de faire contrôler l’ap-

pareil une fois par an, en s’adressant à un

Centre d’Assistance Agréé.

• Les propriétaires de ces appareils doivent

former périodiquement leur personnel sur

l’utilisation des machines et les mesures de

sécurité.

• Pendant la cuisson, éviter le contact avec

les parties externes des appareils pouvant

chauffer (par ex. vitre de la porte) .

mo d a l i T é S d’e m P l o i

• L’appareil peut être utilisé pour la cuisson

au four de crèmes, gâteaux, sauces et piz-

zas, pour faire gratiner des aliments et pour

décongeler les produits alimentaires.

• Éviter de saler les produits alimentaires

dans l’enceinte du four.

•

Veiller à distribuer uniformément les aliments

dans les plats à four.

Fig.11

• Laisser au moins 4 cm entre chaque plan.

L’air chaud doit pouvoir circuler aussi bien au-

dessus qu’au-dessous de l’aliment à cuire.

• Ne pas utiliser de plats à four ayant des bords

plus hauts que nécessaire. Les bords consti-

tuent une barrière pour la circulation de l’air.

• Pour le premier allumage du four, il est conseillé

de le laisser fonctionner à vide et à la tempéra-

ture maximale pendant 1 heure environ.

Ceci permettra d’éliminer les éventuelles

odeurs désagréables dues aux graisses de

protection utilisées en usine.

• Laisser de l’espace entre les plats se trou-

vant sur un même plan de cuisson.

• Faire préchauffer le four. Il est préférable d’in-

troduite l’aliment dans le four déjà chaud.

• Pendant la cuisson, les plats à four et les

grilles atteignent des températures très élevées : attention aux risques de brûlures.

Page 26

26

0

5

10

15

20

25

30

40

50

60

70

8090

100

110

120

)

/

²&

UTILISATION DU FOUR

lé g e n d e ba n d e a u

1) BOUTON PROGRAMMATION TEMPS DE

CUISSON

Programme le temps de cuisson de 0 à 120 mi-

nutes ou en fonctionnement continu.

2) BOUTON PROGRAMMATION TEMPÉRATURE

Programme la température de l’enceinte du four

de 50 à 520° F

3) INTERRUPTEUR GÉNÉRAL MARCHE/ARRÊT

al l u m a g e e T u T i l i S a T i o n

Pour allumer le four, agir sur l’interrupteur général 3 ON/OFF.

Programmer le temps de cuisson en tournant

le bouton 2 programmation temps.

Agir ensuite sur le bouton 2 qui permet de

programmer la température de cuisson désirée ; en laissant le bouton 2 sur la position ‘0’,

seuls l’éclairage et le ventilateur fonctionnent

tandis que le four ne chauffe pas.

ar r ê T

La cuisson s’interrompt automatiquement

quand le temps de cuisson programmé avec

le bouton 1 est écoulé

Reporter tous les boutons sur “0” et éteindre

l’interrupteur général 3 ON/OFF.

Page 27

27

FRANÇAIS

ENTRETIEN ORDINAIRE

ne T T o y a g e d e l’e n c e i n T e d u f o u r

Avant toute opération d’entretien, débrancher le four de l’alimentation électrique.

Pour le nettoyage, enler des vêtements de protection, des gants et un masque tel que prévu par les

normes en vigueur.

A la fin de chaque journée de travail , nettoyer

l’intérieur du four avec des produits spéciaux en suivant les recommandations de votre fournisseur et en

évitant d’employer des produits acides, corrosifs ou

non appropriés au type de nettoyage requis .

Pour faciliter le nettoyage, enlever les diffuseurs latéraux (en les soulevant légèrement an de les déga-

ger des ergots de fixation).

Chaque jour, nettoyer les parties en acier inox avec de

l’eau savonneuse, en ayant soin de rincer abondamment. Puis essuyer soigneusement.

Éviter absolument de nettoyer l’acier inox avec de

la paille de fer ou des brosses en acier ordinaire car

en se déposant les des particules de fer pourraient

s’oxyder et provoquer des points de rouille.

Utiliser éventuellement de la laine d’acier inoxydable, passée dans le sens du satinage.

Au cas où l’appareil ne serait pas utilisé pendant une

longue période de temps, le protéger avec un voile

d’huile de vaseline passée avec un chiffon doux sur

toutes les surfaces ; en outre, aérer régulièrement

les locaux.

• Nettoyer l’enceinte du four de tous les résidus

d’aliments ou de graisses, après chaque cycle

de cuisson, et selon l’utilisation plus ou moins

intensive du four.

• L’association de graisses, chaleur, circulation forcée salit le four de façon manifeste. Seul un nettoyage quotidien évitera de devoir effectuer des

opérations difciles par la suite.

• Sauces ou sucs de cuisson : les graisses ou les sucs

de cuisson qui coulent des aliments tombent sur la

sole du four ; ils sont évacués à travers le canal situé

dans la partie centrale de l’enceinte et éliminés.

• Pour le nettoyage du four, utiliser un produit dégraissant prévu à cet effet (non mousseux) conseillé par

votre fournisseur habituel (mieux en spray pour atteindre les zones derrière le panneau de protection).

Ne pas utiliser de substances abrasives, corrosives,

des racloirs ou des éponges en inox (g. 12).

Fig.12

Il est recommandé de respecter les mesures de

sécurité relatives à la protection de la peau et

des yeux indiquées sur l’étiquette des produits

d’entretien utilisés. Pour le nettoyage, procéder

de la façon suivante :

a) Faire chauffer l’enceinte du four à une température

d’environ 158-176° F et la nettoyer avec le produit

dégraissant selon les quantités conseillées.

b) Fermer le four et le faire chauffer.

Page 28

28

c) Laisser agir le produit d’entretien pendant 20-

2

1

A

A

30 minutes environ puis éteindre le four.

d) Ouvrir le four avec prudence en protégeant la

peau et aux yeux ;

e) Retirer les plats à four ou les grilles, extraire les sup-

ports des grilles xés latéralement et sur le panneau de protection, enlever le panneau de pro-

tection en dévissant les vis de blocage. Laver ces

éléments à part (même dans le lave-vaisselle).

f) Nettoyer et rincer l’enceinte du four et le venti-

lateur à l’eau claire.

g) Remonter le panneau de protection et les sup-

ports de grilles ; faire sécher l’enceinte du four

en allumant le cycle CONVECTION.

Pour faciliter le nettoyage de l’enceinte du four, la

porte du four peut être complètement enlevée en

quelques gestes simples, en suivant les différents

passages illustrés sur la gure 13 ; pour la remonter,

effectuer les mêmes opérations en sens inverse.

ne T T o y a g e d e l a P o r T e v i T r é e

Pour accéder à la vitre interne de la porte du four,

agir sur le bandeau inférieur “A”, ouvrir la vitre exter-

ne “B” en la soulevant du bas vers le haut ; de cette

façon, vous pourrez accéder aux parties internes de

la vitre pour la nettoyer. Une fois terminé, refermer

la vitre en la poussant lentement vers le bas jusqu’à

entendre le déclic sur le composant “A”.

Fig.14

ne T T o y a g e d u v e n T i l a T e u r

Contrôler périodiquement l’état de propreté du ventilateur, en veillant à ce que ne s’accumule pas trop

de graisse sur les pales, ce qui pourrait provoquer

une réduction du nombre de tours du moteur et par

conséquent une surchauffe ainsi qu’ une mauvaise

distribution de la chaleur et donc une cuisson irré-

gulière.

ATTENTION : ne pas laver l’appareil au moyen de

jets d’eau directs à haute pression car les éventuelles projections d’eau sur les composants électriques

pourraient compromettre le bon fonctionnement de

l’appareil et de ses systèmes de sécurité.

Fig.13

Page 29

29

FRANÇAIS

QUE FAIRE EN CAS DE PANNE OU

D’ARRÊT PROLONGÉ

• Éteindre l’interrupteur électrique général et fer-

mer les robinets de l’eau et du gaz posées en

amont de l’appareil par votre installateur.

• Placer tous les boutons du bandeau de com-

• Appeler le service d’assistance après-vente

• Nettoyez l’extérieur et l’intérieur de l’appareil.

guide Pour la réParaTion deS PanneS

mande sur 0.

(uniquement en cas de panne).

Pr o b l è m e ca u S e P r o b a b l e So l u T i o n

Unité débranchée

Fusibles

Le four ne s’allume pas

Le four ne chauffe pas

L’éclairage ne fonctionne pas interrupteur/éclairage

Les moteurs ne fonctionnent pas Contacteur moteur/ Moteur

Le four s’éteint à l’improviste

Câbles/bornier

Interrupteur

Thermostat de sécurité

Contacteur résistance

Résistance brûlée Remplacer la résistance

Thermostat

Thermostat de sécurité Presser la touche rouge sur le thermostat

Court-circuit

Contrôler le branchement puis rebran-

cher si nécessaire

Contrôler les fusibles et les remplacer

si nécessaire

Contrôler les branchements des câbles,

les ls éventuellement débranchés puis

les rebrancher le cas échéant

Contrôler l’interrupteur et la tension

d’entrée et de sortie.

Contrôler le thermostat de sécurité et

presser la touche rouge

Contrôler la tension d’entrée et de sortie du contacteur puis le remplacer si

nécessaire

Contrôler la température avec un ther-

momètre manuel et remplacer le ther-

mostat si nécessaire.

Contrôler l’interrupteur et les lampes ;

les remplacer si nécessaire

Contrôler la tension d’entrée et de sor-

tie du contacteur. Contrôler le moteur,

remplacer le contacteur ou le moteur

si nécessaire

Contrôler les fusibles et les remplacer

si nécessaire Si l’anomalie persiste, utiliser des instruments de test adéquats

pour contrôler toutes les parties de

façon à déterminer celle qui est à remplacer.

Page 30

30

Page 31

31

ESPAÑOL

Estimado cliente,

Le agradecemos la preferencia que ha demostrado por nuestros productos.

Estamos seguros de que el aparato que ha adquirido responderá a sus expectativas, y que le ayudará en su trabajo durante mucho tiempo y de forma fiable, prestando siempre un rendimiento del más alto nivel.

un servicio post-venta y una asistencia técnica eficientes y funcionales.

La instalación y el uso de su aparato son simples e inmediatos. Aún así, le rogamos que lea este manual de

instrucciones con mucha ATENCIÓN, y que lo conserve con cuidado para posibles consultas en el futuro.

Le deseamos un Buen trabajo.

Además, le aseguramos

El Fabricante se reserva el derecho de cesar la producción de cualquier modelo o de implementar modificaciones sin estar

obligado por ello a efectuar estas modificaciones en productos ya entregados.

El Fabricante no se hace responsable de posibles errores de transcripción o impresión.

El Fabricante, además, no puede ser considerado responsable si se usan los aparatos de forma impropia o distinta de la

especificada en este manual.

Page 32

32

ÍNDICE

DATOS TÉCNICOS

Placa de la matrícula ........................................................................................................................................................... 32

Bornera de alimentación ................................................................................................................................................... 32

Asistencia Post-Venta .......................................................................................................................................................... 32

Datos técnicos del horno Speedy .................................................................................................................................. 33

Parte reservada al instalador ...................................................................................................................................................34

Normas de seguridad ........................................................................................................................................................34

Normas ecológicas .............................................................................................................................................................. 34

Transporte y desembalaje ...............................................................................................................................................34

Normas de instalación ........................................................................................................................................................35

Conexiones eléctricas .........................................................................................................................................................36

Automatismos de control y de seguridad del aparato ........................................................................................... 37

Sustitución de las partes de repuesto ..........................................................................................................................37

Parte reservada al usuario .......................................................................................................................................................39

Normas generales de seguridad .....................................................................................................................................39

Utilización del horno ...........................................................................................................................................................40

Mantenimiento ordinario ................................................................................................................................................... 41

Comportamiento en caso de averías o periodos de inactividad ........................................................................ 43

COMPONENTES ..........................................................................................................................................................................44

ESQUEMA ELÉCTRICO ..............................................................................................................................................................46

PLACA DE LA MATRÍCULA

La placa de las características está pegada a la parte

delantera del aparato, debajo de la cubeta colectora

de gotas o en el lado derecho.

BORNERA DE ALIMENTACIÓN

La bornera de alimentación se encuentra dentro del

lado derecho del aparato; la placa que se encuentra

cerca de la bornera indica el tipo de conexión posible.

ASISTENCIA POST-VENTA

aS i S T e n c i a d e fu n c i o n a m i e n T o

Para todas aquellas personas que hayan elegido la

calidad de uno de nuestros hornos, la empresa, en

colaboración con chefs profesionales externos, es

capaz de proporcionar consejos acerca del correcto

funcionamiento de los hornos, con la posibilidad de

intervenciones a domicilio.

Además, se organizan habitualmente seminarios acer-

ca de las técnicas de cocción impartidos por chefs seleccionados que también ponemos a disposición de

nuestra clientela para resolver cualquier problema en

materia culinaria.

aS i S T e n c i a Té c n i c a

El perfecto funcionamiento a lo largo del tiempo de

todos nuestros productos queda garantizado por una

extendida red continua de asistencia técnica, proporcionada por técnicos especializados listos para inter-

venir de inmediato para asegurar la continuidad del

trabajo de los trabajadores de la restauración.

ga r a n T í a

Todos nuestros productos se someten a minuciosas

pruebas de funcionamiento antes de llegar al merca-

do, como demuestra el certicado de ensayo que se

adjunta con cada uno, y la garantía de un año.

Page 33

33

ESPAÑOL

DATOS TÉCNICOS HORNO SPEEDY

v

v

v

Dimension

LxPxH

Dimensiones exteriores:

68,5x55x64 cm - 27”x25 1/2”x22

1/4”

Dimensiones interiores:

54x36x37cm-21 1/2”x14 1/2”x16 1/8”

Dimensiones de las rejillas:

52,7x36,8 cm - 1/2 size

Para obtener más información, consultar el esquema eléctrico al final del

manual

N° ban-

dejas

o rejillas

Alimentación

4 1Phase 15

Amp 240V

Clavija NEMA

Potencia

Kw 3,2

60Hz

6-20P

estándar

Page 34

34

PARTE RESERVADA AL INSTALADOR

NORMAS DE SEGURIDAD

• El encargado de la instalación debe

leer con atención este manual antes

de la instalación del aparato.

• La instalación y las posteriores operaciones

de mantenimiento, limpieza, inspección y

reparación deben realizarse con la alimen-

tación eléctrica desconectada.

• Las operaciones de instalación de los apa-

ratos deben responder a las normas en

vigor en el país de utilización. De lo

contrario, el fabricante no se responsabiliza

ni aplica la garantía en caso de daños directos o indirectos.

• La instalación, regulación y asistencia deben ser realizadas por personal cualificado y en el respeto de las

leyes para la prevención de accidentes del país de utilización. Además,

el encargado de la instalación debe

respetar las normas anti-incendio.

• El fabricante declina toda responsabilidad

por daños causados por un uso impropio

del producto, un desplazamiento con medios no adecuados, modificaciones no au-

torizadas y, en cualquier caso, por cualquier

cosa no contemplada en este manual.

ciclaje están marcados de las siguientes formas:

POLIETILENO: película exterior del embalaje,

bolsa con las instrucciones, etc.

POLIPROPILENO: flejes, etc.

TRANSPORTE Y DESEMBALAJE

Cualquier desplazamiento del aparato debe tener lugar con un medio adecuado, como un

carro elevador o un transpallets de horquillas:

éstas deben superar la mitad del tamaño del

producto (ver fig. 1).

En caso de que, temporalmente, se deba almacenar el aparato, conservarlo en un lugar cubierto y ventilado, con una temperatura entre

-10°C y 50°C y una humedad de hasta 95%.

NORMAS ECOLÓGICAS

Todos los materiales usados para el embalaje

son compatibles con las normas de protección

del medio ambiente. Éstos se pueden conservar sin peligro o se pueden desechar según las

leyes en vigor en el país de utilización.

No dejar al alcance de niños o animales

los plásticos de cobertura, ya que son

potencialmente peligrosos.

Los componentes de material plástico sujetos a re-

Fig. 1

Equiparse con guantes de protección y eliminar el embalaje, elevar el aparato con un carro

elevador, quitar la base y colocarlo en el lugar

de instalación.

Tras haber quitado el embalaje, comprobar

de inmediato la integridad del aparato.

En caso de dudas, no usar el aparato y

ponerse en contacto con el distribuidor

autorizado.

Page 35

35

ESPAÑOL

NORMAS DE INSTALACIÓN

50mm

50mm

50mm

co l o c a c i ó n y P r e d i S P o S i c i ó n P a r a e l u S o

1) Colocar la máquina en el lugar previsto se-

gún estas normas de instalación:

- Comprobar que haya suciente espacio

(mínimo 50 cm) desde paredes u obstáculos que podrían dicultar la correcta circulación del aire (fig. 2).

Fig. 2

-

Comprobar que haya una cierta libertad de

movimiento para las operaciones de mantenimiento.

- Evitar colocar los aparatos en lugares con

poco intercambio de aire, en lugares expuestos directamente a los rayos del sol,

con temperaturas elevadas, cerca de fuentes de calor o expuestos al viento (fig. 3).

- La temperatura del aire ambiente no puede

ser superior a 89°F. Por encima de éstos,

no se garantiza el buen funcionamiento de

la máquina.

Fig. 3

-

Instalar el aparato bajo una campana de funcionamiento eficiente para la aspiración de los vapores.

2) Quitar la película que cubre algunas partes del

aparato antes de ponerlo en funcionamiento.

3) Limpiarlo esmeradamente eliminando tam-

bién los residuos de cola sin utilizar sustancias abrasivas.

4) Realizar la nivelación con un nivel de bur-

buja y regular la altura mediante los pies

especiales (fig. 4).

Fig. 4

Page 36

36

CONEXIONES ELÉCTRICAS

El aparato está predispuesto para su funcionamiento a la tensión indicada en la placa de

características.

Todos los aparatos se entregan con el cable de

alimentación.

Es necesario montar una clavija normalizada

adecuada para la carga indicada en la placa

de la matrícula. Para acceder a la bornera de

conexión, quitar el panel del lado derecho del

aparato, desenroscando los tornillos de fijación

(fig. 5).

ambiente, y debe ser de tipo SJTO clavija de 20

A 250 V P sección 3xAWG12.

La conexión a la línea eléctrica debe realizarse interponiendo un interruptor automático de

capacidad adecuada (véase “Datos técnicos”

del aparato) en el cual la distancia de apertura

entre los contactos debe ser, por lo menos, de

3 mm.

Además, durante el funcionamiento del aparato, la tensión de alimentación no debe alejarse del valor de la tensión nominal en más de

±10%.

El aparato DEBE estar conectado a tierra mediante el borne indicado con el símbolo de tierra en la bornera de conexión.

Además debe introducirse un sistema equipo-

tencial (cuya eficiencia debe controlarse

como prevén las normas vigentes) utilizando

el borne con el símbolo equipotencial (g. 6).

Éste se encuentra cerca de la entrada del cable

eléctrico en el plano del fondo del horno.

El fabricante declina toda responsabilidad

en caso de que esta norma de prevención

de accidentes no se respete.

Fig. 5

El cable flexible para la conexión con la línea

eléctrica no debe tener características inferiores

a las del tipo de aislamiento de goma mod.

H07RN F y su sección debe corresponder a la

indicada en el punto “Datos técnicos” del aparato. El cable, además, se debe anclar sobre el

armazón con el sujetacables adecuado, a cuyo

tornillo se puede acceder a través del oricio

del armazón. En cualquier caso, se debe montar de tal forma que no alcance en ningún pun-

to una temperatura 122°F por encima de la del

Page 37

37

ESPAÑOL

COMPROBACIONES Y PRUEBAS

, .

Antes del encendido, realizar los siguientes controles:

- Comprobar que la válvula de limitación y

la instalación sean capaces de soportar la

carga del aparato (ver placa y datos técnicos).

- Cerciorarse de que la instalación de alimentación posea una toma de tierra eficaz

según las normas y las disposiciones vigentes.

- Vericar que la toma o el interruptor omnipolar usados para la conexión sean de fácil

acceso con el aparato instalado.

- Comprobar la conexión eléctrica

- Comprobar las absorciones

- Realizar un ciclo completo de cocción.

las resistencias.

Te r m o S T a T o d e S e g u r i d a d d e l a c á m a r a d e l

h o r n o

El termostato de seguridad desconecta las resistencias en caso de temperaturas demasiado

elevadas en la cámara del horno. Debe rearmarse a mano. Para acceder al termostato de

seguridad, desmontar la trasera del horno. En

caso de que intervenga, se debe avisar a la

asistencia técnica.

Todos los componentes están protegidos por

fusibles de tipo: CLASE CC, G 600 V 20 A.

Fig. 6

AUTOMATISMOS DE CONTROL Y

DE SEGURIDAD DEL APARATO

Pr o T e c c i ó n d e l c i r c u i T o e l é c T r i c o a u x i l i a r

Está controlado mediante fusibles colocados

en una bornera al final de la línea.

Pr o T e c c i ó n d e l m o T o -v e n T i l a d o r d e l a c á m a -

r a

Un telerruptor detiene el motor en caso de mal

funcionamiento o de sobrecarga. Se encuentra

detrás del horno y debe rearmase a mano. Su

intervención conlleva la parada del motor y de

Fig. 7

SUSTITUCIÓN DE LAS PARTES DE REPUESTO

Las sustituciones de las partes de repuesto deben ser efectuadas exclusivamente

por personal cualificado y autorizado.

Antes de llevar a cabo la sustitución de las partes de repuesto, como se indica a continuación,

es necesario apagar el interruptor general y

cerrar las llaves de paso del agua (instala-

Page 38

38

das previamente por su instalador).

1

2

B

A

C

S u S T i T u c i ó n d e l o S m o T o r e S : es necesario qui-

tar la trasera desenroscando los 4 tornillos de

jación “A” y los 4 tornillos “B” que los sostienen (fig. 8).

Fig. 8

Pr o t e c c i ó n e x t e r i o r : quitar los 4 tornillos de

fijación posteriores “C” (fig. 9).

mo T o r d e 30 W: extraer el ventilador como

se indica más arriba, desconectar el motor de

la red de alimentación eléctrica, desatornillar

los 4 tornillos de fijación y sustituir. Antes de

volver a montar el ventilador, comprobar que

no haya fricción entre el eje motor y el casquillo

de bronce que se encuentra dentro del horno.

En caso contrario, aflojar los tornillos de fijación

del casquillo y volver a atornillarlos tras haber

eliminado las fricciones y haber centrado bien

el casquillo en el eje del motor.

re S i S T e n c i a S : desconectar las conexiones de

las resistencias en el exterior de la cámara, desatornillar las resistencias dentro de la cámara y

cambiarlas.

co n T r o l e S e l e c T r o m e c á n i c o S : todos los com-

ponentes eléctricos están a la vista. Para cambiarlos hay que desconectar las conexiones,

quitar los pomos, desatornillar los tornillos o las

tuercas de fijación y cambiar dichos componentes. Atención: para los termostatos regulables,

el termostato de seguridad y el termómetro hay

que extraer los bulbos de la cámara tras haber

desatornillado la protección y los soportes. Una

vez efectuada la sustitución, volver a sellar con

silicona para altas temperaturas los orificios de

paso de los capilares.

gu a rn i c i ó n d e l a n T e r a c á m a r a : está insertada

sencillamente a presión, sólo hay que extraerla tirando y despegándola de su propio alojamiento; prestar atención a la posición original

de la misma para luego insertar la nueva en la

misma posición.

Su S T i T u c i ó n d e l a g u ar n i c i ó n d e v i d r io y d e

l a S b o m b i l l a S d e l a c á m a r a : comprobar y

sustituir, si fuera necesario, las bombillas dentro

de la cámara del horno (fig. 10).

Fig. 9

ve n T i l a d o r d e l m o T o r , d e l a S r e S i S T e n c i a S y d e

l o S b u l b o S : también es necesario acceder al inte-

rior del horno quitando las bandejas y rejillas con

sus soportes y, por último, el conductor.

Fig. 10

Page 39

39

ESPAÑOL

PARTE RESERVADA AL USUARIO

NORMAS GENERALES DE SEGURIDAD

• Este manual forma parte de la do-

cumentación que

se entrega con el

aparato, y contiene

toda la información

necesaria para el uso correcto y el mantenimiento del producto.

• Antes de poner en funcionamiento el hor-

no leer atentamente las instrucciones

de uso contenidas en este manual,

prestando especial atención a las normas

concernientes a los automatismos de control y a los dispositivos de seguridad.

• El usuario está obligado a leer con atención

todas las indicaciones que se contienen en

éste y a conservarlo con cuidado en un lugar

accesible a todos los usuarios autorizados;

• Los aparatos son de tipo profesional y deben ser usados sólo por personal cuali-

ficado y para la finalidad para la que

han sido creados, es decir, para la coc-

ción de alimentos en cocinas industriales.

•

Apagar siempre el interruptor eléctrico princi-

pal cuando se termine de usar el horno, sobre todo durante las operaciones de mantenimiento y reparación o en caso de prolongada

inactividad.

• Se recomienda que, una vez al año, haga

que un Centro de Asistencia Autorizado re-

vise su aparato.

• Los propietarios de los aparatos deben, con

periodicidad, formar a su personal para la

utilización de las máquinas y suministrarles

instrucciones de seguridad.

• Durante la cocción, las partes exteriores del

aparato (por ejemplo, el cristal de la puerta)

pueden calentarse. Tener cuidado al tocarlas.

no r m a S g e n e r a l e S d e u S o

• El aparato se puede usar para la cocción al

horno de cremas, dulces, salsas y pizzas;

para gratinar y para descongelar productos

alimenticios refrigerados y congelados.

• Evitar añadir sal a productos alimenticios en

la cámara de cocción.

•

Intentar distribuir los alimentos de forma uniforme en las bandejas, evitando concentraciones.

Fig. 11

• Entre un piso y el otro debe haber, por lo

menos, 4 cm. El aire caliente debe ser capaz de circular por encima y por debajo del

alimento que se está cociendo.

• No usar bandejas con bordes más altos de

lo necesario. Los bordes son barreras para

la circulación del aire.

• La primera vez que se use el horno, es aconsejable dejarlo funcionar vacío y a la temperatura

máxima durante una hora aproximadamente.

De esta forma, es posible eliminar posi-

bles olores desagradables causados por los

aceites de protección usados en la fábrica.

• En un mismo piso de cocción, dejar espacio entre los platos.

• Precalentar el horno. Es mejor poner la comida en el horno con éste ya caliente.

• Las bandejas y rejillas, durante la cocción,

alcanzan temperaturas muy elevadas: tener

cuidado: peligro de quemaduras.

Page 40

40

0

5

10

15

20

25

30

40

50

60

70

8090

100

110

120

)

/

²&

UTILIZACIÓN DEL HORNO

le y e n d a d e l c u a d r o d e m a n d o S

1) POMO DE REGULACIÓN DEL TIEMPO

Regula el tiempo de cocción, de 0 a 120 minutos

o en funcionamiento continuo.

2) POMO DE REGULACIÓN DE LA TEMPERATURA

Regula la temperatura de la cámara de 50 a

520°F

3) INTERRUPTOR GENERAL ON/OFF

en c e n d i d o y uT i li z a c i ó n

Para encender el horno, actuar sobre el interruptor general 3 ON/OFF.

Configurar el tiempo de cocción girando el

mando 2 de regulación del tiempo.

A continuación, actuar sobre el pomo 2 que

permite la regulación de la temperatura de

cocción deseada. Si se deja el pomo 2 en la

posición ‘0’ se activarán sólo las funciones de

luz y ventilador, pero la cámara del horno no

se calentará.

aP a g a d o

La cocción termina automáticamente cuando

acaba el tiempo de cocción regulado con el

pomo 1.

De todas formas, llevar todos los mandos a “O”

y apagar el interruptor general 3 ON/OFF.

Page 41

41

ESPAÑOL

MANTENIMIENTO ORDINARIO

Antes de realizar las operaciones de

mantenimiento, quitar la alimentación

eléctrica del aparato.

Durante la limpieza, llevar puestos los elementos de protección, como guantes o máscara,

previstos por la ley.

Al final de cada jornada de trabajo limpiar

el interior del horno con productos apropiados

según los consejos de su distribuidor. Se deben evitar los productos ácidos, corrosivos o no

adecuados para el tipo de limpieza necesaria.

Para facilitar la limpieza, quitar los difusores laterales levantándolos ligeramente de manera

que se liberen de los pernos de sujeción.

Limpiar diariamente las partes de acero inoxidable con una solución tibia de agua jabonosa y aclarar meticulosamente con abundante

agua. A continuación, secar.

Evitar absolutamente limpiar el acero inoxidable con estropajos o cepillos de acero común

porque pueden depositar partículas ferrosas

que al oxidarse provocan puntos de óxido.

Si se considera necesario, puede utilizarse lana

de acero inoxidable pasándola en el sentido

del satinado.

Si el equipo permanece inactivo durante largos

periodos de tiempo, extender una capa de protección pasando sobre todas las superficies de

acero un poco de algodón con aceite de vaseli-

na; ventilar también regularmente los locales.

li m P i e z a d e l a c á m a r a d e l h o r n o

•

En proporción con el uso más o menos in-

tenso al que se somete la cámara del horno,

después de cada proceso de cocción será ne-

cesario limpiarla dejándola libre de residuos

de alimentos o grasas en su interior.

• La combinación de grasas, calor y circulación forzada ensucia notablemente el horno. Sólo una limpieza diaria permitirá evitar

difíciles operaciones posteriores de mantenimiento.

• Salsas o grasas de cocción: las salsas o las

grasas de cocción de las comidas caen sobre el fondo de la cámara del horno, se di-

rigen hacia el desagüe que se encuentra en

la parte central de la cámara y se eliminan.

• Para la limpieza del horno, usar un producto desengrasador adecuado (que no cree

espuma) que le recomiende su vendedor

de productos de limpieza (mejor en aerosol, para alcanzar las zonas de detrás del

escudo de protección). No usar sustancias

abrasivas o corrosivas, o rascadores o estropajos de acero inoxidable (fig. 12).

Fig. 12

Se recomienda respetar las indicaciones de

seguridad para la protección de piel y ojos

que se entregan con los productos de limpieza que se van a usar. Para la limpieza,

proceder en este orden:

a) Calentar la cámara a unos 158-176°F y

limpiarla con el detergente desengrasante

en las proporciones adecuadas que se recomiendan.

b) Cerrar el horno y calentarlo.

c) Dejar actuar el detergente durante unos

20-30 minutos y apagar el horno.

Page 42

42

d) Abrir prudentemente, con atención para

2

1

A

A

proteger la piel y los ojos;

e) Extraer del interior de la cámara las rejillas

y bandejas, sacar las guías de soporte de

las rejillas que están enganchadas a los

lados del escudo y desmontar el escudo