Page 1

Be sure bowl corners fit on outside edge of the top tray piece. The

lid cover will not fit properly if the bowl is not correctly positioned.

Unscrew two knobs and lower bowl to drain out remaining solution

underside of lamp cover with warm water and mild detergent.

POWER.

G & MG & ID Series Granita Machines

Operators

Manual

For the machine to function properly, it is important that the cleaning procedures be carried out daily.

DAILY CARE & CLEANING INSTRUCTIONS:

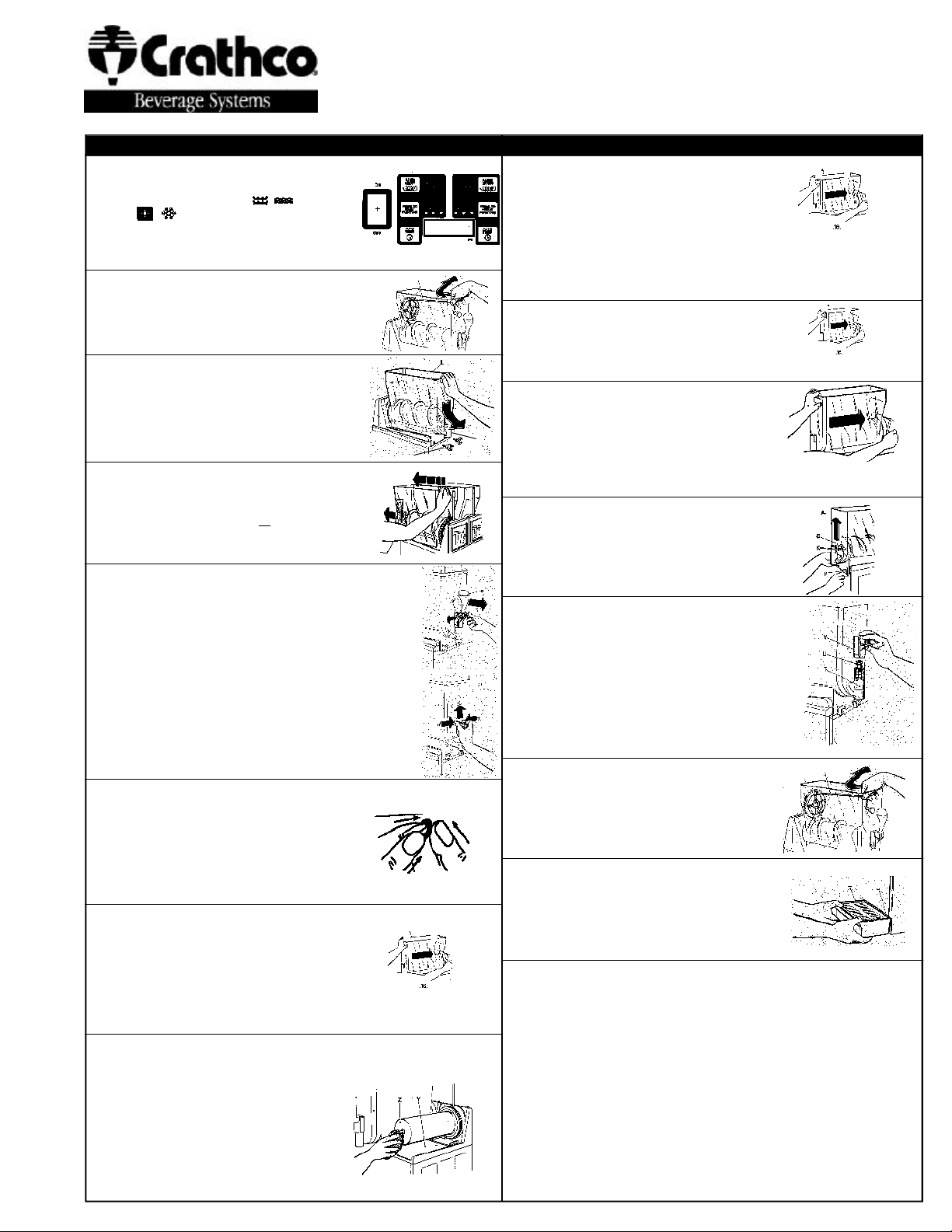

TO DISASSEMBLE TO RE-ASSEMBLE

TURN OFF ALL SWITCHES, EMPTY BOWL

1

& UNPLUG UNIT

• Turn off refrigeration / and

/ freezing switches and empty the

bowls of their remaining product

• Turn off auger switches and power switch

• Unplug the unit

REMOVE MIXING ROD

2

Pull out the mixing rod (O) by

pushing it slightly backwards

to remove it from its position

REMOVE KNOBS SECURING BOWL -

3

DRAIN EXCESS PRODUCT

• Unscrew and remove the two knobs (P)

• Then lower the bowl to drain out

any remaining product through the

dispensing valve (l)

REMOVE BOWLS

4

Remove bowl by pulling it outwards,

lightly tapping the back of bowl so

it comes out of position or by applying

slight downward pressure to the top front

edge of the bowl.

REMOVE DISPENSING VALVE

5

• Remove the pin (G) and slide the

handle out from it’s seat.

• Simultaneously apply pressure to the

securing tabs, lift the dispensing valve

out of its position.

• Disassemble remaining valve assembly

parts

REMOVE O-RINGS FROM DISPENSING VALVE

6

• Pinch o-ring between thumb

and index finger

• Squeeze and push o-ring out

of the groove

• Roll o-ring out of the groove with

your other thumb

REMOVE MIXING UNIT PARTS & DRIP TRAY

7

• Unscrew bolt (S) clockwise

• Pull off auger and gear ring assembly (U)

• Remove bowl seal (T) and bell shaped shaft

seal (X)

• Remove drip tray by lifting up the front edge,

while lowering the rear edge and pulling

it towards you

CLEAN ALL PARTS

8

• Thoroughly clean all parts removed

above as well as the base (Y) and

evaporator (Z).

• Wash with warm water using

a mild dish detergent and rinse

thoroughly with clean water.

Allow to air dry.

CAUTION: DO NOT USE ABRASIVE CLEANERS OR SCRUB PADS.

ABRASIVES WILL SCRATCH PLASTIC PARTS AND OTHER FINISHES.

S X

PUT ON BOWL SEAL AND SHAFT SEAL

9

• Moisten bowl seal (T) with water

and put back on

• Check for wear of bell shaped rubber

shaft seal (see below ) replace if needed

• Lubricate inside of bell shaped shaft

O

I

P

T

U

CAUTION: MAKE SURE LAMP COVER HAS BEEN DISCONNECTED FROM

seal (X) with food grade lubricant. Put

back seal making sure flared side faces

the cylinder

PUT ON GEAR RING/AUGER ASSEMBLY

10

• Put gear ring/auger assembly (U)

back in position

• Secure parts in place by screwing on

the bolt (S) counterclockwise

PUT ON BOWL

11

• Lightly moisten rear inner part of bowl

with food grade lubricant

• Position bowl into place making sure

it has a tight hold on the bowl seal •

•

SECURE BOWL WITH KNOBS

12

Keep bowl lifted until the hole in lower bowl

edge is aligned with hole in front panel then

tightly screw on the knobs (P) without exerting

excessive pressure to avoid cracking the bowl

REASSEMBLE DISPENSING VALVE

13

• Lubricate o-rings with food grade

lubricant and place o-rings on valve

• Place spring over valve stem

• While pushing up on valve, insert

metal bar on handle under hook on valve

• Slide valve back into position until it

completely snaps into place

• Reassemble the handle (B) with the rele-

vant pin (G ) (See #5).

REASSEMBLE MIXING ROD

14

• Reassemble mixing rod (O) so that

its gears are aligned with the lower

gear ring

• Insert front pin into position at

front of bowl

INSTALL DRIP TRAY

15

• Reinstall drip tray, (AA) making sure that

the condensation drainage tube (AB) is

reinserted into its correct fixed position

allowing it to drain into the tray

• Plug unit into appropriate power supply

SANITIZING UNIT

16

• Fill bowl with a mix of water and sanitizing solution

• Turn auger on for 10 minutes to sanitize all parts

• Turn off auger

• Drain bowl through dispensing valve

•

• Clean tray underneath bowl and lubricate rear bowl seal

• Reattach bowl

• Screw knobs back on

• Disconnect lamp cover from power. With clean cloth wash

Allow to air dry and wipe with cloth that has been dipped in

sanitizing mixture

S

X U

S X

B

K

O

O

T

T

U

AA

AB

Page 2

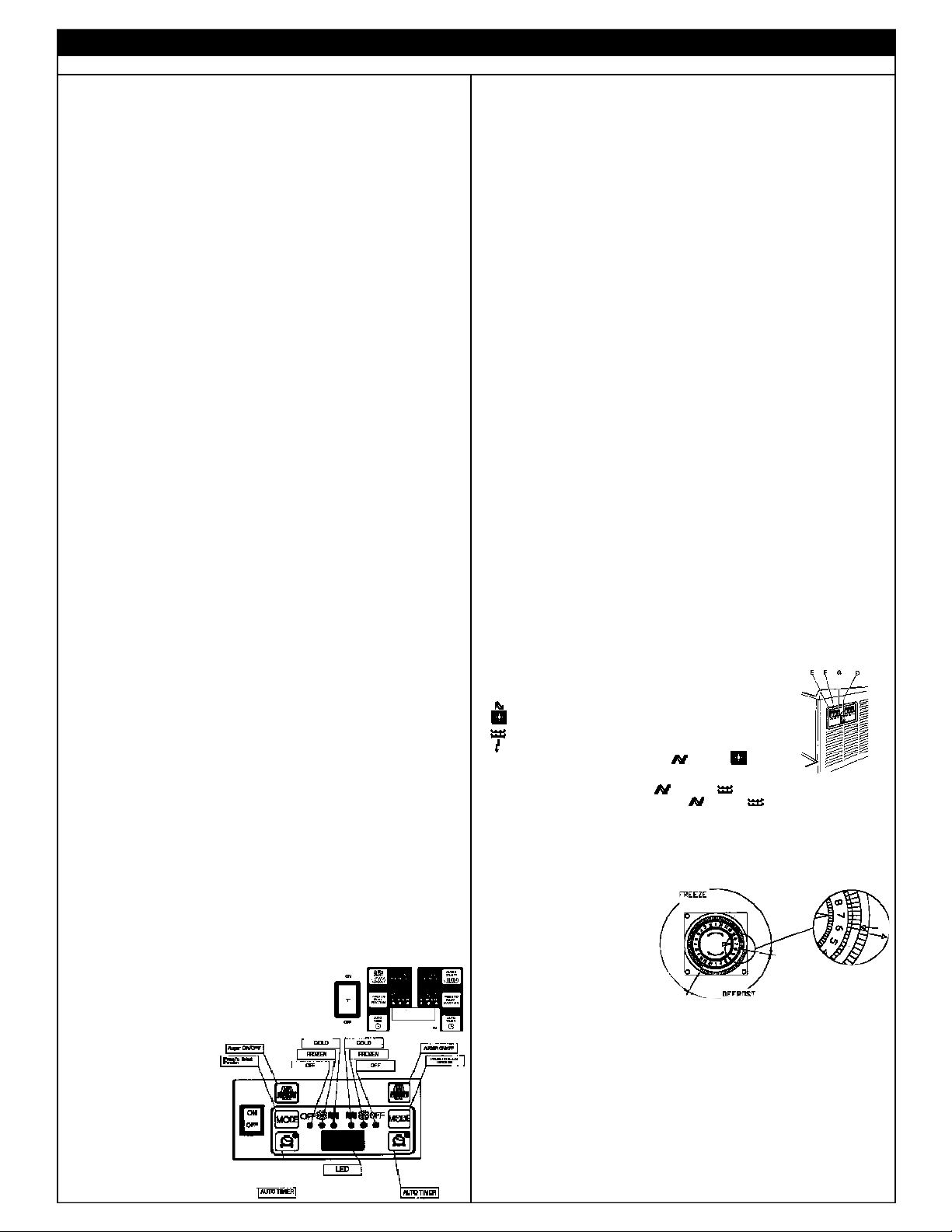

PROGRAMMING

To access the control panel, open the cover on the right side of the unit

G23-2B ELECTRONIC MODEL GUIDE:

MAIN POWER SWITCH:

1. Turns unit ON.

2. Selects 12/24 time or FÞ/CÞ temperature display when turned ON

while simultaneously depressing the auger button.

3. Sets current time when turned ON while simultaneously depressing

the “Mode/Press To Select Function” button.

AUGER ON/OFF BUTTON:

1. Turns auger ON and OFF when main power switch is ON.

2. Must be ON to permit defrost time to be reset.

3. Must be ON to activate the “Mode/Press To Select Function” button

to select manual “OFF”, “FREEZE” or “COOLING” functions.

MODE/PRESS TOSELECT FUNCTION BUTTON:

1. Use to manually select “OFF”, “FREEZE” or “COOLING” functions

when auger is turned ON.

2, Accesses defrost timer reset mode when depressed for an extended

period when auger is turned ON.

3. Locks in hours, minutes and final time settings after they are reset

using the “Auto Timer” button.

4. Does not function when light on “Auto Timer” button is illuminated.

“AUTOTIMER” BUTTON:

1. Turns auto defrost mode ON or OFF (light on switch indicates when

auto defrost mode is activated).

2, Used to adjust the hours and minutes settings when readjusting

current time or auto defrost timer.

ENTER TIME PROGRAMMING ON INITIAL INSTALLATION OR IN THE

EVENT OF ATIME CHANGE:

1. Turn OFF power switch.

2. While pressing left “Press to Select Function” button, turn ON power

switch while continuing to hold the “Press To Select Function” button

until the display illuminates (hour digits will start to blink).

3. First set hour by pressing the “Auto Timer” clock button until the

appropriate hour is shown.

Note: When using a 12 hour clock the time is P.M. when the dot at the bottom right corner of the LED is lit; when dot is not lit it is A.M.)

4. To set the minutes press the left “Press To Select Function” button,

then press the “Auto Timer” clock button until the appropriate minutes

are set.

5. To save your settings press the “Press To Select Function” button

one more time.

G23-2B SETTING DEFROST TIMER (Night Setting):

1. Turn the power switch on.

2. Then press “Auger ON/OFF” button on for the side you are setting.

3. Then press and hold the “Press to Select Function” button until you

hear a long beep and the LED and clock light begins to blink.

4. Press the “Auto Timer” clock button to set the hour you want it to turn

to refrigeration mode and then press “Press to Select Function” to

save the setting.

5. Then press the “Auto Timer” clock to set the minutes to complete

time

setting that you want it to turn to refrigeration mode. Then press the

“Press to Select Function” button to save the setting.

6. Proceed to setting the time you want the machine to turn to freezing

mode by following steps 4 and 5 above. Then press the “Press to

Select Function” button to save the time settings for freeze mode.

Note: Once the settings have been saved, the unit will save the settings,

even when the power switch is turned off.

When the light on the “Auto Timer” clock button is “on”, the defrost timer is

activated. To turn off the defrost timer, press the clock buttons until the

lights on the clock buttons turn off.

G23-2B - TO OPERATE IN AUTOMATIC MODE (WITH DEFROST TIMER

ACTIVATED)

1. Turn power switch on and wait for LED to light up.

2. To operate in defrost mode the light on the “Auto Timer” clock button

should be illuminated.

3. If it is not, press the “Auto Timer” clock button

to turn on automatic mode.

G23-2B OPERATE IN MANUAL MODE (WITHOUT

DEFROST TIMER ACTIVATED)

1. Turn power switch on

and wait for LED to light

up.

2. Make sure clock button

is off (LED light on clock

button should not be lit

up).

3. First turn auger on by

pressing “Auger

ON/OFF” button until it

beeps. (Note: The auger

-To access the operating panel, open the cover on the right side

of the unit.

must be on before unit will allow the cooling or freezing mode to activate.)

4. Then select refrigeration or freezing mode by pressing the “Press to

Select Function” button until the light under the selection you desire is lit

up. Note: In the cooling mode the LED will read the actual temperature of

the product (The temperature setting is preset to NSF standards and is

not adjustable.) In the freezing mode the LED will read the current time.

ERROR MESSAGES

“FILTER CLEANING” ALARM

A filter cleaning alarm will activate when the unit is running hot due to insufficient internal air circulation. When this occurs a “Filtr” message will appear on

the touchpad LED readout and an intermittent audible tone will also sound to

alert the operator of this condition.

The “Filtr” message will appear when the alarm activates (a beeping sound

every 4-5 seconds). To determine the condition that caused the alarm and correct problem, see list of conditions below:

• Condition: Filter is dirty and needs to be cleaned

Corrective Action: Clean and replace filter following instructions.

• Condition: Unit is positioned too close to a wall or other objects restricting

air flow and causing the machine to run at a higher temperature.

Corrective Action: Reposition unit to maximize ventilation space.

• Condition: Filter is not properly installed.

Corrective Action: Properly install filter.

• Condition: Unit has been installed near a heat source, such as a coffee

machine, ice maker or cold beverage machine which expels hot air from its

vents, causing the machine to run at a high temperature. (Installation near

a heat source should be avoided)

Corrective Action: Reposition unit to maximize ventilation.

“SYSTEM OVER TEMPERATURE” ALARM

• A system over temperature alarm will activate as a safety when the unit has

overheated to protect the compressor.

• The system automatically goes to “OFF” status where the compressor’s operations are stopped, while augers will keep working to avoid forming ice

blocks.

• When this “Err” message will appear on the touch pad LED readout accompanied by a continuous buzzer sound to alert the operator of this condition.

• When this alarm activates, turn off all switches. Then determine the condition

from the list above.

MG23-2B & ID2.2 TRADITIONAL ROCKER SWITCH MODEL

GUIDE

Important: The mixing parts/auger switch should be on prior

to activating the freezing or refrigeration switches.

(E) activates the mixing parts/spiral auger

(F) activates the freezing of the product

(G) activates the refrigeration of the product

(D) is the main power switch

FROZEN BEVERAGE - select (E) and (F)

Note: There is a 4 minute delay before the compressor starts.

COLD BEVERAGE - select (E) and (G)

STANDBY (Night Setting) - select (E) and (G)

* Defrost timers are installed in each unit and can be set to automatically

place units in defrost mode and back to frozen mode. All switches must be

on for defrost timer to properly function.

MG23-2B SETTING DEFROST TIMER (& ID2.2 When Equipped)

NOTE: All switches (power, auger, refrigeration and freeze) must be “on” for

defrost timer to properly function.

• Setting Current Time - Rotate

the program disc, in the

direction of the arrows,

to align the correct time of

day with the time of day mark

• Setting Defrost Mode Push the switch activator toward

the outer edge of the

program disc. Freeze time

is set by pushing the switch actuators toward the center of the time switch.

The light and dark shaded areas of the program disc indicate day and

night. Each actuator is equivalent to 15 minutes

• The drawing shows a defrost time from 11:00 to 6:15

THE TIMER IS BATTERY BACKED TO PROTECT SETTINGS DURING

POWER FAILURE. THE BATTERY BACK-UP FEATURE WILL FAIL IF

POWER IS REMOVED FROM THE UNIT FOR MORE THAN 2 WEEKS

Page 3

The following Preventative Maintenance Items should be performed per the recommended schedule in order to maximize the life of your machine and to insure

2. Check bell shaped shaft seal for wear and replace when needed (every 1-6 months or more often if necessary). Seal is worn if edges that touch barrel

Reassemble the rear back-lit merchandiser making sure that its slots are

d

c

a b

i

Key Replacement Parts

a) Drip Tray - Black 90409

Drip Tray - White 90026

b) Drip Tray Grid - Black 90408

Drip Tray Grid - White 90025

c) Incandescent Light Bulb 90142

d) Knob to secure Bowl - Black 90426

Knob to secure Bowl - White 90024

e) Upper Mixing Bar 90065

f) Seal for Bowl 90023

g) Dispensing Valve Handle - Black 90401

Dispensing Valve Handle - White 90041

h) Handle Securing Pin - Black 90402

Handle Securing Pin - White 90042

g h

e

f

m n

j

k

l

p q

o

ITEM DESCRIPTION PART NUMBERITEM DESCRIPTION PART NUMBER

i) Auger 90444

j) Spindle Bushing 90069

k) Shaft Seal, Rubber Bell Shaped - Black 90066

l) Securing Nut for Auger 90068

m)Dispensing Valve Spring 90044

n) Dispensing Valve Upper Body 90043

o) Food Grade Lubricant 90112

p) Dispensing Valve Lower Body - 90403

G & GM Series

Dispensing Valve Lower Body - 90045

ID Series

q) Dispensing Valve O-ring 90046

IMPORTANT-PREVENTATIVE MAINTENANCE

warranty coverage. (For a checklist of all P.M. items, contact GCS or check the website.)

1. Lubricate bell shaped shaft seal and dispense valve o-rings following daily cleaning procedure.

curl back.

3. Clean air filter weekly and condenser monthly or more often if necessary.

4. Check dispense valve o-rings for wear and replace as needed (every 3-6 months during complete PM or more often if necessary).

5. Perform complete PM every 3-6 months.

WARNING Disconnect the unit from its power supply prior to performing

!

any maintenance procedures. Failure to do so could result in electric

shock from hazardous parts or serious burns from hot surfaces.

REMOVING AND CLEANING THE FILTER IF EQUIPPED

(G & MG MODELS STANDARD; ID MODELS OPTIONAL)

In order to guarantee an efficient refrigerating system, it is

essential that the filter be properly cleaned, according to the

following procedures:

Attention: Failure to maintain a clean filter and condenser

!

will cause damage to the unit not covered by warranty.

• Unscrew the knob (K) on rear panel in order to have the

full back panel in your hands - (G, MG) on ID pull filter

cover from unit at bottom of cover, pull down to remove.

• Remove the filter (W) held inside the back panel (X) and

clean it properly using water or vacuum. Allow to dry.

• Put the clean dry filter back to its position and reinstall the back panel on

machine by screwing in the knob (K) or reattaching filter cover.

CLEANING CONDENSER

• Remove the back panel

• Using a dry brush or vacuum, remove the dust

that has accumulated between the fins of the

condenser

CHANGING LIGHT BULB

• To access the lightbulb insert the tip of a coin or

small screwdriver in the slot on the cover and

rotate to pop the panel open

• Holding the cover, carefully remove the lightbulb.

• Insert the new bulb and replace the light cover

REAR MERCHANDISER LIGHTS

• In order to access the lightbulb from the rear back

lit merchandiser, remove the rear merchandiser by

sliding it upwards.

• Then remove the lightbulb(s). Insert the new bulb(s).

•

inserted properly in the relevant brackets.

Page 4

INSTALLATION CONSISTENCY ADJUSTMENTS

Part # 90386

POSITIONING THE MACHINE

The machine must be well ventilated, with an 8” (20 cm) clearance on the sides and back of the machine. Do not install

near a heat source such as ovens, coffee machines, cold or

frozen beverage dispensers or ice machines (equipment with

compressors that expel hot air through its vents). Do not position near dust producing units such as a Powdered

Cappuccino or Cocoa dispenser. A room temperature

between 59ÞF (15ÞC) and 77ÞF (25ÞC) is recommended

REMOVE SHIPPING PIN

Attention: Shipping pin attached to tag located behind each bow must

!

be removed before starting machines.

CONSISTENCY ADJUSTMENTS

• Unplug the machine

• Product in bowl should be within proper fill range

• Change the thickness of product

by turning the screw (M) on the

back of bowl clockwise for thinner

product or counterclockwise for

thicker product

• The indicator gauge (N), located on the

8"

(20 cm)

back of the bowl, shows the degree of

adjustment (+/-) (+) = thicker, (-) = thinner

TOO THICK OF A PRODUCT CAN BE PREVENTED BY SWITCHING THE

FREEZING MODE (F) "OFF" OR BY REFILLING THE BOWL WHEN

PRODUCT IS BELOW MINIMUM FILL LINE

PRODUCT HINTS

• To maintain product quality place unit in standby (refrigeration) mode at

night to allow product to thaw out, and then refreeze the next day. This

will promote smoother product and smaller ice crystal growth. (Defrost

INSTALLING THE TOP LID MERCHANDISER

(requires Phillips head screwdriver)

1. Remove hole plugs and screws.

2. Remove or replace graphic by sliding

it around the outside edge of the lid’s

clear plastic base. Position bottom edge of

header in grooved area.Reassemble the

top cover onto the clear plastic base. The

top edge of header should slide into top

cover grooved area.

INSTALLING REAR GRAPHIC

1. Pinch or bend graphic and pull it out to

remove.

CONNECTION TOMAIN POWER SUPPLY

Install in properly grounded, electrical receptacle that is in compliance with current

national safety standards. Grindmaster Crathco Systems, Inc. is not responsible for

damage and/or injury caused by failure to follow above precautions.

• Only connect to a dedicated outlet.

timer can be programmed to do this for you automatically at preset

times.)

HELPFUL HINTS

PREPARING PRODUCT

• Make sure that your product has a 13% minimum

sugar content (BRIX). A lower concentrate could

damage the mixing parts and gear motors.

NEVER USE ONLY WATER.

• Premix all product in a separate container.

NEVER pour dry powder, crystals or concentrate

into a dry bowl.

• There is no need to remove lid for refilling.

Simply slide lid back until “stops” are reached.

• Note and follow minimum and maximum fill

lines on bowl. Do not overfill, or run the unit

without enough product.

• Altering the cord or plug will void the warranty.

• Do not compress, bend or bunch power cord or use extension cord.

TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

The machine over-freezes, making the auger

movement slow or stopped

Product is leaking out of the bowl

The machine does not cool, or cools only

partially, but the compressors are running

The cover does not fit properly on the bowl

Product is leaking from the dispensing valve

Product is flowing into drain tray through

drainage tube

The auger and/or the upper mixing unit is

not turning

• The product brix is too low

• The screw setting for the product consistency control system is

set too far toward the “+” position

• The level of the product in the bowl is too low, exposing the

auger

• One of the bowl seals is not in place

• Freezer is in defrost mode

• The space around the machine is inadequate for ventilation

• The condenser fins are clogged with airborne particles

• The bowl is incorrectly positioned.The lower right and/or left

corner edge of bowl is not over the lower triangle edge

• The dispening valve has been incompletely or incorrectly

replaced in its position

• The free movement of the dispensing valve is impeded

• Dispensing valve o-rings are damaged

• The bell shaped “shaft” seal between the front of the cylinder

and the auger hub has not been reinstalled properly

• Auger not turned on

• Check the product brix and correct

• Reset the screw toward the “-” position to

produce a thinner consistency product

• Add more product or turn the refrigeration “Off”

• Replace or reposition the seals

• Return to freeze mode

• Allow at least 8" between the machine and

anything next to it; keep away from heat sources

• Remove the side panels and using a brush or

compressed air to clean the condenser

• Remove bowl and position properly

• Reassemble and replace

• Clean and lubricate the valve and valve cylinder with

the lubricant provided with the machine

• Replace the o-rings

• Find the seal and put it back in place

• Turn auger on

Grindmaster Crathco Systems, Inc. 1999

PRINTED IN USA

If you still need help, call our service department at (800) 695-4500 (Monday through Friday, 8 am - 6 pm EST) or an authorized service center in your

area. Please have the model and serial numbers ready so that accurate information may be given.

Prior authorization must be obtained from Grindmaster Crathco Systems’ Technical Services Department for all warranty claims.

0101 Form # CC-904-04

Loading...

Loading...