Page 1

Autofill System

Operator Manual

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

Safety Information...............................2

Specifications .......................................3

Installation ...........................................3

Operation .............................................4

Cleaning and Sanitizing ......................4

Troubleshooting Guide........................5

Parts List ...............................................6

Parts Diagram.......................................7

Flow Diagram.......................................8

Wiring Diagram ...................................8

Thank you for purchasing this quality autofill system. For your safety and the safety of others, read all warnings

and the operator manual before installing or using the product. Properly instruct all operators. Keep training

records. For future reference, record serial number here:

Table of Contents

Model 2001-000

Grindmaster-Cecilware provides the

industry’s BEST warranty. Visit gmcw.com

for warranty terms and conditions.

Model 2002-000

Notice: This system is not certified for

use with dairy products.

Bubbler Ratio 4:1 Ratio 5:1

Single 2001-001 2001-000

Double 2001-003 2001-002

Remote Single 2001-005

Remote Double 2001-004

Granita* Ratio 4:1 Ratio 5:1

Single 2002-001 2002-000

©2018 Grindmaster-Cecilware

Printed in USA

0118 Form # CC-387-04

Part # 390-00090

Activate your warranty now at

http://gmcw.com/warranty-registration

*for use with models NHV-2UL-AF, MT2ULAF,

MT2ULAFBL, MT3ULAFBL

Page 2

GB Series Cecilware

®

2

Use the product for its intended purpose only. Any other usage is inappropriate and may be dangerous. The

manufacturer assumes no responsibility for injury, loss, or damage resulting from improper machine use.

CAUTION

Do not alter or deform the power cord or plug in any way! Altering or deforming the plug may cause electrical

shock, damage unit and will void warranty.

The Bubbler Autofill must only be connected to a three wire 120 VAC, 60 Hz electrical circuit.

To prevent the possibility of electrocution, burns, or other injuries and to prevent damage, do not immerse in

water or any cleaning liquids.

Do not operate a damaged Autofill. Inspect the power supply cord, concentrate supply and water supply often.

If cord or plug is damaged or worn, do not use your Autofill. Turn off the water supply and disconnect the

electrical power.

Turn off and unplug the Autofill before cleaning or maintenance.

Disconnect power if the machine functions abnormally and notify qualified service personnel for repairs. Do

not permit non-qualified service personnel to attempt repairs. No user serviceable components inside. Do not

disassemble.

WARNING

Safety Information

2 Crathco

®

Autofill System

Important Safety Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

For your safety and the safety of others, read all warnings and the operator manual before installing or using

the product.

DANGER: This term warns the user of imminent hazard that will result in serious injury or death.

WARNING: This term refers to a potential hazard or unsafe practice, which could result in serious injury or death.

CAUTION: This term refers to a potential hazard or unsafe practice, which could result in minor or moderate

injury.

NOTICE: This term refers to information that needs special attention or must be fully understood.

Observe machine voltage configuration. Do not apply improper voltage to machine or damage to machine may

occur.

Do not use extension cord (Bubbler Autofill units).

Do not allow water to be splashed or poured on front, sides, top, or back.

A qualified professional should perform installation, maintenance and repairs.

This equipment must be installed in accordance with the appropriate national and local codes of the country

and/or region in which the appliance is installed.

When turning the machine off for an extended period, be sure to evacuate the water and concentrate inside

the piping completely, otherwise the water and concentrate inside the machine could freeze and lead to damage

or cause mold to appear.

This unit is not certified for use with dairy products.

Highly acidic or caustic concentrates may not be compatible with the materials of this system. Thoroughly

evaluate chemical resistance and compatibility, especially at pH < 4 and pH > 10.

NOTICE

Page 3

NEMA 5-15P

Mechanical

MIXING RATIO: 5:1, or 4:1

ELECTRICAL: 120 Volts, 60 Hz, 1 Phase, 2 Amps

PUMP DESIGN: Positive Displacement

PUMP POWER SOURCE: Potable Water

TEMPERATURE LIMITS: 34 - 120° F [2-45° C]

FLOW RATE: Typical 2-3 oz. [60-90 cc] per sec.

OPERATING PRESSURE: 50 PSI. [3.4 bar] MAX. / 25 PSI.

[1.7 bar] MIN.

Water Inlet Connection requirements:

The Autofill unit can use any standard municipal water

supply as well as any commercial-grade filtered,

distilled, de-ionized, or purified water. Do not connect

to reverse osmosis water supply. Recommended water

pressure should be 50 psig with a 3/4” standard GHT

fitting to the inlet valve of the unit. It is required to

install a manual shut-off valve between the main water

supply and the unit.

Electrical Connection requirements (only

Bubbler units)

A NEMA 5-15R receptacle is required on a 15 amp

circuit. (Granita Autofill units do not have an external

power cord.)

Installation

Unpacking Instructions

Carefully unpack the machine and immediately inspect

for shipping damage. The packaging may contain

unattached parts. Your machine was shipped in a carton

designed to give it maximum protection in normal

handling. It was thoroughly inspected before leaving

the factory. In case of damage, contact the shipper, not

Grindmaster-Cecilware.

This unit and any associated water supply lines must be

compliant and maintained in accordance with all local,

state and federal laws associated with commercial

beverage dispensing equipment and use of potable

water supply lines. Water pipe connections and fixtures

directly connected to potable water supply shall be

sized, installed, and maintained in accordance with

Federal, State, and Local codes. The equipment must be

installed with adequate backflow protection to comply

with applicable federal, state, and local codes. If

backflow protection built into the unit does not meet

local requirements, install protective device. If a check

valve type backflow preventer is used for water supply

protection, a screen of at least 100 mesh (100 strands

per 1.0 in [25 mm]) shall be installed immediately

upstream. The screen shall be accessible and removable

for cleaning or replacement. (Required for NSF

approved water hook-up)

Always ensure that the machine power switch is in the

OFF position and unplugged from power supply when

making or maintaining electrical connections.

Prime unit before using. See step 8.

1. Place Autofill unit on a stable surface.

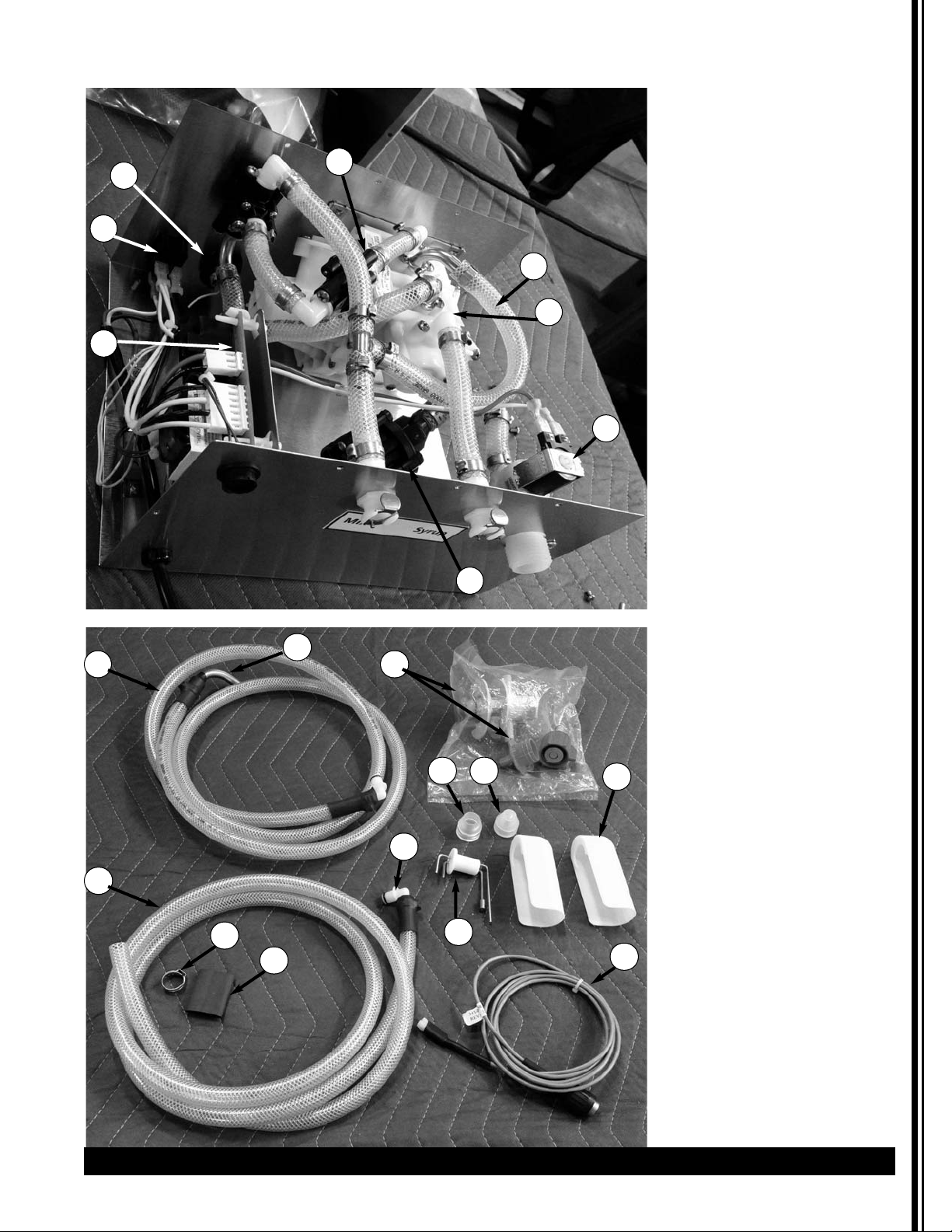

2. Attach liquid concentrate (syrup) line to autofill and

concentrate supply. Accessory kit contains several

syrup supply connection ends. First slide heat shrink

tube over hose. Then attach appropriate connection

end to hose using provided clamp. Crimp in place

(see picture below). Position heat shrink tube over

clamp and end of hose (see picture below), and

then use hot water or heat gun to attach shrink

tube. (Heat shrink is used for sanitation purposes.)

Other end of hose attaches to the “SYRUP” port on

Autofill unit. Verify it is fully attached.

3. Connect water inlet line to potable water supply

125 PSI MAX/ 25 PSI MIN. Open water supply valve.

4. Granita: Attach digital electronic control line into

back of Granita (see diagram below). Ensure “UP”

label is on top of control plug. Attach other end to

Autofill unit by inserting, then twisting into

position (bayonet connection).

Autofill System Crathco

®

3

Specifications

NOTICE: Do not reuse old hose. Only use new hose.

back of Granita

“UP” label towards

top of unit

Switch

Outlet Hose Connection

Page 4

4 Crathco

®

Autofill System

5. Bubbler: Insert probe through larger grommet in

bowl. Attach digital control line to probe. Attach

other end of control line to Autofill unit by

inserting, then twisting into position (bayonet

connection).

6. Insert output hose to Autofill connection marked

“MIX” and verify fully seated.

7. Bubbler: Plug unit into a grounded 3 prong outlet.

Do not use extension cord.

Priming:

8. Place a container under the output hose. Granita:

On Granita beverage dispenser, hold power switch

to “II” position until proper mix of syrup and water

is flowing from the outlet hose. Bubbler: Turn

power switch to “ON” and allow the unit to

operate until proper mix of syrup and water is

flowing from the outlet hose. Turn power switch to

“OFF”.

9. Bubbler: Attach output hose fill nozzle through

larger grommet on back of Bubbler bowl. Install

grommets in bowl such that flat surface is inside

bowl and taper is located outside to ensure splash

shield will seat properly. Attach shields to inside of

bowl if using spray unit (see picture below).

10. Granita: Loosen elbow connection on back of

Granita machine with a Phillips screwdriver. Install

output hose to elbow attachment and tighten

screw.

11. Confirm that all tubing connections are properly

clamped, fittings are tight, and lines are not kinked.

12. Visually check for leaks at all connections.

13. Clean and sanitize the autofill (see Cleaning and

Sanitizing section).

Operation

Your new autofill system is easy to operate and

maintain. Before you place it in service, please have all

personnel familiarize themselves with these

instructions. Keep this manual in a convenient

place for ready reference.

If you need help, call Grindmaster-Cecilware Technical

Service Department for help, (502) 425-4776 or (800)

695-4500 (USA & Canada only) 8 AM - 6 PM EST.

Cleaning and Sanitizing

All equipment in the system requires periodic

sanitization. The frequency of this procedure is

dependent on the water condition, temperature, and

concentrate type.

Sanitize in accordance with local health department

regulations. Grindmaster-Cecilware recommends

cleaning and sanitizing at least every week.

Materials required:

• Non-sudsing liquid detergent (such as common

household automatic dishwasher liquid

detergent)

• Sanitizing agent. Recommended sanitizer bleach, Sodium Hypochlorite

• Clean five (5) US gallon [19 liter] bucket or

container

• Five (5) US gallon [19 liter] bucket or container

for used detergent/sanitizer

• Measuring cup

• An adapter fitting on the concentrate suction

line to allow sanitizing agent to enter the

autofill. A connector cut from an empty liquid

concentrate will work.

Cleaning

1. Turn power switch to “OFF” on Autofill unit and

empty bowl. For Bubbler, detach probe from control

line and clean and sanitize separately. For Granita,

turn off power to Granita.

2. Fill the bucket with four (4) gallons [15.14 L] of

liquid detergent mixed with warm water (120 180°F) [48-82°C]. Measure four (4) ounces (½ cup)

[118cc] of the liquid detergent and add to the

water.

3. Disconnect the outlet hose from the beverage

dispenser. Place an empty container under the

output hose.

4. Disconnect the concentrate line from the liquid

concentrate supply and install the adapter on the

quick disconnect so the line is open to the cleaning

solution. Place concentrate line into the bucket of

Installation (continued)

NOTICE: All sanitizing agents in the food zone must

comply with 21 CFR 178.1010.

NOTICE: Concentrates that contain pulp,

particulates, or solids will require more frequent

sanitation to prevent build-up. Concentrates with

especially “stringy” pulp will require even more

frequent sanitation.

WARNING: Do not alter or deform the plug in

any way! Altering or deforming the plug may cause

electrical shock, damage unit and will cause personal

injury.

Shields in place

for spray units

NOTICE: Granita Autofill unit is controlled from the

Granita dispenser.

Page 5

Autofill System Crathco

®

5

Cleaning and Sanitizing (continued)

cleaning solution. Be sure the inlet of the liquid

concentrate line stays at the bottom of the bucket.

5. Move lever on Autofill unit to "Sanitize" mode.

6. For Bubbler: Push and hold “Sanitize” button on

Autofill, turn on power switch, and then release

button. Allow unit to run until ALL the solution is

pulled through the concentrate inlet fitting into the

Autofill and out through the water outlet line.

When the bucket is about half empty, turn Sanitize

lever to “Dispense” position and allow to run for

one minute. Then turn Sanitize lever back to the

“Sanitize” position until bucket is empty and then

turn power switch to “OFF”

7. For Granita: Turn on Granita and dispense product

until level is below the autofill probe. Push and hold

switch in “II” position on Granita unit to run ALL

the solution through the concentrate inlet fitting

into the autofill and out the water outlet line.

8. Dispose of contents of the bucket and rinse bucket.

Sanitizing

9. Fill the bucket with four (4) gallons [15.14 L] of

water. Add sanitizing agent per instructions

provided with sanitizing agent. Note: Two (2)

ounces (¼ cup) [60 cc] of bleach, Sodium

Hypochlorite from an unopened container, may be

used as a sanitizing agent. Stir and mix the contents

of the bucket thoroughly.

10. Place concentrate line into the bucket of sanitizing

solution. Be sure the inlet of the liquid concentrate

line stays at the bottom of the bucket.

11. Move lever to "Sanitize" mode.

12. For Bubbler: Push and hold “Sanitize” button on

Autofill, turn on power switch, and then release

button. Allow unit to run until ALL the solution is

pulled through the concentrate inlet fitting into the

Autofill and out through the water outlet line.

When the bucket is about half empty, turn Sanitize

lever to “Dispense” position and allow to run for

one minute. Then turn Sanitize lever back to the

“Sanitize” position until bucket is empty.

13. For Granita: Push and hold switch in II position on

Granita unit to run ALL the solution through the

concentrate inlet fitting into the autofill and out

the water outlet line. When the bucket is about half

empty, turn Sanitize lever to “Dispense” position

and allow to run for one minute. Then turn Sanitize

lever back to the “Sanitize” position until bucket is

empty.

14. Reconnect the inlet line to the concentrate supply.

Product Purge

15. Push and release “Sanitize” button on Autofill, (for

Bubbler) or push and hold switch on Granita unit in

“II” position, allowing the pump to operate until all

sanitizing solution is purged from the system.

16. Reconnect the outlet hose to the beverage

dispenser.

17. Return the valve to the "Dispense" mode.

18. Dispose of contents of the bucket and rinse bucket.

Before you call for help, please read the following:

I. PUMP WILL NOT CYCLE:

• Verify there is adequate water pressure (30-50

psi.[2-3.4 bar]) at water inlet fitting.

• Verify that the dispenser valve operation

(switch/solenoid), passages, and lines are

unrestricted. Flush and sanitize pump and outlet

lines from pump fittings to the dispenser if

restricted.

• Check for liquid in the liquid concentrate supply. If

empty, replace with new box of concentrate.

• Check for plugged, kinked, or restricted inlet

tubing. Flush and sanitize pump and outlet lines

from pump fittings to the dispenser if restricted.

• Verify electrical connection, plug is properly seated,

and power switch is turned on.

II. NO CONCENTRATE (PUMP CYCLES) / IMPROPER

BRIX:

• Verify that the concentrate passage is opening

completely when installed on the B-I-B connector. If

concentrate is supplied from a tank, verify that the

vent is open.

• Inspect for vacuum leaks at the concentrate inlet

side. Carefully look for air bubbles at connections

and fittings while the pump is cycling.

• Determine if there was air packaged with the

concentrate when the bags where filled. Stand the

box up on end and pull the connector up, allowing

air to rise up to the bag connector. Install liquid

concentrate fitting and engage it on the bag

connector opening the passage. Slowly press the

bag down, expelling the air until concentrate

appears, release and remove the liquid concentrate

fitting.

• Inspect for debris or improper closing of the liquid

concentrate fitting that interferes with their

operation.

WARNING: To reduce the risk of electrical shock, unplug the power cord before repairing or replacing

any internal components of the unit. Before any attempt to replace a component, be sure to check all electrical

connections for proper contact. Only a qualified service technician should perform electrical and mechanical

adjustments or repairs.

Troubleshooting Guide

Page 6

6 Crathco

®

Autofill System

III. PUMP CYCLES INTERMITTENTLY/ WILL NOT

SHUT-OFF/ DRIPS:

• If the pump continues to cycle after liquid

concentrate supply has emptied, verify that there

are no vacuum leaks.

Determine if the concentrate bag has an excessive

(more than 1 cubic inch [16.4 cc]) amount of air.

NOTE: If the concentrate is moved above the pump,

head pressure from the liquid concentrate may be

substantial enough to cause the dispenser to drip.

Valve Inspection

Some concentrates, after prolonged periods of contact

without regular sanitizing, may cause the valves to

become stiff or clogged with pulp and/or particulates.

If a situation of this type is suspected, valve cartridges

(4 each) can be removed for inspection.

Turn off water supply valve and relieve pressure.

Remove each assembly by loosening the screw holding

the cartridge. Turn the cartridge and then pull it out of

the housing (use of tools may be required).

If you still need help, call Grindmaster-Cecilware

Technical Service Department, (502) 425-4776 or (800)

695-4500 (USA & Canada only) (Monday through Friday

8 AM - 6 PM EST). Please have the model and serial

number ready so that accurate information can be

given.

Prior authorization must be obtained from

Grindmaster-Cecilware for all warranty claims.

Grindmaster-Cecilware provides the industry’s

BEST warranty. Visit our website at gmcw.com for

warranty terms and conditions.

WARNING: To reduce the risk of electrical shock, unplug the power cord before repairing or replacing

any internal components of the unit. Before any attempt to replace a component, be sure to check all electrical

connections for proper contact. Only a qualified service technician should perform electrical and mechanical

adjustments or repairs.

Troubleshooting Guide (continued)

Parts List

# Part No. Bubbler Granita Description

1 349-00011 x Control Board_Level (Bubbler units)

2 99066 x On-Off Switch Rocker Switch (Bubbler units)

3 63195 x Switch, Sealed (Bubbler units)

4 280-00038 x x Reverse Flow Inhibitor - (2) for Single, (4) for Double

5 61153 x x Tubing_3/8 ID X 5/8 OD

6 310-00019 x x Brix Pump_5:1 Ratio

6 310-00018 x x Brix Pump_4:1 Ratio

7 280-00071 x Valve_120V Inlet 1.3 GPM (Single Bubbler units)

7 280-00080 x Valve Dual Inlet 0.8 GPM – 120V (Dual Bubbler units)

7 280-00056 x Valve_Water Inlet (Single Granita units)

8 310-00021 x x Water Pressurer Reducer 30 PSI

250-00175 x Bubbler Accessory Kit

9 Mix tubing with EL and SS fill nozzle_3/8 ID (72 IN.)

10 Syrup tubing with EL and open end_3/8 ID (72 IN.)

11 Clamp, 11/16" Uniform Seal (1)

12 3/4" ID_Heat Shrink (1.5 IN.)

14 Level Sensor (1)

15 Wire Harness_Level Sensor_72 IN. (1)

16 Shield_Splash (2)

17 Plug/Seal (Solid) (1)

18 Seal, Silicone 15MM (1)

19 Kit, Bib Adapter (1)

19 250-00171 x x Kit, Bib Adapter

Adapter_Bib_Coke (1)

Adapter_Bib_Coke_Generic (1)

Adapter_Bib_Liquibox Universal (1)

250-00177 x Remote Install Accessory Kit

11 Clamp, 11/16" Uniform Seal (4)

12 3/4" ID_Heat Shrink (6 IN.)

13 El_3/8_QC (2)

14 Level Sensor (1)

15 Wire Harness_Level Sensor_60 FT. (1)

17 Plug/Seal (Solid) (1)

18 Seal, Silicone 15MM (1)

19 Kit, Bib Adapter (1)

20 Nozzle_SS_Fill (1)

not shown

250-00183 x 100 ft Cable for Remote Install (1)

250-00176 x Frozen Accessory Kit

10 Syrup tubing with EL and open end_3/8 ID (72 IN.)

11 Clamp, 11/16" Uniform Seal (1)

12 3/4" ID_Heat Shrink (1.5 IN.)

13 El_3/8_QC (1)

19 Kit, Bib Adapter (1)

not shown Mix tubing with both ends attached_1/4" ID (72 IN.)

not shown Wire Harness_Level Senser_Frozen (1)

Page 7

Autofill System Crathco

®

7

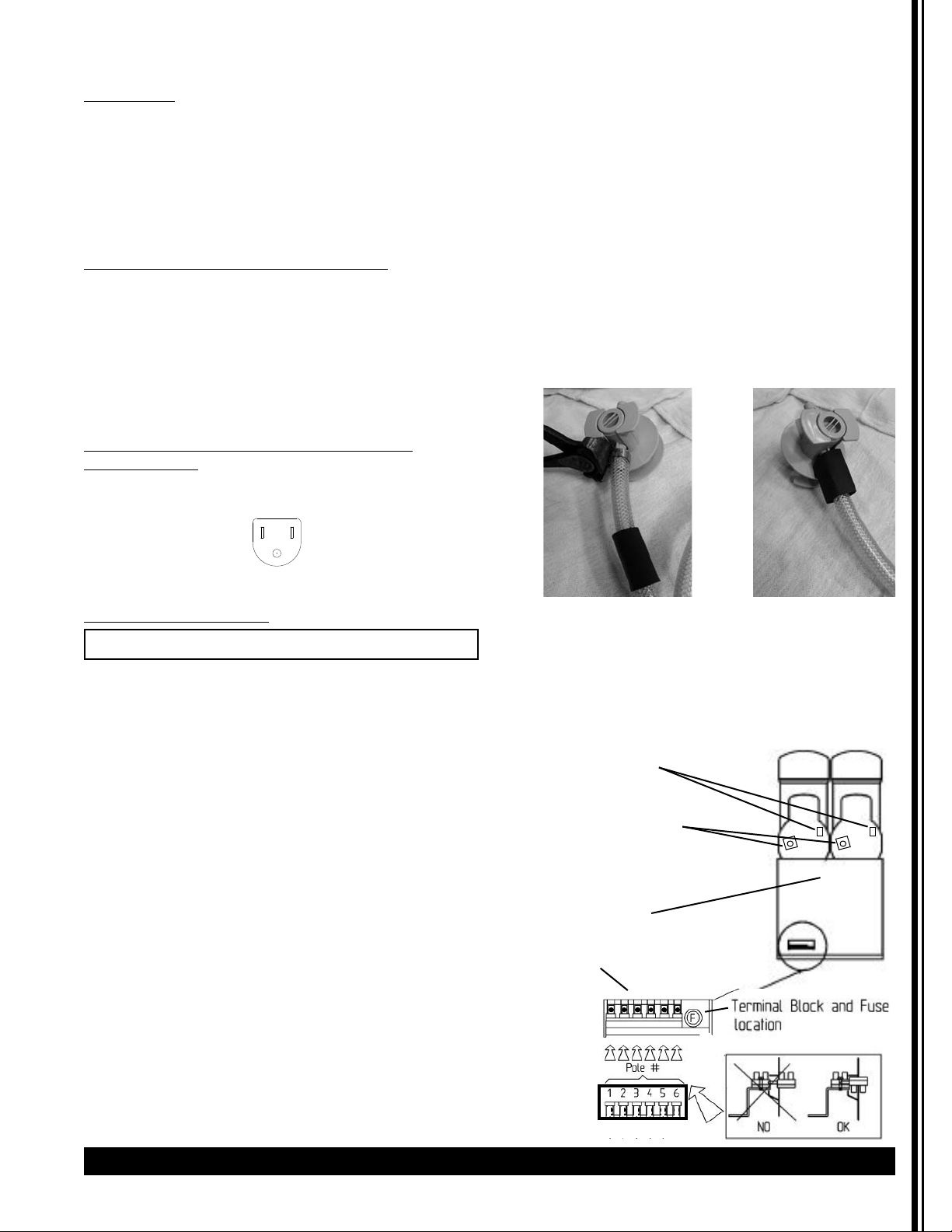

Parts Diagram

9

10

19

16

1

3

2

18

17

11

12

15

14

7

8

6

4

5

13

20

(Single Autofill shown)

(Accessory kit shown)

Page 8

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

©2018 Grindmaster-Cecilware

Printed in USA

0118 Form # CC-387-04

Part # 390-00090

Wiring Diagram

Bubbler

Flow Diagram

NOTE: This is the wiring diagram for the

Bubbler Liquid Autofill System. No wiring

diagram is necessary for the Granita Autofill

System.

Sanitize knob

“Normal” position

Sanitize knob

“Sanitize” position

LIQUID AUTOFILL

HOSE CONNECTION DIAGRAM

Loading...

Loading...