Crary Tile Pro Owner's & Parts Manual

OWNER'S/PARTS

MANUAL

TILE PRO

Manual P/N: 90807-00

Rev. 090114

RECORD SERIAL NUMBER HERE

HOW TO REACH US

ADDRESS

Tile Pro

Crary Agricultural Solutions, LLC

P.O. Box 237

Morgan, MN 56266

GPS/LASER CONTROLS

TECHNICAL SUPPORT

Kenton Johnson

Ph: 507.430.5729

kenton.johnson@crarytilepro.com

TELEPHONE

FAX NUMBER

Monday-Friday

8 am-5pm (CST)

PLOW SETUP/

GENERAL QUESTIONS

Ph: 507.828.4548

wayne.weber@crarytilepro.com

For Parts and Service:

Ph: 507.249.3176 •

Fax: 507.249.3146

Wayne Weber

HOURS INTERNET

Online: www.crarytilepro.com

SALES

SUPPORT

Stan Isfeld

Ph: 504.430.7677

stan.isfeld@crarytilepro.com

DISCLAIMER

This document is based on information available at the time of its publication. While efforts have been made to be accurate, the information contained herein does not purport to cover all details or variations, nor to provide for every possible contingency in connection with installation, operation, or maintenance. Features may be described herein which

are not present in all systems. Crary Agricultural Solutions assumes no obligation of notice to holders of this document

with respect to changes subsequently made.

Crary Agricultural Solutions assumes no responsibility for the accuracy, completeness, sufciency, or usefulness of the

information contained herein.

SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Crary Agricultural Solutions is continually making improvements and developing new equipment. In doing so, we reserve the right to make changes or add improvements to our product without obligation for equipment previously sold.

Because modication to this machine may affect the performance, function, and safety of its operation, no modications

are to be made without the written permission of Crary Agricultural Solutions. Part replacements should be with original

equipment supplied by Crary Agricultural Solutions.

THE CRARY AGRICULTURAL SOLUTIONS STATEMENT OF PRODUCT SAFETY

As a manufacturer of specialized agricultural equipment, Crary Agricultural Solutions fully recognizes its responsibility

of providing its customers products that perform their expected use in a reasonably safe manner. Safety considerations

shall be an integral and high priority part of all engineering/design analysis and judgments involving Crary products. It

is our stated policy that our products will be manufactured to comply with the safety standards specied by the American

Society of Agricultural Engineers, the National Electrical Code, the Society of Automotive Engineers, and/or any other

applicable recognized standards at the time manufactured. However, this statement should not be construed to mean

that our product will safeguard against a customer’s own carelessness or neglect in violating common safety practices

specied in each product’s manual, nor will we be liable for any such act.

SERIAL NUMBER LOCATION

Always give your authorized Crary dealer the serial number

of your machine when ordering parts, requesting service, or

any other information. The serial number decal is located on

the front, left hand end of the air manifold.

Please record the serial number in the space provided on

the front cover and on the warranty and registration card.

© 2014, Crary Agricultural Solutions, LLC, All rights reserved. Produced and printed in the USA.

Serial Number Decal

LIMITED WARRANTY

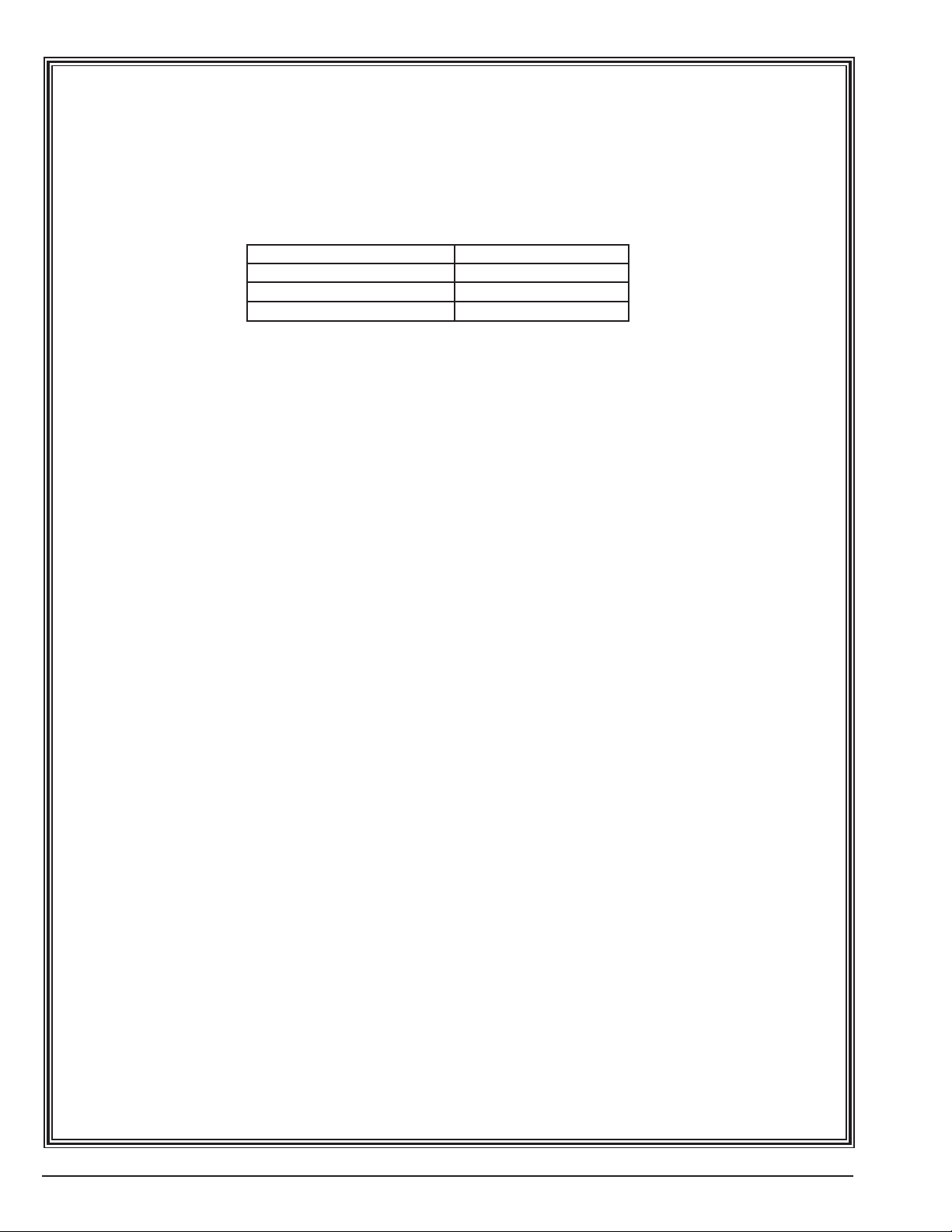

This warranty applies to all Crary Tile Pro equipment manufactured by Crary Agricultural Solutions, LLC (Crary).

Crary warrants to the original owner of each new Crary Tile Pro product to be free from defects in material and

workmanship, under normal use and service. The warranty shall extend as shown below from date of delivery. The

product is warranted to the original owner as evidenced by a completed warranty registration on le at Crary and

is non-transferable beyond the initial purchaser.

Product Warranty Length

Crary Tile Pro Plow 1 year

Crary Tile Pro Trailers 1 year

Crary Tile Pro Spool/Carriers 1 year

THE WARRANTY REGISTRATION MUST BE COMPLETED AND RETURNED TO CRARY WITHIN 10 DAYS OF

DELIVERY OF THE PRODUCT TO THE ORIGINAL OWNER OR THE WARRANTY WILL BE VOID.

In the event of a failure, return the product, at your cost, along with proof of purchase to the selling Crary dealer.

Crary will, at its option, repair or replace any parts found to be defective in material or workmanship. Warranty on

any repairs will not extend beyond the product warranty. Repair or attempted repair by anyone other than a Crary

dealer as well as subsequent failure or damage that may occur as a result of that work will not be paid under this

warranty. Crary does not warrant replacement components not manufactured or sold by Crary.

This warranty applies only to parts or components that are defective in material or workmanship.

This warranty does not cover wear items including but not limited to knife tips, ground engaging components,

bearings, tires etc.

1. This warranty does not cover normal maintenance, service or adjustments.

2. This warranty does not cover depreciation or damage due to misuse, negligence, accident or improper maintenance.

3. This warranty does not cover damage due to improper setup, installation or adjustment.

4. This warranty does not cover damage due to unauthorized modifications of the product.

5. This warranty does not cover damage, deemed by a Crary representative, due to excessive stress or by exceeding the products ability and manufacturer’s intended use of the product.

Any warranty of any grade control, hydraulic components or guidance components sold on, or installed on, Crary

products are subject to the original manufacture warranty and are not the responsibility of Crary.

Crary is not liable for any property damage, personal injury or death resulting from the unauthorized modication

or alteration of a Crary product or from the owner’s failure to assemble, install, maintain or operate the product in

accordance with the provisions of the Owner’s manual. Crary is not liable for any damages or expenses incurred

on the host machine or on any non Crary equipment through the use of these products.

New replacement parts made by Crary carry a full 90-day, parts only, warranty from the date they are purchased.

Crary is not liable for indirect, incidental or consequential damages or injuries including but not limited to loss of

crops, loss of prots, rental of substitute equipment or other commercial loss.

This warranty gives you specic legal rights. You may have other rights that may vary from area to area.

Crary makes no warranties, representations or promises, expressed or implied as to the performance of its products

other than those set forth in this warranty. Neither the dealer nor any other person has any authority to make any

representations, warranties or promises on behalf of Crary or to modify the terms or limitations of this warranty in

any way. Crary, at its discretion, may periodically offer limited, written enhancements to this warranty

CRARY AGRICULTURAL SOLUTIONS, LLC IS A WHOLLY OWNED SUBSIDIARY OF CRARY INDUSTRIES,

INC AND RESERVES THE RIGHT TO CHANGE THE DESIGN AND/OR SPECIFICATIONS OF ITS PRODUCTS

AND WARRANTIES AT ANY TIME WITHOUT OBLIGATION TO PREVIOUS PURCHASERS OF ITS PRODUCTS.

PN:90807-00 R090114

Tile Plow Owner’s/Parts Manual

iii

iv

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

TABLE OF CONTENTS

DESCRIPTION PAGE DESCRIPTION PAGE

INTRODUCTION .................................................... 1

SAFETY .................................................................2

2.1 SAFETY ALERT SYMBOL ................................................................... 2

2.2 CALL BEFORE YOU DIG ..................................................................... 3

2.3 GENERAL SAFETY.............................................................................. 4

2.4 OPERATING SAFETY .......................................................................... 5

2.5 MAINTENANCE SAFETY .................................................................... 5

2.6 HYDRAULIC SAFETY .......................................................................... 6

2.7 TRANSPORT SAFETY ......................................................................... 6

2.8 STORAGE SAFETY ............................................................................. 6

2.9 ASSEMBLY SAFETY ............................................................................ 6

2.10 SAFETY DECALS .............................................................................. 7

2.11 SIGN-OFF FORM ............................................................................... 8

SAFETY DECALS ..................................................9

ASSEMBLY .......................................................... 10

4.1 UNLOADING ...................................................................................... 10

4.2 HYDRAULIC HOSE IDENTIFICATION ................................................11

4.3 POWER FEEDER (PF-100) ............................................................... 12

OPERATION ........................................................ 14

5.1 MACHINE COMPONENTS ................................................................ 15

5.2 INITIAL ADJUSTMENTS .................................................................... 16

5.3 PRE-OPERATION CHECKLIST ......................................................... 16

5.4 PITCH GRADING WITH A LASER ..................................................... 17

5.5 PITCH GRADING WITH GPS ............................................................ 17

5.6 DUAL GRADING WITH GPS ............................................................. 18

5.7 PARALLEL GRADING MODE ............................................................ 18

5.8 PARALLEL GRADING WITH A LASER .............................................. 19

5.9 PARALLEL GRADING WITH GPS ..................................................... 19

5.10 TRANSPORTING ............................................................................. 20

5.11 STORAGE ........................................................................................ 20

SERVICE & MAINTENANCE ...............................21

6.1 MAINTENANCE CHECKLIST ............................................................ 21

6.2 FLUIDS AND LUBRICANTS............................................................... 22

6.3 GREASING......................................................................................... 22

TROUBLESHOOTING ......................................... 23

SPECIFICATIONS ................................................ 24

8.1 TILE PLOW SPECIFICATIONS .......................................................... 24

8.2 HYDRAULIC FITTING TORQUE ....................................................... 25

8.3 BOLT TORQUE .................................................................................. 26

PN:90807-00 R090114

Tile Plow Owner’s/Parts Manual

v

vi

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

1

Section

Congratulations on your choice of a new Crary Tile Plow to complement your farming operation. This equipment has

been designed and manufactured to meet the needs of a discerning agricultural industry for the efcient growing of crops.

Safe, efcient, and trouble free operation of your Tile Plow requires that you and anyone else who will be operating or

maintaining the equipment, read and understand the Safety, Operation, Maintenance and Troubleshooting information

contained within the owner’s manual. Check each item referred to and acquaint yourself with the adjustments required

to obtain efcient operation.

This manual covers Tile Plows manufactured by Crary Agricultural Solutions for ??? tractors. Differences are explained

where appropriate. Use the Table of Contents as a guide to locate required information.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your Crary Tile Pro

dealer or distributor if you need assistance, information, or additional copies of the manual.

Many people have worked on the design, production, and delivery of this machine. They have built into it the highest

quality of materials and workmanship. The information in this manual is based on the knowledge, study, and experience

of these people through years of manufacturing specialized farming machinery.

The performance of the machine depends on proper maintenance and adjustment. Even if you are an experienced

operator of this or similar equipment, we ask you to read the owner’s manual before operating the machine. Keep the

manual handy for future reference. It has been carefully prepared, organized, and illustrated to assist you in nding the

information you need. Your Crary dealer will be happy to answer any further questions you may have about the machine.

INTRODUCTION

OPERATOR ORIENTATION - All references to left, right, front and rear of the equipment, as mentioned throughout the

manual, are determined by standing behind the machine and facing the direction of forward travel.

PN:90807-00 R090114

Tile Plow Owner’s/Parts Manual

1

2

Section

SAFETY

2.1 SAFETY ALERT SYMBOL

This Safety Alert Symbol means:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert symbol identies important

safety messages on the Tile Plow and in

the manual. When you see this symbol, be

alert to the possibility of personal injury or

death. Follow the instructions in the safety

message.

Why is SAFETY important to you?

3 Big Reasons

1. Accidents Disable and Kill

2. Accidents Cost

3. Accidents Can Be Avoided

SIGNAL WORDS:

Note the use of the signal words DANGER, WARNING,

CAUTION, IMPORTANT and NOTE with the safety

messages. The appropriate signal word for each message has been selected using the following guidelines:

DANGER - Indicates an imminently hazardous situation

that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme

situations, typically for ma chine components that, for

functional purposes, cannot be guarded.

WARNING - Indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury,

and includes hazards that are exposed when guards are

removed. It may also be used to alert against unsafe

prac tices.

CAUTION - Indicates a potentially hazardous situation

that, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

IMPORTANT - Instructions that must be followed to

ensure proper installation/operation of equipment.

NOTE - General statements to assist the reader.

2

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

2.2 CALL BEFORE YOU DIG

One free, easy call gets your utility lines

marked AND helps protect you from

injury and expense.

Safe Digging Is No Accident:

Always Call 811 Before You Dig

Know what’s below. Always call 811 before you dig.

Visit call811.com for more information.

CALL

DIG

BEFORE YOU

ALWAYS

INSERT

CALL CENTER

LOGO HERE

You really have no idea what is under the ground.

SAFETY

Call 811 rst.

It’s a free service and could save

your life!

PN:90807-00 R090114

Tile Plow Owner’s/Parts Manual

3

SAFETY

2.3 GENERAL SAFETY

YOU are responsible for the SAFE operation and mainte-

nance of your Tile Plow. You must ensure that you and any-

one else who is going to operate, maintain or work around

the machine are familiar with the operat ing and maintenance

procedures and related safety information contained in this

manual. This manual will alert you to all good safety practices that should be adhered to while operat ing the machine.

Remember, YOU are the key to safety. Good safety practices not only protect you but also the people around you.

Make these practices a working part of your safety program.

Be certain that EVERYONE operating this equipment is

familiar with the recommended operating and maintenance

procedures and follows all the safety precautions. Most

accidents can be prevented. Do not risk injury or death by

ignoring good safety practices.

• Owners must give operating instruc tions to operators or employees before allowing them to operate

the equipment, and annually thereafter per OSHA

(Occupational Safety and Health Administration)

regulation 1928.57.

• The most important safety device on this equipment

is a safe operator. It is the operator’s responsibility

to read and under stand ALL Safety and Operating

instructions in the manual and to follow them.

• A person who has not read and understood all

operating and safety instructions is not qualified

to operate the equipment. An untrained operator

exposes himself and bystanders to possible serious injury or death.

• Do not modify the equipment in any way. Unauthor-

ized modification may impair the function and/or

safety and could affect the life of the equipment.

1. Read and understand the

Owner’s Manual and all safety decals before operating,

maintaining, adjusting or

servicing the machine.

2. Only trained persons shall

operate the equipment. An

untrained operator is not

qualified to operate the equipment.

3. Have a first-aid kit available for use,

should the need arise, and know how

to use it.

4. Provide a fire extinguisher for use in

case of an accident. Store in a highly

visible place.

5. Do not allow children, spectators or

bystanders within hazard area of equipment.

6. Wear appropriate protective gear. This

list includes but is not limited to:

• A hard hat.

• Protective shoes with slip

resistant soles.

• Protective goggles.

• Heavy gloves.

• Hearing protection.

• Respirator or filter mask.

7. Wear suitable ear protection during

prolonged exposure to excessive

noise.

8. Place all controls in neutral or off, stop engine, set parking brake, chock wheels, remove ignition key and wait

for all moving parts to stop, before servicing, adjusting,

repairing or unplugging.

9. Review safety related items annually with all personnel

who will be operating or maintain ing the equipment.

Think SAFETY! Work SAFELY!

4

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

2.4 OPERATING SAFETY 2.5 MAINTENANCE SAFETY

SAFETY

1. Read and understand the owner’s manual and all safety

decals before servicing, adjusting or repairing.

2. Install and secure all guards and shields before starting

or operating.

3. Keep hands, feet, hair and clothing away from all moving and/or rotating parts.

4. Place all controls in neutral or off, stop engine, set parking brake, chock wheels, remove ignition key and wait

for all moving parts to stop before servicing, adjusting,

repairing or unplugging.

5. Clear the area of bystanders, especially small children,

before starting.

6. Keep all hydraulic lines, fittings, and couplers tight and

free of leaks before and during use.

7. Clean reflectors and lights before transporting.

8. Review safety related items annually with all personnel who will be operating or maintaining the Tile Plow.

9. Shut the tractor off when connecting the equipment

hydraulics.

1. Follow ALL operating, maintenance, and safety information in this manual.

2. Support the equipment with blocks or safety stands

when working around it.

3. Follow good shop practices:

• Keep service area clean

and dry.

• Be sure electrical outlets and

tools are properly grounded.

• Use adequate light for the

job at hand.

4. Use only tools, jacks and hoists of sufficient capacity

for the job.

5. Place all controls in neutral or off, stop engine, set parking brake, chock wheels, remove ignition key and wait

for all moving parts to stop before servicing, adjusting,

repairing or unplugging.

6. When maintenance work is completed, install and secure all guards before resuming work.

7. Relieve pressure from hydraulic circuit before servicing

or disconnecting from tractor.

8. Keep hands, feet, hair and clothing away from all moving and/or rotating parts.

9. Clear the area of bystanders, especially small children,

when carrying out any maintenance and repairs or making any adjustments.

10. Keep safety decals clean. Replace any decal that is

damaged or not clearly visible.

11. First-class maintenance is a prerequisite for the safest

operation of your equipment. Maintenance, including

lubrications, should be performed with the equipment

stopped and locked out.

Think SAFETY! Work SAFELY!

PN:90807-00 R090114

Tile Plow Owner’s/Parts Manual

5

SAFETY

2.6 HYDRAULIC SAFETY

1. Always place all hydraulic controls in neutral before disconnecting from tractor or working on hydraulic system.

2. Make sure that all components in the hydraulic system

are kept in good condition and are clean.

3. Relieve pressure before working on the hydraulic

system.

4. Replace any worn, cut, abraded, flattened or crimped

hoses.

5. Do not attempt any makeshift repairs to the hydraulic

fittings or hoses by using tape, clamps or cements.

The hydraulic system operates under extremely highpressure. Such repairs will fail suddenly and create a

hazardous and unsafe condition.

6. Wear proper hand and eye protection when searching

for a high-pressure hydraulic leak.

Use a piece of wood or cardboard

as a backstop instead of hands to

isolate and identify a leak.

7. If injured by a concentrated highpressure stream of hydraulic fluid,

seek medical attention immediately. Serious infection or toxic reaction can develop from hydraulic

fluid piercing the skin surface.

2.7 TRANSPORT SAFETY

1. Make sure you are in compliance with all local regulations regarding transporting equipment on public roads

and highways.

2. It is the responsibility of the owner to know the lighting

and marking requirements of the local highway authorities and to install and maintain the equipment to provide

compliance with the regulations. Add extra lights when

transporting at night or during periods of limited visibility.

2.8 STORAGE SAFETY

1. Store the unit in an area away from human activity.

2. Do not permit children to play on or around the stored

equipment.

3. Plow should be stored on level ground with the boot

NOT supporting the weight of the plow.

2.9 ASSEMBLY SAFETY

8. Before applying pressure to the

system, make sure all components are tight and that

lines, hoses, and couplings are not damaged.

Think SAFETY! Work SAFELY!

1. Assemble in an area with sufficient space to handle

the largest component and access to all sides of the

equipment

2. Use only lifts, cranes and tools with sufficient capacity

for the load.

3. When necessary, have someone assist you.

4. Do not allow spectators in the working area.

5. Be sure to read the Maintenance Safety section.

6

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

2.10 SAFETY DECALS

1. Keep safety decals clean and legible at all times.

2. Replace safety decals that are missing or have become

illegible.

3. Replaced parts that displayed a safety decal should

also display the current decal.

4. Decals that need to be replaced are to be placed back

in the original location.

5. Safety decals are available from your authorized dealer

or the factory.

HOW TO INSTALL SAFETY DECALS:

1. Be sure that the installation area is clean and dry.

2. Be sure temperature is above 50°F (10°C).

3. Decide on the exact position before you remove the

backing paper.

SAFETY

4. Remove the smaller portion of the split backing paper.

5. Align the decal over the specified area and carefully

press the small portion with the exposed sticky backing in place.

6. Slowly peel back the remaining paper and carefully

smooth the remaining portion of the decal in place.

7. Small air pockets can be pierced with a pin and

smoothed out using the piece of decal backing paper.

PN:90807-00 R090114

Think SAFETY! Work SAFELY!

Tile Plow Owner’s/Parts Manual

7

SAFETY

2.11 SIGN-OFF FORM

Crary Agricultural Solutions follows the general safety standards specied by the American Society of Agricultural Engineers (ASAE) and the Occupational Safety and Health Administration (OSHA). Anyone who will be operating and/

or maintaining the equipment must read and clearly understand ALL safety, operating and maintenance information

presented in this manual.

Do not operate or allow anyone else to operate this equipment until such information has been reviewed. Annually review

this information before the season start-up.

Make these periodic reviews of safety and operation a standard practice for all of your equipment. An untrained operator

is unqualied to operate this equipment.

A sign-off sheet is provided for your record keeping to show that all personnel who will be working with the equipment have

read and understood the information in the owner’s manual and have been instructed in the operation of the equipment.

SIGN - OFF FORM

DATE EMPLOYEE SIGNATURE EMPLOYER SIGNATURE

8

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

3

Section

Good safety requires that you familiarize yourself with the various safety decals, the type of warning and the area, or

particular function related to that area, that requires your SAFETY AWARENESS.

SAFETY DECALS

Think SAFETY! Work SAFELY!

PN: 32901-000

PN: 32893-00

REMEMBER - If safety decals have been damaged, removed or become illegible or parts have been replaced without

safety decals, new decals must be applied. New safety decals are available from the manufacturer or an authorized dealer.

PN:90807-00 R090114

Tile Plow Owner’s/Parts Manual

9

4

Section

Read all instructions to become familiar with the parts and

procedure used before starting the actual work. You may

refer to the parts catalog in the back of this manual for additional aid.

ASSEMBLY

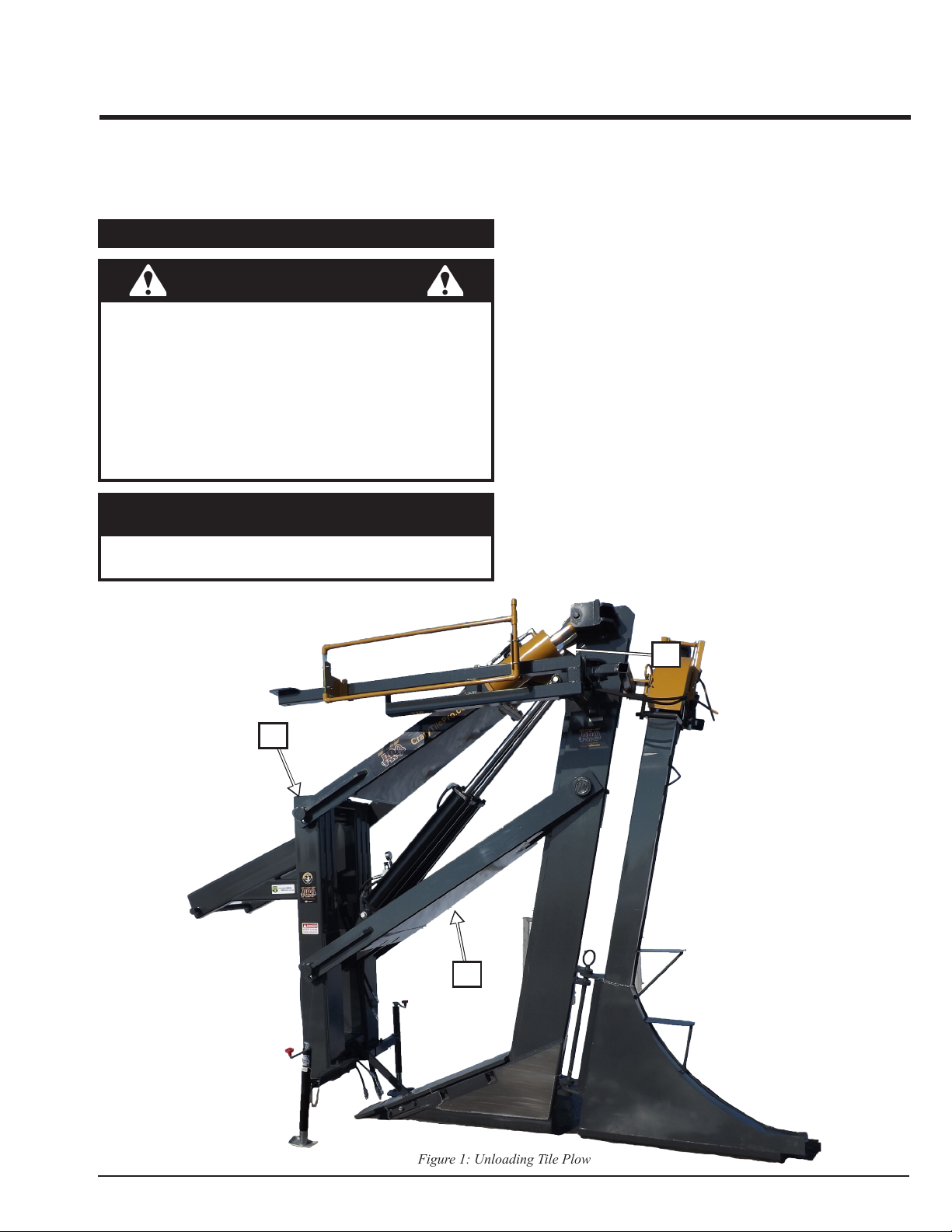

4.1 UNLOADING

WARNING

1. Assemble in an area with sufficient space to handle

the largest component and access to all sides of

the machine.

2. Use only lifts, cranes and tools with sufficient capacity for the load.

3. When necessary, have someone assist you.

4. Do not allow spectators in the working area.

CAUTION

Do not wrap chains on, or near hydraulic cylinder rods

or cylinder bodies.

Unload the plow using one of the following methods. (Figure 1)

METHOD 1:

1. Attach a heavy duty chain or strap at point #1. Loop

the other end around the shank at the block where the

upper cylinders connect to the shank at point #2 and

make a solid connection.

2. Lift at mid point of the chain or strap where a balance

point can be established.

3. Lift and drive the trailer away or back away from the

trailer and set the plow on solid level ground.

METHOD 2:

1. Take the forks on a large front end loader or forklift and

place them under the lower frame #3.

2. On one side of the forks add wooden block so that when

the plow is raised it remains level.

3. Lift the plow off the trailer and set on solid level ground.

#1

#2

#3

10

Figure 1: Unloading Tile Plow

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

ASSEMBLY

4.1 UNLOADING (CONTINUED)

Make sure that the jack stands are solidly bolted on and in

the perpendicular position to the ground. (Figure 2) Do not

over extend the arms as they may become unstable and fail.

4.2 HYDRAULIC HOSE IDENTIFICATION

Hoses are identied with an attached colored zip tie

• Elevation Up =Red

• Elevation Down = Yellow

• Pitch Up = Purple

• Pitch Down = Green

Figure 2: Jacks properly attached.

PN:90807-00 R090114

Figure 3: Jack

Tile Plow Owner’s/Parts Manual

11

ASSEMBLY

4.3 POWER FEEDER (PF-100)

Bolt the grey swing arm mounting bracket to the laser arm

as shown in Figure 4.

Figure 4: Power Feeder Mounting Bracket

Place the swing arm in the bracket and adjust the arm so

the center of the mounting pin of the arm assembly is in the

center of the plow shank. (Figure 5)

Mount the power feeder to the arm assembly using the

silver colored pin and clip.

Figure 6: Mount Power Feeder

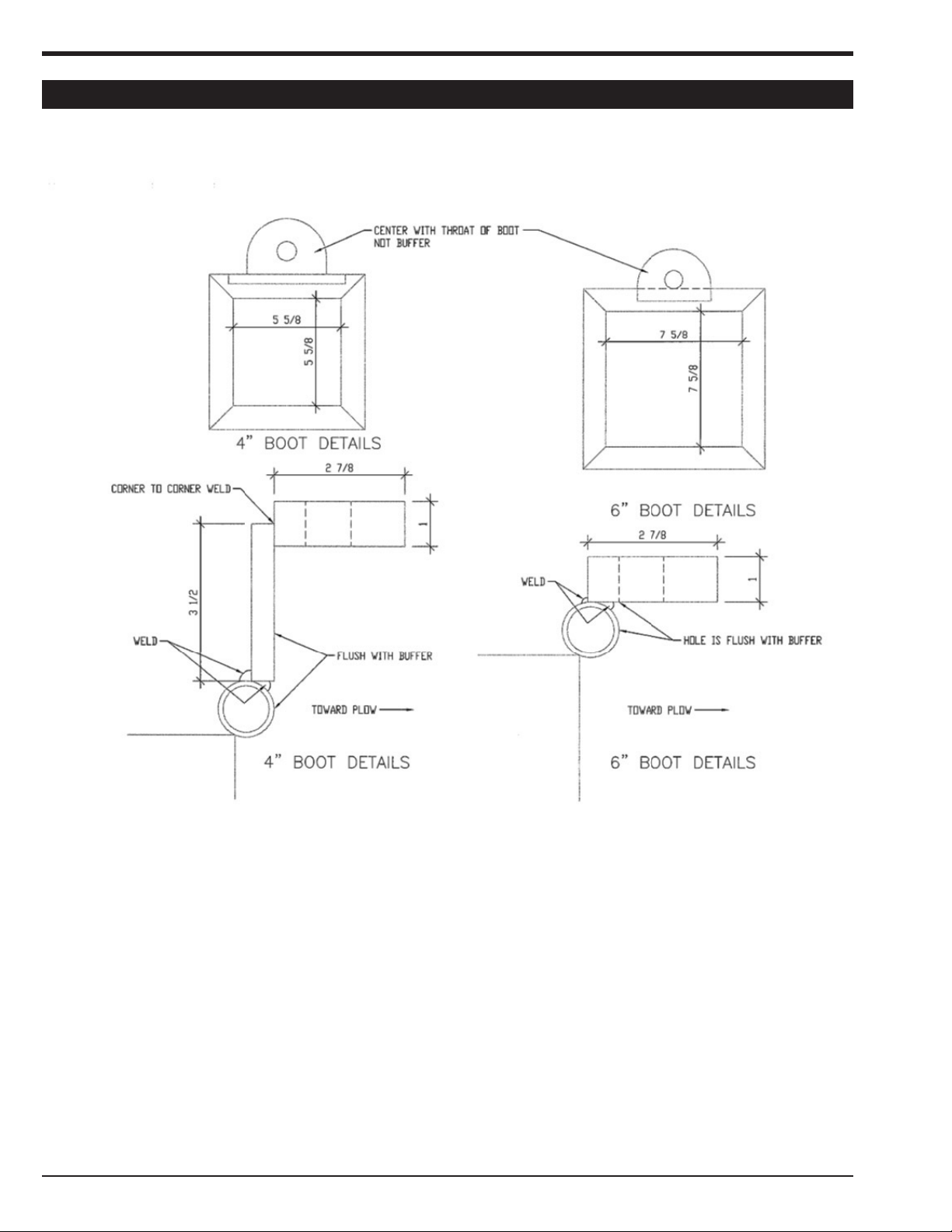

The 4” and 6” boots will need to have a mounting bracket

welded to them as shown in Figure 8

12

Figure 5: Power Feeder Swing Arm

Tile Plow Owner’s/Parts Manual

Figure 7: Welded Mounting Bracket

PN:90807-00 R090114

4.3 POWER FEEDER (PF-100)

ASSEMBLY

PN:90807-00 R090114

Figure 8: Weld Locations

Tile Plow Owner’s/Parts Manual

13

5

Section

OPERATION

WARNING

1. Read and understand the owner’s manual and all

safety signs before servicing, adjusting or repairing.

2. Install and secure all guards and shields before starting or operating.

3. Keep hands, feet, hair and clothing away from all

moving and/or rotating parts.

4. Place all controls in neutral or off, stop engine, set

parking brake, chock wheels, remove ignition key

and wait for all moving parts to stop before servicing,

adjusting, repairing or unplugging.

It is the responsibility of the owner or operator to read this

manual and to train all other operators before they start

working with the equipment. In addition to the design and

conguration of equipment, hazard control and accident

prevention are dependent upon the awareness, concern,

and prudence of personnel involved in the operation, transport, maintenance and storage of equipment or in the use

and maintenance of facilities.

5. Clear the area of bystanders, especially small children, before starting.

6. Keep all hydraulic lines, fittings, and couplers tight

and free of leaks before and during use.

7. Clean reflectors and lights before transporting.

8. Review safety related items annually with all personnel who will be operating or maintaining the equipment.

9. Shut the tractor off when connecting the equipment

hydraulics.

Follow all safety instructions exactly. Safety is everyone’s

business. By following recommended procedures, a safe

working environment is provided for the operator, bystanders and the area around the work site. Untrained operators

are not qualied to operate the machine.

Many features incorporated into this equipment are the

result of suggestions made by customers like you. Read

this manual carefully to learn how to operate the machine

safely and how to set it to provide maximum efciency. By

following the operating instructions in conjunction with a

good maintenance program, your equipment will provide

many years of trouble-free service.

14

Tile Plow Owner’s/Parts Manual

PN:90807-00 R090114

Loading...

Loading...