Cranesmart Systems 30UTX Users manual

Pipelayer LMI 4 System

User Manual

Updated: July 14, 2017

Edition 1.0

Cranesmart Pipelayer LMI 4

User Manual

Contents

1. The User Interface ............................................................................................................................ 3

1.1. The Home Screen ..................................................................................................................................................... 4

1.2. The Menu Screens ................................................................................................................................................... 6

1.3. The Value Entry Screen .......................................................................................................................................... 8

2. Normal Operation .......................................................................................................................... 10

2.1. Load Indication ....................................................................................................................................................... 10

Load Calibration ........................................................................................................................................... 12

Load Limits ..................................................................................................................................................... 13

Load Tare ........................................................................................................................................................ 15

2.2. Angle Indication ..................................................................................................................................................... 17

Angle Calibration ......................................................................................................................................... 18

Angle Limits ................................................................................................................................................... 20

2.3. Overhang Indication ............................................................................................................................................. 22

2.4. Tip Height Indication ............................................................................................................................................ 24

2.5. Level Indication ....................................................................................................................................................... 26

Level Calibration .......................................................................................................................................... 27

Level Limits .................................................................................................................................................... 29

3. The Configuration Menu ............................................................................................................... 30

3.1. Winch .......................................................................................................................................................................... 31

3.2. POL (Parts of Line) ................................................................................................................................................. 31

3.3. Boom Length ........................................................................................................................................................... 31

4. The Settings Menu ......................................................................................................................... 32

4.1. Limits .......................................................................................................................................................................... 32

4.2. Calibration ................................................................................................................................................................ 34

Copyright © Cranesmart Systems Inc. 1

Cranesmart Systems Pipelayer User Manual

4.3. Panel ........................................................................................................................................................................... 35

4.4. Enable/Disable ........................................................................................................................................................ 36

4.5. Units ............................................................................................................................................................................ 36

4.6. Permission Level ..................................................................................................................................................... 37

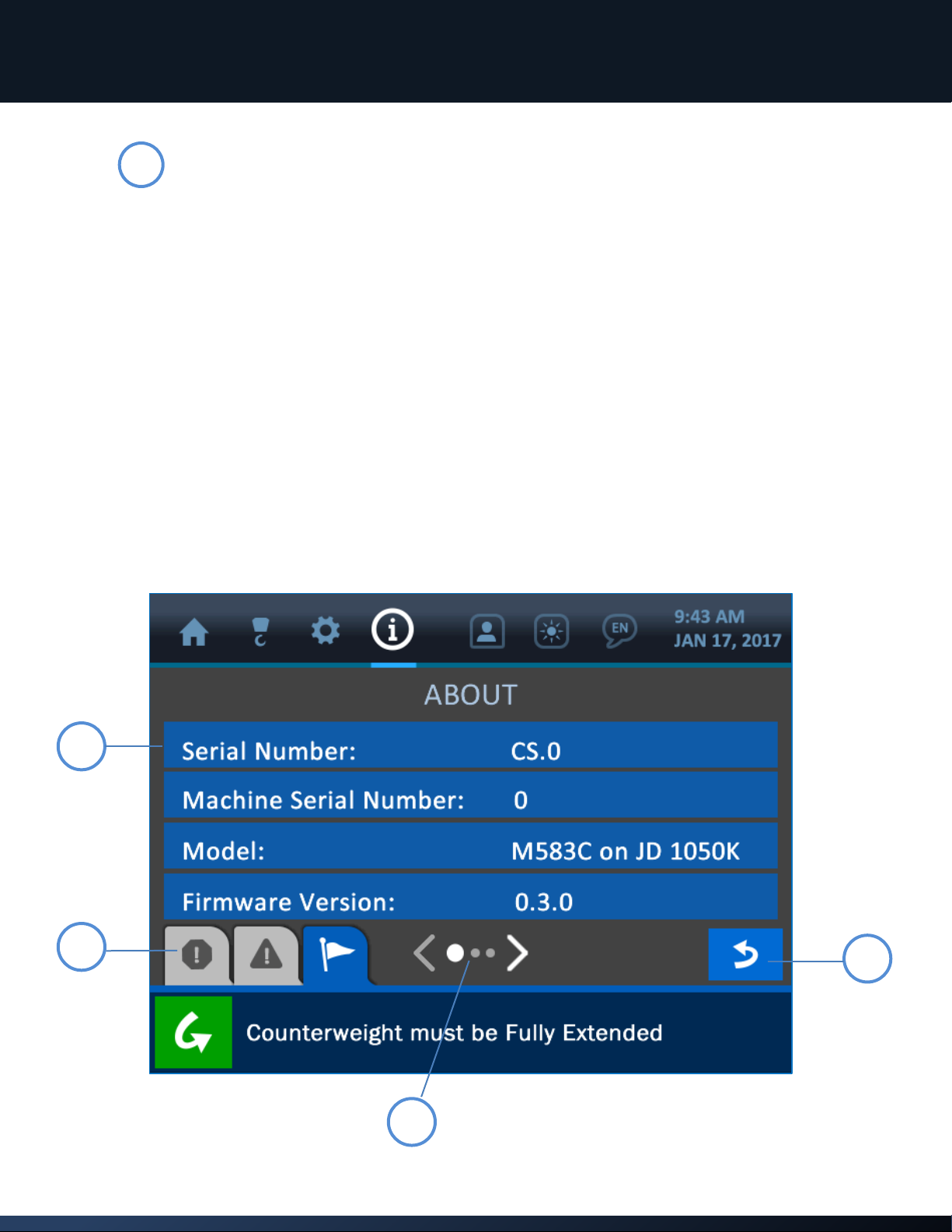

5. The Information Menu ................................................................................................................... 38

5.1. About .......................................................................................................................................................................... 39

5.2. Limits .......................................................................................................................................................................... 40

5.3. Transducers .............................................................................................................................................................. 41

5.4. Panel ........................................................................................................................................................................... 42

6. The Permission Menu..................................................................................................................... 43

6.1. Entering the Permission Level Code ................................................................................................................ 44

6.2. Supervisor Access Screens .................................................................................................................................. 45

7. The LCD Brightness Screen ............................................................................................................ 49

8. The Time and Date Screen ............................................................................................................. 50

9. Troubleshooting ............................................................................................................................. 51

9.1. Alarm and Warning Screens ............................................................................................................................... 51

9.2. Replacing a Transducer Battery ........................................................................................................................ 52

10. Appendix ......................................................................................................................................... 53

10.1. Load Pin Installation .......................................................................................................................................... 53

10.2. Anti-2-Block Installation (Optional)............................................................................................................. 56

10.3. Boom Angle Transducer Installation ........................................................................................................... 58

10.4. Level Transducer Installation ......................................................................................................................... 59

10.5. Display Panel Installation ................................................................................................................................ 60

10.6. Alarm Shutoffs (White Wire) .......................................................................................................................... 61

10.7. Display Panel Wiring Diagram ....................................................................................................................... 62

10.8. Shut-off Bypass Plug (optional – not included with visual / audible alarm only systems) ..... 63

10.9. Initial System Setup ........................................................................................................................................... 64

10.10. System Screen Flowchart ................................................................................................................................ 65

Copyright © Cranesmart Systems Inc. 2

Cranesmart Systems Pipelayer User Manual

Warranty

Cranesmart Systems warrants to the purchaser of each new Cranesmart System that any part thereof

which proves to be defective in material or workmanship within two (2) years from date of delivery

will be repaired or replaced at no charge if the system is returned to us in Edmonton, Alberta with all

freight charges prepaid

Alberta at (888) 562-3222 or (780) 437

This warranty does not cover defects resulting from accident, alteration, improper use, or failure of the

purchaser to follow normal oper

PLEASE NOTE:

Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

This device complies with part 15 of FCC rules, and Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including interference

that may cause undesired operation of the device.

The display panel is a category 2 item as per

Opening the display panel voids the warranty.

. If a performance problem should occur, contact our office in Edmonton,

2986.

-

ating procedures as outlined in this instruction manual.

IC and FCC radio certification.

No components of the system are to be submerged in

This warranty is in lieu of any warranty or merchantability and of all other warranties ,

expressed or implied, all of which are hereby excluded.

The display panel operates at an input range of 12 - 24 VDC at 1 A

The wireless transducers operate at 3.6 VDC at 30 mA (battery).

Cranesmart Systems shall in no event be liable for any special, indirect, or consequential damages

whatsoever and neither assumes nor authorises any person to assume for it any other obligation or

water.

liability.

Copyright © Cranesmart Systems Inc. 3

Cranesmart Systems Pipelayer User Manual

1

2 3 4

5

6

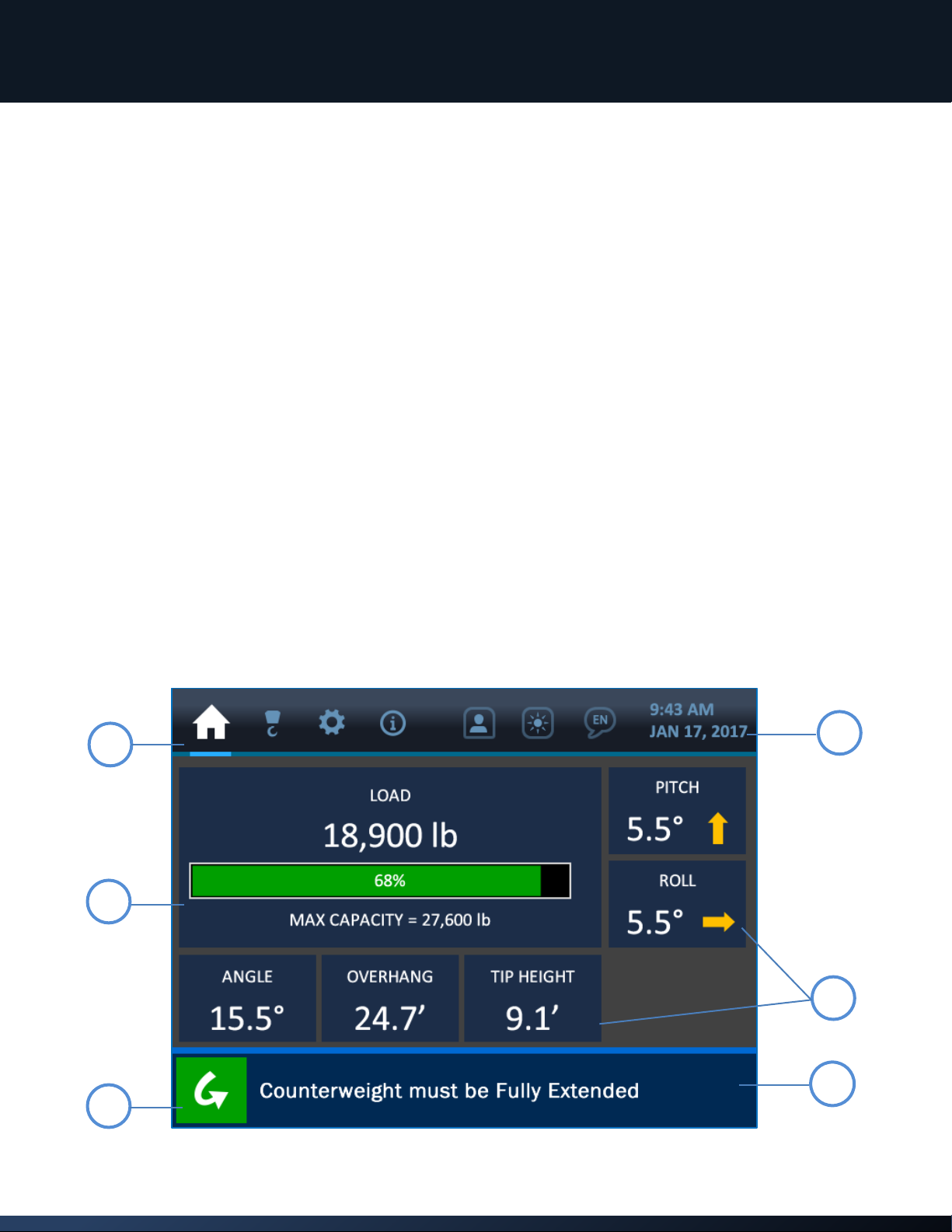

1. The User Interface

The new Cranesmart Pipelayer LMI 4 System utilizes a large full color touchscreen display panel, which

is described generally, in this section. All information, parameters, menus and alarms are displayed

and accessible directly via the touchscreen, with no need to use the hardware buttons located

beneath the display. (These buttons will be integrated in later versions of the system for extended

functionality).

NOTE: The touchscreen does not respond to increasing pressure on its surface - to make a

selection, use only light contact directly overtop the desired screen button to avoid potentially

damaging the screen.

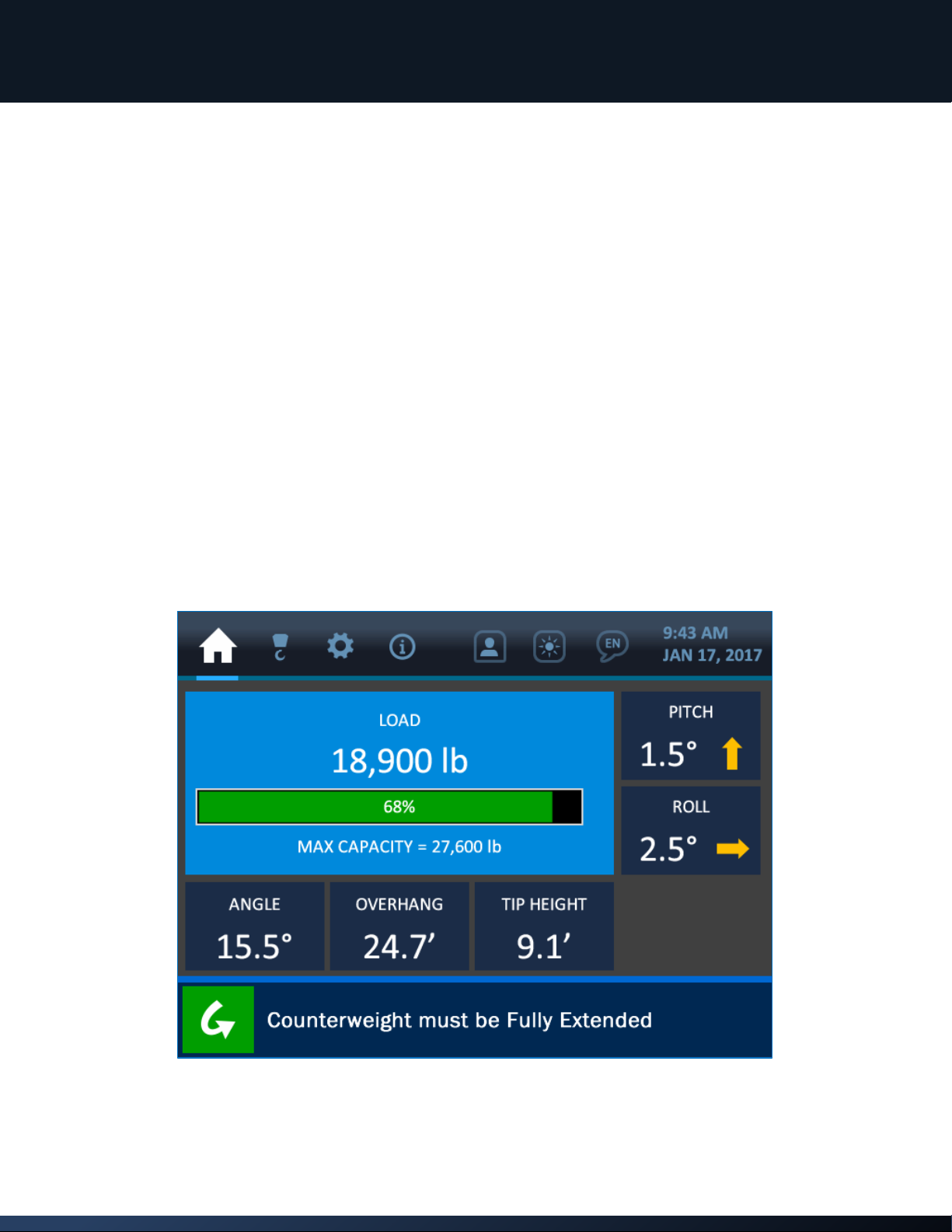

1.1. The Home Screen

Illustrated below is the Home Screen, which is the main screen for normal operation. The

system updates in real time, all the most important parameters of the system and displays

them here for the operator. The elements of the display are labeled and explained on the

following page.

Copyright © Cranesmart Systems Inc. 4

Cranesmart Systems Pipelayer User Manual

1

2

3

4

5

Menu Tabs

Across the top of the display are the Menu Tabs for accessing the main functions of

the system. From left to right, the tabs represent these menus: Home /

Configurations / Settings / Information / Permission Level / Brightness / Language.

These tabs are visible and accessible at all times.

Load Display

The primary section of the Home Screen shows the load information. Here, the

current load on the hook is displayed in the chosen units of measurement, as well as

the (programmed) maximum load allowed for the system. The current load as

compared to the maximum is also displayed visually as a bar graph and percentage.

Bypass Button

Pressing this button will shut off any audible alarm and dismiss any warning message

for a period of 30 seconds. The display will show this time interval counting down,

until the timer runs out completely and the alarm is reactivated. A more detailed

description of the alarms and their displays are found in section 9: Troubleshooting

(page 50)

Clock

The upper right area of the screen shows the system clock. The time of day as well

as the month day and year are displayed clearly for the operator. This information

can be changed by pressing the screen directly over the clock display, which will

open the Time and Date Screen (page 49).

Secondary Parameters Display

Surrounding the load display are other important parameters being monitored by

the system. Information related to the machine’s boom (angle, overhang, and tip

height) is located below the load display. Information related to the machine’s level

(pitch and roll) is located to the right of the load display. Pressing the area of the

screen overtop each parameter shown will open an associated menu for that

parameter, where certain values can be changed or displayed.

Copyright © Cranesmart Systems Inc. 5

Cranesmart Systems Pipelayer User Manual

3

4 1 2

6

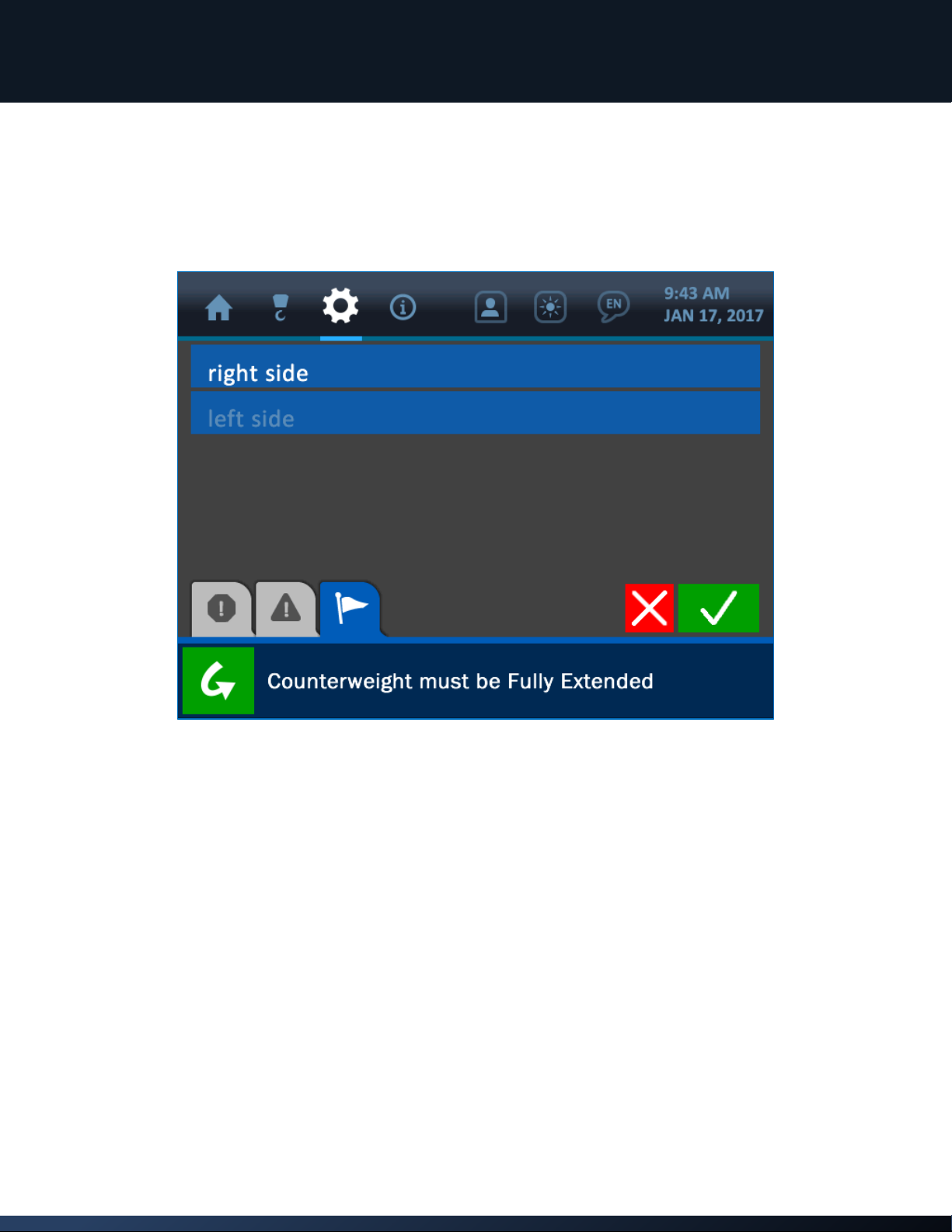

Alarm and Notification Bar

The lower section of the screen shows the Alarm and Notification Bar. As shown in

the screenshot, the system pictured is experiencing no alarms and shows the default

notification, ‘Counterweight must be Fully Extended’. In case of an alarm, an

associated message would be displayed in this area, with color changes to indicate

the problem visually. Further description of the alarms and their displays are found

in section 9: Troubleshooting (page 50).

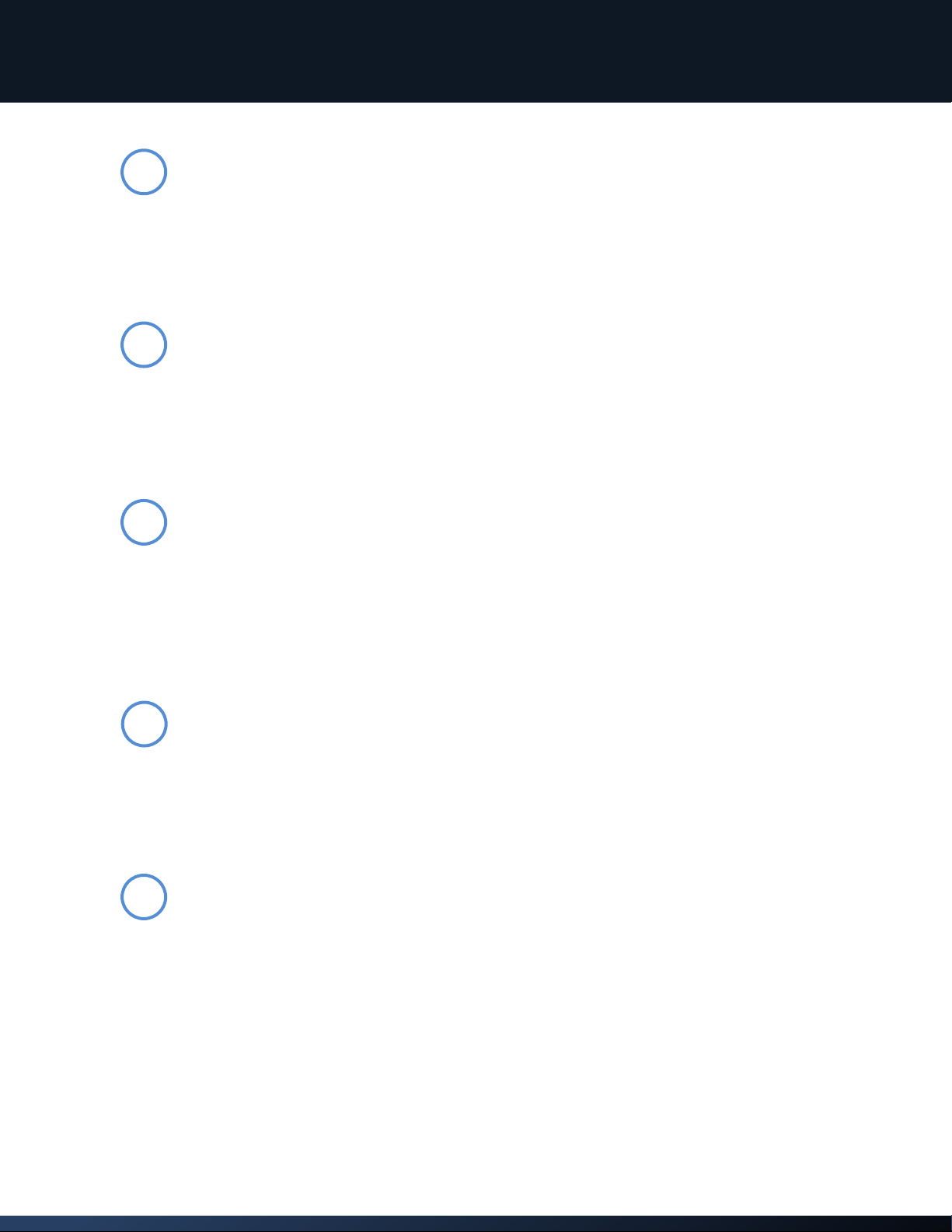

1.2. The Menu Screens

Shown below is an example of a typical Menu Screen. Its various components are described on

the following page.

Copyright © Cranesmart Systems Inc. 6

Cranesmart Systems Pipelayer User Manual

1

2

3

4

Banner Buttons

Every listed item on a menu screen is shown overtop a blue ‘banner button’. If the

item is changeable or linked to a further submenu, pressing anywhere on its banner

button will advance the display to show more associated options.

Message Tabs

Across the bottom of the menu screens are the various message tabs that display

different kinds of information to the operator. The tabs in order from left to right

are: Alarms / Warnings / Notifications.

Page Indicator

This symbol indicates that more menu items are available, but cannot all be

displayed simultaneously. Pressing anywhere directly overtop this symbol will

advance the display to the subsequent page(s) of the menu, until eventually cycling

back to the first page.

Back Button

Pressing this button will re-open the previously viewed screen, making menu

navigation faster and easier.

Copyright © Cranesmart Systems Inc. 7

Cranesmart Systems Pipelayer User Manual

5

3

4 1 2

1

2

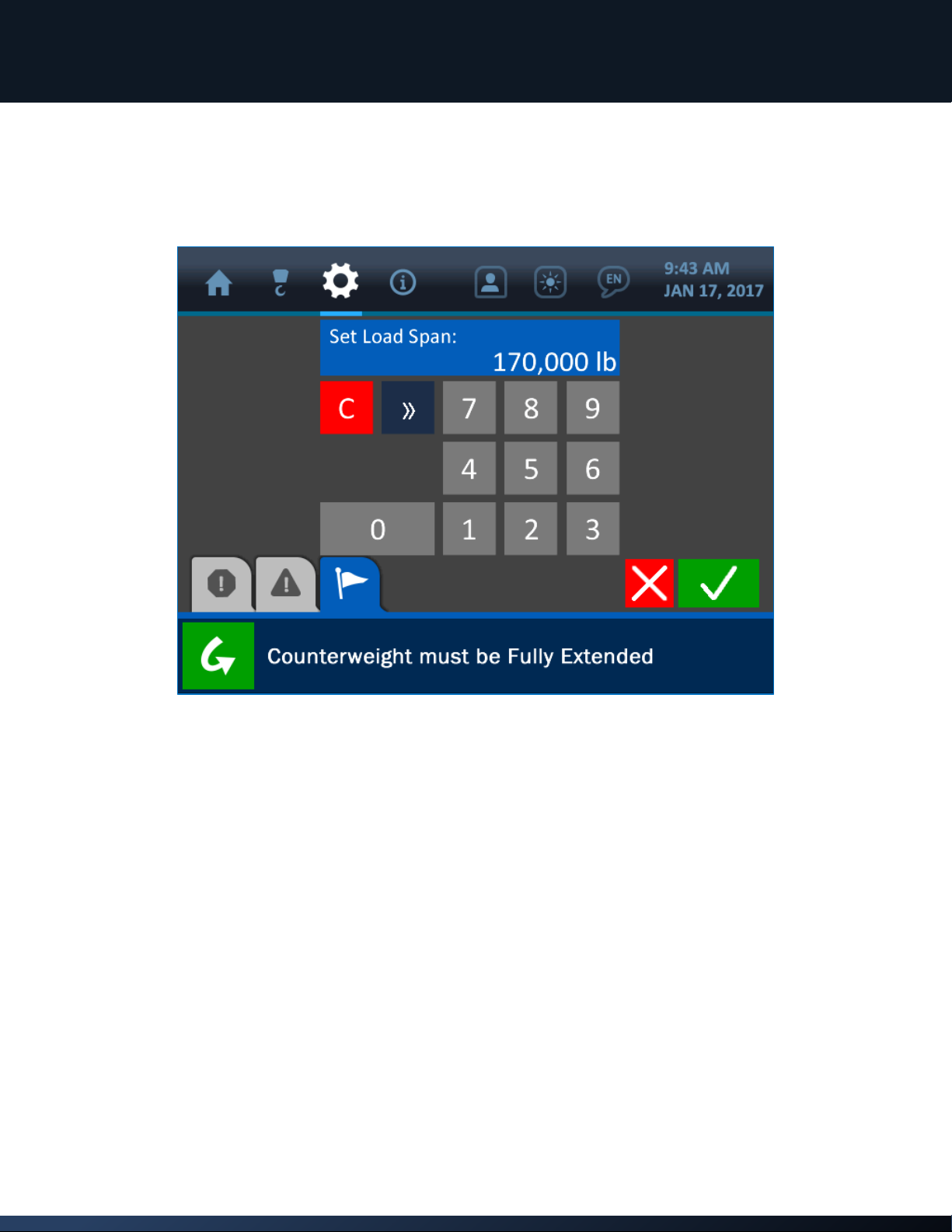

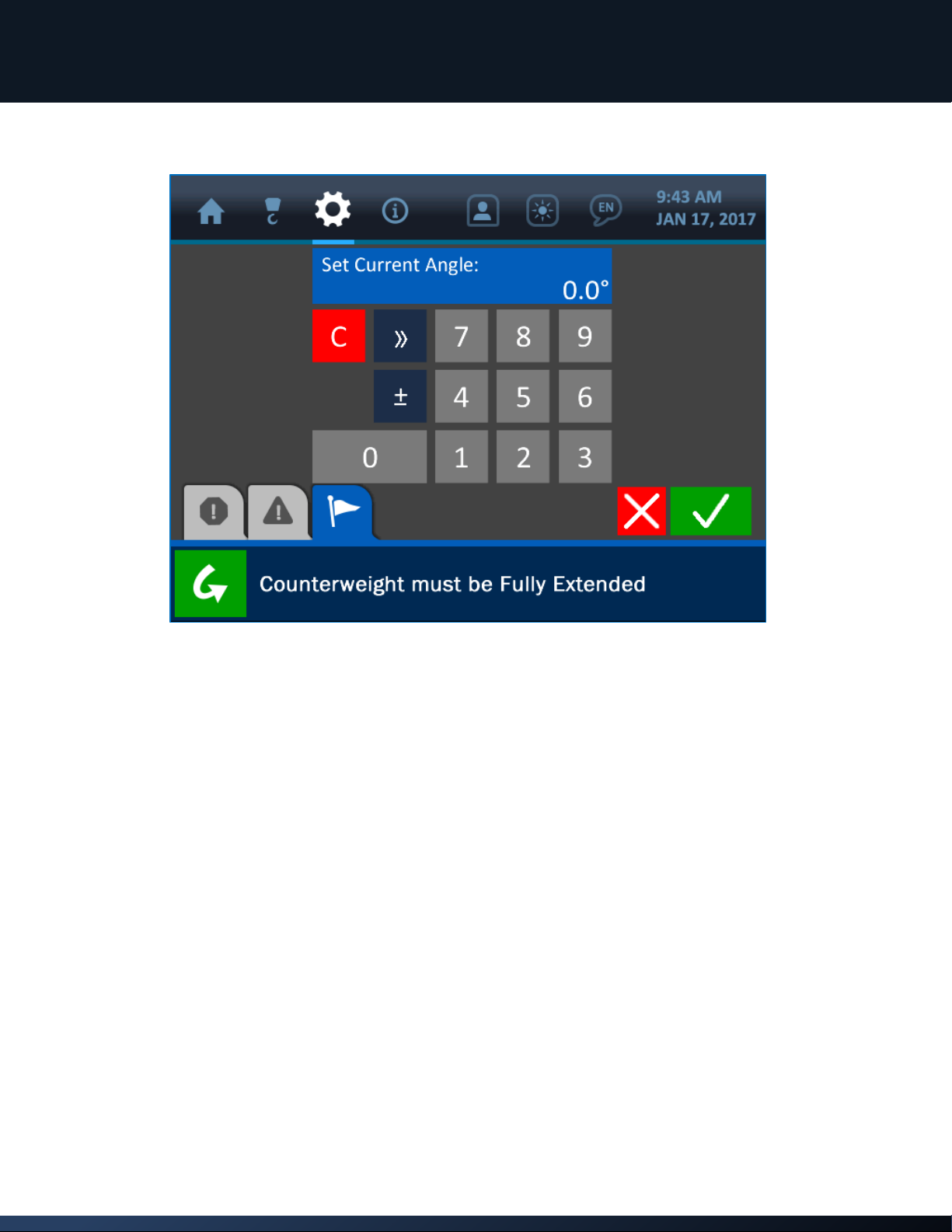

1.3. The Value Entry Screen

Shown below is an example of a typical Value Entry Screen. This is the format used for any

instance where a numerical parameter must be set or changed. The various components of

this screen are labeled and described below.

Value Window

The value in question will be displayed in this area, showing updates as they are

made by pressing the keypad buttons.

Clear Button

Pressing this button will clear the Value Window, setting the value to 0.

Copyright © Cranesmart Systems Inc. 8

Cranesmart Systems Pipelayer User Manual

3

4

5

Delete Button

Pressing the Delete Button will delete the last digit displayed in the Value Window.

Keypad

Press the keypad buttons to set the new value to be used, as displayed in the Value

Window.

Cancel and Accept Buttons

Pressing the (red) Cancel Button will nullify any changes made on this screen and

open the previous page displayed. The (green) Accept Button will confirm and save

any changes made and open the previously displayed page.

Copyright © Cranesmart Systems Inc. 9

Cranesmart Systems Pipelayer User Manual

2. Normal Operation

The Cranesmart LMI 4 Pipelayer interface was designed to present the user with all the most

important, real-time information regarding the machine in use, for the safest and easiest possible

operation. This section of the manual explains each parameter display of the Home Screen and other

screens used during normal operation, how to view and change important settings, and the ways the

system indicates potential danger.

NOTE: See the previous section 1: The User Interface (page 3) for explanations of the screen

formats and common functions used throughout the system.

2.1. Load Indication

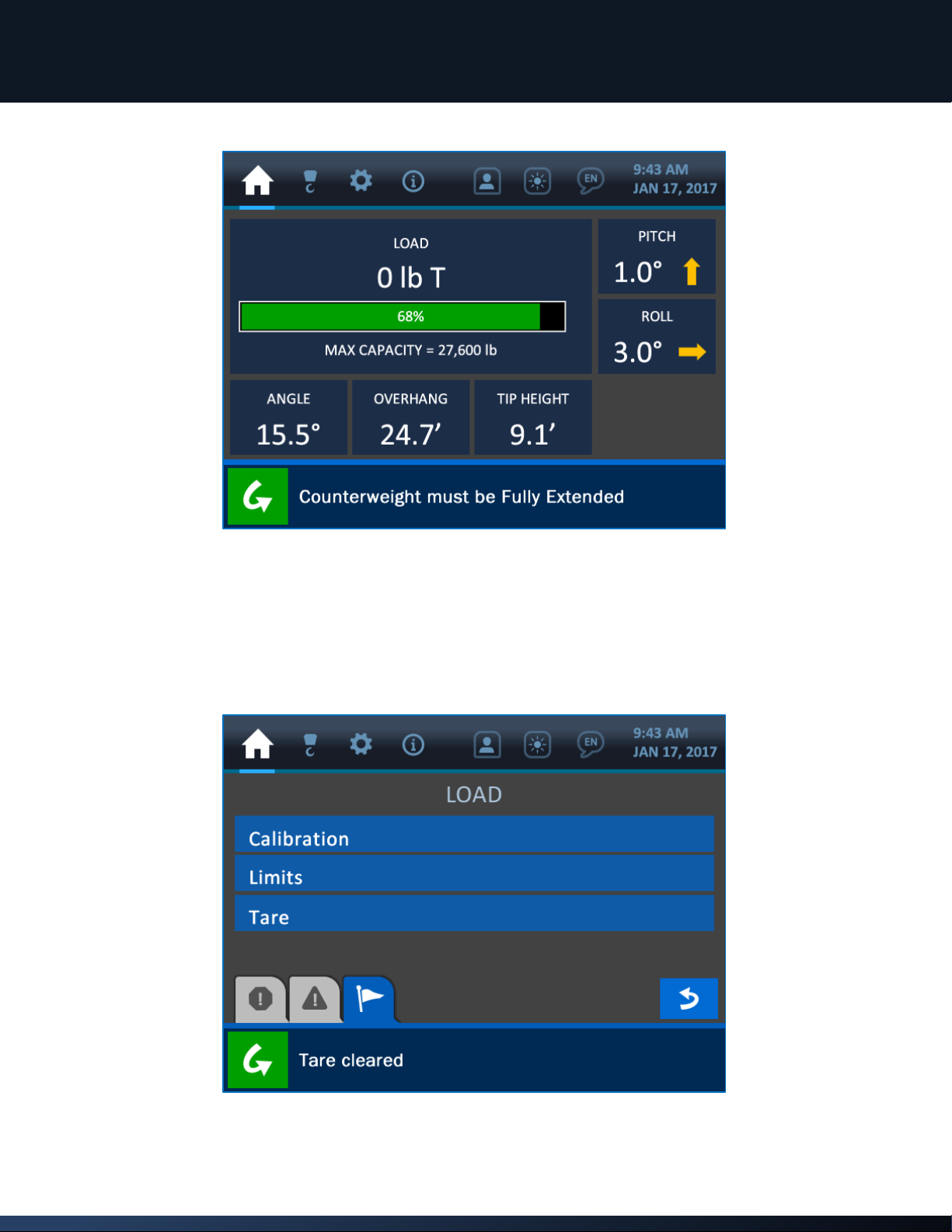

Shown below is the Home Screen, with the Load Indication area emphasised.

Copyright © Cranesmart Systems Inc. 10

Cranesmart Systems Pipelayer User Manual

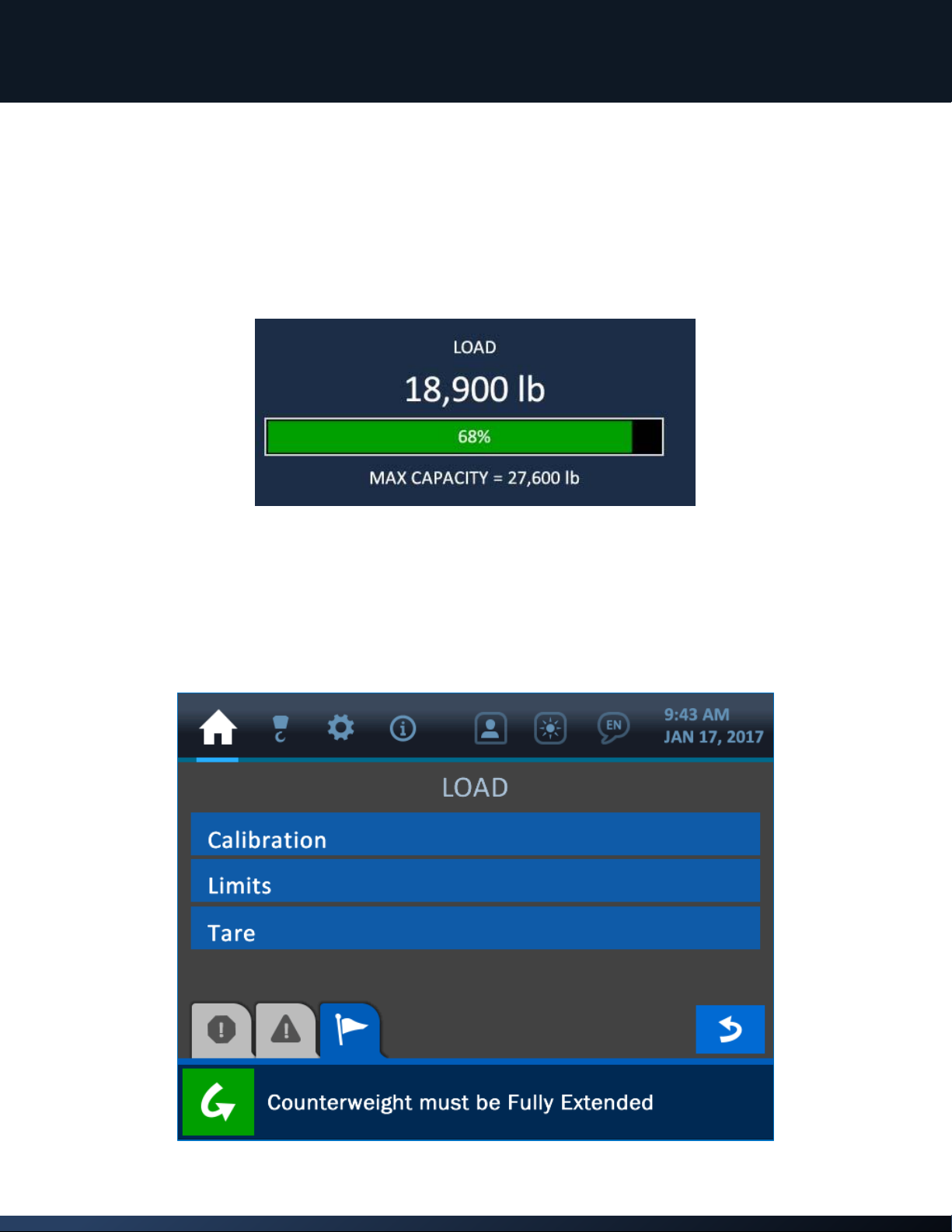

As shown in the previous screenshot, and the detail image below, the load is indicated by

several factors at any given time. The current load on the hook is shown, as well as a bar graph

and percentage indicating how close the current load is to the maximum capacity of the

machine. This max load limit is set by a supervisor, and is shown below the bar graph as ‘MAX

CAPACITY’.

Pressing anywhere directly overtop the load indication section of the screen will open the Load

Options Screen, as shown below. This menu screen offers 3 options for the load: Calibration,

Limits, and Tare. These options are described on the following pages.

Copyright © Cranesmart Systems Inc. 11

Cranesmart Systems Pipelayer User Manual

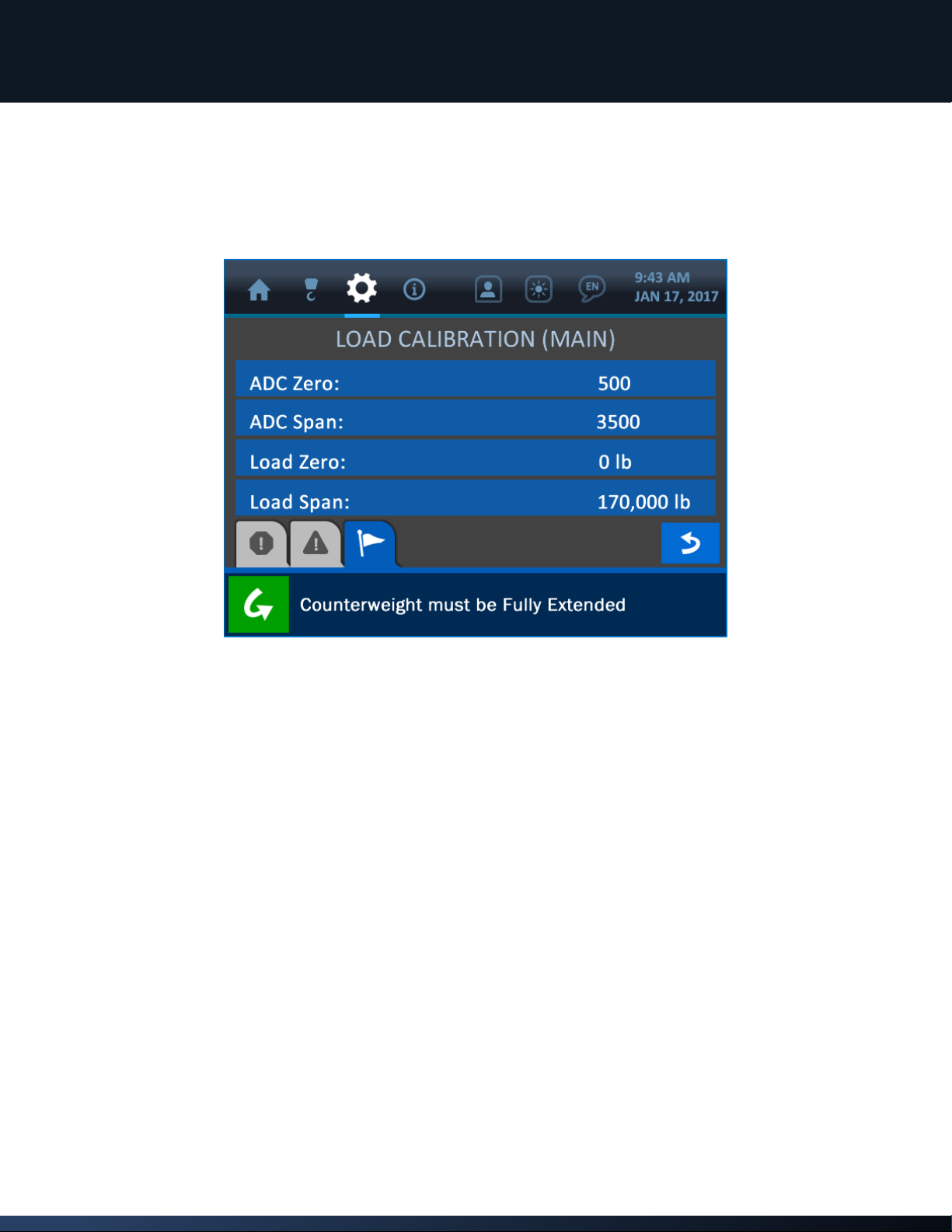

Load Calibration

The Load Calibration Menu displays the current settings for the following parameters:

ADC Zero: indicates the system’s Analog to Digital conversion value when there is no

load on the hook

ADC Span: indicates the system’s Analog to Digital conversion value when the maximum

possible load is on the hook (before the system shows a load alarm)

Load Zero: indicates the displayed load value when there is no load on the hook

Load Span: indicates the displayed load value when there is a maximum load on the

hook (before the system shows a load alarm)

Copyright © Cranesmart Systems Inc. 12

Cranesmart Systems Pipelayer User Manual

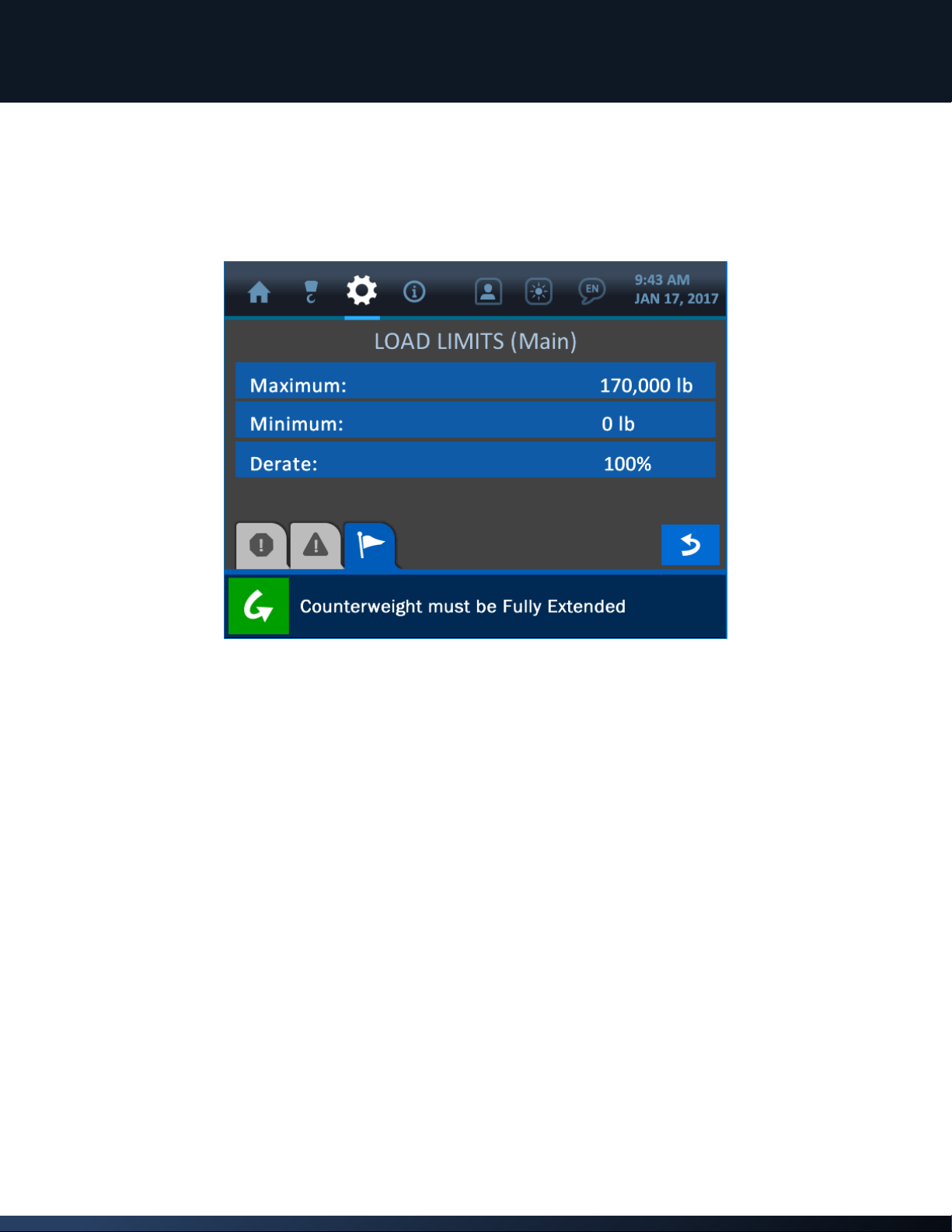

Load Limits

The Load Limits Menu displays the current settings for the following parameters:

Maximum: the current maximum load allowed before the system displays a load alarm

condition

Minimum: the current minimum load value recognized by the system for proper display

Derate: this value indicates the capacity of the load chart that the system is set to

recognize. If for example, the Derate value is set to 100%, the entire load chart

itself used at full capacity. If the Derate value were to be set at 50%, the

machine would be enabled to function at only half of its actual capacity before

the system shows an alarm state.

Copyright © Cranesmart Systems Inc. 13

Cranesmart Systems Pipelayer User Manual

To edit any of the load parameter values, simply press the screen directly overtop the

option to be changed to open the Value Entry Screen for that respective option.

Once the Value Entry Screen is opened, use the keypad to enter the desired value for the

parameter, and press the (green) Accept Button to save the change.

NOTE: See section 1.3: The Value Entry Screen (page 7) for a detailed description of

how the value entry screens function.

Copyright © Cranesmart Systems Inc. 14

Cranesmart Systems Pipelayer User Manual

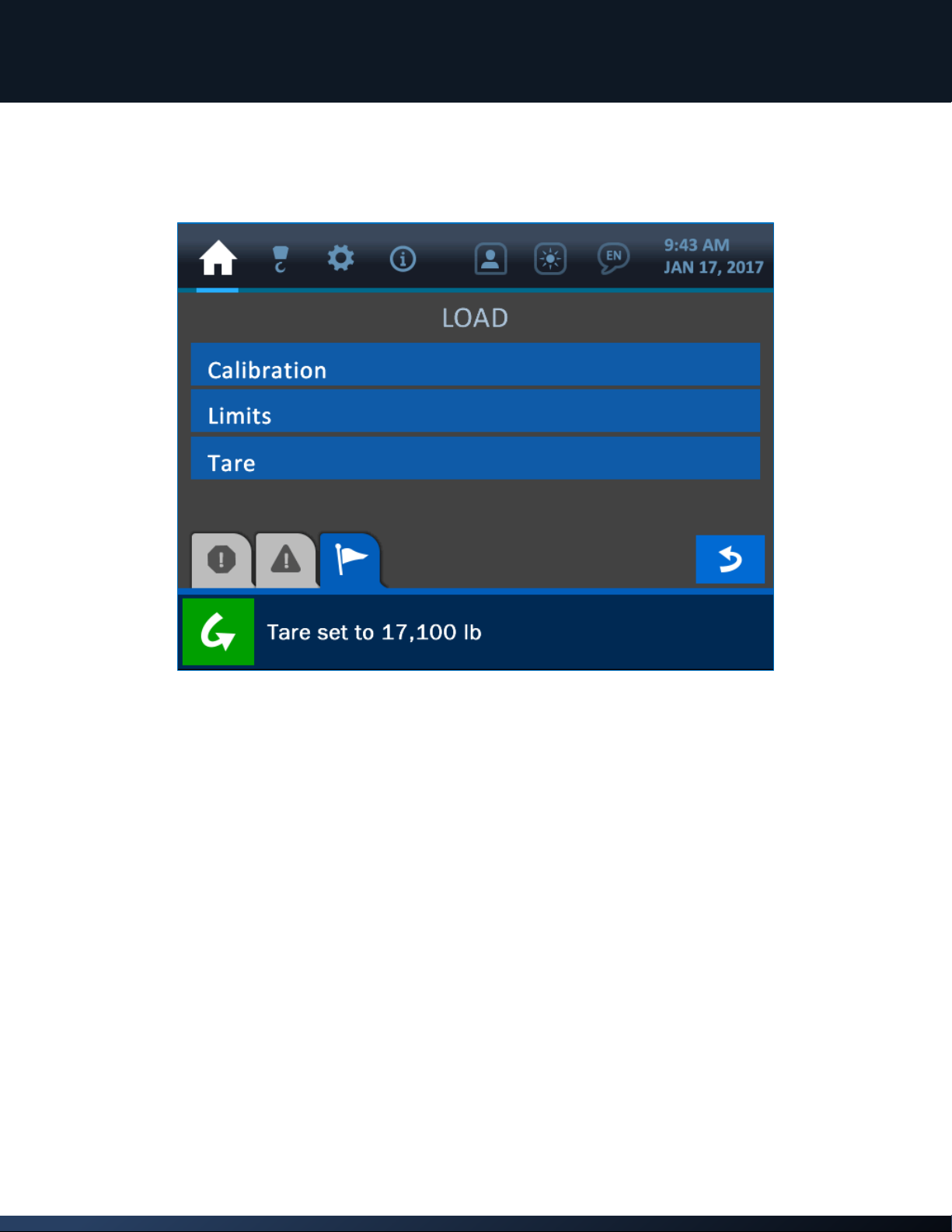

Load Tare

The Load Tare option enables an operator to set the current weight on the hook to zero.

To do this, simply press the ‘Tare’ banner button on the Load Options Screen. For the

example of this screenshot, the system shown is displaying in the Notification Bar (along

the bottom of the screen) that the current load of 17,100 lb has been set to zero. This is

further indicated by the following screenshot of the modified Home Screen – the current

load shows 0 lb and the ‘T’ symbol shows that this zero load is the result of the Tare

operation.

Copyright © Cranesmart Systems Inc. 15

Cranesmart Systems Pipelayer User Manual

Load Set to 0 by Tare Option

Tare Option Cleared

To clear the tare set point, simply re-enter the Load Options screen, and press the Tare

banner button again. The Notification Bar will indicate that the tare has been cleared, as

shown in the screenshot below.

Copyright © Cranesmart Systems Inc. 16

Cranesmart Systems Pipelayer User Manual

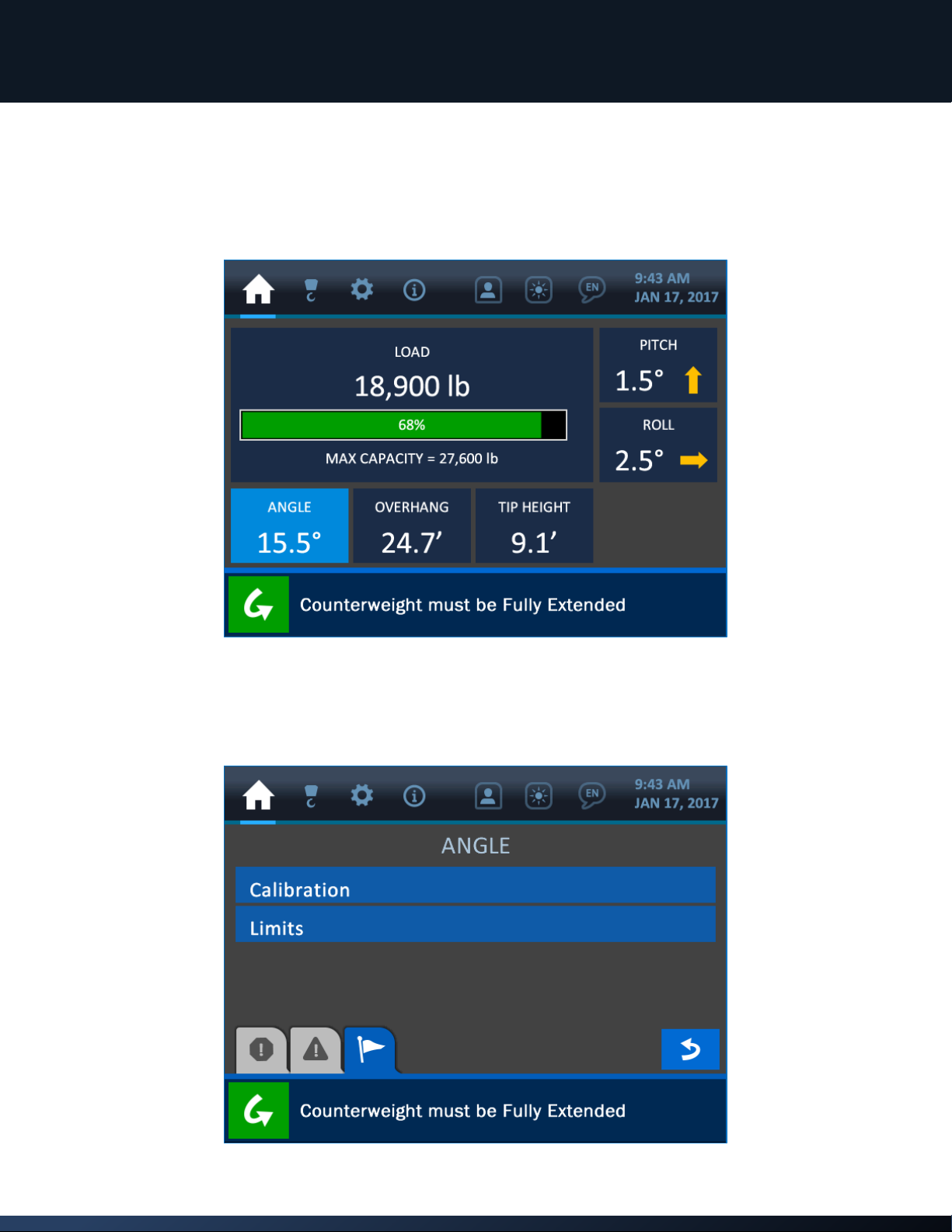

2.2. Angle Indication

Shown below is the Home Screen, with the Angle Indication area emphasised.

As illustrated above, the current boom angle is shown in degrees, to the resolution of 0.1°.

Pressing anywhere directly overtop the angle indication section of the screen will open the

Angle Options Screen, where angle calibration and limits options are available.

Copyright © Cranesmart Systems Inc. 17

Cranesmart Systems Pipelayer User Manual

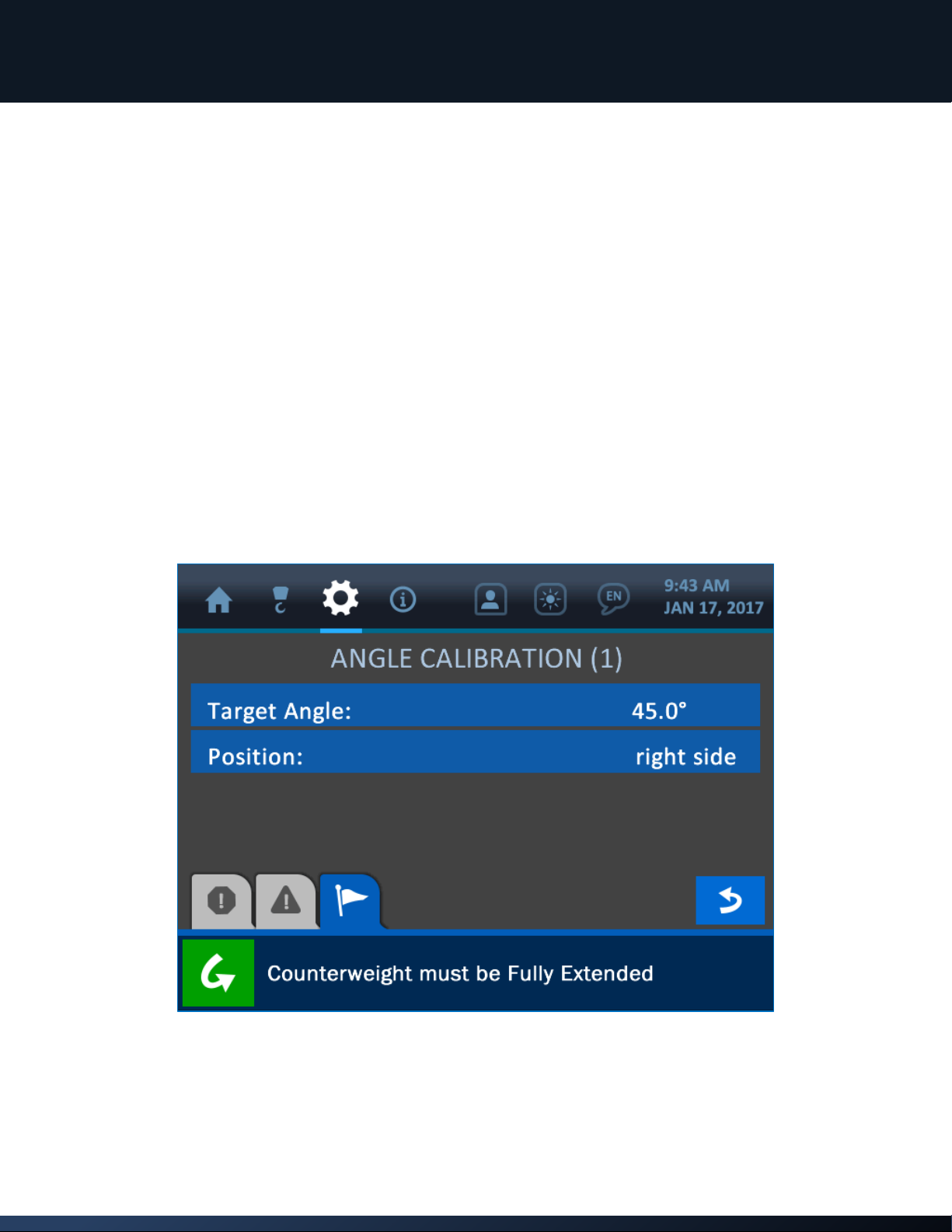

Angle Calibration

The Angle Calibration Menu allows the operator to set a target angle and orientation for

the angle transducer.

Concerning the Target Angle, set this value to what the system should be reading at a

known boom angle. If the machine boom is currently at 0° but the system is displaying a

different value, using the Target Angle Option will compensate for this discrepancy, by

introducing an offset value in order to make the display more accurate.

NOTE: The boom can be set to any angle, as long as that angle is known to be

accurate by some other means (for example a level, applied to the boom

horizontally or vertically). The resolution of the angle indicator is 1.0°.

To change the target angle value, simply press the screen directly overtop the target

angle option to enter the Value Entry Screen for this parameter.

Copyright © Cranesmart Systems Inc. 18

Cranesmart Systems Pipelayer User Manual

Once the Value Entry Screen is opened, use the keypad to enter the desired value for the

parameter, and press the (green) Accept Button to save the change.

NOTE: See section 1.3: The Value Entry Screen (page 7) for a detailed description of

how the value entry screens function.

The Position option simply ensures that the system displays the boom angle correctly by

indicating which side of the boom the transducer is mounted on (in relation to the

operator’s viewpoint). As shown in the following screenshot, selecting this option will

open a submenu, allowing the choice of either the left or right side of the boom.

Copyright © Cranesmart Systems Inc. 19

Cranesmart Systems Pipelayer User Manual

Selecting either option for the orientation will automatically enter that selection into the

system and return the user to the Angle Calibration Screen.

Angle Limits

The Angle Limits Menu should initially show the default values for a Maximum of 180°

and a Minimum of -180°. This simply ensures that the angle transducer is given its full

potential range to operate in, though these values can be changed at any time to

accommodate special circumstances of operation.

Copyright © Cranesmart Systems Inc. 20

Loading...

Loading...