Page 1

Tier 3

English 80390486

0 of 130

Page 2

Table of Contents

GENERAL INFORMATION .................................................................................. 3

Vender Safety Precautions .................................................................................................. 3

Product Identification ........................................................................................................... 3

CE Mark & IIA Declaration ................................................................................................... 3

Physical Characteristics ...................................................................................................... 3

INSTALLATION & SETUP ............................................................................ 3 - 10

Receiving Inspection ........................................................................................................... 3

Unpacking the Vender ................................................................................................... 3 - 4

Electrical Requirements ....................................................................................................... 4

Power Supply & Grounding Requirements .................................................................... 4 - 5

Installation & Setup Instructions .................................................................................... 5 - 6

Placing the Vender on Location ...................................................................................... 6 -7

Acceptable Ambient Operating Temperature Range .......................................................... 7

Storage Conditions .............................................................................................................. 7

Leveling the Vender ............................................................................................................. 7

Clearance Requirements ..................................................................................................... 7

Installing Labels & Product ID Cards ................................................................................... 7

Coin Changers and Other Accessories ......................................................................... 7 - 8

Set Temperature Control ..................................................................................................... 8

Loading the Vender ............................................................................................................. 8

Loading the Coin Changer ................................................................................................... 8

Power AC Distribution Box .................................................................................................. 8

Vending Machine Controllers ........................................................................................ 8 - 9

Touch Screen Display/Keypad ............................................................................................ 9

Refrigeration System ........................................................................................................... 9

Shelf Assembly .................................................................................................................... 9

Double Gate Assembly ........................................................................................................ 9

Slide / Pusher Assembly ...................................................................................................... 9

Deliver (Picker) Cup Assembly ............................................................................................ 9

Refrigeration Deck Clamp Assembly ................................................................................... 9

Belt Tensioning Adjustment Components ................................................................... 9 – 10

The Pill ............................................................................................................................... 10

Pill Lighting ........................................................................................................................ 10

PROGRAMMING ........................................................................................ 10 - 97

General .............................................................................................................................. 10

Move Thru the Menu Icons ................................................................................................ 10

Display of Products & Nutritional Information ............................................................ 10 - 11

Normal Operation Messages ............................................................................................. 11

Initial Programming ............................................................................................................ 11

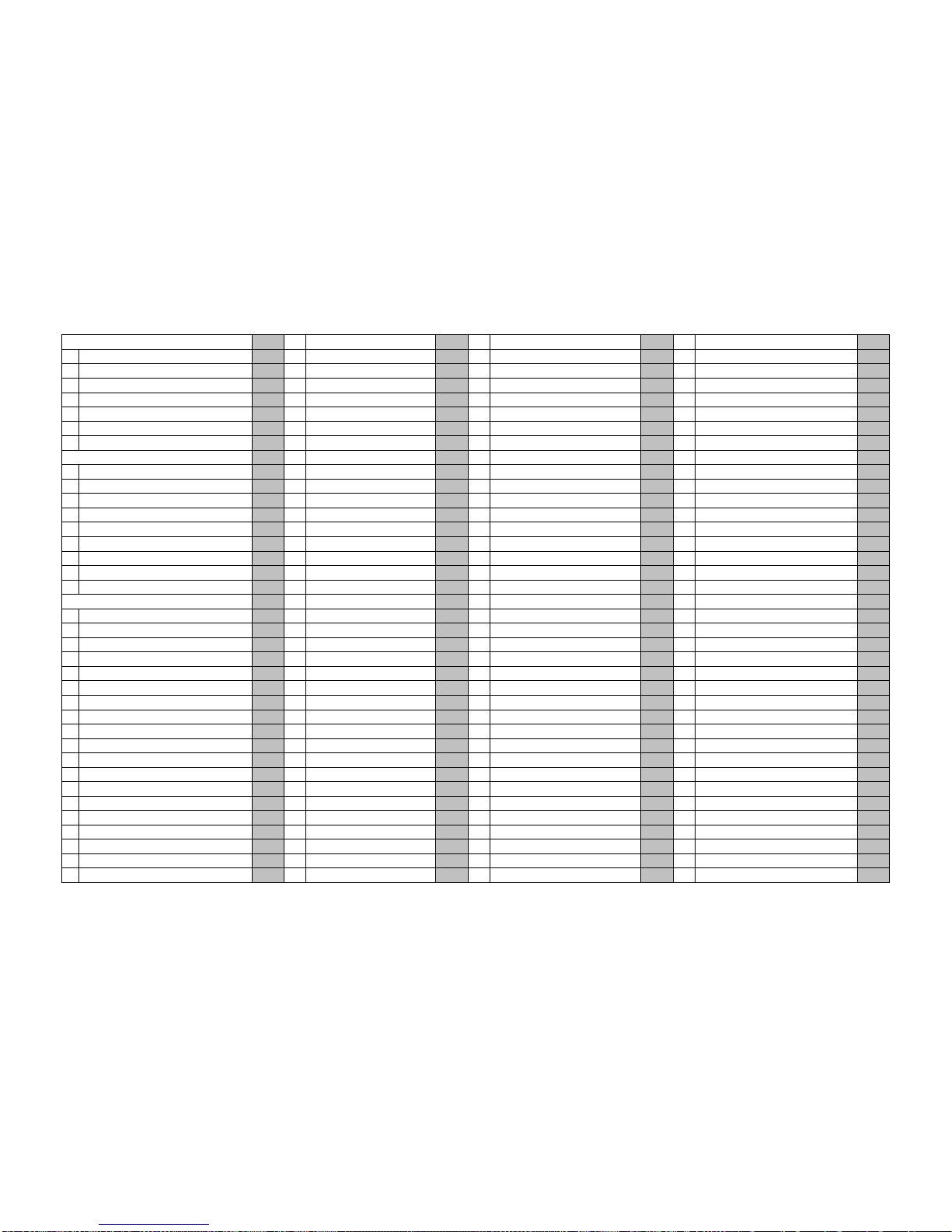

Quick Reference Menu Items .................................................................................... 12 - 13

Data Recall ................................................................................................................14 – 21

Diagnostics ................................................................................................................21 – 32

Test ............................................................................................................................33 – 37

Price ...........................................................................................................................37 – 38

Product Configuration ................................................................................................38 – 44

Special Vend Modes ..................................................................................................45 – 54

Monetary ....................................................................................................................54 – 58

System Settings .........................................................................................................59 – 70

Security Codes .......................................................................................................... 71 - 77

Timed Events ............................................................................................................. 77 - 84

Telemetry ................................................................................................................... 84 - 92

Machine Configuration ............................................................................................... 93 - 97

CONTROL BOARD .................................................................................. 98 - 100

LED Driver Controller Connections ................................................................................... 98

I/O Controller Connections ................................................................................................ 99

Atlas Controller Connections ........................................................................................... 100

1 of 130

Page 3

TROUBLESHOOTING ........................................................................... 101 – 120

–

XY Issues ............................................................................................................... 101 - 103

XY Not Working Flow Chart ............................................................................................. 104

Picker Motor Failure Flow Chart ...................................................................................... 105

X Motor Failure Flow Chart .............................................................................................. 106

Y Motor Failure Flow Chart .............................................................................................. 107

XY Slams to Top/Right or Left Flow Chart ...................................................................... 108

Picker Cup Not Working Flow Chart ................................................................................ 109

Picker Cup at Wrong Location Y Axis Flow Chart ........................................................... 110

Picker Cup at Wrong Location X Axis Flow Chart ........................................................... 111

Delivery Port Door Flow Chart ......................................................................................... 112

Coin Acceptance.............................................................................................................. 113

Bill Acceptors ................................................................................................................... 113

I/O Control Board ............................................................................................................. 113

All Coins Rejected Flow Chart ......................................................................................... 114

All Bills Rejected Flow Chart ........................................................................................... 115

Incorrect Change Dispensed Flow Chart ........................................................................ 116

Selection Will Not Vend Flow Chart ................................................................................. 117

Ice / Frost on Evaporator Flow Chart............................................................................... 118

Condensate on Outside of Product Door Flow Chart ...................................................... 118

Compressor Will Not Stop Flow Chart ............................................................................. 118

Compressor Will Not Start Flow Chart ............................................................................ 119

Machine Not Cooling Flow Chart ..................................................................................... 120

MAJOR COMPONENT DESCRIPTION ........................................................... 121

AC Distribution Box ......................................................................................................... 121

Service door Switches ..................................................................................................... 121

GENERAL MAINTENANCE .................................................................... 121 - 123

Power ............................................................................................................................... 121

Cleaning ................................................................................................................. 122 - 123

ELECTRICAL DIAGRAMS & SCHEMATICS ........................................ 124 – 127

Block Diagram Domestic ................................................................................................. 124

Block Diagram Export ...................................................................................................... 125

Compressor Parts Diagram - Domestic ........................................................................... 126

Compressor Parts Diagram - Export ............................................................................... 127

SHIPPING BRACKET REMOVAL ................................................................... 128

High Voltage Warning / Electrical

Warning Danger electricity, electric

shock.

Hazard Warning: Beware of moving machinery

Entanglement hazard. Keep hands, loose clothing,

and long hair away from moving parts.

A Gener ic Warning.

CAUTION: This machine is designed for indoor

usage only. Any other usage will void the

Manufacturer’s Warranty.

CAUTION: The electronic system components in this

machine utilize static sensitive components. Precautions

for handling sensitive devices should be observed when

handling these items.

2 of 130

Page 4

VENDER SAFETY PRECAUTIONS

Please read this manual in its entirety. This service

information is intended for use by a qualified service

technician who is familiar with proper and safe

procedures to be followed when repairing, replacing or

adjusting any Crane Merchandising Systems vender

components. All repairs should be performed by a

qualified service technician who is equipped with the

proper tools and replacement components, using

genuine Crane Merchandising Systems factory parts.

The appliance is not to be used by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision or

instruction. Children must be supervised not to play

with the appliance.

REPAIRS AND/OR SERVICING

ATTEMPTED BY UNQUALIFIED

PERSONS CAN RESULT IN

HAZARDS DEVELOPING DUE TO

IMPROPER ASSEMBLY OR

ADJUSTMENTS WHILE

PERFORMING SUCH REPAIRS.

PERSONS NOT HAVING A PROPER

BACKGROUND MAY SUBJECT

THEMSELVES TO THE RISK OF

INJURY OR ELECTRICAL SHOCK

WHICH CAN BE SERIOUS OR EVEN

FATAL.

edge of the product refrigerated area visible through

the glass door.

CE Mark & IIA Declaration:

An updated CE Mark or IIA Declaration document can

be provided upon request: If needed please contact

Technical Support Manager in Williston, SC. Phone:

1- 803-266-5001 or email bstaubs@cranems.com .

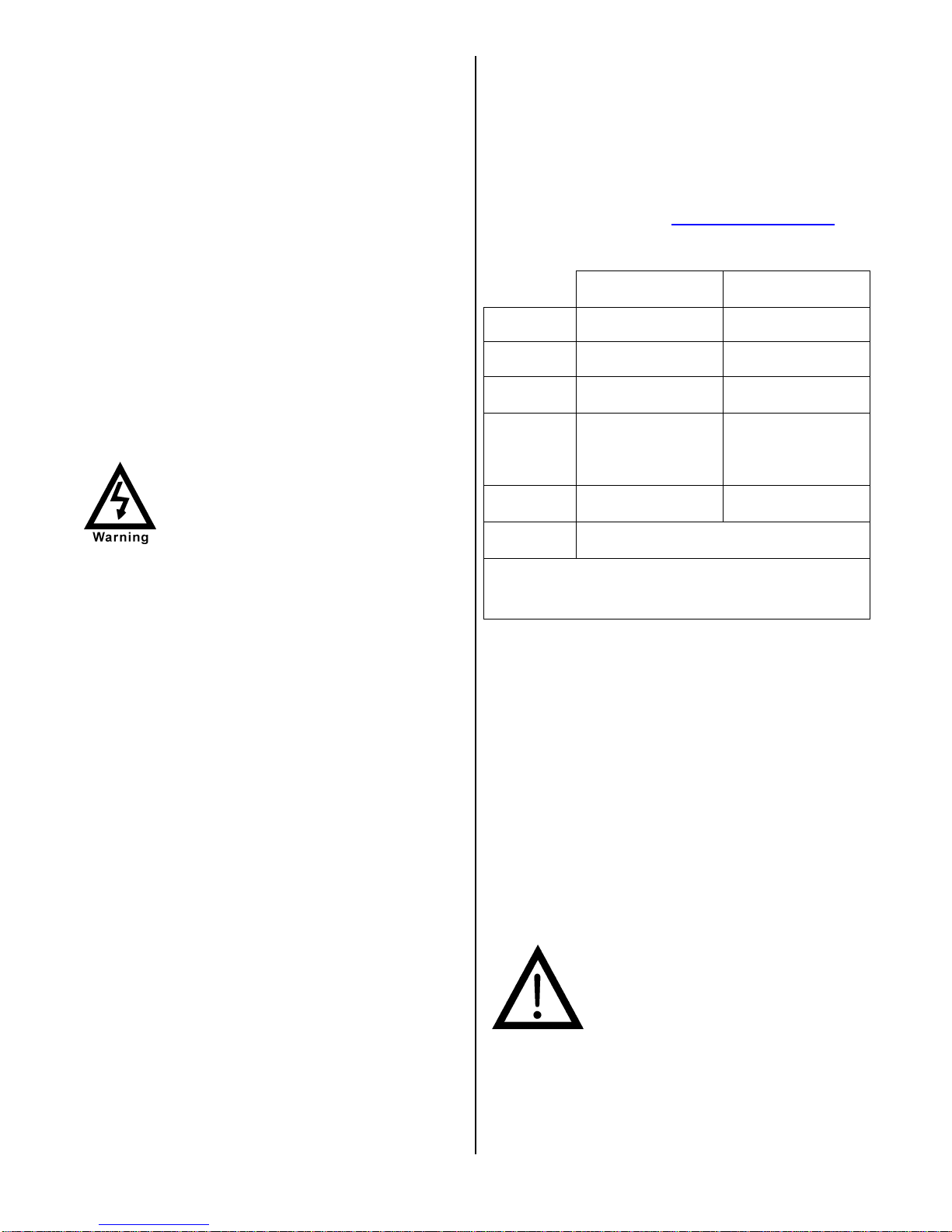

PHYSICAL CHARACTERISTICS

DN5800-6

DN5800-E6

HEIGHT

WIDTH

DEPTH

CABINET

DEPTH

WITH

SERVICE

DOOR

SHIPPING

WEIGHT

Noise

Level

Glass Door width = 37.5” (952.5 mm) 5800’s.

Glass Door width = 28.1” (713.74 mm) 3800’s.

Glass Door height = 68” (1727.2 mm) both.

73” (1854.2 mm) 73” (1854.2 mm)

47” (1193.8 mm) 40” (1016 mm)

32.05”

(814.07 mm)

33.5”

(850.9 mm)

710 lbs.

(322.05kg)

Operates at < 70db.

DN3800-6

DN3800-E6

32.05”

(814.07 mm)

33.5”

(850.9 mm)

648 lbs.

(293.93kg)

PRODUCT IDENTIFICATION

First production of BevMax 6 5800-6/3800-6 Domestic

and BevMax 6 5800-E6/3800-E6 Export Venders was

March/April 2013. The production date of Crane

Merchandising Systems products is determined by the

date code incorporated in the serial number.

The vender serial number takes the form xxxx-yyyy

zz. The first 4 digits (xxxx) identify the specific

vender. The next 4 digits (yyyy) identify the

manufacturing run that the vender was built in. The

last two alpha characters (zz) identify the quarter and

the year the vender was built. The first alpha

character identifies the quarter as follows:

The second alpha character identifies the year:

H = 2009 L = 2013

I = 2010 M = 2014

J = 2011 N = 2015

K = 2012 O = 2016

The Serial Number decals are located on the top left

corner of the back of the vender and on the left front

A= 1

B= 2

C= 3

D= 4

st

Quarter

nd

Quarter

rd

Quarter

th

Quarter

RECEIVING INSPECTION

DO NOT STORE THE VENDER OUTSIDE.

Upon receipt, inspect the vender for any shipping

damage. Note any damage on the bill of lading and

report any damage to the delivering carrier and follow

their instructions. Although the terms of sale are FOB

shipping point, which requires the consignee to

originate shipping damage claims, Crane

Merchandising Systems will gladly help if you must file

a claim.

UNPACKING THE VENDER

Remove the stretch wrap, fiberboard edge protectors

and corrugated front protector from the outside of

vender.

Do not store the vender with stretch

wrap on. Stretch wrap could bond to

the vender’s surface, which could

damage the finish.

Remove the shipping boards from the bottom of the

vender. The shipping boards are attached by the

leveling legs. To avoid unnecessary damage to the

leveling legs or base, remove the shipping boards by

using a 1-1/2 inch or 38mm socket type wrench to

unscrew the leveling legs. Be sure to replace the legs

3 of 130

Page 5

after removing the shipping boards. Once the skid

boards are removed there is 3” (76.2 mm) from base

flange to the floor with the leveling legs screwed all

the way in.

Once the vender is unpacked, check the “B” Tray area

for any additional parts, price/product labels,

service/operation manual or other information

concerning factory-equipped accessories such as coin

mechanism and validator.

It is recommended the vender be vend tested before

shipping to the location. In programming see ”Test

Mode”, # 9 “Test Vend” to perform test vends.

Note: Remove tape from ends of top

lamp in the top lamp assembly after

placing the Vender on location, but

before plugging the Vender in to an AC

power supply.

WARNING: TO AVOID THE

POSSIBILITY OF A FIRE

HAZARD, DO NOT STORE

ANYTHING OR ALLOW

DEBRIS OF ANY KIND TO

ACCUMULATE IN THE

BOTTOM OF THE SERVICE

AREA, IN AND AROUND THE

REFRIGERATION

COMPARTMENT OF THE

CABINET, OR IN FRONT OF

THE EVAPORATOR AND

CONDENSER COILS.

WARNING: ENSURE THAT

POWER IS DISCONNECTED

FROM THE VENDER BEFORE

INSPECTING OR REPLACING

THE LAMPS, OTHER

ELECTRICAL COMPONENTS,

OR WORKING WITH OR

ADJUSTING THE VENDING

MECHANISM. FAILURE TO

COMPLY WITH THESE

INSTRUCTIONS MAY

SUBJECT THE USER TO THE

RISK OF ELECTRICAL

SHOCK OR MECHANICAL

INJURY, WHICH CAN BE

SERIOUS OR FATAL.

ELECTRICAL POWER NEEDED

Refer to the cabinet serial number plate to determine

the correct voltage and frequency for the machine. In

the US and Canada this is 120Vac, 60Hz, 1P. In

Europe, Australia, and other export countries, this is

220/230/240Vac, 50Hz, 1P depending upon your

country voltage. The serial plate also specifies the

ampere rating of the machine. This machine must be

plugged into a properly rated receptacle with its own

circuit protection (fuse or circuit breaker).

Equipment Nominal Power Requirements

120V / 10.2 A = *1224W (1.224kw)

220V / 5.8 A = *1276W (1.276kw)

240V / 5.8 A = *1392W (1.392kw)

*Note: Watts = V X A

DO NOT USE AN EXTENSION CORD.

POWER SUPPLY CORD and GROUNDING

REQUIREMENTS

In accordance with the National Electrical Code and

Underwriters Laboratories Inc., domestic vending

machines are equipped with a three-wire power

supply cord and Ground Fault Circuit Interrupter

(GFCI). The GFCI device is provided as part of the

power supply cord and is either incorporated directly

into the plug or mounted on the cord adjacent to the

plug.

WARNING

• The GFCI protects against current

leakage caused by ground faults.

The GFCI is not designed to protect

against over current or short

circuits.

• DO NOT use the TEST and RESET

buttons on the GFCI as an ON/OFF

switch.

• The vending machine supply cord

MUST be plugged directly into a

properly grounded, 3 wire

receptacle that is properly

protected by a fuse or circuit

breaker. If the receptacle will not

accept the power cord plug, it must

be replaced with a properly

grounded, 3 wire receptacle in

accordance with the National

Electrical Code and Local Codes

and Ordinances. The work should

be done by a qualified electrician.

DO NOT USE A 3 WIRE TO 2

WIRE ADAPTOR

4 of 130

Page 6

DO NOT REMOVE THE GROUND

PIN ON THE PLUG OR IN ANY WAY

BYPASS, MODIFY, DEFEAT, OR

DESTROY THE GROUNDING

SYSTEM OF THE VENDING

MACHINE

• DO NOT USE WITH AN EXTENSION CORD.

• DO NOT REMOVE THE WARNING TAG

ATTACHED TO THE POWER SUPPLY CORD.

• The GFCI must be tested frequently and before

each use in accordance with the instructions

provided on the GFCI device. IF THE GFCI

DOES NOT PASS THE TEST, DO NOT USE

THE MACHINE. Unplug the supply cord from the

receptacle and call the Crane Merchandising

Systems Technical Support Group for assistance

at 1-803-266-5001.

The BevMax 6 is supplied with a service cord for the

country of use and is terminated in a grounding type

plug. The wall receptacle for this machine must be

properly polarized, grounded, and of the correct

voltage. Note: Operating the machine from a source

of low voltage will VOID YOUR WARRANTY. Each

machine should have its own 15 Amp electrical circuit

and that circuit should be protected with a circuit

breaker or fuse conforming to local regulations.

1. Voltage Check – Place the leads of a

voltmeter across the LINE (LIVE) and

NEUTRAL terminals of the wall receptacle.

The volt meter should indicate 110-130 volts

ac for 120 volt, 60 Hz locations, or 220-240

volts ac for 230 volt, 50 Hz locations.

2. Polarity Check - Place the leads of a

voltmeter across the LINE (LIVE) and

GROUND terminals of the wall receptacle.

The volt meter should indicate 110-130 volts

ac for 120 volt, 60 Hz locations, or 220-240

volts ac for 230 volt, 50 Hz locations.

3. Noise Potential Check - Place the leads of a

voltmeter across the NEUTRAL and

GROUND terminals of the wall receptacle.

The volt meter should indicate 0 volts ac. A

measurement greater than 1.5-2.0 volts ac

could result in problems for the machines

electronic circuitry caused by electrical noise.

It is recommended that the machine be located so that

the GFCI device will be accessible after the machine

is installed. After installation, visually inspect the

GFCI and power supply cord to be sure it is not

crushed, pinched, or stretched.

Protect the power supply cord during transportation

and use. Periodically inspect the power supply cord

for damage. If the cord or plug is worn or damaged, it

must be replaced with a power supply cord of the

same type, size and specification as originally

provided with the machine. DO NOT USE THE

VENDING MACHINE UNTIL THE WORN OR

DAMAGED CORD IS REPLACED.

FAILURE TO COMPLY WITH

THESE INSTRUCTIONS MAY

SUBJECT THE USER TO THE RISK

OF INJURY OR ELECTRICAL

SHOCK WHICH CAN BE SERIOUS

OR FATAL. PERIODICALLY

INSPECT THE POWER SUPPLY

CORD FOR DAMAGE. IF THE

CORD BECOMES DAMAGED IT

MUST BE REPLACED WITH THE

SAME SIZE AND TYPE CORD.

CONTACT CRANE

MERCHANDISING SYSTEMS FOR

ASSISTANCE.

INSTALLATION AND SETUP

INSTRUCTIONS

ELECTRONIC LOCK

The electronic lock provided in the vender consists of

a door mounted, motor driven 2 point latching system,

cabinet mounted latch and strike system, an infrared

controlled CPU, and a remote control key (FOB). The

design is modular and allows for easy field service.

The electronic remote key (FOB) features a rolling

code system which cannot be decoded if it is lost or

stolen. After the vender has been unlocked, a new

key can be programmed into it any number of times.

If a key is lost or stolen, it is recommended you

change the lock code in the field as soon as possible.

Changing the lock code requires a new key and

pressing the PROGRAM button on the lock inside the

vender. The lock does not need to be changed for rekeying.

Important: For security reasons all Electronic

Door Lock Venders are shipped less

keys. Customers will need to contact

the Electronic Door Lock

manufacturer to order keys.

A power bypass connector, located in the product

delivery port, allows auxiliary power to be applied via

a battery pack to the electronic lock in the event that

power is not available or there has been a failure of

the internal power supply. In the event of an

emergency, battery power is applied to the connector

and the door can be opened and closed using the

FOB.

The electronics uses an infrared transmission system,

which functions similar to a television remote control.

The transmission signal is line-of-sight, which requires

you to aim the remote at a specific place at close

range to prevent the accidental opening of several

venders at the same time.

5 of 130

Page 7

TO OPEN THE ELECTRONIC DOOR LOCK:

1. Plug the vender into a properly powered

outlet.

2. Hold the key FOB 0 to 3” (76.2 mm) in front of

the Delivery Port Door and press the button

on the key FOB.

Note: The wide end of the FOB should face

the door.

3. The lock will begin releasing the door. The

display will indicate OPENED. After the motor

has stopped running, you can pull the door

open.

TO CLOSE THE ELECTRONIC DOOR LOCK:

CAUTION: DO NOT SLAM THE DOOR CLOSED.

Slamming the door closed can damage the electronic

locking device.

1. Push the door to the cabinet until the lock

motor starts. The display will indicate:

CLOSED

2. Continue to push the door for approximately 2

to 3 seconds after the lock motor starts. The

lock will pull the door closed tightly.

3. When the lock motor stops the door will be

locked. Before leaving the vender, ensure

that the door is locked.

The electronic door lock assembly is supplied by

TriTeq Lock and Security. Crane Merchandising

Systems does not carry parts for the TriTeq Electronic

Door Lock. For parts and assistance, please contact:

TriTeq

701 Gullo

Elk Grove Village, IL 60007

Tel: 847-640-7002

Fax: 847-640-7008

Email: triteqlock.com

MANUAL LOCK

Open the service door on the right side using the key

provided in the coin return cup, or if shipped with a

locking clip, remove the clip and install the lock.

Ensure there is no power to the AC Distribution Box.

On venders with a main power switch on the AC

Distribution Box the switch needs to be in the OFF

position. On venders with a main power quick

disconnect plug on the AC Distribution Box the quick

disconnect plug needs to be unplugged. Check that

all connectors are firmly seated on the control board

and at the various components on the service door

(coin mech, keypad, etc.).

Retrieve the main power plug from the hole in the rear

of the vender and plug the cord in a properly

grounded 120VAC, 15 Amp receptacle (U.S. and

Canada).

Open the service door and apply power to the AC

distribution Box (if equipped with a bill acceptor, the

acceptor should cycle twice). The display on the door

will briefly show the software version in use as

“Software ###.## (ie 74#.#1) followed by the default

idle message “ENJOY A REFRESHING DRINK”, the

fluorescent lamp should be lit and the cooling unit

should start. If the display shows “OUT OF

SERVICE”, or the cooling unit fails to start, refer to the

TROUBLESHOOTING SECTION beginning on page

101.

SERVICE NOTE

Battery Backup

The battery backup is used to maintain the date and

time in case of power interruptions, or any time the

main power is off. When the vender is shipped, the

battery is connected and memory is being maintained.

If the vender is to be stored for long periods of time,

disconnecting the battery is recommended. The

following steps will guide you through this procedure.

• Open the service door, turn the main power

switch to the off position or unplug the main

power harness located on the front of the

power box.

• Locate the control board mounted on the rear

wall.

• Remove the battery from its holder (B1).

PLACING THE VENDER ON LOCATION

!! CAUTION !!

DO NOT TRANSPORT THE

VENDER TO OR FROM THE

LOCATION LOADED WITH

PRODUCT OR DAMAGE TO THE

VENDER MAY RESULT.

The vender is intended for INDOOR USE ONLY.

Indoor Use Only is defined as inside a structure

constructed with four walls and a roof, and sufficiently

protected from ambient conditions and not subjected

to the effects of weathering. The vender should be

kept out of direct sunlight and away from any heat

source. Do not use this vender in an environment

where flammable or explosive vapors are present.

This machine is not suitable for installation in an area

where a water jet or hose and nozzle may be used.

The vender must be on a solid, flat and level surface.

Ensure the flooring can bear the weight load of a fully

loaded vender (approximately 1109 lbs. or 413kg).

The vender must be positioned close enough to an

electrical outlet so that an extension cord is not

required. If the machine will be subject to user misuse

or vandalism, it is recommended that the vender be

secured to the floor or wall as described in Crane

Merchandising Systems / Dixie-Narco Technical

Bulletin 344. Due to the large size and weight of the

Vender, never attempt to move the Vender with a

6 of 130

Page 8

Hand Truck or Stair Climber. Use a pallet jack or

Vender/Cooler Dollies at all times when moving the

Vender. The vender should never be slid or pushed in

place. Never side load the leveling legs; doing so will

cause damage to the legs. Do not transport the

vender to or from customer locations loaded with

product, as damage may result due to excessive

weight. Be sure to test vender for proper operation

before putting in to service on location. Call the Crane

Merchandising Systems Technical Service

Department or your Crane Merchandising Systems

Representative for assistance.

ACCEPTABLE AMBIENT OPERATING

TEMPERATURE RANGE

Generic and Pepsi BevMax 6 5800-6/3800-6

equipment manufactured by Crane

Merchandising Systems is designed to work

properly in a temperature range of 75°F to 90°F

(23°C to 32°C) in still air 65% Relative Humidity

non-condensing. Usage outside the range may

cause unacceptable appearance or performance.

STORAGE CONDITIONS

The machine is capable of being stored in a

temperature range of 0°F to 155°F (-18°C to

68°C). Storage temperatures below 32°F (0°C)

require the operator to take the required

precautions to insure that any water is removed

from the condensate system prior to storage.

LEVEL THE VENDER

Adjust the front leveling legs, ensuring that an even

gap exists between the glass door and the top

security angle and receiver box, and then level the

cabinet front to rear. A carpenter’s level will help

verify that the vender is level. Leveling legs are

adjusted using a wrench or socket 1 ½” or 38 mm in

size. If the vender is to be used in a bank of

equipment, check the top and sides for proper

alignment. If you are unable to properly level the

vender, select an alternate location. NEVER PLACE

OBJECTS UNDER THE LEVELING LEGS OF THE

VENDER.

DANGER

THE VENDER MUST BE PROPERLY

LOCATED AND LEVELED. IF THE

MACHINE WILL BE SUBJECT TO

USER MISUSE OR VANDALISM IT IS

RECOMMENDED THAT THE

VENDER BE SECURED TO THE

FLOOR OR WALL AS DESCRIBED

IN CRANE MERCHANDISING

SYSTEMS DIXIE-NARCO

TECHNICAL BULLETIN 344 TO

MINIMIZE THE RISK OF INJURY OR

DEATH FROM TIPPING. CALL THE

CRANE MERCHANDISING

SYSTEMS TECHNICAL SERVICE

DEPARTMENT OR YOUR CRANE

MERCHANDISING SYSTEMS

REPRESENTATIVE FOR

ASSISTANCE.

CLEARANCE REQUIREMENTS

Do not block the rear of the vender. Maintain a

minimum of 4 inches (10 cm) from the wall to ensure

adequate airflow to the condenser and compressor.

At the rear of the vender, make sure nothing obstructs

the air exhaust at the bottom of the cabinet.

WARNING

TO AVOID THE POSSIBILITY OF A

FIRE HAZARD, DO NOT STORE

ANYTHING OR ALLOW DEBRIS OF

ANY KIND TO ACCUMULATE IN THE

BOTTOM OF THE DOOR, IN THE

BOTTOM OF THE SERVICE AREA,

IN AND AROUND THE

REFRIGERATION COMPARTMENT

OF THE CABINET, OR IN FRONT OF

THE EVAPORATOR AND

CONDENSER COILS.

INSTALLING PRICE LABELS

Pricing labels included in the literature package kit.

Remove the pricing label sheets from the service

manual package and gently remove the label

corresponding to the vend price of each selection by

tearing at the perforation. The label is installed at the

top of the front knuckle. Once installed, push the label

firmly against the front of the knuckle. This will insure

the label is locked in place.

INSTALLING PRODUCT ID CARDS

To assist with consistent loading, product ID cards

can be installed in the product pusher to designate to

the route driver which product the column is set for.

To install the flavor card, simply detach it from the

sheet at the perforation and slide it into the slots in the

product pusher. Contact your graphics supplier to

purchase as needed.

COIN CHANGERS & OTHER

ACCESSORIES

The vender is capable of accepting multiple forms of

payment systems using MDB or Executive (export

only) interface. If the coin changer and other MDB

accessories are not factory installed, refer to the

instructions received form the manufacturer of the

coin changer and other accessories for proper set-up

and installation.

7 of 130

Page 9

The vender will support the following Domestic MDB

coin changers:

All available NRI MDB

All available Currenza MDB

All available Mars MDB

All available Conlux MDB

All available Coinco MDB

The vender will support the following Domestic MDB

Bill validators:

All available Cashcode MDB

All available Currenza MDB

All available Mars MDB

All available Conlux MDB

All available Coinco MDB

The vender will support Domestic MDB card readers.

SETTING THE TEMPERATURE CONTROL

This vender is equipped with an electronic

temperature sensor. Defrost is controlled both

electronically based on run time of the compressor

and with a manual Defrost thermostat. The temp

sensor is factory pre-set to maintain a cabinet

temperature of 37º Fahrenheit (2.7ºC). It is also a

good practice to ensure the proper operating

temperature prior to installing the vender on location.

To set the temperature, apply power to the vender

and allow it to run for several hours with the glass

door closed or until the minimum cabinet temperature

is achieved. Then, using the method below, verify the

temperature inside the cabinet:

With an electronic temperature sensor, use the

keypad on the service door to show cabinet

temperature in Fahrenheit by pressing the F key

followed by the asterisk () key or in Centigrade by

pressing the C key followed by the asterisk key. The

temperature will be shown on the digital display

located on the front of the service door.

The manual Defrost thermostat is located in the

bottom left of the service area. The Defrost control is

preset and is not adjustable.

LOADING THE VENDER

CAN/BOTTLE DRINK TRAYS

The BevMax 6 5800-6/3800-6 Vender does not

require spacers or shims to vend most packages.

Load product in each column one package at a time

insuring that the package being loaded is in front of

the product pusher. Insure that the package is stable

within the column (doesn’t move excessively from side

to side). After loading the vender, test vend each

column to insure proper operation. Please contact a

Service Representative or refer to the proper

Technical Publication for any special settings you may

need.

LOADING CHANGE TUBES

The changer tubes can be loaded using one of the

following methods:

1. Load the coin mechanism with coins to the

desired level by inserting coins in the loading

slots on the coin tube front.

Minimum coin tube levels are:

6-8 nickels

7-8 dimes

5-6 quarters

Note: A low coin level in the coin tubes will

interfere with operation of the bill validator.

2. For exact cash accountability and to insure

maximum dollar bill acceptance, load the

mechanism utilizing the coin insert slot on the

front of the vender while in the coin TUBE

FILL/DISPENSE mode in the test menu in the

programming section of Technical Manual for

more information.

For additional information about coin mechanism,

refer to the manufacturer’s instructions.

POWER AC DISTRIBUTION BOX

The power distribution box is where the 120VAC or

220VAC input voltage is broken down to the main

operating voltages of the vender (24 VAC and 12

VAC) by a transformer. Those voltages are sent to

the controller via the P1 (3 pin) connector. Domestic

Venders contain a 15 Amp Outlet which provides

power to the Refrigeration Unit. It contains a main

power switch/plug that allows power to the AC

Distribution Box to distribute AC power to the lights,

evaporator fan, and refrigeration system, which are

always energized when the vender is powered up. It

is located inside the service area, mounted to the

back wall.

VENDING MACHINE CONTROLLERS

Atlas Control Board

The Atlas Control Board is located on the inside of the

Service Door. It controls all the logic functions of the

machine. It communicates with its peripherals (I/O

Board, Display Board, Coin Mechanism, Bill Validator,

Card Reader, Etc.) in an MDB format. It has 3 USB

ports, has built in telemetry, CCM connection WLAN

(Zigbee), soft boot, service button, multiple LED’s for

troubleshooting, interfaces with the I/O and LED

boards. Note: USB3 should be used for uploading or

downloading files including firmware updates.

I/O Controller

The I/O Controller is the heart of the Glass Front

Vender and is located on the rear wall inside the

service area. After receiving the message from the

Atlas Control Board to vend a particular selection, it

determines the necessary steps to make that happen

and then executes them. It then advises the Atlas

Control Board of its status. It is SIM Card

8 of 130

Page 10

programmable, which controls all aspects of the

vender. It also contains the power supply which

regulates the voltages required to operate the motors

as well as the coin mechanism, digital display, and all

logic functions in the vender. The machine operating

system is essentially a computer and will take a little

while when you first apply power to the machine.

TOUCH SCREEN DISPLAY/KEYPAD

The Touch Screen Display/Keypad is located on the

front of the service door. It consists of an approximate

7.5” X 4.25” (190.5 mm X 107.95 mm) touch screen

display. The touch screen display utilizes icons to

move through the menu. The touch screen display is

where the vender programming is accomplished and

where the customers make their selections.

REFRIGERATION SYSTEM

The refrigeration system is a single piece unit and is

hermetically sealed. The Model BevMax 6 units

consist of a 1/3 plus horsepower compressor, with a

single fin and tube style condensing unit with one

condenser fan, condensation overflow pan,

evaporator, and evaporator fan motor. The

refrigeration unit is located behind the refrigeration

unit cover panels, mounted in the bottom of the

cabinet. This unit is designed for easy removal and

replacement from the front or rear of the vender as a

complete assembly. An electronic thermostat

regulates the cabinet temperature. The control of the

thermostat is attached to the evaporator coils and

reads the temperature of air being pulled in to the

evaporator coil.

SHELF ASSEMBLY

Typically, there are 5 shelf assemblies in every

vender; however, this can vary depending upon the

configuration specified at the time of ordering. Each

can/bottle shelf consists of 9 or 7 columns. Each shelf

is capable of holding a variety of packages. The shelf

assembly consists of the tray, where all of the

following parts are mounted: Double Gate assembly

and the slide/pusher assembly. These items are

discussed in detail below.

knuckle assembly and connects to a gear box below

the tray. When a selection is made, the plunger

pushes the lever toward the back of the tray. At the

same time the front knuckle is opened into a flat

position, the rear knuckle is closed to a blocking

position, holding the remaining product out of the gate

area, and the kicker is extended to firmly push the

front displayed product off of the tray. The plunger is

energized for approximately 1-½ seconds to allow

ample time for the displayed product to be ejected

from the shelf. The plunger is then released and the

front knuckle returns to the blocking position, the rear

knuckle and kicker return to their standby position and

the next product slides into the vend display position.

SLIDE/PUSHER ASSEMBLY (Can/Bottle

Trays)

The slide/pusher is located on the bottom of each

product column. Its purpose is to provide a slick,

friction resistant surface for the product to rest on.

The tall product pusher is mounted on the top of the

slide and incorporates a coil spring in the body that

attaches to the bottom of the slide through a slit. This

spring adds needed tension to insure that all products

in the column remain tight against each other and are

allowed to progress into the gate area. Periodic

cleaning and lubrication of the slides is recommended.

DO NOT USE SOLVENTS OR ABRASIVE

MATERIALS TO CLEAN ANY PORTION OF THE

TRAY.

DELIVERY (PICKER) CUP ASSEMBLY

The delivery (picker) cup assembly is located on the

XY vend mechanism. Its purpose is to pick the

product from the column and deliver the product to the

delivery port assembly. The delivery (picker) cup

assembly is mounted on the XY assembly and bolts in

position.

The X axis runs left to right. The X axis assembly is

cabinet mounted to prevent any cabinet torque and

has one belt to synchronize the top and bottom when

the X moves left or right.

The Y axis runs up and down and has the delivery

(picker) cup assembly attached. A top channel is

used to contain and hide the e chain and wiring.

Both X and Y motors have encoders for positioning.

DOUBLE GATE ASSEMBLY (Can/Bottle

Trays)

The double gate assembly is mounted on the front

portion of the tray assembly and contains the vending

mechanism. Incorporated in the gate assembly are

the front and rear knuckle assemblies as well as the

product kicker. In standby operation, the front knuckle

is in the blocking position, which holds the front

displayed product in position to be vended. The rear

knuckle assembly is in a flat position, which allows

product to enter the gate area, and the kicker is flush

to the rear knuckle assembly. A stainless steel pin is

inserted through the rear most portion of the front

REFRIGERATION DECK CLAMP

ASSEMBLY

The refrigeration deck clamp assembly is located on

the rear left side of the cabinet base plate. Its

purpose is to secure the refrigeration assembly tight

against the vertical base plate for refrigerated air flow

in to the cabinet. A 7/16” wrench or socket is needed

to adjust the bolt.

9 of 130

Page 11

BELT TENSION ADJUSTMENT

COMPONENTS

The belt tensioning adjustment components have

been revised to ease adjusting belts when needed.

The X Belt Idler Tensioning Assembly in the upper left

hand corner of cabinet now includes a thumb screw.

Adjustments should only be needed if a belt is

replaced.

The Bottom X Drive Tensioner Assembly in the lower

right hand corner of cabinet has a plastic spring

loaded tensioning wheel to keep the belt against the

pulley when moving and does not require any

adjustments.

The Pill (Sign)

The Pill is what we refer to the polycarbonate front on

the service door. The Pill covers the Surround

Lighting and surrounds the Touchscreen, Integrated

Payment System, and Payment Options. You must

know the payment options you wish to use to have the

correct Pill installed for your order. Pills may be

ordered and replaced in the field as required.

Pill Lighting

• Surround Lighting

The Surround Lighting can be changed in

programming to Red, Blue, White, Green, Purple,

Orange, or Yellow. The Surround and LED Lighting

are controlled by the LED Driver Board. Surround

Lighting is powered by J7 & J8 of the LED Driver

Board.

• LED Integrated Lighting

The LED Lighting lights up the integrated coin and bill

insert and card swipe openings. The Surround and

LED Lighting are controlled by the LED Driver Board.

LED Lighting is powered by J9, J16, & J18 of the LED

Driver Board.

PROGRAMMING

GENERAL INFORMATION

• In order to fully utilize the many features of

your vender it is important that you first

understand the options available and

procedures for programming the vending

controller unit (control board). All

programming, testing, and service functions

are accomplished by using the touch screen

in an easy to follow display prompted format.

In stand-alone operation there are twelve

programming modes for servicing, testing,

and setting up your vender. The Operator

programming modes are accessed by

opening the service door and entering the 4

digit PIN number when prompted for it on the

display. From the factory this PIN number is

set to 3333. Once entered the Touch screen

will show programming option icons that need

to be pressed to access menu modes. There

are several other programming modes that

provide different menu options. They include

Driver Menu, Manufacturing Menu, and

Engineering Menu options. Information for

these modes is covered in the Security Codes

Mode programming section of this manual.

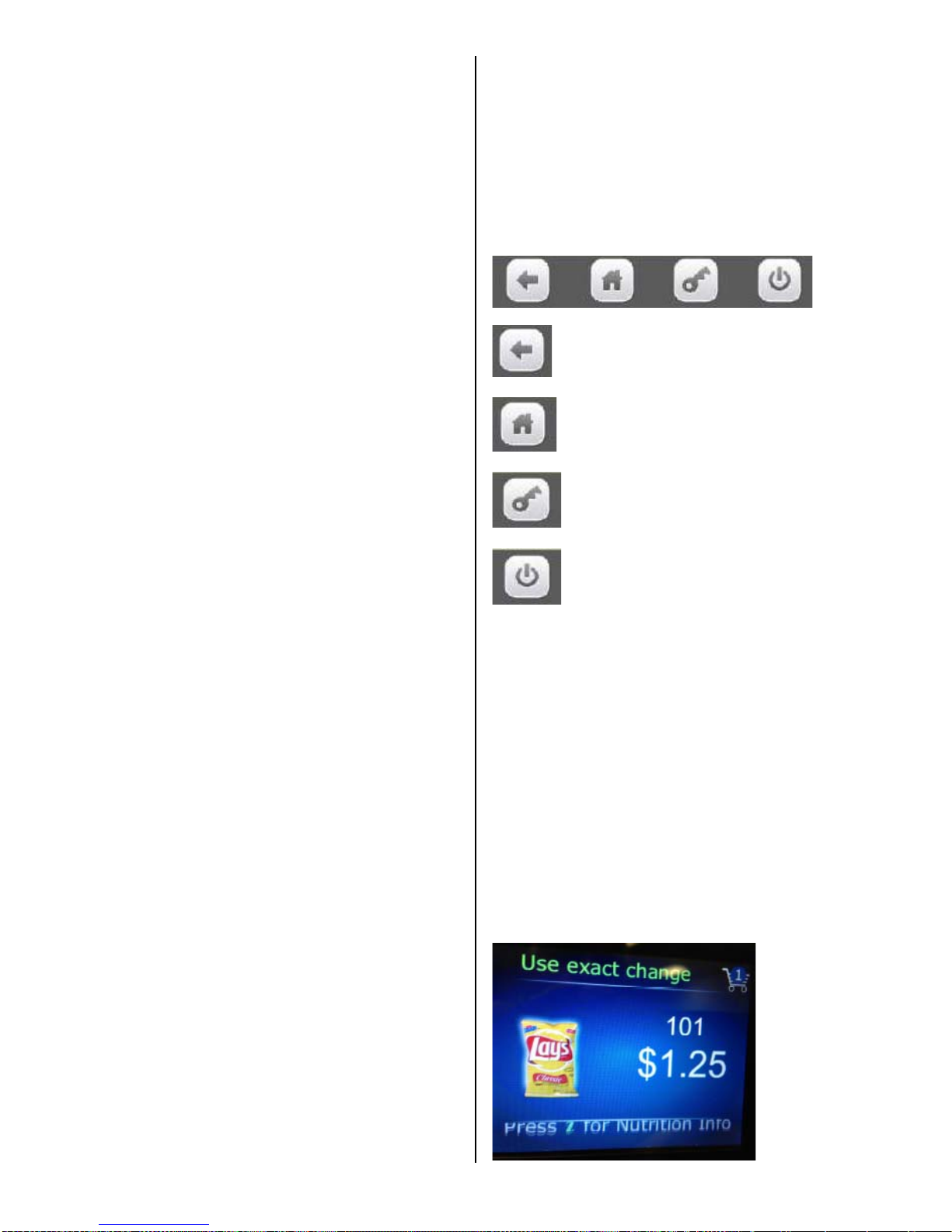

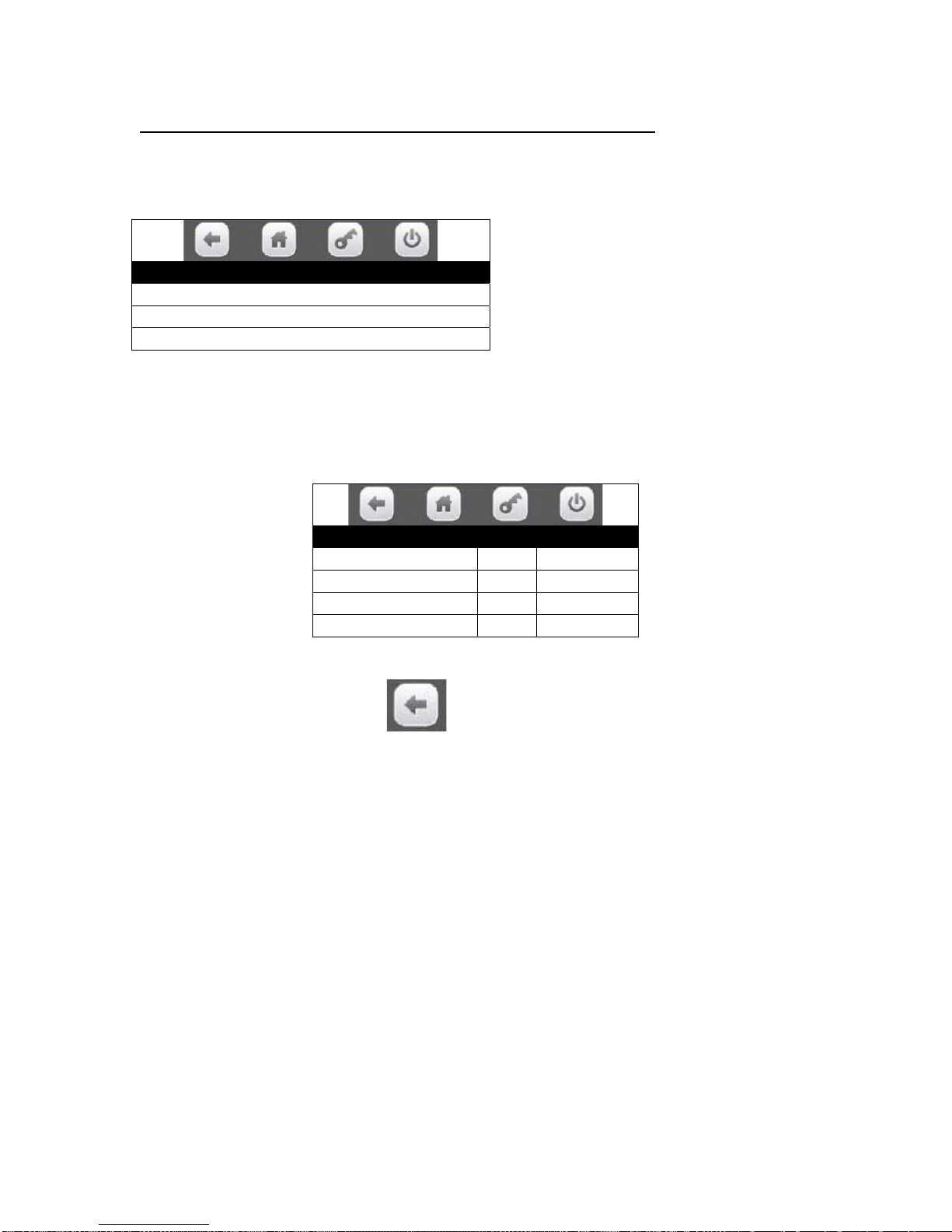

To Move through the Menu:

goes back one step in program.

goes back to the home menu screen.

not used at this time

not used at this time

DISPLAY of PRODUCTS and

NUTRITIONAL INFORMATION

Allows the consumer to view the product, cost, and

nutritional information of the selected product before

making a purchase. Crane Merchandising Systems is

providing the nutritional content information based on

information provided by the product manufacturers,

and Crane Merchandising Systems cannot accept

responsibility for content created by others.

• Press the product selection number. The

display will show a picture of the product

and the price of the product. Sample:

10 of 130

Page 12

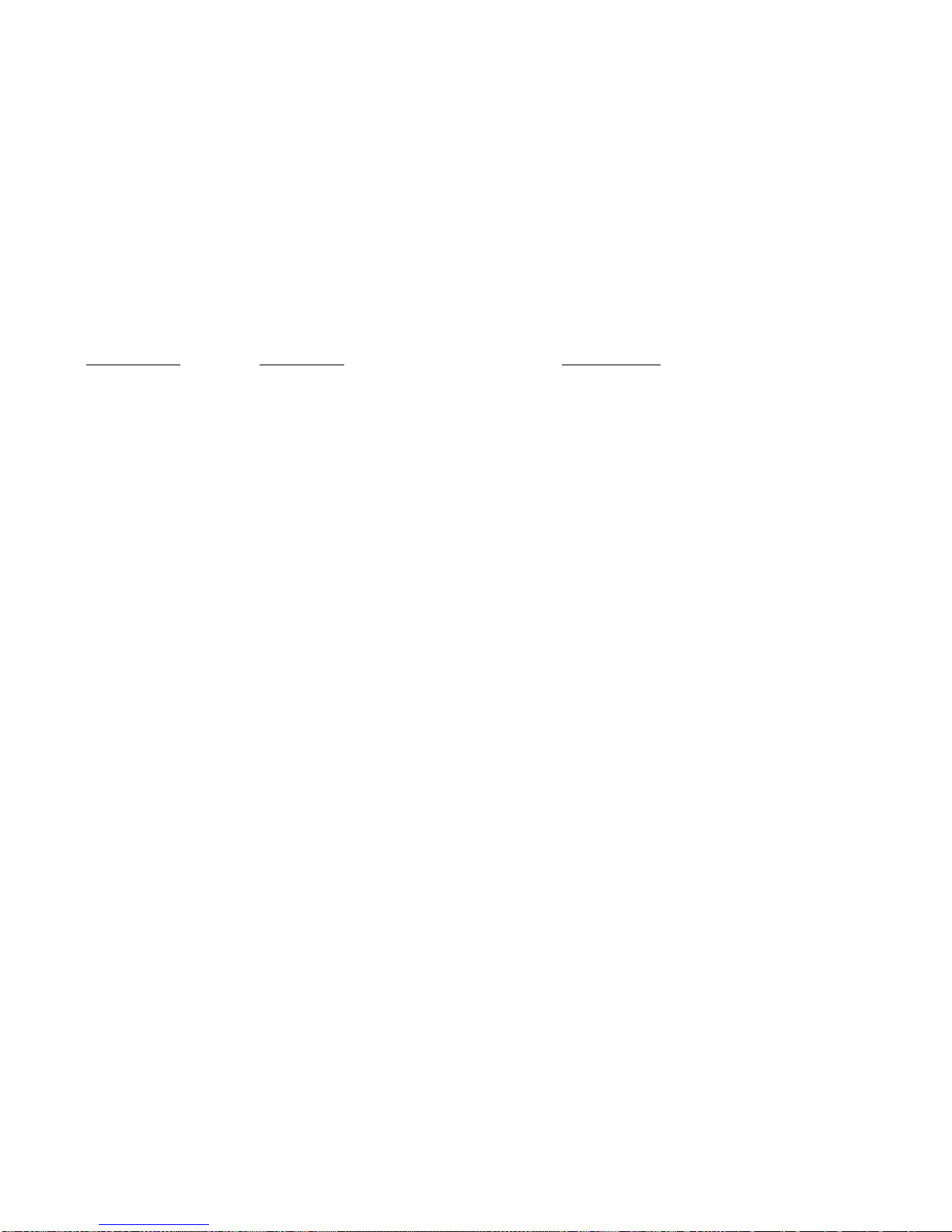

• Press the icon as instructed to view the

nutritional information of the product. Sample:

Nutritional Information

Serving Size

Calories 240

% Daily Value

Total Fat 16g

25%

Sodium 250mg

11%

Total Carbohydrates 23g

8%

Sugar 1g

Protein 3g

Not a significant source of

Other nutrients

NORMAL OPERATION MESSAGES

At initial power-up, the program will start just like your

home computer and the Touch screen will display

Crane, followed by a running list of all activities being

checked during power up. The lights on vender will

cycle on and off, validator if installed will cycle, coin

return plunger motor will cycle, and then:

• If Errors exist, an error list will be displayed that

includes the time and date of the error. To exit or

escape to the home screen press the back arrow icon

on Touch Venders.

• If No errors exist, the home screen will appear with

programming menus.

INITIAL PROGRAMMING

TO VIEW DATA RECALL

To view a listing of the Data recorded for nonresettable sales data, resettable sales data, events,

and identification numbers enter the “DATA RECALL”

mode by opening the service door, entering the PIN

number, and pressing Data Recall icon on screen.

Use the top arrow and bottom arrow on the right side

of the screen to scroll through the multiple screens if

needed. Refer to the “Data Recall” programming

section for descriptions of available Data that is

recorded to be displayed.

TO VIEW ERRORS REGISTERED

To view a listing of errors along with the date and time

they occurred enter the “Diagnostics” mode by

opening the service door, entering the PIN number,

and pressing the Diagnostics icon. Use the top arrow

and bottom arrow on the right side of the screen to

scroll through the multiple screens if numerous errors

have been recorded. Refer to the “Diagnostics”

programming section for error descriptions, probable

causes, and possible solutions for many of the errors

that may display.

TO TEST VENDER OPERATIONS

To test the different operations of the vender enter the

“Test” mode by opening the service door, entering the

PIN number, and pressing the Test icon. Follow the

menu prompts or refer to the “Test” programming

section in this manual for step by step instructions to

perform tests for vending, coin return motor, surround

lighting, screen, refrigeration, MagTech Head,

cashless system, monetary, port & cup sensors,

platform movement, and lighting.

TO SET PRICES

To set the prices enter the “Price” mode by opening

the service door, entering the PIN number, and

pressing the Price icon. Follow the menu prompts or

refer to the “Price” programming section in this

manual for step by step instructions. This menu

allows you to set regular prices for an individual item,

a complete tray, or the entire machine. For other

pricing options you need to refer to the following

programming sections: “Special Vend Modes” or

“Timed Events”.

TO SET DATE/TIME

To set the date and time enter the “System Settings”

mode by opening the service door, entering the PIN

number, and pressing the System Settings icon.

Follow the menu prompts or refer to the “Time & Date”

programming section in this manual for step by step

instructions.

TO SET NEW PIN

To set a new PIN enter the “Security Codes” mode by

opening the service door, entering the PIN number,

and pressing the Security Code icon. Follow the

menu prompts or refer to the “Security Codes”

programming section in this manual for step by step

instructions.

TO SET STS

To set Space to Sales open the service door, enter

the PIN number, and press the Product Configuration

icon, then press the FIFO Setup icon or refer to the

FIFO Setup programming section in this manual for

step by step instructions.

For all other options please refer to the programming

quick reference chart on the following pages and the

related programming section in this manual for step by

step instructions.

11 of 130

Page 13

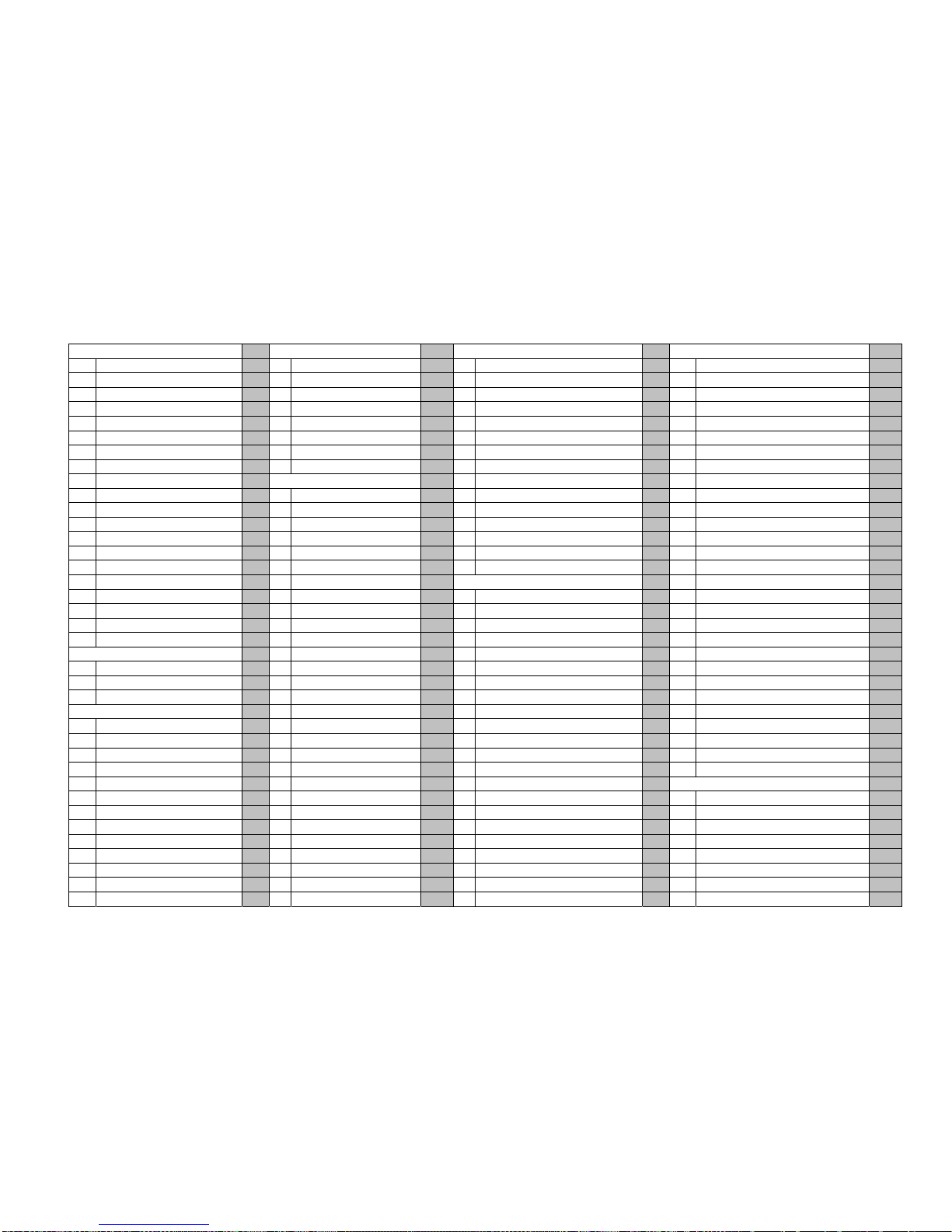

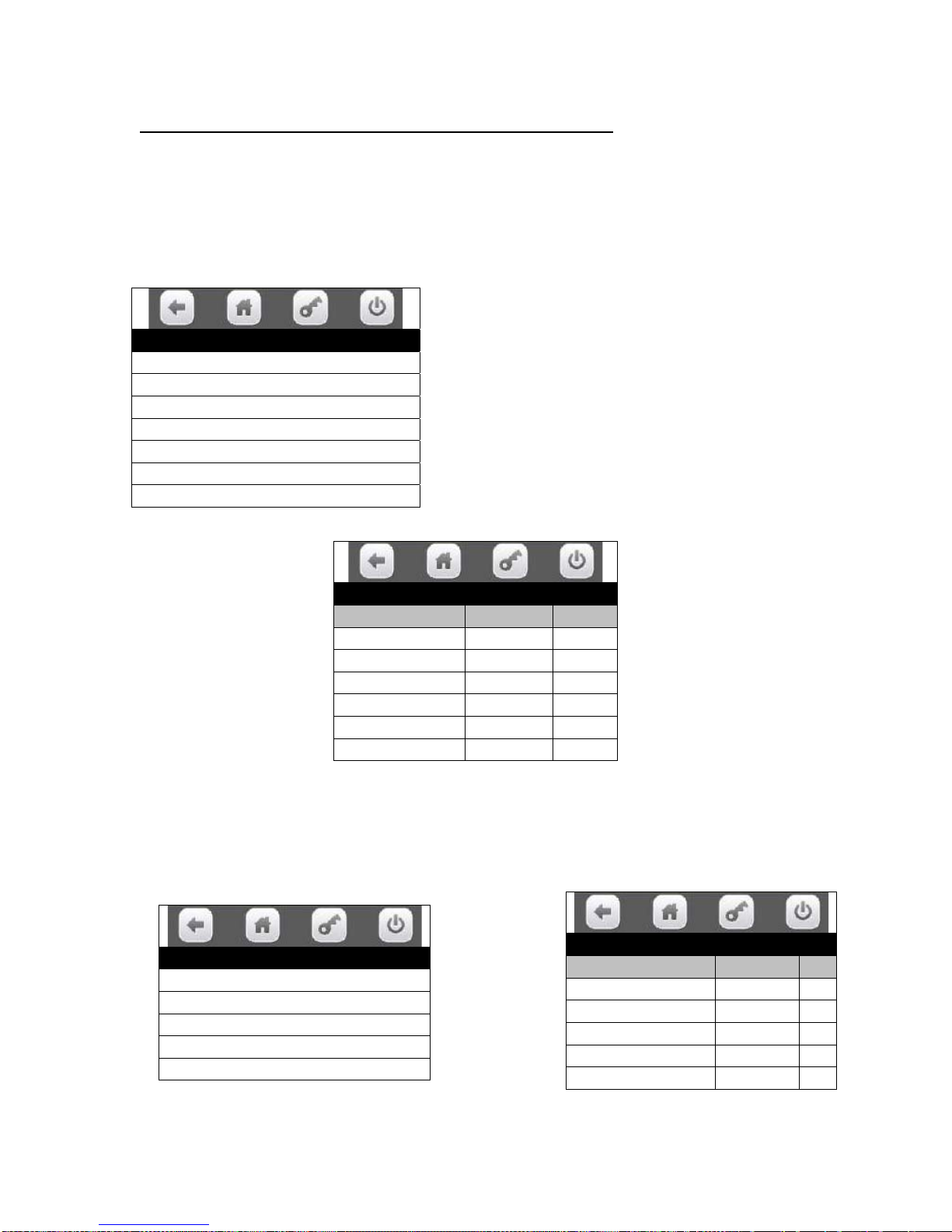

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 KEYPAD

Page 12 of 128

Data Recall Pg Price Pg Special Vend Modes Pg System Settings Pg

1 Non-Resettable Sales Data 14 1 By Tray 1 37 1 Free vend 45 1 Machine Information 59

1. Overall Totals 14 2 By Tray 2 37 2 Winner Mode 45 2 Time & Date 60

2. by Tray 15 3 By Tray 3 37 1. Add Group 45 3 Language 62

3. by Product 15 4 By Tray 4 37 2. Delete Group 47 4 DTS (Data Transfer System) 63

4. Cash 16 5 By Tray 5 37 3. Edit Group 47 1. DTS Standby mode 63

5. Cashless 16 6 By Entire Machine 37 4. Winner Selections Mappings 48 2. DTS Audit List 63

6. Bill Data 16 7 By Individual Selection 38 3 Combo Vends 48 3. CA304/CA308 Data Type 64

2 Resettable Sales Data 17 1. Discount Type 48 4. OnBoard Cashless Data 64

1. Overall Totals 17

Product Configuration

2. Add New Combo 48 5. Data Reset on Transfer 64

2. by Tray 17 1 Selection Configuration 39 3. Delete Promotion 50 6. Event Data Reset on Transfer 64

3. by Product 18 1. Tray 1 39 4. Edit Promotion 51 7. Pass-Code Reset 64

4. Cash 18 2. Tray 2 39 5. Combo Vend Selection 52 8. DTS Cache Settings 65

5. Cashless 19 3. Tray 3 39 4 Token Enable 53 5 Software Updates 65

6. Bill Data 19 4. Tray 4 39 5 Rapid vend 53 6 Backup/Restore 66

7. Clear Data 19 5. Tray 5 39 6 Multivend Discount 54 7 Clone (copy) Configurations 67

3 Events 20 2 FIFO Set-Up 39

Monetary

1. Prepare Flash Drive 67

1. Power Losses 20 1. Add Group Menu 39 1 Coins In/Out 55 2. Create Config Clone 67

2. Door Events History 20 2. Delete Group 40 1. Stop Dispensing 55 3. Install Config Clone 67

4 Identification Numbers 21 3. Edit FIFO Group 41 2. 0.05 55 4. Remove Clone from Stick 67

Mech, Validator, Cashless 21 4. FIFO Mappings 42 3. 0.10 55 8 Clone (copy) Board 68

Diagnostics

3 UPC/EAN Codes 42 4. 0.25 55 9 Screen Brightness 68

1 Screen Data 21 4 Shopping Cart Set-Up 43 5. Set Up Channels 55 10 LED Color 68

2 Diagnostics Errors 22 1. Shopping Cart Size 43 2 Bill Validator 56 11 Idle Time Out 69

2. Max. Fund Amount 44 3 Coin Mechanism 56 12 Advertisements 69

Test

5 View Plan-O-Gram 44 4 Card Reader A 56 13 Custom Messages 70

1 Test Vend 33 1. Tray 1 44 5 Card Reader B 56 14 Automatic Reboot Settings 70

2 Coin Return Motor 33 2. Tray 2 44 6 On Board Cashless Enable 57 15 SKip Main Menu 70

3 Surround Lighting Test 34 3. Tray 3 44 7 Correct Change Parms 57

4 Screen Test 34 4. Tray 4 44 1. Declining Balance 57

5 Refrigeration System 34 5. Tray 5 44 2. Force Vend 57

Security Codes

6 MagTeck Head Test 35 3. Accept on low change 57 1 Enter PIN 71

7 Cashless system test 35 4. Low change message 58 1. Details for Driver PIN 71

8 Monetary 35 5. Credit for failed vend 58 2. Details for Operator PIN 71

9 Port & Cup Sensors 36 6. Allow consumer over pay 58 3. Details for Engineers PIN 73

10 Platform Movement 36 8 Stack Bills 58 4. Details for Manufacturers PIN 74

11 Turn Lighting Off 37 1. Wait 58 2 Change Driver PIN 71

2. Stack Immediately 58 3 Change Operator PIN 71

9 Cash Discount 58

Page 14

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 KEYPAD

Page 13 of 128

Timed Events

1 Time of Day Events 77

1. Price Adjust 77

2. Free Vend 79

3. Inhibit 81

2 Backup Events 82

3 Power Savings Events 83

Telemetry

1 Assign Unit 84

2 Ping Server 86

3 Get Network Status 86

4 Show Network Config 87

5 Load Network Config 87

6 Radio Setup 87

7 How Telemetry Works 90

8 Definitions 91

Machine Configuration

1 Refrigeration Settings 93

2 Space to Sales 94

3 Picker Cup Sensor 95

4 Port Sensor 95

5 Manual Key Switch 95

6 Firmware Information 96

Cabinet Offsets 96

EVS Compliance 96

Shelf Location 97

Model # 97

Encoder Resolution # 97

Page 15

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

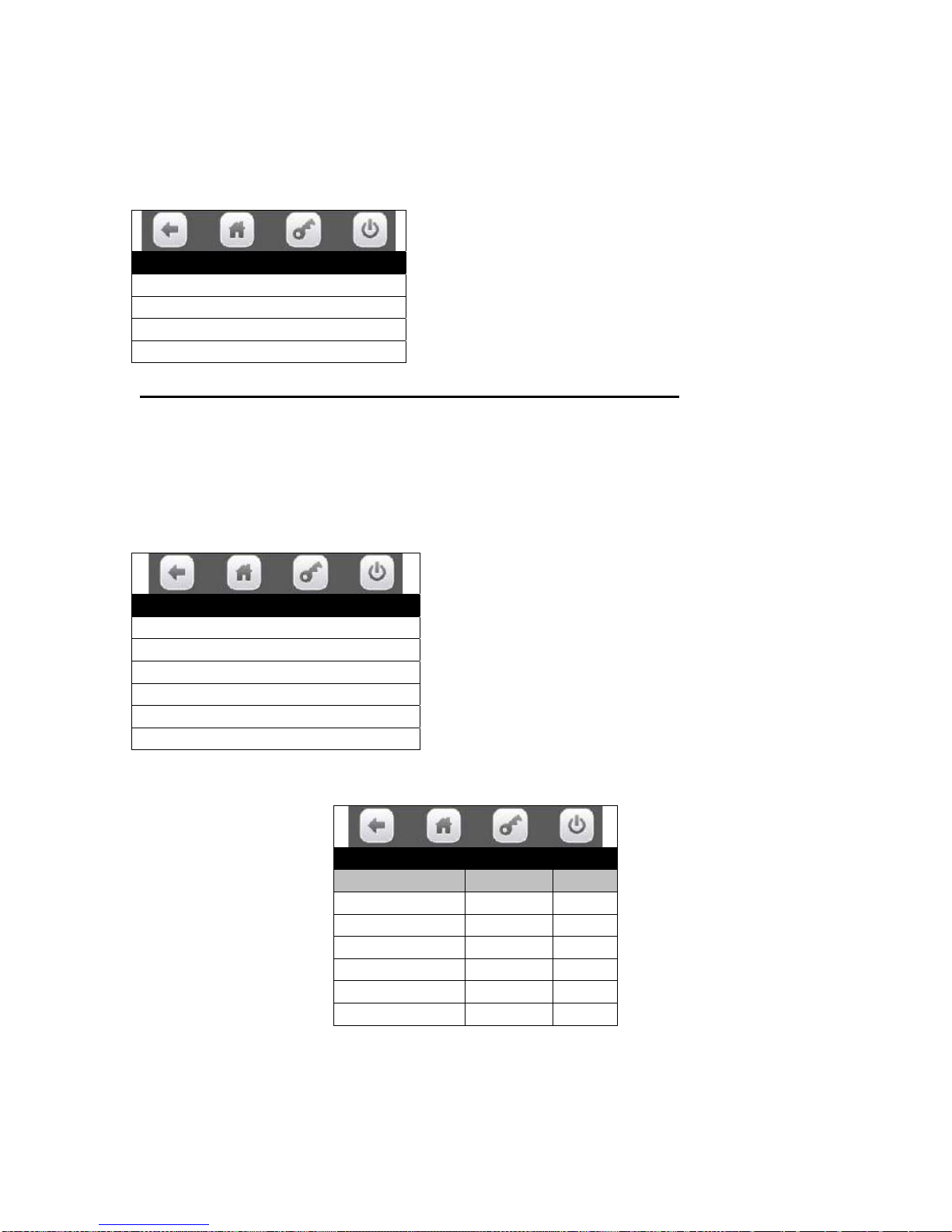

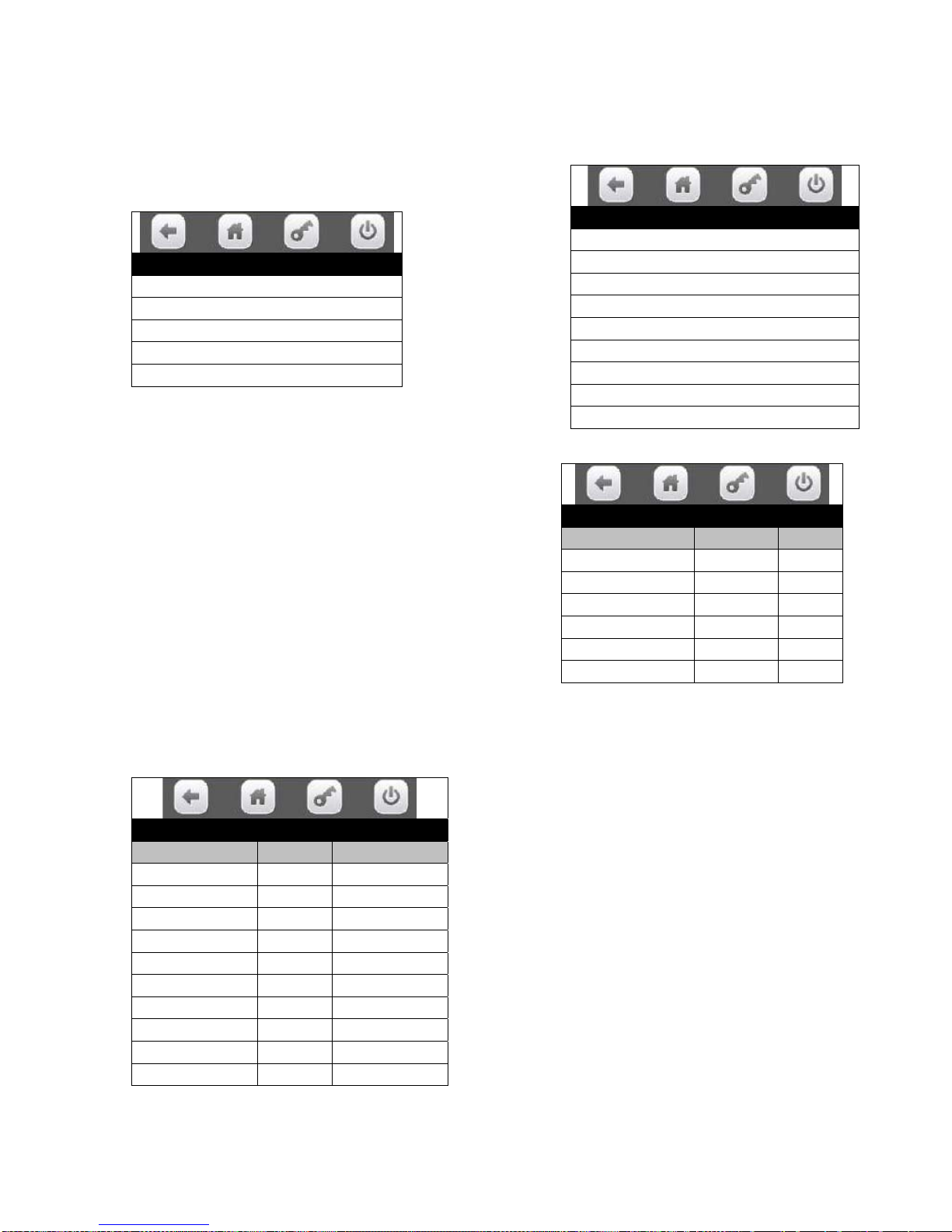

1. DATA RECALL……………………………Press icon to bring up a list.

Press the Data Recall icon brings up a list of the groups in this function.

Data Recall

Non Resettable Sales Data >

Resettable Sales Data >

Events >

Identification Numbers >

1. Non-Resettable Sales Data – Press the icon to bring up a screen

Press the Non Resettable icon will bring up a screen listing the sub-groups that contain

the data in this group.

TECH TIP – The listings in this group are a running total and will not be reset when a

DEX read is done or the “DATA CLEAR” function is used.

Non Resettable Sales Data

Over-All Totals >

By Tray >

By Product >

Cash >

Cashless >

Bill Data >

1. Overall Totals – Press the icon to bring up a table listing data.

Press the screen to choose a group.

Choosing a group will bring up the first screen in

the chosen group.

Press an icon to choose a Sub-Group.

Choosing a Sub-Group will bring up the first

screen in that Sub-Group.

Overall Totals

#

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Test Vend $0.00 0

Free Vend $0.00 0

Token Vend $0.00 0

Page 14 of 128

Page 16

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

2. By Tray – Press the icon to bring up a screen listing all trays.

Press icon to select a tray and you will bring up a screen with a table listing data as

shown.

By Tray

Tray #1 >

Tray #2 >

Tray #3 >

Tray #4 >

Tray #5 >

Tray 1 Data

#

Sales $0.00 0

Discounts $0.00 0

Surcharges $0.00 0

Test Vend $0.00 0

Free Vend $0.00 0

3. By Product – Press the icon to bring up a screen listing all trays

Press an icon to select a tray and you will bring up a screen listing the product selections

on that tray.

By Product

Tray #1 >

Tray #2 >

Tray #3 >

Tray #4 >

Tray #5 >

Tray #1

101 101>

102 102>

103 103>

104 104>

105 105>

106 106>

107 107>

108 108>

109 109>

Press an icon to select an individual product selection and you will bring up a table listing

dollar values and number of vends for that product. This table includes a line to include

the Price of the product set in the selection. The date and time of the last vend of the

selected product is displayed below the table.

101

#

Price $0.00

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Test Vend $0.00 0

Free Vend $0.00 0

Last Vend Date / Time

Page 15 of 128

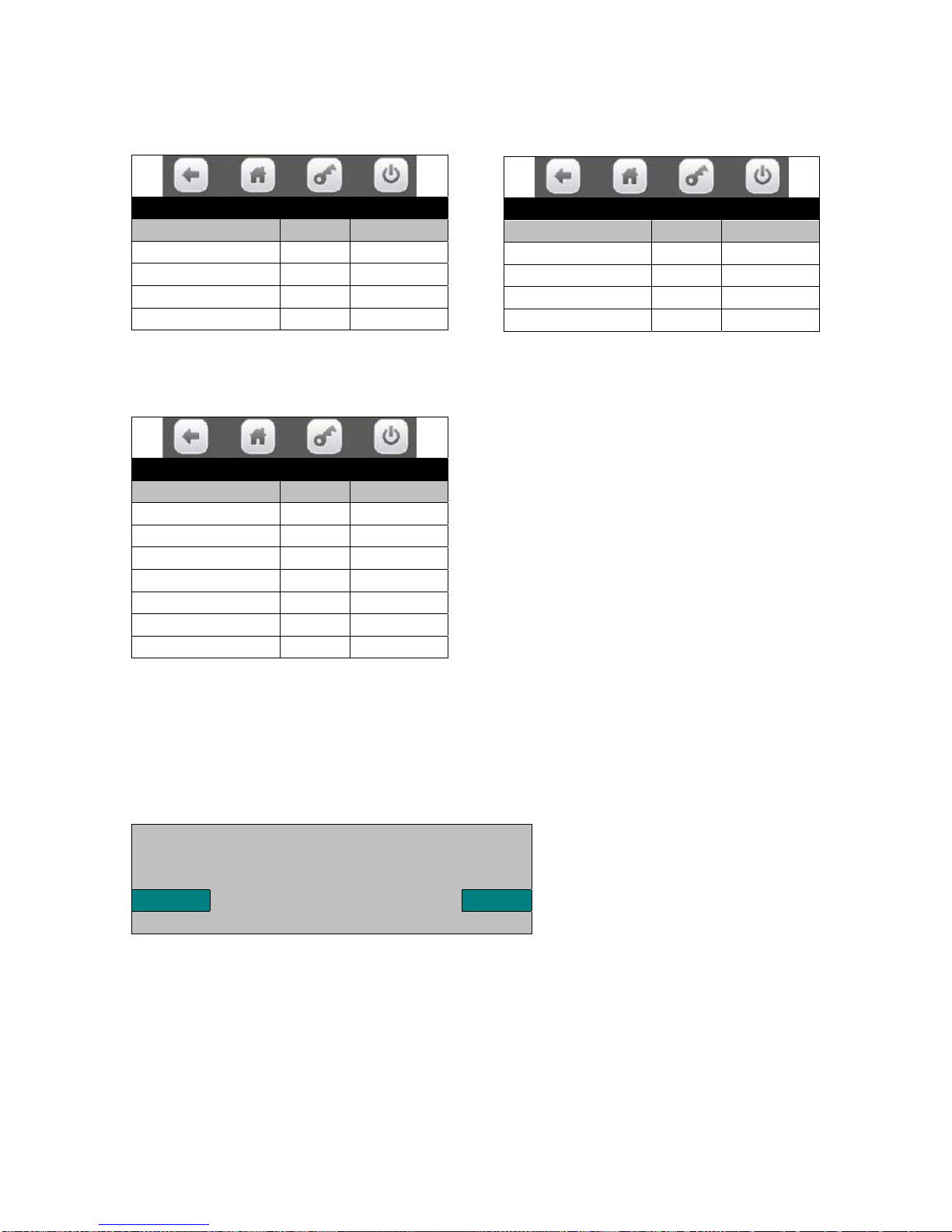

Page 17

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

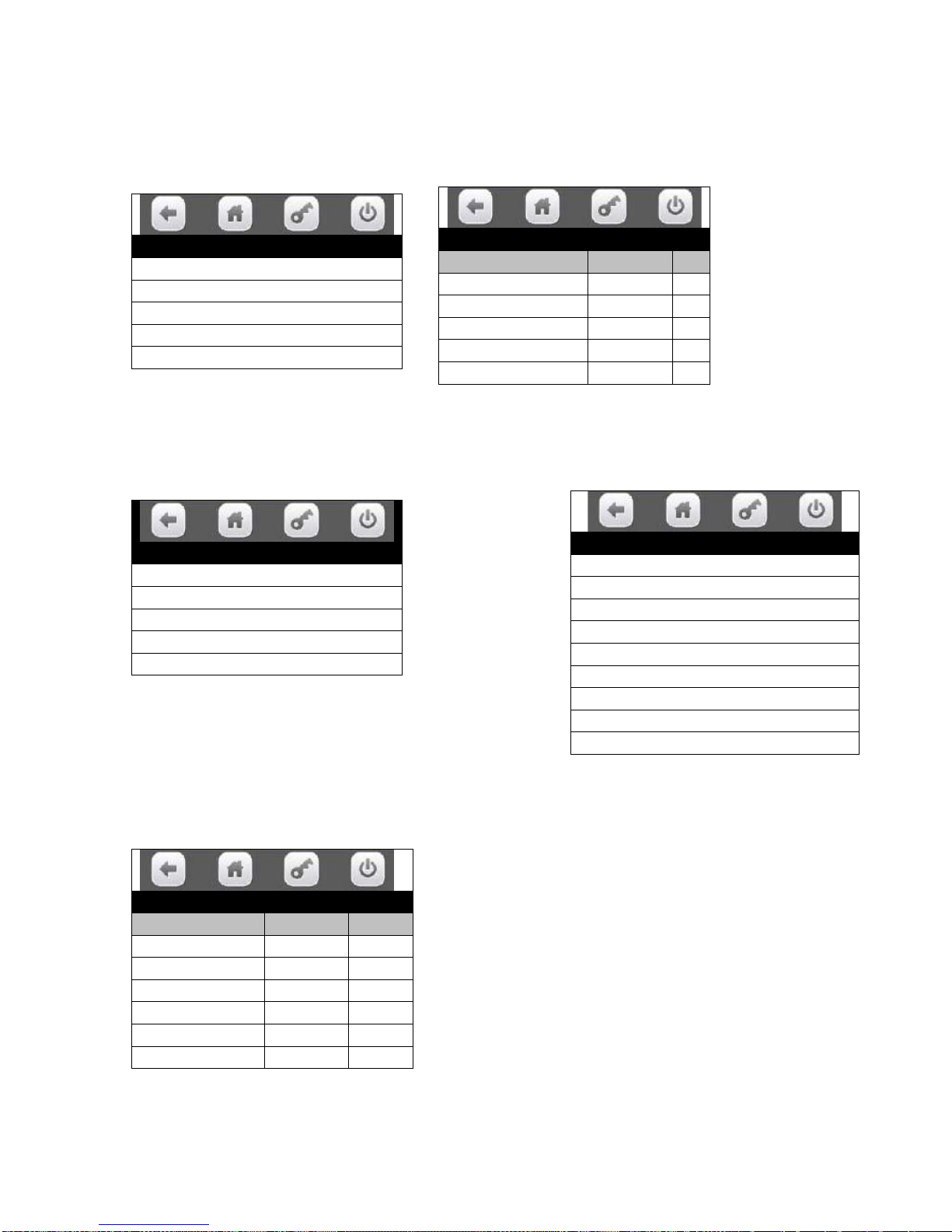

4. Cash – Press the icon to bring up a table listing Cash Data.

.

Cash

#

Cash In $0.00 ______

To Cash Box $0.00 ______

To Tubes $0.00 ______

Bills In $0.00 ______

Dispensed $0.00 ______

Manual Dispensed $0.00 ______

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Over Pay $0.00 0

5. Cashless – Press the icon to bring up a table listing Cashless Data.

Cashless A #

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Revalue $0.00 0

Cashless #

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Revalue $0.00 0

6. Bill Data – Press the icon to bring up a table listing Bill Data.

The contents of the recycler unit have been listed below the table.

Bill Data

In Out

One $0.00 $0.00

Two $0.00

Five $0.00 $0.00

Ten $0.00

Twenty $0.00

Fifty $0.00

Hundred $0.00

Recycler Contents $0.00

Page 16 of 128

Page 18

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

2. Resettable Sales Data – Press the icon to bring up a list

Press the icon will bring up a screen listing the sub-groups that contain the data in this

group.

TECH TIP – The listings in the resettable group are identical to the listings in the nonresettable group with the exception of the “CLEAR DATA” function which allows the

totals to be set back to Zero.

Resettable Sales Data

Overall Totals >

By Tray >

By Product >

Cash >

Cashless >

Bill Data >

Clear Data >

1. Overall Totals – Press the icon to bring up a table listing data.

Press the icon to choose a Sub-Group.

Choosing a Sub-Group will bring up the first

screen in the chosen Sub-Group.

Overall Totals

#

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Test Vend $0.00 0

Free Vend $0.00 0

Token Vend $0.00 0

2. By Tray – Press the icon to bring up a screen listing all trays.

Press a numeric Key to select a tray and you will bring up a screen with a table listing

data as shown.

By Tray

1) Tray #1 >

2) Tray #2 >

3) Tray #3 >

4) Tray #4 >

5) Tray #5 >

Tray 1 Data

#

Sales $0.00 0

Discounts $0.00 0

Surcharges $0.00 0

Test Vend $0.00 0

Free Vend $0.00 0

Page 17 of 128

Page 19

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

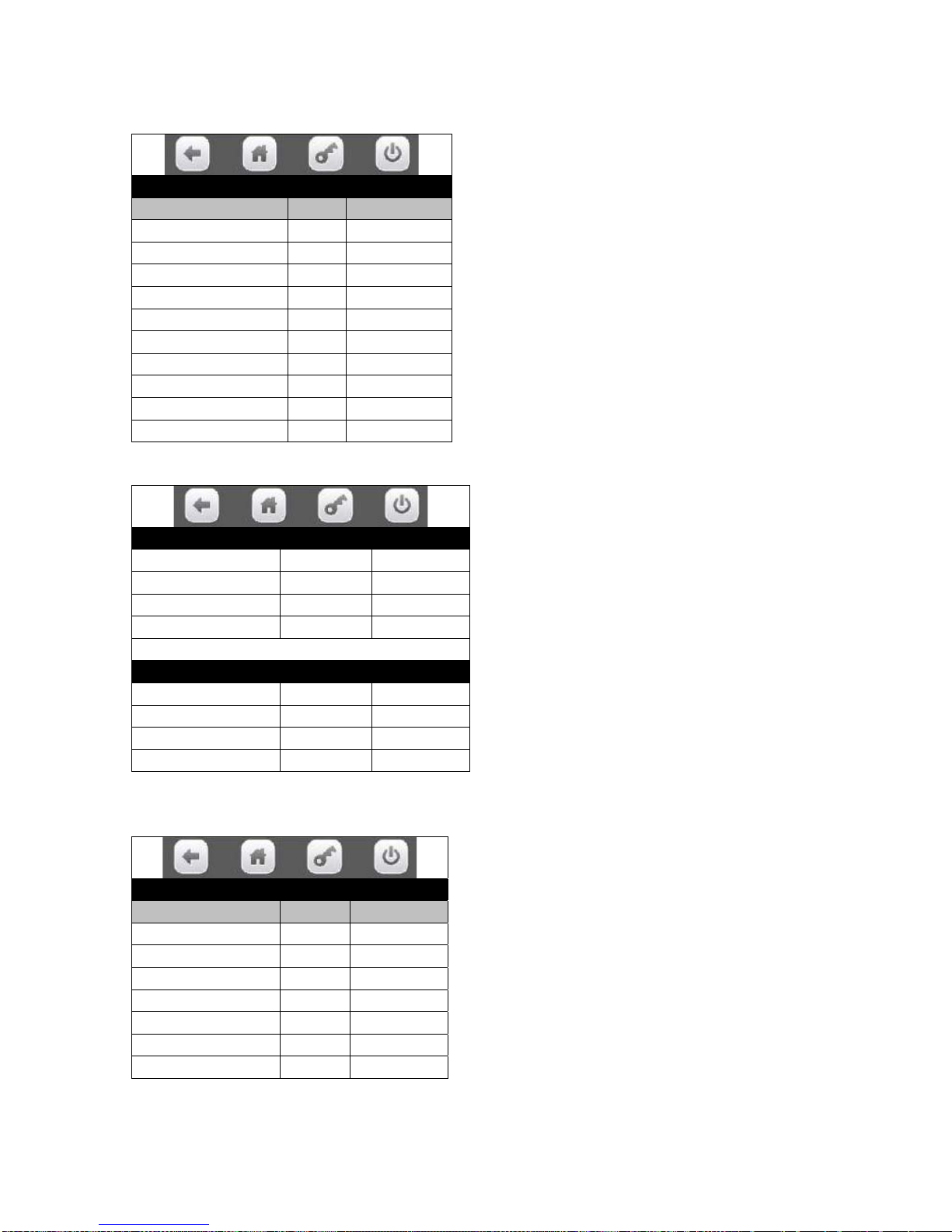

3. By Product – Press the icon to bring up a screen listing all trays

Press an icon to select a tray and you will bring up a screen listing the product selections

on that tray.

By Product

Tray #1 >

Tray #2 >

Tray #3 >

Tray #4 >

Tray #5 >

Press an icon to select an individual product selection and you will bring up a table listing

dollar values and number of vends for that product.

This table includes a line to include the Price of the

product set in the selection. The date and time of the

last vend of the selected product is displayed below

the table.

4. Cash – Press the icon to bring up a table listing Cash Data.

Cash

#

Cash In $0.00 ______

To Cash Box $0.00 ______

To Tubes $0.00 ______

Bills In $0.00 ______

Dispensed $0.00 ______

Manual $0.00 ______

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Over Pay $0.00 0

Tray #1

101 101>

102 102>

103 103>

104 104>

105 105>

106 106>

107 107>

108 108>

109 109>

101

#

Price $0.00

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Test Vend $0.00 0

Free Vend $0.00 0

Last Vend Date / Time

Page 18 of 128

Page 20

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

5. Cashless – Press the icon to bring up a table listing Cashless Data.

Cashless A

#

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Revalue $0.00 0

Cashless B

#

Sales $0.00 0

Discounts $0.00 0

Surcharge $0.00 0

Revalue $0.00 0

6. Bill Data – Press the icon to bring up a table listing Bill Data.

The contents of the recycler unit have been listed below the table.

Bill Data

In Out

One $0.00 $0.00

Two $0.00

Five $0.00 $0.00

Ten $0.00

Twenty $0.00

Fifty $0.00

Hundred $0.00

Recycler Contents $0.00

7. Clear Data – Press the icon to clear resettable data.

Press the icon will bring up a screen asking you if you are sure you want to clear the

resettable data. Respond by pressing the Yes or No icon.

Do you really want to clear all

Resettable data?

Yes No

This is also the data that is cleared each time the machine successfully transmits a

DEX file.

Page 19 of 128

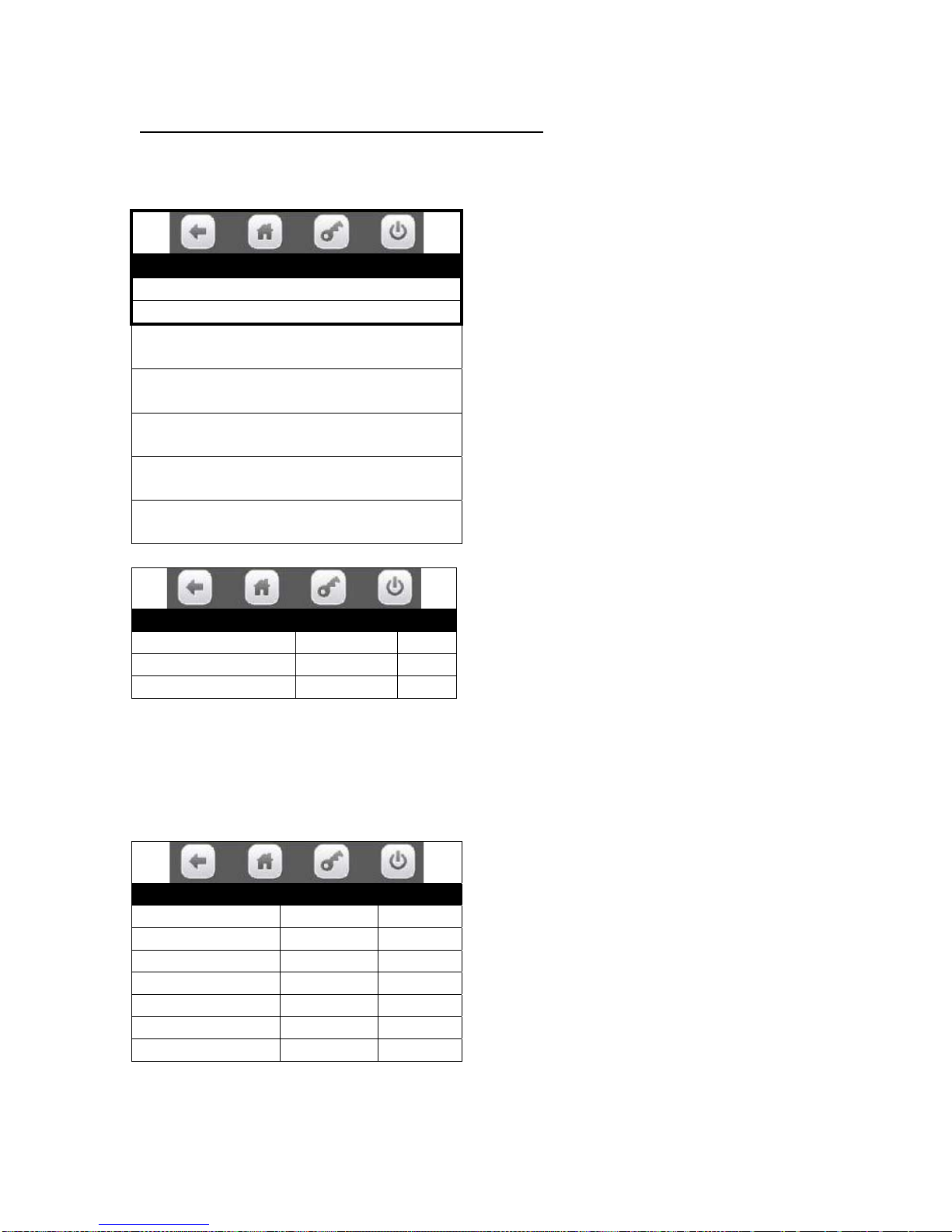

Page 21

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

3. EVENTS – Press the icon to bring up a screen

Press the icon will bring up a screen which is divided into two sections.

The top section of the screen allows you to view recorded data for each type of event.

Events

Power Losses >

Door Events History >

Last Data Clear

Date/Time

Last Vend

Date/Time-Selection

Last Price Change

Date/Time

Last Clock Set

Date/Time

Last Health Control Event

Date/Time-Selection

Power Losses

Duration Date Time

1 hours 09 minutes 04/24/2013 08:26

0 hours 12 minutes 04/12/2013 17:30

The data is recorded in order of occurrence and can be a valuable diagnostic tool to

determine if a power outage is the cause of a reported problem.

2. Door Events History – Press the icon will bring up a screen listing data about recorded

door events.

Door Events History

Event date time

Open Door ##/##/## 00:00:00

Closed Door ##/##/## 00:00:00

Open Door ##/##/## 00:00:00

Closed Door ##/##/## 00:00:00

Open Door ##/##/## 00:00:00

Closed Door ##/##/## 00:00:00

Press the icon to bring up a list for each type

of event.

The Last Data Clear data would include

both a manual clear and a successful DEX

read.

1. Power losses – Press the icon to bring

up a listing of data about recorded power

losses or a message of “No Power Losses”

registered

The data is recorded in order of occurrence

and can be a valuable tool used to determine

if the door has been opened and closed at a

time when it should not have been.

Page 20 of 128

Page 22

BEVMAX MEDIA – PROGRAMMING MAP

SOFTWARE VERSION 10.7.2 Touch

4. Identification Numbers – Press the icon to bring up a screen.

Press the icon will bring up a screen listing the ID numbers for the devices listed or a

message “not connected’.

Identification Numbers

Bill Validator #############

Card Reader #############

Coin Mechanism ############

2. DIAGNOSTICS……………..Press the icon to bring up a screen.

Press the icon will bring up a screen listing the errors along with the time and date they

occurred or a message of “No Errors Registered” will display.

Diagnostics

time date

Coin Tube 1 Empty 14:35 04/12/2013

Cabinet not cooling 09:45 03/25/2013

Coin Tube 2 Empty 17:00 02/28/2013

This screen will automatically come up when the service mode is entered if errors

currently exist. You may use the icon to back up to a previous menu in the

service screens.

List of many of the Errors/causes/solutions follow:

Page 21 of 128

Page 23

Page 22 of 128

Error Description Probable Cause Possible Solutions

Stuck Keys Fatal. Stuck keys on keypad or shorted connections/harness. Check connectors to be properly installed.

Check harness for damage.

Replace the keypad.

No Monetary Device Fatal. The control board has not been able to detect a Check connectors to be properly installed.

working monetary device. Check harness for damage.

Check for faulty bill validator/harnessing.

Retest without the bill validator and harnessing

installed.

Replace the coin mechanism.

Coin Mech No Comms. No Communications are occurring between the Check connectors to be properly installed

coin mechanism and the control board. Check harness for damage

Retest without the bill validator and harnessing

installed.

Replace the coin mechanism.

Coin Mech ROM Error Coin Mech ROM Error Replace the coin mechanism.

Coin Mech Acceptor Coin Mech Acceptor Unplugged. Check the connections within the coin mechanism

Unplugged. Replace the coin acceptor.

Replace the coin Mechanism.

Coin Mech Acceptor Coins or other items are stuck in the acceptor Remove the coins or other items from the acceptor.

Jammed. causing the gate to remain open. Replace the acceptor.

Replace the coin mechanism.

Coin Mech Payout Jammed. Coin pay out motor or solenoid is stuck in cycle. Check for and remove bent coins or other items

causing the jam.

Replace the coin mechanism.

Coin Mech Sensor Error. Bad coin mechanism sensor. Check for an item causing a blockage and remove.

Replace the coin mechanism.

Coin Mech All Tubes Error. Coin mechanism not sensing any pay out tubes. Check for proper pay out cassette placement.

Replace the payout cassette.

Replace the coin mechanism.

Page 24

Page 23 of 128

ErrorDescription ProbableCausePossibleSolutions

Coin Mech Tube Error. Coin mechanism not sensing a payout tube. Check for proper pay out cassette placement.

Replace the payout cassette.

Replace the coin mechanism.

Coin Mech Disabled. Coin mechanism has been disabled by the board Power down the machine and re-start.

Remove bill validator and/or card reader from system.

Replace the coin mechanism.

Reset the control board.

Replace the control board.

Exec Price Error. Executive coin mechanism error. Check for a price set outside of allowed parameters.

Replace executive coin mechanism.

No Monetary Device. No monetary device detected by the board. Check connectors to be properly installed.

Check harness for damage.

Retest without the bill validator and harnessing

installed.

Replace the coin mechanism.

Coin Return Motor Not Control board not sensing the presence Check the connection J6 on the I/O board to the

Present. of a coin return motor. coin return motor.

Home the coin return motor.

Replace the coin return motor.

Check for damage to harnessing.

Reset or replace the control board.

Coin Return motor Run The board has determined that the coin Check the connections to the coin return motor.

Time Timeout. return motor should have arrived at home Home the coin return motor.

position, but it has not. Replace the coin return motor.

Check for damage to harnessing.

Reset or replace the control board.

Coin Return Motor Short Coin return motor has shorted out. Check connections and harnessing for damage.

Circuit. Replace the coin return motor.

Coin Return Motor Drive The coin return motor is not engaging the Check for damaged or missing drive linkage.

Failure. coin return arm on the coin mechanism. Check for proper mounting of coin mechanism.

Check for damage on coin mechanism pay out parts.

Page 25

Page 24 of 128

ErrorDescription ProbableCausePossibleSolutions

Low Change. The coin mechanism has reported a low or Add coins to the tubes using the coins in/out screen in

empty condition in one or more of the coin the monetary section of the service modes.

pay out tubes. Do vends with coins to add coins to the tubes.

Replace coin mechanism.

No IO Comm. The control board is not communicating with Check for proper connections on the I/O board.

the I/O board. Check for proper connections on the control board.

Check for damage to the harnessing.

Remove the monetary devices from the system and

check for restored communication.

Replace the I/O board.

Reset and/or replace the control board.

Please Wait. The board is asking you to wait while it completes Wait for the board to finish the operation.

an ongoing operation. Re-start the machine and let it re-boot.

Remove monetary devices and re-start the machine.

Reset and/or replace the control board.

No Selections Available. The control board is not sensing any motors Check for motors to be homed.

available for use. Check for motors and harnesses to be connected.

Check for power to I/O board.

Replace I/O board.

Reset and/or replace control board.

All Selections Disabled. The control board has disabled all the motors in Check SureVend settings and operation.

the machine. Check motors to be homed and connected properly.

Check for a timed event to be enabled causing the

Condition.

Check/replace I/O board.

Reset/replace control board.

IO Board Voltage. The control board has detected improper voltage Check voltage to the machine.

for I/O board operation. Check voltage to the I/O board.

Replace the I/O board.

Init Failed. The control board has failed to initialize successfully. Power down and re-start the machine.

Power down, disconnect monetary devices and

re-start the machine.

Replace the control board.

Page 26

Page 25 of 128

ErrorDescription ProbableCausePossibleSolutions

Health Control Active. The control board has detected a temperature Check for clean screens and condenser.

condition which is outside the allowed parameters Check for acceptable clearance behind the machine.

and has stopped allowing sales of involved products. Check temperature sensor for accurate readings.

Check refrigeration system for proper function.

Anti Jackpot Error. The control board has detected multiple attempts to Check SureVend calibration.

vend a product from a selection and has not seen a Check SureVend function.

successful delivery. Check motor function.

# XXX Sold Out. The control board has determined that a selection is Check to see that there is product.

sold out. (XXX indicates the selection number Check SureVend calibration.

involved). Check SureVend function.

Check motor function.

Factory Init. An attempt to restore factory default settings has Power down, power up, try again.

been unsuccessful. Power down, remove monetary devices and try again.

Replace the control board and reset.

Card Reader No Comms. The control board is not able to communicate with Check connections for the card reader.

the card reader. Check for damage to the harness (cut, pinched, etc.).

Replace the card reader.

Reset the control board.

Replace the control board.

Card Reader Comms Error. The control board is not communicating with the Check the connections and harness for damage.

Card reader. Check the settings on the board and on the reader.

Replace the reader.

Reset and/or replace the board.

Bill Validator No Comms. The control board is not communicating with the Check the connections and settings for the validator.

bill validator. Replace the harness.

Replace the validator.

Bill Validator Motor Error. The validator has reported an error to a drive motor Check for a broken belt or blockage.

within the validator. Replace the bill validator.

Bill Validator Sensor Error. The validator has reported an error to a sensor within Check for a sensor blockage.

the validator. Replace the bill validator.

Page 27

Page 26 of 128

ErrorDescription ProbableCausePossibleSolutions

Bill Validator ROM Erro. An error has been detected in a main chip in the Replace the bill validator.

Validator.

Bill Validator Acceptor A jam in the bill path has been detected. Check the bill path for items that are blocking sensors.

Jammed. Check to see that the bill path gates are not open.

Replace the bill validator.

Bill Validator Stacker Error. An error has been reported concerning the bill box. Check the bill box to be mounted to the validator

properly.

Replace the bill box.

Replace the bill validator.

Bill Validator Stacker Full. The bill validator is reporting that the bill box is full Check for bills and remove them.

of bills. Replace the bill box.

Replace the bill validator.

Bill Validator Disabled. The control board has disabled the bill validator. Check for coins in the payout tubes of the coin

Mechanism.

Check for a fault with the bill validator.

Check Winner Prize. The control board has detected a failed winner vend. Check for the presence of product.

Check motor function.

POWER OFF. The control board has detected a power outage. Check the power cord and plug.

Check the circuit breaker.

Check the On/Off switch in the machine.

DOOR OPEN. The control board is reporting that the door has Check to see if someone has been in the machine.

been opened. Check the door switch.

Check switch connections and harnessing for damage.

Power Save mode. The machine is in a power save event. Let the event complete.

Modify or eliminate the event in the software settings.

Sold Out Machine. The control board has determined that all selections Check SureVend settings and function.

in the machine are sold out. Check for vend motor function.

Check harnessing connections.

Check for board function (selection configuration).

Page 28

Page 27 of 128