Crane Merchandising Systems BevMAX 4 Series, DN5800-4, DN5800-E4, DN3800-4, DN3800-E4 Technical Manual

Page 1

Glassfront Vender

Models DN5800-4, DN5800-E4, DN3800-4, DN3800-E4

Production 8900-0001BH & higher

Tier 2

Operation

Manufactured by

Service

Parts

Troubleshooting

Manual

Crane Merchandising Systems

P.O. Drawer 719

Williston, SC 29853-0719

803-266-5001

fax: 803-266-5049

Visit us on the web:

www.dixienarco.com

803,904,660.11

Page 2

Table of Contents

GENERAL INFORMATION ..................................................................................3

Vender Safety Precautions..................................................................................................3

Product Identification ...........................................................................................................3

Physical Characteristics ......................................................................................................3

INSTALLATION & SETUP...............................................................................3 - 9

Receiving Inspection ...........................................................................................................3

Unpacking the Vender ................................................................................................... 3 - 4

Electrical Requirements.......................................................................................................4

Ground the Vender ........................................................................................................ 4 - 5

Installation & Setup Instructions ..........................................................................................5

Placing the Vender on Location...........................................................................................6

Acceptable Ambient Operating Temperature Range ..........................................................6

Leveling the Vender.............................................................................................................6

Spacing the Vender .............................................................................................................6

Installing Labels & Product ID Cards............................................................................. 6 - 7

Coin Changers and Other Accessories ...............................................................................7

Set Temperature Control .....................................................................................................7

Loading the Vender .............................................................................................................7

Loading the Coin Changer...................................................................................................7

Power AC Distribution Box ..................................................................................................7

Vending Machine Controller (VMC)............................................................................... 7 - 8

Keypad.................................................................................................................................8

Digital Display ......................................................................................................................8

Refrigeration System ...........................................................................................................8

Shelf Assembly ....................................................................................................................8

Double Gate Assembly........................................................................................................8

Slide / Pusher Assembly......................................................................................................8

Delivery (Picker) Cup Assembly..........................................................................................8

Refrigeration Deck Clamp ............................................................................................. 8 - 9

Belt Tension Adjustment......................................................................................................9

PROGRAMMING.........................................................................................10 - 32

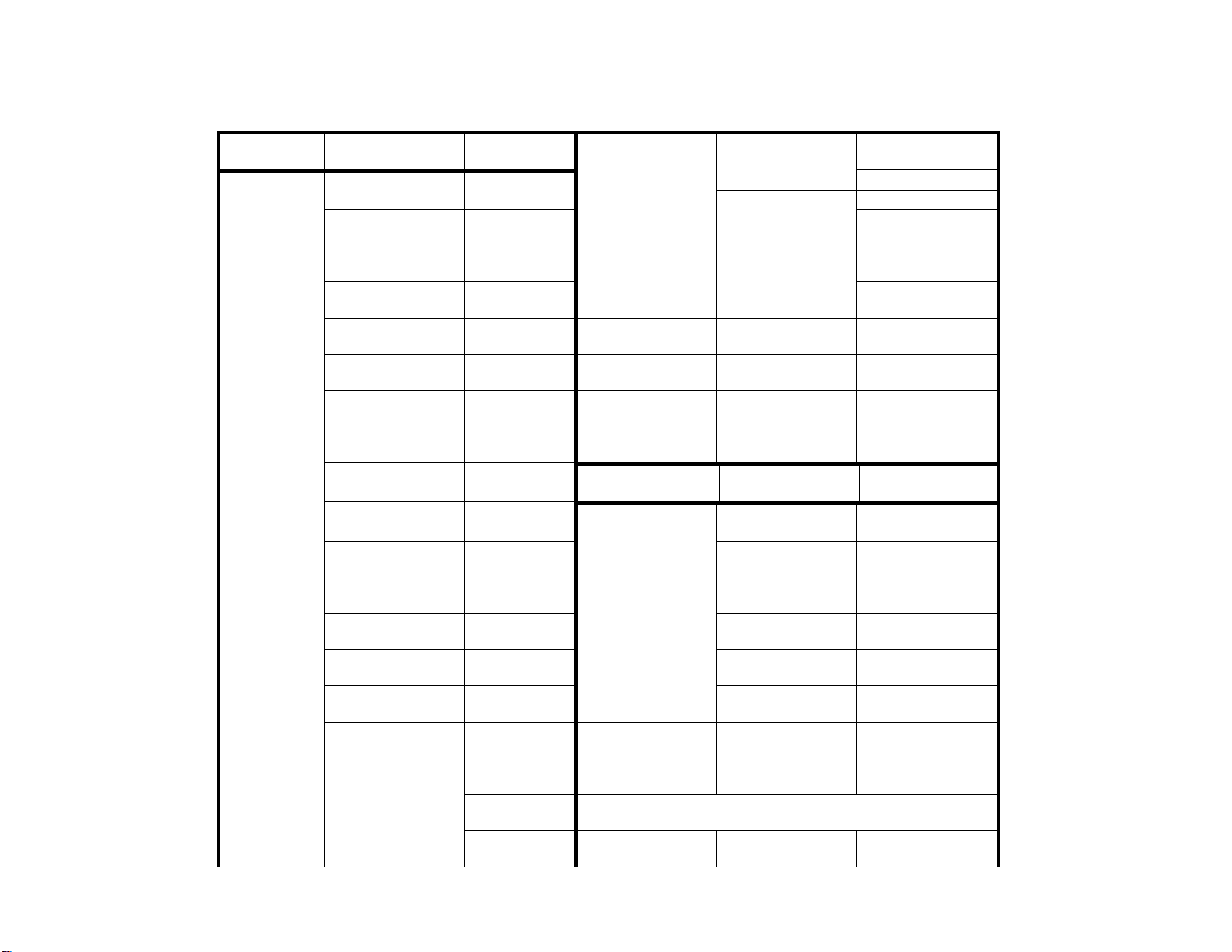

Coca-Cola EVS BevMax 4 Programming.................................................................. 10 - 24

Quick Reference Menu Items .................................................................................... 25 - 26

Dixie-Narco Factory Diagnostics Programming ....................................................... 27 – 32

MAJOR COMPONENT DESCRIPTION .............................................................32

AC Distribution Box ...........................................................................................................32

Service Door Switches ......................................................................................................32

GENERAL MAINTENANCE ........................................................................33 - 34

Power.................................................................................................................................33

Cleaning..................................................................................................................... 33 - 34

Update Software................................................................................................................34

CONTROL BOARD ........................................................................................... 35

Controller Connections ......................................................................................................35

TROUBLESHOOTING................................................................................ 36 – 55

XY Issues................................................................................................................... 36 - 38

XY Not Working Flow Chart...............................................................................................39

Plunger Home Flow Chart .................................................................................................40

X Axis Home Flow Chart ...................................................................................................41

Y Axis Home Flow Chart ...................................................................................................42

XY Slams to Top/Right or Left Flow Chart ........................................................................43

Picker Cup Not Working Flow Chart..................................................................................44

Picker Cup at Wrong Location Y Axis Flow Chart.............................................................45

Picker Cup at Wrong Location X Axis Flow Chart.............................................................46

Delivery Port Door Flow Chart...........................................................................................47

Coin Acceptance................................................................................................................48

1 of 97

Page 3

–

Bill Acceptors.....................................................................................................................48

Control Board.....................................................................................................................48

All Coins Rejected Flow Chart...........................................................................................49

All Bills Rejected Flow Chart .............................................................................................50

Incorrect Change Dispensed Flow Chart ..........................................................................51

Selection Will Not Vend Flow Chart...................................................................................52

Ice / Frost on Evaporator Flow Chart.................................................................................53

Condensate on Outside of Product Door Flow Chart ........................................................53

Compressor Will Not Stop Flow Chart...............................................................................53

Compressor Will Not Start Flow Chart ..............................................................................54

Machine Not Cooling Flow Chart.......................................................................................55

ELECTRICAL DIAGRAMS & SCHEMATICS.............................................. 56 – 68

Block Diagram Domestic ...................................................................................................56

Block Diagram Export........................................................................................................57

Vender Wiring Diagram Cabinet (Domestic & Export) .............................................. 58 - 59

Vender Wiring Diagram Door (Domestic & Export)...........................................................60

Vender Wiring Diagram Power & Fluorescent Lighting w/ JST (Domestic only)...............61

Vender Wiring Diagram Power & Fluorescent Lighting (Export only) ...............................62

Vender Wiring Diagram Power & LED Lighting (Export only) ...........................................63

Vender Wiring Diagram Power & LED Lighting (Domestic only).......................................64

Domestic Compressor Parts Diagram...............................................................................65

Export Compressor Parts Diagram....................................................................................66

Domestic AC Distribution Box J2 Port Test Voltages........................................................67

Export AC Distribution Box J2 Port Test Voltages ............................................................68

PARTS LIST AND DIAGRAMS ................................................................69 – 104

Machine Front View.................................................................................................. 71 – 72

Cabinet Detail Product Area ..................................................................................... 73 – 74

Cabinet Detail Service Door Area.............................................................................. 75 - 76

XY Motor Picker Unit ................................................................................................ 77 – 78

Delivery (Picker) Cup Assembly............................................................................... 79 – 80

Service Door Outside ............................................................................................... 81 – 82

Service Door Inside .................................................................................................. 83 – 84

Gate Tray Detail........................................................................................................ 85 – 86

AC Distribution Box ................................................................................................... 87 - 88

Lighting - Fluorescent ........................................................................................................89

Lighting - LED....................................................................................................................90

Refrigeration Unit Plastic Evap Box Fin & Tube Condenser .................................... 91 – 92

Refrigeration Unit Metal Evap Box Fin & Tube Condenser...................................... 93 – 94

Electronics ................................................................................................................. 95 - 96

Harnesses................................................................................................................. 97 – 98

Labels / Decals / Misc......................................................................................................100

Screws & Nuts ...................................................................................................... 101 – 102

Washers, Bolts, & Misc. Hardware....................................................................... 103 – 104

High Voltage Warning / Electrical Warning

Danger electricity, electric shock.

A Generic Warning.

Hazard Warning: Beware of moving machinery

Entanglement hazard. Keep hands, loose clothing,

and long hair away from moving parts.

2 of 97

Page 4

VENDER SAFETY PRECAUTIONS

Please read this manual in its entirety. This service

information is intended for use by a qualified service

technician who is familiar with proper and safe

procedures to be followed when repairing, replacing or

adjusting any Crane Merchandising Systems DixieNarco vender components. All repairs should be

performed by a qualified service technician who is

equipped with the proper tools and replacement

components, using genuine Crane Merchandising

Systems factory parts.

REPAIRS AND/OR SERVICING

ATTEMPTED BY UNQUALIFIED

PERSONS CAN RESULT IN

HAZARDS DEVELOPING DUE TO

IMPROPER ASSEMBLY OR

ADJUSTMENTS WHILE

PERFORMING SUCH REPAIRS.

PERSONS NOT HAVING A PROPER

BACKGROUND MAY SUBJECT

THEMSELVES TO THE RISK OF

INJURY OR ELECTRICAL SHOCK

WHICH CAN BE SERIOUS OR EVEN

FATAL.

PRODUCT IDENTIFICATION

First production of Coca-Cola BevMax 4 5800-4/38004 Domestic and BevMax 4 5800-E4/3800-E4 Export

Venders was May 2009. The production date of

Crane Merchandising Systems Dixie-Narco products

is determined by the date code incorporated in the

serial number.

The vender serial number takes the form xxxx-yyyy

zz. The first 4 digits (xxxx) identify the specific

vender. The next 4 digits (yyyy) identify the

manufacturing run that the vender was built in. The

last two alpha characters (zz) identify the quarter and

the year the vender was built. The first alpha

character identifies the quarter as follows:

The second alpha character identifies the year:

H = 2009 K = 2012

I = 2010 L = 2013

J = 2011 M = 2014

A= 1

B= 2

C= 3

D= 4

st

Quarter

nd

Quarter

rd

Quarter

th

Quarter

CE Mark & IIA Declaration:

An updated CE Mark or IIA Declaration document can

be provided upon request: If needed please contact

Technical Support Manager in Williston, SC. Phone:

Bryan Staubs 1- 803-266-8805 or email

bstaubs@cranems.com.

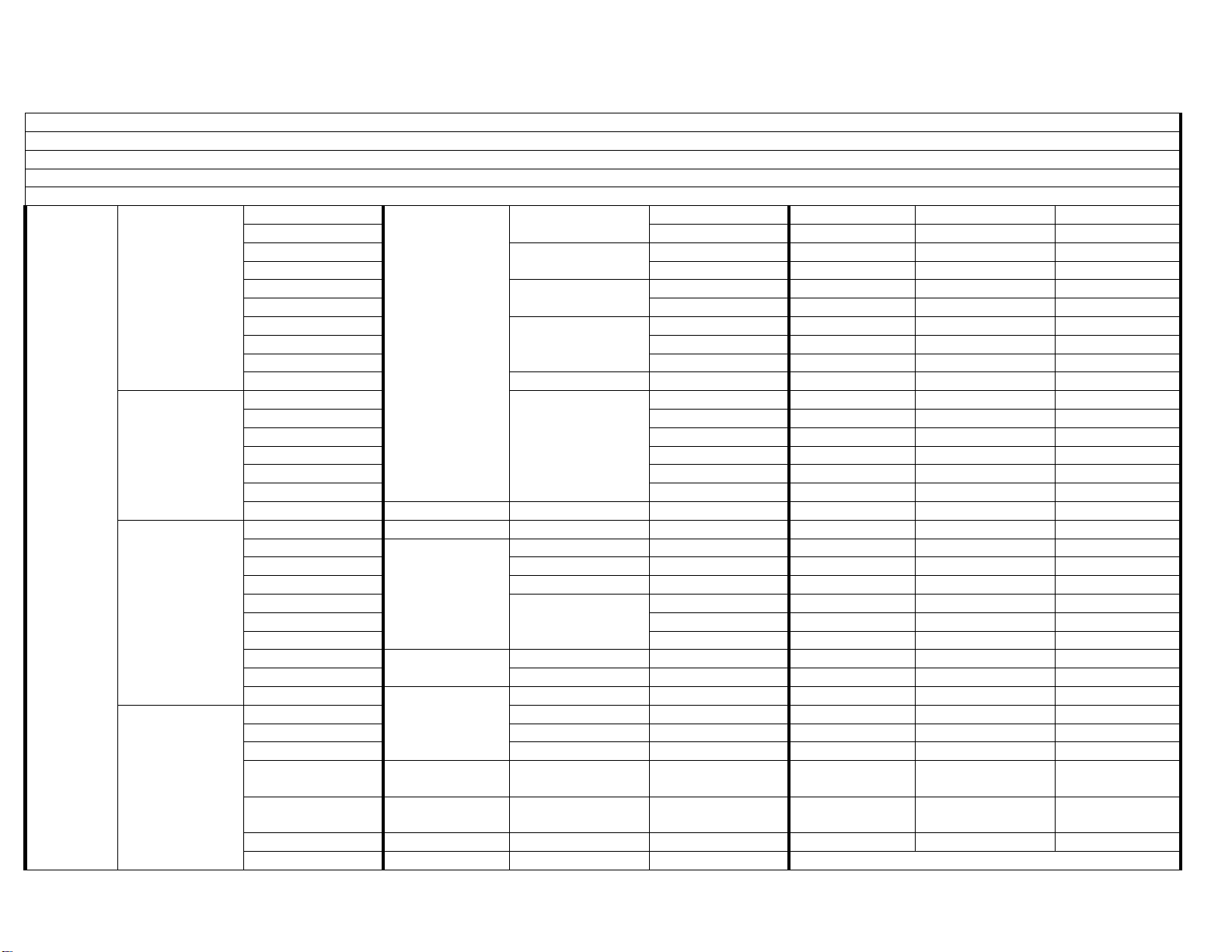

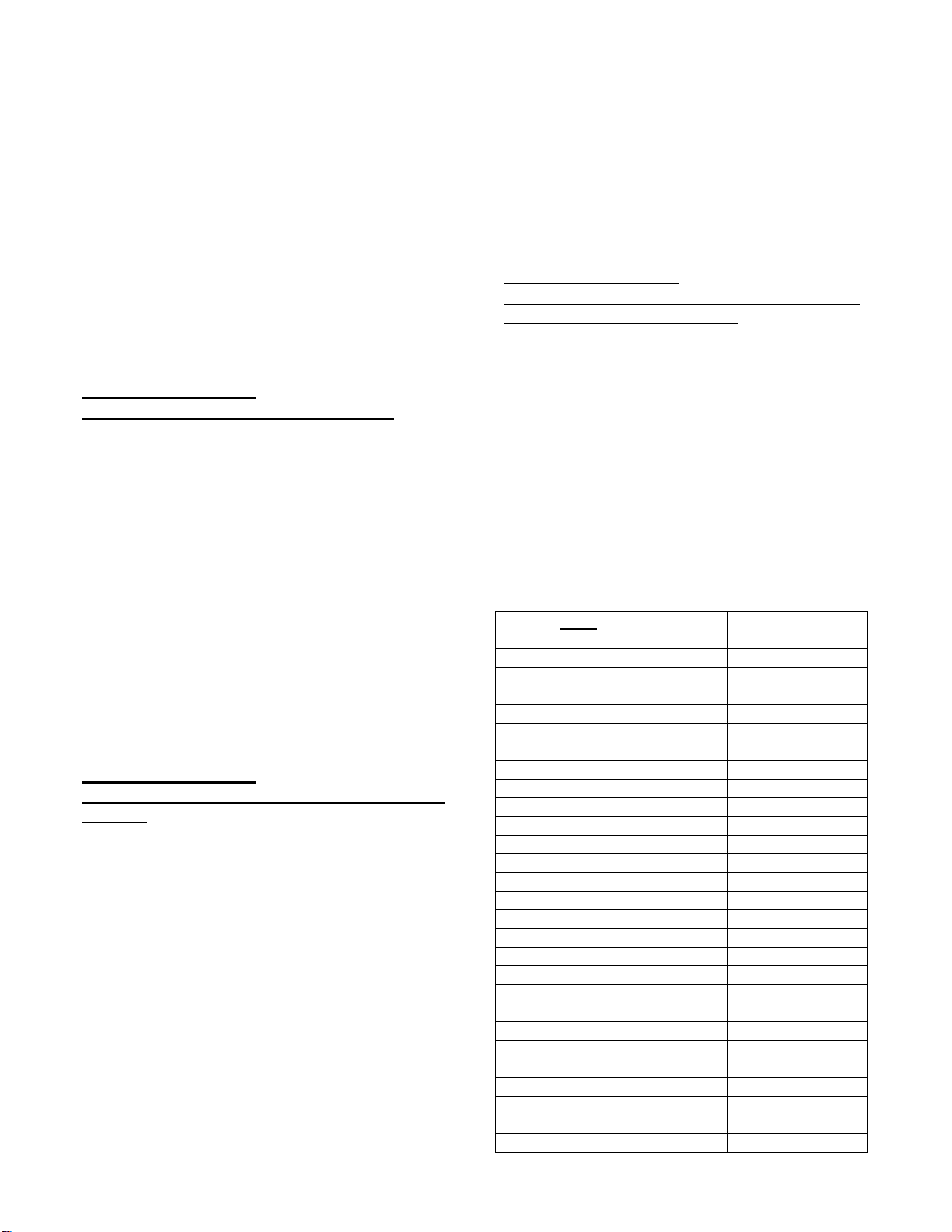

PHYSICAL CHARACTERISTICS

DN5800-4

DN5800-E4

HEIGHT

WIDTH

DEPTH

CABINET

DEPTH

WITH

SERVICE

DOOR

BASE

SHIPPING

WEIGHT

Noise

Level

Glass door width is 37.5” (952.5 mm) 5800’s, 28.1”

(713.74 mm) 3800’s, height is 68” (1727.2 mm) both.

72” (1828.8 mm) 72” (1828.8 mm)

47” (1193.8 mm) 39” (990.6 mm)

32” (812.8 mm) 32” (812.8 mm)

33.5” (850.9 mm) 33.5” (850.9 mm)

3.5” (88.9 mm) 3.5” (88.9 mm)

764 lbs.

(346.54kg)

Operates at < 70db.

DN3800-4

DN3800-E4

675 lbs.

(306.17g)

RECEIVING INSPECTION

DO NOT STORE THE VENDER OUTSIDE.

Upon receipt, inspect the vender for any shipping

damage. If there is any damage, have the delivery

driver note the damage on the bill of lading and notify

Crane Merchandising Systems. Although the terms of

sale are FOB shipping point, which requires the

consignee to originate shipping damage claims, Crane

Merchandising Systems will gladly help if you must file

a claim.

UNPACKING THE VENDER

Remove the stretch wrap, fiberboard edge protectors

and corrugated front protector from the outside of

vender.

Do not store the vender with stretch

wrap on. Stretch wrap could bond to

the vender’s surface, which could

damage the finish.

Remove the shipping boards from the bottom of the

vender. The shipping boards are attached by the

leveling legs. To avoid unnecessary damage to the

leveling legs or base, remove the shipping boards by

using a 1-1/2 inch or 38mm socket type wrench to

unscrew the leveling legs. Be sure to replace the legs

after removing the shipping boards. Once the skid

3 of 97

Page 5

boards are removed there is 3” (76.2 mm) from base

flange to the floor with the leveling legs screwed all

the way in.

Once the vender is unpacked, check the “B” Tray area

for any additional parts, price/product labels,

service/operation manual or other information

concerning factory-equipped accessories such as coin

mech and validator.

It is recommended the vender be vend tested before

shipping to the location. See Pg 12, “Test Modes”.

Note: Remove tape from ends of top

lamp in the top lamp assembly after

placing the Vender on location, but

before plugging the Vender in to an AC

power supply.

WARNING: TO AVOID THE

POSSIBILITY OF A FIRE

HAZARD, DO NOT STORE

ANYTHING OR ALLOW

DEBRIS OF ANY KIND TO

ACCUMULATE AROUND,

UNDER OR BEHIND THE

CABINET, IN THE BOTTOM

OF THE SERVICE AREA, IN

AND AROUND THE

REFRIGERATION

COMPARTMENT OF THE

CABINET, OR IN FRONT OF

THE EVAPORATOR AND

CONDENSER COILS.

WARNING: ENSURE THAT

POWER IS DISCONNECTED

FROM THE VENDER BEFORE

INSPECTING OR REPLACING

THE LAMPS, OTHER

ELECTRICAL COMPONENTS,

OR WORKING WITH OR

ADJUSTING THE VENDING

MECHANISM. FAILURE TO

COMPLY WITH THESE

INSTRUCTIONS MAY

SUBJECT THE USER TO THE

RISK OF ELECTRICAL

SHOCK OR MECHANICAL

INJURY, WHICH CAN BE

SERIOUS OR FATAL.

ELECTRICAL POWER NEEDED

Refer to the cabinet serial number plate to determine

the correct voltage and frequency for the machine. In

the US and Canada this is 120Vac, 60Hz, 1P. In

Europe, Australia, and other export countries, this is

220/230/240Vac, 50Hz, 1P depending upon your

country voltage. The serial plate also specifies the

ampere rating of the machine. This machine must be

plugged into a properly rated receptacle with its own

circuit protection (fuse or circuit breaker).

Equipment Nominal Power Requirements -

120V / 10.2 A = *1224W (1.224kw)

220V / 5.8 A = *1276W (1.276kw)

240V / 5.8 A = *1392W (1.392kw)

*Note: Watts = V X A

DO NOT USE AN EXTENSION CORD.

POWER SUPPLY CORD and

GROUNDING REQUIREMENTS

In accordance with the National Electrical Code and

Underwriters Laboratories Inc., domestic vending

machines are equipped with a three-wire power supply

cord and Ground Fault Circuit Interrupter (GFCI).

The GFCI device is provided as part of the power

supply cord and is either incorporated directly into the

plug or mounted on the cord adjacent to the plug.

WARNING

• The GFCI protects against current

leakage caused by ground faults.

The GFCI is not designed to

protect against over current or

short circuits.

• DO NOT use the TEST and

RESET buttons on the GFCI as an

ON/OFF switch.

• The vending machine supply cord

MUST be plugged directly into a

properly grounded, 3 wire

receptacle that is properly

protected by a fuse or circuit

breaker. If the receptacle will not

accept the power cord plug, it must

be replaced with a properly

grounded, 3 wire receptacle in

accordance with the National

Electrical Code and Local Codes

and Ordinances. The work should

be done by a qualified electrician.

DO NOT USE A 3 WIRE TO 2

WIRE ADAPTOR

4 of 97

Page 6

DO NOT REMOVE THE

GROUND PIN ON THE PLUG OR

IN ANY WAY BYPASS, MODIFY,

DEFEAT, OR DESTROY THE

GROUNDING SYSTEM OF THE

VENDING MACHINE

• DO NOT USE WITH AN EXTENSION

CORD.

• DO NOT REMOVE THE WARNING TAG

ATTACHED TO THE POWER SUPPLY CORD.

• The GFCI must be tested frequently and before

each use in accordance with the instructions

provided on the GFCI device. IF THE GFCI

DOES NOT PASS THE TEST, DO NOT USE

THE MACHINE. Unplug the supply cord from

the receptacle and call the Crane Merchandising

Systems Technical Support Group for assistance

at 1-803-266-5001.

It is recommended that the machine be located so that

the GFCI device will be accessible after the machine

is installed. After installation, visually inspect the

GFCI and power supply cord to be sure it is not

crushed, pinched, or stretched.

Protect the power supply cord during transportation

and use. Periodically inspect the power supply cord

for damage. If the cord or plug is worn or damaged, it

must be replaced with a power supply cord of the

same type, size and specification as originally

provided with the machine. DO NOT USE THE

VENDING MACHINE UNTIL THE WORN OR

DAMAGED CORD IS REPLACED.

FAILURE TO COMPLY WITH

THESE INSTRUCTIONS MAY

SUBJECT THE USER TO THE

RISK OF INJURY OR

ELECTRICAL SHOCK WHICH

CAN BE SERIOUS OR FATAL.

PERIODICALLY INSPECT THE

POWER SUPPLY CORD FOR

DAMAGE. IF THE CORD

BECOMES DAMAGED IT MUST

BE REPLACED WITH THE

SAME SIZE AND TYPE CORD.

CONTACT CRANE

MERCHANDISING SYSTEMS

FOR ASSISTANCE.

INSTALLATION AND SETUP

INSTRUCTIONS

MANUAL LOCK

Open the service door on the right side using the key

provided in the coin return cup, or if shipped with a

locking clip, remove the clip and install the lock.

Ensure there is no power to the AC Distribution Box.

On venders with a main power switch on the AC

Distribution Box the switch needs to be in the OFF

position. On venders with a main power quick

disconnect plug on the AC Distribution Box the quick

disconnect plug needs to be unplugged. Check that

all connectors are firmly seated on the control board

and at the various components on the service door

(coin mech, keypad, etc.).

Retrieve the main power plug from the hole in the rear

of the vender and plug the cord in a properly

grounded 120VAC, 15 Amp receptacle (U.S. and

Canada).

Open the service door and apply power to the AC

Distribution Box (if equipped with a bill acceptor, the

acceptor should cycle twice). The display on the door

will briefly show the software version in use as

“Software ###.## (i.e. ###.01) followed by the default

idle message “ENJOY A REFRESHING DRINK”, the

fluorescent lamp should be lit and the cooling unit

should start. If the display shows “OUT OF

SERVICE”, or the cooling unit fails to start, refer to the

TROUBLESHOOTING SECTION beginning on page

36.

SERVICE NOTE

Battery Backup

The battery backup is used to maintain the date and

time in case of power interruptions, or any time the

main power is off. When the vender is shipped, the

battery is connected and memory is being maintained.

If the vender is to be stored for long periods of time,

disconnecting the battery is recommended. The

following steps will guide you through this procedure.

• Open the service door, turn the main power

switch to the off position or unplug the main

power harness located on the front of the

power box.

• Locate the control board mounted on the rear

wall.

• Remove the battery from its holder (B1).

5 of 97

Page 7

PLACING THE VENDER ON

LOCATION

!! CAUTION !!

DO NOT TRANSPORT THE

VENDER TO OR FROM THE

LOCATION LOADED WITH

PRODUCT OR DAMAGE TO THE

VENDER MAY RESULT.

The vender is intended for INDOOR USE ONLY. It

should be kept out of direct sunlight and away form

any heat source. This machine is not suitable for

installation in an area where a water jet or hose and

nozzle may be used.

The vender must be on a solid, flat and level surface.

Ensure the flooring can bear the weight load of a fully

loaded vender (approximately 1109 lbs. or 413kg).

The vender must be positioned close enough to an

electrical outlet so that an extension cord is not

required. If the machine will be subject to user misuse

or vandalism, it is recommended that the vender be

secured to the floor or wall as described in Crane

Merchandising Systems / Dixie-Narco Technical

Bulletin 344. Due to the large size and weight of the

Vender, never attempt to move the Vender with a

Hand Truck or Stair Climber. Use a pallet jack or

Vender/Cooler Dollies at all times when moving the

Vender. The vender should never be slid or pushed in

place. Never side load the leveling legs; doing so will

cause damage to the legs. Do not transport the

vender to or from customer locations loaded with

product, as damage may result due to excessive

weight. Call the Crane Merchandising Systems

Technical Service Department or your Crane

Merchandising Systems Representative for

assistance.

ACCEPTABLE AMBIENT OPERATING

TEMPERATURE RANGE.

Coke BevMax 4 5800-4/3800-4 equipment

manufactured by Crane Merchandising Systems is

designed to work properly in a temperature range of

75°F to 90°F (23°C to 32°C) in still air 65% R.H. noncondensing.

LEVEL THE VENDER

Adjust the front leveling legs, ensuring that an even

gap exists between the glass door and the top

security angle and receiver box, and then level the

cabinet front to rear. A carpenter’s level will help

verify that the vender is level. Leveling legs are

adjusted using a wrench or socket 1 ½” or 38 mm in

size. If the vender is to be used in a bank of

equipment, check the top and sides for proper

alignment. If you are unable to properly level the

vender, select an alternate location. NEVER PLACE

OBJECTS UNDER THE LEVELING LEGS OF THE

VENDER.

DANGER

THE VENDER MUST BE PROPERLY

LOCATED AND LEVELED. IF THE

MACHINE WILL BE SUBJECT TO

USER MISUSE OR VANDALISM IT IS

RECOMMENDED THAT THE

VENDER BE SECURED TO THE

FLOOR OR WALL AS DESCRIBED IN

CRANE MERCHANDISING

SYSTEMS DIXIE-NARCO

TECHNICAL BULLETIN 344 TO

MINIMIZE THE RISK OF INJURY OR

DEATH FROM TIPPING. CALL THE

CRANE MERCHANDISING

SYSTEMS TECHNICAL SERVICE

DEPARTMENT OR YOUR CRANE

MERCHANDISING SYSTEMS

REPRESENTATIVE FOR

ASSISTANCE.

SPACE THE VENDER

Do not block the rear of the vender. Maintain a

minimum of 4 inches (10 cm) from the wall to ensure

adequate airflow to the condenser and compressor.

At the rear of the vender, make sure nothing obstructs

the air exhaust at the bottom of the cabinet.

WARNING

TO AVOID THE POSSIBILITY OF A

FIRE HAZARD, DO NOT STORE

ANYTHING OR ALLOW DEBRIS OF

ANY KIND TO ACCUMULATE

AROUND, UNDER OR BEHIND THE

CABINET, IN THE BOTTOM OF THE

SERVICE AREA, IN AND AROUND

THE REFRIGERATION

COMPARTMENT OF THE CABINET,

OR IN FRONT OF THE

EVAPORATOR AND CONDENSER

COILS.

INSTALLING PRICE LABELS

Pricing labels included in the literature package kit.

Remove the pricing label sheets from the service

manual package and gently remove the label

corresponding to the vend price of each selection by

tearing at the perforation. The label is installed at the

top of the front knuckle. Once installed, push the label

firmly against the front of the knuckle. This will insure

the label is locked in place.

INSTALLING PRODUCT ID CARDS

To assist with consistent loading, product ID cards

can be installed in the product pusher to designate to

the route driver which product the column is set for.

To install the flavor card, simply detach it from the

sheet at the perforation and slide it into the slots in the

6 of 97

Page 8

product pusher. Contact your graphics supplier to

purchase as needed.

COIN CHANGERS & OTHER

ACCESSORIES

The vender can have an MDB coin changer installed

and can have an MDB bill acceptor installed as well.

Note: BevMax 4 5800-4/3800-4 will work with an MDB

bill acceptor only. If the MDB coin changer and other

MDB accessories are not factory installed, refer to the

instructions received form the manufacturer of the

MDB coin changer and other MDB accessories for

proper set-up and installation.

The vender will support the following Domestic MDB

coin changers:

All available NRI MDB

All available Coinco MDB

All available Mars MDB

All available Conlux MDB

The vender will support the following domestic MDB

Bill validators:

All available Cashcode MDB

All available Coinco MDB

All available Mars MDB

All available Conlux MDB

The vender will support MDB card readers.

SETTING THE TEMPERATURE

CONTROL

This vender is equipped with an electronic

temperature sensor. Defrost is controlled both

electronically based on run time of the compressor

and with a manual Defrost thermostat. The temp

sensor is factory pre-set to maintain a cabinet

temperature of 35º Fahrenheit (1.7ºC). It is also a

good practice to ensure the proper operating

temperature prior to installing the vender on location.

To set the temperature, apply power to the vender

and allow it to run for several hours with the glass

door closed or until the minimum cabinet temperature

is achieved. Then, using the method below, verify the

temperature inside the cabinet:

With an electronic temperature sensor, use the

keypad on the service door to show cabinet

temperature in Fahrenheit by pressing the F key

followed by the asterisk () key or in Centigrade by

pressing the C key followed by the asterisk key. The

temperature will be shown on the digital display

located on the front of the service door.

The manual Defrost thermostat is located on the side

of the refrigeration unit. The Defrost control is preset

and is not adjustable.

LOADING THE VENDER

CAN/BOTTLE DRINK TRAYS

The BevMax 4 5800-4/3800-4 Vender does not

require spacers or shims to vend most packages.

Load product in each column one package at a time

insuring that the package being loaded is in front of

the product pusher. Insure that the package is stable

within the column (doesn’t move excessively from side

to side). After loading the vender, test vend each

column to insure proper operation. Please contact a

Service Representative or refer to the proper

Technical Publication for any special settings you may

need.

LOADING CHANGE TUBES

The changer tubes can be loaded using one of the

following methods:

1. Load the coin mechanism with coins to the

desired level by inserting coins in the loading

slots on the coin tube front.

Minimum coin tube levels are:

6-8 nickels

7-8 dimes

5-6 quarters

Note: A low coin level in the coin tubes will

interfere with operation of the bill validator.

2. For exact cash accountability and to insure

maximum dollar bill acceptance, load the

mechanism utilizing the coin insert slot on the

front of the vender while in the coin Tube Fill

mode in the programming section of Technical

Manual for more information.

For additional information about coin mechanism,

refer to the manufacturer’s instructions.

POWER AC DISTRIBUTION BOX

The power distribution box is where the 120VAC or

220VAC input voltage is broken down to the main

operating voltages of the vender (24 VAC and 12

VAC) by a transformer. Those voltages are sent to

the controller via the P1 (3 pin) connector. Domestic

Venders contain a 15 Amp Outlet which provides

power to the Refrigeration Unit. It contains a main

power switch/plug that allows power to the AC

Distribution Box to distribute AC power to the lights,

evaporator fan, and refrigeration system, which are

always energized when the vender is powered up. It

is located inside the service area, mounted to the

back wall.

VENDING MACHINE CONTROLLER (VMC)

The vending machine controller is the heart of the

Glass Front Vender and is located on the rear wall

inside the service area. It is flash programmable and

may or may not include the program chip (EPROM),

which controls all aspects of the vender. It also

contains the power supply which regulates the

voltages required to operate the motors as well as the

7 of 97

Page 9

coin mechanism, digital display, and all logic functions

in the vender.

KEYPAD

The keypad is located on the front of the service door.

It consists of a 6” X 3” (15.2 mm X 7.6 mm) matrix,

tactile feel membrane switch pad and an overlay. The

pad utilizes the letters A thru F on the left side and

numbers 1 thru 0 along with the symbol and CLR to

the right. The keypad is where the vender

programming is accomplished and where the

customers make their selections.

DIGITAL DISPLAY

The digital display is located directly above the

keypad on the front of the service door. It is used to

convey information to the consumer as well as to the

person programming the vender.

REFRIGERATION SYSTEM

The refrigeration system is a single piece unit and is

hermetically sealed. The Model BevMax 4 units

consist of a 1/3 plus horsepower compressor, with a

single fin and tube style condensing unit with one

condenser fan, condensation overflow pan,

evaporator, and evaporator fan motor. The

refrigeration unit is located behind the refrigeration

unit cover panels, mounted in the bottom of the

cabinet. This unit is designed for easy removal and

replacement from the front or rear of the vender as a

complete assembly. An electronic thermostat

regulates the cabinet temperature. The control of the

thermostat is attached to the evaporator coils and

reads the temperature of air being pulled in to the

evaporator coil.

SHELF ASSEMBLY

Typically, there are 5 shelf assemblies in every

vender; however, this can vary depending upon the

configuration specified at the time of ordering. Each

can/bottle shelf consists of 9 or 7 columns. Each shelf

is capable of holding a variety of packages. The shelf

assembly consists of the tray, where all of the

following parts are mounted: Double Gate assembly,

and the slide/pusher assembly. These items are

discussed in detail below.

DOUBLE GATE ASSEMBLY (Can/Bottle

Trays)

The double gate assembly is mounted on the front

portion of the tray assembly and contains the vending

mechanism. Incorporated in the gate assembly are

the front and rear knuckle assemblies as well as the

product kicker. In standby operation, the front knuckle

is in the blocking position, which holds the front

displayed product in position to be vended. The rear

knuckle assembly is in a flat position, which allows

product to enter the gate area, and the kicker is flush

to the rear knuckle assembly. A stainless steel pin is

inserted through the rear most portion of the front

knuckle assembly and connects to a gear box below

the tray. When a selection is made, the plunger

pushes the lever toward the back of the tray. At the

same time the front knuckle is opened into a flat

position, the rear knuckle is closed to a blocking

position, holding the remaining product out of the gate

area, and the kicker is extended to firmly push the

front displayed product off of the tray. The plunger is

energized for approximately 1-½ seconds to allow

ample time for the displayed product to be ejected

from the shelf. The plunger is then released and the

front knuckle returns to the blocking position, the rear

knuckle and kicker return to their standby position and

the next product slides into the vend display position.

SLIDE/PUSHER ASSEMBLY (Can/Bottle

Trays)

The slide/pusher is located on the bottom of each

product column. Its purpose is to provide a slick,

friction resistant surface for the product to rest on.

The tall product pusher is mounted on the top of the

slide and incorporates a coil spring in the body that

attaches to the bottom of the slide through a slit. This

spring adds needed tension to insure that all products

in the column remain tight against each other and are

allowed to progress into the gate area. Although

these pushers reduce the effects of dirt and grime,

periodic cleaning and lubrication of the slides is

recommended. DO NOT USE SOLVENTS OR

ABRASIVE MATERIALS TO CLEAN ANY PORTION

OF THE TRAY.

DELIVERY (PICKER) CUP ASSEMBLY

The delivery (picker) cup assembly is located on the

XY vend mechanism. Its purpose is to pick the

product from the column and deliver the product to the

delivery port assembly. The delivery (picker) cup

assembly is mounted on the XY assembly and bolts in

position.

The X axis runs left to right. The X axis assembly is

cabinet mounted to prevent any cabinet torque and

has one belt to synchronize the top and bottom when

the X moves left or right.

The Y axis runs up and down and has the delivery

(picker) cup assembly attached. A top channel is

used to contain and hide the e chain and wiring.

Both X and Y motors have encoders for positioning.

REFRIGERATION DECK CLAMP

ASSEMBLY

The refrigeration deck clamp assembly is located on

the rear left side of the cabinet base plate. Its

purpose is to secure the refrigeration assembly tight

against the vertical base plate for refrigerated air flow

8 of 97

Page 10

in to the cabinet. A 7/16” wrench or socket is needed

to adjust the bolt.

BELT TENSION ADJUSTMENT

COMPONENTS

The belt tensioning adjustment components have

been designed to ease adjusting belts when needed.

The X Belt Idler Tensioning Assembly in the upper left

hand corner of cabinet now includes a thumb screw.

Adjustments should only be needed if a belt is

replaced.

The Bottom X Drive Tensioner Assembly in the lower

right hand corner of cabinet has a plastic spring

loaded tensioner designed to keep the belt against the

pulley when moving and does not require any

adjustments.

9 of 97

Page 11

COCA-COLA

BevMax 4

(70x.x1 Software)

PROGRAMMING METHOD

NORMAL MODE:

In normal mode, on power up display will show

software installed in vender, then change to

POS message or decimal point and / or vend

price. When money is inserted, the display

indicates the total amount of the deposit. The

keys on the keypad are used to select the

product. In normal mode you may access an

external menu for reading historical sales

counters, cash counters, error codes, No Error

Codes, or return to normal mode.

SERVICE MODE:

If configuration switch 4 is set to “Config 4 0”,

when the door is opened, “No Error Codes” or a

list of Error codes will show on the display. If

configuration switch 4 is set to “Config 4 1”,

when the door is opened, “Cash - ####-##.##”,

“Card - ######.##”, “Sale - ####-####”, “ Error

Codes”, or “No Errors” will show on the display.

NOTE: Card is only shown if a card reader is

present. The service mode is entered when the

door is open and the service switch on the

controller is pressed. The operator can now use

the keypad to move through the main routine

menu.

Key number 1: Abort/Cancel - will return to

previous menu prompt.

Key number 2: Scroll Up - forward in menu.

Key number 3: Scroll Down - backward in menu.

Key number 4: Enter/Save/Clear - Allows you to

enter a specific routine, save

what you have programmed, or

clear the error prompts.

Note: Routines with * are password protected.

They can only be viewed and entered after the

password is entered at the “Password Entry”

prompt.

EXTERNAL MENU MODE:

The information available in this mode is

obtainable with the door closed or open as long

as the vender is in normal mode, by entering the

password which is set at 4, 2, 3, 1. Note: 4231 is

the factory default and can be programmed to

any four digit combination. Information available

is historical cash counted, interval cash counted

for each selection, historical sale (total number

of vends), interval vends counted for each

selection, error codes, and return. Refer to the

“Cash Counters”, “Sales Counters”, and “Error

Codes” routines for instructions to move through

the menus.

PROGRAMMING MENU

“Error Codes” - ERROR ROUTINE

This function allows you to enter the error

readout routine. “Error Codes” will appear when

you press the service button on the control

board. Press key number 4, if there have been

no Error Codes since the last reset, the display

will read “No Errors”. If one or more Error Codes

have occurred, the display will show the first

error code that occurred. The following are error

codes that may be displayed and detailed

information accessed: “No Errors”, “Vend

Mechanism”, “Control System”, “Selection

Switch”, “Changer”, “Bill Validator”, “Card

Reader”, “Remote Vend Mech”,

“Selection/Display”, “Refrigeration”, “Health

Timer”.

Press key number 2 or 3 to scroll through any

error codes that are present.

Important: If there is only one problem, it will be

the only error code shown when you enter the

error code submenus.

With an error code showing on the display,

press key number 4 to access detailed

information.

After making repairs with an error code showing

on the display, press and hold key number 4 for

2 seconds will clear the error.

Press key number 1 to return to “Error Codes”.

“Vend Mechanism” - Vend

Mechanism Summary Error Codes

Press key number 4 and the display will show

the following:

- “HORIZ”, X (horizontal) motor issue.

- “VERT”, Y (vertical) motor issue.

- “PICKI”, picker home switch issue.

- “PICKO”, picker out switch issue.

- “PICKRS”, picker return spring issue.

- “PORT”, port door switch/board issue.

- “VS”, port vend sensor board issue.

- “XHOME”, X (horizontal) motor home

switch issue.

- “YHOME”, Y (vertical) motor home

switch issue.

- “MOTOR”, port/delivery cup motor

issue.

Press key number 1 will return to “Vend

10 of 97

Page 12

Mechanism” if all vend mech Error Codes have

not been cleared. If all vend mech Error Codes

have been cleared the next error mode will be

displayed, or “No Error Codes” if there are no

Error Codes. Press key number 1 will return to

“Error Codes”.

“Control System” - Control System

Summary Error Codes

Press key number 4 and the display will show one of

the following:

- “Door Switch”, indicating a door switch in the

open position for more than 1 hour.

- “RAM Checksum”, indicating the check sum for

service mode settings memory has been

corrupted.

- “Scale Factor”, indicating a peripheral has

introduced a scaling factor that is

incompatible with current setting.

“FRAM”, memory module read/write error.

- “RTC”, RTC read/write error, real time clock

issue.

- ‘Low Battery”, low battery issue.

- “PWROUT”, power lost.

Press key number 1 will return to “Control System” if all

control system Error Codes have not been cleared. If

all control system Error Codes have been cleared the

next error code will be displayed, or “No Error Codes” if

there are no Error Codes. Press key number 1 will

return to “Error Codes”.

“CHANGER” - Changer Summary Error

Codes

Press key number 4 and the display will show one of

the following:

- “Changer Comm”, indicating a changer

communication error (No communication for

more than 2 seconds).

- “Tube Sense”, indicating a tube sensor error.

- “Changer Inlet”, indicating an inlet chute blocked

error (no coins sensed in acceptor for 96 hours).

- “Tube Jam #”, indicating a tube jam error.

- “Changer ROM”, indicating a changer ROM

check sum error (failed changer).

- “Excessive Escrow”, indicating excessive escrow

attempts (more than 255 since last coin sensed).

- “Coin Jam”, indicating a coin jam reported by coin

mech.

- “Low Acceptance”, indicating a low coin

acceptance rate (less than 80%).

- “Acceptor Disconnected”, indicating an acceptor

is unplugged.

- “Coin Routing Err”, indicating a coin was missrouted.

Press key number 1 will return to “CHANGER” if all

changer Error Codes have not been cleared.

If all changer Error Codes have been cleared the

next error code will be displayed or “No Error

Codes” if there are no Error Codes. Press key

number 1 will return to “Error Codes”.

“Bill Validator” - Bill Validator Summary

Error Codes

Press key number 4 and the display will show one of

the following:

- “Bill Val Comm” indicating a bill validator

communication error (No communication for more

than 5 seconds).

- “Bill Stack Full” indicating the bill stacker is full.

- “Bill Motor Error” indicating a defective motor in

the validator.

- “Bill Jam ” indicating a bill jam in the validator.

- “Bill Val ROM” indicating a check sum error.

- “Bill Stack Open” indicating an open stacker.

- “Bill Sense Err” indicating a bill validator sensor

error.

Press key number 1 will return to “Bill Validator” if all

changer Error Codes have not been cleared.

If all validator Error Codes have been cleared the

next error code will be displayed or “No Error

Codes” if there are no Error Codes.

Press key number 1 will return to “Error Codes”.

“Card Reader” - Card Reader Summary

Error Codes

Press key number 4 and the display will show one of

the following:

- “Card Reader Comm”, indicating no card reader

communication for 5 seconds.

- “Card Reader #”, indicating the most recent “non-

transient error” from the card reader (failed card

reader).

Press key number 1 will return to “Card Reader” if all

changer Error have not been cleared. If all card reader

Error Codes have been cleared the next error code will

be displayed or “No Error Codes” if there are no Error

Codes. Press key number 1 will return to “Error

Codes”. Press key number 2 will scroll to the next

routine.

“OLM” – On Line Module Summary Error

Codes

Press key number 4 and the display will show one of

the following:

- “On Line Network”, error reported by the OLM.

- “On Line Internal”, error reported by the OLM.

Press key number 1 will return to “OLM” if all OLM

Errors have not been cleared. If all OLM Error Codes

have been cleared the next error code will be displayed

or “No Error Codes” if there are no Error Codes. Press

key number 1 will return to “Error Codes”. Press key

number 2 will scroll to the next routine.

11 of 97

Page 13

“Remote Vend Mech” - Remote Vend

Mechanism (USD) Error.

Press key number 4 and the display shows one of the

following.

- “Remote Vend Comm #”, indicates no

communication for 5 seconds with remote vend

mech at address “#”.

- “Remote Vend #”, indicates error code number “#”

from the remote vend mech at address “a”.

Press key number 1 will return to “Remote Vend Mech”

if all remote vend mechanism Error Codes have not

been cleared. If all remote vend mechanism Error

Codes have been cleared the next error code will be

displayed, or “No Error Codes” if there are no Error

Codes. Press key number 1 will return to “Error

Codes”. Press key number 2 will scroll to the next

routine.

“SAT” – Satellite Device Error.

Press key number 4 and the display shows one of the

following.

- “SATC”, satellite communication issue.

- “BADM”, bad motor reported.

- “MISM”, missing motor reported.

Press key number 1 will return to “SAT” if all SAT Error

Codes have not been cleared. If all SAT Error Codes

have been cleared the next error code will be displayed,

or “No Error Codes” if there are no Error Codes. Press

key number 1 will return to “Error Codes”. Press key

number 2 will scroll to the next routine.

“Select/Display” - Selection / Display

Device (ASD) Error

Press key number 4 and the display shows:

- “Select/Display Comm”, indicating no

communication to selection / display device for

five seconds.

Press key number 1 will return to “Select/Display” if all

selection / display device Error Codes have not been

cleared. If all selection / display device error have been

cleared the next error code will be displayed or “No

Error Codes” if there are no Error Codes.

Press key number 1 will return to “Error Codes”.

Press key number 2 will scroll to the next routine.

“Refrigeration” - Refrigeration Summary

Error Codes

Press key number 4 and the display shows one of the

following:

- “Temp Sense Err”, indicating the temperature

sensor is defective or unplugged.

- “Temp Too Cold”, indicating the cabinet

temperature is 3

- “Temp Too Hot”, indicating the cabinet

temperature is 3

0

F below lower limit.

0

F above upper limit.

- “Not Cooling”, indicating the cooling system has

failed to decrease temperature 1

hour while the compressor is running.

- “Health Timer” – Health Timer Error

The initial pull down time has not met the

health timer constraints. Refer to “Health

Timer” section for details. Press and hold

key number 4 for 2 seconds will clear the

error and the display will show “No Error

Codes”.

- “Health Code” – Health Code Error

The health code cooling constraints have

not been met. Refer to “Health Timer”

section for details. Press and hold key

number 4 for 2 seconds will clear the error

and the display will show “No Error

Codes”.

Press key number 1 will return to “Refrigeration” if all

refrigeration summary errors have not been cleared. If

all refrigeration summary Error Codes have been

cleared the next error code will be displayed, or “No

Error Codes” if there are no Error Codes. Press key

number 1 will return to “Error Codes”. Press key

number 2 will scroll to the next routine.

0

F per

“Coin Pay Out” - COIN PAYOUT ROUTINE

This function allows you to dump coins from the coin

mechanism. Note: If a coin mech is not installed, you

will not be able to enter the program to display

information. Press key number 4 to enter mode and the

lowest coin value dispensable will show on the display.

Press key number 2 or 3 to scroll through the different

coin values available. Press and hold key number 4 to

dump the coins whose value is shown on the display.

Press key number 1 will return to “Coin Pay Out”. Press

key number 2 to scroll to the next routine.

“Tube Fill” - TUBE FILL ROUTINE

This function allows you to count the coins loaded in the

top (separator) of the coin mech that will be routed to an

inventory tube. Note: If a coin mech is not installed,

you will not be able to enter the program to display

information. Press key number 4 to enter mode and the

total number of the coin type being loaded will be

displayed and counted in the vender controller as they

are accepted. The controller will inhibit the acceptance

of any coin which does not go to a tube during this

procedure. If a tube full status is detected, that coin type

will be inhibited. When you finish loading all coins press

key number 1 to return to “Tube Fill”. Press key number

2 to scroll to the next routine.

“Test Modes” - TEST ROUTINE

This function allows you to diagnose different functions

of the vender. Press key number 4 and the display will

show “Test vend”. For additional Dixie-Narco Factory

Diagnostics refer to page 27. Press key number 2 or 3

12 of 97

Page 14

to scroll through the test routines available. Press key

number 1 to return to “Test Modes”.

“Test Vend” - Vend Testing

This function allows you to test vend each column.

Press key number 4 and the display will show

“Column A1”. Press key numbers 2 or 3 to scroll

through the columns available to run in motor test.

Press and hold the Power Interrupt (PI) switch.

Press key number 4 to vend from the column

displayed. Press key number 1 will return to “Test

Vend”. Press key number 2 to scroll to next test

mode.

“Test Sel Switch” - Select Switch Test

This function allows you to test each selection.

Press key number 4 and the display will show

“Selection 4”. Then press any key and the display

will show the last key number pressed.

Press and hold key number 1 for approximately 5

seconds will return to “Test Sel Switch”. Press

key number 2 to scroll to the next test mode.

“Test Display” - Display Test

This function allows you to test all segments in the

display. Press key number 4 and a lower case

alphabet will display, then turn off , then an upper

case alphabet will display alternating until key

number 1 has been pressed to return to “Test

Display”. Press key number 2 to scroll to next test

mode.

“Test Relays” - RELAY TEST

This function allows you to test the relay electronic

control of the compressor (“Compressor #”), the

evaporator fan(s) (“Fan #”), and the sign front light

(“Light#”).

CAUTION: Disconnect power to the compressor

before testing the compressor relay. Failure to

disconnect power to the compressor before testing

the relay could result in damaging the compressor.

Press key number 4 and the display will show

“Compressor #”, where # is the state of the relay - 0

= not activated or off; 1 = activated or on. Press key

number 4 to toggle the relay on and off. Press key

number 2 to scroll to “Fan #”, where # is the state of

the relay - 0 = not activated or off, 1 = activated or

on. Press key number 4 to toggle the fan(s) on and

off. Press key number 2 to scroll to “Light #”, where

# is the state of the relay - 0 = not activated or off; 1

= activated or on. Press key number 4 to toggle the

lights on and off. Press key number 1 to return to

“Test Modes”. Press key number 2 to scroll to

“Password Entry”.

* “Password Entry” - PASSWORD

ROUTINE

This function allows you to enter the following routines

which are not accessible until the operator enters a

password, which is set as 4-2-3-1. To enter the

password, press key number 4 until the display goes

blank. Then press key number 2, then 3, then 1, and

then 4, and “Cash Counters” should appear on the

display. If not entered properly, the display will return to

“Password Entry” after approximately 16 seconds. If

entered correctly, the display will go to the next function

“Cash”.

* “Cash Counters” - CASH COUNTER

ROUTINE

This function will show the user the vender historical

total cash counted and the interval cash counted for

each selection for the vender. Press key number 4 and

“Cash Tot”/”######.##” will show on the display where

the 8"#” characters are the historical total cash counters

that have been recorded. Note: Leading zeros are not

displayed. Example: Display flashes “Cash Tot”, then

“262500”. This is $2625.00 historical total cash. Press

key number 2 to scroll to “Card Tot”/######.##”, where

the 8# characters are the historical card reader cash

counters. Note: Leading zeros are not displayed.

Press key number 2 or 3 to display “Cash Sel

A1”/”######.##” where the 8"#” characters are the

interval cash counters for that selection. Note: Leading

zeros are not displayed. Pressing key number 2 or 3 at

this time will scroll through the available selection cash

counters. Example: Display flashes “Cash Sel A1”,

then “520.50”. This is $520.50 interval cash for

selection A1. Press key number 1 to return to “Cash

Tot”/”######.##”. Press key number 1 to return to

“Cash Counters”. Press key number 2 to scroll to the

next routine.

* “Sales Counters” - SALES COUNTER

ROUTINE

This function will show the user the vender historical

total number of vends and the interval vends counted

for each selection for the vender. Press key number 4

and “Sales Tot”/”########” will show on the display

where the 8"#” characters are the historical total vend

counters that have been recorded. Note: Leading

zeros are not displayed. Example: Display flashes

“Sales Tot”, then “1325”. This is 1325 historical vends.

If in a BevMax 4 with a Snack Vender attached you will

also have available Drink Sales # & Snack Sales #.

Press key number 2 to display Drink Sales # (if Snack

Vender attached). Press key number 2 to display

Snack Sales # (if Snack Vender attached).

Press key number 2 to display “Sales Sel

A2”/”########”, where the 8"#” characters are the

interval vend counters for that selection. Note: Leading

zeros are not displayed. Pressing key number 2 or 3 at

13 of 97

Page 15

this time will scroll through the available selection vend

counters. Example: Display flashes “Sales Sel A1” then

“145”. This is 145 interval vends counted for selection

A1. Pressing key number 1 will return to “Sales

Tot”/”########”. Press key number 1 to return to

“Sales Counter”. Press key number 2 to scroll to the

next routine.

“Price Mode”- This function will only

display if “EXE” is turned on in the “Coke

Factory Setup” mode.

This function is used to set the price mode to either

VMC holding the prices or the EXE Coin Mech holding

the prices. Press Key 4 to enter menu. The current

setting is displayed as “Price Holding: On” or “Price

Holding Off”. Press key 2 to select the desired price

mode On or Off. Press key 4 to confirm setting. Press

key 1 to exit menu.

Note: If Price mode is set for “Price Holding”, then the

Price Program will allow the user to set the price lines

for each selection. It will operate the same as setting

prices, except the user will be prompted to set a price

line rather than a price.

“Price Program” - PRICE SETTING

ROUTINE

This function allows the user to set pricing. When

Configuration Code 1 is programmed to “Config 1 0”

the vender is set for single price vending. When

Configure Code 1 is set to “Config 1 1”, the vender is

set for multi-pricing (or a price for each selection needs

to be set). Note: This routine is lockable when using a

data collection device.

Single Price price setting:

Press key number 4 “Single Price” will show on

display. Press the ”4” key and “Price Sel #.## will

show on display. Press key “2” to increase the

vend price or key “3” to decrease the vend price.

With the display showing the vend price you

require, press key “4” to save. All selections will

be set to vend at the saved vend price.

Multiprice price setting:

Press key 4 and display will show “All Selections”.

Press key 2 to scroll from “All Selections” to

individual tray selections “A, B, C, D, E”. With the

display showing the All settings of the tray you

wish to set price in press the key 4 to enter. At “All

Selections” when you press 4 and enter the

display will show “#.##” or current price set. Press

key “2” to increase the vend price or key “3” to

decrease the vend price. With the display

showing the vend price you require, press key “4”

to save. If you select an individual tray letter to set

price in, when you press 4 and enter the display

will show “All Selections (for tray A only)”. Press

key 2 to scroll to A1 thru A9 then back to All

Selections (for A tray only)”. At the position you

wish to set price when you press 4 and enter the

display will show “#.##” or current price set. Press

key “2” to increase the vend price or key “3” to

decrease the vend price. With the display

showing the vend price you require, press key “4”

to save.

Factory default setting is “Single Price”. Press key

number 1 to return to “Price Program”. Press key

number 2 to scroll to the next routine.

Price line setting:

This function will only display if Price Holding: On” is

set. It will operate the same as setting prices except

the user will be prompted to set a price line rather

than a price.

IMPORTANT: If Enable Snack Vender is set to

“1” or on the vender must be set for Multiprice

price setting. When scrolling through to select

where to set prices you will see the following;

“All Drink Selections, A, B, C, D, E, and then All

Snack Selections. At “All’ Snack Selections”

Press key 2 to scroll from “All Snack Selections” to

individual tray selections “21, 22, 23, 24,25, 26”.

With the display showing the setting of the tray you

wish to set price in press the key 4 to enter. At

“All’ Selections” when you press 4 and enter the

display will show “#.##” or current price set. Press

key “2” to increase the vend price or key “3” to

decrease the vend price. With the display

showing the vend price you require, press key “4”

to save. If you select an individual tray number to

set price in, when you press 4 and enter the

display will show “All Selections (for tray 21 only)”.

Press key 2 to scroll to 211 thru 21# then back to

All Selections (for 21 tray only)”. At the position

you wish to set price when you press 4 and enter

the display will show “#.##” or current price set.

Press key “2” to increase the vend price or key “3”

to decrease the vend price. With the display

showing the vend price you require, press key “4”

to save.

“View PL Assignments”- This function

will only display when EXE in the

“Coke Factory Setup” is turned on.

This function allows the user to see which

selections are assigned to which price lines. Even

if price holding is turned off, this menu will show

what the price line assignments will be when price

holding mode is enabled. To enter this menu press

key 4. Press key 2 to scroll through the price lines

0-100. Press key 1 to exit menu.

“View PL Value”- This function will

only display when EXE in the “Coke

Factory Setup” is turned on.

This menu allows the user see the value of each

Price line held by the EXE coin mech. In order to

14 of 97

Page 16

see this value, the “Display Price” feature on the

EXE coin mech must be turned on.

Note: If no price is programmed in the EXE coin

mech for the requested price line, or if the “Display

Price” feature is not turned on in the Coin Mech

this menu will show “not available”. Enter this

menu by pressing key 4. Press key 2 or key 3 to

select the desired price line. Press key 4, the

display will show “requesting,,,”. After the EXE

Coin Mech has responded with the value of the

price line, it will be shown. If the EXE CM does

not respond with the value, then “not available” will

be shown. Press key 2 or 3 to select another price

line or press 1 to exit menu.

“Quick Payback”- This function will

only display when EXE in the “Coke

Factory Setup” is turned on.

This menu allows the user to set the VMC to pay

back change immediately after a vend is

requested. With this option set, the price of the

vend is always deducted from the available credit

after a selection is made, even if the vender fails to

deliver the selected item. To enter this menu press

key 4. The current setting will display as “Quick

Payback; On or “Quick Payback Off”. Press key 2

to select the desired mode ON or OFF. Press key

4 to confirm. Press key 1 to exit menu.

“StS Programming” – SPACE TO SALES

ROUTINE

This function allows you to change the space to sale

settings. Press key number 4 and “Option #” or

“Custom StS” will show on the display, which indicates

the current space to sales option. For the 7 options

available, see list below. Press key number 2 to scroll

through the options. Press key number 4 with the

desired option showing on the display to save that

option and return to “StS Programming”.

Space to Sales Options:

“Option 1” 1 to 1 = Columns are assigned to

selections with the same number.

“Option 2” Tray = Full tray assigned.

Example: selections A1 thru A9

vend from columns A1 thru A9

sequentially.

“Option 3” Half Tray = Half tray assigned.

Example: selections A1 thru A5

vend from columns A1 thru A5

sequentially and selections A6

thru A9 vend from columns A6

thru A9 sequentially.

“Option 4” Groups of 3 = Groups of 3

columns are assigned sequentially

to work with associated selections.

Example: selections A1 thru A3

vend from columns A1 thru A3

sequentially.

“Option 5” Combined groups of 2 & 3 =

Selection grouping per tray will be

assigned columns 1 & 2; 3 & 4; 5 &

6; 7, 8, & 9 working with associated

selections.

“Option 6” Combined groups of 3 = Selection

grouping per tray will be assigned

columns 1, 2, & 3; 4 & 5; 6 & 7; 8 &

9 working with associated

selections.

“Custom StS” Custom space to sales = Allows

you to assign columns in blocks

working with associated

selections.

With “Custom StS” showing, press key number 4

and “Clear Settings?” will show on display. Press

key number 4 and wait a few seconds will clear the

current space to sale settings. Press key number 1

will return to “Custom StS”. Press key number 4

and wait a few seconds will show “Selection A1”

alternating with columns assigned to blocks. Press

key number 4 will show “First?A1” or the individual

selection to start a block. Press key number 3 to

scroll to “First?E9” or the largest selection available.

Press key number 4 will show “Last?A1” or the last

column for custom space to sales blocks. Press key

number 2 will show “Last?A1” or the largest column for

custom space to sales blocks available. Press key

number 4 will show “Save Setting?” Press key number

4 will save the new settings.

* “Config Switches” - MACHINE

CONFIGURATION

This function allows the user to access and change the

programming of the following machine configuration

settings. Note: This routine is lockable when using a

data collection device. If you press key number 4 and

the display shows “Locked Menu”, this means

configuration setting changes will not be allowed. If

“Config 1” is displayed, then configuration setting

changes will be allowed. “Locked Menu” can only be

enabled or disabled through DEX interrogation. If

“Config 1” is displayed, the listed settings are available.

Note: You must press key number 4 with the

configuration code displayed if you wish to enter the

edit mode. The “0” or “1” will be flashing to

acknowledge you are in the edit mode.

IMPORTANT: All machine configuration codes are

disabled coming from the factory (Config # 0).

Config 1 - Configuration Switch 1 - Multi-Price

Setting Mode

This code is used to enable the single price

mode “Config 1 0” or multi-price mode “Config

1 1”. Press key number 4 and “Config 1 #” will

be displayed, with the “#” flashing. Press key

numbers 2 or 3 to scroll between “Config 1 0”

15 of 97

Page 17

and “Config 1 1”. Press key number 4 with the

display flashing the setting you wish to use.

Press key number 1 to return to “Config 1”.

Press key number 2 to scroll to “Config 2”.

Config 2 - Configuration Switch 2 - Optional

Features Enable

This code is used to allow (Config 2 1) the

following optional features to be displayed and

enabled: “Lighting Control”, “Select Discount”,

“Over-ride Switch”, “Select Block 1”, and “Select

Block 2”. Press key number 4 and “Config 2 #”

will be displayed with the # flashing. Press key

numbers 2 or 3 to scroll between “Config 2 0”

and “Config 2 1”. Press key number 4 with the

display flashing the setting you wish to use.

Press key number 1 to return to “Config 2”.

Press key number 2 to scroll to “Config 3”.

Config 3 - Configuration Switch 3 - POS

Message

This code is used to disable the point of sale

message. Config 3 0 = enabled, Config 3 1 =

disabled. Press key number 4 and “Config 3 #”

will be displayed, with the “#” flashing. Press

key numbers 2 or 3 to scroll between “Config 3

0” and “Config 3 1”. Press key number 4 with

the display flashing the setting you wish to use.

Press key number 1 to return to “Config 3”.

Press key number 2 to scroll to “Config 4”.

Config 4 - Configuration Switch 4 - Automatic

Viewing of Historical Sales and Cash

Accounting, Error Codes or No Error Codes

This code is used to enable viewing of historical

sales, historical cash, Error Codes or No Errors

automatically when the door is opened. To

enable automatic viewing option enter “Config

1”; to disable enter “Config 4 At “Config 4 0”

Error Codes or No Errors automatically

displays when the door is open. Press key

number 4 and “Config 4 #” will be displayed,

with the “#” flashing. Press key number 2 or 3

to scroll between “Config 4 0” and “Config 4 1”.

Press key number 4 with the display flashing

the setting you wish to use. Press key number

1 to return to “Config 4”. Press key number 2

to scroll to “Config 5”.

Config 5 - Configuration Switch 5 – Door

Switch Reset Status

This code is used to reset all interval data when

the door switch is cycled and at least one data

register is read via the display when set at

“Config 5 1” or to reset all interval data only

when the “RESET” command is received via

handheld or portable computer when set at

“Config 5 0”. Press key number 4 and “Config 5

#” will be displayed, with the “#” flashing. Press

key numbers 2 or 3 to scroll between “Config 5

0” and “Config 5 1”. Press key number 4 with

the display flashing the setting you wish to use.

Press key number 1 to return to “Config 5”.

Press key number 2 to scroll to “Config 6”.

Config 6 - Configuration Switch 6 - Reserved

this code is reserved for future use. Press key

number 2 to scroll to “Config 7”.

Config 7 - Configuration Switch 7 - Save

Credit

This code is used to determine how long a

credit will be saved. C7 0 will save the credit

for five minutes. Config 7 1 will save the credit

indefinitely. Press key number 4 and “Config 7

#” will be displayed, with the “#” flashing. Press

key number 2 or 3 to scroll between Config 7 0

and Config 7 1. Press key number 4 with the

display flashing the setting you wish to use.

Press key number 1 to return to “Config 7”.

Press key number 2 to scroll to “Config 8”.

Config 8 - Configuration Switch 8 - Force Vend

This code is used to determine escrow to

select or escrow to price. Config 8 0 will set

vender to escrow to select and Config 8 1 will

set vender to escrow to price. Press key

number 4 and “Config 8 #” will be displayed,

with the “#” flashing. Press key number 2 or 3

to scroll between Config 8 0 and Config 8 1.

Press key number 4 with the display flashing

the setting you wish to use. Press key number

1 to return to “Config 8”. Press key number 2

to scroll to “Config 9”.

Config 9 - Configuration Switch 9 - Multi Vend

This code is used to allow multiple vends

without re-depositing funds. Config 9 0 will not

allow multiple vends and Config 9 1 will allow

multiple vends. Press key number 4 and

“Config 9 #” will be displayed, with the “#”

flashing. Press key number 2 or 3 to scroll

between Config 9 0 and Config 9 1. Press key

number 4 with the display flashing the setting

you wish to use. Press key number 1 to return

to “Config 9”. Press key number 2 to scroll to

“Config 10”.

Config 10 - Configuration Switch 10 - Bill

Escrow Inhibit

This code is used to allow last bill that meets or

exceeds maximum vend price to be held in

escrow. Config 10 0 will escrow bill and Config

10 1 will not escrow bill (or stack the bill). Press

key number 4 and “Config 10 #” will be

displayed, with the “#” flashing. Press key

16 of 97

Page 18

number 2 or 3 to scroll between Config 10 0

and Config 10 1. Press key number 4 with the

display flashing the setting you wish to use.

Press key number 1 to return to “Config 1 0”.

Press key number 2 to scroll to the next

configuration code. Press key number 1 to

return to “Config Switches”. Press key number

2 will scroll to next routine.

*”Correct Change” - CORRECT CHANGE

ONLY CONTROL ROUTINE

This function is used to allow consumer overpay, set a

correct change value, and set an unconditional

acceptance value. Press key number 4 will enter

“ConsumerOverpay#”.

“ConsumerOverpay #” - Allow Consumer

Overpay

This function allows the vender to vend with the

risk of not being able to return the full amount of

change. This function has to be turned on to be

able to allow consumer overpay. Press key

number 4 and display will show

“ConsumerOverpay #”, where “#” is flashing.

“ConsumerOverpay1” will allow consumer

overpay (customer could potentially be

shortchanged) and “ConsumerOverpay0” will

not allow consumer overpay (will not allow

customer to be shortchanged). Press key

number 2 or 3 to scroll between ”

ConsumerOverpay0” and

“ConsumerOverpay1”. Press key number 4 with

the display blinking the setting you wish to use.

Display will return to “ConsumerOverpay#”.

Press key number 2 to scroll to “Corr Chg

value”.

“Corr Chg Value” - Correct Change Value

This is the function that the control board will

use to set a value which will turn on the

correct change indicator. Note: If “Uncond

Accept” is set, the “Corr Chg Value” should

be equal to or less than the “Uncond

Accept”. Note: If the value set is 00.00, the

correct change indicator will never come on.

If the controller determines that it cannot return

the exact amount of the correct change value or

any value less than it, then the indicator will be

turned on. Press key number 4 and the display

will show “##.##’. Press key number 2 or 3 to