Page 1

5900333

RR

TM

Optipay BV

DBV-301 Bill Validator

Operation and Maintenance Manual

(Revision 1)

Includes configuration setup using a Palm Pilot

Setting Module

May 05

1-800-628-8363

RR

JCM Part Number 980-000103.Rev. 1

5900333

Page 2

JCM is a registered trademark of JCM American Corporation. All other product names mentioned herein may be

registered trademarks or trademarks of their respective companies. Furthermore,

in each case throughout this publication.

™

, ® and © are not always mentioned

Page 3

Optipay™ BV

Table of Contents

TOC

Page

1 GENERAL INFORMATION...................................................................................1-1

Model and Type Classification ................................................................................... 1-1

Precautions .................................................................................................................. 1-2

User cautions ............................................................................................................................1-2

Component Names...................................................................................................... 1-3

General Specifications................................................................................................ 1-4

Retrieving Bills ............................................................................................................ 1-5

Cabling .........................................................................................................................1-6

Dimensions .................................................................................................................. 1-7

Cash Box Label............................................................................................................ 1-8

DIP Switch Label.......................................................................................................... 1-8

Country Codes............................................................................................................. 1-9

2 INSTALLATION / OPERATION ............................................................................2-1

Installation....................................................................................................................2-1

Mounting the unit ....................................................................................................................... 2-1

Removing the bill guide .............................................................................................................2-1

Input/Output Circuitry ................................................................................................. 2-2

Connector Pin Assignment ........................................................................................ 2-2

DIP Switch Settings..................................................................................................... 2-3

Operational Flowchart................................................................................................. 2-4

Clearing a Bill Jam ...................................................................................................... 2-5

When a bill is jammed in the Stacker section: ........................................................................... 2-5

When a bill is jammed in the Validator section: ......................................................................... 2-5

Preventive Maintenance.............................................................................................. 2-5

Cash box Preventive Maintenance (P/M).................................................................................. 2-6

3 MDB PROTOCOL .................................................................................................3-1

4 DISASSEMBLY.....................................................................................................4-1

Circuit Board Disassembly......................................................................................... 4-1

Removing the CPU and Power Supply boards ......................................................................... 4-1

Pusher Mechanism Disassembly............................................................................... 4-3

Timing Belt removals .................................................................................................................4-3

Removing the drive and stack motor ......................................................................................... 4-3

Upper Guide Disassembly .......................................................................................... 4-5

Sensor board removal ...............................................................................................................4-5

O-ring removal...........................................................................................................................4-6

Lower Guide Disassembly.......................................................................................... 4-6

MAG board removal ..................................................................................................................4-6

5 WIRING DIAGRAMS.............................................................................................5-1

DBV-301 Interconnect ................................................................................................. 5-1

DBV-301 Interconnect Continued.............................................................................................. 5-2

6 TROUBLE SHOOTING .........................................................................................6-1

Introduction.................................................................................................................. 6-1

Failure Classifications ................................................................................................ 6-1

Test Mode Entry Failure Flowchart ............................................................................ 6-1

5900333 © 2005 JCM-American Corporation

i

Page 4

Optipay™ BV

Table of Contents

Continued

Test mode entry failure flowchart (continued)............................................................................6-2

Incorrect initial operation flowchart............................................................................................ 6-3

Rejected or poorly accepts bills flowchart .................................................................................6-4

Improper bill transfer flowchart ..................................................................................................6-5

Page

7 FLASH MEMORY DOWNLOAD ...........................................................................7-1

Tool Requirements ...................................................................................................... 7-1

Requirements ............................................................................................................................7-1

Information Menu Selection ....................................................................................... 7-1

Diagnostics Menu Selection....................................................................................... 7-3

Program Download Menu Selection .......................................................................... 7-3

Selecting a Download ROM ........................................................................................ 7-3

Accepting Log Menu Selection .................................................................................. 7-4

DIP Switch Settings..................................................................................................... 7-6

Test mode set-up ....................................................................................................................... 7-6

Setting the test mode switches..................................................................................................7-6

Test Mode Details ........................................................................................................ 7-8

Acceptor Sensor Test Details ....................................................................................................7-8

Stacker SensorTest Details .......................................................................................................7-8

DIP Switch Logic Test................................................................................................................7-9

Error Codes.................................................................................................................. 7-9

Error Code Table ....................................................................................................................... 7-9

Reject Code Table ................................................................................................................... 7-10

Sensors, Circuit Boards, Motors and Cash Box Locations....................................7-11

8 EXPLODED VIEWS/PARTS LISTS ......................................................................8-1

DBV Primary Component Parts.................................................................................. 8-1

DBV Primary Parts List ............................................................................................... 8-2

Frame and Upper/Lower Guide Exploded View........................................................ 8-2

Frame and Upper/Lower Guide Parts List................................................................. 8-3

Pusher Mechanism Assembly Exploded View ......................................................... 8-5

Pusher Mechanism Assembly Exploded View Parts List ........................................ 8-6

Cash Box Unit Exploded View.................................................................................... 8-7

Cash Box Unit Parts List............................................................................................. 8-8

9 INDEX....................................................................................................................9-1

5900333 © 2005 JCM-American Corporation

ii

Page 5

Optipay™ BV

List of Figures

LOF

Figure 1-1 Optipay™ BV DBV-301 Bill Validator ................................................... 1-1

Figure 1-2 Precautionary Symbols......................................................................... 1-2

Figure 1-3 Bill Validator Top and Rear View.......................................................... 1-3

Figure 1-4 Bill Validator Bottom and Right Side View............................................ 1-3

Figure 1-5 Initial Bill Retrieval Steps ...................................................................... 1-5

Figure 1-6 Final Bill Retrieval Steps....................................................................... 1-5

Figure 1-7 Cable Connector Locations .................................................................. 1-6

Figure 1-8 Bill Validator Dimensions...................................................................... 1-7

Figure 1-9 Cash Box Front Label........................................................................... 1-8

Figure 1-10 DIP Switch Side Label .......................................................................... 1-8

Figure 2-1 Bill Validator Mounting Locations ......................................................... 2-1

Figure 2-2 Bill Validator Removal .......................................................................... 2-1

Figure 2-3 Bill Guide Removal ............................................................................... 2-1

Figure 2-4 Bill Validator-to-Controller I/O Circuit and Pin-out Identification

Schematic............................................................................................. 2-2

Figure 2-5 Bill Validator’s Plug Interconnect Pin Assignment Diagram ................. 2-2

Figure 2-6 Typical Interconnect Plug Pin Assignment Diagram............................. 2-3

Figure 2-7 DIP Switch Location ............................................................................. 2-3

Figure 2-8 Bill Validator Operational Flowchart ..................................................... 2-4

Figure 2-9 Clearing a Jammed Stacker Bill ........................................................... 2-5

Figure 2-10 Clearing a Jammed Validator ............................................................... 2-5

Figure 2-11 Upper Guide and Stacker Sensors and Rollers.................................... 2-5

Figure 2-12 Lower Guide Sensors and Rollers........................................................ 2-5

Figure 2-13 Cash Box Sensors................................................................................ 2-6

Figure 4-1 Bill Validator Mounting Locations ......................................................... 4-1

Figure 4-2 Lower Guide Removal .......................................................................... 4-1

Figure 4-3 Validator Cover Removal...................................................................... 4-1

Figure 4-4 Validator Face Plate Removal .............................................................. 4-1

Figure 4-5 Face Plate Rear Mounting View ........................................................... 4-2

Figure 4-6 Screw and Connector Removal and Circuit Board Access .................. 4-2

Figure 4-7 CPU Board Connector Removals......................................................... 4-2

Figure 4-8 CPU and Power Supply Board Connector Separation ......................... 4-2

Figure 4-9 Side Guide Removal............................................................................. 4-3

Figure 4-10 Front Guide Removal ........................................................................... 4-3

Figure 4-11 Pusher Mechanism Removal................................................................ 4-3

Figure 4-12 Timing Belt Removal ............................................................................ 4-3

Figure 4-13 Pusher Shaft C-Clip Ring Removal ...................................................... 4-4

Figure 4-14 Pusher Plate Removal.......................................................................... 4-4

Page

5900333 © 2005 JCM-American Corporation

iii

Page 6

Optipay™ BV

List of Figures

Continued

Figure 4-15 Shaft and Sleeve Removal ................................................................... 4-4

Figure 4-16 Retaining Screw Removals .................................................................. 4-4

Figure 4-17 Motor Guide Removal........................................................................... 4-4

Figure 4-18 Drive and Stack Motor Removal........................................................... 4-5

Figure 4-19 Upper Guide Removal .......................................................................... 4-5

Figure 4-20 Upper Guide Gear Removals ............................................................... 4-5

Figure 4-21 Sensor Board Removal ........................................................................ 4-5

Figure 4-22 Flexible Ribbon Cable Removal ........................................................... 4-5

Figure 4-23 Short Shaft and Gear Removal ............................................................ 4-6

Figure 4-24 Lower Long Shaft and Gear Removal .................................................. 4-6

Figure 4-25 Upper Long Shaft and Gear Removal .................................................. 4-6

Figure 4-26 O-Ring Removals ................................................................................. 4-6

Figure 4-27 Lower Bill Guide Removal .................................................................... 4-6

Figure 4-28 MAG Board Removal............................................................................ 4-7

Figure 4-29 Disconnect MAG Board Connector ...................................................... 4-7

Figure 5-1 DBV-301 Bill Validator Interconnect Wiring Diagram (Part 1) .............. 5-1

Figure 5-2 DBV-301 Bill Validator Interconnect Wiring Diagram (Part 2) .............. 5-2

Figure 6-1 DBV-301 Bill Validator Test Mode Failure Flow Chart

Diagram (Part 1) ................................................................................... 6-1

Figure 6-2 DBV-301 Bill Validator Test Mode Failure Flow Chart

Diagram (Part 2) ................................................................................... 6-2

Figure 6-3 DBV-301 Bill Validator Incorrect Initial Operation Flow Chart

Diagram ................................................................................................ 6-3

Figure 6-4 DBV-301 Bill Validator Rejects or Poorly Accepts Bills Flow Chart

Diagram ................................................................................................ 6-4

Figure 6-5 DBV-301 Bill Validator Improper bill transfer Flow Chart Diagram ....... 6-5

Figure 7-1 Typical M100/500 Series Palm Pilot® Handheld & Software ............... 7-1

Figure 7-2 PSP-03 Application Selection............................................................... 7-1

Figure 7-3 Settings Menu Selection....................................................................... 7-2

Figure 7-4 Information Menu Selection.................................................................. 7-2

Figure 7-5 Typical Configuration Settings.............................................................. 7-2

Figure 7-6 Acceptor Mode Selection...................................................................... 7-2

Figure 7-7 Acceptor Screen Functions .................................................................. 7-2

Figure 7-8 Returning to the Settings Screen.......................................................... 7-2

Figure 7-9 Diagnostics Mode Selection ................................................................. 7-3

Figure 7-10 Diagnostics Screen Functions .............................................................. 7-3

Figure 7-11 Program Download Menu Selection ..................................................... 7-3

Figure 7-12 Program Download Screen .................................................................. 7-3

Figure 7-13 ROM Select Screen.............................................................................. 7-4

Page

5900333 © 2005 JCM-American Corporation

iv

Page 7

Optipay™ BV

List of Figures

Continued

Figure 7-14 Download Transfer Screen................................................................... 7-4

Figure 7-15 Download Send Command................................................................... 7-4

Figure 7-16 Accepting Log Mode Selection ............................................................. 7-4

Figure 7-17 Accepting Log Menu............................................................................. 7-5

Figure 7-18 Viewing Record Log Data..................................................................... 7-5

Figure 7-19 Viewing Specific Log Data 1................................................................. 7-5

Figure 7-20 Viewing Page Two Log Data ................................................................ 7-5

Figure 7-21 Viewing Page Three Log Data.............................................................. 7-5

Figure 7-22 Viewing Page Four Log Data................................................................ 7-6

Figure 7-23 Sensors, Circuit Boards, and Motor Locations Diagram..................... 7-11

Figure 8-1 DBV Dual Bill Validator Primary Component Parts Exploded View

Diagram ................................................................................................ 8-1

Figure 8-2 Frame and Upper/Lower Guide Exploded View Diagram..................... 8-2

Figure 8-3 Pusher Mechanism Assembly Exploded View Diagram....................... 8-5

Figure 8-4 Cash Box Unit Exploded View.............................................................. 8-7

Page

5900333 © 2005 JCM-American Corporation

v

Page 8

Optipay™ BV List of Figures

THIS PAGE INTENTIONALLY LEFT BLANK

5900333 © 2005 JCM-American Corporation

vi

Page 9

Optipay™ BV

List of Tables

LOT

Table 1-1 Model Number Specifications ................................................................1-2

Table 1-2 Type Number Specifications..................................................................1-2

Table 1-3 DBV-301 Bill Validator Specifications....................................................1-4

Table 1-4 Cash Box Label Features ......................................................................1-8

Table 1-5 DIP Switch Label Features ....................................................................1-8

Table 1-6 Country Codes.......................................................................................1-9

Table 2-1 Connector Pin Designations ..................................................................2-2

Table 7-1 DIP Switch 1 Test Mode Settings ..........................................................7-6

Table 7-2 Acceptor Sensor Test Detail Listing ......................................................7-8

Table 7-3 Stacker Sensor Test Detail Listing ........................................................7-8

Table 7-4 Resulting DIP Switch Setting LED Flash Details ...................................7-9

Table 7-5 Error Code Blink Listing .........................................................................7-9

Table 7-6 Reject Code Listing .............................................................................7-10

Table 8-1 DBV Primary Parts List ..........................................................................8-2

Table 8-2 Frame and Upper/Lower Guide Parts List .............................................8-3

Table 8-3 Frame and Upper/Lower Guide Parts List .............................................8-6

Table 8-4 Cash Box Unit Parts List........................................................................8-8

Page

5900333 © 2005 JCM-American Corporation

vii

Page 10

Optipay™ BV List of Tables

THIS PAGE INTENTIONALLY LEFT BLANK

5900333 © 2005 JCM-American Corporation

viii

Page 11

Optipay™ BV

DBV-301 Bill Validator

Section 1

1 GENERAL INFORMATION

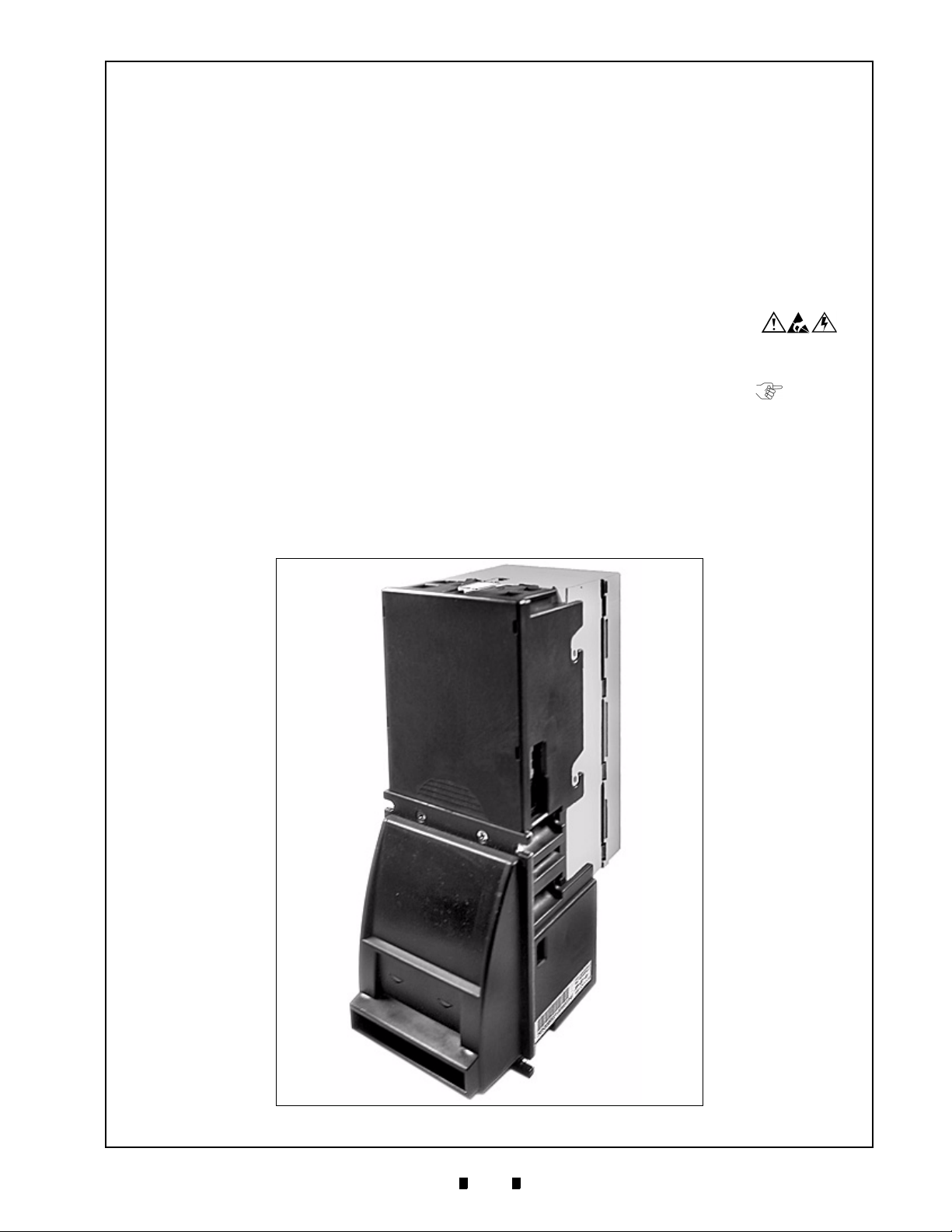

This section provides a general overview of the

advantages and options of the Optipay

DBV-301 Bill Validator pictured in Figure 1-1 .

This first section is designed to help you navigate

through this manual with ease and contains the following information:

•

Model and Type Classifications

•

Precautions

•

Component Names

•

General Specifications

•

Retrieving Bills

•

Cabling

•

Dimensions

•

Country Codes

™

BV

In order to make operation of this device and make

navigation within this manual easier, the following

illustrations were used within the text:

•

Safety instructions, which need to be

observed in order to protect the operators and

equipment, have been written in bold text and

have been given the pictographs:

•

Special Notes, which effect the use of the Bill

Validator, have been written in italic text and

have been given the pictograph:

•

Steps, requiring the operator to perform

specific actions are given sequential numbers

(1., 2., 3. etc.).

Model and Type Classification

Tables 1-1 and 1-2 provide definitions for the

model and type number codes found on the unit.

Figure 1-1 Optipay™ BV DBV-301 Bill Validator

5900333 © 2005 JCM-American Corporation

1-1

Page 12

Section 1 Optipay™ BV General Information

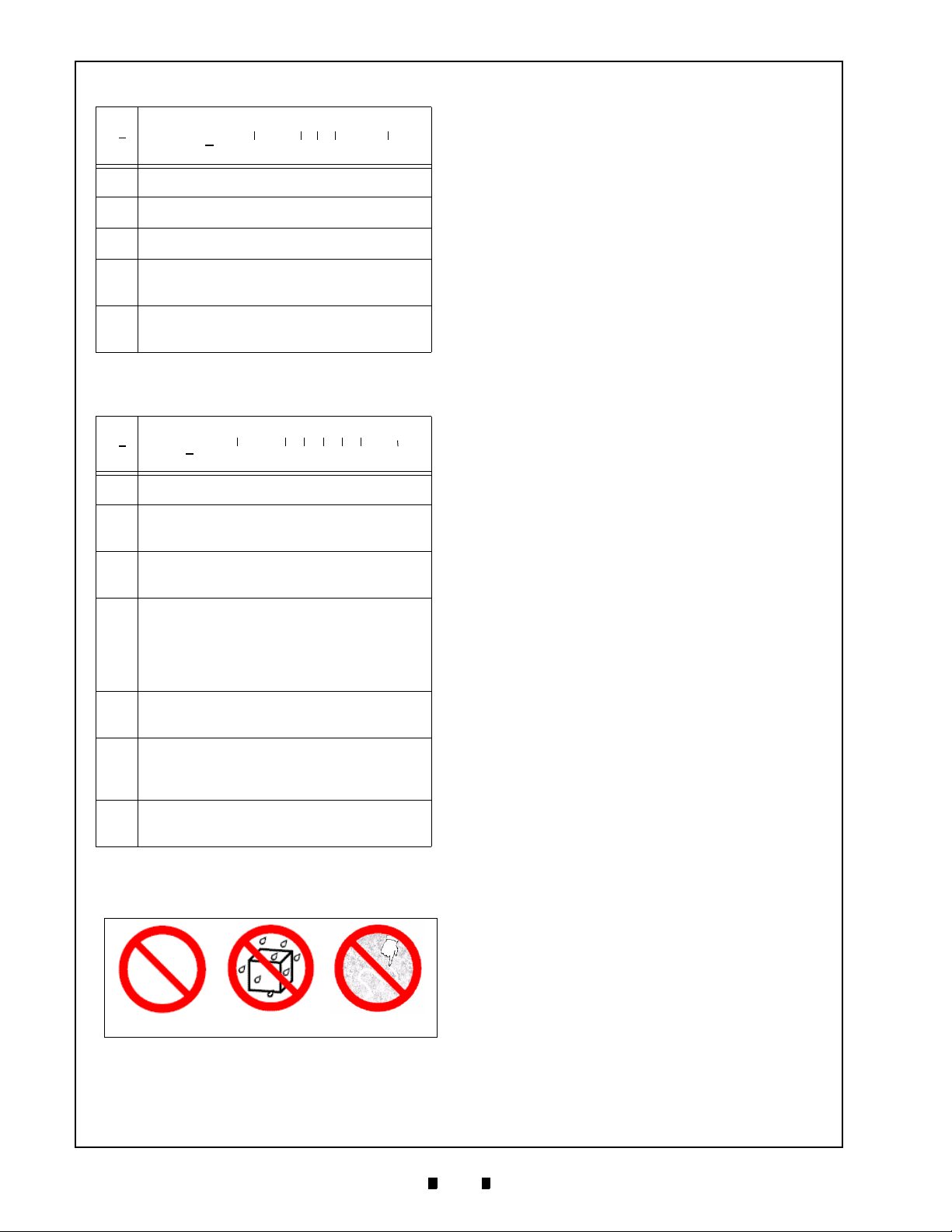

Table 1-1: Model Number Specifications

o

N

(1) Model Name

(2) Series Name

(3) CPU Board Type 0 : JCM Standard

(4) Power supply

(5) Stacker Type SU : Upward vertical

o

N

(1) Country Code

(2) Cash Box Capacity

(3) Faceplate Type

(4) Guide Width

(5) Cash Box Type

(6) Recycle Type (Optional)

(7) Interface Type

Model : DBV - 3 0 1 - SU

o

N

(1) (2)(3)(4) (5)

1 : 24 V DC

stacking

Table 1-2: Type Number Specifications

Type : * * * - * * * * * - D3

o

(1) (2)(3)(4)(5)(6) (7)

N

3 : 300 notes capacity

1 : JCM Standard

1 : 66 mm width

2 : 67 mm width

3 : 70 mm width

4 : 72 mm width

1 : Upward bill ejection box

0 : without recycle unit

1 : with recycle unit

D3 : ID-0D3 (MDB interface)

Precautions

1. (

Type 1

) Do not insert a torn, folded, or wet

bill, as this action may cause a bill jam inside

the unit.

2. (

Type 2

) Do not expose the unit to water.

The unit contains several precision electronic devices which can be damaged if

water or any liquid is sprayed or spilled into

the unit.

3. (

Type 3

) Do not install the unit into a dusty

environment. Dust may affect the sensor’s

performance.

User cautions

1. Be sure to turn the power off before plugging

or unplugging connectors.

2. Firmly close the unit’s transport path when

applying power.

3. When closing the units, ensure they click

into place. Make sure to open and close the

units gently, and take care that no dust or

other foreign objects enter when opening the

guides.

4. Do not allow inventory stock to endure high

temperature, high humidity or a dusty

environment.

5. Do not throw the unit or allow it to fall to the

ground.

6. If the bill validator is dirty due to dust, foreign objects, or other such debris adhering to

it, bill acceptance rate will degrade. Be sure

to clean the validator at least once a month.

Use a soft cloth to wipe dust from the magnetic head and the optical sensor. Never use

organic solvents, such as paint thinner or

benzene to clean the device. Use a soft cloth

to wipe dust from the rollers and belts.

7. Inserting worn or damaged bills may cause a

jam. Shuffle new bills well before inserting

them, otherwise they may stick to one other

and could cause a jam.

Type 1 Type 2 Type 3

Figure 1-2 Precautionary Symbols

Symbol definitions are as follows:

5900333 © 2005 JCM-American Corporation

1-2

Page 13

General Information Optipay™ BV Section 1

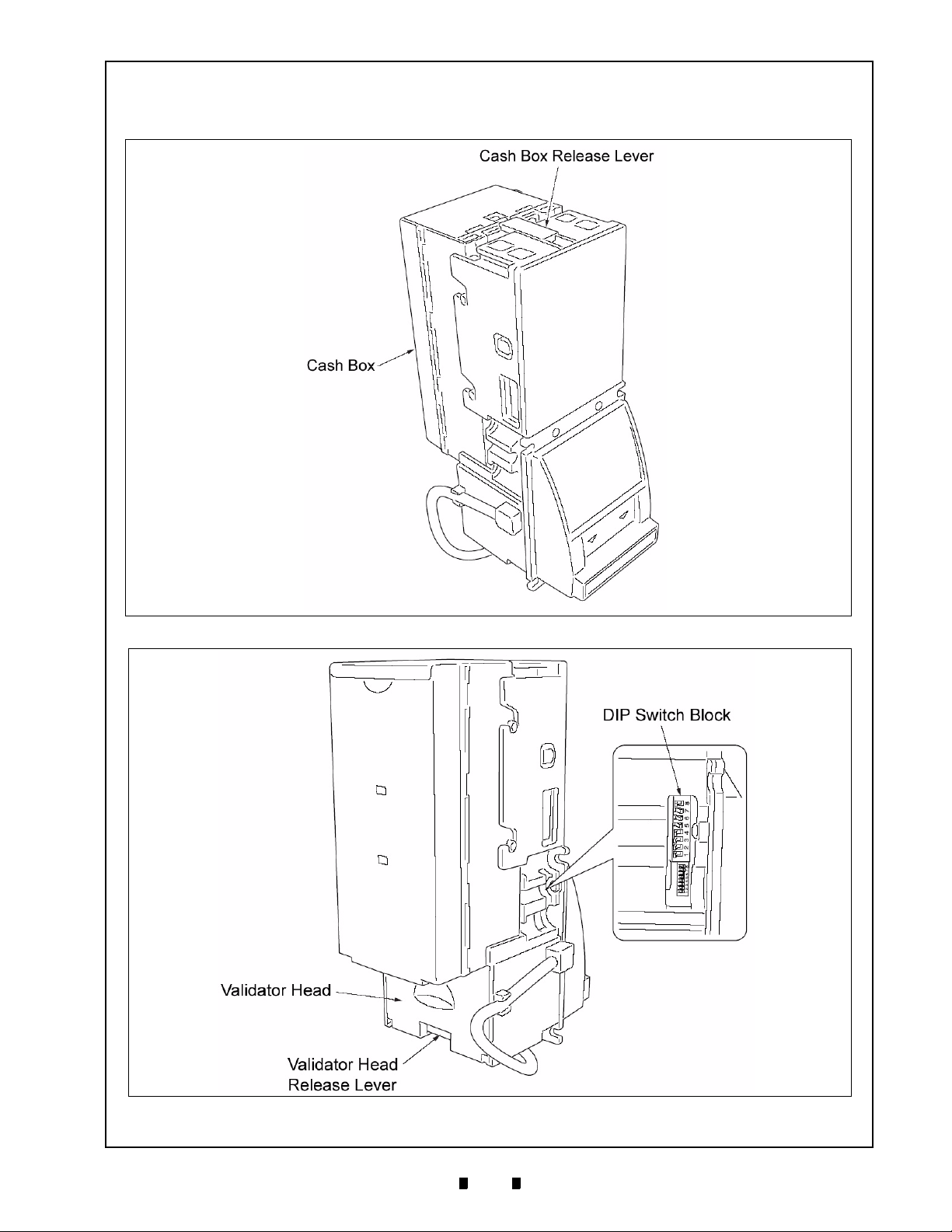

Component Names

Figure 1-3 and Figure 1-4 illustrate the primary DBV-301 component part names and locations.

Figure 1-3 Bill Validator Top and Rear View

Figure 1-4 Bill Validator Bottom and Right Side View

5900333 © 2005, JCM American, Corporation

1-3

Page 14

Section 1 Optipay™ BV General Information

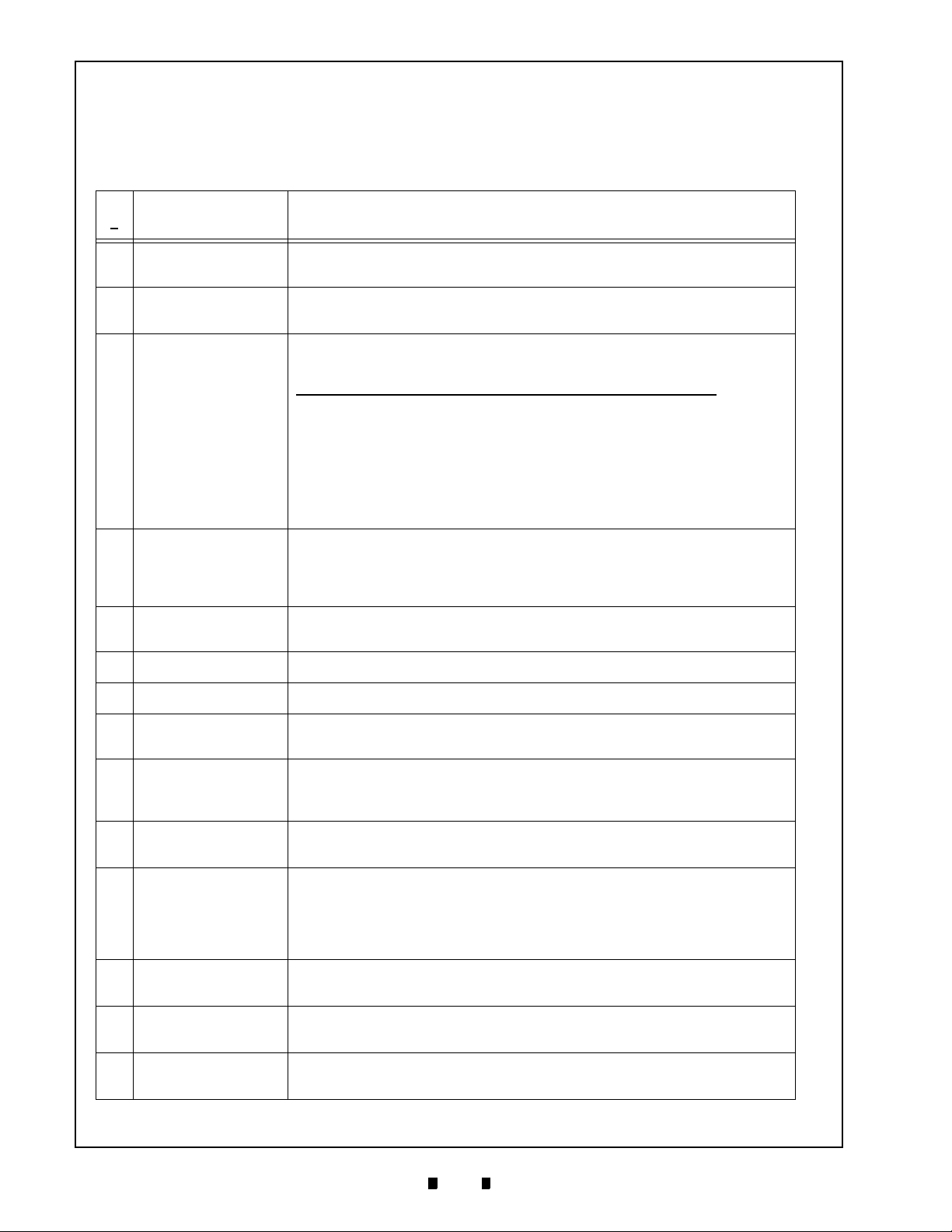

General Specifications

Table 1-3: lists the general specifications for the

Titan DBV-301 Bill Validator.

Table 1-3: DBV-301 Bill Validator Specifications

N

o

1 Acceptable

MODEL SPECIFICATION

Refer to the separate “Software Specifications”

Denominations:

2 Insertion Direc-

Refer to the separate “Software Specifications”

tions:

3 Acceptance Rate: Refer to the separate “Software Specifications”

The acceptance rate will be calculated as follows:

First acceptance number of sheets + Re-insertion acceptance number of sheets

*1 = Acceptance following subsequent re-insertions

Test bill total

Note: The following bill types are excluded:

a) Bills with excessive or poor magnetism or unclear graphics

b) Double (dual) notes

c) Worn, dirty, wet, torn or excessively wrinkled bills

d) Bills having folded corners or edges

e) Bills having the wrong cut dimensions or printing displacement

4 Processing speed: Approximately 2 seconds

(time from bill insertion to credit signal output)

Approximately 3 seconds

(time from bill insertion to bill stack completion)

5 Cash box:

a) Capacity: Approximately 300 bills

b) Ejection directions: Rear ejection

*1

x 100 (%)

6 Interface: MDB interface (photo coupler isolation)

7 Escrow: 1 Bill

8 Indication:

a) Indication LED (green LED at front side)

b) Condition LEDs (green, yellow and red LEDs at rear side)

9 Power supply: 24 V DC (±5%), 2.5 A

Correspondence to an MDB interface standard power supply is possi-

ble

10Power consumption

11Environmental con-

ditions:

a) Standby status: 0.2 A

b) Operation status: 0.4 A (0.9 A maximum)

a) Operational temperature: -15 °C to 60 °C

b) Operational humidity: 15 to 95% RH (no condensing)

c) Storage temperature: -20 °C to 60 °C

d) Storage humidity: 15 to 95% RH (no condensing)

e) Light disturbance: Direct sunlight should be avoided

12Outline dimensions: 4.11 in. (104.5 mm) Width, 9.58 in. (243.5 mm) Height, 6.10 in. (155

mm) Depth (with faceplate)

13Weight: Approximately 2.64 lbs. (1.2 kg)

14Mounting: Horizontal Mounting

(verify with your sales representative prior to selecting a final attachment angle)

5900333 © 2005 JCM-American Corporation

1-4

Page 15

General Information Optipay™ BV Section 1

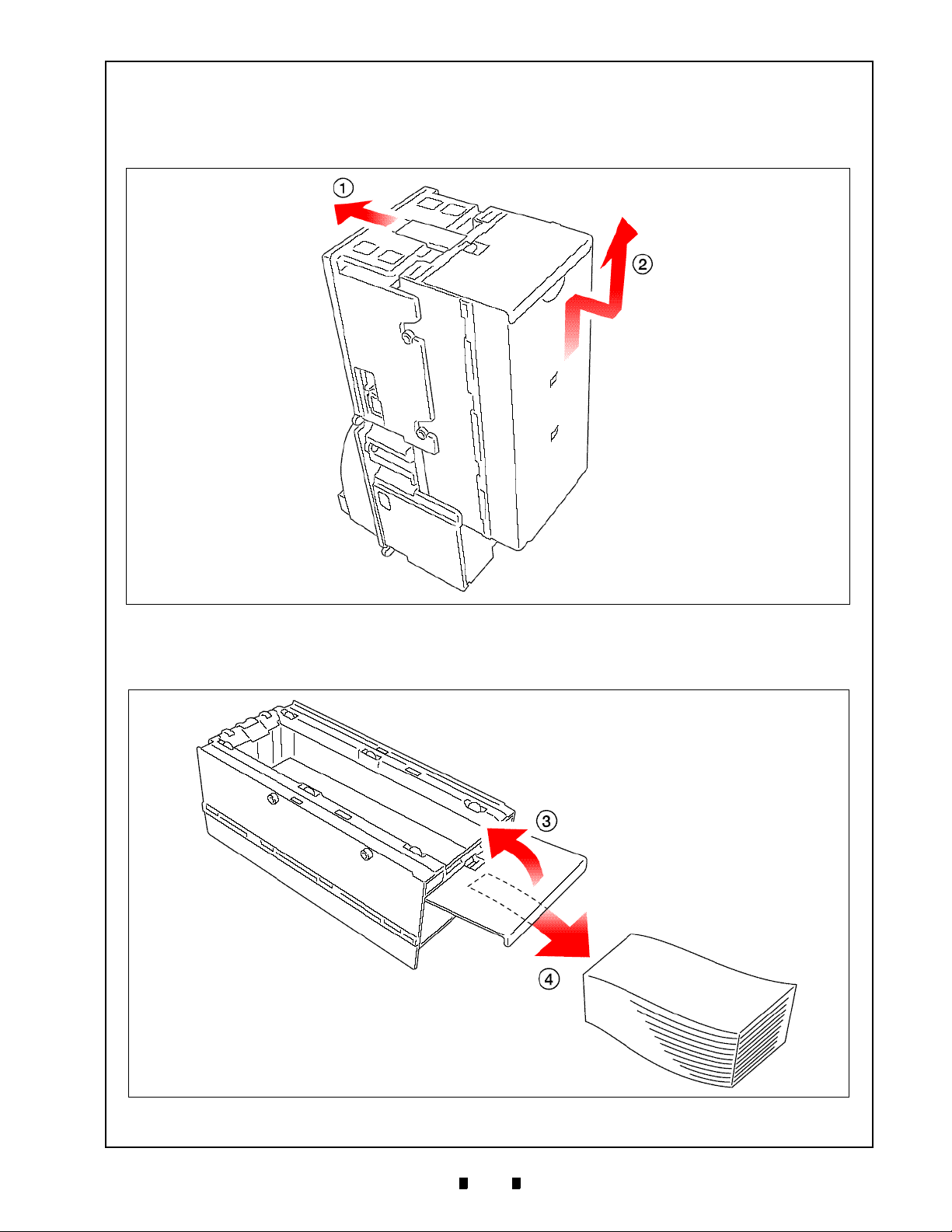

Retrieving Bills

1. Pull the cash box release lever in the arrow

c

direction illustrated in Figure 1-5 .

2. Lift the cash box in the

and remove it.

d

arrow direction

Figure 1-5 Initial Bill Retrieval Steps

3. Open the cash box cover in the

direction illustrated in Figure 1-6 .

e

arrow

4. Remove the bills in the f arrow direction.

Figure 1-6 Final Bill Retrieval Steps

5900333 © 2005 JCM-American Corporation

1-5

Page 16

1-6

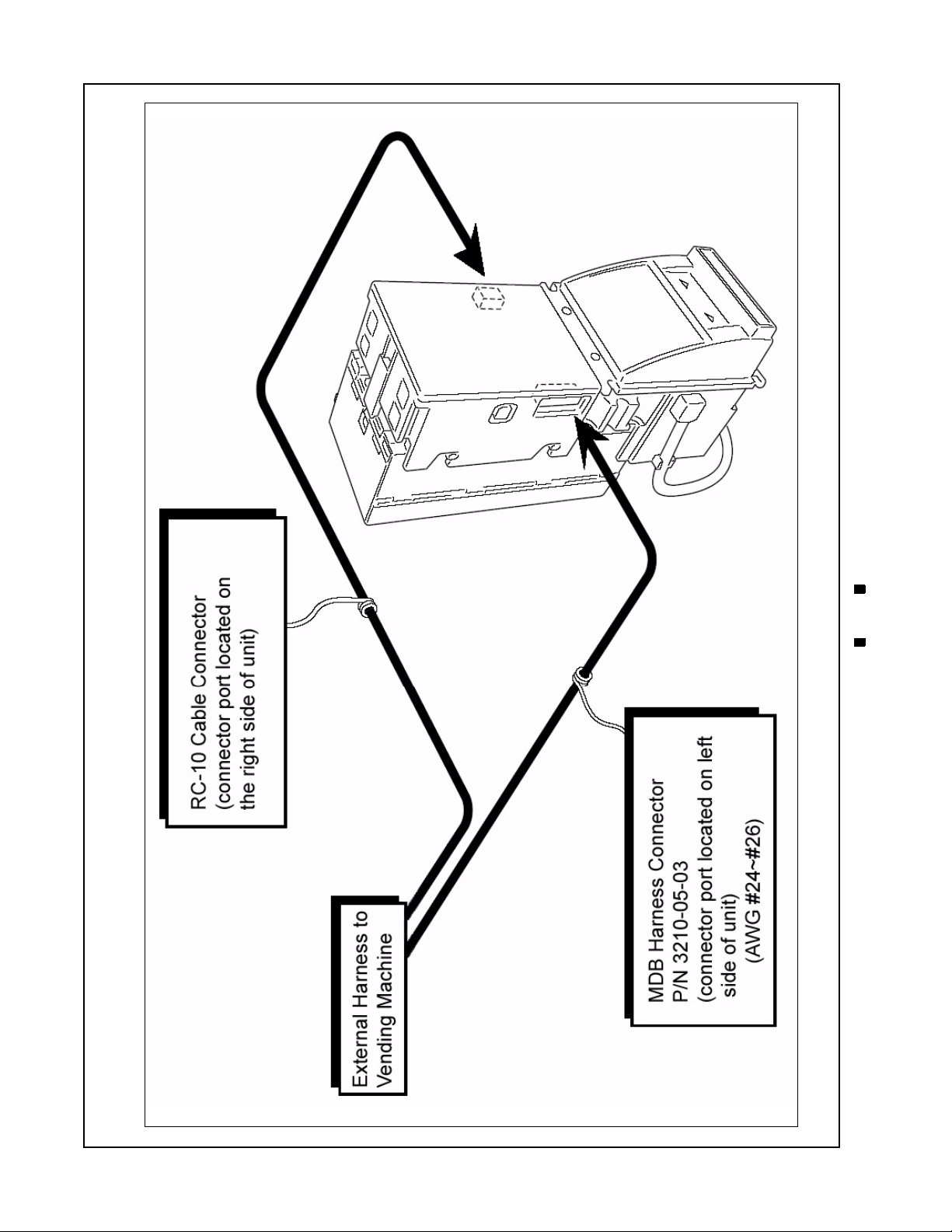

Figure 1-7 Cable Connector Locations

Section 1 Optipay™ BV Running H/F 1

Figure 1-7 illustrates the cabling connection locations for installing the DBV--301 Bill Validator.

Cabling

5900333 © 2005, JCM American, Corporation

Page 17

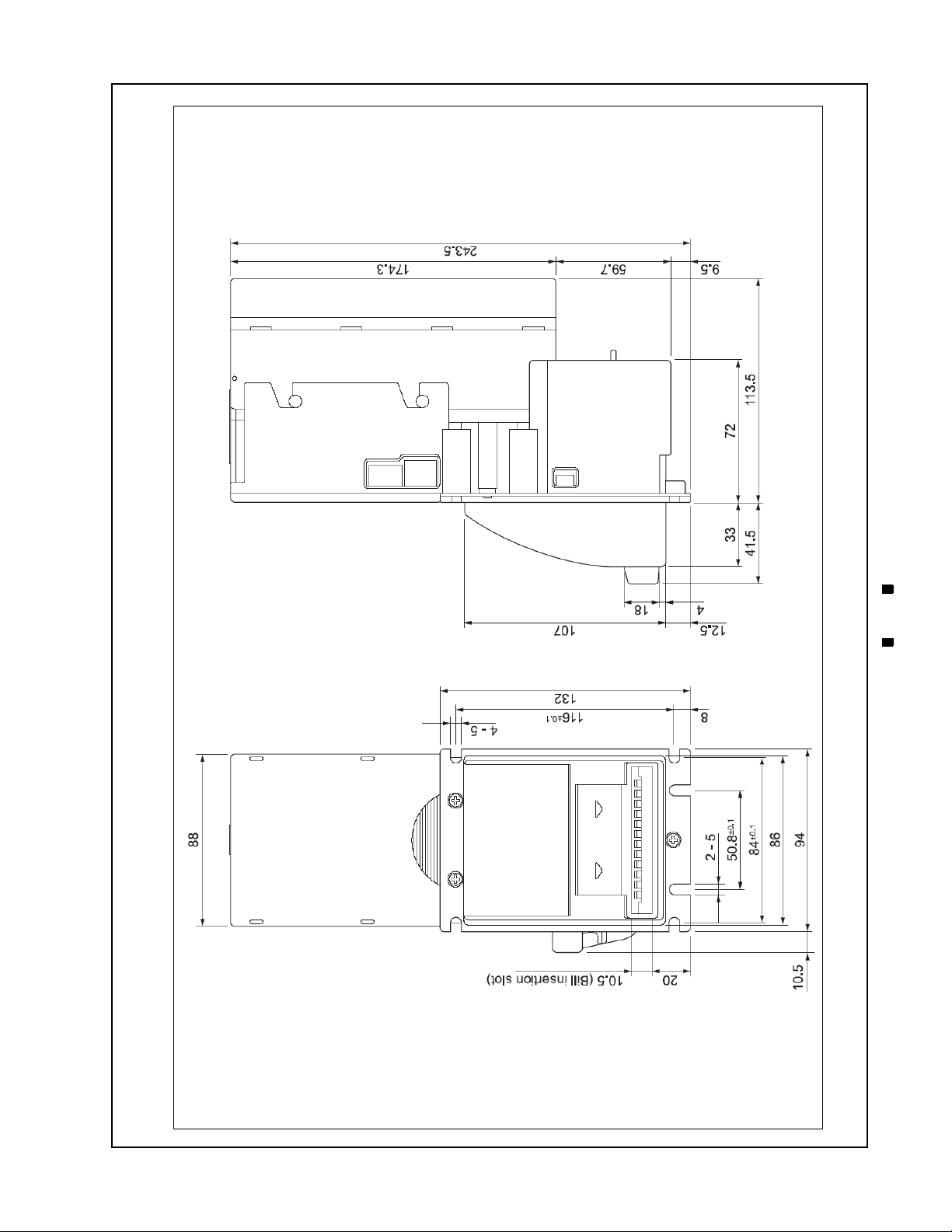

Figure 1-8 Bill Validator Dimensions

1-7

Dimensions

General Information Optipay™ BV Section 1

Figure 1-8 illustrates the relative dimensions of the DBV--301 Bill Validator.

5900333 © 2005, JCM American, Corporation

Page 18

Section 1 Optipay™ BV General Information

Cash Box Label

1

2

3

10

Table 1-4: Cash Box Label Features

1. Cash Box removal

step instruction

arrows

9

8

7

2. Diagnostic LED

Flash indication

columns label

3. Diagnostic LED

column color labels

4. Note path access

step instructions

5. Note path access

step instruction

arrows

above)

(related to #4

6. column labeling

Diagnostic LED

location listings

7. Diagnostic

Description column

8. Cash Box removal

step instructions

9. JCM contact

information

10. JCM Logo.

Table 1-5: DIP Switch Label Features

1. JCM Logo 4. Arrow addressing

actual position of

DIP Switches and I/

O header connector

locations

restricted to vertical

placement positioning)

(Label is

4

Figure 1-9 Cash Box Front Label

DIP Switch Label

1

2

3

2. JCM contact

information

6

5

Figure 1-10 DIP Switch Side Label

3. Diagnostic/Inhibit

DIP Switch position

label

5. External Validatorto-vending machine

header connector

6. Interface DIP Switch

Block switch position

label.

6

5

4

5900333 © 2005 JCM-American Corporation

1-8

Page 19

General Information Optipay™ BV Section 1

Country Codes

Table 1-6: Country Codes

Country Country Code

Antilles ANT

Argentine ARG

Australia AUS

Austria AUT

Austria AUT4

Barbados BRB

Belgium BEL

Botswana BWA

Brazil BRA

Bulgaria BGR

Canada CAN

Canada CAN

Chile CHL

China CHN

Colombia COL

Costa Rica CRI

Croatia HRV

Cyprus CYP

Czech Republic CZE

Denmark DNK

Estonia ESTE

Estonia EST2

European Union EUR

Finland FIN

France FRA

Germany DEU

Germany DEU1

Germany DEU2

Germany/Sweden DEU/SWE

Great Britain (England) GBR

Table 1-6: Country Codes (Continued)

Country Country Code

Great Britain (England) GBR-B

Great Britain/Gibraltar GBR/GBI

Great Britain/Isle Of Man GBR/MAN

Greece GRC

Greece GRC-B

Guatemala MGT

Honduras HND

Hong Kong HKG

Hungary HUN

Iceland ISL

India IND

Israel ISR

Italy ITA

Italy ITA8

Italy ITA9

Japan JPN

Kazakhstan KAZ

Kazakhstan KAZ1

Latvia LVA

Lithuania LTU

Malaysia MYS

Malaysia MYS1

Malta MLT

Mauritius MUS

Mexico MEX

Moldova MDA

Morocco MAR

Namibia NAM

Netherlands NLD

Netherlands NLD-B

New Zealand NZL

5900333 © 2005 JCM-American Corporation

1-9

Page 20

Section 1 Optipay™ BV General Information

Table 1-6: Country Codes (Continued)

Country Country Code

New Zealand NZL1

New Zealand NZL-B

North Ireland NIRL

Norway NOR

Norway NOR1

Peru PER

Peru PER1

Philippines PHL

Philippines PHL1

Poland POL

Poland POL1

Poland POL1-B

Portugal PRT

Qatar QAT

Republic Of Ireland IRL

Republic Of Korea KOR

Table 1-6: Country Codes (Continued)

Country Country Code

Switzerland CHE-B

Taiwan (Republic Of

TWN

China)

Tanzania TZA

Thailand THA

Trinidad & Tobago TTO

Ukraine UKR

Ukraine UKR1

United Arab Emirates ARE

United States USA

Uruguay URY

Uruguay URY1

Venezuela VEN

Venezuela VEN1

Venezuela VEN2

Venezuela VEN-B

Republic Of Korea KOR-B

Romania ROM

Russia RUS

Russia RUS-B

Saudi Arabia SAU

Singapore SGP

Singapore SGP-B

Slovakia SVK

Slovenia SVN

South Africa ZAF

Spain ESP

Sri Lanka LKA

Sweden SWE

Switzerland CHE

Switzerland CHE3

5900333 © 2005 JCM-American Corporation

1-10

Page 21

Optipay™ BV

DBV-301 Bill Validator

Section 2

2 INSTALLATION / OPERATION

This section provides installation and operation

instructions for the Optipay

Validator. The information within contains the following features:

•

Installation

•

Input/Output Circuits

•

Pin Assignment

•

Connector

•

DIP Switch Settings

•

Operation Flowchart

•

Clearing a Bill Jam

•

Preventive Maintenance

™

BV

DBV-301 Bill

Installation

Mounting the unit

Mount the DBV-301 Bill Validator as follows:

(See Figure 2-1).

Removing the bill guide

1. Remove the faceplate and the DBV-301 Bill

Validator (i.e., reverse the “Mounting the

unit” instructions previously referenced).

2. Remove the bill guide following the arrow

c

and d directional paths indicated in Fig-

ure 2-2.

Figure 2-1 Bill Validator Mounting Locations

1. Attach the faceplate and the bill insertion

guide using four M5 hexhead screws

2. Attach the DBV-301 and its faceplate using

four M3 hexhead screws and double flat

washers

d

.

c

.

Figure 2-2 Bill Validator Removal

3. Remove the bottom bill guide following the

e

arrow

Reverse the procedure to reinstall.

direction indicated in Figure 2-3.

Figure 2-3 Bill Guide Removal

5900333 © 2005 JCM-American Corporation

2-1

Page 22

Section 2 Optipay™ BV Installation / Operation

Input/Output Circuitry

Figure 2-4 illustrates the Bill Validator-to-Controller component schematic and interconnecting pin designation diagram.

Figure 2-4 Bill Validator-to-Controller I/O Circuit and Pin-out Identification Schematic

Connector Pin Assignment

Figure 2-5illustrates the Bill Validator’s plug interconnect pin assignment diagram and Table 2-1lists each

pin’s function.

Figure 2-5 Bill Validator’s Plug Interconnect Pin Assignment Diagram

Table 2-1 Connector Pin Designations

Pin No. Signal Name I/O

1V

2V

1 DC +24 V power

DD

1Ground

SS

I/O

*

Signal Description

3 NC Not used

4 NC Not used

5 TXD1 OUT Photo coupler: output signal line from bill validator to controller

6 RXD2 IN Photo coupler: input signal line from bill validator to controller

7 SG2 Photo coupler: signal ground

8 NC Not used

9 NC Not used

10 NC Not used

11 NC Not used

12 NC Not used

13 NC Not used

14 NC Not used

15 NC Not used.

16 NC Not used

17 NC Not used

18 NC Not used.

* I/O (In/Out) viewed from the Bill Validator side.

5900333 © 2005, JCM American, Corporation

2-2

Page 23

Installation / Operation Optipay™ BV Section 2

Connector Types

•

Right Angle Dual Header

53107-1820 (MOLEX)

Polyester (w/glass inclusion)

•

Header Housing (recommended)

51030-0920 (MOLEX)

Polyester (w/glass inclusion)

•

Dual Clip

51041-1800 (MOLEX)

Polyester (w/glass inclusion)

•

Terminal

50083-8114 (MOLEX)

Wire Gauge AWG#24 ~ 26

•

Separate Wire (recommended)

UL1007 AWG#24 ~ 26

Figure 2-6 illustrates a typical interconnect plug pin configuration.

Figure 2-6 Typical Interconnect Plug Pin Assignment Diagram

DIP Switch Settings

Verify the current software in the DBV before attempting to reinstall it. The DIP switch settings are determined by the software. See software specifications provided separately for your software’s DIP switch settings. See Figure 2-7 for the DIP Switch location.

Figure 2-7 DIP Switch Location

5900333 © 2005, JCM American, Corporation

2-3

Page 24

Section 2 Optipay™ BV Installation / Operation

Operational Flowchart

Figure 2-8 depicts a typical bill acceptance flow process.

Figure 2-8 Bill Validator Operational Flowchart

5900333 © 2005, JCM American, Corporation

2-4

Page 25

Installation / Operation Optipay™ BV Section 2

Clearing a Bill Jam

When a bill is jammed in the Stacker section:

1. Remove the cash box.

2. Remove the jammed bill following the arrow

path shown in Figure 2-9.

Preventive Maintenance

The DBV-301 sensor lenses c are made of a transparent polymer material; handle them with care. It

is important to keep the bill path, rollers

belts clean (See Figure 2-11, and Figure 2-12 for

locations).

d

, and

Figure 2-9 Clearing a Jammed Stacker Bill

When a bill is jammed in the Validator

section:

1. Lift the Validator head release lever and pull

out the Lower Guide.

2. Remove the jammed bill.

Figure 2-11 Upper Guide and Stacker

Sensors and Rollers

Figure 2-12 Lower Guide Sensors and Rollers

Figure 2-10 Clearing a Jammed Validator

5900333 © 2005 JCM-American Corporation

To clean the lenses, use a lint-free cloth and a mild

non-abrasive detergent such as liquid dish soap

mixed with water.

2-5

Page 26

Section 2 Optipay™ BV Installation / Operation

Do not use alcohol or thinner for

cleaning.

Note: JCM does not recommend using

cleaning cards, cleaning pads, or cleaning

solutions of any kind

.

Cash box Preventive Maintenance (P/M)

Perform periodic P/M on the Cash Boxes to ensure

proper operation. The Cash Box sensor lenses

are made of a transparent polymer material; handle

them with care (See Figure 2-13).

c

Figure 2-13 Cash Box Sensors

Use compressed air to blow out loose paper fibers

and other debris that can build up over time. Check

all moving parts for wear and proper positioning. If

the unit does not operate properly, it can cause bill

jams. After completing the P/M, re-calibration is

recommended (Refer to Section 7).

5900333 © 2005 JCM-American Corporation

2-6

Page 27

3 MDB PROTOCOL

NOTE: The latest MDB Protocol Specifications may be found at www.Vending.org

Optipay™ BV

DBV-301 Bill Validator

Section 3

5900333 © 2005 JCM-American Corporation

3-1

Page 28

Optipay™ BV

THIS PAGE INTENTIONALLY LEFT BLANK

5900333 © 2005 JCM-American Corporation

3-2

Page 29

Optipay™ BV

DBV-301 Bill Validator

Section 4

4 DISASSEMBLY

This section provides disassembly instructions for

the Optipay

information within contains the following features:

1. Circuit Board Disassembly

2. Pusher Mechanism Disassembly

3. Upper Guide Disassembly

4. Lower Guide Disassembly

Circuit Board Disassembly

Removing the CPU and Power Supply

boards

1. Pull the cash box release lever c and

™

BV

DBV-301 Bill Validator. The

remove the cash box

d

(See Figure 4-1).

Figure 4-2 Lower Guide Removal

Figure 4-1 Bill Validator Mounting Locations

2. Lift the Validator head release lever and pull

out the Lower Guide following the arrow

and directional path indicated in Figure 4-2.

3. Slide the base cover upward and remove the

cover (See Figure 4-3).

4. Remove four securing screws and remove

the face plate (See Figure 4-4 and

Figure 4-5).

5900333 © 2005 JCM-American Corporation

Figure 4-3 Validator Cover Removal

Figure 4-4 Validator Face Plate Removal

4-1

Page 30

Section 4 Optipay™ BV Disassembly

Figure 4-5 Face Plate Rear Mounting View

5. Lay the assembly on its back and remove the

6 screws shown in Figure 4-6. Then disconnect the four plug connectors indicated by

the four small arrows in Figure 4-6.

6. Open the board assembly access box following the large arrow direction in Figure 4-6.

Figure 4-7 CPU Board Connector Removals

9. Separate the CPU board and Power Supply

board connectors (See Figure 4-8)

.

Small

Arrows

Figure 4-6 Screw and Connector Removal and

Circuit Board Access

7. Release the ribbon cable connector lock and

remove the flexible ribbon cable shown by

the small arrows in the Figure 4-7 close-up

box (See Figure 4-7 a).

8. Disconnect the CPU board signal cable connector (See large arrow in Figure 4-7 b).

Figure 4-8 CPU and Power Supply Board

Connector Separation

5900333 © 2005 JCM-American Corporation

4-2

Page 31

Disassembly Optipay™ BV Section 4

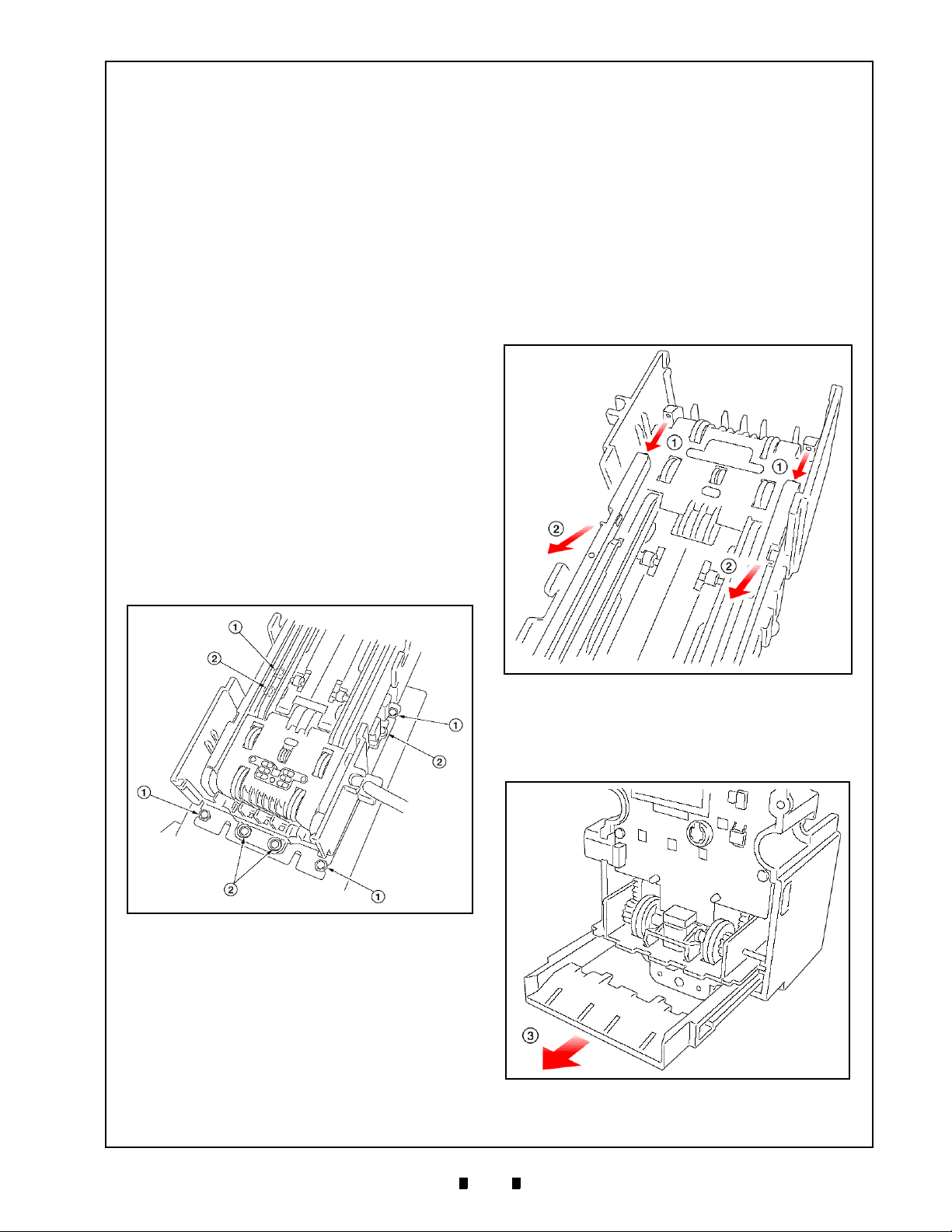

Pusher Mechanism Disassembly

Timing Belt removals

1. Remove the CPU board and power supply

board as previously described (See “Removing the CPU and Power Supply boards” on

page 4-1).

2. Remove the Side Bill Guides by following

the

c

and d arrow directions shown in

Figure 4-9.

Figure 4-9 Side Guide Removal

3. Remove the Front Bill Guide following the

large directional arrow shown in Figure 4-

10.

Figure 4-10 Front Guide Removal

4. Remove the pusher mechanism retaining

screw and remove the assembly following

the large directional arrow shown in

Figure 4-11.

Figure 4-11 Pusher Mechanism Removal

5. Remove the two timing belts from the

Pusher Mechanism assembly

(See Figure 4-12). Once the belts are

removed, remove their related tension rollers

on each side as well (See Figure 4-12 a).

Figure 4-12 Timing Belt Removal

Removing the drive and stack motor

1. Remove the two shaft retaining C-clip rings

and pull the shaft out of the pusher plate

(See Figure 4-13).

5900333 © 2005 JCM-American Corporation

4-3

Page 32

Section 4 Optipay™ BV Disassembly

Figure 4-15 Shaft and Sleeve Removal

Figure 4-13 Pusher Shaft C-Clip Ring Removal

2. Slide the pusher plate in the direction indicated by the arrow in Figure 4-14 and

remove the plate.

Figure 4-14 Pusher Plate Removal

3. Remove one of the shaft retaining C-clip

rings and pull the shaft out of the pusher

arm; then remove the two sleeve spacers

(See Figure 4-15).

4. Lift the pusher arm and remove the five

retaining screws shown in Figure 4-16, then

tip the assembly to the side and remove the

loose pin (See Figure 4-16 a).

5. Turn the Pusher Mechanism assembly over

and remove the motor guide

(See Figure 4-17).

Figure 4-16 Retaining Screw Removals

Figure 4-17 Motor Guide Removal

5900333 © 2005 JCM-American Corporation

4-4

Page 33

Disassembly Optipay™ BV Section 4

6. Remove the drive and stack motor from the

motor guide assembly (See Figure 4-18).

Figure 4-18 Drive and Stack Motor Removal

Upper Guide Disassembly

3. Pull the two shafts out and remove the two

small and two large gears (See Figure 4-20).

Figure 4-20 Upper Guide Gear Removals

4. Remove the two retaining Sensor board

screws and remove the Sensor board from

the assembly (See Figure 4-21).

Sensor board removal

1. Remove the Pusher Mechanism assembly

(See “Pusher Mechanism Disassembly” on

page 4-3).

2. Remove the two Upper Guide retaining

screws and pull the Upper Guide out of the

assembly (See Figure 4-19).

Figure 4-21 Sensor Board Removal

5. Release the ribbon cable connector lock and

remove the flexible ribbon cable from the

Sensor board (See Figure 4-22 arrows).

Figure 4-19 Upper Guide Removal

5900333 © 2005 JCM-American Corporation

Figure 4-22 Flexible Ribbon Cable Removal

4-5

Page 34

Section 4 Optipay™ BV Disassembly

O-ring removal

1. Pull the two short gear shafts out and remove

the two gears they retained (See Figure 4-

23).

Figure 4-25 Upper Long Shaft and Gear Removal

Figure 4-23 Short Shaft and Gear Removal

2. Pull the lower long gear shaft out and

remove the two gears it retained (See Figure

4-24).

Figure 4-24 Lower Long Shaft and Gear Removal

3. Pull the upper long gear shaft out and

remove the two gears, springs and bushings

it retained (See Figure 4-25)

4. Remove the two concentric O-rings from

each gears just removed from the upper shaft

assembly (See Figure 4-26).

Figure 4-26 O-Ring Removals

Lower Guide Disassembly

MAG board removal

1. Remove the Lower Bill Guide retaining

screw and remove the Lower Bill Guide’s

cover following the large arrow direction

shown in Figure 4-27

.

5900333 © 2005 JCM-American Corporation

Figure 4-27 Lower Bill Guide Removal

4-6

Page 35

Disassembly Optipay™ BV Section 4

2. Remove the two screws retaining the MAG

board to the assembly and lift the MAG

board (See Figure 4-28).

Figure 4-28 MAG Board Removal

3. Disconnect the board connector and remove

the MAG board (See Figure 4-29).

Figure 4-29 Disconnect MAG Board Connector

5900333 © 2005 JCM-American Corporation

4-7

Page 36

Optipay™ BV

THIS PAGE INTENTIONALLY LEFT BLANK

5900333 © 2005 JCM-American Corporation

4-8

Page 37

Optipay™ BV

DBV-301 Bill Validator

Section 5

5 WIRING DIAGRAMS

This section provides the Wiring Diagram interconnect for the Optipay

dator (See Figure 5-1 and Figure 5-2).

™

BV

DBV-301 Bill Vali-

DBV-301 Interconnect

This section contains the following information:

1. DBV-301-SU Interconnect (Part 1)

2. DBV-301-SU Interconnect (Part 2)

Figure 5-1 DBV-301 Bill Validator Interconnect Wiring Diagram (Part 1)

5900333 © 2005 JCM-American Corporation

5-1

Page 38

Section 5 Optipay™ BV Wiring DiagramS

DBV-301 Interconnect Continued

Figure 5-2 DBV-301 Bill Validator Interconnect Wiring Diagram (Part 2)

5900333 © 2005, JCM American, Corporation

5-2

Page 39

Optipay™ BV

DBV-301 Bill Validator

Section 6

6 TROUBLE SHOOTING

This section provides the Trouble Shooting

procedures for the Optipay

Validator. The information within contains the

following features:

•

DBV-301-SU

Trouble Shooting

™

DBV-301 Bill

Introduction

Most failures within the Bill Validator occur due to

minor causes. It is important to check that the internal connectors are properly mated and that the harness is also firmly connected before replacing

parts.

Poor bill acceptance is often due to iron content

that adheres to the magnetic head or to the magnetic head roller. Therefore, the Bill Validator

should always be cleaned first.

To determine the cause of a failure and those of

small defective parts, it is important to observe the

operating state of the Bill Validator when power is

first applied. This condition also allows the cause

of a failure to be determined using the test mode.

When the Bill Validator head has been disassembled for repair, or when the Sensor board has been

replaced, the sensor should be readjusted.

All repairs should be performed by referring to the

adjustment procedure, the wiring diagrams and the

various disassembly procedures.

Failure Classifications

The cause of a failure can be broadly classified into

the following four failure conditions. Check for the

following operating fault states:

1. Test mode fails entry (See Figure 6-1and 2).

2. Incorrect initial operation (See Figure 6-3).

3. Rejected or poorly accepts bills (See Figure

6-4).

4. Improper bill transfer (See Figure 6-5).

Test Mode Entry Failure Flowchart

The Figure 6-1 and 2 Flowcharts diagram the failure conditions related to entering test correctly.

Figure 6-1 DBV-301 Bill Validator Test Mode Failure Flow Chart Diagram (Part 1)

5900333 © 2005 JCM-American Corporation

6-1

Page 40

Section 6 Optipay™ BV Trouble Shooting

Test mode entry failure flowchart (continued)

Figure 6-2 DBV-301 Bill Validator Test Mode Failure Flow Chart Diagram (Part 2)

5900333 © 2005, JCM American, Corporation

6-2

Page 41

Trouble Shooting Optipay™ BV Section 6

Incorrect initial operation flowchart

The Figure 6-3 Flowchart diagrams the LED indications available when an incorrect initial operational

fault occurs.

Figure 6-3 DBV-301 Bill Validator Incorrect Initial Operation Flow Chart Diagram

5900333 © 2005, JCM American, Corporation

6-3

Page 42

Section 6 Optipay™ BV Trouble Shooting

Rejected or poorly accepts bills flowchart

The Figure 6-4 Flowchart diagrams the fault conditions related to Bill Validator rejects or poorly accepts

bills.

Figure 6-4 DBV-301 Bill Validator Rejects or Poorly Accepts Bills Flow Chart Diagram

5900333 © 2005, JCM American, Corporation

6-4

Page 43

Trouble Shooting Optipay™ BV Section 6

Improper bill transfer flowchart

The Figure 6-5 Flowchart diagrams the fault conditions related to Improper bill transfers.

Figure 6-5 DBV-301 Bill Validator Improper bill transfer Flow Chart Diagram

5900333 © 2005, JCM American, Corporation

6-5

Page 44

Optipay™ BV

THIS PAGE INTENTIONALLY LEFT BLANK

5900333 © 2005 JCM-American Corporation

6-6

Page 45

Optipay™ BV

DBV-301 Bill Validator

Section 7

7 FLASH MEMORY DOWNLOAD

This section provides download instructions for the

Optipay™

mation within contains the following

features:

•

•

•

•

•

•

•

•

•

•

•

BV

DBV-301 Bill Acceptor. The infor-

Downloading to Flash Memory Description

Tool Requirements

Information Menu Selection

Diagnostics Menu Selection

Program Download Menu Selection

Selecting a Download ROM

Starting the Download Program

Downloading Procedure Examples

DIP Switch Settings

Error Codes

Sensors, Circuit Boards, and Motor Locations

a

Tool Requirements

A Palm Pilot® handheld device is required to

configure the DBV-301 Bill Acceptor using JCM

PSP-03

Requirements

©

Acceptor Program software.

•

A Palm Pilot Handheld – M100, 500 and

Tungsten Series Handhelds (See Figure 7-1 )

•

Titan Acceptor Communication Cable

•

JCM PSP-03 Acceptor Program for the

Palm Pilot handheld

•

PC with Windows 2000 or XP O/S

•

Palm Pilot Application Suite

•

Hot Sync Cradle or Cable*

*Refer to the Palm Pilot User’s manual

for program installation and Hot Sync

instructions.

Figure 7-1 Typical M100/500 Series Palm

®

Handheld & Software

Pilot

Information Menu Selection

1. Turn on the Palm Pilot® and select the JCM

PSP-03 main menu application (See Figure

7-1 a or See Figure 7-2 a).

a

Figure 7-2 PSP-03 Application Selection

2. Select the

main menu screen

(See Figure 7-3 a).

Settings

button on the

5900333 © 2005 JCM-American Corporation

7-1

Page 46

Section 7 Optipay™ BV Flash Memory Download

3. Select the

Information…

button on the

menu screen. (See Figure 7-4 a)

or

Back

to return to the previous screen.

a

Figure 7-3 Settings Menu Selection

a

5. Once back on the

Acceptor…

the

button (See Figure 7-6 a).

“Settings”

screen, select

a

Figure 7-6 Acceptor Mode Selection

With future firmware releases, the

screen will be used to configure the Bill

Validator settings as well (See Figure 7-7 ),

for the present however, select

Back

return to the main menu screen.

to

Figure 7-4 Information Menu

Selection

4. The following typical configuration settings

for a validator are shown in Figure 7-5

when the

“Information…”

button is selected:

a. The Firmware Version – V1.02C

b. The Enable/Disable DIP Switch Settings

c. The bill values enabled ($1 and $5 Bills)

d. The

“Rec”

button to enter refreshed data

from the Validator and

e. The

“Back”

“Settings”

button to return to the

Screen.

a

b

c

d

e

Figure 7-7 Acceptor Screen Functions

6. Once on the

Back

the

main menu screen

button again to return to the

menu screen, select

(See Figure 7-8 ).

Figure 7-8 Returning to the Settings Screen

Figure 7-5 Typical Configuration Settings

5900333 © 2005 JCM-American Corporation

7-2

Page 47

Flash Memory Download Optipay™ BV Section 7

Diagnostics Menu Selection

7. On the

screen select the

(See Figure 7-9 a).

a

Figure 7-9 Diagnostics Mode Selection

8. The screen is used to test

the following DBV functions:

a. Forward Motor Speed RPM

b. Reverse Motor Speed RPM

c. Stacker Test

d. Run Test

e. Solenoid Test

f. Sensor 1 Transmit/Receive Test

g. Sensor 2 Transmit/Receive Test

h. Dip Switch Settings Test

Diagnostics

main menu

button

(See Figure 7-10 “a” through “h”)

Program Download Menu Selection

1. Select the

main menu screen

(See Figure 7-11 a).

a

Figure 7-11 Program Download Menu Selection

2. Select the software version to be downloaded (See Figure 7-12 a), and then

3. Select

Validator (See Figure 7-12 b).

a

Program Download

Send

to transmit the software to the

button on the

Figure 7-10 Diagnostics Screen Functions

9. Select the

Back

button to return to the

menu screen.

a

b

b

c

d

e

f

g

h

Figure 7-12 Program Download Screen

NOTE: The

loaded firmware version. To select from the

available versions loaded, mouse-click any

open area inside of the

Rom Name:

box shows the

Rom Name:

box.

Selecting a Download ROM

Having mouse-clicked any open area inside of the

Rom Name:

1. Select the firmware version from the

2. Click the

box:

available list on the

screen that

appears (See Figure 7-13 a), then

Back

button to return to the

main menu screen (See

Figure 7-13 b).

5900333 © 2005 JCM-American Corporation

7-3

Page 48

Section 7 Optipay™ BV Flash Memory Download

3. Select

Send

on the

main menu to start the selected firmware

download (See Figure 7-15 a).

a

b

Figure 7-13 ROM Select Screen

4. During the download incrementing numbers

will appear in an inset

window left of the correct final value shown

at right (See Figure 7-14 a).

b

a

Figure 7-15 Download Send Command

Accepting Log Menu Selection

1. On the

screen, select the

button (See Figure 7-16 ).

Accepting Log

c

main menu

menu

a

Figure 7-14 Download Transfer Screen

NOTE: Ensure that the number of data

bytes loaded versus the total data bytes

needed to complete the download process

agree when the download is complete (i.e.,

a = b in Figure 7-14 ).

b

5. Once the download is complete, verify that

the program version listed on the

Download”

screen agrees with your initial

“Program

selection (See Figure 7-15 b).

6. Click the

Back

button to return to the on the

main menu screen

(See Figure 7-15 c).

a

Figure 7-16 Accepting Log Mode Selection

2. In the

a.

Rec

b.

Init

to download the

to initialize or clear the validator

menu choose:

Accepting Log

memory

Del

c.

to clear all downloaded Accepting

Logs, or

d.

Back

to return to the

3. Click on the

main screen of Figure 7-16 .

download record number

itself to view the related log data (See

Figure 7-18 a). The

screen

illustrated in Figure 7-19 will then appear.

4. Select

Next

to view additional pages of the

selected (See Figure 7-19 )

5900333 © 2005 JCM-American Corporation

7-4

Page 49

Flash Memory Download Optipay™ BV Section 7

b

a

Figure 7-17 Accepting Log Menu

c

d

a

Figure 7-18 Viewing Record Log Data

a

Figure 7-19 Viewing Specific Log Data 1

5. .Page two of the

lists the last

16 bills accepted, their denomination and the

direction in which the bill was inserted

(See Figure 7-20 ).

6. Page three lists the total bill denominations

counted and their date code, those accepted

and those rejected as follows:

a. The specific bill type count

b. The denomination and its sort date code

(Example 1 = 1$ of series 1990, 87 bills

accepted, 0 rejected)

a

Figure 7-20 Viewing Page Two Log Data

c. The number of the specific bills accepted

d. The number of the specific bills rejected

(See Figure 7-21 a, b, c, and d respectively)

b

a

Figure 7-21 Viewing Page Three Log Data

c

d

7. Page four, shown in Figure 7-22 , lists the

following information from top to bottom:

a.

RC Bills:

Number of bills stored in the

Recycler

–

(the amount operator loaded plus

customer loaded) minus the (amount

operator dispensed plus customer

dispensed)

b.

BOX STK:

Number of bills stacked in the

Cash Box

–

(the amount of notes stacked during

customer operation) plus (amount of

notes stacked during a manual RC-10

stacking operation)

c.

Recycle Operation:

Number of bills

loaded by operation mode

–

the amount of bills dispensed from the

RC-10 during a normal customer

transaction

d.

Manual:

= Number of bills loaded manu-

ally

5900333 © 2005 JCM-American Corporation

7-5

Page 50

Section 7 Optipay™ BV Flash Memory Download

b

d

f

h

j

l

Figure 7-22 Viewing Page Four Log Data

–

the amount of bills loaded into the

RC-10 by using the manual load

function

e.

Payout Operation:

Number of bills dis-

pensed by using the operation mode

–

the amount of bills dispensed from

RC-10 during a normal customer

transaction

Manual:

f.

Number of bills dispensed by

manual

–

the amount of bills dispensed from

RC-10 by using the manual dispense

function

g.

Gather:

Number of bills dispensed to

Cash Box

–

the amount of bills dispensed from

RC-10 to the Cash Box during a

manual dispense function

h.

Empty:

Number of times the Recycler

was empty

i.

FULL:

Number of times the Recycler

became FULL

Abnormal:

j.

Number of times the Recycler

had trouble (including bill jams)

Rec STK:

k.

a

c

e

g

i

k

DIP Switch Settings

Test mode set-up

To enter the test mode, set the following DIP

switches to:

stacked in the Cash Box during loading

l.

Pay STK:

stacked in the Cash Box when dispensing.

Number of bills mandatory

Number of bills mandatory

1. Turn switch 8 ON, turn switches 1 to 7 OFF,

and supply power to the unit.

2. The Faceplate LEDs will blink and the

Green, Yellow and Red Status LED indicator

on the rear of the unit will illuminate (turn

ON).

3. Keep switch 8 ON, then

4. Set switches 1 through 7 according to the test

mode you wish to conduct.

5. Now turn switch 8 OFF to begin the selected

test.

The Faceplate LEDs will go out along with

the Green, Yellow and Red LED Status

indicator LEDs located on the rear of the

unit.

6. Turn switch 8 ON to finish the test.

The Faceplate LEDs will blink and the

Green, Yellow and Red Status LED indicator

on the rear of the unit will illuminate (turn

ON).

Setting the test mode switches

Column 1 of Table 7-1 lists the various DIP

Switch Block settings for activating the desired

tests chosen from the “

listed in Column 2 of Table 7-1 .

Test Mode Descriptions”

Table 7-1 DIP Switch 1 Test Mode Settings

DIP Switch 1

No. 1 2 3 4 5 6 7 8

Transport Motor Forward Rotation Test (BOX set)

1) Normal: Status LEDs (Green, Yellow & Red) blink once

2) Fast: Status LEDs (Green, Yellow & Red) blink twice

3) Slow: Status LEDs (Green, Yellow & Red) blink 3 times

4) Abnormal: Status LEDs (Green, Yellow & Red) blink 6 times

Transport Motor Reverse Rotation Test (BOX set)

1) Normal: Status LEDs (Green, Yellow & Red) blink once

2) Fast: Status LEDs (Green, Yellow & Red) blink twice

3) Slow: Status LEDs (Green, Yellow & Red) blink 3 times

4) Abnormal: Status LEDs (Green, Yellow & Red) blink 6 times

5900333 © 2005 JCM-American Corporation

Test Mode Description

7-6

Page 51

Flash Memory Download Optipay™ BV Section 7

Table 7-1 DIP Switch 1 Test Mode Settings (Continued)

DIP Switch 1

No. 1 2 3 4 5 6 7 8

Test Mode Description

Stacker Test (BOX set)

1) Normal: Status LEDs all OFF

2) Stacker FULL: Status LED (Yellow) blinks once

3) Stacker JAM/LOCK: Status LED (Red) blinks twice

4) Box error: Status LED (Yellow) blinks 10 times

Running Test (BOX set)

1) Normal: Status LEDs all OFF

2) Stacker FULL: Status LED (Yellow) blinks once

3) Stacker JAM/LOCK: Status LED (Red) blinks twice

4) Acceptor JAM: Status LED (Yellow) blinks 4 times

5) Motor SPEED: Status LED (Red) blinks 5 times

6) Motor LOCK: Status LED (Red) blinks 6 times

7) BOX Error: Status LED (Yellow) blinks 10 times

Serial Insertion Prevention Lever Test

1) Normal: Status LEDs all OFF

2) Sensor ABN: Status LED (Green, Yellow & Red) 4 blinks each

3) Motor LOCK: Status LED (Green,Yellow & Red) 6 blinks each

Acceptor Sensor Test

[Refer to details concerning the Acceptor Sensor Test in Table 7-2]

Stacker Sensor Test

[Refer to details concerning the Stacker Sensor Test in Table 7-3]

Acceptance Test (BOX set)

Stack Motor Forward Rotation Test (pusher plate remains at HOME position)

1) Normal: Status LEDs (Green, Yellow & Red) 1 blink each

2) Fast: Status LEDs (Green, Yellow & Red) 2 blinks each

3) Slow: Status LEDs (Green, Yellow & Red) 3 blinks each

4) Abnormal: Status LEDs (Green, Yellow & Red) 6 blinks each

Stack Motor Reverse Rotation Test (pusher plate remains at HOME position)

1) Normal: Status LEDs (Green, Yellow & Red) 1 blink each

2) Fast: Status LEDs (Green, Yellow & Red) 2 blinks each

3) Slow: Status LEDs (Green, Yellow & Red) 3 blinks each

4) Abnormal: Status LEDs (Green, Yellow & Red) 6 blinks each

I/O Pulse Interface Line Test

1) InLine1 (Low: OutLine1 = Low, Hi: Outline1 = Hi)

2) InLine2 (Low: OutLine2 = Hi, Hi: Outline2 = Low)

3) InLine3 (Low: OutLine3 = Hi, Hi: Outline3 = Low)

4) 500md Interval: OutLine4 = Hi/Low

DIP Switch Test

[Refer to details concerning the DIP Switch Test in Table 7-4 on page 7-9]

5900333 © 2005 JCM-American Corporation

7-7

Page 52

Section 7 Optipay™ BV Flash Memory Download

Test Mode Details

Acceptor Sensor Test Details

When a bill is inside the unit, the Faceplate LEDs and the Green, Yellow and Red Status LEDs Illuminate

(turn ON).

NOTE: Multiple sensors can be tested simultaneously.

Table 7-2 Acceptor Sensor Test Detail Listing

No. 1 2 3 4 5 6 7 8 Sensor Name

LEV (Serial Insertion Prevention Lever)

PSF (f0t_ir: Entrance)

PSML (l1t_rd: RED Left 1)

PSMR (r1t_rd: RED Right 1)

PSL (l3t_ir: Infrared Left 3)

PSR (r3t_ir: Infrared Right 3)

PSE (ext_ir: Exit)

Stacker SensorTest Details

When a bill is inside the unit, the Faceplate LEDs and the Green, Yellow and Red Status LEDs Illuminate

(turn ON).

NOTE: All sensors must be tested individually.

Table 7-3 Stacker Sensor Test Detail Listing

No. 1 2 3 4 5 6 7 8 Sensor Name

PSL (Transport Unit Left Sensor detects a bill)

Reversed

PSR (Transport Unit Right Sensor detects a bill)

HOME (pusher plate is at HOME position)

BOX (Cash Box is in proper position)

Stack Motor Encoder (when shielded)

5900333 © 2005, JCM American, Corporation

7-8

Page 53

Flash Memory Download Optipay™ BV Section 7

Table 7-3 Stacker Sensor Test Detail Listing (Continued)

No. 1 2 3 4 5 6 7 8 Sensor Name

Transport Motor Encoder (when shielded)

DIP Switch Logic Test

Test results are indicated by making the following switch settings and observing the Condition LED blinking indications listed in the Table 7-4 tests:

1. Begin by setting DIP Switch 1 Block switches 1 through 8 all ON, and apply power to the unit.

The Front Panel Green Indicator LEDs will begin flashing and the Green, Yellow and Red Condition

LEDs will all steadily illuminate (lite).

2. Now change DIP Switch 1 Block switch number 8 to OFF. The Front Panel Green Indicator LEDs

will go out and the Green, Yellow and Red Condition LEDs will all begin to repeatedly blink single

flashes (See Table 7-4 Test 1).

3. Now turn DIP Switch Block 2 switches 1 through 8 all ON. The Front Panel Green Indicator LEDs

will remain out and the Green, Yellow and Red Condition LEDs will begin repeatedly blinking

in double flash sets (See Table 7-4 Test 2).

4. Now turn even numbered switches (i.e., 2, 4 & 6) on both DIP Switch Block 1 and

Block 2 OFF. The Green, Yellow and Red Condition LEDs will then begin repeatedly blinking three

flashes at a time. (See Table 7-4 Test 3).

DIP Switch

Table 7-4 Resulting DIP Switch Setting LED Flash Details

Test

No.

1 Condition LEDs Blink once (1 time)

2 Condition LEDs Blink twice (2 times)

3 Condition LEDs Blink three times (3

DIP Switch 1

No. 1 2 3 4 5 6 7 8

DIP Switch 2

No. 1 2 3 4 5 6 7 8

Condition LED Blink Indications

times)

Error Codes

Error Code Table

Table 7-5 lists the color error code and number of blinks for each test result.

Table 7-5 Error Code Blink Listing

Blink Number LED Color Status Error Description

1 Yellow Stacker Full

2 Red Stacker Jam (in pusher mechanism zone)

3 Yellow Acceptor Jam (in sensor zone)

4 Yellow Transport Jam

5 Red Motor Speed Error

6RedMotor Lock

5900333 © 2005, JCM American, Corporation

7-9

Page 54

Section 7 Optipay™ BV Flash Memory Download

Table 7-5 Error Code Blink Listing (Continued)

Blink Number LED Color Status Error Description

7 — Reserved (unused)

8 — Reserved (unused)

9 Yellow Entrance Lever Jam

10 Yellow BOX not Secure in Position

11 — Reserved (unused)

12 Yellow Tampering (bill fishing, bill movement incorrect, etc.)

13 — Reserved (unused)

14 — Reserved (unused)

15 Red EEPROM Read/Write Error

Reject Code Table

Table 7-6 lists the reject code and number of blinks for each test result.

Table 7-6 Reject Code Listing

Blink Number LED Color Status Code Reject Description

1 Green RJ_SLA Insertion Error

2 Green RJ_MAG Magnetic Error

3 Green RJ_PAP Particle Matter in the Transport Path

4 Green RJ_XRT Correction Error/Scaling Error

5 Green RJ_SYN Transport Error

6 Green RJ_PTO Bill Denomination Identification Error

7 Green RJ_PIR Photo Pattern Error (1)

8 Green RJ_PHV Photo Level Error

9 Green RJ_INH Inhibited Denomination

10 Green RJ_REJ Reject Command Activation

11 Green RJ_LVR Exit Sensor Error (foreign particle detected)

12 Green RJ_BSW Escrow Position Error

13 Green RJ_LGO Bill Length Error

14 Green RJ_2CL Photo Pattern Error (2)

15 Green RJ_FAKE Bill inserted does not match the genuine note

characteristics

5900333 © 2005, JCM American, Corporation

7-10

Page 55

Flash Memory Download Optipay™ BV Section 7

Sensors, Circuit Boards, Motors and Cash Box Locations

Figure 7-23 Sensors, Circuit Boards, and Motor Locations Diagram

5900333 © 2005, JCM American, Corporation

7-11

Page 56

Optipay™ BV

THIS PAGE INTENTIONALLY LEFT BLANK

5900333 © 2005 JCM-American Corporation

7-12

Page 57

Optipay™ BV

DBV-301 Bill Validator

Section 8

8 EXPLODED VIEWS/PARTS LISTS

This section provides the following wiring diagrams for theOptipay™

Validator (See Figure 8-1through Figure 8-4).

•

DBV Primary Component Parts

•

Frame and Upper/Lower Guide Exploded

View

DBV Primary Component Parts

BV DBV-301 Bill

•

Frame and Upper/Lower Guide Parts List

•

Pusher Mechanism Assembly Exploded View

•

Pusher Mechanism Assembly Exploded View

Parts List

•

Cash Box Unit Exploded View

•

Cash Box Unit Parts List

5900333

Figure 8-1 DBV Dual Bill Validator Primary Component Parts Exploded View Diagram

© 2005 JCM-American Corporation

8-1

Page 58

Section 8 Optipay™ BV Exploded Views/Parts Lists

DBV Primary Parts List

Table 8-1

No. EDP No. Part No. Description Remarks

1 095379 3210-05-03 MDB Connector

DBV Primary Parts List

Frame and Upper/Lower Guide Exploded View

5900333

Figure 8-2 Frame and Upper/Lower Guide Exploded View Diagram

© 2005, JCM American, Corporation

8-2

Page 59

Exploded Views/Parts Lists Optipay™ BV Section 8

Frame and Upper/Lower Guide Parts List

Table 8-2: Frame and Upper/Lower Guide Parts List

No. EDP No. Part No. Description Remarks

101 095517 4019GE0103 GEAR C

102 094010 4019-3210-06-03C-01 SENSOR PCB ASSY

103 095378 FFC28PIN 60MM FLEXIBLE HARNESS

104 095472 4019RE0102 UPPER GUIDE

105 095523 4019RO0101 ROLLER A

106 066077 0643CS0102A TRANSPORT ROLLER SP

107 095478 4019RE0107 ROLLER GUIDE B

108 095477 4019RE0106 ROLLER GUIDE A

109 095532 4019SH0103 ROLLER SHAFT B

110 095531 4019SH0102 ROLLER SHAFT A

111 095485 4019RE0114 SENSOR GUIDE C

112 095483 4019RE0112 SENSOR GUIDE A

113 100448 4019CS0101 LEVER SPRING

114 101151 Z3240-6115 PBT BUSHING

115 095481 4019RE0110 LEVER

116 095515 4019GE0101 GEAR A

117 095516 4019GE0102 GEAR B

118 094209 4019-3210-06-02D-01 MAG PCB ASSY

119 095377 3210-05-01A HARNESS

120 095474 4019RE0103 LOWER GUIDE

121 075183 C-125 SPRING (NO.1024)

122 101904 DC-158 SPRING

123 095479 4019RE0108 ROLLER GUIDE C

124 095524 4019RO0102 ROLLER B

125 092230 2X12 PARALELL PIN

126 095530 4019SH0101 LOCK SHAFT

127 003707 C-CLIP Φ3 SUS

128 064533 C-147 SPRING (NO.1052)

129 095476 4019RE0105 LOWER GUIDE COVER

130 094012 4019-3210-06-05-01 SMALL PCB ASSY

131 095380 3210-05-06B TRANSPORT HARNESS (Left)

132 095381 3210-05-07 TRANSPORT HARNESS (Right)

133 095471 4019RE0101 BASE FRAME

134 095482 4019RE0111 BOX STOPPER

135 095880 DC-097 SPRING

136 095505 4019RE0401 FACE PLATE

137 095506 4019RE0402 LEDGUIDE

138 095529 4019PT0401 FP BRACKET

5900333

© 2005, JCM American, Corporation

8-3

Page 60

Section 8 Optipay™ BV Exploded Views/Parts Lists

Table 8-2: Frame and Upper/Lower Guide Parts List (Continued)

No. EDP No. Part No. Description Remarks

139 094138 4019-3210-06-01D-01 CPU PCB ASSY

140 095376 LSEP1114A1 POWER SUPPLY ASSY

141 095507 4019RE0403 FB GUIDE-67

142 095508 4019RE0404 SB GUIDE-67L

143 095509 4019RE0405 SB GUIDE-67R

144 095475 4019RE0104 BASE COVER

145 095876 0-RING P-16 (EPDM70)

146 095484 4019RE0113 SENSOR GUIDE B

147 101906 4019PE0103 SG REFLECTOR SEAL

148 095480 4019RE0109 ROLLER GUIDE D

149 095533 4019SH0104 ROLLER SHAFT C

150 072396 0666RE0126A PRISM GUIDE

151 055413 2.6X6 BINDING P TIGHT

152 005332 3X5 FLAT HEAD VIS CM

153 100121 3X6 SCREW w/WASHER FE CM

5900333

© 2005, JCM American, Corporation

8-4

Page 61

Exploded Views/Parts Lists Optipay™ BV Section 8

Pusher Mechanism Assembly Exploded View

5900333

Figure 8-3 Pusher Mechanism Assembly Exploded View Diagram

© 2005, JCM American, Corporation

8-5

Page 62

Section 8 Optipay™ BV Exploded Views/Parts Lists

Pusher Mechanism Assembly

Exploded View Parts List

Table 8-3: Frame and Upper/Lower Guide Parts List

No. EDP No. Part No. Description Remarks

201 095528 4019PT0201 MOTOR

202 103044 4040GE0202 WORM

203 095486 4019RE0201 MOTOR

204 095519 4019GE0202 GEAR

205 095542 4019SH0209 GEAR

206 095879 2X5X0.3 FLAT