Crane Composites Trowels User Manual

Installation Guide

for STANDARD FRP and

INNOVATIVE FINISHES FRP

Wall, Ceiling and Laminated Panel Installations

Where Tradition & Innovation Converge

Topics

General Information 3

Safety Precautions, Supplies, Equipment and Storage Information

Installation Preparation 4

Wall Preparation, Choose an Adhesive, Environmental Considerations

Pre-Installation Planning 6

FRP with Performance and Presence

Basic FRP Installation Steps 6

Cutting Instructions 6

Attaching to Wall 7

Adhesive, Spacing, Panel Sequence, Panel Finishing

Seam Treatment Options 8

Moldings, Color Coordinating Caulk, Fasteners, Seam Sealant

Specialty Installations 13

Ceiling Panels, Car Washes, Laminated Panels

Disclaimer

PLEASE READ ALL INSTRUCTIONS BEFORE BEGINNING INSTALLATION

These guidelines are provided in good faith to help prevent installation problems caused by common errors. The manufacturer and/or

distributor of the product bears no responsibility for installation actions taken or not taken. There are many nuances of installation that

are assumed to be general construction knowledge to an experienced installer; such nuances are not included in these instructions.

Rather, these installation guidelines are strictly recommendations and are not intended to serve as a step-by-step, foolproof installation

checklist. Selection of an experienced FRP installer is the sole responsibility of the project owner and architect. Crane Composites does

not accept any responsibility for job failure resulting from or associated with improper job site environmental conditions.

Factory Mutual Approval

Fire-X Glasbord (FXE and FSFM) is the only fi berglass reinforced interior wall and ceiling panel that is accepted under Factory Mutual

Research approved FRP, Plastic Interior Finish Materials when installed in accordance with Factory Mutual Research Approval

Standard 4880. This information is available at www.approvalguide.com and www.FRP.com/FMApproved.pdf.

NOTE: Please contact your local FM Global Representative to provide a fi eld exemption of alternative methods of installation.

General Information

Safety Information

WHEN CUTTING OR DRILLING, ALWAYS WEAR PROTECTIVE GLASSES OR GOGGLES AND A FACE MASK WHICH COVERS

THE FACE AND MOUTH. Itching due to glass fi bers may be avoided by the use of barrier creams on exposed skin areas. Hearing

protection is also recommended.

Supplies and Equipment

Supplies will vary depending on wall substrate, adhesive choice and seam treatment selection.

STANDARD FRP TOOLS NEEDED

• Crane Composites Laminate Roller (Part # R50ROLLER)

• Crane Composites V-notched Trowel 3/16′′ x 1/4′′ x 5/16′′ (Part # R50TROWEL)

• Circular saw with fi ne tooth carbide tipped saw blade

• Swivel-head 18 gauge shears

• Drywall Roto-Zip®

• Jig-Saw

• Flat edge fi nishing tool (putty knife or equivalent)

MATERIALS NEEDED

• Crane Composites Standard FRP or Innovative Finishes Panels

• Adhesive - Crane Advanced Polymer Adhesive (R53829) or Crane Fast Grab Adhesive (R53828)

Refer to page 5 for assistance in selecting the appropriate adhesive

• Soap and water for clean-up (Latex or Polymer adhesives)

• Saw horses

• Plywood larger than panels

• Dry, lint free rags

• Sandpaper or Paper Tiger® Wallpaper Removal Tool for roughing up wall

• Tape measure

• Utility knife

• Six-penny fi nishing nails

• Carbide tipped laminate cutter

• IMPORTANT NOTE: If installation room has high humidity (65% or higher) then a portable low-cost dehumidifi er unit is suggested.

SEAM TREATMENT

• Moldings

• Color Coordinating Caulk

• Seam Sealant (cleanroom only)

• Cleanroom Wall System Seam Sealant - 7555 Urethane Sealant (R53827)

• Applicator - Pneumatic Dual Chamber Applicator Gun (R50CAULKGUN)

• 400ml Static Mixing Tips - 3/8′′ x 11′′ x 24 EL

• Finishing Kit - Inline Seam and Radial Seam Finishers for seam smoothing (R50SEAM-KIT)

• Panel Tape - 1′′ by 144 yds (R53522)

• Solvent for clean-up (IPA, acetone)

• Protective gloves needed when using seam sealant

Storage

Panels should be stored indoors on a solid, fl at, dry surface other than the fl oor. Do not stack on concrete fl oor or any other surface that

emits moisture. Lay panels fl at with proper support on the ends of panels. Do not stand panels on edge. All FRP panels must be stored

inside. Optimum storage conditions are 60° to 75° (16°C to 24°C) and 35% to 55% relative humidity

(Figure 1)

.

Figure 1

3

Installation Preparation

Pre-Conditioning

Before beginning the installation, the installer must determine that the environment of the jobsite meets or exceeds all requirements

specifi ed in the installation guide. Prior to installing, remove the packaging and allow the panels to acclimate to the room temperature

and humidity for 24 hours. Acclimation temperature range should be 60°F to 75°F (16°C to 24°C) and relative humidity should be 35%

to 55%. Ideally, both the room temperature and humidity during acclimation and installation should be the same as the fi nal operating

conditions.

Installation Conditions

Installation should not begin until building is enclosed (windows and doors are installed), permanent heating and cooling equipment is in

operation, and residual moisture from plaster, concrete, or terrazzo work has dissipated. Installation temperature range should be 60°F

to 75°F (16°C to 24°C) and relative humidity range should be 35% to 55%.

Wall Preparation

Every attempt is made to inspect panels for cosmetic and physical abnormalities prior to shipment, however, all panels should be

inspected for any defects prior to installation. The installer assumes all responsibility for full inspection of product before installation.

panels are not acceptable, contact your Customer Service Representative (CSR) immediately.

or questionable quality. Crane Composites, Inc. will not be responsible for installation or removal costs of unacceptable panels. Walls

should be fl at and even. Remove high spots and fi ll in low spots prior to beginning installation. Remove any foreign matter that may

interfere with the adhesive bond. The wall substrate must be dry and free from dirt, dust, and grease. Installation over uneven surfaces

will result in little or no adhesion to the wall substrate, therefore bubbling due to air pockets will form behind the panel.

PAINTED OR PRIMED SURFACES

Painted surfaces will not allow solvent-free or solvent-based adhesives to dry. Consequently, they will not achieve full bond strength.

Painted surfaces must be perforated with a wallpaper removal tool to rough up the wall. If you do not have that tool available, surfaces

must be gouged with a minimum 20 grit heavy sandpaper to break the moisture barrier of the paint. All loose paint, dirt and residue

must be removed prior to installation. Refer to page 4 for assistance in selecting the appropriate adhesive.

Do not install panels of unacceptable

If

NEW GYPSUM BOARD OR DRYWALL

New gypsum should not be painted or primed.

coat is not necessary or desirable. Any extremely uneven areas should be fi lled. Remove all drywall dust.

PLYWOOD

Plywood walls must be fl at and even, and warped plywood should be removed and replaced. Solvent-Free adhesive cannot be used on

any installation over pressure treated or fi re-rated plywood.

CONCRETE BLOCK AND BRICK

Concrete block and brick wall surfaces are by nature uneven, and FRP panels installed directly to these surfaces will likely develop

loose spots, bulges and buckles. An alternate method is to install gypsum board, cement board or another appropriate substrate over

the furring and then install FRP panels according to the standard installation instructions. If it is the owner or contractor’s preference

to install FRP panels directly to a concrete block or brick wall, it is recommended that the panels be installed with Crane Advanced

Polymer Adhesive.

NON-POROUS SURFACES

Non-porous surfaces (i.e., ceramic tile, glazed block, moisture resistant substrates, and metal panels) do not provide a good surface

for adhesive bonding. General-purpose latex-based, polymer or solvent-based adhesives will not dry properly on a non-porous surface.

Advanced polymer is recommended in these applications. Installation over this type of surface can be accomplished with rivets or you

may contact an adhesive manufacturer for additional recommendations.

Tapered joints need only a fi ll and taped coating using a setting joint compound. A fi nish

Environmental Considerations

The following special conditions require additional preparation or installation techniques:

DIRECT SUNLIGHT

Prolonged Direct Sunlight on panels may cause abnormal fading and/or rapid expansion depending upon amount of heat buildup. Use

caution in these areas.

4

HIGH HUMIDITY ROOMS

Acclimate panels in the operating humidity conditions. Carefully follow the guidelines in this installation guide for expansion/contraction

spacing and sealing. (see Expansion Joint Chart, pg 5). Failure to seal moisture entry points with silicone sealant can cause swelling

of the substrate resulting in warping, curling, delamination or bond line separation. Use an adhesive that is recommended for high

humidity conditions. A vapor barrier (e.g. 6 mil poly sheet) may be required. *Follow the architect or owner’s specifi cations or check your

local building codes for specifi c requirements.

LOW TEMPERATURE CONDITIONS

Acclimate panels in the operating temperature conditions. Carefully follow the guidelines in this installation guide for expansion/

contraction spacing and sealing (see Expansion Joint Chart, pg 6). Use an adhesive that is recommended for low temperature

conditions.

A vapor barrier (e.g., 6 mil poly sheet) may be required. Follow the architect or owner’s specifi cations or check your local

building codes for specifi c requirements.

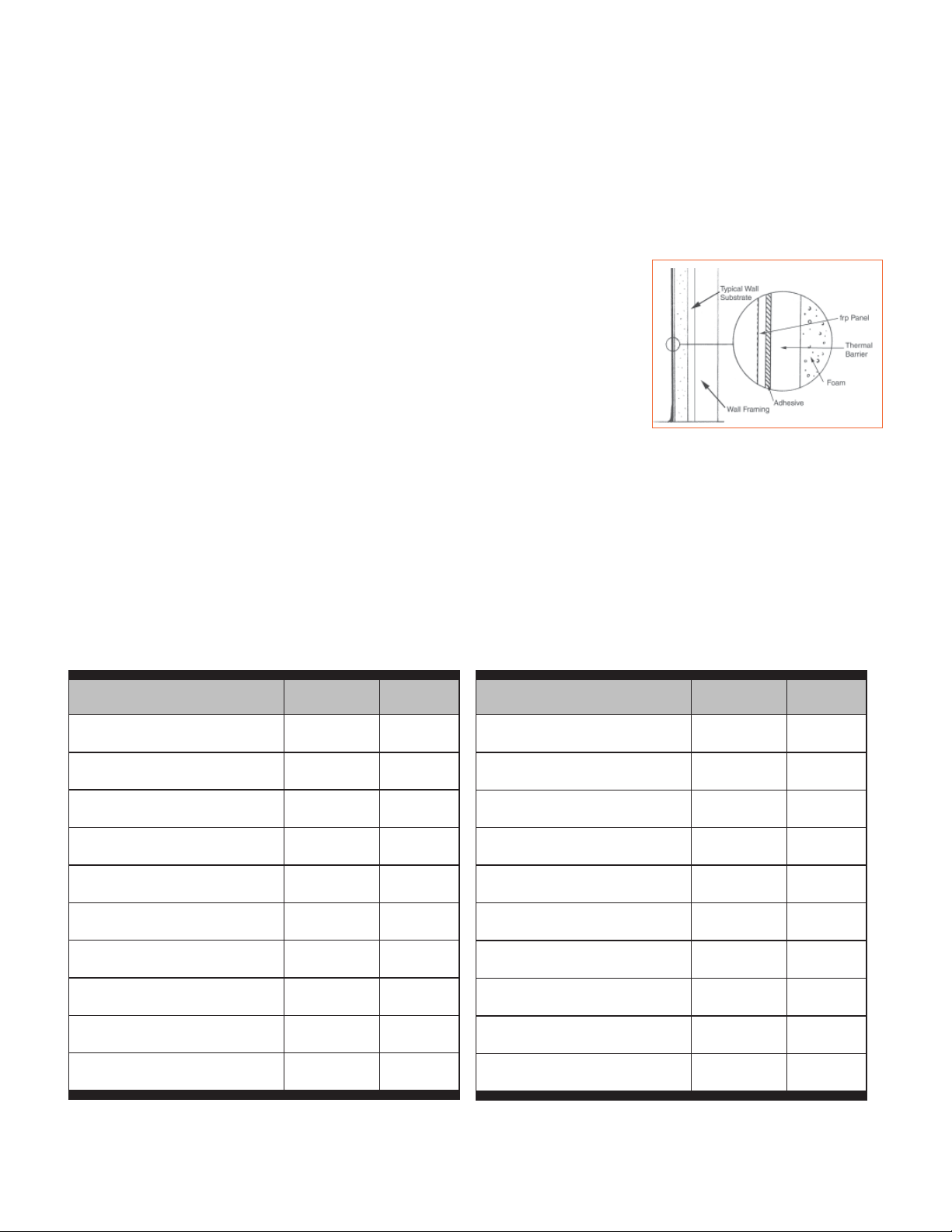

FOAM INSULATION

An approved thermal barrier system (e.g., gypsum board) must be used between the FRP

panels and any foam insulation

(Figure 2). Check your local building codes for specifi c

requirements.

NEAR HEAT SOURCE

FRP panels will discolor when installed behind or near a heat source

which radiates

temperatures exceeding 130°F (55°C), such as cookers, ovens, and deep fryers. Stainless

steel is recommended for these types of areas.

Figure 2

Choose an Adhesive

The following information provides assistance on selecting the appropriate adhesive for installation:

CRANE ADVANCED POLYMER ADHESIVE

Porous and most non-porous substrates, Interior and exterior applications, Fiberglass faced, mold resistant and fi recode core drywall,

drywall, steel, foamboard, vinyl, PVC, FRP,ceramic tile, laminate, sealed and unsealed concrete

CRANE FAST GRAB ADHESIVE

Porous substrates, Interior drywall applications, Non-treated plywood

ADHESIVE RECOMMENDATIONS FOR VARIOUS SUBSTRATES

FRP to:

Advanced

Polymer

Fast Grab

Standard unpainted drywall YES YES

Standard unpainted plywood YES YES

Treated plywood YES NO

Fire rated plywood YES NO

Cement board YES NO

Fiberglass faced, mold resistant

and fi recode core drywall

YES NO

DensGlass YES NO

FRP YES NO

Traditional Greenboard YES NO

FRP to:

Advanced

Polymer

Stainless steel YES NO

Metal YES NO

Aluminum YES NO

Galvanized metal YES NO

Cement block

(above grade or inside wall)

Cement block

(below grade or outside wall)

Painted walls

(if paint is well anchored)

YES NO

YES NO

YES NO

Polystyrene foam YES NO

Polyurethane foam YES NO

Fast Grab

Ceramic tile YES NO

Foil-faced insulation YES NO

Refer to form #6846 for additional Crane Adhesive installation information.

5

Loading...

Loading...