Crane ChemPharma & Energy 200 User Manual

brands you trust.

Technical Datasheet

CENTER LINE® - Resilient Seated Buttery Valves

Now All Ductile Iron Body Standard on Series 200

INDEX:

Series 200 2-6

Series 225-250 7-9

Series 800 10-11

Handles 12

Gear Operators 13-15

Figure Number Systems 16-19

Technical Data 20-22

www.cranecpe.comCrane ChemPharma & Energy

Series 200 Overview

Available in sizes 2" to 48".

Available in Wafer or Lug style body (2" to 30").

Double flange available 28" to 48" valves.

Wafer body features four alignment holes.

Pressure ratings for tight shutoff at temperatures up to the

maximum limit of the seat material:

2" to 12" — 200 psi, 125 psi for PTFE/Buna seat.

14" to 48" — 150 psi.

Ideal for on-off or throttling services.

Available with handles (2" to 12"), manual gear operators

(2" to 48"), and electric or pneumatic actuators (2" to 48").

Refer to Crane automation bulletin for details of pneumatic and

electric actuators.

Compatible with ASME B16.1 and ASME B16.5 flanges.

Valves 2" to 20" meet the intent and have passed the

AWWA C-504-87 Section 5 proof of design tests.

Type approval certification from ABS & USCG Category A

for marine applications (2" to 48").

Bi-directional dead-end capability to 200 psi (2" to 12")

and 150 psi (14" to 24") is standard on lug valves.

Operators mounted perpendicular to pipe.

For bolting information, consult the Center Line Installation and

Maintenance Manual.

Vacuum Service Rating: zero leakage at 24" of mercury.

Commercial cleaning available for Oxygen level 2.

CE/PED Certification available for sizes 2" to 24".

Designed to comply with MSS SP-67 and MSS SP-25.

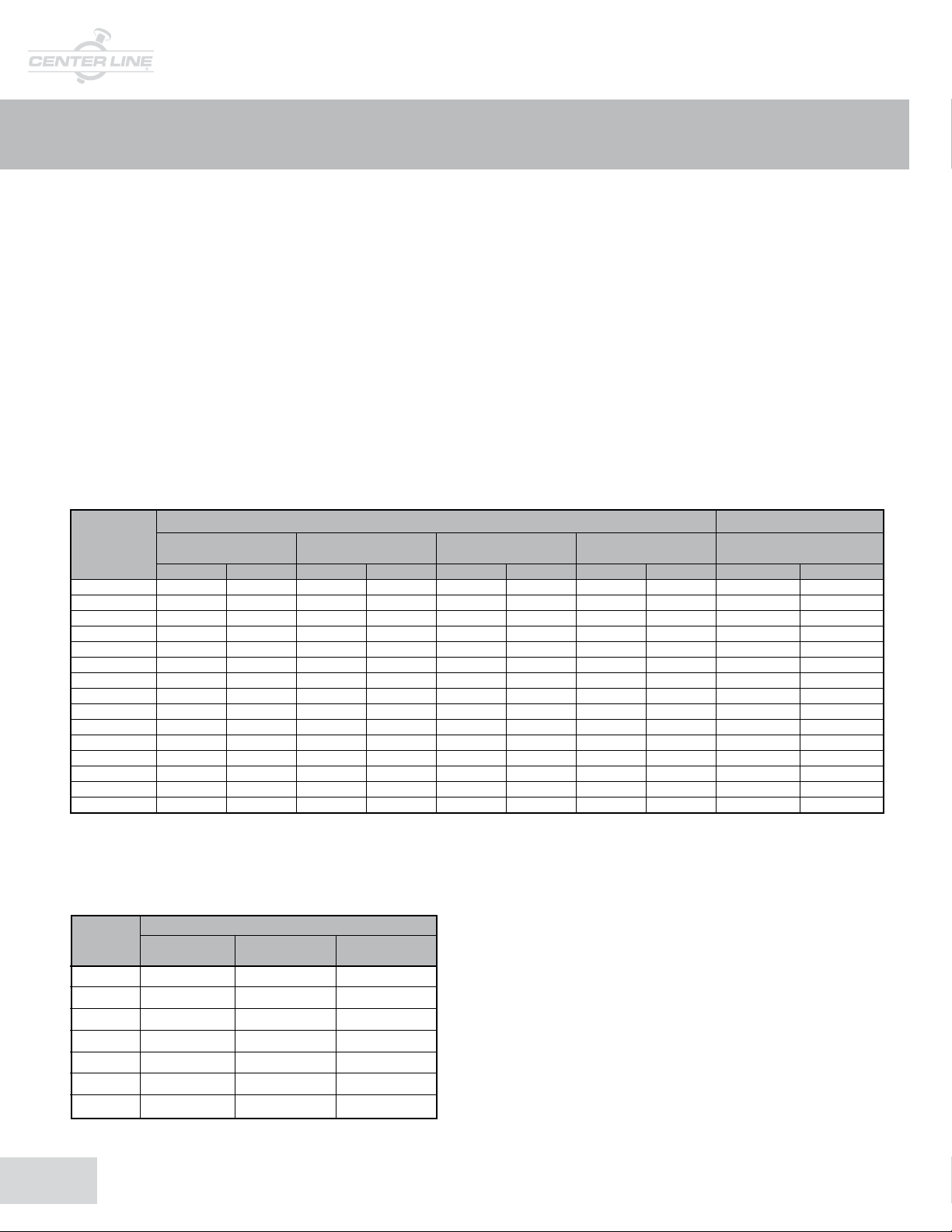

Valve Seating Torques (In-Lbs.) 2" to 30"

Valve

Size

2" 106 100 117 106 129 111 14 0 117 - -

2 ½" 152 150 166 163 181 176 19 5 189 - -

3" 213 207 230 220 248 232 265 244 - 4" 321 290 386 323 450 357 515 390 - 5" 481 423 598 4 81 715 540 832 598 - 6" 692 599 878 691 1,063 783 1,24 8 875 - -

8" 1,326 1,060 1,716 1,18 3 2 ,106 1,307 2,49 6 1,43 0 1,124 819

10" 2,239 1,671 3,010 1, 872 3,780 2 ,074 4, 550 2,2 75 1,363 909

12" 3,9 59 2,568 4,953 2,795 5,9 48 3,02 3 6,942 3,250 2,457 1,445

14" 4,881 2,640 6,226 3,070 7, 570 3,500 - - 4,400 2,300

16" 7, 02 0 4,26 0 8,580 4,880 10 ,140 5,50 0 - - 5,9 00 3,60 0

18" 10,105 6,287 12 ,202 7, 243 14, 300 8,200 - - 8,300 5,5 00

20" 13,923 8,360 16,58 2 9,1 80 19,24 0 10,000 - - 11,1 00 6,70 0

24" 23, 617 15,427 26,953 16,813 30,290 18,2 00 - - 1 7,3 00 1 2,10 0

30" 39, 721 27, 31 3 43,391 29,40 7 47,060 31,500 - - 2 7,3 00 21,100

50 PSI ∆P

Bushing

Bronze PTFE Bronze PTFE Bronze PTFE Bronze PTFE Bronze PTFE

Standard Disc Differential Pressure Undercut Differential Pressure

100 PSI ∆P

Bushing

150 PSI ∆P

Bushing

200 PSI ∆P

Bushing

75 PSI ∆P

Bushing

Valve Seating Torques

(In-Lbs.) 28" to 48" Double Flanged

Standard Disc Differential Pressure

Valve 50 PSI 100 PSI 150 PSI

Size Wet Wet Wet

28" 23,718 26,639 28,957

30" 28,320 30,860 33,338

32" 32,418 35,073 38,126

36" 40,622 43,480 46,524

40" 68,924 74,048 78,995

42" 69,747 74,632 79,862

48" 96,598 103,837 111,112

2

Crane ChemPharma & Energy

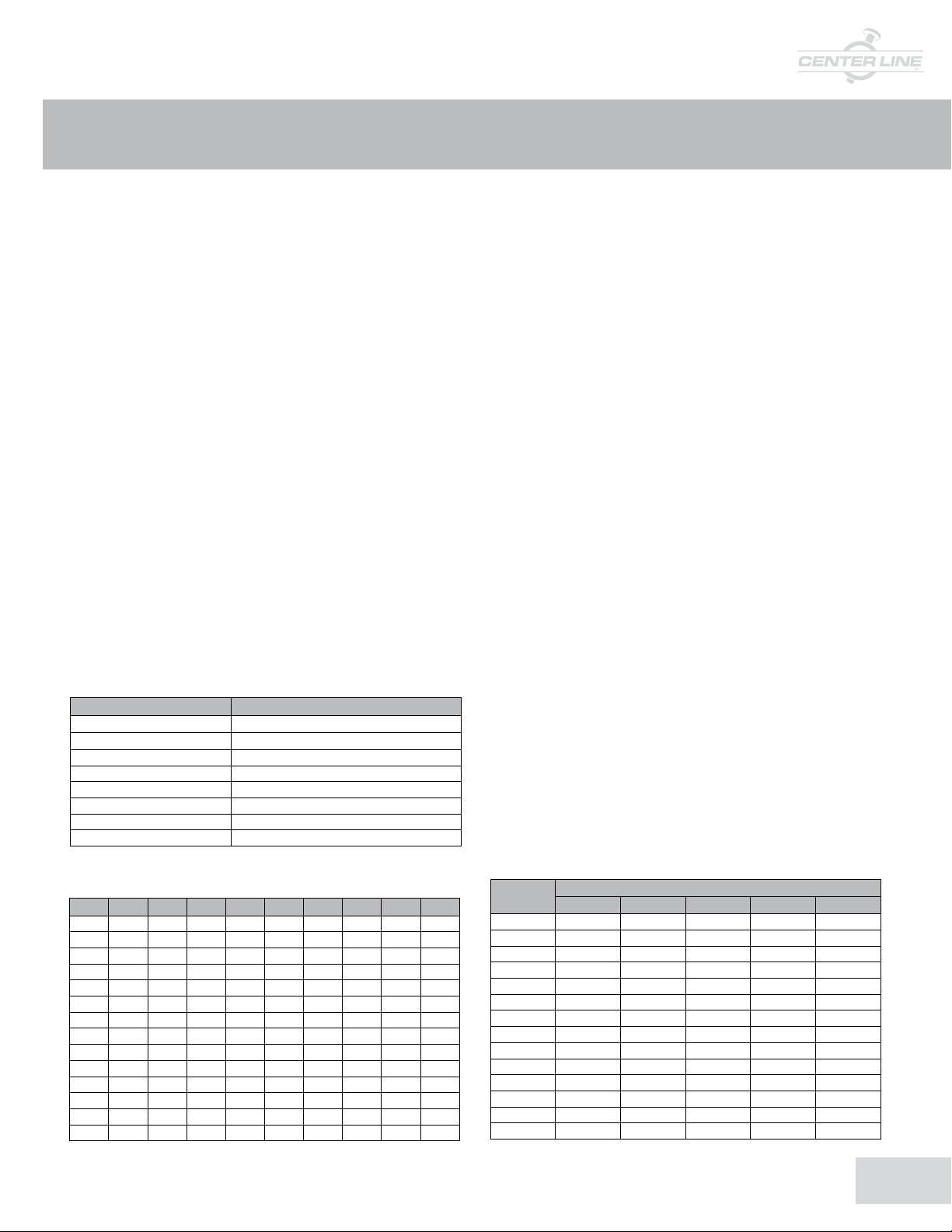

All torques shown in these charts were derived from test data using water

at 60°F. For torques using dry gases, multiply these numbers by 2.0. For

torques involving other media, please consult the factory.

There is no safety factor included in the numbers shown on these charts.

For actuator sizing, Crane recommends that these values be multiplied

by 1.2 for single valve applications, or 2.0 for 3-way (“tee”) applications.

For PTFE/Buna seats multiply the numbers shown by 2.0.

Under certain conditions, hydrodynamic torque can meet or exceed

seating and unseating torques. When designing valve systems,

hydrodynamic torque must be considered to help assure correct

selection for the application.

www.cranecpe.com

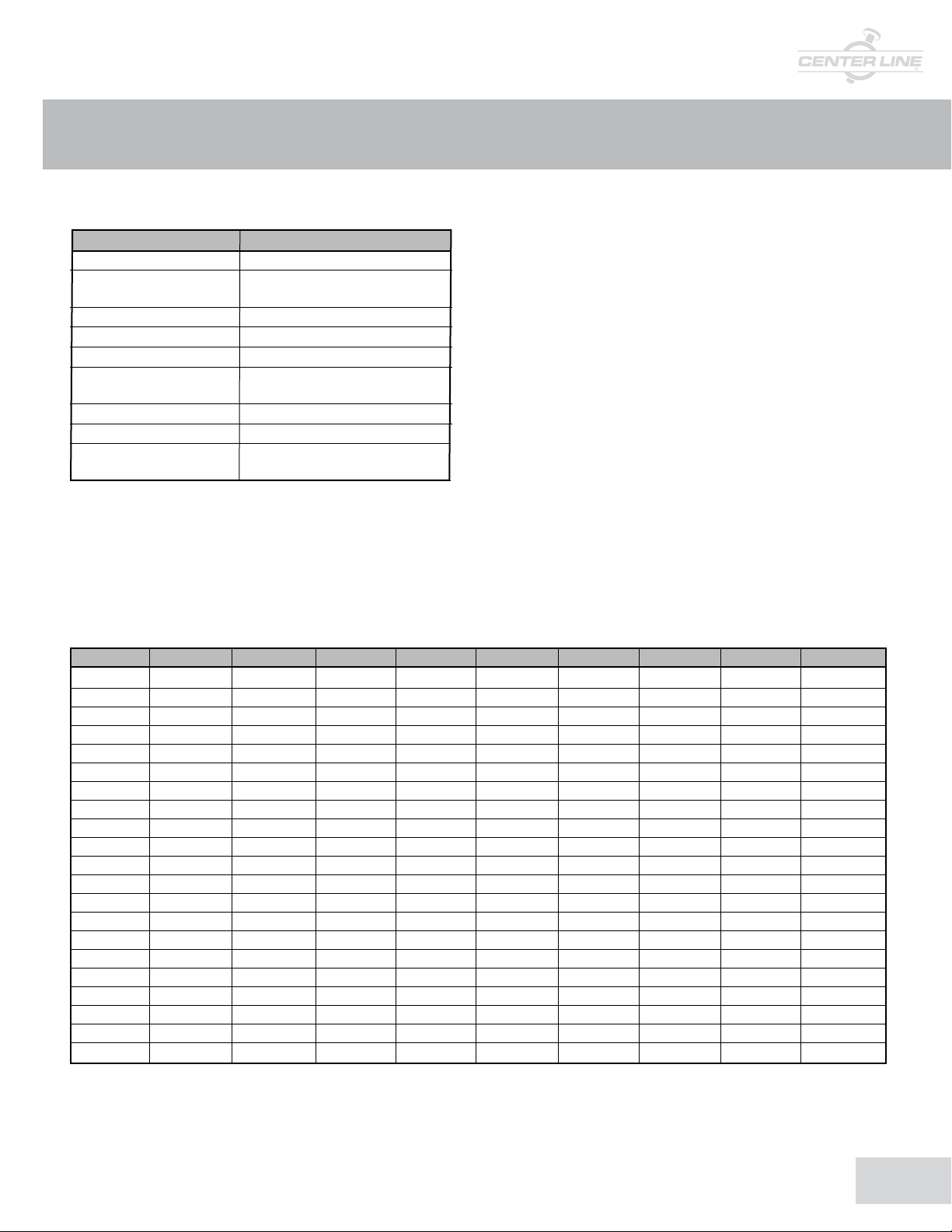

Series 200 Temperature Ratings and Cv Values

Seat Temperature Ratings

Material Temperature Ratings °F

Buna-N +10 to 180

Abrasive Resistant +10 to 180

Buna-N

Neoprene +20 to 200

EPDM (2"- 16") -30 to 275

EPDM (18" & Above) -30 to 225

EPDM, Food Grade -30 to 225

(2" - 12")

Viton

High Temp. Viton® +10 to 400

PTFE over Buna-N

(125 psi, 2" - 12") +40 to 250

®

+10 to 275

Although elastomers have an effective operating temperature

range, when used in valves, these ranges may have to be

modified. The temperature ranges shown in the table have been

adjusted accordingly.

For Low Temperature: While the seat materials selected for

use in Center Line butterfly valves are capable of withstanding

lower temperatures without damage, the durometer of the

elastomer is changed. This “hardening” of the seat may increase

the operating torque beyond the structural limits of the stem

and/or the disc to stem configuration.

For High Temperature: When using High Temperature Viton®,

the operating pressure of the valve is reduced above 275°F.

Field Replacement: Replacing seats in sizes 14" and above

requires factory service.

CV Values – Valve Sizing Coecients (US-GPM @ 1∆P) 2" to 48"

Size 10° 20° 30° 40° 50° 60° 70° 80° 90°

2" 0.06 3 7 15 27 44 70 105 115

2 ½" 0.10 6 12 25 45 75 119 178 196

3" 0.20 9 18 39 70 116 183 275 302

4" 0.30 17 36 78 139 230 364 546 600

5" 0.50 29 61 133 237 392 620 930 1022

6" 0.80 45 95 205 366 605 958 1437 1579

8" 2 89 188 408 727 1202 1903 2854 3136

10" 3 151 320 694 1237 2047 3240 4859 5340

12" 4 234 495 1072 1911 3162 5005 7507 8250

14" 6 338 715 1549 2761 4568 7230 10844 11917

16" 8 464 983 2130 3797 6282 9942 14913 16388

18" 11 615 1302 2822 5028 8320 13168 19752 21705

20" 14 791 1647 3628 6465 10698 16931 25396 27908

24" 22 1222 2587 5605 9989 16528 26157 39236 43116

28" 36 1813 3639 6636 10000 14949 22769 34898 49500

30" 37 2080 4406 9546 17010 28147 44545 66818 73426

32" 45 2387 4791 8736 13788 20613 31395 48117 38250

36" 260 3050 6730 12740 20220 32500 52500 79600 87500

40" 84 4183 8395 15307 24159 36166 55084 84425 119750

42" 350 4095 9040 17108 27150 43640 70500 106890 117500

48" 455 5365 11840 22400 30600 51200 92300 140000 154000

www.cranecpe.com

Crane ChemPharma & Energy

3

O

P

of valve

of pipe

Body

Disc

C

L

C

L

J Di a.

C

For 30" Valves

H

“F” Dia.

4 Holes Eq. Sp.

on “G” Dia. BC

From 2" to 24" Valves

“F” Dia.

4 Holes Eq. Sp.

on “G” Dia. BC

J Sq.

C

For 2"-24" Valves

“K” Bolt Circle

“L

1

” Dia.

“M

1

” No. of Holes

E Dia.

D

P

B

A

Lug Style Body

P

“K” Bolt Circle

“L

2

” Dia.

“M

2

” No. of Holes

E Dia.

D

N

B

A

Wafer Style Body

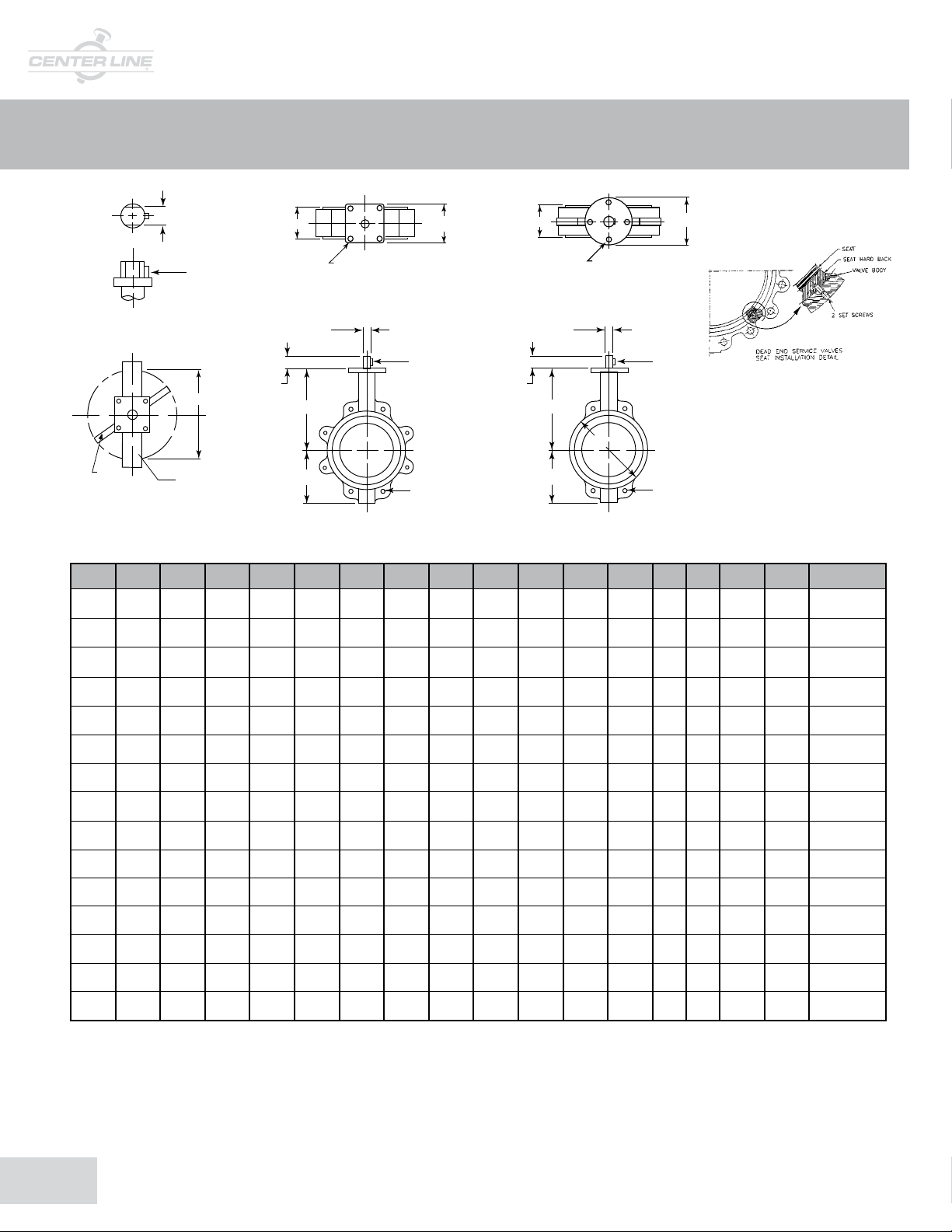

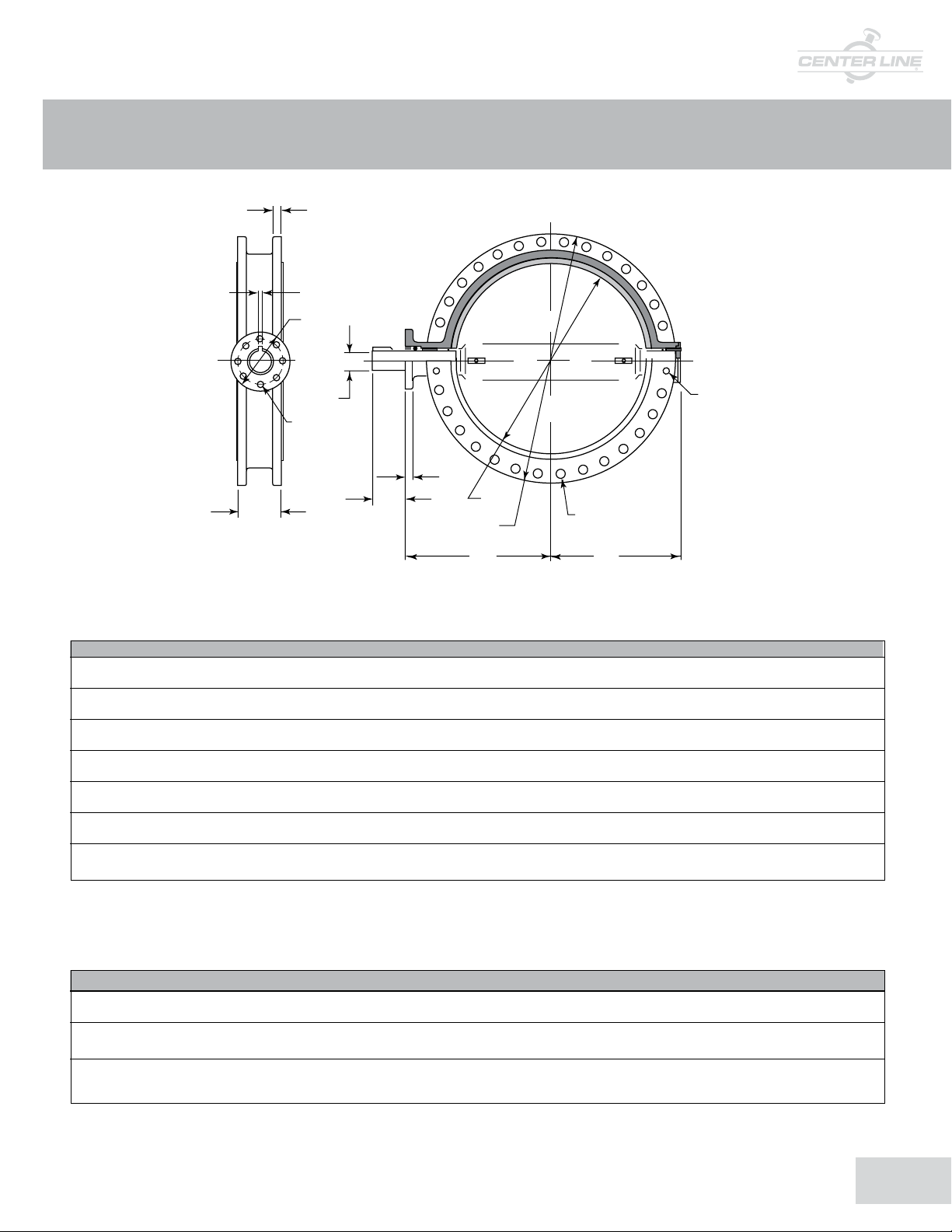

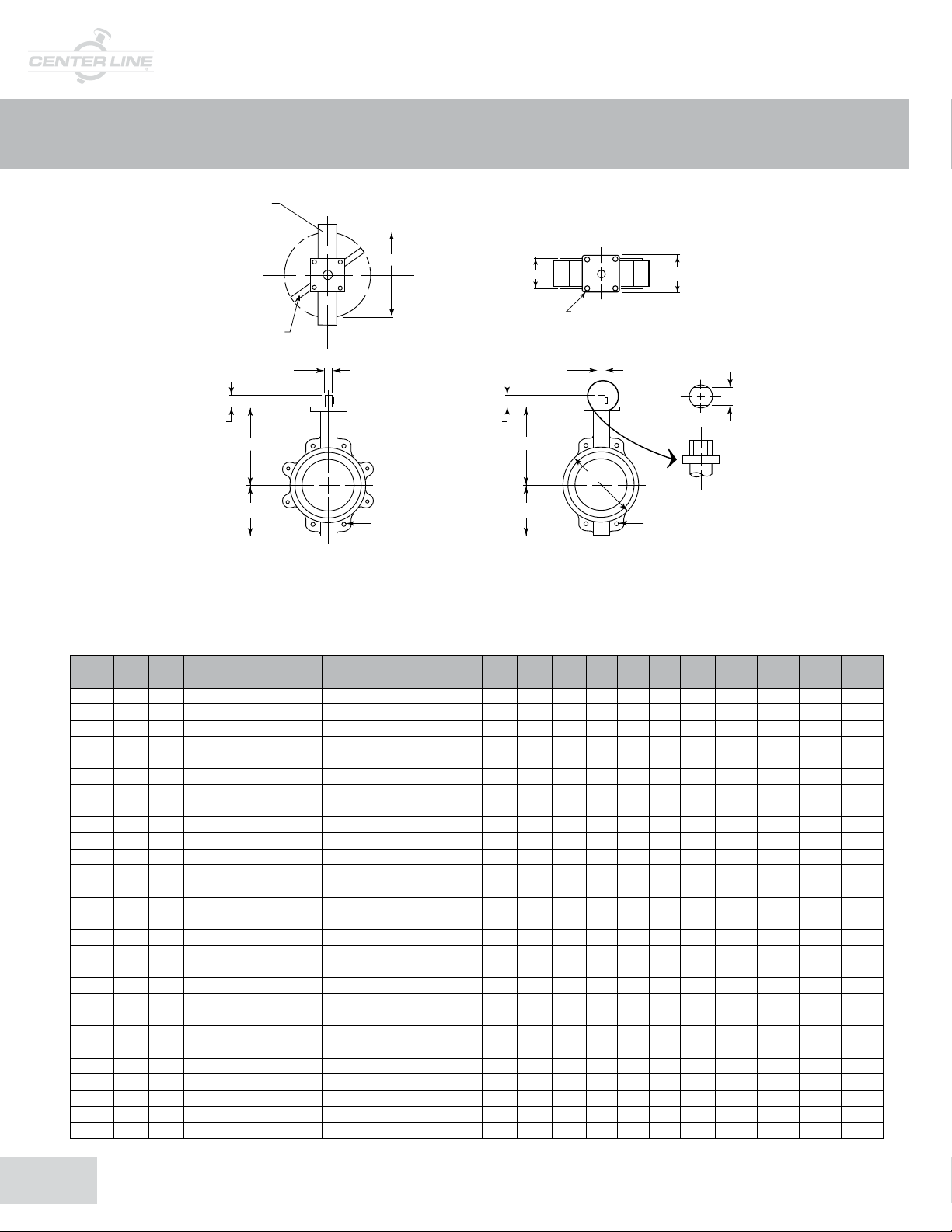

Series 200 Dimensions

Dimensions 2" - 30" Wafer and Lug

For installation and maintenance instructions, please refer to the IOM manual available at w ww.cranevalvelit.com

Inches /

mm

2

100 200.03 114.30 53.98 31.75 15.88 9.53 70 12 69.85 190.50 17.46 158.75 89.9

125 212.73 127.00 60.33 31.75 19.05 9.53 70 14 69.85 215.90 20.64 190.50 110.7

150 225.43 139.70 60.33 31.75 19.05 9.53 70 14 69.85 241.30 20.64 212.73 145.3

200 260.35 174.63 63.50 44.45 22.23 11.11 102 17 95.33 298.45 20.64 269.88 193.0

10" 11

250 292.10 203.20 69.85 44.45 28.58 11.11 102 22 95.33 361.95 23.81 327.03 241.3

12" 13

300 336.55 244.48 79.38 44.45 31.75 11.11 102 24 95.33 431.80 23.81 403.23 290.8

14" 14

350 368.30 266.70 79.38 44.45 31.75 11.11 102 24 95.33 476.25 26.99 434.98 324.6

16" 15

400 400.05 327.02 88.90 50.80 33.34 22.23 165 27 165.10 539.75 26.99 488.95 380.2

18" 16

450 422.28 346.08 107.95 50.80 38.10 22.23 165 27 165.10 577.85 31.75 539.75 427.5 .

20" 18

500 479.43 384.18 136.53 63.50 41.28 22.23 165 32 165.10 635.00 31.75 650.88 474.2

24" 22

600 561.98 466.73 155.58 69.85 50.80 22.23 165 36 165.10 749.30 34.93 708.03 574.5

30" 25

750 647.70 628.65 171.45 82.55 63.50 22.23 215.90 285.75 914.40 31.75 873.13 726.4

L1 and M1 refer to Lug style valves, L2 and M2 refer to Wafer Style. “C” dimension is listed with elastomer in the relaxed condition. Approximately 1/8" total compression is required

for proper sealing with pipe flanges. Valves are designed for installation between ASME B16.1 Class 125 (Iron) and B16.5 Class 150 (Steel) flanges. Gaskets are not needed, and should

not be used since the seat face seals against the mating flange. If the valve is to be installed in bet ween any other flanges, consult your Center Line agent or the factory for additional

information. Center Line recommends that a blind flange be used on end of line applications.

“O” dimension is the valve clearance dimension.

A B C D E F G H

1

2" 6 3/

50 161.93 80.96 47.63 31.75 12.70 9.53 70 10 69.85 120.65 17.46 101.60 32.0

1

/2" 6 7/

65 174.63 88.90 50.80 31.75 12.70 9.53 70 10 69.85 139.70 17.46 120.65 46.5

3" 7

80 180.98 95.25 50.80 31.75 12.70 9.53 70 10 69.85 152.40 17.46 127.00 64.5

4" 7

5" 8

6" 8

8" 10

8

8

1

/

8

7

/

8

3

/

8

7

/

8

1

/46 7/

1

/

2

1

/49 5/

1

/210 1/

3

/412 7/

5

/813 5/

7

/815 1/

1

/818 3/

1

/224 3/

3 3/

16

3 1/

2

3 3/

4

4 1/

2

5 2 3/

5 1/

2

8

8 2 3/

8

2

8

8

8

8

4

1 7/

1 1/

8

4

2 1 1/

2 1 1/

2 1/

2 3/

2 1/

3 1/

3 1/

3 1/

4 1/

5 3/

6 1/

63/

4

4

1 1/

8

4

1 1/

8

4

1 1/

8

4

1 3/

2

4

1 3/

4

4

1 3/

8

4

1 3/

8

4

2 1 5/

2

2 1 1/

4

2 3/

8

4

2 3/

8

4

31/

4

4

1 1/

1 1/

1 1/

1 5/

3

/

/

2

1

/

2

1

/

2

5

/

8

3

/

4

3

/

4

7

/

8

8

4

4

16

2

8

2

21/

2

2.76 0.39 2 3⁄

8

3

/

2.76 0.39 2 3⁄

8

3

/

2.76 0.39 2 3⁄

8

3

/

2.76 0.47 2 3⁄

8

3

/

2.76 0.55 2 3⁄

8

3

/

2.76 0.55 2 3⁄

8

7

/

4.02 0.67 3 3⁄

16

7

/

4.02 0.87 3 3⁄

16

7

/

4.02 0.95 3 3⁄

16

7

/

4.02 0.95 3 3⁄

16

7

/

6.50 1.06 6 1⁄

8

7

/

6.50 1.06 6 1⁄

8

7

/

6.50 1.26 6 1⁄

8

7

/

6.50 1.42 6 1⁄

8

7

/

81/

8

2

N/A 111/

J

4 3⁄

4

5 1⁄

4

4

7 1⁄

4

8 1⁄

4

9 1⁄

4

11 3⁄

4

14 1⁄

4

4

18 3⁄

4

21 1⁄

2

22 3⁄411/8 - 7 11⁄

2

2

29 1⁄211/4 - 7 13⁄

2

4

K L

5

4

5

2

5

6

5

2

3

2

3

2

3

4

4

17

4

4

25 11/8 - 7 11⁄

1

⁄8-11

⁄8-11

⁄8-11

⁄8-11

⁄4-10

⁄4-10

⁄4-10

7

⁄8-9

7

⁄8-9

1-8 11⁄

1-8 11⁄

L

M1M

2

11

⁄

16

11

⁄

16

11

⁄

16

11

⁄

16

13

⁄

16

13

⁄

16

13

⁄

16

15

⁄

16

15

⁄

16

16

16

4

4

8

2

4 4 4 1.26 Woodruff #3

4 4 4 3⁄4 1.83 Woodruff #3

4 4 5 2.54 Woodruff #3

8 4 6 1⁄

8 4 7 1⁄

8 4 8 3⁄

8 4 10 5⁄

12 4 12 7⁄

12 4 15 7⁄811.45 Woodruff #15

12 4 17 1⁄812.78 Woodruff #15

16 4 19 1⁄414.975⁄16" Sq. x 1 3/4"

16 4 21 1⁄416.833⁄8" Sq. x 1 1⁄2"

20 4 23 5⁄818.673⁄8" Sq. x 1 3⁄4"

20 4 27 7⁄822.621⁄2" Sq. x 2 1⁄4"

36 11/4 - 7 11/4 28 4 343/

N O P

3.54 Woodruff #9

4

4.36 Woodruff #9

2

5.72 Woodruff #9

8

7.6 Woodruff #9

8

9.5 Woodruff #15

8

28.65⁄8" Sq. x 2 5⁄8"

8

4

Crane ChemPharma & Energy

www.cranecpe.com

A

B

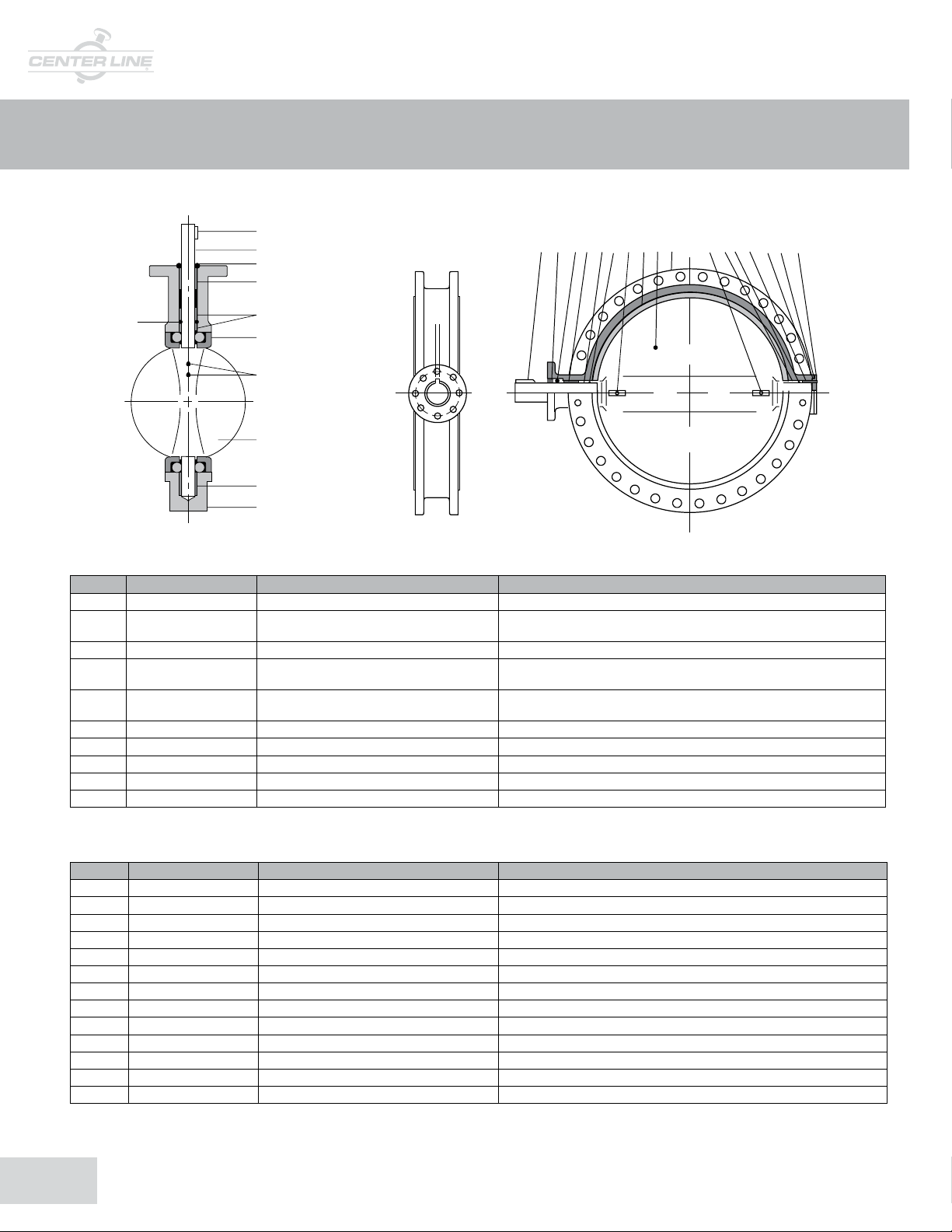

Series 200 Dimensions

E

M

Q DIA

(4) HOLES

THREAD SIZE R

EACH FLANGE

FACE

C

H

(8) HOLES F

DIA ON G

BOLT

CIRCLE

S

N DIA

P DIA

J- NO. OF HOLES

K- DIA OF HOLES

L- BOLT CIRCLE

D

*Dimensions 28" - 48" Double Flanged

For installation and maintenance instructions, please refer to the IOM manual

A B C D E F G H J K L M N P Q R S

28 in 24.6 20.5 6.6 3.7 2.2 0.7 10 2.5 24 1.4 34 0.7 Sq. 36.6 27.8 11.8 1.25 - 7 1.3

mm 626 521 165 95 54 18 254 63.4 24 35 863.4 18 Sq. 930 695 300 – 33

30 in 26.0 21.8 6.7 3.7 2.2 0.7 10 2.5 24 1.4 36 0.7 Sq. 39.4 29.8 11.8 1.25 - 7 1.3

mm 660 554 167 95 54 18 254 63.4 24 35 914.4 18 Sq. 984 744 300 – 33

32 in 26.2 23.3 7.6 3.7 2.4 0.7 10 2.5 24 1.6 39.5 0.7 Sq. 42.4 31.8 11.8 1.5 - 6 1.3

mm 666 591 190 95 60.3 18 254 63.4 24 41.3 978 18 Sq. 1060 795 300 – 33

36 in 28.4 25.6 8.1 5.1 2.4 0.7 10 3 28 1.6 42.75 0.8 Sq. 47 34.0 11.8 1.5 - 6 1.3

mm 722 650 203 130 60.3 18 254 75 28 41.3 1086 20 Sq. 1169 864.7 300 – 33

40 in 31.7 28.1 8.7 5.1 2.4 0.7 10 3.3 32 1.6 47.25 0.9 Sq. 51.6 38.6 11.8 1.5 - 6 1.5

mm 806 713 218 130 60.3 18 254 85 32 41.3 1200 22 Sq. 1289 965 300 – 38

42 in 34.1 30.3 10 5.9 2.6 0.7 10 3.3 32 1.6 49.5 0.9 Sq. 53 40.5 11.8 1.5 - 6 1.4

mm 865 770 251 150 66 18 254 85 32 41.3 1257 22 Sq. 1346 1030 300 – 35

48 in 36.9 33.7 10.9 5.9 2.8 0.9 11.7 4.1 40 1.6 56 1.1 Sq. 59.5 45.7 13.8 1.5 - 6 1.5

mm 938 855 276.4 150 70 22 298 105 40 41.3 1422 28 Sq. 1511 1160 350 – 38

*Please note that dimensions apply to standard product only.

Weights 2" - 48" – lbs (kg)

2" 2 ½" 3" 4" 5" 6" 8" 10" 12" 14" 16" 18" 20" 24" 28" 30" 32" 36" 40" 42" 48"

Wafer 6 7 10 13 18 20 32 42 70 95 117 165 275 440 – 740 – – – – –

(2.7) (3.2) (4.5) (5.9) (8.2) (9.1) (14.5) (19.1) (31.7) (43.1) (53.1) (74.8) (124.7) (199.6) (335.7)

Lug 7 8 14 26 28 31 49 72 105 155 195 230 396 610 – 1050 – – – – –

(3.2) (3.6) (6.4) (11.8) (12.7) (14.1) (22.2) (32.7) (47.6) (70.3) (88.5) (104.3) (179.6) (276.7) (476.3)

Flanged – – – – – – – – – – – – – – 1173 1173 1525 1949 2141 2495 3711

– – – – – – – – – – – – – – (533) (533) (693) (886) (973) (1134) (1687)

Note: Technical data subject to change without notice.

www.cranecpe.com

Crane ChemPharma & Energy

5

6

4

7

7

8

9

3

5*

2

10

1

81079 376521 6 47911 13 12

Series 200 Materials of Construction

Sizes 2"-30"

*Quantity of 3

pins required for

30" lug or wafer

style valves.

Sizes 28"-48"

Bill of Materials 2" - 30"

Item Description Materials Optional Materials

1 Body Ductile Iron (A 536 65-45-12) Ductile Iron (A 536 65-45-12), (A395 60-4 0-18)

2 Disc

3 Seat Buna-N or EPDM Neoprene, Viton®, PTFE, FDA, Abrasion Resistant

4 Shaft

5 Taper Pins

6 Key Carbon Steel No Option Available

7 O-Ring Buna-N No Option Available

8 Bushing PTFE Luberized Bronze

9 Bushing PTFE Luberized Bronze

10 Bushing PTFE Luberize d Bronze

†ENP plated for 2"-12" valves

Ductile Iron†

(A536 65-45-12)

416 Stainless Steel

(A5 82-416)

416 Stainless Steel

(A5 82-416)

Aluminum Bronze (B148-C954), 316 SS (A351-CF8M),

Monel® (A494-M30C)

316 Stainless Steel (A276/A479-316),

Monel® (B164-K40 0 CL-B), 17-4PH (A564- 630/1150)

316 Stainless Steel (A276/A479-316),

Monel® (B164-K40 0 CL-B), 17-4PH (A564- 630/1150)

Bill of Materials 28" - 48"

Item Description Materials Optional Materials

1 Body Ductile Iron (A 536 65-45-12) Ductile Iron (A 395 60-4 0-18)

2 Disc Ductile Iron (A 536 65-45-12) Aluminum Bronze (B148-C954), 316 SS (A351-CF8M)

3 Upper Shaf t 416 Stainless Steel (A582-416) 316 SS (std. w/ 316 SS disc) (A276/A479-316)

4 Lower Shaft 416 Stainless Steel (A582-416) 316 SS (std. w/ 316 SS disc) (A276/A479-316)

5 Seat Buna-N or EPDM Vito n®

6 Taper Pin 416 Stainless Steel (A582-416) 316 Stainless Steel (A276/A479-316)

7 O -Ring Buna-N No Option Available

8 Key Carbon Steel N o Option Available

6

9 Bushing TFE Luberized Bronze

10 Bushing TFE Luberize d Bronze

11 T hrust Wa sher TFE Luberized Bronze

12 End Plate Ductile No Option Available

13 O-Ring Buna-N No Option Available

Monel® is a registered trademark of Special Metals Corporation.

Crane ChemPharma & Energy

www.cranecpe.com

Series 225 - 250 Overview

• Available in sizes 2" to 24".

• Pressure Rating: 285 psi at 100°F. Pressure/Temperature rating

above 100°F with downstream flange installed. Available

option: Bi-directional dead-end service capability without

downstream flange to 200 psi (2" to 12") and 150 psi (14" to 24").

• Available in Wafer or Lug style body.

• Wafer body features four alignment holes.

• Available in ASME Class 300 Lug Body bolt pattern

(2" to 12"). Series 225 only.

• Ideal for on-off or throttling services.

• Available with handles (2" to 6"), manual gear operators,

electric actuators and pneumatic actuators (2" to 24").

• Refer to Crane automation bulletin for details of pneumatic

and electric actuators.

• Compatible with ASME B16.1 Class 125 (Iron) and ASME B16.5

Class 150 (Steel) flanges or optional Class 300 (Steel) Lug only.

• Valves 14" and larger are rated at a maximum 150 psi when a

companion flange is not used in dead end service.

• For bolting information, consult the Center Line Installation

and Maintenance Manual.

• Vacuum Service Rating: zero leakage at 24" of mercury.

• Commercial cleaning available for Oxygen level 2.

• Type approval certification from ABS for Marine applications

(2" to 24").

• CE/PED Certification available for sizes 2" to 24".

Seat Temperature Ratings

Material Temperature Rating °F

Buna-N +10 to 180

EPDM (2"-16") -30 to 275

EPDM (18"-24") -30 to 225

Abrasive Resistant Buna-N +10 to 180

Neoprene +20 to 200

Vito n® +10 to 275

High Temperature Viton® +10 to 400

PTFE (Series 250 only) +40 to 250

All torques shown on the chart were derived from test data

using water at 60°F. For torques using dry gases, multiply these

numbers by 2.0. For torques involving other media, please

consult the factory.

There is no safety factor included in the numbers shown on

this chart. For actuator sizing, Center Line recommends that

these values be multiplied by 1.2 for single valve applications,

or 2.0 for 3-way (“tee”) applications.

For PTFE seats multiply the numbers shown on this chart by 2.0.

Under certain conditions, hydrodynamic torque can meet or

exceed seating and unseating torques. When designing valve

systems, hydrodynamic torque must be considered to help

assure correct selection for the application.

Although elastomers have an effective operating temperature

range, when used in valves, these ranges may have to be

modified. The temperature ranges shown in the table have

been adjusted accordingly.

For Low Temperature: While the seat materials selected for

use in Center Line butterfly valves are capable of withstanding

lower temperatures without damage, the durometer of the

elastomer is changed. This “hardening” of the seat may increase

the operating torque beyond the structural limits of the stem

and/or the disc to stem configuration.

For High Temperature: When using High Temperature Viton®,

the operating pressure of the valve is reduced above 275°F.

Field Replacement: Replacing seats in sizes 14" and above

requires factory service.

CV Values – Valve Sizing Coecients

(US-GPM @ 1∆P)

Size 10° 20° 30° 40° 50° 60° 70 ° 80° 90°

2" 0.06 3 7 15 27 44 70 105 115

2 ½" 0.1 0 6 12 25 45 75 119 178 196

3" 0.20 9 18 39 70 116 183 275 302

4" 0.30 17 36 78 139 230 364 546 600

5" 0.50 29 61 133 237 392 620 930 102 2

6" 0.80 34 94 153 257 422 706 115 4 1320

8" 2 56 154 251 422 693 115 8 1892 2165

10" 3 87 238 385 654 107 3 1794 2931 3353

12" 4 15 3 417 681 114 5 1879 3142 5132 5827

14" 6 183 500 816 13 72 2252 3765 6150 7037

16" 8 271 740 120 8 2031 3333 5573 910 4 10,416

18" 11 318 867 1417 2382 39 09 6535 10,676 12,215

20" 14 415 11 33 1851 3112 5107 8538 13,948 15,959

24" 22 543 148 2 2421 4069 6678 11,16 5 18 ,240 20, 869

www.cranecpe.com

Valve Seating Torques (in-lbs.)

Valve

Size

2" 136 142 148 15 4 164

2 ½" 152 16 0 168 176 189

3" 2 24 229 234 239 247

4" 380 392 404 416 436

5" 451 477 503 52 9 572

6" 875 946 1016 1087 120 6

8" 14 76 1559 16 42 1726 1867

10" 2451 2613 2775 2937 3213

12" 390 0 4111 4323 4534 4893

14" 518 9 5467 5 744 6022 6494

16" 10,985 11,5 69 12 ,154 12,7 38 13,732

18" 13, 946 14,6 88 15,431 16 ,173 1 7,43 4

20" 14,69 5 15,478 16, 260 17, 0 43 18,37 3

24" 2 9,738 31,321 32,9 03 34,486 3 7,176

50 PSI 10 0 PSI 150 PSI 200 PSI 285 PSI

Standard Disc Differential Pressure

Crane ChemPharma & Energy

7

“K ” Bolt Circle

“L

1

” Dia.

“M

1

” No. of Holes

E Dia.

D

B

A

Lug Style Body

O

of valve

of pipe

Body

Disc

“F” Dia.

4 Holes Eq. Sp.

on “G” Dia. BC

From 2" to 24" Valves

J Sq.

C

C

L

C

L

“K ” Bolt Circle

“L

2

” Dia.

“M

2

” No. of Holes

E Dia.

D

N

B

A

H

Wafer Style Body

Series 225 - 250 Dimensions

Dimensions and Weights

For installation and maintenance instructions, please refer to the IOM manual available at w ww.cranevalvelit.com

Inches /

2

A B C D E F G H

mm

2" 6 3/83 3/161 7/81 1/

50 161.93 80.96

1

/2" 6 7/83 1/22

65 174.63 88.90

47.63

50.80

3" 7 1/83 3/42

80 18 0.98 95.25

50.80

4" 7 7/84 1/22 1/81 1/

100 20 0.03 114.3 0 53.98 31. 75 15.8 8 9.53 70 12 69.85 190.5 0 200.03 17.4 6

3

/85

5" 8

125 212. 73 127.00

6" 8 7/85 1/22 3/81 1/

150 2 25.43 139.70

200 260.35 174.63 63.50 4 4.45 22.23 11.11 102 17 95.33 2 98.45 330.20 20.6 4

10" 11

1

8" 10

/46 7/82 1/21 3/

1

/28 2 3/41 3/41 1/

2 3/81 1/

60.33

60.33

250 2 92.1 0 203.20 69.85 44.45 28.58 11.11 102 22 95. 33 361.9 5 3 87. 35 23. 81

12" 13 1/49 5/83 1/81 3/41 1/

300 336.55 24 4.48 79.3 8 44.45 31.75 11 .11 102 24 95. 33 431.80 450.85 2 3.81

14" 14

350 368.30

16" 15

400 400.05

18" 16

450 422.28

20" 18

500 479.43

1

/211 3 1/81 3/41 1/

279.00

3

/412 3 1/22 1 5/

5

/813 1/44 1/42 1 5/

7

/814 5/85 3/82 1/21 5/

79.3 8 44.4 5 31.75 11.11 102 24 95.33 476.25 - 26.99

305.00

88.90 50.80 33.34 22.23 165 27 1 65.1 0 5 39.75 - 26.99

336.55

10 7.9 5 50.80 41.28 22.23 16 5 32 1 65.1 0 5 77. 85 -

371.48 136. 53

1

3

/

4

31.75 12.70 9.53 70 10 69.8 5 120. 65 127.00 17.4 6 101.60 2.72 kg 4.0 8 kg 4.08 kg 32 .0

1 1/

4

31.75 12.70 9.53 70 10 69.8 5 139.7 0 149.2 3 17.4 6 120.6 5 3.1 8 kg 5.90 kg 5.9 0 kg 46.5

1 1/

4

31.75 12.70 9.53 70 10 69.8 5 152.4 0 168.28 17.4 6

4

4

31.75 19.0 5 9.5 3 70 14 69.85 215.90 2 34.95 20.64

4

31.75 19.0 5 9.5 3 70 17 69.85 241.30 26 9.88 20.64

4

63.50 41.28 22.23 165 32 1 65.1 0 635.00 -

/82.76 0.39 2 3⁄44 3⁄455⁄8-115⁄8-1111⁄164

2

1

3

/

/82.76 0.39 2 3⁄45 1⁄25 7⁄

2

1

3

/

/82.76 0.39 2 3⁄46 6 5⁄

2

5

3

/

/82.76 0.47 2 3⁄47 1⁄27 7⁄

8

3

3

/

/82.76 0.55 2 3⁄48 1⁄29 1⁄

4

3

3

/

/82.76 0.55 2 3⁄49 1⁄210 5⁄

4

7

7

/

/164.02 0.67 3 3⁄411 3/4133⁄4-107⁄8-913⁄168 12 4

8

7

/164.02 0.87 3 3⁄414 1⁄415 1⁄

8

7

/164.02 0.95 3 3⁄417 17 3⁄

4

7

/164.02 0.95 3 3⁄418 3/4- 1- 8 - 11⁄1612 - 4 17 5⁄8109 lb s. 17 8 lbs. - 12.81

4

7

/86.50 1.0 6 6 1⁄221 1/4- 1- 8 - 11⁄1616 - 4

16

7

/86.50 1.26 6 1⁄222 3/4- 11⁄8-7 -

8

7

/8 6.50 1.26 6 1⁄225 - 11⁄8-7 -

8

24" 22 1/818 6 1/82 3/437/86.50 2.36 6 1⁄229 1⁄2- 11⁄4-7 -

600 561.9 8

457.20

155.5 8 69.8 5 76.20 22.23 165 60 16 5.10 749. 30 - 708.03 229.52 kg 318.42 kg 573.3

J

300#

K

K

8

8

8

4

8

300#

L

1

5

⁄8-113⁄4-1011⁄164 8 4 4 3⁄47 lbs. 13 lbs. 13 lbs. 1.8 3

5

⁄8-113⁄4-1011⁄164 8 4 5 10 lbs. 14 lb s. 14 lbs. 2.54

5

⁄8-113⁄4-1011⁄168 8 4 6 1/413 lb s. 19 lbs. 24 lbs . 3.5 4

3

⁄4-103⁄4-1013⁄168 8 4

3

⁄4-103⁄4-1013⁄168 12 4 8 3⁄821 lbs . 31 lbs . 38 lbs. 5. 74

L2M

L

1

300#

1

M2N Wafer Lug

M

1

4

4 4 6 lbs. 9 lbs. 9 lbs. 1.26

127.00

4.54 kg 6. 35 kg 6 .35 kg 64.5

158.75

5.90 kg 8.62 kg 10.89 kg 8 9.9

7 1/218 lb s. 22 lbs. 29 lb s. 4.36

190. 50

8.1 6 kg 9.98 kg 1 3.15 kg 110 .7

212.7 3

9.53 kg 14. 06 kg 1 7.24 kg 145.8

10 5⁄834 lbs. 49 lbs. 67 lbs. 7.63

269. 88

7

⁄8-9 1-815⁄1612 16 4

4

7

⁄8-9 1 1⁄8-715⁄1612 16 4 15 7⁄874 l bs. 105 lbs. 14 4 lbs. 11. 5

4

15.42 kg 22.23 kg 30.39 kg 19 3.8

12 7⁄845 lbs. 62 lbs. 100 lbs. 9. 54

327.03

20.41 kg 28 .12 k g 45.36 kg 242 .3

403.23

33.57 kg 47.63 kg 65.32 kg 29 2.1

4 47. 68

49.4 4 kg 80 .74 kg 325.4

20 1⁄4135 lb s. 224 l bs. - 15

514.35

11⁄416 - 4

31.75 54 6.1 0

11⁄8-7

20 - 4

11⁄4-7

20 - 4 27 7⁄8506 lbs. 702 lbs . - 22.57

61.24 kg 101.60 kg 381.0

21 1⁄2190 lbs . 265 lbs. - 16 .87

86.1 8 kg 120.20 kg 428.5

23 3⁄4316 lb s. 455 lbs . - 18.69

603.25

143.34 kg 206.38 kg 474.7

300#

Lug

O

8

Crane ChemPharma & Energy

www.cranecpe.com

Loading...

Loading...