Crane Dominator PRO Z4000 Series Installation, Operating And Maintenance Instructions

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

These instructions cover the general

points of notice for the following

Z4000 Series units;

• Flow management system for fan coil

units.

• Solder adaptor for end fitting onto

copper tube as per BS EN 1254-1.

• Taper thread to form a mechanical seal

as per BS EN 10226.

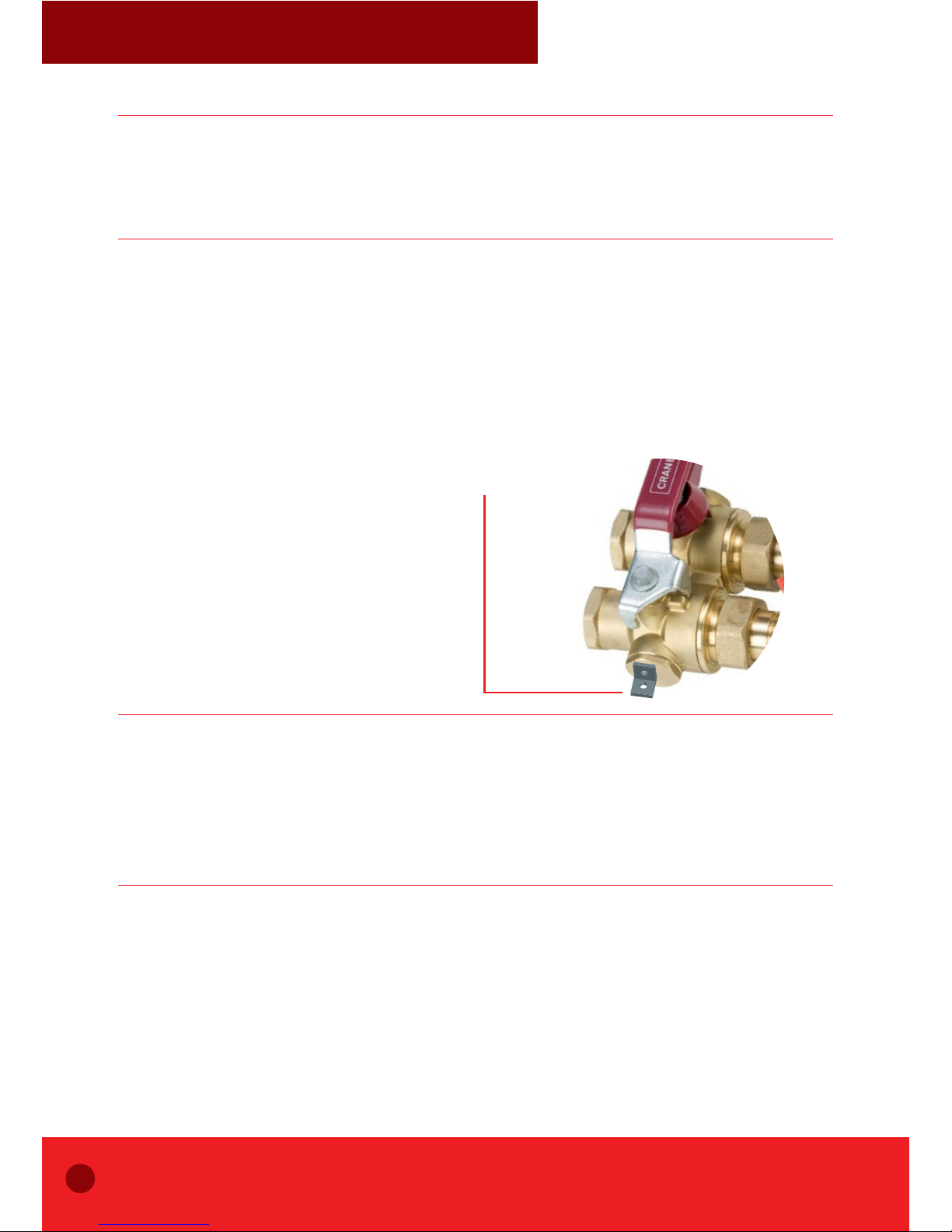

• Combines essential control components

and connecting pipework into one

compact, fully assembled unit ready to

connect.

• The Dominator Pro is compact and ultra

light weight.

• The bypass valve unit comprises two 3

Way Ball valves.

• Includes the Crane PICV (Pressure

Independent Control Valve) for optimum

flow control.

®

Z4000 SERIES

CRANE FLUID SYSTEMS DOMINATOR PRO Z4000 SERIES

02

INSTALLATION

The valve may be installed directly or remotely to a load (typically a Fan Coil Unit).The direction

of flow should be such that the PICV is on the return from the load.

PREPARATION/FITTING

Steel tube - cut square and de-burr internally and externally, thread to BS EN 10226-2 and fit to

Dominator using PTFE tape to BS7786:1995 or other recommended jointing compound. Other

types of piping system can be used providing a suitable adaptor with a threaded end is utilised.

Whilst fitting pipe and/or adapters it is important that the wrench is positioned close to

the joint to be assembled, in order to avoid damaging the valve.

The Dominator Pro shall be supported using proprietary mounting brackets or other suitable

devices see FIGURE 2 this enables the pipework to be well supported and avoids undue strain

on the joints of the Dominator Pro.

OPERATION

Bypass valve

The bypass valve has four primary modes of operation. It is factory set in Isolation/Flushing i.e.

the bypass mode. The mode of operation can be changed by setting the ‘T’ handles/levers as

indicated in Figure 1.

MAINTENANCE

Bypass valve

This valve is intended for group 2 liquids only, as defined by the Pressure Equipment Directive

2014/68/EU.

For further assistance please call our technical helpline on +44 (0) 1473 277400 or email us at:

enquiries@cranefs.com.

Following a policy of continuous improvement, Crane Fluid Systems reserves the right to alter

specifications shown in this document and the e-catalogue without prior notice.

FIGURE 2:

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

Loading...

Loading...