Crane Deming 3904 Series, Deming 3914 Series Installation, Operation & Maintenance Manual

DEMING

®

Manual Index

DEMING

INSTALLATION, OPERATION & MAINTENANCE MANUAL

End-suction Centrifugal Pumps

Series: 3904

3914

IMPORTANT! Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

change product without prior written notifi cation.

A Crane Co. Company

420 Third Street 83 West Drive, Bramton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com

Form No. 119996-Rev. E

SAFETY FIRST!

Please Read This Before Installing Or Operating Pump.

This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information,

observe the following symbols:

IMPORTANT! Warns about hazards that can result

in personal injury orIndicates factors concerned with

assembly, installation, operation, or maintenance which

could result in damage to the machine or equipment if

ignored.

CAUTION! Warns about hazards that can or will cause minor

personal injury or property damage if ignored. Used with symbols

below.

WARNING! Warns about hazards that can or will cause serious

personal injury, death, or major property damage if ignored. Used

with symbols below.

Hazardous fl uids can

cause fi re or explo-

sions, burnes or death

could result.

Biohazard can cause

serious personal injury.

Rotating machinery

Amputation or severe

laceration can result.

Only qualifi ed personnel should install, operate and repair

pump. Any wiring of pumps should be performed by a qualifi ed

electrician.

WARNING ! To reduce risk of electrical shock, pumps and

control panels must be properly grounded in accordance

with the National Electric Code (NEC) or the Canadian

Electrical Code (CEC) and all applicable state, province,

local codes and ordinances. Improper grounding voids

warranty.

WARNING! To reduce risk of electrical shock, always

disconnect the pump from the power source before

handling or servicing. Lock out power and tag.

WARNING! Operation against a closed

discharge valve will cause premature bearing

and seal failure on any pump, and on end

suction and self priming pump the heat build

may cause the generation of steam with resulting dangerous

pressures. It is recommended that a high case temperature

switch or pressure relief valve be installed on the pump body.

CAUTION ! Pumps build up heat and pressure

during operation-allow time for pumps to cool

before handling or servicing.

Extremely hot - Severe

burnes can occur on contact.

Hazardous fl uids can Hazard-

ous pressure, eruptions or explosions could cause personal

injury or property damage.

Hazardous voltage can

shock, burn or cause death.

WARNING ! Do not wear loose clothing that may

become entangled in moving parts.

WARNING ! Keep clear of suction and discharge

openings. DO NOT insert fi ngers in pump with power

connected.

Always wear eye protection when working on pumps.

Make sure lifting handles are securely fastened each

time before lifting. DO NOT operate pump without safety

devices in place. Always replace safety devices that

have been removed during service or repair. Secure the

pump in its operating position so it can not tip over, fall

or slide.

DO NOT exceed manufacturers recommendation for

maximum performance, as this could cause the motor

to overheat.

WARNING ! To reduce risk of electrical shock, all wiring

and junction connections should be made per the NEC

or CEC and applicable state or province and local

codes. Requirements may vary depending on usage

and location.

WARNING! Products returned must be cleaned,

sanitized, or decontaminated as necessary prior to

shipment, to insure that employees will not be exposed

to health hazards in handling said material. All Applicable

Laws And Regulations Shall Apply.

Bronze/brass and bronze/brass fi tted pumps may

contain lead levels higher than considered safe for

potable water systems. Lead is known to cause cancer

and birth defects or other reproductive harm. Various

government agencies have determined that leaded

copper alloys should not be used in potable water

applications. For non-leaded copper alloy materials of

construction, please contact factory.

Crane Pumps & Systems, Inc. is not responsible for

losses, injury, or death resulting from a failure to observe

these safety precautions, misuse or abuse of pumps or

equipment.

WARNING ! Do not pump hazardous materials

(fl ammable, caustic, etc.) unless the pump is specifi cally

designed and designated to handle them.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Deming® is a registered trademark of Crane Pumps & Systems, Inc.

1996, 10/06 Alteration Rights Reserved

2

A - GENERAL INFORMATION

TO THE PURCHASER:

Congratulations! You are the owner of one of the fi nest

pumps on the market today. These pumps are products

engineered and manufactured of high quality components.

With years of pump building experience along with a

continuing quality assurance program combine to produce

a pump which will stand up to the toughest applications.

B - BEFORE YOU BEGIN

Motor driven pumps are carefully aligned on sub-base

before shipment. However, after they are placed upon the

foundation and sub-base is bolted down, the alignment

must be rechecked and in MOST CASES it will be found

necessary to carefully realign the unit. Quite often a noisy

pump is due to pump and motor not being properly aligned.

IN SUCH CASES WE DISCLAIM ALL RESPONSIBILITY

FOR PROPER WORKING OF PUMP.

Check local codes and requirements before installation.

Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

RECEIVING:

Upon receiving the pump, it should be inspected for

damage or shortages. If damage has occurred, fi le a claim

immediately with the company that delivered the pump.

If the manual is removed from the crating, do not lose or

misplace.

STORAGE:

Short Term - Pumps are manufactured for effi cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as

factory assembled, in a dry atmosphere with constant

temperatures for up to six (6) months.

Long Term - Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained between +40 deg. F and

+120 deg. F. Pump should be stored in its original shipping

container and before initial start up, rotate impeller by hand

to assure seal and impeller rotate freely.

SERVICE CENTERS:

For the location of the nearest Deming Service Center,

check your Deming representative or Crane Pumps &

Systems Service Department in Piqua, Ohio, telephone

(937) 778-8947 or Crane Pumps & Systems Canada, Inc.,

Bramton, Ontario, (905) 457-6223.

C - INSTALLATION

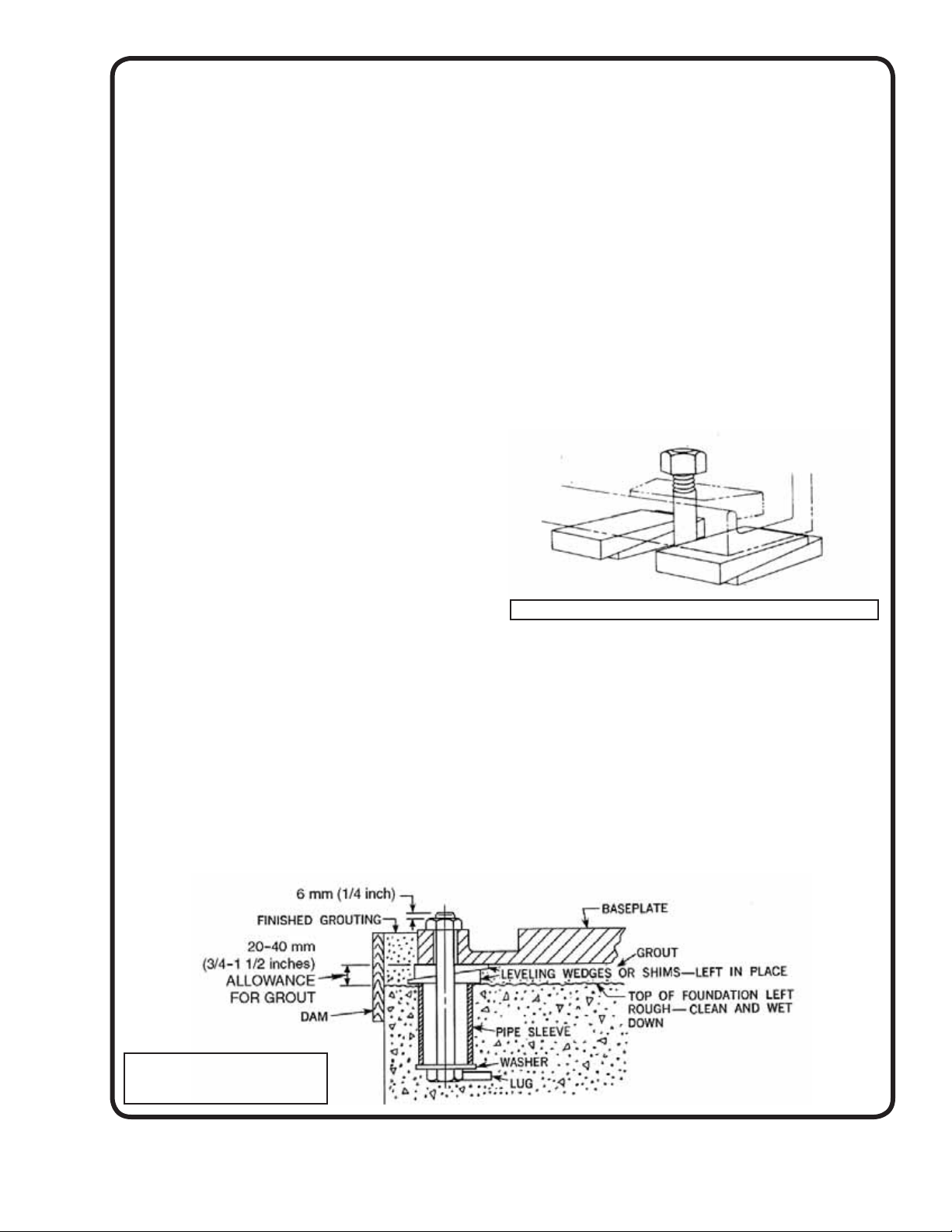

1. A good rigid foundation must be provided for pump

base.

2. Place pumping unit on foundation with bolts, of the

proper size, imbedded in the concrete. A pipe sleeve,

about 2½” diameters larger than the bolt, should be

used to allow for fi nal positioning of the bolts. See

Figure 1. Level sub-base, to give a space of about 3/4”

for grouting, using rectangular metal blocks and shims,

or wedges having a small taper as shown in Figure 2.

Figure 2. Adjusting Wedges for Mounting

3. Align the pump and motor shafts at the fl exible coupling.

Hold a straight edge on the top of the coupling so that it

extends over both halves. Straight edge should rest

evenly across both rims of the coupling halves when the

straight edge is placed on the top, sides and bottom with

no light showing between the straight edge and rim of

the coupling. Also check vertical alignment of the

coupling faces with a thickness gauge. Faces must be

parallel and spaced about 1/8” apart when the motor

rotor is at its extreme position towards the pump. This

safe guards the pump shaft being crowded endwise by

the motor shaft end play. By proper adjustment of metal

shims under pump or motor, both halves of the fl exible

coupling can be brought into alignment See Figure 3.

Figure 1. Foundation Bolt

Location and Anchorage

3

Loading...

Loading...