Page 1

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

AUTOMATIC AIR VENT

D2003 & D2004

FUNCTION

Automatic air vent valves are designed to remove the air

that accumulates in heating and air conditioning systems

without the need for manual intervention. This prevents

harmful phenomena that may compromise the life and the

performance of the heating system and which include:

• Corrosion due to the oxygen.

• Pockets of air trapped in the heating emitters.

• Cavitation in the circulation pumps.

PRODUCT LIFE CYCLE

The life of the piping products is dependent on its application, frequency of use and freedom

from misuse. Compatibility with the system into which it is installed must be considered. The

properties of the fluid being transported such as pressure, temperature and the nature of the

fluid must be taken into account to minimise or avoid premature failure or non-operability.

A well-designed system will take into consideration all the factors considered in the piping

products design, but additionally electrolytic interaction between dissimilar metals in the piping

products and the system must be examined. Before commissioning a system, it should be

flushed to eliminate debris and chemically cleaned as appropriate to eliminate contamination,

all of which will prolong the life of the piping products.

LIMITS OF USE

These valves have been categorised in accordance with the Pressure Equipment Directive

2014/68/EU.

The fluid to be transported is limited to group 2 liquids i.e. non-hazardous.

On no account must these valves be used on any group 1 liquids, group 1 gases, group 2

gases or unstable fluids.

Note:- Valves are classified as SEP (sound engineering practice) and as such cannot be CE marked

and do not require a declaration of conformity.

Page 2

AUTOMATIC AIR VENT: D2003 & D2004

2 3

AUTOMATIC AIR VENT: D2003 & D2004

OPERATING

During operation the upper cap in the standard version (black plastic cap for sizes 3/8” & 1/2”)

must be loosened.

The upper cap for the hygroscopic version (sizes 3/4” & 1”) must be completely hand tightened.

It is not advisable to fit the valve in places which could be subject to freezing.

Hygroscopic cap

3/4” and 1” models are equipped with a hygroscopic safety cap. Its functionality is based on

the properties of the fibre discs that serve as the seal cartridge and whose volume increases

by 50% as soon as they become wet and thus cause the valve to close. This way, possible

damages are avoided in case of leakage.

Models with shut-off

The automatic shut-off valve, which forms a seal with the valve body by means of an O-ring

made of EPDM, facilitates maintenance operations by shutting off the water flow when the valve

is removed and also allows for easy inspection

Note:- maximum discharge pressure 2.5 bar, system pressure must be under 2.5 bar to allow the air to

discharge automatically.

OPERATING PRESSURES AND TEMPERATURES

Not suitable for fatigue loading, creep conditions, fire testing, fire hazard environment, corrosive

or erosive service, transporting fluids with abrasive solids.

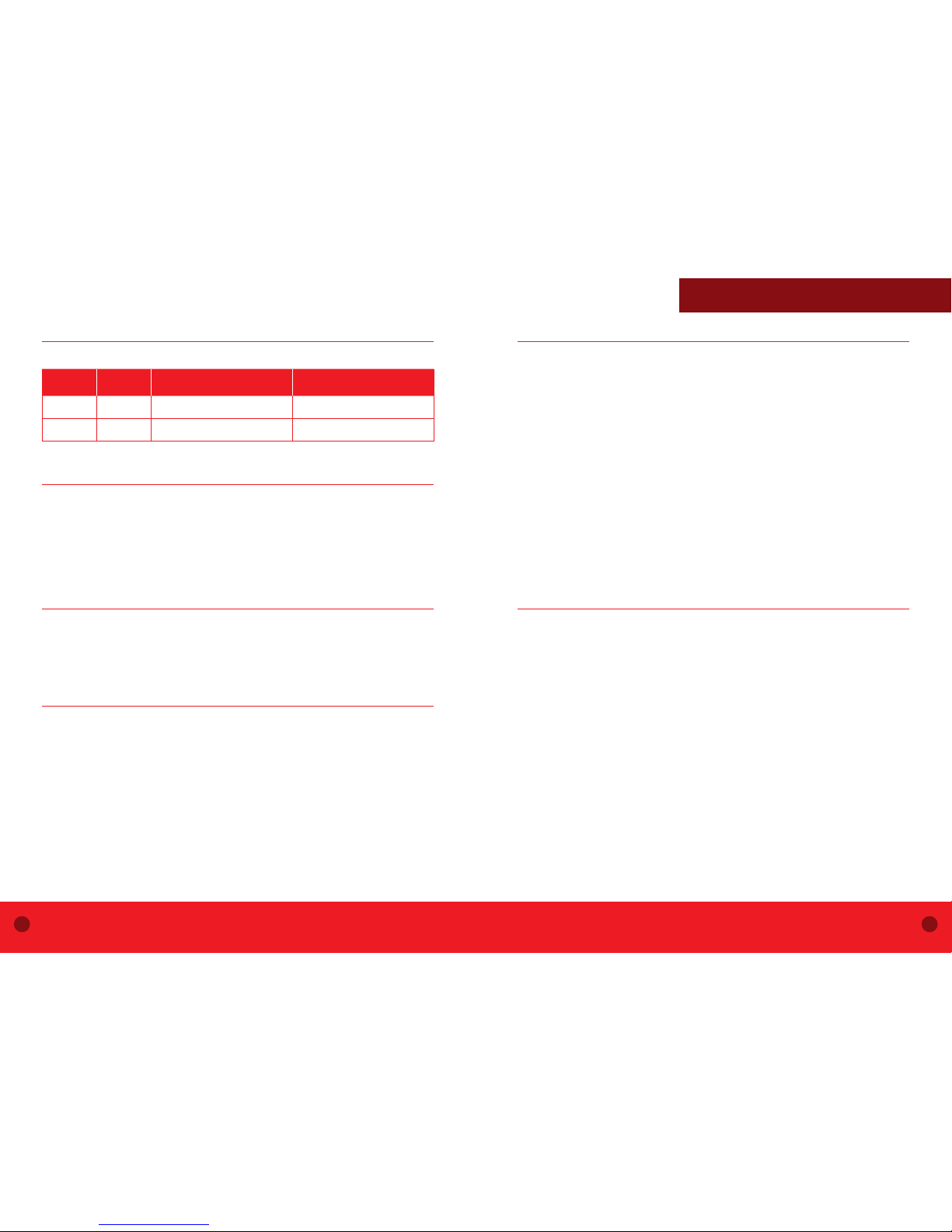

PRESSURE/TEMPERATURE RATING

These air vents are suitable for use up to 10 bar pressure rating. They must be installed in a

piping system where the normal pressure and temperature do not exceed the above ratings.

The maximum allowable pressure is for non-shock conditions. Water hammer and impact for

example, should be avoided.

If the limits of use specified in these instructions are exceeded or if the valve is used on

applications for which it was not designed, a potential hazard could result.

LAYOUT AND SITING

Care should be taken regarding orientation of the automatic air vent to enable full efficiency to

expel air from the system.

It should be considered at the design stage where air vents will be located to give access for

inspection maintenance and repair.

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

Fig. No PN

Non-shock pressure at

temperature range

Non-shock pressure at

max. temperature

D2003 PN10 10 bar from -10°C to 120°C 10 bar at 120°C

D2004 PN10 10 bar -10°C to 110°C 10 bar at 110°C

INSTALLATION

These air vents are threaded BSP parallel (external) and require a seal washer to ensure

leak tightness.

Air vents are precision manufactured items and as such, should not be subjected to misuse

such as careless handling, allowing dirt to enter, lack of system cleaning before operation and

excessive force during assembly.

All special packaging material must be removed.

The valve is installed in the vertical position, on the air separator, on manifolds, on riser pipes

and generally in parts of the system where a concentration of air pockets is to be expected.

MAINTENANCE

The D2003 & D2004 air vent is maintenance free.

However, the system should be at zero pressure and ambient temperature prior to

any inspection.

Maintenance Engineers & Operators are reminded to use correct fitting tools and equipment.

A full risk assessment and methodology statement must be compiled prior to any maintenance.

The risk assessment must take into account the possibility of the limits of use being exceeded

whereby a potential hazard could result.

A maintenance programme should therefore include checks on the development of unforeseen

conditions, which could lead to failure.

Page 3

www.cranebsu.com

CFS_D2003_D2004_0916

003B00D2003D799_v2

CRANE HOUSE, EPSILON TERRACE,

WEST ROAD, IPSWICH,

SUFFOLK IP3 9FJ

TELEPHONE: +44 (0)1473 277300

FAX: +44 (0)1473 277301

EMAIL: enquiries@cranefs.com

www.cranefs.com

Every effort has been made to ensure that the information contained in

this publication is accurate at the time of publishing. Crane Ltd assumes

no responsibility or liability for typographical errors or omissions or

for any misinterpretation of the information within the publication and

reserves the right to change without notice.

• Designed and manufactured under quality management

systems in accordance with BS EN ISO 9001:2008

FM311 ISO 9001

Loading...

Loading...