Page 1

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THERMOSTATIC MIXING VALVES

D1088 & D1089

INTRODUCTION

Are self-acting Thermostatic Mixing Valves designed to blend hot and cold water, to ensure a

constant, safe outlet temperature and prevent scalding.

• Design and manufactured to comply with

BS EN1287 and BS EN1111.

• Have been independently tested and

certified as meeting the requirements of the

D08 specification under the TMV3 scheme.

• The D1089 includes right angle isolation

valves.

• Both the D1088 & D1089 thermostatic

mixing valves are certified under the

BuildCert TMV2 & TMV3 schemes and are

WRAS approved products listed in the

WRAS Approvals Directory:

- BuildCert Approval Number (TMV3):

BC1802/1016 (for TMV3)

- BuildCert Approval Number (TMV2):

BC1801/1016 (for TMV2)

- WRAS Scheme Approval Number:

1301096 (WRAS)

D1089

D1088

Page 2

THERMOSTATIC MIXING VALVES: D1088 & D1089

2

TECHNICAL SPECIFICATION

Factory Setting

41°C

Temperature Setting Range

30°C to 50°C

Minimum Hot to Mix Temperature

10°C

Temperature Stability

±2°C

Maximum Working Pressure

10 Bar

Min Flow Rate

5 l/min

Table 1

GENERAL INSTALLATION – TMV2 & TMV3

These instructions are issued as guidelines only and may not cover all installation conditions –

if unsure please contact our Technical Helpline before installation.

• Crane FS products are designed for installation and use within suitably designed systems

reflecting CIBSE, BSRIA and HVAC guidelines. Particular care should be taking with regards

to accessibility to valve for setting/adjustment, tube cutting, jointing & bracketing/supports.

• The thermostatic mixing valve must be installed in accordance with the regulations of the

local water company and the Water Supply (Water Fittings) Regulations 1999.

• The D1088 & D1089 are suitable for single outlet applications only.

• The D1088 & D1089 can be installed in any orientation.

• Flush hot & cold supply pipework before connection.

• For the D1088, where isolation valves are not supplied, isolation valves in the water supply

inlets should be fitted as close as practical to the TMV.

• For D1088, wafer strainers are supplied as shown in figure 5.

• For D1089, strainers are supplied and located in the isolation valve body.

TMV3

The D1088 and D1089 have been approved as TYPE 3 valves under the TMV3 scheme. They

have been designed and manufactured for use in Healthcare and Commercial installations and

complying with NHS Estates requirements D 08.

LIMITS OF USE

The D1088 & D1089 have been approved for use on the following designated systems.

Code Operating Pressure Application

HP-S, LP-S High Pressure Shower Temperature 41ºC

HP-W, LP-W High Pressure Washbasin Temperature 41ºC

HP-B, LP-B High Pressure Bidet Temperature 38ºC

HP-T44, LP-T44 High Pressure Bath Fill Temperature 44ºC

HP-T46, LP-T46 High Pressure

Bath Fill (assisted)

Temperature 46ºC

Table 2 - Mixed Water Temperature

Note 1 - HP: High Pressure LP: Low Pressure Note 2 - 15mm not acceptable for LP Tub Fill, LP-T44 & LP-T46.

Page 3

3

THERMOSTATIC MIXING VALVES: D1088 & D1089

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

CONDITIONS OF USE

Operating Pressure Range High Pressure Low Pressure

Maximum Static Pressure 10 bar 10 bar

Flow Pressure - Hot & Cold 1 to 5 bar 0.2 - 1 bar

Hot Supply Temperature 52 to 65ºC 52 to 65ºC

Cold Supply Temperature 5 to 20ºC 5 to 20ºC

Table 3 - Normal Conditions of Use for Type 3 Valves

Note 1: The valve may perform adequately outside the conditions in table 3 but the TMV3 scheme approval does

not apply.

Note 2: The highest flow rates will be achieved under balanced pressure conditions, but the pressure at the valve

inlets must be within a ratio of 2:1 under flow conditions and the size and layout of pipe work and fittings must take

this into account.

PRE-COMMISSIONING CHECKS

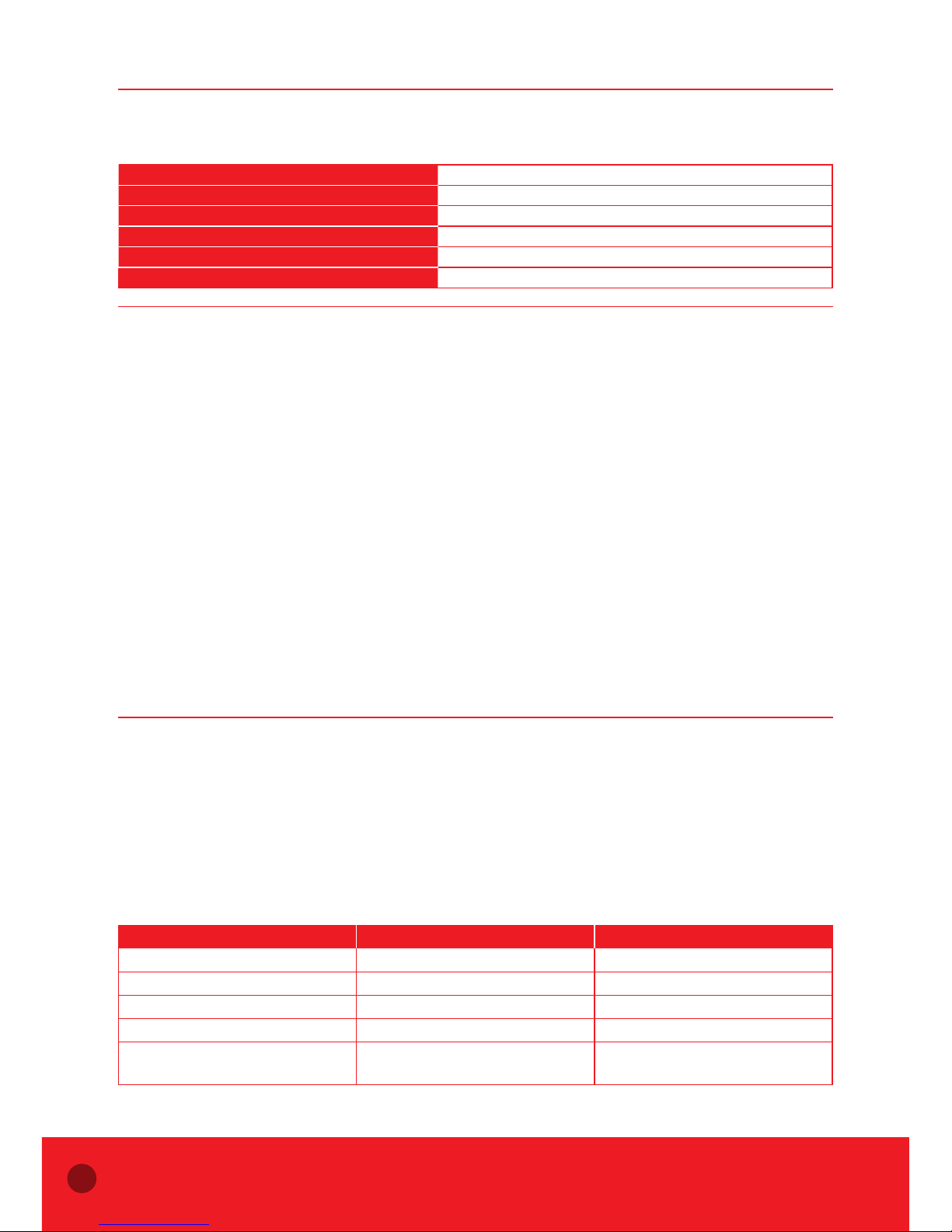

Follow this method for adjusting the water temperature:

1. Remove the maroon plastic protective cap on top of the valve with a

screw-driver.

2. Back-out the nut, using a monkey spanner:

- To increase the temperature turn anti-clockwise

- To decrease the temperature turn clockwise

- To set the valve to a maximum mixed water temperature in

accordance with the valve application (See Table 4).

Once the correct outlet temperature is set the internal mechanism must

be tested at least 3 times by:

• Alternately isolate the hot & cold water supply. This causes the internal

piston to travel its full stroke and will ensure correct operation

of the valve.

• With hot & cold isolation valves and the terminal outlet fully open retest

the flow temperature. If the set temperature has moved, repeat the

commissioning process.

• A fail safe test must be carried out by isolating the cold

supply. Once isolated, the flow must reduce, within a couple

of seconds, to a trickle - depending on site conditions, supply

temperature/pressure.

• Then repeat fail safe test isolating the hot supply. Once

isolated, the flow must reduce to a trickle within a couple of

seconds – depending on site conditions.

• If either the cold or hot fail safe function does not operate, check;

- Supply pressures

- Supply temperatures

- Hot water supply is at least 10ºC above required mix temperature,

i.e. minimum hot to mix temperature

Figure 1 - D1088 pictured,

cap removal

Figure 2 - D1088 pictured,

temperature setting

Screw driver

Screw

The blue plastic

protective cap

Nut

Page 4

THERMOSTATIC MIXING VALVES: D1088 & D1089

4

COMMISIONING

Since the installed supply conditions are likely to be different from those applied in the

laboratory tests, it is appropriate, at commissioning, to carry out some simple checks and tests

on each mixing valve to provide a performance reference point for future in-service tests.

a) The designation (TMV3) of the Thermostatic Mixing Valve matches the intended application.

b) The supply pressures are within the range of operating pressures for the designation of

the valve.

c) The supply temperatures are within the range permitted for the valve and within guidance

information on the prevention of legionella etc.

d) Record the temperature of the hot and cold water supplies.

e) Record the temperature of the mixed water at the largest draw-off flow rate.

f) Record the temperature of the mixed water at a smaller draw-off flow rate.

g) Isolate the cold water supply to the mixing valve and monitor the mixed water temperature.

h) Record the maximum temperature achieved as a result of (g) and the final

stabilised temperature.

Note: The final stabilised mixed water temperature should not exceed the values in the following table.

i) Use recording equipment such as a thermometer etc. used for the measurements.

Application Mixed Water Temperature

Bidet 40°C

Shower 43°C

Washbasin 43°C

Bath (44°C Fill) 46°C

Bath (46°C Fill) 48°C

Table 4 - Guide to Maximum Stabilised Temperatures Recorded During Site Tests

Page 5

5

THERMOSTATIC MIXING VALVES: D1088 & D1089

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

IN SERVICE TESTING

Purpose

The purpose of in-service tests is to regularly monitor and record the performance of the

Thermostatic Mixing Valve. Deterioration in performance can indicate the need for service work

on the valve and/or the water supplies.

Service Work Procedure

Using the same measuring equipment or equipment to the same specification as used in the

commissioning of the valve, adjust the temperature of the mixed water in accordance with the

requirement of the application. Carry out the following sequence:

a) Record the temperature of the hot and cold water supplies.

b) Record the temperature of the mixed water at the largest draw-off flow rate.

c) Record the temperature of the mixed water at a smaller draw-off flow rate, which shall be

measured.

If the mixed water temperature has changed significantly from the previous test results

(e.g.> 1 K), record the change and before re-adjusting the mixed water temperature check:

a) That any in-line or integral strainers are clean.

b) Any in-line or integral check valves or other anti-back siphonage devices are in good

working order.

c) Any isolating valves are fully open.

With an acceptable mixed water temperature, complete the following procedure:

a) Record the temperature of the hot and cold water supplies.

b) Record the temperature of the mixed water at the largest draw-off flow rate.

c) Record the temperature of the mixed water at a smaller draw-off flow rate, which shall be

measured.

d) Isolate the cold water supply to the mixing valve and monitor the mixed water temperature.

e) Record the maximum temperature achieved as a result of (d) and the final

stabilised temperature.

f) Record the equipment, thermometer etc. used for the measurements.

If at step (e) the final mixed water temperature is greater than the values in the above table and/

or the maximum temperature exceeds the corresponding value from the previous results by

more than about 2 K, the need for service work is indicated.

Note: In-service tests should be carried out with a frequency, which identifies a need for service work before an

unsafe water temperature can result. In the absence of any other instruction or guidance, the following procedure

described in Annex F of D08 may be used.

Page 6

THERMOSTATIC MIXING VALVES: D1088 & D1089

6

FREQUENCY OF IN-SERVICE TESTS (Annex F of D08)

General

In the absence of any other instruction or guidance on the means of determining the

appropriate frequency of in-service testing, the following procedure may be used:

a) 6 to 8 weeks after commissioning carry out the tests detailed in “In-Service Tests”.

b) 12 to 15 weeks after commissioning carry out the tests detailed in “In-Service Tests”.

Depending on the results of the above tests, several possibilities exist:

a) If no significant changes (e.g. ≤ 1 K) in mixed water temperatures are recorded between

commissioning and 6 to 8 week testing, or between commissioning and 12-15 week testing

the next in-service test can be deferred to 24 to 28 weeks after commissioning.

b) If small changes (e.g. 1 to 2 K) in mixed water temperatures are recorded in only one

of these periods, necessitating adjustment of the mixed water temperature, then the next

in-service test can be deferred to 24 to 28 weeks after commissioning.

c) If small changes (e.g. 1 to 2 K) in mixed water temperatures are recorded in both of these

periods, necessitating adjustment of the mixed water temperature, then the next in-service

test should be carried out at 18 to 21 weeks after commissioning.

d) If significant changes (e.g. > 2 K) in mixed water temperatures are recorded in either of

these periods, necessitating service work, then the next in-service test should be carried out

at 18 to 21 weeks after commissioning.

The general principle to be observed after the first 2 or 3 in-service tests is that the intervals of

future tests should be set to those which previous tests have shown can be achieved with no

more than a small change in mixed water temperature.

Page 7

7

THERMOSTATIC MIXING VALVES: D1088 & D1089

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

TMV2

The valves covered by these instructions have been specifically designed and manufactured as

being in compliance with BS EN1287 and BS EN1111. It has been independently tested and

approved as a TYPE 2 valve under TMV2 scheme for use in domestic situations.

LIMITS OF USE

The D1088 & D1089 have been approved for use on the following designated systems.

Code Operating Pressure Application

HP-S, LP-S High Pressure Shower Temperature 41ºC

HP-W, LP-W High Pressure Washbasin Temperature 41ºC

HP-B, LP-B High Pressure Bidet Temperature 38ºC

HP-T44 High Pressure Bath Fill Temperature 44ºC

Table 5 - Mixed Water Temperature

Note 1: HP: High Pressure LP: Low Pressure

Note 2: 46°C is the maximum permissible mixed water temperature from the bath tap. The maximum temperature

takes account of the allowable temperature tolerances inherent in thermostatic mixing valves and temperature losses

in metal baths. 46°C is not a safe bathing temperature for adults or children.

Note 3: The British Burns Association recommends 37 to 37.5°C as a comfortable bathing temperature for children.

In premises covered by the Care Standards Act 2000, the maximum mixed water outlet temperature is 43°C.

CONDITIONS OF USE

Operating Pressure Range High Pressure Low Pressure

Maximum Static Pressure 10 bar 10 bar

Flow Pressure - Hot & Cold 0.5 bar to 5.0 bar 0.1 bar to 1.0 bar

Hot Supply Temperature 55 to 65ºC 55 to 65ºC

Cold Supply Temperature ≤25°C ≤25°C

Table 6 - Normal Conditions of Use for Type 2 Valves

Note 1: Valves operating outside table 6’s conditions cannot be guarantees by the Scheme to operate as

Type 2 valves.

Note 2: Valves approved for designation of use H.P only, must state: - If a water supply is fed by gravity then the

supply pressure should be verified to ensure the conditions of use are appropriate for the valve.

Note 3: Valves approved for designation of use LP Tub applications that only achieve the minimum flow rate

requirement at a supply pressure of 0.2 bar must indicate that the minimum supply pressure for LP Tub application

is 0.2 bar.

Page 8

THERMOSTATIC MIXING VALVES: D1088 & D1089

8

PRE-COMMISSIONING CHECKS

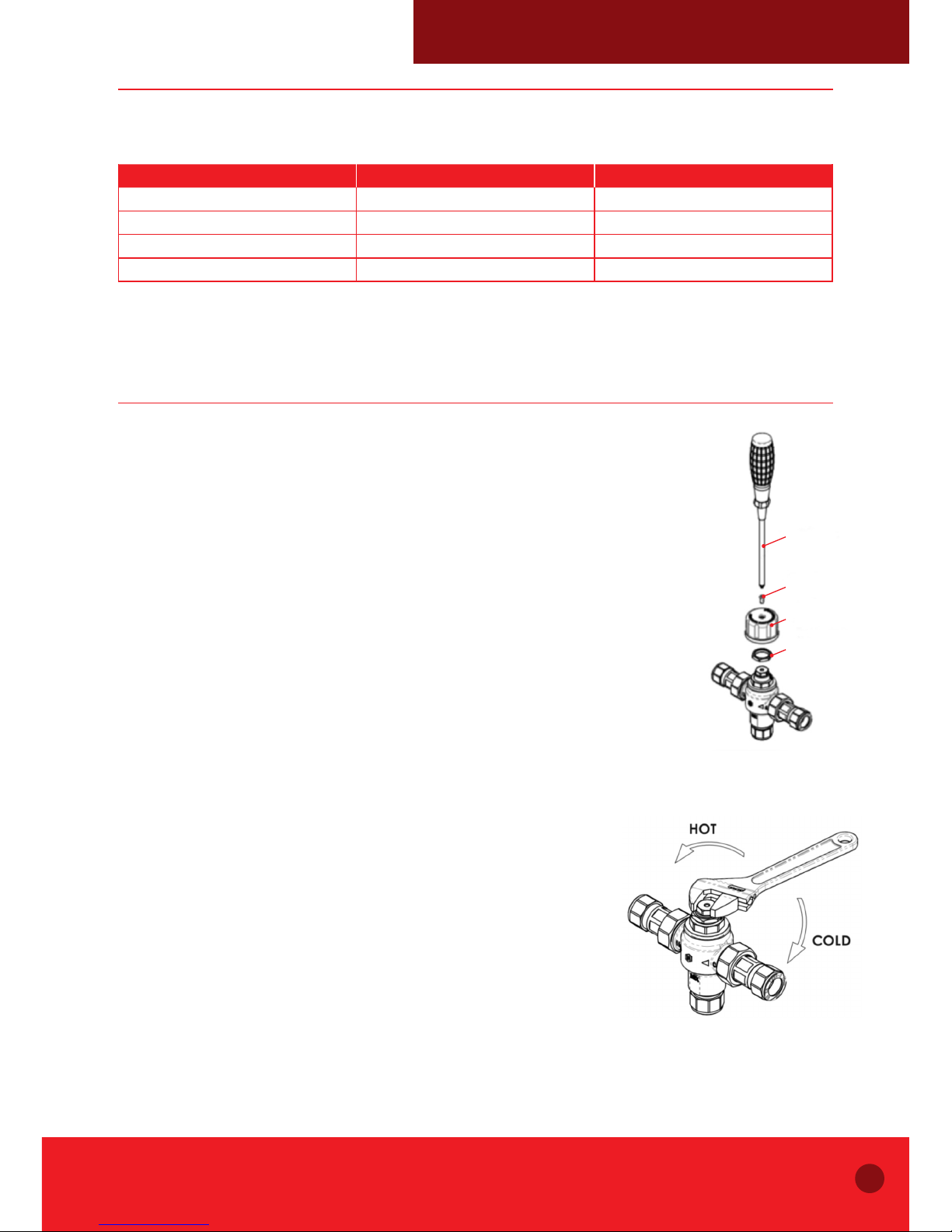

Follow this method for adjusting the water temperature:

1. Remove the maroon plastic protective cap on top of the valve with

a screw-driver.

2. Back-out the nut, using a monkey spanner:

- To increase the temperature turn anti-clockwise

- To decrease the temperature turn clockwise

- To set the valve to a maximum mixed water temperature in

accordance with the valve application (See Table 7).

Once the correct outlet temperature is set the internal mechanism must

be tested at least 3 times by:

• Alternately isolate the hot & cold water supply. This causes the

internal piston to travel its full stroke and will ensure correct operation

of the valve.

• With hot & cold isolation valves and the terminal outlet fully

open retest the flow temperature. If the set temperature has

moved, repeat the commissioning process

• A fail safe test must be carried out by isolating the cold

supply. Once isolated, the flow must reduce, within a

couple of seconds, to a trickle – depending on site

conditions, supply temperature/pressure

• Then repeat fail safe test isolating the hot supply. Once

isolated, the flow must reduce to a trickle within a couple of

seconds – depending on site conditions.

• If either the cold or hot fail safe function does not operate, check;

- Supply pressures

- Supply temperatures

- Hot water supply is at least 10ºC above required mix temperature, i.e. minimum

hot to mix temperature

• TMVs shall be located in such a way that it can be easy accessed for maintenance and

commissioning purposes.

Figure 3 - D1088 pictured,

cap removal

Figure 4 - D1088 pictured,

temperature setting

Screw driver

Screw

The blue plastic

protective cap

Nut

Page 9

9

THERMOSTATIC MIXING VALVES: D1088 & D1089

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

COMMISIONING

Since the installed supply conditions are likely to be different from those applied in the

laboratory tests, it is appropriate, at commissioning, to carry out some simple checks and tests

on each mixing valve to provide a performance reference point for future in-service tests.

a) The designation (TMV2) of the Thermostatic Mixing Valve matches the intended application.

b) The supply pressures are within the valves operating range.

c) The supply temperatures are within the range permitted for the valve and within guidance

information on the prevention of legionella etc.

d) Record the temperature of the hot and cold water supplies.

e) Record the temperature of the mixed water at the largest draw-off flow rate.

f) Record the temperature of the mixed water at a smaller draw-off flow rate.

g) Isolate the cold water supply to the mixing valve and monitor the mixed water temperature.

h) Record the maximum temperature achieved as a result of (g) and the final stabilised

temperature.

i) NOTE: The final stabilised mixed water temperature should not exceed the values in the

following table.

j) Use recording equipment, such as a thermometer etc.

k) The mixed water temperature at the terminal fitting must never exceed 46°C.

Application Mixed Water Temperature

Bidet 40°C

Shower 43°C

Washbasin 43°C

Bath (44°C Fill) 46°C

Table 7 - Guide to Maximum Stabilised Temperatures Recorded During Site Tests

Page 10

THERMOSTATIC MIXING VALVES: D1088 & D1089

10

IN SERVICE TESTING

It is a requirement that all TMV2 approved valves shall be verified against the original set

temperature results once a year. When commissioning/testing is due the following performance

checks shall be carried out:

1. Measure the mixed water temperature at the outlet.

2. Temperature readings should be taken at the normal flow rate after allowing for the system

to stabilise.

3. The sensing part of the thermometer probe must be fully submerged in the water that is to

be tested.

4. Carry out the cold water supply isolation test by isolating the cold water supply to the TMV,

wait for five seconds if water is still flowing check that the temperature is below 46°C.

5. Any TMV that has been adjusted or serviced must be re-commissioned and re-tested in

accordance with the manufactures’ instructions.

6. If there is no significant change to the outlet temperature (±2°C or less change from the

original settings) and the fail-safe shut of is functioning, then the valve is working correctly

and no further service work is required.

Note: If there is residual flow during the commissioning or the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of the water seeping from the valve is more than 2°C above the

designated maximum mixed water outlet temperature setting of the valve. The installation of thermostatic mixing

valves must comply with the requirements of the Water Supply (Water Fittings) Regulations 1999.

Page 11

11

THERMOSTATIC MIXING VALVES: D1088 & D1089

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

MAINTENANCE - TMV2 & TMV3

Most domestic water supplies contain calcium which will separate out when the water is

heated in a system. The degree and speed of scaling may vary depending on factors such

as water flow rates, system design, the hardness of the water and the temperature to which

the water is heated.

Deposits of scale may over time form in the valve, particularly at the hot inlet. The formation of

the scale may adversely affect the performance of the valve which will be detected during the

in-service testing. If this occurs it will be necessary to remove the valve for de-scaling

and service.

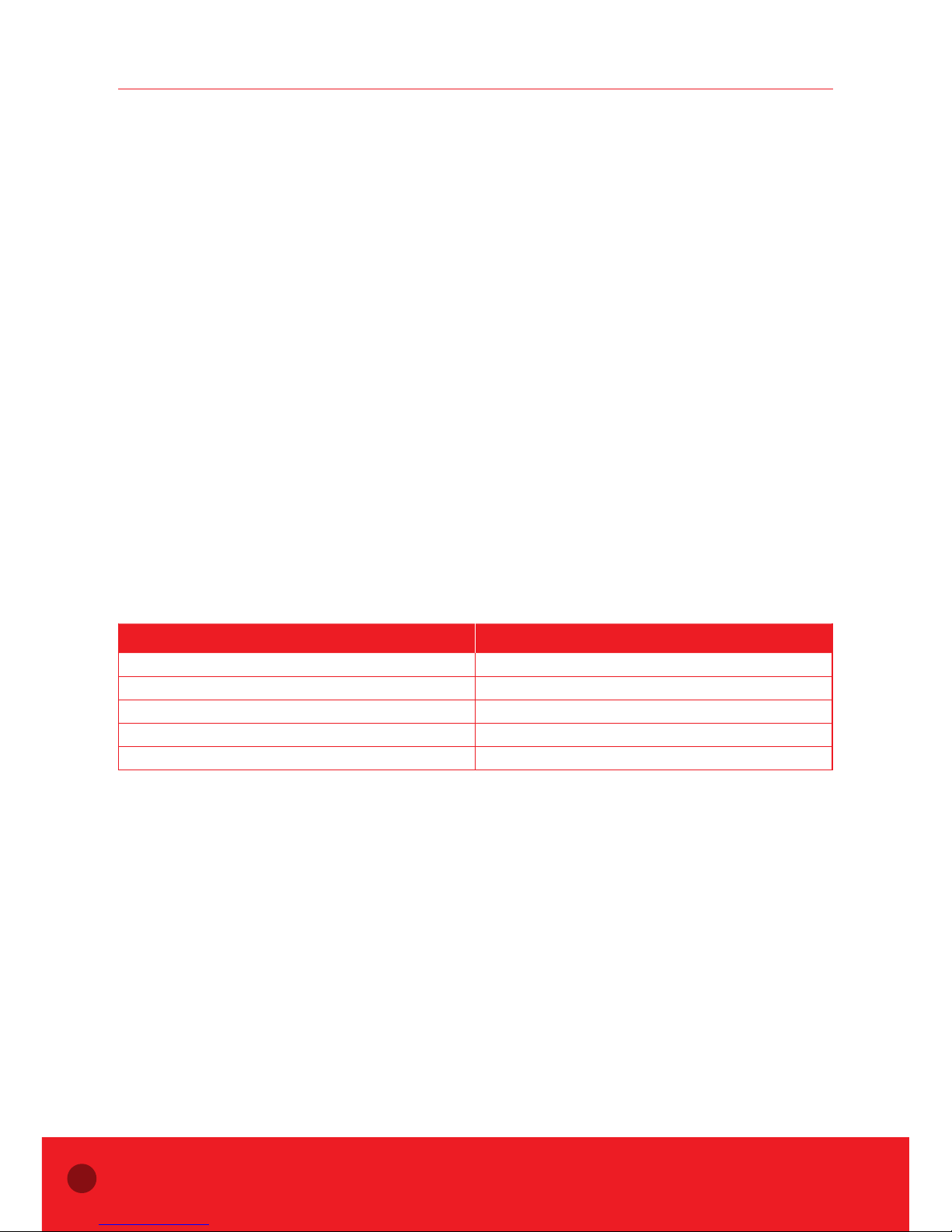

If required, the internal working parts can be removed and cleaned as follows:

1. Isolate hot and cold water supply.

2. Remove the valve to a clean working area.

3. Remove the protective cap.

4. Unscrew the headwork of the valve.

5. Carefully remove the temperature-sensitive and piston assembly, put to one side.

6. Remove the main spring and flow guide, carefully put to one side.

7. Inspect the components for contamination or damage.

8. Clean or replace as necessary.

9. Remove the O-ring.

10. Clean the valve body and Headwork using a propriety de-scaler (approved for use on

potable water applications).

11. Thoroughly rinse the body and headwork in clean potable water.

12. Carefully fit new O-ring to body.

13. Carefully re-fit all components and perform the commissioning sequence.

If after cleaning the valve and replacing the O-ring seals the valve does not function correctly,

it may be necessary to replace the thermal element.

Figure 5 - D1088 pictured, exploded views

Fixing Screw

Protective Cap

Headwork

Thermal element

and piston assembly

Flow guide

Main spring

O-ring

Sealing Gaskets

Union Nut

Tailpiece Assembly

Check Valve

Tai lp ie ce

Wafer Strainer

Olives

Compression Nut

Page 12

www.cranebsu.com

CFS_D1088_D1089_1117

0ED17254D_V2

CRANE HOUSE, EPSILON TERRACE,

WEST ROAD, IPSWICH,

SUFFOLK IP3 9FJ

TELEPHONE: +44 (0)1473 277300

FAX: +44 (0)1473 277301

EMAIL: enquiries@cranefs.com

www.cranefs.com

Every effort has been made to ensure that the information contained in

this publication is accurate at the time of publishing. Crane FS assumes

no responsibility or liability for typographical errors or omissions or

for any misinterpretation of the information within the publication and

reserves the right to change without notice.

• Designed and manufactured under quality management

systems in accordance with BS EN ISO 9001:2008

FM311 ISO 9001

Loading...

Loading...