Crane 3TSS1.38-45-36/210, 4TSC8-40-110/1000, 4TSC4-45-48/50, 4TSSC6-40-48/500, 4TSSC5.1-65-110/1000 User Manual

Page 1

TSS TSC TSSC series

Instruction for

installation, maintenance

and operation of

solar pump

Users' manual for solar pumps

series TSS, TSC и TSSC

Crane Ltd, Bulgaria, 4004 Plovdiv, 26 Komatevsko shose Str., phone +35932657578, fax +35932657580,

e-mail: office@crane-bg.com, www.crane-bg.com

Page 2

CONTENT

Version 1

I. Introduction

II. Important safety

instructions

III. Solar pumps' specification

IV. Guidelines for

installation and exploitation

of solar pumps

V. Indicators for operation and

fault instructions

VI. Cleaning and maintenance

of PV module

VII. Protection of the

environment

VIII. Contacts, warranty and

service maintenance

page 3

page 3

page 4

page 8

page 15

page 18

page 18

page 18

2

Page 3

I. Introduction

The Solar pumps allow you to extract water in areas, where aren't mains supplies, but with directly

transformation of solar energy into electricity.

Please read and apply herewith given instructions, so you can use the Cranes' solar pumps full

capacity. In case you don't observe them, this might result in personal injuries and product damages.

The present instructions are giving information about the safety measures, which should be undertaken

during the time of delivery and installation of the solar pumps, together with the technical instructions,

which should be followed while installing, mounting, wiring and maintaining.

Please keep these instructions during the whole service life of the solar pump. Read and observe very

carefully herewith given instructions.

The product warranty will be invalid if the written instructions for mounting and solar pump exploitation

are not complied with.

II. Important safety instructions

1. Strict observance of the installation instruction and solar pump exploitation are obligatory!

2. Do not use a part from the equipment or whole equipment set for activities which are not subject

of the exploitation instructions. Otherwise Crane Ltd or/and its representatives will not be held

under liability for damages, loss or injuries caused from the product to persons or movable and

non-movable property caused because of non-observation of the exploitation instructions

3. The right maintenance and exploitation ensure optimum result and long service life of the solar

pump.

4. Never instal the solar pomp on places in near vicinity of children or animals.

5. Do not use abrasive chemicals for cleaning of any part of this product.

3

Page 4

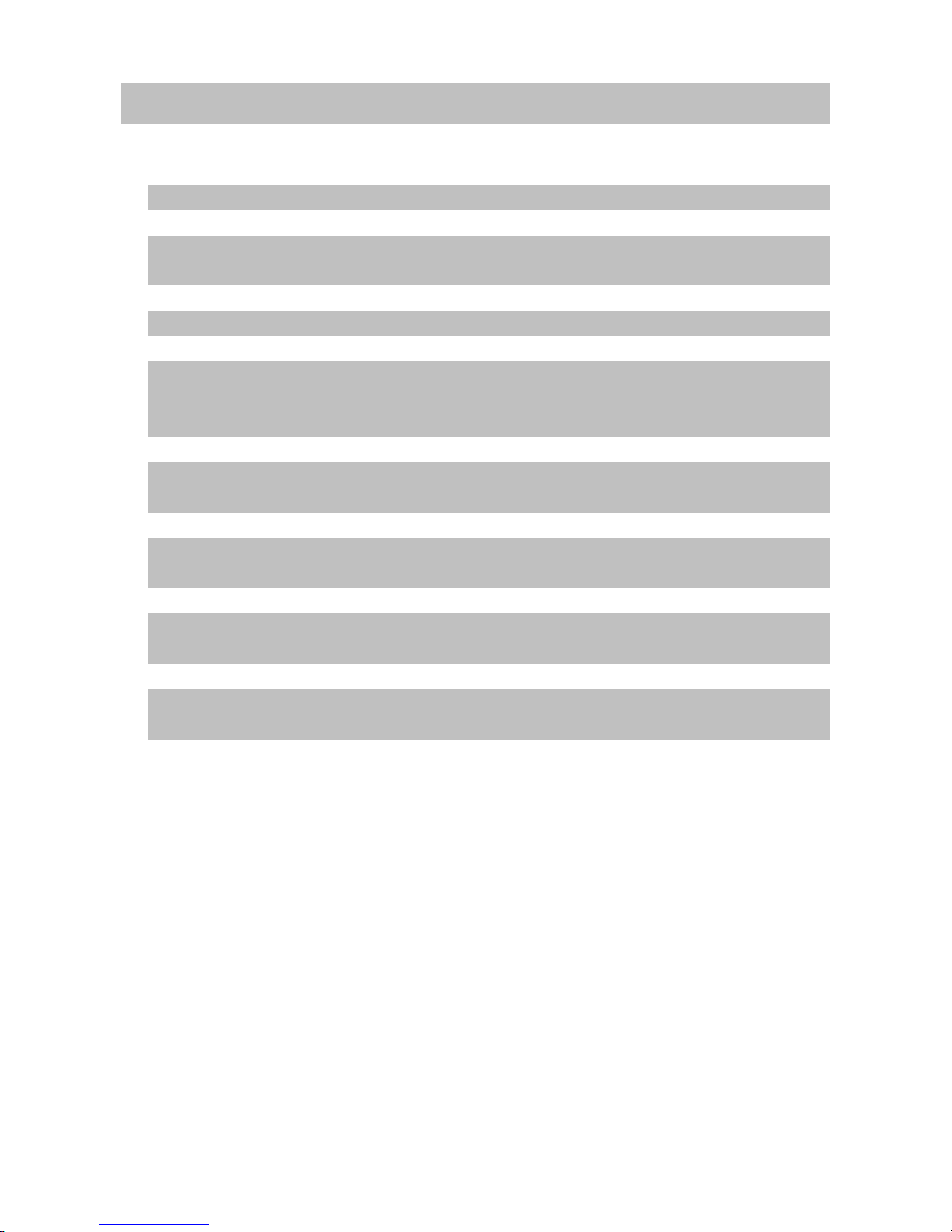

III. Solar pumps' specification

Type

Quantity

Picture

Submersible solar pump

1 piece

Controller 1 piece

Solar flashlight

1 piece

Screw (screw pump)

1 piece

Turbine (centrifugal pump,

plastic impeller)

1 piece

Insulation tape and thermal

shrink hose

3 pieces

Water lever sensors

3 pieces

Cable 2х1.5 mm

2

6 m

Manual 1 piece

4

Page 5

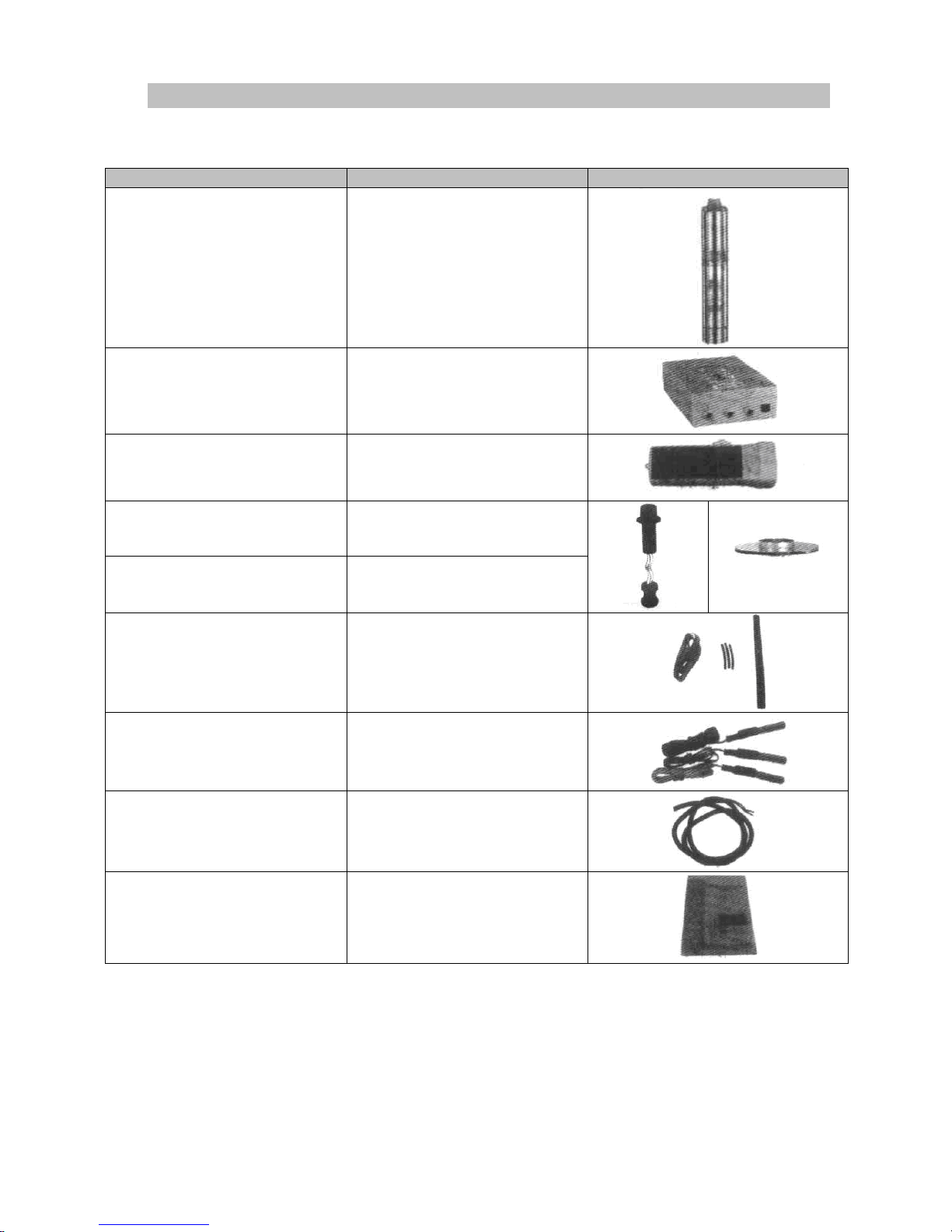

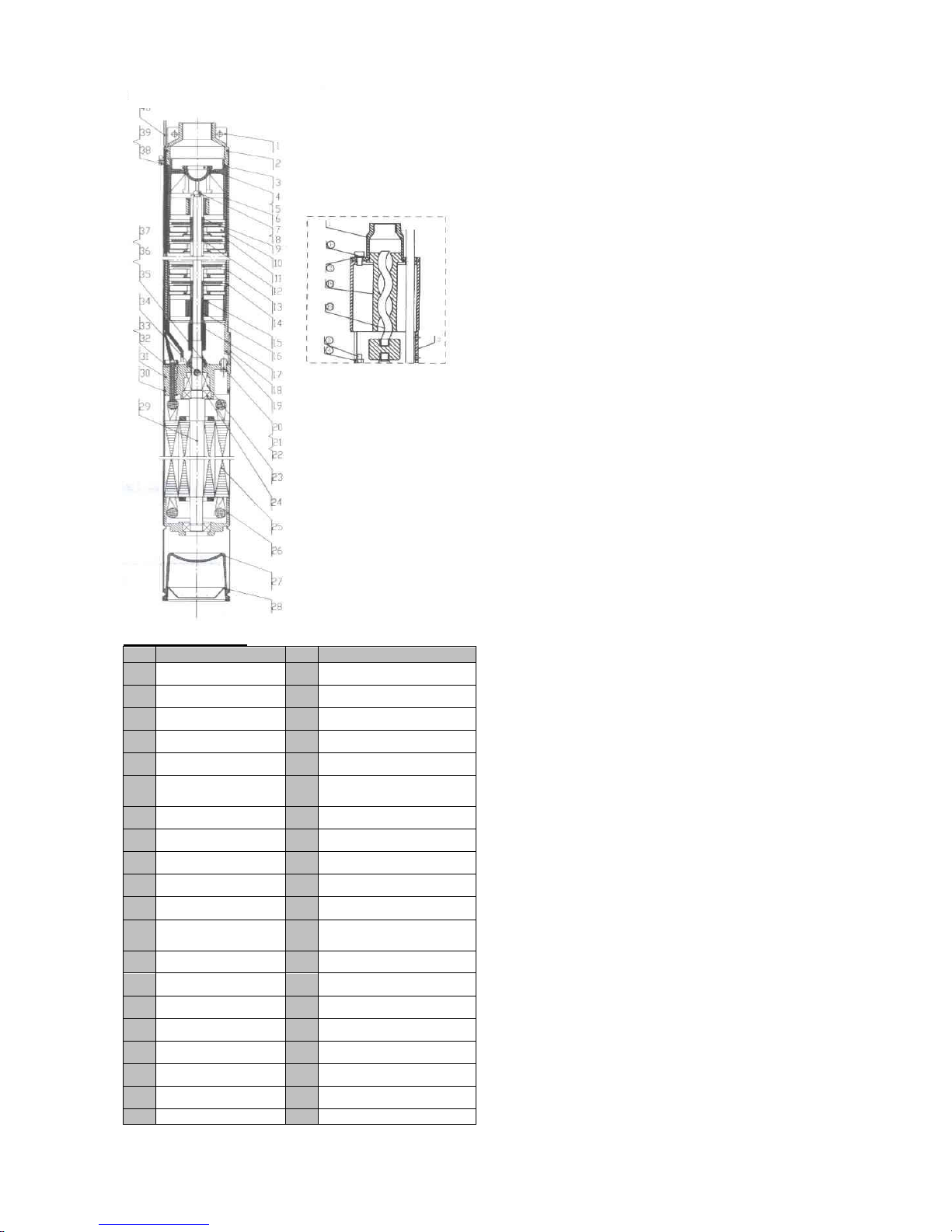

Water filled motor

№

Part

№

Part

1

Inlet area

15

Housing pump base

2

Outlet area

16

Plate pump base

3

Bearing nest

17

Adjustable nut

4

Cover

18

Screw bush

5

Bearing

19

Screw

6

Motor corps

(1)

Bolt

7

Stator

(2)

Spring washer

8

Rotor

(3)

Bolt

9

Cover

(4)

Hexagonal nut

10

Bearing nest

(5)

Key

11

Bearing

(6)

Spring washer

12

Plate

(7)

Hexagonal nut

13

Bearing nes water

lubricated

(8)

Heads' oil sealing

14

Bearing nest

(9)

Pins

5

Screw pump

Centrifugal pump

Page 6

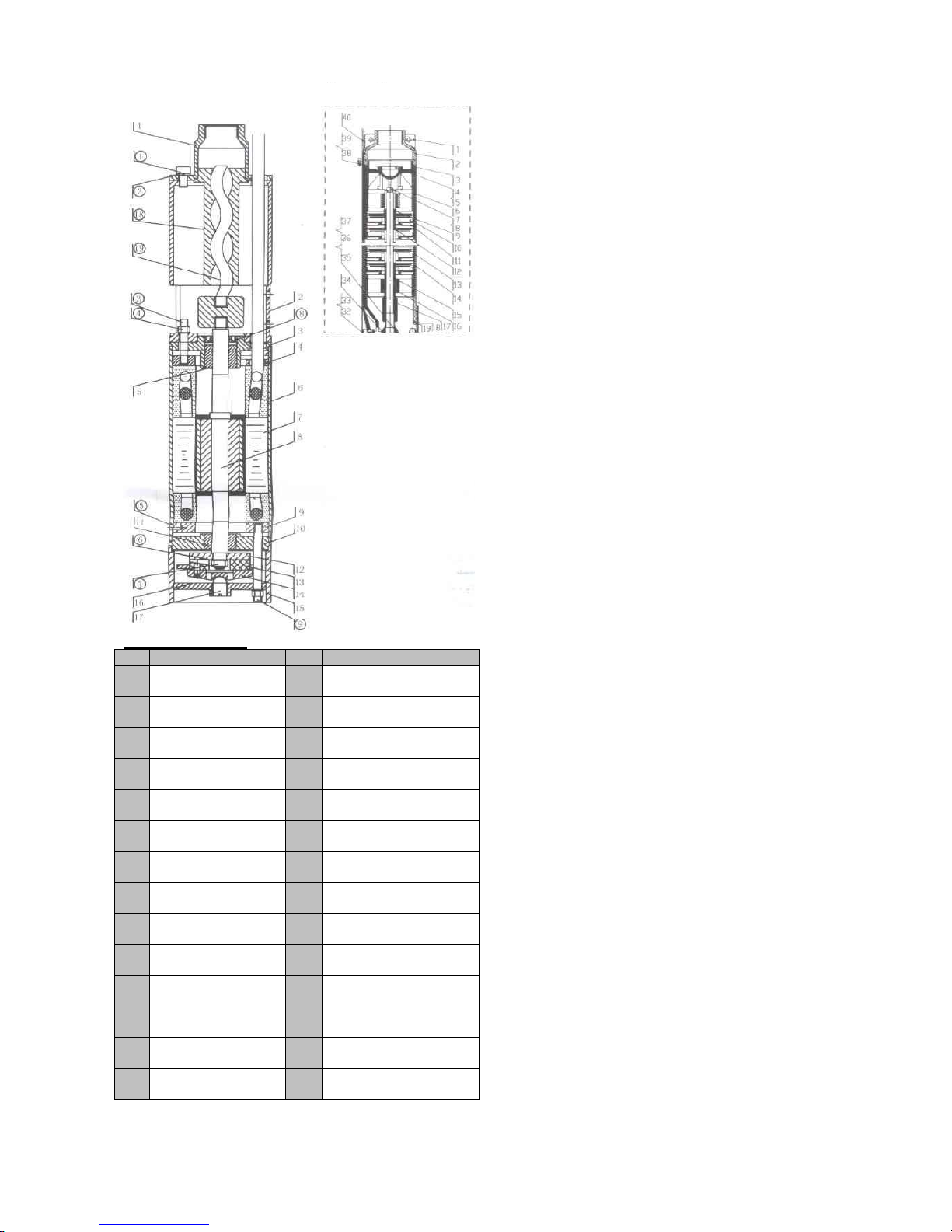

Water filled motor

№

Част

№

Част

1

Wire hole

21

Spring washer M8

2

O – ring

22

Nut M8

3

Valve housing

23

Mechanical seal

4

Valve

24

Ball bearing

5

O – ring

25

Stator

6

Limiting bearing

housing

26

Lower bearing housing

7

Nut

27

Rubber

8

Spring washer

28

Diaphragm

9

Washer

29

Working parts

10

Turbine

30

O - ring

11

Pomps' cover

31

Upper bearing housing

12

Rubber spring

washer

32

Plate

13

Pumps' corps

33

Cable bush

14

Motors' housing

34

Hollow pin

15

Limiting bearing

35

Anti-sand bush

16

Bearing bush

36

Anti-sand washer

17

Coupling

37

Washer

18

Cover

38

Washer

19

Nozzle

39

Bolt

20

Bolt M8х25

40

Cable

6

Centrifugal pump

Screw pump

Page 7

1. There is a three-phases brushless motor built in the pump, who directly drives a screw (for a

screw pump) or a turbine (for centrifugal pump) and has passed a special control test.

2. The motor is with simple and reliable construction, small volume and small weight.

3. The special double-plastic technology for motor encapsulating makes it suitable to be used

under water, as its insulation resistance exceeds 500 MegaOhms. The motors' bearings are

water-lubricated, which excludes a need of other lubricating materials (such as oils and

greases), which might be thrown in the water. This protects the environment.

4. The controller is especially designed to work with this type pumps, supplied trough photovoltaic

modules as it has built in МРРТ (maximum power point tracker), which moves the pannels

working point and as this extracts the maximal possible power. The built in protections from

short-cut, over-voltage and overheat protects the controller as well as the pump from damages.

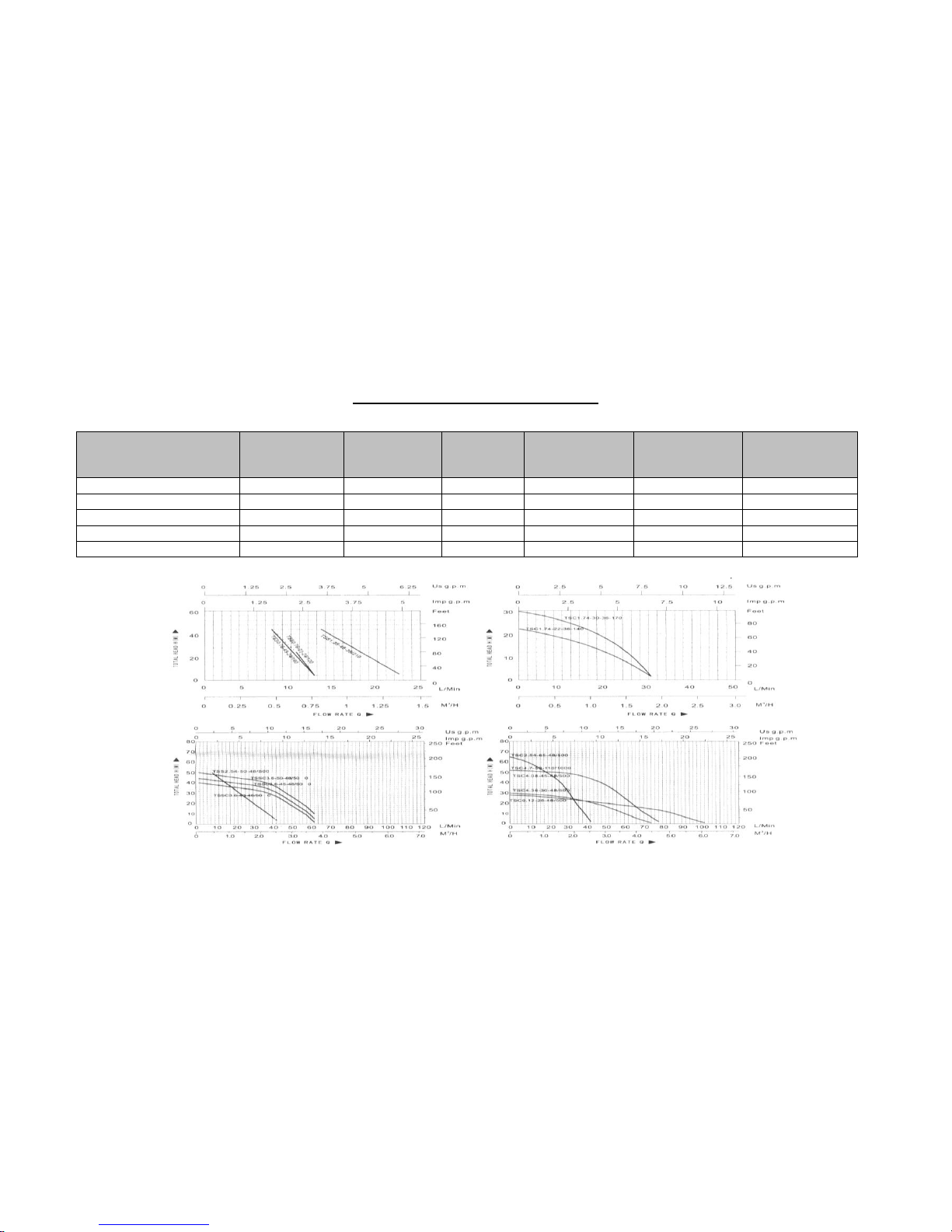

Technical characteristics

Type

Voltage

(V) DC

Power

(W)

Flow

(m3/h)

Maximal

displacement

(m)

Output

Pumps'

diameter

(mm)

3TSS1.38-45-36/210

36

210

1.38

45

¾”

76

4TSC4-45-48/500

48

500

4.00

45

1 ¼”

100

4TSC8-40-110/1000

110

1000

8.00

40

1 ¼”

100

4TSSC6-40-48/500

48

500

6.00

40

1 ¼”

100

4TSSC5.1-65-110/1000

110

1000

5.10

65

1 ¼”

100

7

Page 8

IV. Guidelines for installation and exploitation of solar pumps

Photovoltaic module (PV) selection

1. Operating principle:

The photovoltaic module converts the solar energy into electric energy (DC) → DC electric

energy enters into the controller → the controller stabilize the voltage, charges the accumulator

(option only for model 3TSS1,38) and produces voltage that conforms the pumps motor → the

pump extracts water

2. Solar pump system's advantages:

a. Much easier and more widely used than any other electrically driven pumps

b. Economic and environment friendly, because of renewable energy source usage.

3. Photovoltaic module(s) and accumulator selection

a. The PV module power is necessary to be selected in a way of being 30% or more than the

power consumed by the pump. The PV voltage must comply with the pumps' operating voltage

and the maximal voltage of the controllers' inlet.

b. The number of the accumulators used depends from the selection that we made about the

accumulators' voltage and the voltage of the pump. The voltage needed for a certain pump is

formed trough serial connection of the accumulators. The accumulators capacity should be

selected in accordance with the pumps' power and the time during which the accumulator can

supply the pump without being discharged under the threshold. It is not recommended to

connect accumulators in parallel connection to increase the total capacity, especially in

the cases when the accumulators are with different capacity!!!

Type

PV module

Solar pump

controler

V(DC)

Battery

Voltage

(V) DC

Power

(Wp)

Capacity

(Ah)/Voltage

(V)/Quantity

Connection

3TSS1.38-45-

36/210

36

210

1.38

100Аh / 12V / 3 бр.

Serial

* if 2 or more PV modules are to be connected – please pay attention about the way of the connection

A. If you connect 2 or more PV modules in series, the voltage in the 2 ends of the circuit will be equal to

the voltage of one module multiplied with the panels number, and the current will be equal to the current

of one module.

B. If you connect 2 or more PV modules in parallel, the current of the whole circuit will be equal to the

current of one module multiplied with the modules number, and the voltage will be equal to the voltage

of one module.

C. The connection of photovoltaic modules with different parameters is not recommended!!!

8

Photovoltaic module

Solar pump controler

Reservoir

Battery

Water pump

Page 9

INSTRUCTION FOR THE CONNECTION OF A CONTROLER FOR

SOLAR PUMP MODEL - 3TSS1.38-55-36/210

Cable terminal scheme

Mode selection

I: Mode photovoltaic panel

0: Switched off

II: Mode accumulator

Scheme and connection sequence

a). Open the package and check the controller for transport damages

b). Please set the switch in mode “switched off” position “0” before connection

c). Connect the controller as it is shown on picture 1

1. Connect the pump (be careful for the polarity U,V,W)

2. Connect the photovoltaic modules in series scheme to X+ and X-

3. Connect the accumulator to Y+ and Y-

4. Connect the level sensors to TC, TH, WC, WL, WH

9

Page 10

WARNING

1. After the first pump start, it will work about 2 minutes, then the controller will provide self-test for

about 30 seconds and will restart the pump.

2. If you wish full accumulator charge, please select mode “accumulator” position “II” and stop the

pumps' work (there are 2 possibilities of doing it:: 1> outer reservoir (if there is such) to be full'

2> to switch off the sensor of terminal WC.

3. Limit voltage values of open loop for photovoltaic modules:

Rated voltage (V)

Maximal voltage of open

loop (V)

Accumulators' voltage (V)

Maximal operating

current (A)

24V/36V

60V

24V,36V

12A

48V

100V

48V

12A

10

Page 11

INSTALATION INSTRUCTION OF SOLAR PUMPS

MODELS - 4TSC4-45-48/500 И 4TSSC6-40-48/500

Connection scheme

Lights indication:

POW led(green) – Switched on supply

RUN led (green/flashes green) – Motor working/Motor test

MPPT led (flashes green) – The system for working point set-up works

VOLT led (red) – The operating current is out of permissible limits

11

Controler for solar pump

Photovltaic module

Solar pump

Level sensors

Reservoir

Solar Pump

Page 12

CUR led (red) – The operating voltage is out of permissible limits

TANK led (red) – The reservoir is full

WL led (red) – The water level in the drilling is lower than WH sensor

Scheme names:

U;V;W – Motor pump

S+ – Photovoltaic module(+)

S- – Photovoltaic module(-)

WH – Heigh level sensor in the drilling

WL – Low level sensor in the drilling

COM1 – General sensors terminal in the drilling

TH – Level sensor in the reservoir

COM2 – General sensors terminal in the reservoir

ФВ1÷ФВ4 – Photovoltaic modules JLS72M170 (JLS72M160)

Connection sequence:

1. Open the package and check the controller for transport damages

2. Please set the switch in mode “switched off” position “0” before the connection

3. Connect the controller as it is shown on the picture:

ATTENTION! RISK FROM ELECTRIC SHOCK!

Connect the pump (pay attention for the polarity U,V,W)

Connect the photovoltaic module to S+ and S-

Connect the level sensors respectively to TC, TH, WC, WL, WH

WARNING

After the first pump start, it will work about 2 minutes, then the controller will provide self-test for about

30 seconds and will restart the pump.

12

Page 13

INSTALATION INSTRUCTION OF SOLAR PUMPS

MODELS - 4TSC8-40-110/1000 И 4TSSC5.1-65-110/1000

Connection scheme

Lights indication:

Power led(green) – Switched on supply

Run led (green) – Motor working

MPPT led (flashes) – The system for working point set-up works

13

Controler for solar pump

Solar pump

Photovltaic module

Level sensors

Reservoir

Solar Pump

Page 14

Err-I led (red) – The operating current is out of permissible limits

Err-V led (червен) – The operating voltage is out of permissible limits

Tank-F led (червен) – The reservoir is full

Well-l led (червен) – The water level in the drilling is lower

Scheme names:

1;2;3 – Motor pump

B+ – Photovoltaic module (+)

B- – Photovoltaic module (-)

ETH – Grounding

WH – Height level sensor in the drilling

WL – Low level sensor in the drilling

COM1 – General sensors terminal in the drilling

TH – Level sensor in the drilling

COM2 – General sensor terminal in the drilling

ФВ1÷ФВ5 – Photovoltaic modules CPV60M240

Connection sequence:

a). Open the package and check the controller for transport damages

b). Please set the switch in mode “switched off” position “0” before the connection

c). Connect the controller as it is shown on the picture:

ATTENTION! RISK FROM ELECTRIC SHOCK!

1. Connect the pump (pay attention for the polarity 1,2,3)

2. Connect the grounding cable to ETH

3. Connect the photovoltaic module to B+ and B-

Connect the level sensors respectively to TC, TH, WC, WL, WH

WARNING

After the first pump start, it will work about 2 minutes, then the controller will provide self-test for about

30 seconds and will restart the pump.

14

Page 15

Sequence of solar pumps installation

Open the package and check the product entirely

The control switch must be in position ”OFF” (“0” position)

Connect the photovoltaic module(s), accumulator (only if used in the relevan case), pump and

level sensors cables to the cable terminal of the controller in agreement with the connection

scheme. Choose the right cable dimension, fuses, switches and water level sensors.

Tight the fixing screws at the cable terminal with a screwdriver.

Be sure that the photovoltaic module(s) deliver power enough to the controller.

After finishing the upper steps, switch on the control switch (position I), the motor will operate for

10 seconds, after that will stop for 30 seconds (self-test), if the cables and the installation are

right, the pump will restart and work without interruption.

If the pump doesn't work properly, please check the operating indicators and the fault

indications, to find the reason and contact the supplier.

Mount the controller in a dry and well ventilated place. Never expose the controller in outer

atmospheric effect – the controler is not waterproof, and this will lead to its damage.

!!! Notes

The pump must be immersed in the water 15-20 minutes before its first starting. DO NOT

START THE PUMP DRY!, not even for test switching on. The working depth should not be

under 0,5m. It is not recommended the installation of the pump in depth bigger than 20m

under the water level.

During the installation of the submersible pump, there must be a rope connected to it.

Don't lift up the pump through the electric cable, the warranty will be refused if it gets

damaged.

The motors' supplying cables (U,V,W), must be connected to the controllers' cable

terminal (U,V,W) in the right way. Otherwise the motor will reverse and the pump will not

extract any water or very little water.

The water level sensor should be put over pumps' suction level. Otherwise it won't be

able to prevent the pump running dry. If there is no need of level sensor installation,

terminal WH and terminal WC (COM1) should be shortcut-connected.

You must make sure that the pump is positioned on the right depth. The stopping

between the switches ON and OFF should be at least 3 minutes or the pump protection

will be activated and the pump will stop working.

If there is a need of controllers' parameters change, the cover should be opened very

carefully to prevent the interruption of the inner connections.

15

Page 16

When a screw type solar pump will not be used for a long time, please take it out of the

water, wipe the housing and the screw and oil the pump housing with vegetable oil.

The regulating bolt at the base is already set by the quality control before the delivery.

The turning of this bolt by the customer might cause defects, degradation or low

efficiency.

The submersible pumps can be used only in waters with sands less than 0.1%.

The supplying cables cross section shouldn't be less than 2.5 mm2. It should be chosen

in agreement with the cable length and the pumps' capacity.

The pumps' supplying cable can be elongated depending the working deep, as the

connection place should be very well insulated to prevent a shortcut danger and damage

in the controller. The connection and insulation method is shown on picture 1, page 16.

Peel the outer cable covering as well as the covering of the separate wires, as they

should be cut in different length as it is shown on the picture. Connect the three wires,

tight the connections with thinner not insulated wire and weld the connections. Every

separate connection should be insulated with thermal shrink hose. The three

connections are tightly twined with insulation tape and over the tape is put thermal

shrink hose. Make sure that the thermal hose is well stuck and water can not enter from

anywhere. Finally join the three wires to the controllers' terminal as observing the

polarity (U,V,W).

V. Indicators for operation and fault instructions

Indications

Possible reason

Solution

Indication for

supply not

lighted

No supply

Switch on supply key

The connection is wrong or not tight

Check and tight all connections

The controller, photovoltaic module or

battery are damaged

Contact the supplier or the service

Fault indication

lighted

The wires cross section is less than

1.5 mm

2

Choose wires with bigger cross section

than 1.5 mm

2

Motors' rotor is blocked

Clean the pump

Solar radiation intensity is not enough

Wait until solar radiation intensity

increases or correct the module situation

The water level is over the

permissible limit

Correct the pump situation

Indications for

level and fault

lighted

The water level is within

impermissible limits

Wait until the water level raises or

correct the pump situation

There is no water level sensor

Mount the water level sensors in

agreement with the instruction or

connect terminal WH to WC (only if

sensors mounting is not required)

!!! Notes

1. Important for water level sensors:

If the pump works over the water level, there is a danger of pump damage (the warranty is invalid).

16

Page 17

The level sensors' target is to protect the pump from running dry while monitoring the water level and if

necessary sending a signal to the controller to switch off the pump.

The level sensors are three probes from a stainless steel. The probe should not be covered or to

touch conductible parts, so it can work properly.

If it is necessary to elongate the probes' cable, the cable which will be used must be with

suitable cross section, the connection should be welded and insulated with insulating tape and

thermal shrink hose.

2. Level sensors installation:

The cables of the three probes of level sensors must be connected to WH, WL and WC separately.

“WH” probe is installed in upper position to detect the water level in which the pump shoul start if it was

stopped because of water level fall. “WL” probe is installed just over the pump, to detect the water level

where the pump wouldn't run dry. “WC” probe /common point/ is to be installed under the pump level.

Level sensors' working range is between probe “WH” and probe “WL”. When the water level is

lower than probe “WL”, the pump motor will stop working. When the water level raises up to

probe “WH”, the pump motor will start working again. Be careful for the distance between WH and

WL, it must be selected in such way, that the water level to raise for not less than 3 minutes.

17

1. cable

2. 0,5 mm2 bare copper wire

3. coupleable rubber tape

4. plastic insulating tape

Page 18

picture 1

18

Page 19

VI. Cleaning and maintenance of PV module

Crane Ltd modules are manufactured as this to have prolonged service life and require minimal

maintenance.

You should regularly remove accumulated dirt from the PV module(s) (eg dust, pollen,

vegetation, bird droppings, etc.). Such contamination, which overshadows the modules' active

areas can lead to limitation of system performance and decrease the solar pump production.

Please obcerve the following points:

For PV module(s) cleaning use water and soft sponge.

Avoid the water cleaning, when there is a danger of freezing of big temperature

differences between the module, the water and the air.

Hard water used for the cleaning, must be descaler in advance, so the remaining traces

to be avoided. Remove the remaining water from the module.

Do not use abrasive cleaning materials or surface-active agents (eg. Soap). Do

not scrap the contaminations. This might damage the modules' surface.

VII. Protection of the environment

After the service life termination of the solar pump, do not dispose it with normal

household waste, but transmit it to a collection point for waste recycling. This will

help protect the environment.

VIII. Contacts, warranty and service maintenance

Контакти

Contacts

Crane Ltd.

Bulgaria

4004, Plovdiv, 26 Komatevsko shose Str.

Phone: +35932657578

Fax: +35932657580

e-mail: office@crane-bg.com

web: www.crane-bg.com

Warranty conditions

The imported Crane Ltd. guarantee that the product will remain without defects in material and

manufacture for 3 (three) years from the date of delivery.

In case where Crane Ltd establish a defect as a result of the material or manufacture, may at its

assessment, repair the product or deliver new one – in terms EXW Plovdiv, Bulgaria.

19

Page 20

The warranty is not valid in cases when:

The product is damaged by abuse.

Damage due improper installation or connection to improper voltage.

Transportation or movement of the product in improper conditions.

In case the product has been maintained by person who is not authorised from the

manufacturer of the provider

If you do not represent the warranty card and the Invoice when making the claim. The

claim can be applied only when all necessary documents are available.

20

Page 21

WARRANTY CARD

Client: __________________________________________________________________________

Address: ________________________________________________________________________

________________________________________________________________________________

Phone: _________________________________________________________________________

Fax: ____________________________________________________________________________

Mobile phone: ____________________________________________________________________

Model: ___________________________________________________________________________

Product №: ______________________________________________________________________

Bought day: ______________________________________________________________________

Note: ___________________________________________________________________________

_________________________________________________________________________________

Since the Order date, we give 3 years of warranty

for repair with the following conditions:

Warranty conditions:

1. The importer Crane Ltd. guarantee that the solar pumps will remain without defects in

material and manufacture for 3 (three) years from the data of delivery..

2. In case where Crane Ltd establish a defect as a result of the material or manufacture,

may at its discretion, repair the product or deliver new one – in terms EXW Plovdiv,

Bulgaria.

3. The warranty is not valid in cases when:

* The product is damaged by abuse

* Damage due improper installation or connection to improper voltage

* Transportation or movement of the product in improper conditions

* In case the product has been maintained by person who is not authorised from the

manufacturer of the provider

If you do not represent the warranty card and the Invoice when making the claim. The claim can be

applied only when all necessary documents are available

IMPORTANT INSTRUCTIONS

Solar panel position:

As we use the electric energy from photovoltaic pannels for the solar pump supply, is

necessary the right solar pannel orientation regarding the sun. The photovoltaic module have

highest performance when the solar energy falls perpendicularly regarding the pannels' surface.

Every shading guides to photovoltaic pannel performance decrease, and there from, to

decrease of the pumped out water flow.

Submitted: Crane Ltd. Received: ............................................

................................................... ...............................................

.................................................. ...............................................

Crane Ltd, Bulgaria, 4004 Plovdiv, 26, Komatevsko shose Str., phone +35932657578, fax +35932657580,

e-mail: office@crane-bg.com, www.crane-bg.com

Loading...

Loading...