Cranborne THI 10-50c

Wall Hung Gas Fired Condensing Boiler

Room Sealed or Open Flue

INSTALLATION, COMMISSIONING AND SERVICING

INSTRUCTIONS

IMPORTANT NOTE: THESE INSTRUCTIONS MUST BE READ AND UNDERSTOOD

BEFORE INSTALLING, COMMISSIONING, OPERATING OR SERVICING THIS

APPLIANCE.

THE CRANBORNE THI 10-50c BOILER IS INTENDED FOR USE AS A DOMESTIC /

LIGHT COMMERCIAL APPLIANCE FOR HEATING AND DOMESTIC HOT WATER

INSTALLATIONS.

ND

THIS BOILER IS FOR USE ON GROUP H NATURAL GAS (2

PROPANE GAS (3

REQUIRED WITHIN DOCUMENT IS FOUND RELATING TO SPECIFIC GAS TO BE

FIRED BEFORE FIRING BOILER.

THIS BOILER COMPLIES WITH ALL RELEVANT EUROPEAN DIRECTIVES

EC IDENTIFICATION No. CE-0085AR0323

PUBLICATION NO. 500001115

ISSUE 'B'

AUGUST 2003

rd

FAMILY) I3P. PLEASE ENSURE RELEVANT INFORMATION

FAMILY) I

2H

OR LPG-

HAMWORTHY HEATING LTD CRANBORNE THI 10-50c 500001115/B

i

CONTENTS

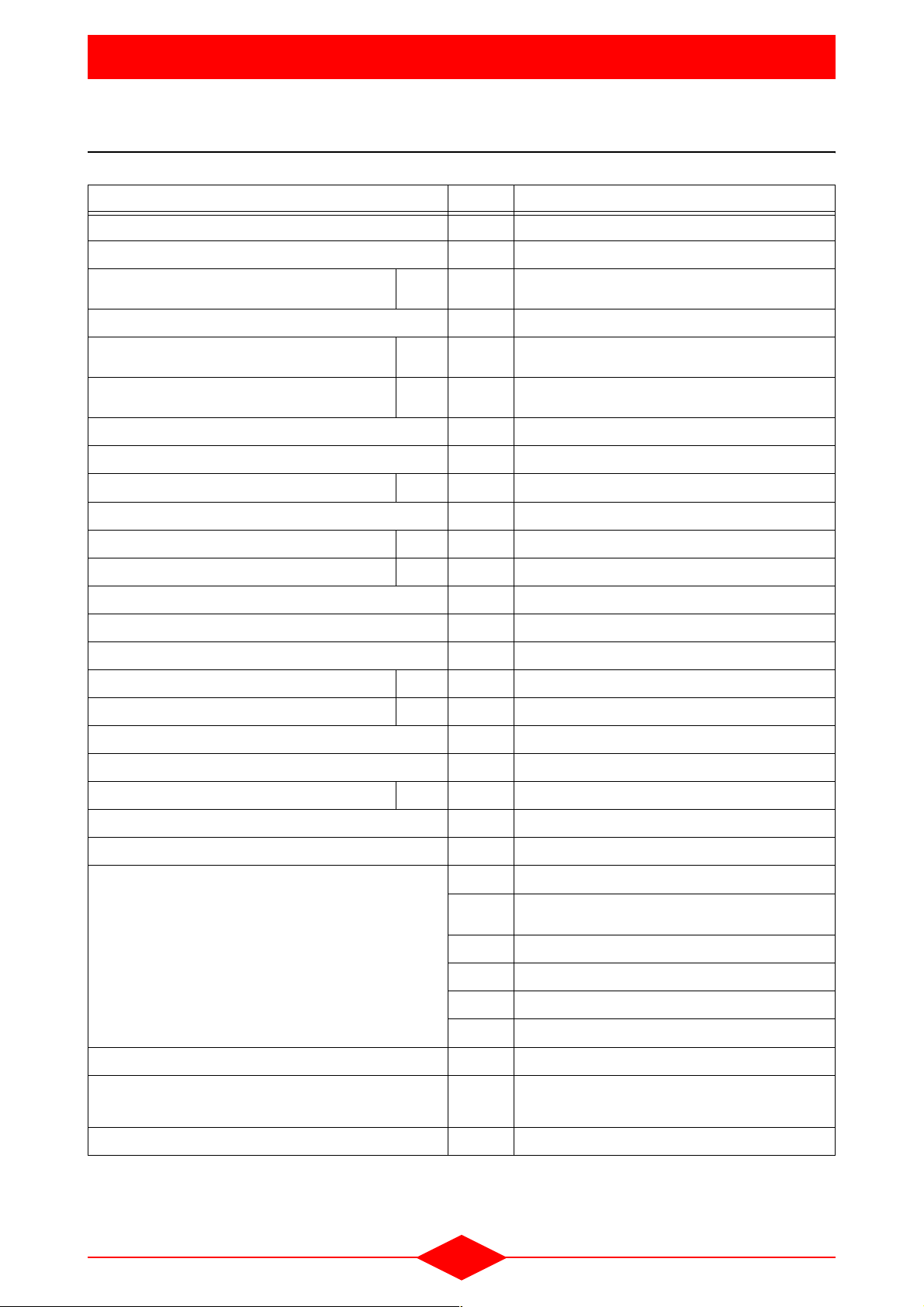

I-PRESENTATION ................................................................................................................................... 5

1-DESCRIPTION ...................................................................................................................................... 5

2-RANGE .................................................................................................................................................. 5

II - TECHNICAL SPECIFICATIONS ........................................................................................................... 6

1-CHARACTERISTICS ............................................................................................................................. 6

2-PIPE CONNECTION DIAMETERS........................................................................................................ 7

3-DIMENSIONS ........................................................................................................................................ 7

4-LIST OF COMPONENTS....................................................................................................................... 8

4.1 - Control panel ............................................................................................................................. 9

5-CIRCULATING PUMP CHARACTERISTICS ...................................................................................... 10

6-PRESSURE DROP IN THE BOILER (HEATING CIRCUIT)................................................................ 10

7-THERMAL EFFICIENCY ..................................................................................................................... 10

III - OPERATION ........................................................................................................................................ 12

1-GENERAL OPERATING PRINCIPLE.................................................................................................. 12

2-OPERATION OF THE LMU MANAGEMENT UNIT............................................................................. 13

2.1 - Normal operating conditions ....................................................................................................13

2.2 - Operating diagram ................................................................................................................... 13

2.3 - Principle of air/gas servo-control system ................................................................................. 15

2.4 - Air pressure variation procedure ............................................................................................. 15

2.5 - Emission of pollutants .............................................................................................................. 15

3-FUNCTIONS ........................................................................................................................................ 16

3.1 - Anti-freeze function .................................................................................................................. 16

3.2 - Anti-legionnella function .......................................................................................................... 16

3.3 - Pump run-on after the end of heating ...................................................................................... 16

3.4 - Pump kick or selector valve kick .............................................................................................. 16

3.5 - Boiler overheat protection ........................................................................................................ 16

3.6 - Monitoring of flue gas temperature .......................................................................................... 17

3.7 - Boiler return temperature control ............................................................................................. 17

3.8 - Monitoring of hydraulic pressure ............................................................................................. 17

3.9 - Anti-short burner cycle protection function .............................................................................. 17

3.10 - Cleaning function ..................................................................................................................... 17

3.11 - Regulator shutdown function ................................................................................................... 17

3.12 - LMU programmable key .......................................................................................................... 18

3.13 - Automatic summer/winter switching (only activated with outside sensor) ............................... 18

4-DIFFERENT VERSIONS OF THE THI ................................................................................................ 19

4.1 - THI basic model (without outside sensor, without room sensor) ............................................. 19

4.2 - THI with outside sensor only ...................................................................................................19

4.3 - THI with outside and room sensors ......................................................................................... 22

- 2 -

CONTENT

IV - INSTALLATION ................................................................................................................................... 23

1-GENERAL............................................................................................................................................ 23

2-VENTILATION ..................................................................................................................................... 24

2.1 - THI models with conventional flue connection ........................................................................ 24

2.2 - THI models with balanced flue connection .............................................................................. 24

3-COMBUSTION PRODUCT FLUEING ................................................................................................. 25

3.1 - Conventional flue outlets (B23 model) ..................................................................................... 25

3.2 - Balanced flue outlet ................................................................................................................. 26

4-SUPPORT BRACKET.......................................................................................................................... 32

5-HYDRAULIC CONNECTION ............................................................................................................... 33

5.1 - Recommendations ................................................................................................................... 33

5.2 - Accessories to connect, install or adjust .................................................................................. 33

5.3 - Under-floor recommendations ................................................................................................. 34

5.4 - Heat exchanger flow rate ......................................................................................................... 34

5.5 - Hydraulic connection for models THI 10-50 C ......................................................................... 35

5.6 - Hydraulic connection for models THI 10-50 C + DHW production system of type BS ............ 35

6-GAS CONNECTION ............................................................................................................................ 36

6.1 - Connection of a gas safety solenoid ........................................................................................ 36

7-ELECTRICAL CONNECTION.............................................................................................................. 36

7.1 - Mains connection ..................................................................................................................... 36

7.2 - Connection of the sensors to the LMU management unit ....................................................... 36

7.3 - Under-floor heating safety ....................................................................................................... 36

7.4 - Wiring diagram ........................................................................................................................ 37

V-SETTINGS OF THE INSTALLATION TYPES ..................................................................................... 38

1-SINGLE CIRCUIT ................................................................................................................................ 38

1.1 - Heating pump relay operation ................................................................................................. 39

1.2 - Hydraulically disconnected operation ...................................................................................... 39

2-DOUBLE CIRCUIT............................................................................................................................... 40

2.1 - Heating pump relay operation ................................................................................................. 41

2.2 - Without room sensor ............................................................................................................... 41

2.3 - With room sensor .................................................................................................................... 41

2.4 - Recommended installation of the 2nd circuit and relay clip-ins on the LMU ........................... 42

3-ACCESS THE SETTINGS VIA THE QAA 73 ROOM SENSOR ......................................................... 43

3.1 - Access the lines 51 to 98 ......................................................................................................... 43

3.2 - Access the lines 501 to 755 ..................................................................................................... 44

VI - COMMISSIONING ............................................................................................................................... 45

1-PROTECTION OF THE INSTALLATION............................................................................................. 45

1.1 - Bionibal .................................................................................................................................... 45

1.2 - Bionibagel ................................................................................................................................ 45

2-FILLING THE INSTALLATION WITH WATER .................................................................................... 46

3-PRESSURE SENSOR ......................................................................................................................... 46

4-GAS SUPPLY ...................................................................................................................................... 46

5-SETTING THE MAXIMUM POWER IN HEATING MODE................................................................... 47

6-VERIFICATIONS PRIOR TO COMMISSIONING................................................................................ 47

7-USER INFORMATION......................................................................................................................... 47

8-COMMISSIONING ............................................................................................................................... 48

9-FLAME SETTING ................................................................................................................................ 49

10 - COMBUSTION PRODUCT CHECKING.............................................................................................. 49

- 3 -

CONTENT

VII - GAS CONVERSION ............................................................................................................................ 50

1-SERVICE PRESSURE CONTROL...................................................................................................... 50

2-GAS CONVERSION ............................................................................................................................ 50

2.1 - Conversion from Natural Gas to Propane ............................................................................... 51

2.2 - Conversion from Propane to Natural gas ................................................................................ 51

3-GAS/CO2/CO/NOX FLOW CONTROL................................................................................................ 52

3.1 - Surveillance procedure ............................................................................................................ 52

3.2 - Setting table ............................................................................................................................. 53

VIII - MAINTENANCE .................................................................................................................................. 54

1-SERVICING THE FAN AND THE BURNER........................................................................................ 54

2-SERVICING THE HEAT EXCHANGER OF THE BOILER SHELL...................................................... 55

3-CHECKING ACCESSORIES ............................................................................................................... 55

4-EXPANSION VESSEL PRE-INFLATION PRESSURE CHECK .......................................................... 55

5-COMBUSTION PRODUCT CONDUITS .............................................................................................. 55

6-DRAINING ........................................................................................................................................... 56

7-SENSOR RESISTANCES ................................................................................................................... 56

IX - OPERATING FAULTS ........................................................................................................................ 57

X-OPTIONS ............................................................................................................................................. 59

1-SET-UP TAKING ROOM TEMPERATURE INTO ACCOUNT (REG 73) ............................................ 59

2- CLIP-IN LPB KIT (REG 130)............................................................................................................... 59

3- SECONDARY CIRCUIT CLIP-IN KIT ................................................................................................. 59

4-DOUBLE CIRCUIT KIT (REG 126)...................................................................................................... 60

5-PROGRAMMABLE RELAY CLIP-IN KIT (REG 127)........................................................................... 60

6-CONTROL UNIT ZHTI 46 (REG 129).................................................................................................. 60

7-CONTROL UNIT ZHTI 47 (REG 128).................................................................................................. 61

9-SELECTOR VALVE KIT FOR CONNECTING THI..C/BS ................................................................... 61

XII - NOMENCLATURE .............................................................................................................................. 64

- 4 -

1 - DESCRIPTION

I - PRESENTATION

Standard description: wall mounted condensation

boiler for hot water heating, sealed combustion cir

cuit, pre-mixing burner with air-gas supply, and

linear power modulation connecting combustion

product types B

(04/00)

The THI boiler is pre-set in the factory for natural

gas H (G20) or propane (G31) depending on the

model.

This boiler comprises all the necessary accessories

for the correct working of a water based central hea

ting circuit specifically:

- one boiler comprising:

• a high performance double walled condensation exchanger,

- a pre-mixing burner, with stainless steel refractory grate,

- a variable speed 230 Volt fan controlled by the regulator,

- a 230 Volt two way gas valve controlled by the air

pressure,

- electronic regulation which ensures power modulation depending on the demands for heating or

DHW (LMU control unit),

- an outside sensor,

- a circulating pump,

- a 3 bar safety-valve,

, C13, C33, following EN 483

23

-

-

OPTIONAL:

- Horizontal flue kit (C13) allowing the boiler to be

connected to a straight horizontal flue.

- Accessories for horizontal connection of the boiler (C13) - (extensions, elbows etc.).

- Flue adapter (C33) allowing the boiler to be connected to a vertical flue.

- Accessories for vertical connection of the boiler

(C

) - (terminal, extensions, elbows etc.).

33

- Adjustment as a function of the room temperature

(REG 73).

- 2nd heating circuit kit allowing the connection of

a secondary heating circuit (REG 126).

- Clip-in kit secondary circuit allowing the connection of a secondary heating circuit.

- Clip-in communication LPB kit used for cascade

or multi-circuit installations (REG 130).

- Clip-in programmable relay kit allowing a secondary pump to work in parallel (REG 127).

- Control unit ZHTi 46 (REG 129) controlling an additional heating circuit.

- Control unit ZHTi 47 (REG 128) allowing cascade

management for two boilers.

-

- a gas conversion set (to propane from natural gas).

2 - RANGE

Models Functions

THI 10-50 C Only heating

- Domestic hot water production system (type BS).

Combustion products

connection

Chimney conduit (B23)

Horizontal flue (C13)

Vertical flue (C33)

- 5 -

II - TECHNICAL SPECIFICATIONS

1 - CHARACTERISTICS

Model THI 10-50 C

Certification CE0085AR0323

Category / Country of destination: GB II

Nominal power 30/50 °C

Heat rate kW 10,0/50,0

Efficiency on PCI 30/50 °C

Efficiency on PCS 30/50 °C

Efficiency according to 92/42 CEE directive (30%) load % 107,7

Useable gases (NG: Natural gas / PG: Propane) NG H - PG

Combustion product temperature maxi °C

Over-heating safety of combustion products

Flow rate of combustion products mini/maxi

Permitted back pressure (C13) maxi Pa

Air flow required for combustion m3/h 61

NO

x

CO

Heating service pressure

60/80 °CkWkW

60/80 °C%%

60/80 °C%%

°C 85

kg/h 18,0/90,0

mg/kWh

mg/kWh

mini/maxi

bar 1/3

< 60

< 50

2H3P

10,7/52,6

9,7/48,7

107,7/105,1

97,4/95,9

96,9/94,6

87,7/86,3

80

100

Heating circuit water temperature maxi °C 80

Water overheating safety thermostat °C 100

Boiler water capacity liter 3,8

Primary water flow 60/80 °C m3/h 2,1

DP water (at nominal flow) mbar 600

Thermal losses (DT 30 K) W 100

Absorbed electrical power in heating mode:

Control alone

Pump speed 1

Pump speed 2

Pump speed 3

Stand By Position

Power supply/frequency 230 V (+ 10%, - 15%)/50 Hz

Protection factor

models B23

model C13/C

Weight packaged kg 80

33

W

W

W 124

W 147

W

mini : 23

maxi : 53

110

9,2

IP 24

IP 44

- 6 -

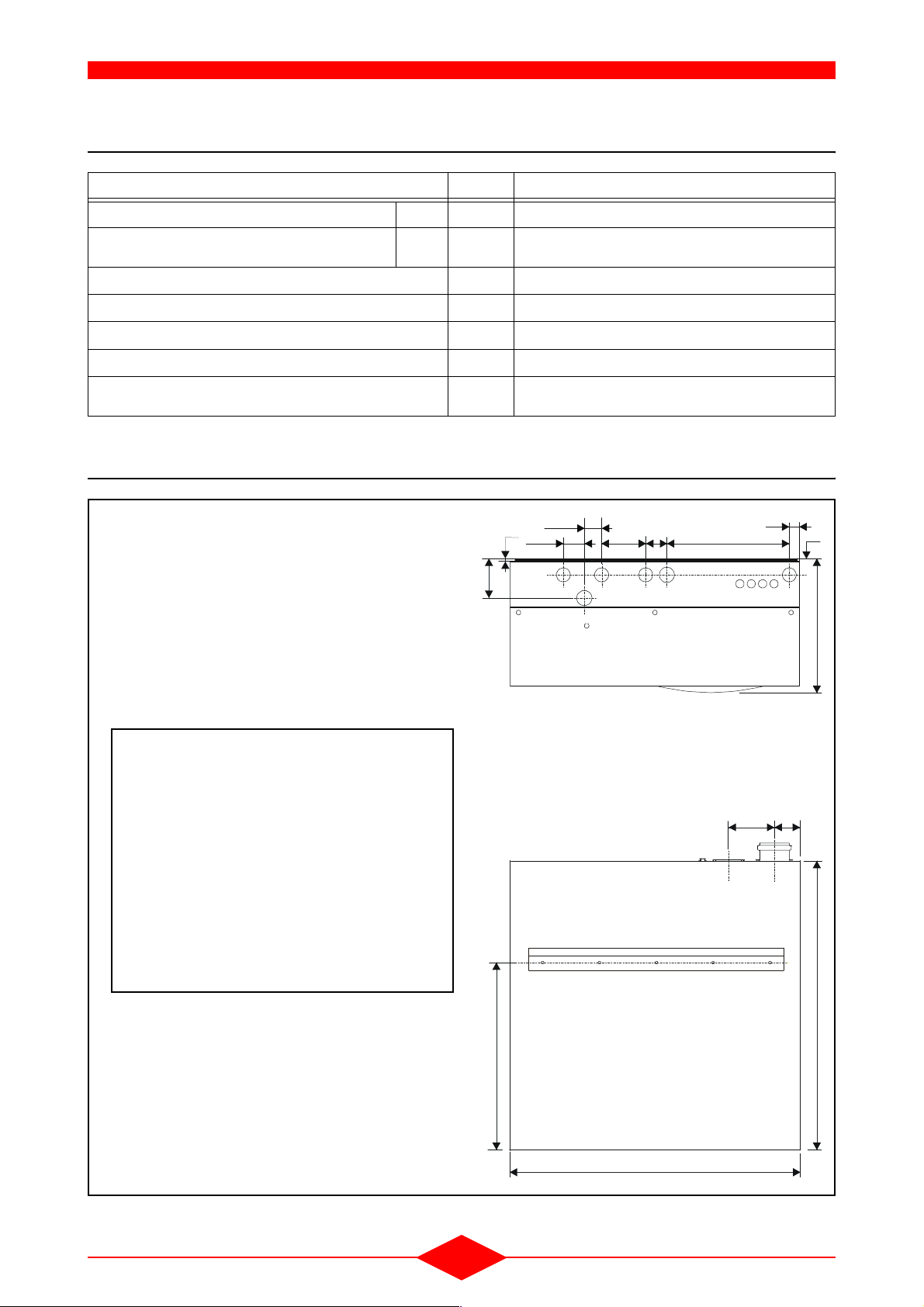

2 - PIPE CONNECTION DIAMETERS

Modèles THI 10-50 C

TECHNICAL SPECIFICATIONS

Æ Combustion products B

Æ Combustion products C

23

13

C

33

mm 80/139

mm

mm

80/125

Æ Gas inlet R1

Æ Heating flow/return R1

Æ Condensation outlet mm 25

Æ Safety valve outlet R3/4

Æ DHW production system connection (option § 9 - page 61)

R1

R3/4 with coupling

3 - DIMENSIONS

Fig. 1

102

19

55,5

45,5

117 56 323 ,5

cd

h

i

27

56

b

g

361

Legend:

a : Combustion products outlet

b : Gas inlet

c : Heating flow

d : Heating return

e : /

f : /

g : Condensate drain

h : Safety valve drain

i : DHW production system connection (option)

495

THI-05- 0

Bottom view

120 67,5

a

Rear view

760

- 7 -

765

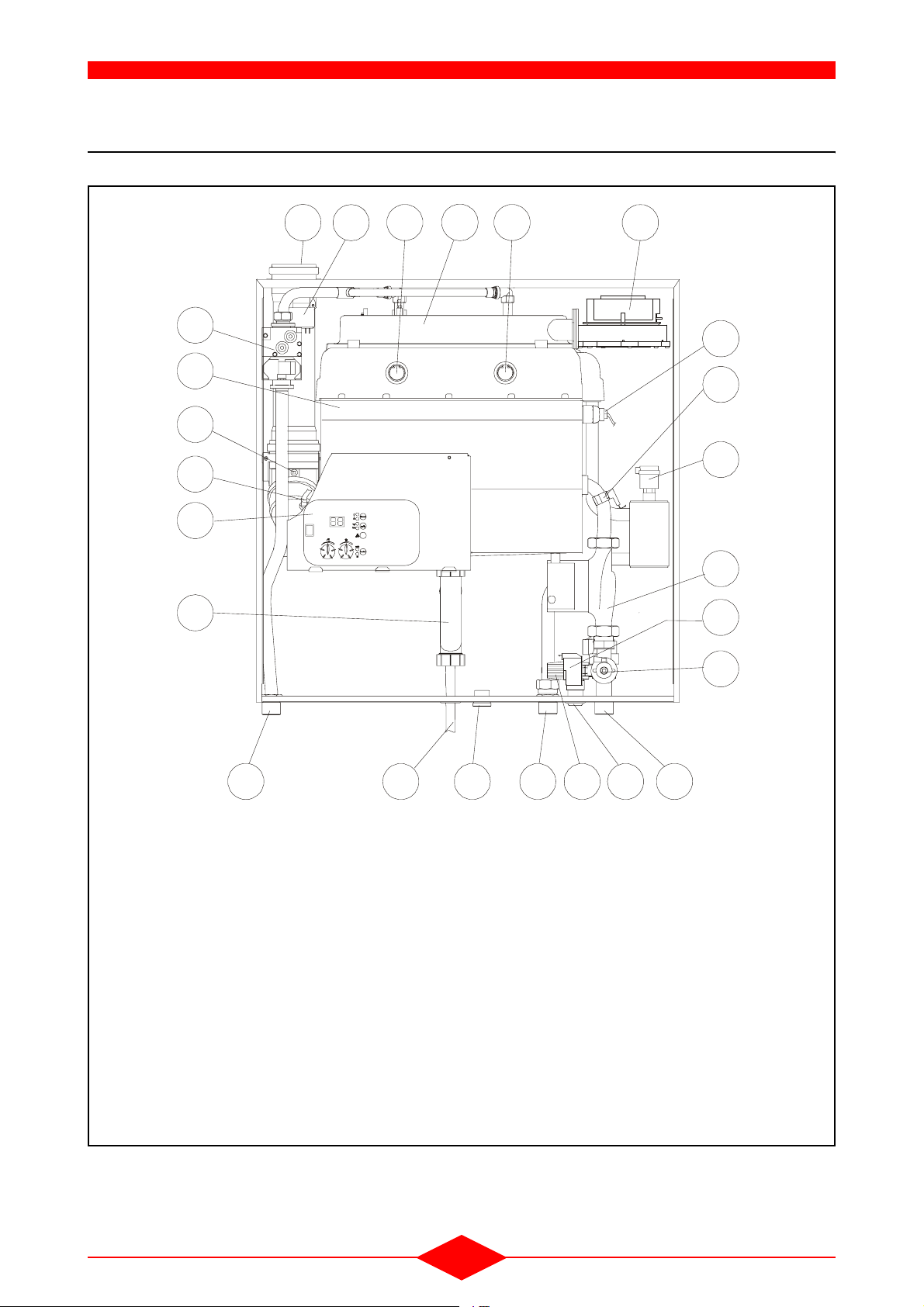

4 - LIST OF COMPONENTS

Fig. 2

TECHNICAL SPECIFICATIONS

104

13

3

13

11

THI-06-0

12

23

5

14

21

2

7

9

16

15

17

18

1

1) Gas inlet

2) Gas unit (solenoids and regulator) 230 V

3) Gas burner

4) Combustion products outlet

5) Flue gas sensor

6) Heating flow

7) Heating outlet and safety sensor

8) Heating return manifold

9) Boiler return sensor

10)Ignition transformer 230 V

11) Fan 230 V

12)Boiler shell

13) Sight-glass

14) Microprocessor control panel

24

15)3 speed pump 230 V

16) Air bleed

17)Pressure sensor

18) Filter and drain tap

19) Safety valve 3 bar

20) Safety valve outlet

21) Siphon trap

22)Condensate drain

23)Combustion check window

24)DHW production system connection (option)

6 8

19

2022

- 8 -

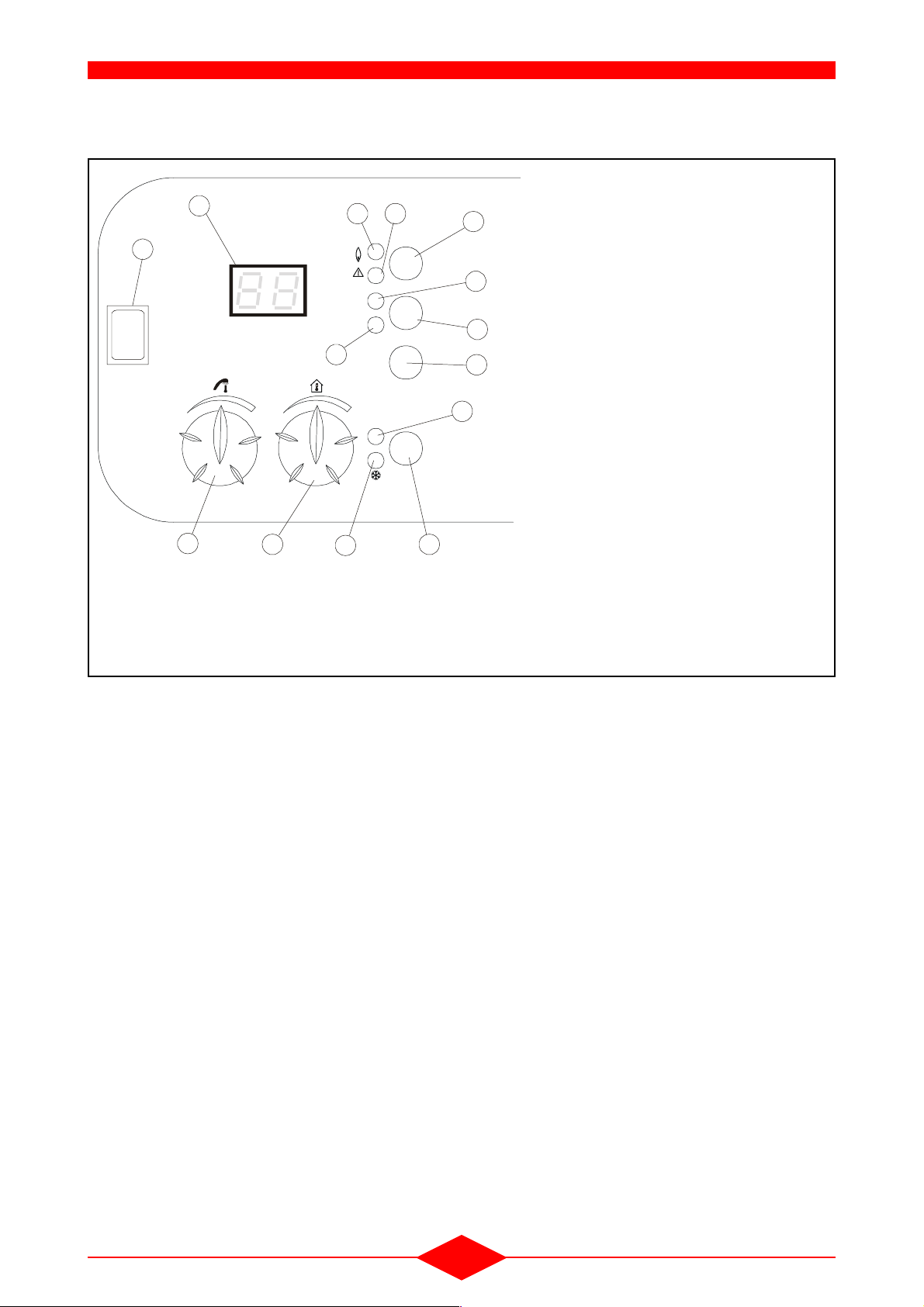

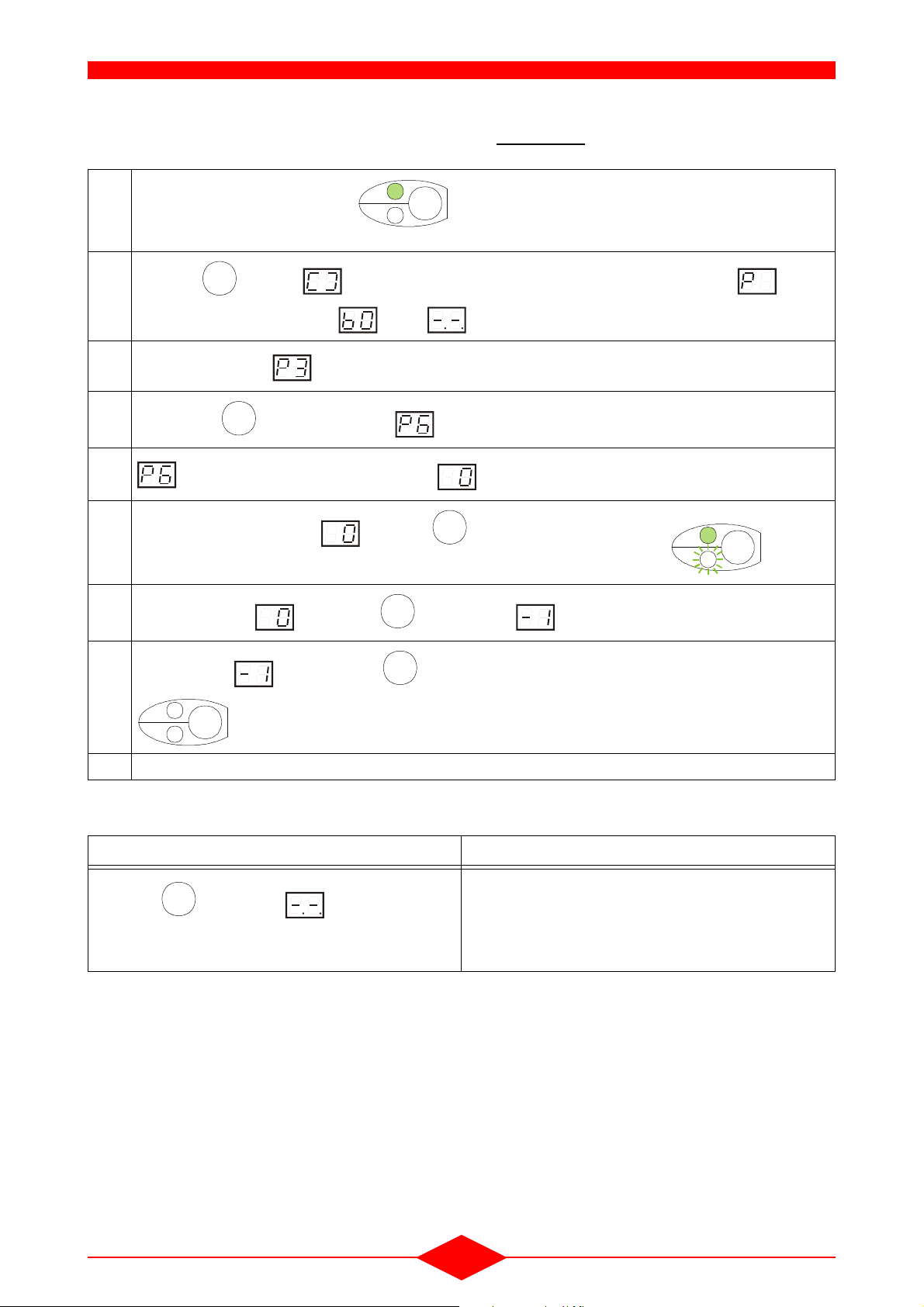

4.1 - Control panel

Fig. 3

13

1112

10

14

Reset

I

°C

bar

Info

8

O

3

* The function of the heating temperature (2) and DHW temperature (3)

potentiometers differs according the 3 examples below.

**The On/Off switch (after initial lighting) should be maintained in the "ON"

position in order to preserve all the automatic functions of the boiler (anti-freeze, anti-legionella functions, etc).

2

j

auto

Function

5

1

9

7

6

4

THI-01-0

TECHNICAL SPECIFICATIONS

1) The "Function" key gives access to 3 operating

modes by simply pressing the key:

auto mode: LED (4) on

winter mode: LED (5) on

summer mode: LED (4) and (5) off

2) Regulation of the heating temperature (setting

read on the display (13)) *

3) Regulation of the DHW temperature (setting

read on the display (13)) *

6) Maintenance key: reserved for servicemen or

maitenance (see overleaf)

7) "Info" key gives access to 5 types of information

on the display (13) by simply pressing the key:

Boiler outlet temperature: LED (9) on

Sensor temperature: LED (9) flashing

Boiler water pressure: LED (8) on

Operating phase: LEDs (8/9) off

Diagnostics: LEDs (8/9) off/

Display (13) flashing

10) Boiler reset button (After each reset, wait for

about 30 seconds before the restart = reset)

11) Alarm: Red LED on

12) Flame indicator: Green LED on

13) Digital display: Alternatively displays the setting

selected by the "Info" key and the current default

code

14) ON/OFF switch (depending on the models) **

THI Without room sensor or outside sensor

The heating (2) and hot water (3) temperatures setting are manually set on the boiler control panel.

- The FUNCTION key (1) gives access to 2 operating modes:

• Auto mode operation (4): no access

• Winter mode operation: LED (5) on

• Summer mode operation: LED (5) off

THI Without room sensor and with outside sensor

Possibility of correcting the heating temperature (2)

computed automatically using the outside tempera

ture and manual setting of the hot water temperature (3) on the boiler control panel. (The room

temperature setting can be changed by + or - 3°C

maximum according to the setting).

- The FUNCTION key (1) gives access to 3 opera-

ting modes:

• Auto mode function:

auto winter = Leds (4) and (5) on

auto summer = Led (4) on + Led (5) off

• Winter mode operation: LED (5) on

• Summer mode operation: LEDs (4) and (5) off

THI With room sensor and outside sensor

Fitting the QAA73 room sensor cancels the functions of the heating temperature setting (2) and hot

water setting (3) on the boiler control panel. All the

temperatures required, together with the heating

programmes, are set on the QAA 73 (refer to the

sensor instructions).

- 9 -

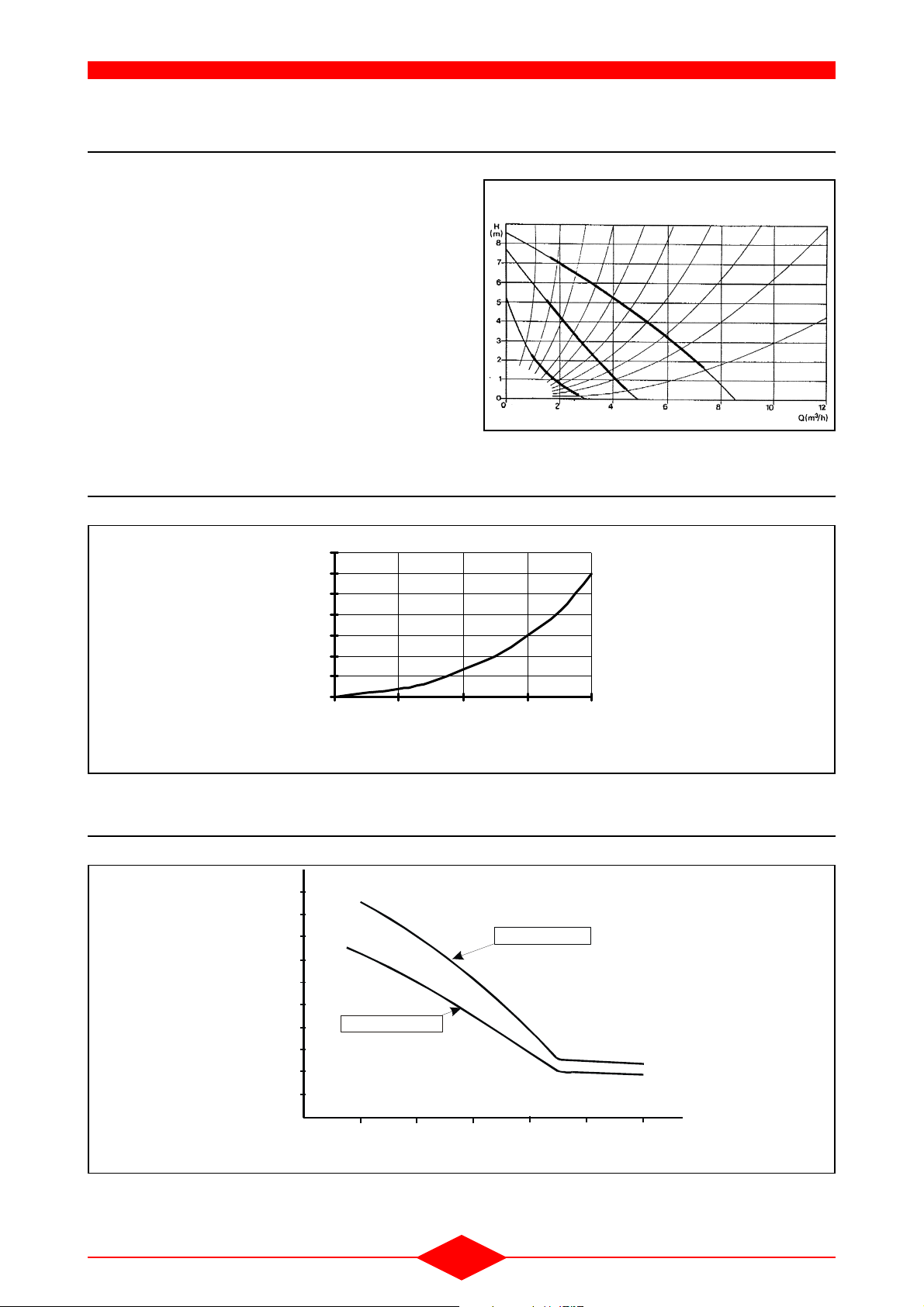

5 - CIRCULATING PUMP CHARACTERISTICS

TECHNICAL SPECIFICATIONS

The boiler’s integrated circulating pump is equipped

with a 3 speed motor (refer to section

1 - page 6).

Fig. 4

Electrical consumption of the heating circulating

pump can be optimised by adapting its speed to the

needs of the installation.

6 - PRESSURE DROP IN THE BOILER (HEATING CIRCUIT)

Fig. 5

7

6

5

4

3

2

1

Pressure drop (mWG)

0

0 500 1000 1500 2000

3

Flow rate (dm

/h)

UPS 25-80-180

7 - THERMAL EFFICIENCY

Fig. 6

1,10

1,08

1,06

1,04

1,02

1,00

0,98

PCI efficiency

0,96

0,94

0,92

0,90

10

Maximum rate

20 30 40

Installation- empératurereturn t

- 10 -

Minimum rate

50

T50-03- 3

60 70

III - OPERATION

1 - GENERAL OPERATING PRINCIPLE

The THI boiler is a very high efficiency condensation

boiler owing to the burner and heat exchanger that

benefit from our longstanding experience.

The over-sized fin tube exchanger and its combustion chamber cooled by water in the upper section,

combines the functions of heat exchanger and con

denser.

Second generation digital control continuously optimizes the operating rate by using information sent to

the microprocessor by the sensors fitted on the boi

ler:

- boiler flow sensor,

- boiler return sensor,

- outside temperature sensor,

- flue gas flue gastemperature sensor,

- room sensor,

- pressure sensor,

- fan speed control (pneumatic air/gas control),

- communication bus with external regulators.

-

-

Each of the sensors is allocated to an algorithm that

optimizes the operation and generates information

or fault codes that can be read from the display of

the control panel or QAA73 room sensor.

- 12 -

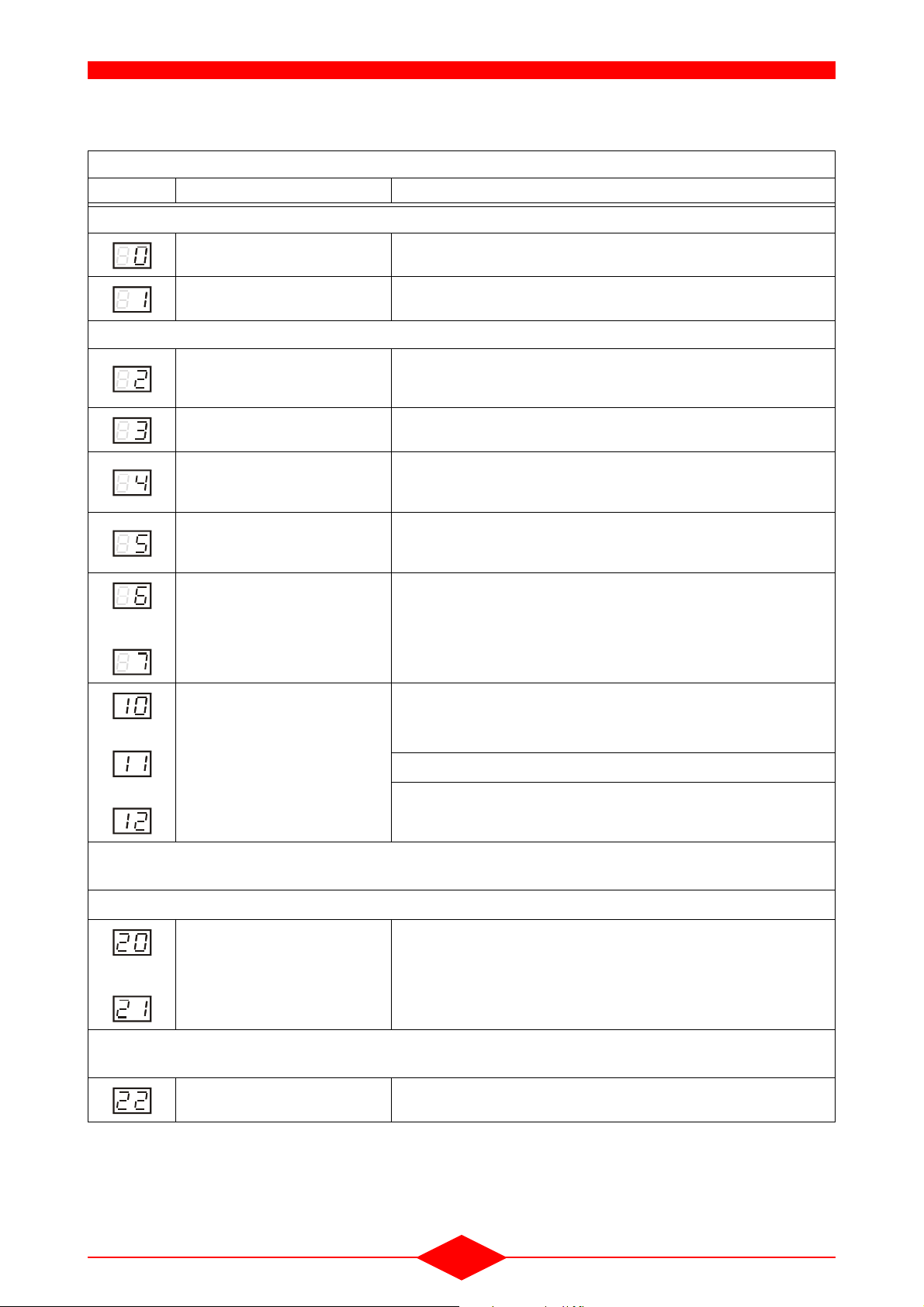

2 - OPERATION OF THE LMU MANAGEMENT UNIT

2.1 - Normal operating conditions

OPERATION

To access the operating phases of the LMU (display

level A4), press the info key (7) three times. The dif

-

Fig. 7

ferent phases will then be displayed (13).

Note:

INFO-0

- The phase display will stop automatically after 8

minutes,

- Otherwise, press the info key 2 times more.

Programming order for normal operating conditions

Display Meaning Display Meaning

Stand-by (no heating request) Ignition - safety time

Start-up blocked Heating mode operation

Fan speed rise time Hot water mode operation

Pre-ventilation time Heating + DHW operation (disabled for

THI)

Waiting time Post-ventilation with last operation

command

Pre-ignition time Return to initial setting

Fault position (display of current fault

code)

°C

bar

Reset

Info

713

2.2 - Operating diagram

Fig. 8

HMI

display:

Phase

Head

demand

Flame

Ignition

BV

LP (2)

LP (3)

LP (4)

NoG_Max

N_Vor

-N_Vor_Delta

+N_VL_Delta

N_VL

+N_ZL_Delta

N_ZL

-N_ZL_Delta

N_TL

-N_TL_Delta

NoG_Null

THI-65-3

7494f01D/0801

Home return

TNB

PH_TNB

Logic on

Logic off

On deviation

transition to home run

TLO

PH_TLO PH_TNN

022 1 2 3 654

Standby

TNN

PH_

STANDBY

PH_

STARTVER

PH_

STANDBY

tv TBRE

THL1

PH_

THL1_1

PH_TV PH_TB RE PH _TW1 PH_TW2 PH_TVZ

Depend on

para meter

setting

TW1 TW2

Deviati on leads to lockout

On deviation transition to

specified or following phase

10 H

11 DHW

12 H+DHW

tsa

Operation

tvz

tsa1 tsa2

PH_

TSA1_1

PH_

THL2

Z Z

Z ZZ Z Z Z

Depend on

parameter

setting

PH_

TSA2_1 PH_TI

Z

PH_

THL2

Z

Z Z

THL2

THL2

ti

PH_

PH_

20 2 4 7 21 99

tn

PH_

MODULATION

PH_

THL2

PH_

THL2

PH_

THL2_1 PH_TN_1

Depend on

parameter

settin g

THL1 (TW1)

PH_

PH_TW1

THL1_2

Depend on

parameter

settin g

Permitted range

Prohibited range

-> Home run

Prohibited range

-> Lockout

tsa

tsa1 tsa2

PH_

TSA1_2

Z Z

PH_

THL2

Z

Depend on

parameter

setting

Z

THL2

PH_

PH_

TSA2_2

THL2_2 PH_TN_2

PH_

THL2

PH_

TSA1_2

Z

Z

Depend on

para meter

setting

Control signal

Ideal signal

Transition criterio n

Triggering forced prepurging

tn

PH_

STOER

Z

Z

Z

- 13 -

Explanation of the operating phases

Display Phase Description

Shut down

PH_STANDBY (unlimited) The boiler is on standby and waiting for a heating request.

OPERATION

PH_STARTVER Start-up is blocked. The corresponding diagnostic code is emitted (shunt

Start-up: heating request

PH_THL1_1 (THL1) Fan speed rise time:

PH_TV (tv) Pre-ventilation time

PH_TBRE + PH_TW1 Tapering time

PH_TVZ (tvz) Pre-ignition time:

PH_TSA1_1 + PH_TSA2_1 (tsa) Safety time

and

PH_TI + PH_MODULATION: Burner operation

and

X10-03).

- This time ends as soon as the fan motor speed reaches the program

for pre-ventilation

- This time ends as soon as the ignition load programmed for pre-ventilation is reached

- Appearance of the ignition arc prior to opening the gas valve, which occurs at the start of phase 6

- A flame signal should be present before the safety time has elapsed. If

this does not occur, another ignition attempt is made.

10: heating operation

11: domestic hot water operation

12: heating and domestic hot water operation (disabled for THI)

and

• PH_TI...............................:

• PH_MODULATION...........:

Flame stabilisation interval.

In this phase, the LMU (regulator) send its results.

Return to standby: The switch from the operating position to the Standby position is split into “shut-down”

and “return to initial setting”

Shut-down: This occurs when the heating request disappears

PH_THL2_1 + PH_TN1 Post-ventilation time

and

- The fan remains on during the post-ventilation time

Return to initial setting: Compulsory switch from the shut-down position to standby. This phase is also

used to bring the boiler to standby position after exceptional events such as a RESET.

PH_TNB + PH_TLO + PH_ TNN:

Return to initial setting

- 14 -

2.3 - Principle of air/gas servo-control system

The gas valve fitted on each boiler is controlled by

the air pressure supplied by the fan, thus guaran

teeing a correct air-gas ratio over the whole modulation range (constant CO2). This ratio remains

constant despite any pressure drop in the combus

tion products outlet or the air intake. The air-gas link

is pneumatic.

Fig. 9

Operating characteristics of the air/gas servo-system

P2: gaz pressure at valve regulator outlet

PL: servo-system air pressure

P2 mbar GN

7

6

5

4

3

2

1

0

01234567PL mbar

OPERATION

2.4 - Air pressure variation procedure

Linear pressure modulation is carried out by a 230 V

variable-speed fan controlled by the LMU which cal

culates the speed needed at any given time to produce the required pressure.

2.5 - Emission of pollutants

This air/gas control combined with high efficiency

pre-mixing burner enables CO and nitrogen oxide

(NOx) emissions to be obtained that lie within the

values laid down by the most demanding of quality

standards.

-

- 15 -

3 - FUNCTIONS

OPERATION

3.1 - Anti-freeze function

- Boiler anti-freeze protection: When the boiler

temperature is below 5°C, the burner and the

heating circuit pump are switched on. When the

temperature increases and exceeds 15°C, the

burner stops and the pump continues to circulate

for 10 minutes.

- Anti-freeze protection for the installation: This

function uses the real outside temperature. It

adopts a different behaviour depending on the

temperature. If no measured outside temperature

is available, the function is blocked.

Different reactions can occur depending on the

outdoor temperature measured:

• If the outdoor temperature is less than or equal

to -5°C, the pumps operate continuously,

• If the temperature lies between -4 and 1.5°C,

the pumps operate for 10 minutes every 6

hours.

• If the outdoor temperature is over 1.5°C, the

pumps shut-down (no heating request).

Any domestic hot water request is given priority.

- Building anti-freeze protection:

The anti-freeze function of the building is a control

function (available with the QAA73 room sensor)

used to maintain the room temperature at a mini

mum value, thus preventing the risk of freezing in

the building.

3.2 - Anti-legionnella function

To provide a substantial degree of protection

against the development of pathogenic bacteria in

the domestic hot water tank during prolonged shutdowns, the domestic hot water must be heated once

a week to a temperature above 60°C.

-

3.3 - Pump run-on after the end of heating

When the heating mode ends, the heating circuit

pump remains on for a certain period (depending on

the settings used : QAA

In hot water storage systems, when domestic hot

water heating ends, the heating circuit pump re

mains on until the boiler temperature drops below

70°C. During this pump run-on period, the selector

valve remains in the “domestic hot water feed” posi

tion.

3.4 - Pump kick or selector valve kick

If the heating circuit pump has not operated or if the

selector valve has not been activated for more than

about 24 hours, these elements are activated during

operating stops for approximately 5 seconds.

3.5 - Boiler overheat protection

The boiler flow sensor in combination with the heating return sensor provide the overheat safety function.

There are two safety levels:

- if the first temperature value is exceeded, this is

signalled by a fault code on the display screen,

• THI 10-50 : 90°C

- if the second temperature value is exceeded

(100°C), it is signalled by an alarm code on the

display. The boiler switches to safety mode. The

boiler must be reset to be restarted.

If the temperature is exceeded, the heat present

must be evacuated through the fan and circulation

pump.

The two elements (fan and circulation pump) remain

on until the boiler shell temperature drops.

73 setting : 544).

-

-

The anti-legionnella function is used for this purpose. It heats the hot water storage tank once a week,

on Monday, after the first load, to a 65°C “anti-le

gionnella” temperature.

-

- 16 -

In the control algorithm, supervision of the temperature difference DT between the flow and return results in the shutdown of the burner if DT is above

56°C.

OPERATION

3.6 - Monitoring of flue gas temperature

The monitoring of flue gas temperature is not

classed as a function related to safety, but is a prio

-

rity factor in the control of the boiler.

- The boiler operates at minimum power if the flue

gas temperature exceeds 85°C,

- The boiler is on "Stand-by" if the flue gas temperature reaches 88°C.

The boiler can only be restarted automatically after

15 minutes if there is no longer a fault.

3.7 - Boiler return temperature control

The information from the return sensor is used in the

event of a very low flow (large

DT) (reduction in bur-

ner power or shut-down of the burner).

It is also enabled for cascade connection.

3.8 - Monitoring of hydraulic pressure

This is a priority function with respect to the control

of the boiler.

- the power of the boiler is limited if the pressure is

above 4 bar,

- the boiler reduces power to 20% if the pressure in

between 0.2 and 0.4 bars (fault code is dis

-

played),

- the boiler sets of an alarm and the pump stops if

the pressure is lower than 0.2 bars (alarm code is

displayed).

The boiler must be reset to clear the fault position if

the minimum value has been exceeded.

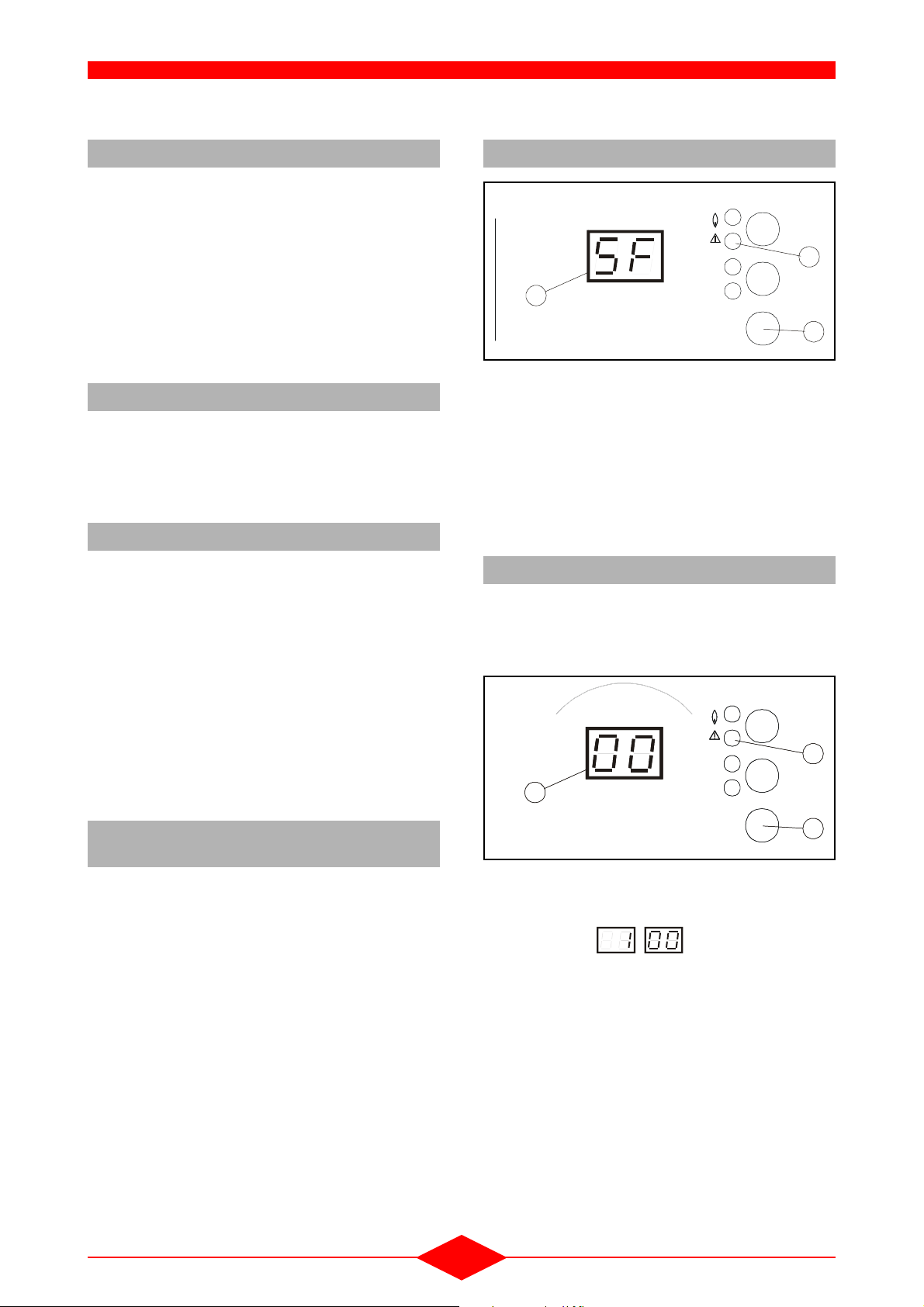

3.10 - Cleaning function

Fig. 10

Reset

11

°C

Info

13

RAMO-SF

bar

j

6

To enable this function, press the clean key (6) until

the red LED (11) lights up then release it. The LED

(11) then starts flashing once per period. The signal

ling coded “SF” is displayed on the screen (13).

Heating takes place at maximum calorific power until arriving at the maximum temperature TKSmax.

To disable the cleaning function, press on the clean

key (6) for 3 seconds then release it.

3.11 - Regulator shutdown function

The regulator shut-down function enables the fan

motor speed to be set manually via a domestic hot

water temperature potentiometer (3), and therefore

the heat output of the boiler.

Fig. 11

Reset

Reset

11

11

13

13

°C

°C

bar

bar

Info

Info

-

3.9 - Anti-short burner cycle protection

function

To prevent the boiler from cutting out suddenly, the

power failure differential is adjusted according to the

real temperature curve of the boiler.

j

j

RAMO-AR

RAMO-AR

- Press the clean key (6) for longer than 8 seconds,

• The red LED (11) flashes twice per period.

• The codes appear on the display

(13) and flash twice. This code corresponds to

the percentage of the boiler heating rate.

The safety function and the “all or nothing” regulator

are operating.

To disable the regulator shutdown function, press

the clean key (6) for 3 seconds then release it.

- 17 -

6

6

OPERATION

3.12 - LMU programmable key

The following functions can be allocated to the programmable key via the setting

KonfigEingang (QAA 73 setting : 614):

- 0: The programmable key function is not used.

- 1: Default, modem function enabled, if the contact

(X10-04) is closed; disabled if the contact is

open.

- 2: Modem function disabled, if the contact (X10-

04) is open; enabled if the contact is closed.

- 3: Hot air curtain function enabled, if the contact

(X10-04) is closed.

Hot air curtain function (swimming pool):

This function enables the boiler setting to be raised

to its maximum value.

It can be enabled in summer and winter modes.

- Modulation of the burner output is maintained.

- Domestic hot water priority is maintained.

- This function is enabled when the contact is

closed.

Modem function:

The modem function allows the boiler to be placed

on "standby" or to be switched off via the telephone.

All protection functions (e.g. anti-freeze function,

pump kick) remain active.

3.13 - Automatic summer/winter switching

(only activated with outside sensor)

The automatic summer/winter switching function

enables summer mode to be switched to winter

mode (and vice versa) throughout the year without

the need for any intervention.

The heating is shut down (when switching from winter mode to summer mode) when the average outside temperature measured over the preceding 24

hours is over the +1°C setting, namely 20°C.

The heating is also started up again (when switching

from summer mode to winter mode) automatically

when the average outside temperature measured

over the preceding 24 hours is below the -1°C set

ting, namely 18°C.

-Note:

The switchover setting is set to 19°C and can only

be changed by using the QAA 73 room sensor.

The automatic mode must obviously be activated

on the boiler as well as on the QAA 73 room sen

sor for the automatic summer/winter switching to

be available.

This function is activated by default in the QAA 73

basic configuration.

-

-

On the other hand, when this function is activated,

some of the other functions are not ensured:

- The antifreeze function of the installation is not

guaranteed.

- The anti-legionella function of the unit is no longer

used.

- 18 -

4 - DIFFERENT VERSIONS OF THE THI

,

,

,

OPERATION

The standard configuration is for the

connection of:

!

- one radiator circuit (CC1),

- one under-floor heating circuit

(CC2) via the 2

nd

circuit clip-in kit.

Fig. 12

auto

Function

23

4

THI-66-0

15

4.1 - THI basic model (without outside

sensor, without room sensor)

The heating and domestic hot water flow temperatures are set manually with the respective potentiometers (2 and 3) on the boiler control panel.

The regulator (LMU management unit) thus sets the

heating rate required to provide the heating and hot

water settings specified by the user.

The “Function” key (1) switches between the summer (hot water only) and winter (heating and hot water) modes. (The auto function is not accessible in

this case).

Please refer to section 4.1 - page 9 - Chapter II TECHNICAL SPECIFICATIONS.

Note: The installation of under-floor heating is not

possible in this configuration.

4.2 - THI with outside sensor only

4.2.1 - Principle

The domestic hot water temperature is set manually

using the potentiometer (3) on the boiler control pa

nel

Refer to section 4.1 - page 9 - Chapter II - TECHNICAL SPECIFICATIONS.

Note:

- An under-floor heating system can be connected

by following the instructions in section

4.2.3 -

page 19.

4.2.2 - Modification of the room temperature

The room temperature setting is pre-set to 20°C on

the LMU management unit, it can be modified if re

-

quired:

- Set the heating temperature potentiometer (2) to

the required value,

- The display indicates the correction made by +/3°C with respect to the 20°C value,

The correction is recognised by the LMU by leaving the potentiometer on the required position.

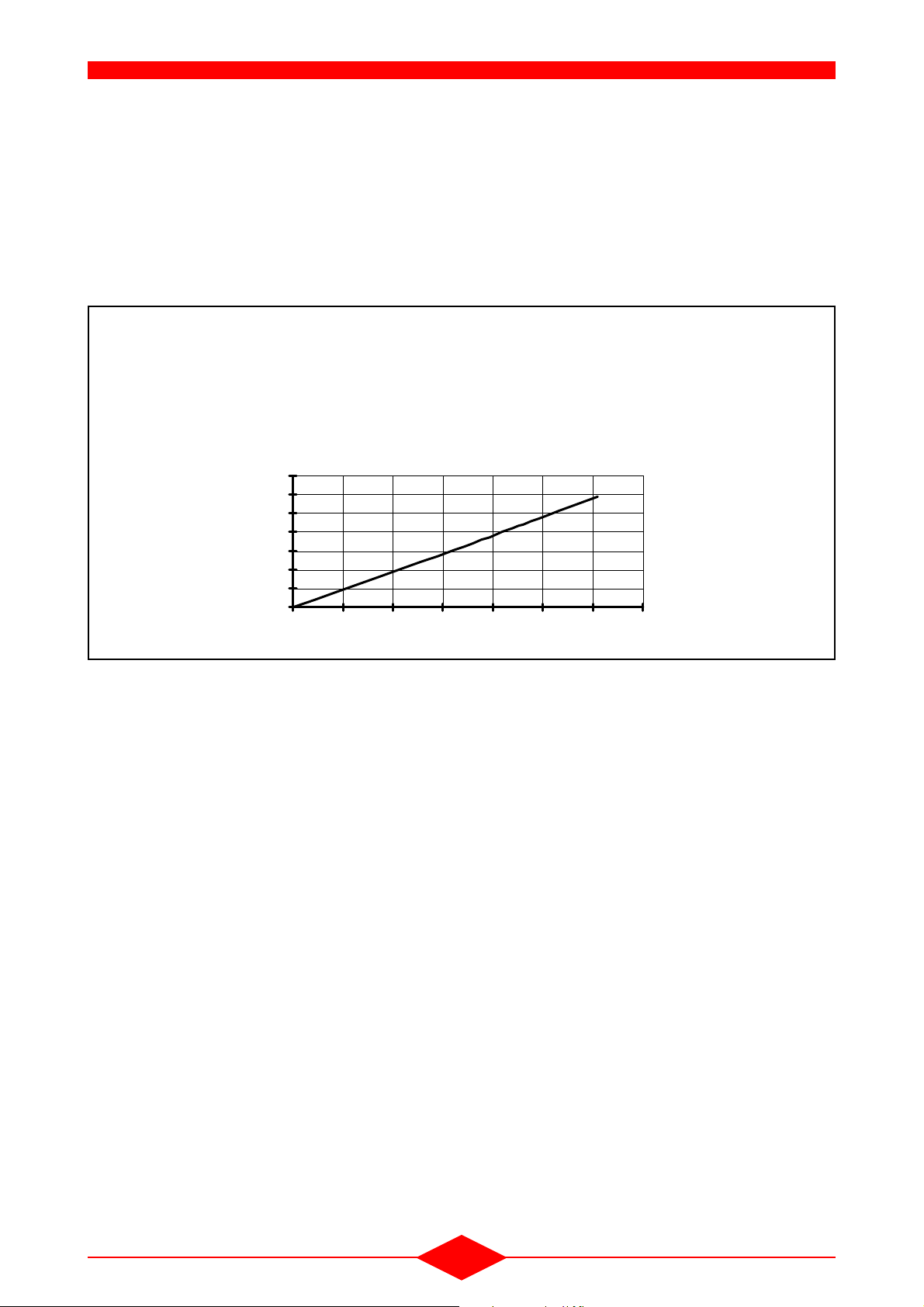

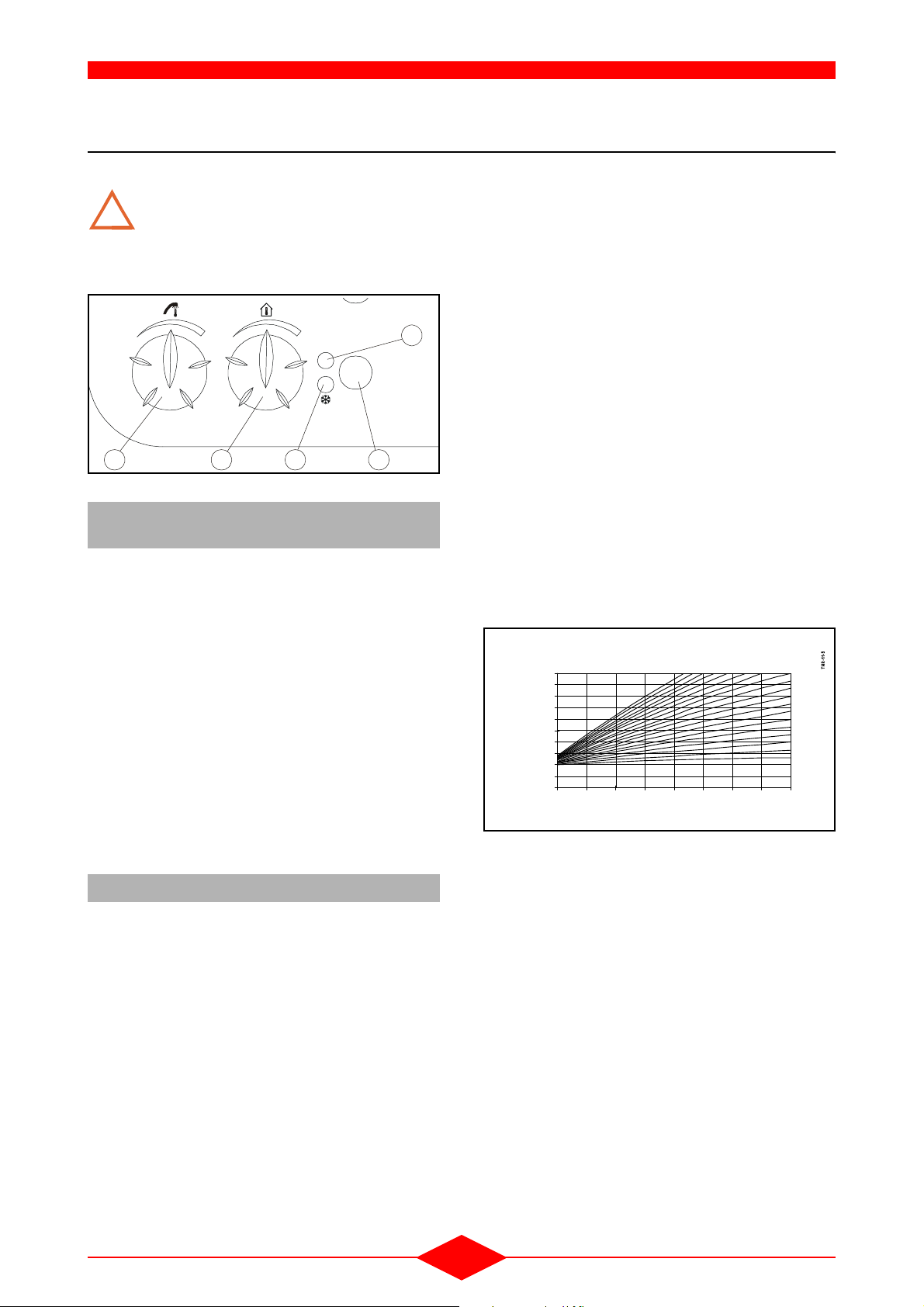

4.2.3 - Modification of the heating curve slope

The heating curve slope depends on the characteristics of the building and the size of the heating installation.

Fig. 13

100

90

80

70

60

50

40

30

Boiler setpoint

temperature (°C)

20

10

0

20 15 10 5 0 -5 -10 -15 -20

Outside temperature (°C)

2,4

2

1,8

1,6

1

4

2

1

1

Slope

0,8

0,6

4

0

0,2

The slope of the heating curve is pre-set in the factory to the value 15 for a radiator system and theoretically gives an room temperature of 20°C for a

standard installation.

Note: The maximum permitted flow temperature is

limited by TKSmax (line 504, via the QAA73

-

room sensor)

The heating flow temperature is calculated automatically by the regulator (LMU management unit), and

determined according to the outside temperature

and the slope of the heating curve. The room tem

perature can be modified by only + or - 3°C using the

heating temperature potentiometer (2).

The “Function” key (1) switches between the summer (hot water only) and winter (heating and hot water) modes.

- 19 -

OPERATION

The characteristics of the living area (heating surface, insulation) may require the pre-set values on the

LMU to be adjusted.

- For a radiator heating system:

• Reset the room temperature by +/-3°C (section

4.2.2 - page 19) then if this correction is not

sufficient,

- For an under-floor heating system:

• Reset the value of the heating curve slope of

15 (factory setting) to 8 (section

20) and according to the installation requirements,

• Modify the room temperature by +/-3°C (section 4.2.2 - page 19).

• Modify the heating curve slope (section 4.2.3.1

- page 20).

4.2.3.1 - Procedure for modifying the parameters of the heating curve slope

Initial display: Green LED “°C” is on

1

The display shows the heating flow temperature.

Press the key until is displayed then release it and press for the same period until is

Info

2

displayed (the display indicates then : intermediate positions).

3

After a few moments, is displayed.

°C

bar

Info

INFO-22

4.2.3.1 - page

4

Press on the key twice until is displayed on the screen.

5

6

7

setting of the slope permutes with the default value of the slope.

Only when the display shows press the key until the “bar” LED flashes:

Increase the value by pressing until the value is displayed.

Store the value by pressing the key for a certain time until the LEDS “°C” and “bar”

Info

Info

Info

Info

8

°C

bar

Info

extinguish

INFO-8

9 Return to the initial display

°C

bar

Info

INFO-15c

- 20 -

4.2.3.2 - Procedure for modifying the parameters of the parallel shift of the heating curve

OPERATION

Initial display: Green LED “°C” is on

1

°C

bar

Info

INFO-22

The display shows the heating flow temperature.

Press the key until is displayed then release it and press for the same period until is

Info

2

displayed (the display indicates then : intermediary positions)

3

After a few moments, is displayed.

4

Press on the key three times until is displayed on the screen.

5

6

7

setting of the parallel shift permutes with the default value of the shift.

Only when the display shows press the key until the “bar” LED flashes:

Increase the value by pressing until the value is displayed.

Info

Info

°C

bar

Info

Info

INFO-15c

Store the value by pressing the key for a certain time until the LEDS “°C” and “bar”

Info

8

°C

bar

Info

extinguish

INFO-8

9 Return to the initial display

4.2.3.3 - Return to the initial display

Procedure Observation

Press the key until the display appears

then release the key.

Info

This enables you to return to the initial position (i.e. the

display shows the heating flow temperature) when the

procedures

4.2.3.1 - page 20 and 4.2.3.2 - page 21 are

being applied or during any other actions on the boiler

control panel.

- 21 -

OPERATION

4.3 - THI with outside and room sensors

Fig. 14

auto

Function

23

4

THI-66-0

15

Installing the QAA73 room sensor on the boiler cancels the functions of the setting potentiometers of

the heating (1) and domestic hot water (2) tempera

tures on the boiler control panel. All the temperatures, the operating settings and the heating

programmes are set on the QAA

73 (please refer to

the instructions supplies with the sensor).

Note:

- For heating by radiators or by under-floor heating,

refer to section

4.2.3 - page 19.

4.3.3 - Auto-adapt function

This function automatically corrects the heating curve by measuring the real room temperature.

The auto-adapt function is deactivated in the basic

configuration. It can be activated via line 77 by using

the +/- keys.

When the auto-adapt function is activated, the room temperature compensa-

!

tion function must also be activated,

section

4.3.2 - page 22.

4.3.1 - Automatic summer/winter switching

Refer to section 3.13 - page 18.

4.3.2 - Room temperature compensation

function

This function corrects the boiler flow temperature

according to the real room temperature measured

by the QAA 73 room sensor.

The QAA 73 can be deactivated or configured differently according to the wishes of the customer (refer

to heating engineer setting line 75).

Note:

- The “room temperature compensation” function is

activated by default on the CC1 heating circuit standard configuration of the sensor.

- The function is activated if the room sensor is pla-

ced in a room whose temperature is typical of the

accommodation. This room must not be fitted

with temperature control radiators. The room sen

sor must be fitted away from sources of heat or

cold.

When the room temperature compensation is inactive, the QAA 73 room sensor becomes a remote

control device acting on the heating curve for the

day-night temperature drops.

-

- 22 -

1 - GENERAL

IV - INSTALLATION

Installing a wall-mounted gas boiler presents no particular difficulty.

The installation of the boiler must be carried out by

a competent person in accordance with the relevant

requirements of the Gas Safety (Installation and

Use) Regulations, Building Regulations, Model Wa

ter Byelaws and the Building Standards (Scotland)

Regulations. It must also comply with the current

I.E.E. Wiring Regulations and the relevant recom

mendations of the following British Standard Codes.

Regulations and the relevant recommendations of

the following British Standard Codes of Practice.

CR331.3 Low pressure installation pipes.

BS.5449.1 Forced circulation hot water systems.

BS.5546 Installation of gas hot water supplies

for domestic purposes.

BS.5440.1 Flues (for gas appliances of rated input

not exceeding 60 kW).

BS.5440.2 Air supply (for gas appliances of rated

input not exceeding 60 kW).

BS.6798 Boilers of rated input not exceeding

60

kW.

Note:

- The boiler is only suitable for installation in a sea-

led system and must not be used with an open

vented system.

LOCATION OF BOILER

-

-

An existing cupboard or compartment may be used

provided it is modified for the purpose. Details of es

sentiel features of cupboard/compartment design,

including airing cupboard installations, are given in

BS.6798.

In siting the boiler, the following limitations MUST be

observed:

1) The position selected for installation MUST allow adequate space for servicing in front of the boiler and for

air circulation around the boiler.

2) This position MUST also permit the provision of a satisfactory balanced flue termination.

Note:

- If the boiler is to be fitted in a timber framed buil-

ding, it should be Jitted in accordance with the

British Gas publication "Guide for Gas Installa

tions in Timber Frame Housing". Reference DM2.

If in doubt, advice must be soughtfrom the Local

Gas Region of British Gas.

When siting the boiler, provision must be made for

the disposal of the condensate, see Section 4 -Con

densate drain.

The pressure relief valve connection should be routed to an external, visible point where the discharge

of steam or water cannot create a hazard to persons

or property. BS.5449: 1 refers.

GAS SUPPLY

Installation pipes should be fitted in accordance with

CP.331.3.

-

-

-

The boiler can be installed on the inner face of an

external wall - and some internal walls - providing

they are flat, vertical and capable of adequately sup

porting the weight of the boiler and any ancillary

equipment.

The boiler may be installed in any room or internal

space, although particular attention is drawn to the

requirements of the current I.E.E. Wiring Regula

tions and, in Scotland, the electrical provisions of

the Building Regulations applicable in Scotland with

respect to the installation of the boiler in a room or

internal space containing a bath or shower. Where

installation is in a room containing a bath or shower,

any electrical switch or boiler control utilising mains

electricity should be situated so that it cannot be tou

ched by a person using the bath or shower.

Where installation will be in an unusual location,

special procedures may be necessary and BS.6798

gives detailed guidance on this subject.

A compartment used to enclose the boiler MUST be

designed and constructed specially for this purpose.

-

-

-

The complete installation must be tested for soundness and purged in accordance with CR331.3.

FLUEING

Detailed recommendations for flueing are given in

BS.5440.1. The following notes are intended for ge

neral guidance.

AIR SUPPLY

a) - For room-sealed systems

Detailed recommendations for air supply are given

in BS.5440.2. The following notes are intended for

general guidance.

Where the boiler is to be installed in a room or internal space, the boiler does not require the room or internal space containing it to have a permanent air

vent.

Where the boiler is to be installed in a cupboard or

compartment, permanent high and low level air

vents are required for cooling purposes in the cup

board or compartment. Both vents must communi-

-

-

- 23 -

INSTALLATION

cate with the same wall to outside air.

The minimum effective area of the permanent air

vents required in the cupboard or compartment are

given in Table 3.

Table 3 AIR VENT AREAS

Position of

air vents

Air from room or

internal space

Air direct

from outside

High level 500 cm² 250 cm²

77.5 in² 39 in²

Low level

500 cm² 250 cm²

77.5 in² 39 in²

b) - For natural draught system:

Detailed requirements are given in BS 5440.2

2 - VENTILATION

WATER CIRCULATION SYSTEM

A suitable expansion vessel must be fitted to the

system external to the boiler and must be sized

to accommodate the expansion of the total water

content of the system. BS7074 and "British Gas

Specifications for Domestic Wet Central Heating

Systems' Part 3 gives guidance in this subject.

The central heating system should be in accordance

with the relevant recommendations given in

BS.6798 and, in addition, for small bore and micro

bore systems - BS.5449.1. The domestic hot water

system, if applicable, should be in accordance with

the relevant recommendations of BS.5546.

Copper tubing, to BS. 287 1. 1, is recommended for

water carrying pipework.

ELECTRICAL SUPPLY

- Wiring external to the boiler must be in accordan-

ce with the I.E.E. Wiring Regulations and any local regulations.

2.1 - THI models with conventional flue

connection

- All fuel burning devices consume a quantity of air

that is proportional to their power. Efficient venti

lation of the installation’s premises is therefore

necessary (according to installation standards).

• High ventilation, with a free section of at least

100 cm², should be placed at least 1.80 m abo

ve the ground, as well as an air inlet, in the

lower part, of a cross-section of 100 cm².

- To avoid any form of corrosion, the combustion

air must be free of any harmful agents. They are

thought to encourage the corrosion of halogena

ted hydrocarbons, containing combinations of

chlorine or fluorine, which can be found in sol

vents, paints, glues, gas propellants and domestic cleaning products, etc.

2.2 - THI models with balanced flue connection

When the THI boiler is installed with the horizontal

-

or vertical balanced flue kits that are supplied as op

tions, the combustion circuit is sealed in relation to

the installation premises.

These sealed units can be installed on premises

-

that either have or do not have windows or air inlets.

However, all measures must be taken to ensure that

the temperature of the installation room does not ex

ceed 45°C (ventilation).

-

-

- 24 -

3 - COMBUSTION PRODUCT FLUEING

INSTALLATION

The combustion product outlet systems described in this manual are sys-

!

tems normally used on the European

market. However, some of them cannot

be used in all the countries of the EEC.

The installer or client must ensure that

the flue system chosen complies with

local installation regulations.

3.1 - Conventional flue outlets (B23 model)

- The THI boiler operates by condensation, which

involves the use of a sealed drain outlet. The

combustion products are saturated with water va

pour and continue to condense onto the walls of

Fig. 15

the lining. The condensates must therefore be

collected at the base of the conduit and directed

to the drain. The condensates are acids (PH4), so

the use of a stainless steel conduit is recommen

ded.

- Systematically check that the condition and the

cross-sectional area of the flue are correctly

adopted to open flued combustion product ex

traction. If they are defective, carry out repairs or

tubing in accordance with the installation stan

dard.

- If the boiler is installed in premises that have mechanical air extraction, check regularly that this

does not cause negative pressure.

- The conventional flue connection must be installed by retaining an upwards slope towards the

-

flue (2% minimum). Use a rigid flue that has a

smaller diameter than that of the boiler

.

-

-

-

Ventilation

Boiler connection

Sealed flue

Æ

139

Alu réduction

139/80

Æ

Boiler

PVC 25

Æ

Tubing ventilation

Sealed tubing

Trap, accessible for

inspection minimum seal

depth 50 mm (for draining

condensates from tubing)

Æ

PVC 32

Traps

(these 2 drains may

be shared)

050-14-3

- 25 -

3.2 - Balanced flue outlet

INSTALLATION

3.2.1 - Balanced flue system installation requirements:

The recommended clearance distances according to the installation standards are:

- A = 0.30 m: minimum clearance distance of the

combustion production extraction outlet axis to

any opening,

-B = 0.30 m:

minimum distance from the axis of the combustion production extraction outlet to any other ventilation air inlet,

-C = 2.00 m:

combustion product extraction outlet and air inlet

of sealed circuit units with openings at less than

2.00m from the ground must be efficiently tam

per-proof so as to prevent any intervention that

could affect correct functioning.

Fig. 16

B

Combustion product extraction outlets that open

out directly onto an outside route (public or priva

te road) less than 1.80m from the ground, except

for condensation installations, must have a fixed

defector that redirects discharged gas more or

less parallel to the wall.

Recommended distances:

-D = 0.30 m:

centre distance from the combustion product extraction outlet to the ground, from a roof overhanging or above a balcony,

- E = 0.60 m:

distance of a combustion product extraction outlet from a hedge or plant,

-

- F = 0.15 m:

space between the combustion product extraction outlet and a gutter or drainpipe.

A

D

F

B

A

A

C

D

B

E

B

AM5-10- 0

- 26 -

INSTALLATION

3.2.2 - General

Check that the air inlet and combustion product extraction outlet tube and bend joints are properly sealed after mounting.

Air intake by the burner and extraction of combustion product is carried outside the premises by using

concentric tubes.

Power is automatically reduced by means of the air/

gas servo-control system. No systematic adjust

ment is required when commissioning the installation. Only the usual CO and CO2 checks should be

carried out (§

3 - page 52 - chapter VII - GAS CONVERSION ). The maximum DP of 100 Pa is obtained with a vertical balanced flue DN 80/125 length

8 metres with two 45° elbows or with a horizontal ba

lanced flue length 4 meters.

Fig. 17

POW ER VARIATI ON DEPENDING ON FLUE AND AIR

47,5

47

46,5

46

45,5

45

Power Kw

44,5

44

0 20406080100120

INLET PRESSURE DROP

P Pascals

D

3.2.3 - Drainage by horizontal balanced flue

(C

)

13

To make assembly easier, apply liquid

soap over 5 cm of the section of the tube

!

to be fitted.

3.2.3.1 - 1 m horizontal balanced flue kit

(option)

See kit assembly guide

Fig. 18

-

050-13- 0

-

Reference

V00.23774 1000

Length

mm

3.2.3.2 - 2 m polypropylene/PVC concentric

flue extensions kit (option)

Fig. 19

- Standard balanced flue length: L = 1 m

- Maximum linear length of horizontal flue:

Lmax = 4 m

Recommendations

Horizontal balanced flue installation is

possible when the wall next to the boiler

!

leads to a well-ventilated area on the out

side.

Do not place the flue terminal at the front

of the building or in an access area (pos

sible obstruction).

The horizontal balanced flue can be fitted

to the right or lefthand side or directly to

the rear of the boiler and can cross a

wall-thickness of 1 metre maximum.

Two balanced flue terminals from two separate boilers, positioned side by side,

must be separated by a minimum distan

ce of 0.3 metres.

When installing the horizontal balanced

flue, use a 2% upward grade towards the

outside for the combustion product tube.

525-11-0

Reference

V00.24245 2000 80 125

-

3.2.3.3 - Polypropylene/PVC concentric bends

Length

mm

Æ int.

mm

Æ ext.

mm

kit (option)

-

-

Fig. 20

Reference Bend type

V00.24246 90° 80 125

Æ int.

mm

Note:

525-25-0

Æ ext.

mm

- Each 90° bend added reduces the total authorised length by 1 m

- 27 -

3.2.3.4 - Installation examples

Please refer to the guide when installing the kit.

Note:

- For lengths greater than 1 m (standard horizontal

flue kit) use the extensions and bends supplied

as an option.

Lmax £ 4 m

3.2.3.4.1 - Straight horizontal balanced flue

INSTALLATION

Fig. 23

Fig. 21

Lmax

050-26- 0

Top v iew

- Rear extraction -

Accessory:

- 1 horizontal balanced flue kit - l = 1 m.

Fig. 22

70

70

Lmax

050-30- 0

70

Top view

- Right-hand extraction -

Accessory:

- 1 horizontal balanced flue kit - l = 1 m.

3.2.3.4.2 - Flue with bend:

Fig. 24

050-27- 0

L1

Lmax

Top view

- Evacuation vers la gauche -

Accessory:

- 1 horizontal balanced flue kit - l = 1 m.

L2

70

Accessories:

- 1 horizontal balanced flue kit - l = 1 m.

- 1 concentric extension kit Ø 80/125 - l = 2 m,

- 1 x 90° concentric bend kit Ø 80/125.

050-29- 0

Lmax = L1 +1 m + L2 £ 4 m

Note :

- Each 90° bend added reduces the total permitted

length by 1m.

- 28 -

INSTALLATION

3.2.4 - Extraction by vertical balanced flue

(C

)

33

Besides the previously mentioned installation regulations pertaining to flues, the vertical flue terminal

must allow a minimum distance of 30 cm between

the roof level (sloping or flat) and the air intake zone.

The proximity of two terminals is also regulated: it is

recommended that two adjoining terminals should

be placed in the same horizontal plane. If this can

not be applied, the axis of the lower terminal must

be at a distance of at least 0.40 m from the closest

point of the air intake hole of the highest terminal.

Maximum length of vertical flue = 8 m

Fig. 25

30 cm

mini

40 cm

mini

3.2.4.1 - Polypropylene/PVC concentric

vertical terminal (option)

For sloping roofs.

Fig. 26

-

FCX-20-0

Reference Colour

N40.28393 Tile 1080 80 125

N40.28394 Black 1080 80 125

(*) Useful length under sleeve tile - l = 0.43 m

Length

(*) mm

Æ int.mmÆ ext.

mm

3.2.4.2 - Sleeve tile with adaptive coupling

(option)

Fig. 27

Recommendations

Horizontal parts must be avoided to

prevent any risk of condensate reten-

!

tion.

It is recommended to use 45° bends rather than 90° bends.

Use fastening collars for the vertical

parts.

Position the terminal at least 1 metre

from a vertical wall (end walls).

Apply liquid soap to approximately 5

cm of the part of the tube to be fitted to

make assembly easier.

FCX-19-0

AM5-22-0

Reference Slope

N40.12165 25 ° - 45 ° Tile* Tile

N40.12166 35 ° - 55 ° Tile* Tile

N40.12167 35 ° - 55 °

Type o f

covering

Slate -

Shingle

Colour

Black

*Suitable for all types of tiles, for flat tiles < 8 mm

use the Slate model

If accessories of any other brand are used, our guarantee of watertightness will be automatically void

3.2.4.3 - Polypropylene/PVC concentric

extensions (option)

Joint fitting.

Fig. 28

AM5-23-0

Reference

Length

mm

Æ int.

mm

Æ ext.

mm

N40.28397 500 80 125

N40.28398 1000 80 125

(*) Useful length after assembly - l = 0.45 m or 0.95 m

- 29 -

INSTALLATION

3.2.4.4 - Polypropylene/PVC concentric

bends (option)

Joint fitting.

Fig. 29

AM5-24-0

45° bend

Reference Type of bend

N40.28395 45° 80 125

N40.28396 90° 80 125

90° bend

Æ int.

mm

Æ ext.

mm

Each 45° bend added reduces the total permitted

length by 0.5m.

Each 90° bend added reduces the total permitted

length by 1m.

3.2.4.5 - Polypropylene roof plate (option)

Fig. 30

3.2.4.7 - Adapting collar for the vertical balanced flue

See assembly instructions for the part.

Fig. 32

THI100-0

Reference V00.24253

AM5-27-0

Reference Colour

A90.12172 noir

3.2.4.6 - Fastening collar (option)

Fig. 31

AM5-26-0

Reference Quantity

B00.29727 3 125

Æ

mm

These collars are essential to fix the vertically positioned extensions so that the boiler outlet does not

bear the weight of the conduits.

- 30 -

INSTALLATION

3.2.4.8 - Installation examples

3.2.4.8.1 - Straight configuration

Fig. 33

L

1

3.2.4.8.2 - Configuration with bends

Fig. 34

2

L

L3

L1

THI101-0

Accessories:

- Vertical balanced flue adapting collars,

- Concentric extensions Ø 80/125,

- 1 concentric vertical terminal Ø 80/125,

- 1 vertical terminal fastening collar (delivered with

vertical terminal),

- 1 sleeve tile with adaptive coupling depending on

the type of roofing and roof slope,

- 1 roof plate,

- 3 fastening collars Ø 125,

Lmax = L1 £ 8 m

THI102-0

Accessories:

- Vertical balanced flue adapting collars,

- 3 concentric extensions Ø 80/125,

- 2 x 45° concentric bends Ø 80/125

- 1 concentric vertical terminal Ø 80/125,

- 1 vertical terminal fastening collar (delivered with

vertical terminal),

- 1 sleeve tile with adaptive coupling depending on

the type of roofing and roof slope,

- 1 roof plate,

- 3 fastening collars Ø 125,

Lmax = L1 + 0,5 m + L2 + 0,5 m + L3 £ 8 m

Note:

- Each 45° bend added reduces the total permitted

length by 0.5m.

- 31 -

4 - SUPPORT BRACKET

Fig. 35

INSTALLATION

H

E

THI 10-50 C 150 82,5 495 265 10 10 - 79 56

Top view

B A A

THI-94-0

Modèles A B C D Emini Fmini G H I

F

7

Rear view

I

E

Æ

A B

A

Top view

D

C

F

- 32 -

5 - HYDRAULIC CONNECTION

5.1 - Recommendations

When the boiler is assembled on an old

installation, make sure that the installa-

!

tion is rinsed with fresh water, so as to

clear any sediment stagnating in areas

where the flow is slow.

To prevent circulation noises in an installation featuring temperature controls,

the following is recommended:

- Do not fit all the radiators with temperature controls,

- Fit a differential valve,

In accordance with the decree of the Ministry of Health for the protection of the

drinking water supply, the filling system

must be fitted with a disconnecter of type

CB (non-controllable pressure zone).

Never position the isolation valve

between the safety control and the

hot water tank (THI 10-50 C + DHW pro

duction system), never between the boiler shell and the expansion vessel.

5.2 - Accessories to connect, install or

adjust

- Bleed:

The bleed of the circulating pump features a flexible tube that can be connected to the outlet (condensate extraction funnel).

- Safety control (for hot water production models):

• The safety control must be installed at a

low point (0.25 m from the floor) in order to

enable the extraction of the domestic hot water

tank by siphoning. Otherwise, use a weld with

a low point drain tap.

• It is normal for the d.h.w. safety control to

leak a little water during the pre-heating of the

hot water tank. If the cold water pressure ex

ceeds 4 bars, the installation of a pressure-reducing valve on the cold water inlet is advised.

INSTALLATION

- Isolating valve:

It is recommended to place isolation valves on

the installation’s flow-returns in order to allow

possible servicing on the boiler without having to

drain the installation.

- Safety valve:

This must be connected to the used water drain

via a siphon funnel.

- Condensate outlet:

The condensate outlet must be connected to an

accessible siphon.

- Header

A header must imperatively equipped the installation.

- Expansion vessel:

The correct operation of the boiler requires an

installation pressure of at least 1 bar.

If the installation is a renovation and uses an

open tank, this must be removed and replaced

with a closed tank to seal the circuit.

The expansion vessel must be sized properly to

guarantee the longevity of the installation. The

vessel should be able to support an expansion of

6% of the total water capacity of the heating cir

cuits. But it is important to note, in order to guarantee this expansion, that the useful capacity of

-

-

a vessel does not equal its actual capacity.

Example:

• Installation: 100 litres

• Domestic hot water tank: 5 litres

• Boiler: 3,8 litres

• Total water capacity: 108,8 litres

Conditions: Using a vessel pre-loaded to 1 bar

(under floor boiler = ground floor

heating + 1 floor), heating safety

valve calibrated at 3 bars, installa

tion filled cold at 1 bar.

• Vessel efficiency calculation (R):

Safety Pressure - Filling pressure()

R

------------- ------------- ------------- ------------ ------------- ------------- -------=

R

+ 1) = the transformation of relative pressures into

abolute pressures

Safety Pressure

31+()11+()–

------------- ------------ ------------- --05,==

31+()

-

-

- 33 -

• Calculation of the useful capacity of the vessel

(Cu):

Cu total volume expansion´=

INSTALLATION

Cu 108 8, 006,´ 65 dm

3

,==

• Calculation of the real capacity of the vessel

(Cr):

Cu

Cr

-------=

R

65,

Cr

--------- 13 litres==

05,

5.3 - Under-floor recommendations

When the boiler directly supplies an under floor heating system and this system is also used to produce

domestic hot water (THI 10-50 C + BS), the header

gives the capacity to absorb the excess heat produ

ced at the end of the hot water heating cycle. In order to ensure mixing, check that the under floor

heating flow is greater than the boiler flow.(refer to §

1 - page 38 - chapter V - SETTINGS OF THE INSTALLATION TYPES).

5.4 - Heat exchanger flow rate

Taking into account the available boiler outlet pressure, the THI 10-50 must be fitted with an extra header (rep. 17, fig. 36 , fig. 37)) and a heating pump

(rep. 18, fig. 36 , fig. 37) ) in order to ensure sufficient flow in both the boiler and the installation. This

pump is controlled by the clip-in relay (optional ex

tra). It allows the boiler pump and the heating pump

to work in parallel. The header has the advantage of

providing total hydraulic independence for the boiler

and heating circuits. (Refer to §

1.2 - page 39 chapter V - SETTINGS OF THE INSTALLATION

TYPES).

- 34 -

INSTALLATION

5.5 -

Hydraulic connection for models THI 10-50 C

Fig. 36

1) Gas inlet

2) Gas cock

3) Boiler

4) Radiator

5) Heating flow isolation valve

6) Heating flow

7) Heating return isolation valve

8) Heating return

9) Cold water inlet

10)Filling valve

11)Filling system

12) Isolation valve

13) Drain for condensates, valve, bleed

14)Removal towards drain

15) QAA73 room sensor (option)

16) Outside sensor QAC 34

17)Header

18) Circulating pump