CRAIN 960 Instruction Manual

OPERATING INSTRUCTIONS:

This Heat Weld Gun is designed for welding seams in solid

vinyl or linoleum sheet goods only. It is not designed for stripping paint, or purposes not described in this manual.

SAFETY INSTRUCTIONS:

Wear safety glasses, ear plugs, and a dust mask when using

this heat weld gun.

Do not operate this heat weld gun near ammable materials,

liquids or gasses.

Do not operate this heat weld gun in wet areas. It is designed

for indoor use, and should be stored indoors.

Do not leave this heat weld gun unattended at any time.

Unplug when not in use.

When changing the pencil-tip nozzle or welding tip, allow the

gun to fully cool.

Use only with 120VAC electricity.

Do not use this heat gun for stripping paint. See the back

panel for additional warnings related to paint removal.

In use this gun becomes very hot. Keep out of contact with

your body. Keep away from your body, and always direct the

nozzle away from your body and other people.

Improper assembly may result in the nozzle or tip falling off

the gun while hot. Keep the nozzle and tip away from your

body at all times.

Use caution when setting the gun down after making a seam.

Hot air continues blowing out of the gun until turned off. The

tip is very hot long after the gun is turned off, and can burn

the oor or skin.

Follow the ooring manufacturer’s recommendations for the

type of groove and depth of groove to be made in the seam,

and use only manufacturer recommended welding rod. Absent recommendations, a good guideline for groove depth is

to at least 1/2 to 2/3 of the material thickness.

A test seam is always advisable before welding the actual

oor. Slower welding speeds on lower heat are advisable

for beginners.

This heat gun has a motor with two layers of electrical insulation. It does not need to be grounded. As a result, it has only

a two prong plug without a ground pole.

This heat gun is a high amperage device. Use only with

heavy gauge power cord. Be aware of the breaker capacity

of the plugs you are using.

JOBSITE PREPARATION:

Clean the seam area of all debris especially cuttings from

the groover prior to seaming. Check that the groove meets

manufacturer’s specications for proper depth and shape.

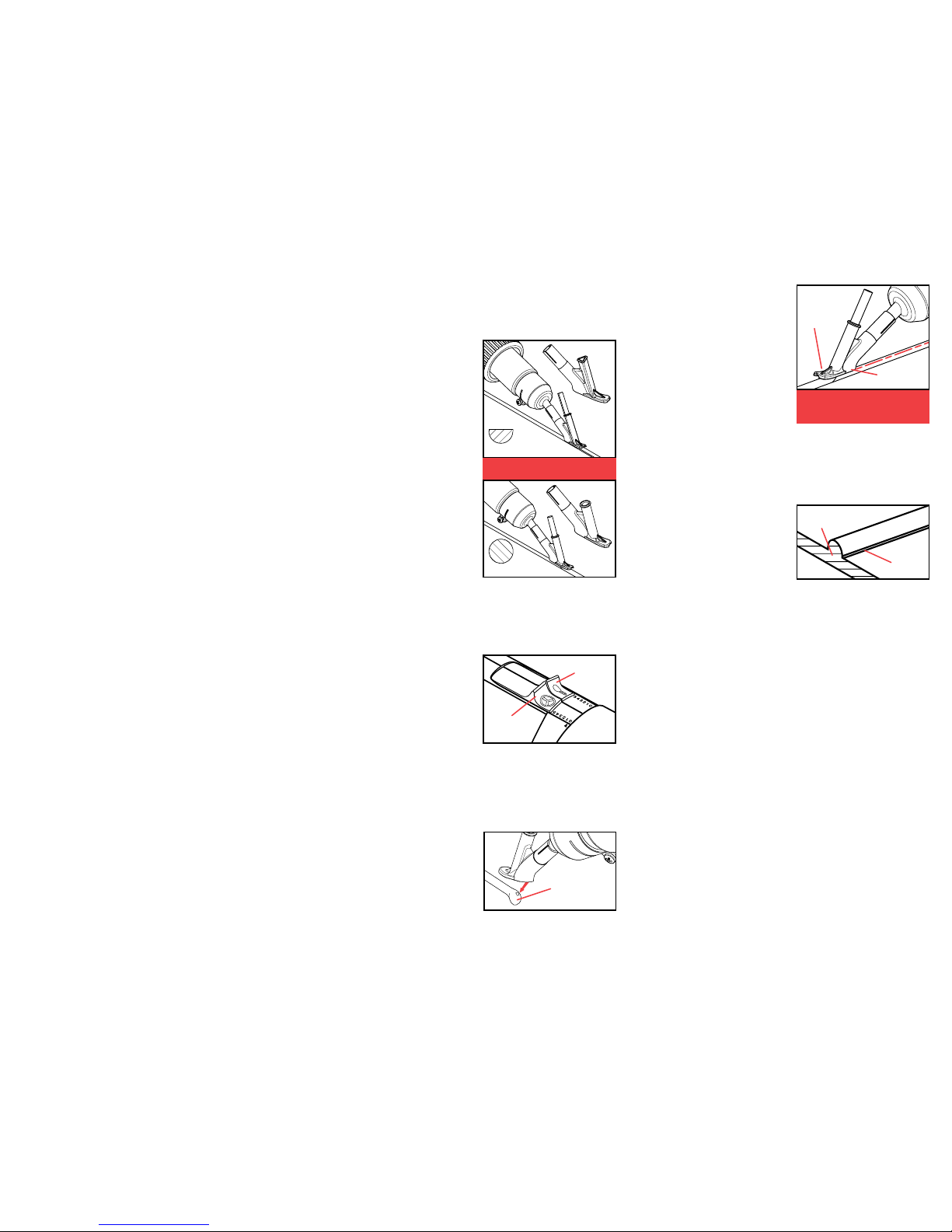

ASSEMBLY – NOZZLE:

Fully cool the heat gun. Place the pencil tip nozzle (No. 963)

on the nozzle of the heat gun. Tighten the screw securely.

Failure to tighten the screw may result in the hot nozzle falling off the gun during use. This can cause a severe burn or

damage the oor.

ASSEMBLY – TIPS:

Fully cool the heat gun. This

heat gun comes with two

tips. The triangular tip (No.

961) has a triangular-shaped

channel for feeding triangular

or “half moon” (“half round”)

welding rod. When welding

this type of rod, the triangular

point must go down into the

groove, and the flat must

face up.

The round tip (No. 962) has a

round channel round welding

rod. This tip should be used

on round welding rod only.

Insert the proper tip into the

end of the pencil tip nozzle and press rmly into the nozzle.

Failure to press into position may result in the hot tip falling

out of the nozzle during use. This can cause a severe burn

or damage the oor.

TEMPERATURE AND AIRFLOW CONTROLS:

The heat gun has two sliding

controls, one for adjusting heat

(red), and the other for adjust-

ing airow (blue). Each sliding

control has numbers from zero

to ve, with zero being lowest

and ve being highest.

TEST SEAM, SEAM SPEED, NOZZLE POSITION:

Many factors affect the performance of the heat gun, including

ambient air, ooring material, and suboor temperature, ooring material and welding rod characteristics, extension cord

length, wire gauge, and supply amperage. A test seam before

each job is the only way to ensure proper performance.

Before making a test seam,

proper temperature can be

estimated by putting the welding rod in front of the speed

tip and watching the results.

The rod should start to liquefy

but should not burn. Once

you adjust for proper melting, it is easier to adjust for other

factors with the test seam.

Under normal conditions, with ambient air about 70º F, for

beginners, a heat setting of about 2 and airow setting about

2 is good to start.

For a complete weld of the

seam area, the seam area must

be pre-heated by the opening

at the bottom of the tip, and the

welding rod must be pre-heated

while in the channel.

The hot air opening towards

the back of the tip should

be kept parallel with the

oor. This is pre-heating the

groove. If the opening is too close, it may burn. If it is too

far, it will not apply sufcient pre-heating to the groove. Keep

the opening centered over the groove to ensure both sides of

the groove are sufciently pre-heated. Use the trailing foot

to press the melting rod into the groove. Keep the trailing

foot constantly on the back of the welding rod.

The correct combination of

temperature, welding speed,

and pressure will create a

weld that forms a tiny ridge

or curl on both sides of the

seam, caused by slight rod

material ow. Look for this at all times while seaming.

Cut a cross section of the test seam with a knife. If the

section is welded into a homogeneous single piece, with no

cracks, will withstand bending, and will not easily pull apart,

the weld is successful.

SEAM WELDING PROCEDURE:

Pre-cut the welding rod to an adequate length for the length of

your seam including coves, then lay it out along the seamline.

Make certain there is plenty of extension cord, and there's

nothing in the way.

Start the weld as close to the wall as possible, but at least

one inch from any coved area. Coved areas must be done

separately AFTER the oor area is welded.

At the start of the weld, the seam must be quickly pre-heated

with the open-end of the speed tip. Quickly thereafter, insert

the welding rod into the channel such that extends out of the

at bottom of the tip. Follow the instructions above for seam

speed and nozzle position. Pull the heat gun down the seam

while constantly feeding the welding rod.

Stop the weld as close as possible to the wall, leaving at least

one inch of the oor unwelded at any cove area. Leave the

excess rod at the seam as you will need it to restart the weld

in the cove procedure (below).

COVE PROCEDURE:

To weld coves, a separate pressure roller (Crain No. 987)

is necessary. Allow the gun to fully cool, and then remove

the welding tip.

TIGHTEN PENCIL TIP SCREW

SECURELY AND SNUG FIT TIPS

kEEP OPENING PARALLEL WITH THE

GR OOV E BOTT OM AND TRAI LING

FOOT ON THE BACk OF THE ROD

HALF

MOON

OR TRIANGULAR

ROUND

AIR

FLOW

TRAILING

FOOT

HOT AIR

OPENING

HEAT

RIDGE

OR

CURL

HOMOGENEOUS

WELD AREA

HEAT

SHOULD

LIQUEFY BUT

NOT BURN!

INSTRUCTION

MANUAL FOR

No. 960 HEAT WELD GUN

Printed by: HF FORM F1960-07-2011

IMPORTANT SAFETY INSTRUCTIONS

READ THESE INSTRUCTIONS!

WARNING: Extreme care should be taken when stripping paint. The peel-

ing, residue and vapors of paint may contain lead, which is poisonous. Any

pre-1977 paint may contain lead and paint applied to homes prior to 1950 is

likely to contain lead. Once deposited on surfaces, hand to mouth contact

can result in the ingestion of lead. Exposure to even low levels of lead can

cause irreversible brain and nervous system damage; young and unborn

children are particularly vulnerable.

Before beginning any paint removal process you should determine whether the

paint you are removing contains lead. This can be done by your local health

department or by a professional who uses a paint analyzer to check the lead

content of the paint to be removed. LEAD-BASED PAINT SHOULD ONLY

BE REMOVED BY A PROFESSIONAL AND SHOULD NOT BE REMOVED

USING A HEAT GUN.

Persons removing paint should follow these guidelines:

1. Move the work outdoors. If this is not possible, keep the work area well

ventilated. Open the windows and put an exhaust fan in one of them. Be

sure the fan is moving the air from inside to outside.

2. Remove or cover any carpets, rugs, furniture, clothing, cooking utensils

and air ducts.

3. Place drop cloths in the work area to catch any paint chips or peelings.

Wear protective clothing such as extra work shirts, overalls and hats.

4. Work in one room at a time. Furnishings should be removed or placed in

the center of the room and covered. Work areas should be sealed off from

the rest of the dwelling by sealing doorways with drop cloths.

5. Children, pregnant or potentially pregnant women, and nursing mothers

should not be present in the work area until the work is done and all cleanup is complete.

6. Wear a dust respirator mask or a dual lter (dust and fume) respirator

mask which has been approved by the Occupational Safety and Health Administration (OSHA), the National Institute of Safety and Health (NIOSH), or

the United States Bureau of Mines. These masks and replaceable lters are

readily available at major hardware stores. Be sure the mask ts. Beards

and facial hair may keep masks from sealing properly. Change lter often.

DISPOSABLE PAPER MASkS ARE NOT ADEQUATE.

7. Use caution when operating the heat gun. Keep the heat gun moving, as

excessive heat will generate fumes which can be inhaled by the operator.

8. Keep food and drink out of the work area. Wash hands, arms and face

and rinse mouth before eating or drinking. Do not smoke, or chew gum or

tobacco in the work area.

9. Clean-up all removed paint and dust by wet-mopping the oors. Use wet

cloth to clean all walls, sills, and other surface where paint or dust is clinging.

DO NOT SWEEP, DRY DUST OR VACUUM. Use a high phosphate detergent

or trisodium phosphate (STP) to wash and mop areas.

10. At the end of each work session put the paint chips and debris in a double

plastic bag, close it with tape or twist ties, and dispose of properly.

11. Remove protective clothing and work shoes in the work area to avoid

carrying dust in to the rest of the dwelling. Wash work clothes separately.

Wipe shoes off with wet rag that is then washed with the work clothes; wash

hair and body thoroughly with soap and water.

SAVE THESE INSTRUCTIONS!

MODEL NO: 960 HEAT WELD GUN

VOLTAGE: 120 VOLTS AC 60 Hz

AMPERAGE: APPROX. 15 AMPS

WATTAGE: 1750 WATTS

TEMP. RANGE: variable 120 - 1250°F

AIRFLOW: variable

AIR PRESSURE: .438 psi / 300 Pa

SPECIFICATIONS:

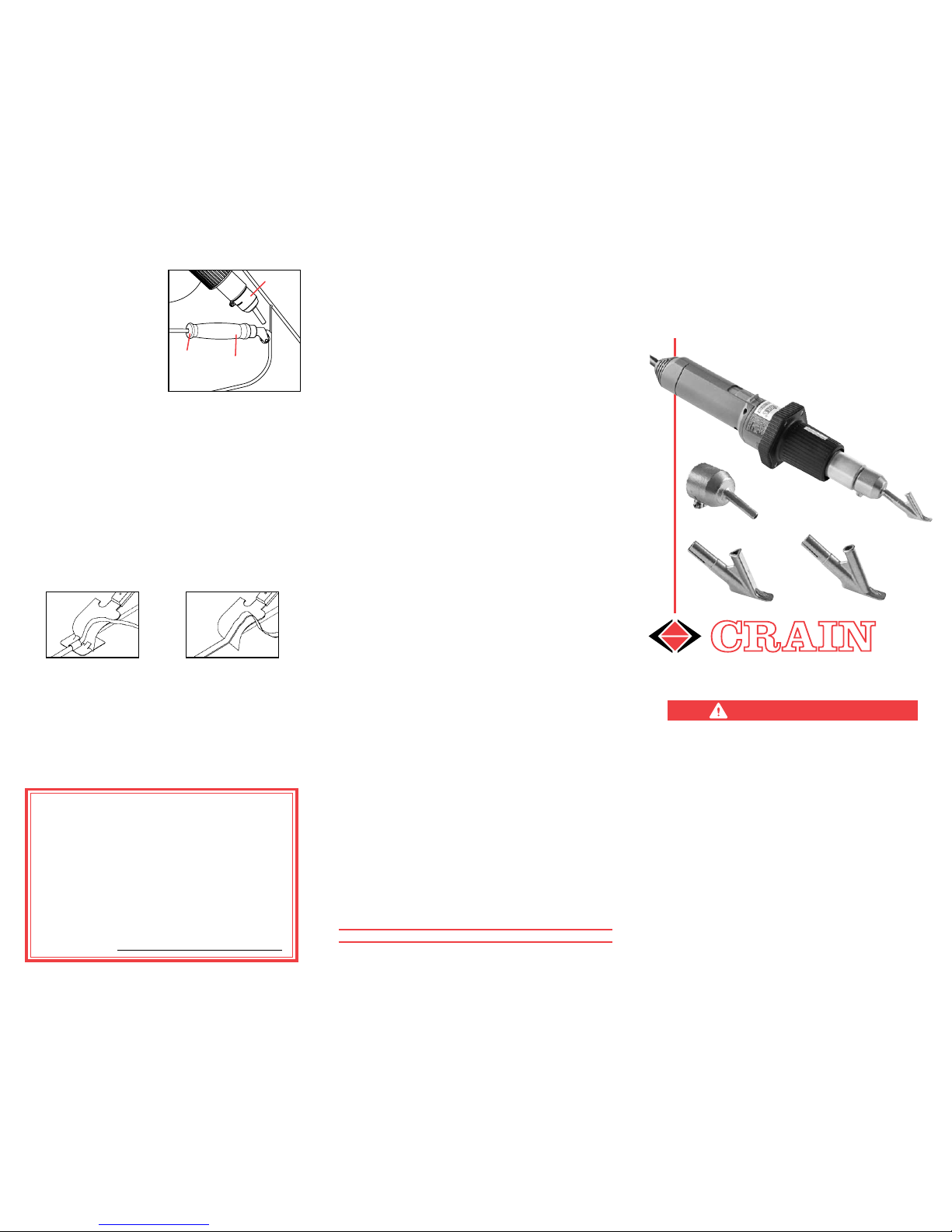

No. 963

No. 961

No. 962

GUARANTEE

This Crain No. 960 Heat Weld Gun is guaranteed to be free

of defects in workmanship and quality of materials for a period of 1 year. Any parts of this Heat Weld Gun found defective subject to the guarantee will be replaced at no charge.

Credit in full or part cannot be extended by the distributor,

nor will a new Heat Weld Gun be given as a replacement

or loaner. Heat Weld Guns subject to this warranty must

be accompanied by same, returned freight PREPAID to

Milpitas, CA, and must be in assembled condition. Heat

gun elements are not covered by this guarantee.

DATE OF MFG.

Milpitas, CA 95035 TEL: (408) 946-6100

www.craintools.com

CRAIN CUTTER CO., INC.

Feed the excess end of the

welding rod into the hollow

center of the pressure roller.

Press the roller onto the back

of the welding rod. Use the

open end of the pencil tip

nozzle to heat the welding

rod and the groove. Proceed

with the roller all the way up

the coved area.

SkIVING AND FINISHING:

Wait for the weld to cool completely, generally at least 20

minutes. Skiving too soon results in a severely concave seam

area. Skiving is done with a Quarter Moon Knife. When using

the Quarter Moon Knife, only the bottom side of the knife is

sharpened and should always face down.

Use a trim guide (Crain No. 986) with a Quarter Moon Knife

(Crain No. 985) for the rst pass. See gure 7.

For the second pass, use only the Quarter Moon Knife. This

takes practice on a test seam. Too low an angle causes the

knife to climb out of the rod and too high an angle causes the

kife to dig into the oor. Use as smooth and continuous a motion

as possible. Interruptions, starts and stops will result in a rough

seam that will be more visible after the oor is polished.

No. 960

PENCIL

TIP

HOLLOW

CENTER

PRESSURE

ROLLER

FIRST PASS WITH QUARTER

MOON KNIFE AND A TRIM GUIDE

SECOND PASS WITH

QUARTER MOON KNIFE ONLY

Figure 7

Figure 8

•

THIS HEAT GUN CAN OPERATE UP TO

1250°F, WHICH CAN CAUSE SEVERE

BURNS. DO NOT TOUCH HOT NOZZLES

OR TIPS. NEVER POINT THE HOT AIR

FLOW AT YOURSELF OR OTHER PEOPLE.

•

ASSEMBLE NOZZLE TIGHTLY ON THE

GUN AND SNUG FIT THE TIPS. OTHERWISE PARTS MAY FALL OFF CAUSING

SEVERE BURNS.

•

TEST SEAMS ARE ALWAYS ADVISABLE.

•

WHEN DONE WELDING, TURN THE HEAT

TO ZERO AND RUN FAN ON COLD TO

PROPERLY COOL ELEMENT. FAILURE TO

DO SO CAUSES ELEMENT FAILURE.

WARNINGS:

Loading...

Loading...