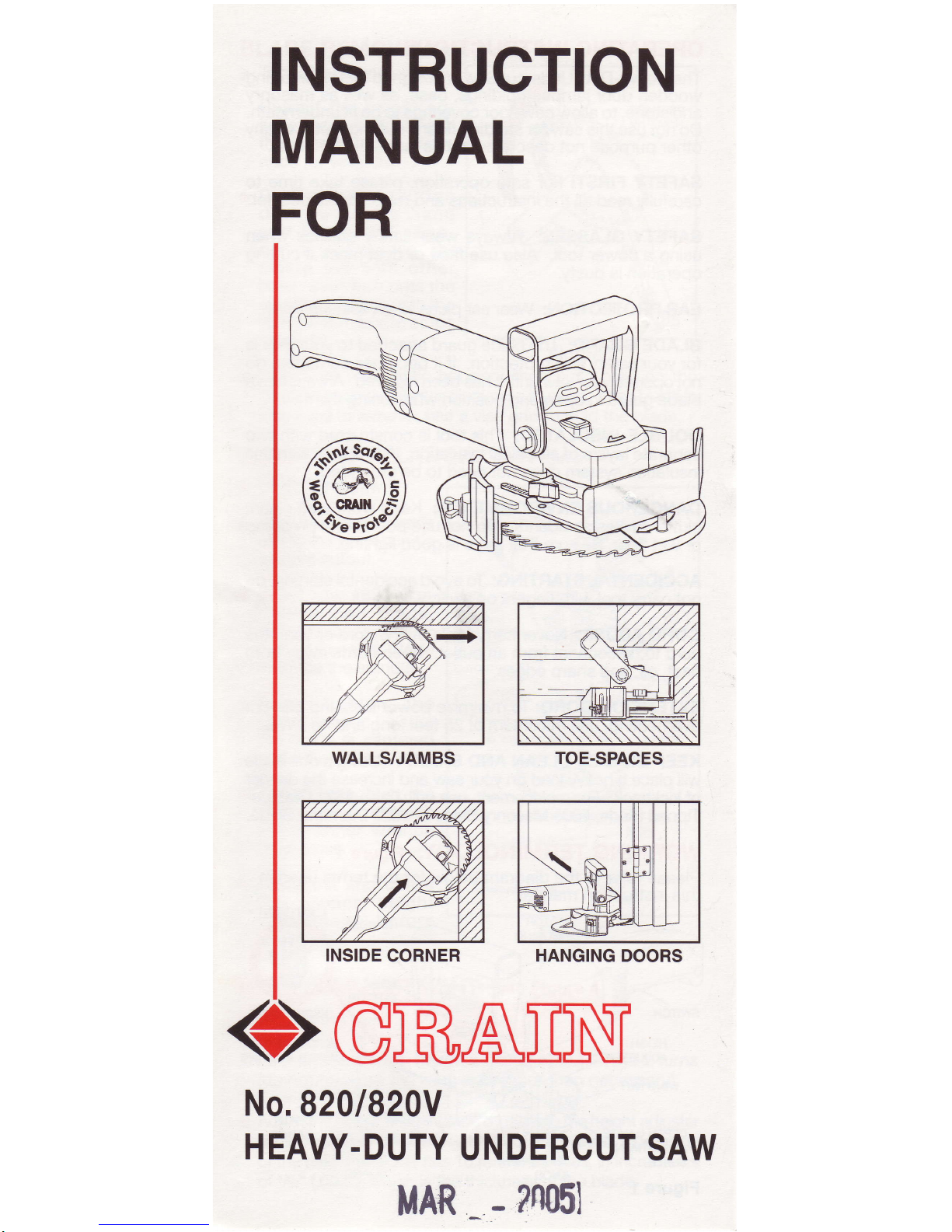

CRAIN 820/820V Operating Instructions Manual

€

INSTRUCTION

MANUAL

FOR

No.

82A1820V

HEAVY.DUTY

UNDERCUT

SAW

MAR

WALLS/JAMBS TOE.SPACES

INSIDE

CORNER

HANGING

DOORS

OPERATI NG I NSTRUCTIONS

The Heavy-Duty

Undercut Saw is designed for

undercutting

wooden

door

jambs,

moldings,

base, as well

as masonry

and stone, to ailow new floor

dovering5 to be fit

underneath'.

Do not use this

saw

for

sanding floors,

cutting metal,

or any

other

purpose

not

described in this instruction

manual.

SAFEW FIRST! For

safe operation,

please

take

time to

carefully read allthe instructions

and rules in this

booklet.

SAFETY

GLASSES:

Always wear

safety

glasses

when

using a

power

tool. Also

use

face

or dust mask if

cutting

operation is

dusty.

EAR PROTECTION:

Wear ear

plugs

when

using

this

saw.

BLADE

GUARD: The blade

guard

attached

to

your

saw

is

for

your

safety and

protection.

lf it

becomes damaged,

do

not

operate

your

saw

until

it has

been

repaired.

Always leave

blade

guard

in operating

position

when

using the

saw.

DOUBLE-INSULATED:

This tool is constructed with

two

separate

layers

of electrical

insulation.

Atool built with this

insulation

system does not need

to

be

grounded.

DANGEROUS

ENVIRONMENTS: Keep work

area clean;

clutter invites accidents. Do not

use

power

tool

on damp

or wet floor. Be sure that there is

good

lighting.

ACCIDENTAL STARTING: To

avoid accidental starting, do

not carry tool with fingers

on switch.

CORD ABUSE: Never

carry

tools by the cord

or

yank

the

cord

to

disconnect

from

an outlet.

Keep

cords away from

heat,

oil, and sharp edges.

EXTENSION

CORD:

To minimize

power

loss

and

prevent

overheating, use

maximum

of

25 feet long

and

16

AWG.

KEEP BLADES

CLEAN AND SHARP: Using a dull blade

will

place

a heavy

load

on

your

saw and

increase

the danger

of

kickback. For replacement,

use only Crain

#821

Carbide-

Tipped Blade,

#805

Masonry Blade or#822 Diamond Blade.

WORKING TERMINOLOGY Fisure 1

Please refer to the

diaoram

below for the terms

used

in

this instruction manual

HEIGHT

ADJUSTER

WING

NUT

DEPTH

GAUGE

ADJUSTMENT

SCALE

Figure 1

THREE-ARM

KNOB

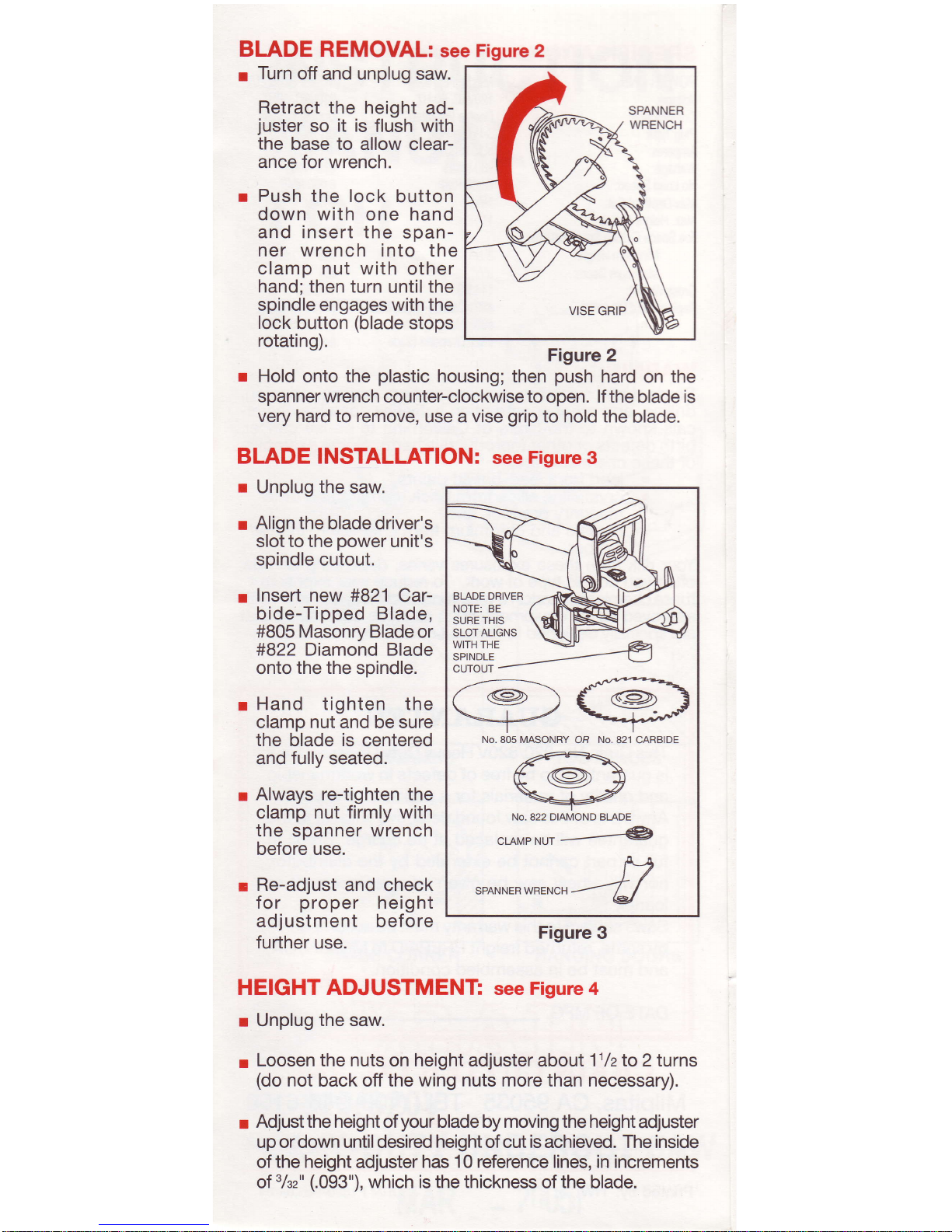

BLADE REMOVAL:

see

Fisure 2

r

Turn

off and

unplug saw.

Retract the

height

ad-

juster

so

it is

flush with

the

base to allow

clear-

ance

for

wrench.

r

Push

the lock

button

down with

one hand

and insert the

spanner wrench into the

clamp

nut with

other

hand; then

turn until the

spindle engages with the

lock

button

(blade

stops

rotating).

Figure

2

r

Hold

onto the

plastic

housing; then

push

hard

on

the

spanner wrench

counter-clockwise to open. lf the

blade

is

very hard to remove,

use a vise

grip

to hold the

blade.

BLADE INSTALLATION:

see Fisure 3

r

Unplug the saw.

r

Align the blade driver's

slot to the

power

unit's

spindle cutout.

r

Insert new #821

Car-

bide-Tipped Blade,

#805 Masonry Bladeor

#822 Diamond Blade

onto

the the

spindle.

r

Hand tighten the

clamp

nut

and be sure

the

blade

is

centered

and

fully

seated.

r

Always re-tighten the

clamp

nut firmly with

the

spanner wrench

before use.

r

Re-adjust

and check

for

proper

height

adjustment before

further use.

HEIGHT ADJUSTMENT see Fisure 4

r

Unplug

the saw.

r

Loosen the nuts on height adjuster

about

11/zIo 2 turns

(do

not back off the

wing nuts

more than necessary).

r

Adjust the height

of

your

blade by moving the height

adjuster

up or down until desired

height

of cut

is

achieved. The inside

of

the height

adjuster

has 10 reference lines, in increments

of

slsz"

(.093"),

which isthethickness

of

the

blade.

3i,'#,fH

@{tr

No.805 MASONRY

OF

No.821

CARBIDE

No.822 DIAMOND BLADE

CLAMPNUT

________@

''ANNERWREN

"

---ry

Figure

3

Loading...

Loading...