CRAIN 775 Instruction Manual

INSTRUCTION

MANUAL

FOR

No. 775 TOE-KICK SAW

FORM F1775-Rev.05/11Printed by: HF

CRAIN CUTTER CO., INC.

1155 WRIGLEY WAY, MILPITAS, CA 95035-5426

TEL: 408-946-6100 FAX: 408-946-4268

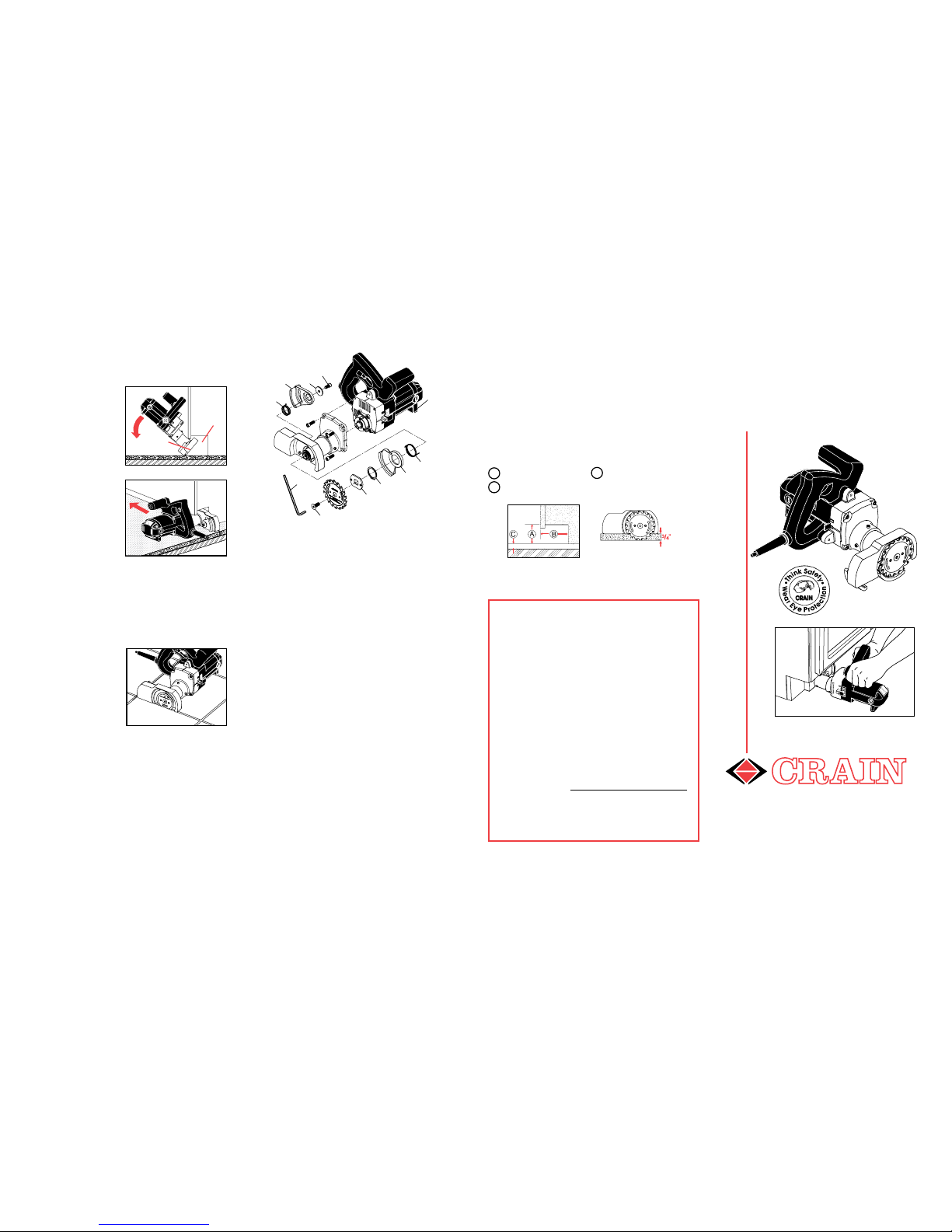

REPLACEMENT

PARTS:

Order No. Description

1775-10 Blade Driver

1785-C Return Spring

1785-E Blade Guard Retainer Ring

1795-A 120V Power Unit

1795-G Carrying Case (not shown)

1795-J Brush Set (not shown)

1795-K Power Cord (not shown)

1795-L Switch (not shown)

1795-N3 Spindle w/ Gear (not shown)

1795-O3 Armature w/ Fan (not shown)

1795-P Primary Guard

1795-R Secondary Guard Return Spring

1795-S Secondary Guard

1795-T Secondary Guard Washer

1795-U Secondary Guard Screw

1800-U Socket Set Screw

1800-V Allen® Wrench

ELECTRICAL: 120 VAC, 11 AMPs, 60 HZ Double

Insulated, 2 1/2 HP Motor, No Load

Speed 4500 RPM

REP. BLADE: #787 Carbide

#789 Diamond

GROSS WT: 11.8 LBS.

DATE OF MFG.

GUARANTEE

SAW SPECIFICATIONS:

This Crain tool is guaranteed to be free of defects

due t o faul ty ma teri al s or wo rkma nsh ip for a

period of 90 days.

During this period, any parts of tools found defective

subject to the guarantee will be replaced at no charge.

Returns should be sent freight PREPAID, in assembled

condition and with a copy of the Bill of Sale (proof of

purchase) to CRAIN CUTTER COMPANY, 1155 Wrigley

Way, Milpitas, CA 95035. New tools or loaners will not

be given for those pending warranty repairs.

No claims shall exceed in amount the suggested sales

price of the product. No other guarantee, oral or written, is expressed or implied.

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from brick, cement and other

masonry product, and

• Arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well-ventilated

area, and work with approved safety equipment, such as

those dust masks that are specially designed to lter out

microscopic particles.

DUST HAZARD WARNING:

No. 787

A MIN. HEIGHT: 3 1/

2

" B MAX. DEPTH: 4"

C MAX. FLOOR THICKNESS:

3

/

4

" - No. 787 Blade

C

MIN. /MAX. DIMS. FOR TOE-KICK TO BE CUT:

CRAIN

No. 787

MAINTENANCE:

If the saw is dropped, the blade guard may be bent,

restricting the full return of the blade guard. With the cord

unplugged, check operation of the blade guard before

each use. Dust build-up can also restrict the full return

of the blade guard. Clear off all dust periodically.

retighten the screw rmly before use. Make sure spindle

lock is pulled out before turning saw on.

DIAMOND BLADE

A diamond blade is available

as an accessory. It's used to

saw out tile under toe spaces or on counters. Also, for

tile repair, it can be used to

remove eld tiles.

Caution: Do not overheat this blade! Cut 6ft. maximum

and allow cooling. Avoid cutting into wood suboors as

this gums up the diamond grit. For best results, lay down

underlayment or plywood at least the width of the saw

so that the diamond blade cuts only to a depth corresponding to the thickness of tile. Make sure no chicken

wire or expanded metal has been installed under tiles

to be cut.

FIGURE 2

1795-A

1785-C

1795-P

1785-E

1775-10

1800-U

1800-V

1795-U

1795-T

1795-S

1795-R

To avoid accidental starting,

DISCON NECT THE SAW

FROM POWER SOURCE

before inserting the cutting

head into the toe-spa ce.

The safest way is by angling it in (Figure 1).

Plug-in the saw. Grasp the

handles rmly and pull the

trigge r. Moving the saw

slowly forward retracts the

guard s and exposes the

blade. Press down on the

handles slowly to p lunge

th e bl ad e in to the cut.

Slowly push the saw forward and along the toe-kick (Figure 2). Do not force the

saw; let the blade cut at the highest RPM possible.

As you complete the cut, release the trigger and make

sure the motor comes to a full stop before removing the

saw from the toe-space. Unplug the saw before removing from the toe-space.

OPERATING:

FIGURE 1

TOESPACE

ANGLE-IN THE

CUTTING HEAD

BLADE CHANGE (continued):

CRAIN

No. 787

Keep hands away from the spindle tube and blade housing

(red area). This is not a handle!

The blade guard attached to your saw is for your safety

and protection. If it becomes damaged, do not operate

your saw until it has been repaired. Always leave blade

guard in operating position when using the saw.

This saw is designed for removal of oors or underlayment under toe-spaces. It cuts ush to the wall of the

toe space. Please note these features of the saw.

LOW-PROFILE CUTTING HEAD: Will t under toe-kicks

as low as 3" in height.

SPINDLE LOCK: For blade changes, the spindle lock

stops the blade rotation, so that the blade can be easily

removed. This is NOT to be used as a motor brake!

CARBIDE BLADES & DEPTH OF CUT: The saw comes

with a 3

3

/8" diameter carbide blade (No. 787) that cuts

underlayment up to

3

/4" thick. It cuts to a xed depth

of

3

/4".

DOUBLE-INSULATED:

This saw is constructed with two separate layers of electrical insulation. A saw built with this insulation system

does not need to be grounded. As a result, this saw

comes with a two-prong plug without a ground pole.

DANGEROUS ENVIRONMENTS:

Keep work area clean; clutter invites accidents. Do not use

on damp or wet oors. This saw may throw sparks. Do not

use around ammable gasses. Be sure lighting is good.

ACCIDENTAL STARTING:

To avoid accidental starting, do not carry saw with ngers

on switch. Do not carry the saw while it is plugged in.

CORD ABUSE AND EXTENSION CORDS:

Nev er car ry saw by the cord or yank the cord to

disconnect from an outlet. Keep cords away from heat,

oil, and sharp edges. If the cord is cut or damaged,

replace immediately.

Avoid using long extension cords, as they will cause some

loss of power. To keep the loss to a minimum and prevent

saw from overheating, use a heavy-duty extension cord

with a minimum wire size based on the length of cord that

is needed: 25' = 16 gauge wire, 50' = 14 gauge wire

WEAR SAFETY GEAR:

GENERAL SAFETY

BLADE GUARD:

Always wear safety glasses and ear plugs when using this

saw. Use face or dust mask if cutting operation is dusty.

In the event of blade binding or any interruption of the

cut, release the switch. Hold the saw motionless until the

blade stops. While the blade is still turning, if you remove

the saw from the cut, or pull the saw backwards, this can

cause saw kickback.

Cut slowly, especially when nails may be present. Keep

motor RPMs high at all times.

This saw is not for use in general sawing. Cutting loose

plywood can bind the blade and cause kickback.

Use only Crain No. 787 or No. 789 blades (see back).

Use new, sharp blades at all times.

This saw plunge starts. Plunge slowly before pushing

forward.

HAND POSITIONING:

FEATURES OF THE SAW:

BLADE CHANGE:

WARNING: Regarding carbide blades, use only Crain

No. 787 Carbide-Tipped Blades. The kickback reducing

clutch is calibrated to this blade diameter ONLY!

WARNING: Check the depth of the underlayment to be

cut. If it is less than

3

/4" thick, to prevent suboor damage,

nail down a strip of additional underlayment at least the

width of the saw to adjust the cutting depth. Make sure

the blade cuts through both underlayment thicknesses.

Cutting through a gap can cause binding and kickback.

WARNING: Don't adjust cutting depth by shimming up

the saw by afxing shims to any of its parts, or by manually holding the saw at an elevation off the oor.

No. 787

CARBIDETIPPED

BLADE

SPINDLE

LOCK

SWITCH

BLADE

GUARD

LOW-PRO

FILE CUTTING HEAD

HEX

WRENCH

CAUTION!

KEEP HANDS

AWAY! BLADE

EXPOSED WHILE

CUTTING

SPINDLE LOCK

LEVER

THIS IS NOT A HANDLE!

KEEP HANDS AWAY

FROM THE SPINDLE

TUBE AND BLADE

HOUSING! (RED AREA)

THESE ARE

THE HANDLES

FACTORY

INSTALLED BLADE:

UNPLUG SAW. REMOVE ALLEN®

WRENCH BEFORE STARTING.

Unplug the saw. Push

an d ho ld t he spi ndle

lock to stop blade rotation. While holding the

spindle lock lever, insert

the

3

/16" hex wrench (provided ) into the blade’s

soc ket se t scr ew and

turn it counter-clockwise

to loosen. Note: For extra leverage, insert an extension

tube onto the hex wrench. Replace with new blade and

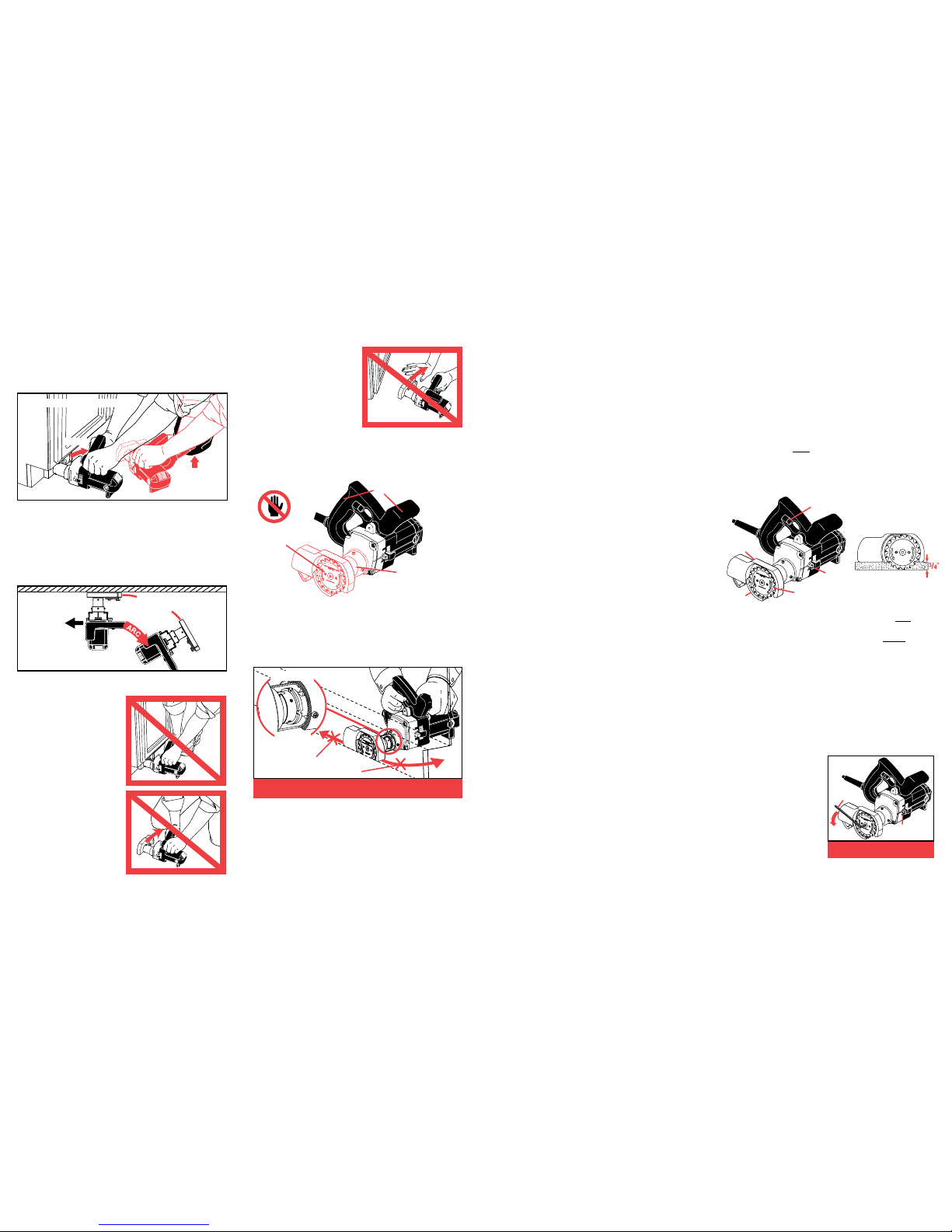

PREVENTING & PREPARING FOR KICKBACK

KICKBACK REDUCING CLUTCH

OTHER KICKBACK PRECAUTIONS

Saw kickback is a sudden reaction to a pinched, bound,

or misaligned saw blade, causing the saw to jump backward towards the user.

Saw kickback is preventable. Cutting straight and forward

helps prevent kickback. This prevents the teeth at the back

of the blade from grabbing in the top surface of the wood,

which causes the saw to jump backward.

Always prepare for saw kickback by keeping both hands

on the handles and gripping rmly. Kneel to the side of the

saw, keeping hands and knees out of the kickback arc.

ALLOW MOTOR TO STOP

AT THE END OF THE CUT:

At the end of a cut, allow the

motor to fully stop b efore

removing the saw from the

cut, or removing hands from

the handles. Otherwise, if

the saw blade is still spinning, the saw can catch and kick back toward the user.

This saw has a kickback reducing clutch that helps reduce

kickback forces. If the saw is abused by making anything

other than straight cuts (curves, angles, etc.), OR by attempting to cut backwards rather than forward, the clutch

may disengage. A loud buzzing sound will occur.

If the clutch disengages, immediately release the switch

and allow the motor to stop. Remove the saw from the

cut and allow the blade guard to extend before restarting

the motor and resuming the cut.

The saw's clutch can withstand about 500 disengagements before the saw will no longer transmit sufcient

power to the blade for cutting. At such time factory

service is required. Don't waste the clutch.

DIRECTION

OF CUT

POTENTIAL

KICK BACK ARC

DO N' T US E F ROM A

STANDING POSITION:

This is a oor saw. Don't

try to use from a standing

posit ion. Bra ce yourse lf

by kneeling, keeping body

weight behind and to the

side of the saw. Keep a

rm grip.

DO N'T US E OU TS IDE

TOE SPACES:

When used with carbi de

tipped blades, this tool is

designed for use under toe

spaces only. Don't use this

saw for cutting loose pieces

of wood, such as plywood.

BODY POSITIONING

KNEE:

KNEEL TO

THE SIDE

DON'T CUT

BACKWARD

KICK

PROPER POSITIONING

KICK

KICK

BZZZZ!

CLUTCH

CUTTING BACKWARD OR CUTTING CURVES MAY

CAUSE CLUTCH TO DISENGAGE.

DON'T CUT

CURVES

Loading...

Loading...